Darfon H5001 Installation Manual

INSTALLATION MANUAL

H5001 HYBRID INVERTER

INSTALLATION MANUAL H5001 HYBRID INVERTER

TABLE OF CONTENTS

IMPORTANT SAFETY WARNINGS .................................................................................................... 3

INTRODUCTION ................................................................................................................................... 4

Product Overview ................................................................................................................................ 4

MOUNTING THE INVERTER ...............................................................................................................5

Installing the Inverter onto the Wall ............................................................................................... 5

PV MODULE (DC) CONNECTION .....................................................................................................6

Connecting the PV Arrays ................................................................................................................ 6

GRID (UTILITY) CONNECTION .......................................................................................................... 7

Connecting to the Grid/Utility ........................................................................................................... 7

BATTERY CONNECTION AND CHARGING REQUIREMENTS ....................................................8

Connecting the Batteries .................................................................................................................. 8

Battery Charging Requirements ...................................................................................................... 9

LOAD (AC OUTPUT) CONNECTION ............................................................................................... 11

Connecting to the Load ..................................................................................................................... 11

OPERATION AND DISPLAY PANEL ............................................................................................... 12

Display Panel Overview .................................................................................................................... 12

Starting the System ............................................................................................................................ 12

Stopping the System ......................................................................................................................... 12

LCD Screen – Icons and Pages ..................................................................................................... 13

Mode Rule Definition ......................................................................................................................... 14

System Settings .................................................................................................................................. 15

Warning and Fault Definition........................................................................................................... 17

GENERATOR [OPTIONAL] ................................................................................................................ 19

Generator Sizing ................................................................................................................................. 19

Automatic Start Generator ............................................................................................................... 19

Generator Application Schematic .................................................................................................. 19

CONFIGURING THE HARDWARE .................................................................................................. 20

Connecting to the hardware .......................................................................................................... 20

USE APPLICATION SOFTWARE MODIFIES PARAMETERS ..................................................... 22

Preparation .......................................................................................................................................... 22

Connecting to the application software and modifies parameters ..................................... 22

Parameters setting tables ............................................................................................................... 25

MAINTENANCE & CLEANING ........................................................................................................ 26.

Wiring Diagram .................................................................................................................................. 26

SPECIFICATIONS .............................................................................................................................. 27

GRID SUPPORT PARAMERTERS ................................................................................................... 28

5-YEAR LIMITED WARRANTY ........................................................................................................ 30

Rev.1 ©2018 Darfon Electronics Corp. 2 | Page

INSTALLATION MANUAL H5001 HYBRID INVERTER

WARNING. This indicates the risk of electric shock. The presence of high voltage levels may constitute a risk of injury or death to users

and/or installers.

CAUTION. Before installing and using this inverter, read all instructions and cautionary markings on the inverter and all appropriate

sections of this guide. Installing this inverter by licensed electricians only.

WARNING. Authorized service personnel should reduce the risk of electrical shock by disconnecting AC, DC and battery power from the

reduce this risk. Internal capacitors can remain charged for 5 minutes after disconnecting all sources of power.

WARNING. Do not disassemble this inverter yourself. It contains no user-serviceable parts. Attempt to service this inverter yourself may

WARNING. To avoid a risk of fire and electric shock, make sure that existing wiring is in good condition and that the wire is not

undersized. Do not operate the Inverter with damaged or substandard wiring.

CAUTION. Under high temperature environment, the cover of this inverter could be hot enough to cause skin burns if accidentally

touched. Ensure that this inverter is away from normal traffic areas.

WARNING. To avoid a risk of the inverter damage, make sure that the working areas no metal particle and keep clean around the

working areas.

WARNING. Use only recommended accessories from installer. Otherwise, not-qualified tools may cause a risk of fire, electric shock, or

injury to persons.

CAUTION. Do not operate the Inverter if it has received a sharp blow, been dropped, or otherwise damaged in any way. If the Inverter is

CAUTION. This inverter is not allowed to operate in parallel. Do not parallel connect more than one unit in AC output connector.

Otherwise, it will damage this inverter.

IMPORTANT SAFETY WARNINGS

PLEASE READ ALL INSTRUCTIONS AND CAUTIONARY MARKINGS ON THE UNIT AND THIS MANUAL BEFORE USING THE

INVERTER. AND, STORE THIS USER MANUAL WHERE IT CAN BE ACCESSED EASILY.

This manual is for qualified personnel. The tasks described in this manual may be performed by qualified personnel only.

Safety Symbols

CAUTION. This indicates important information where failure to comply may result in safety hazards or cause damage to this product.

CAUTION. This indicates the risk of a hot surface. The surface may reach a temperature high enough to cause serious burn injuries.

General Precautions

CAUTION. Normally grounded conductors may be ungrounded and energized when a ground fault is indicated.

CAUTION. This inverter is heavy. It should be lifted by at least two persons for the safety.

inverter before attempting any maintenance or cleaning or working on any circuits connected to the inverter. Turning off controls will not

cause a risk of electrical shock or fire and will void the warranty from the manufacturer.

CAUTION. To reduce risk of fire hazard, do not cover or obstruct the cooling fan.

damaged, call for an RMA (Return Material Authorization).

Rev.1 ©2018 Darfon Electronics Corp. 3 | Page

INSTALLATION MANUAL H5001 HYBRID INVERTER

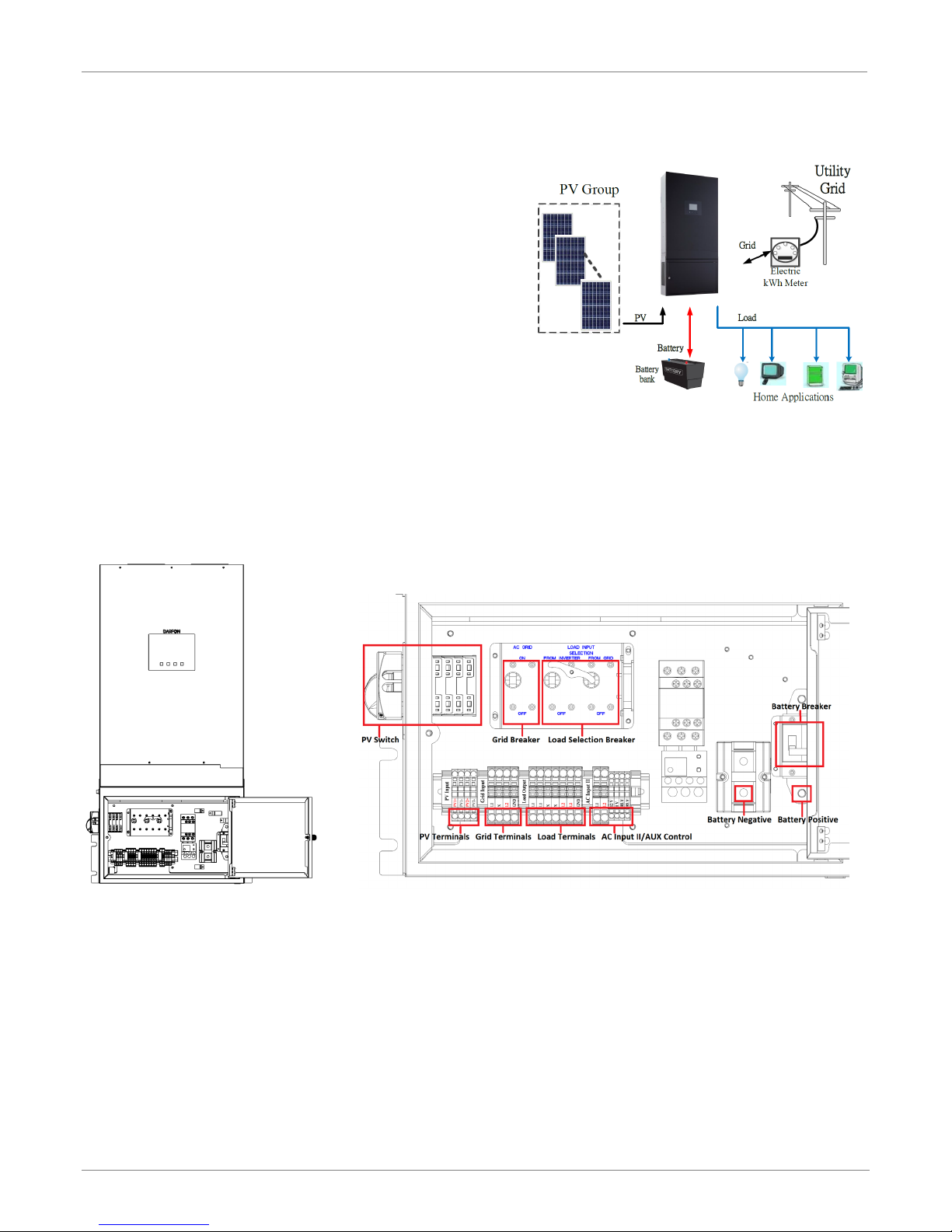

BASIC HYBRID PV STORAGE SYSTEM OVERVIEW

INTRODUCTION

The H5001 hybrid inverter provides power to the essential

load by utilizing power from PV panels, the utility and

batteries. When the PV panels (two string input) generates

enough power, the inverter supports the essential load,

feeds back to the grid and charges the batteries, all at the

same time. When the energy generated by the PV panels is

not sufficient to support the essential load, the inverter takes

power from the utility.

To accommodate various power situations, the H5001 is

designed to handle continuous power from PV panels,

batteries and the utility. When the MPP input voltage from

the PV panels is within the acceptable range, between 250

and 430VDC, the inverter is able to feed the grid and charge

the batteries. This inverter is only compatible with single

crystalline and polycrystalline PV panels, and any other type of PV panels cannot be used.

Notes: When PV input voltage is lower than 250V, the power of the inverter will de-rate. This hybrid inverter has two PV

input.

Product Overview

Distribution Box

A wiring subpanel is pre-assembled at the factory. It consists of breakers, disconnects and batteries paralleled

circuits.

Rev.1 ©2018 Darfon Electronics Corp. 4 | Page

INSTALLATION MANUAL H5001 HYBRID INVERTER

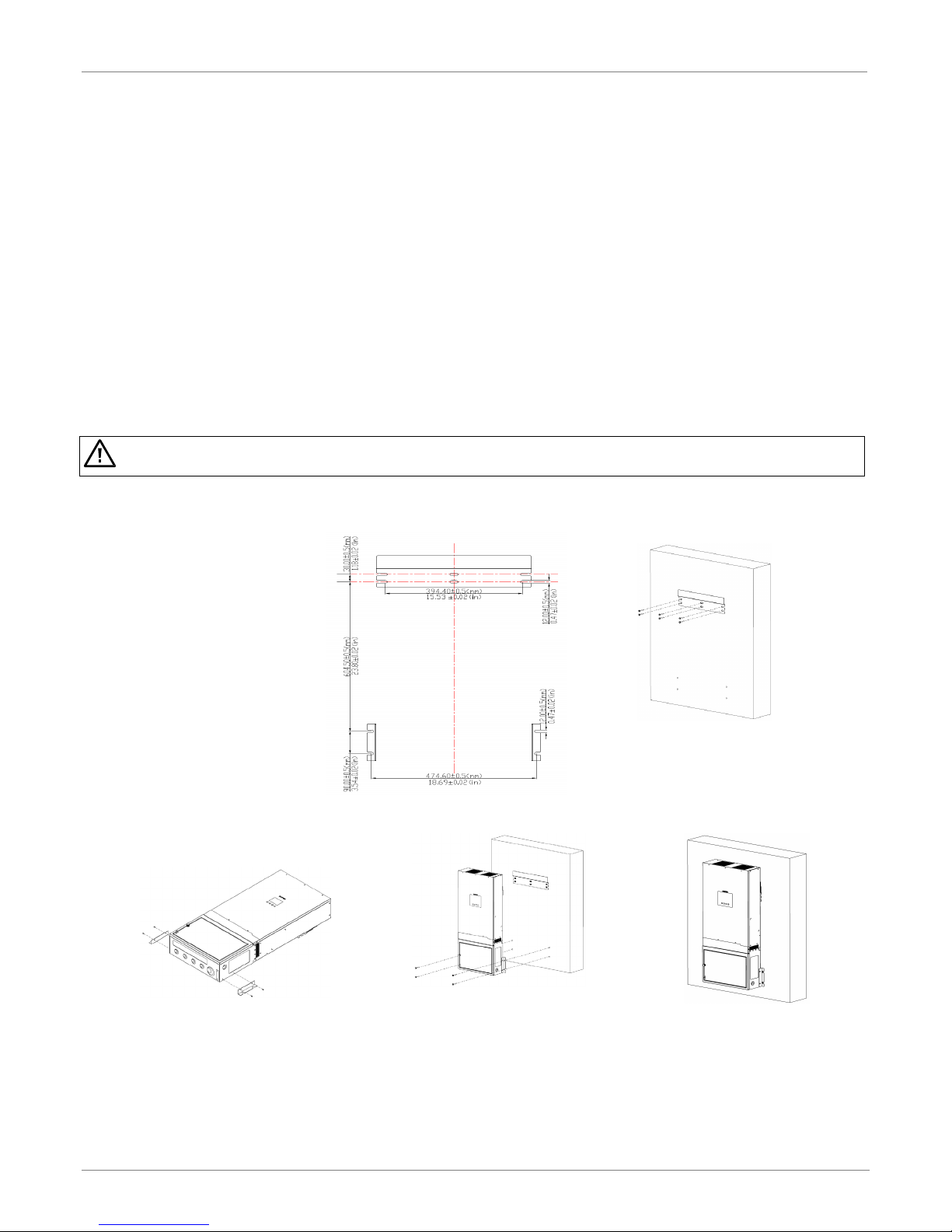

CAUTION. This inverter is heavy (87lb/40kg). Be carefully while lifting and mounting the unit. Installation should be

handled by two people. Do not hang or place additional weight onto the inverter.

MOUNTING THE INVERTER

Before installation, make sure nothing inside the package is damaged. You should have received the following

items in the package: H5001 hybrid inverter, backplate, brackets, screws and this installation manual.

The following considerations must be taken into account before selecting where to install.

• The unit cannot be mounted on flammable construction materials.

• The unit must be mounted to a solid surface.

• The unit should be installed at eye level in order to easily read the LCD display at any time.

• Allow 20cm (8in) of clearance to the sides and 50cm (20in) to the top and bottom of the unit for proper air

circulation to dissipate heat.

• The ambient temperature must be between 0 and 50°C and relative humidity must be between 5 and 85% to

ensure optimal operation. Do not operate where the temperature and humidity are beyond the specified limits.

• The unit has a Pollution Degree rating of PD2. The unit must be mounted in a protected area that is dry, free of

excessive dust and has adequate air flow.

• The unit was designed with an IP20 protection rating and is for indoor applications only.

Installing the Inverter onto the Wall

Step 1. Use the backplate as a

template, and install

anchors as needed.

Note: If installing onto

drywall, Unistrut needs to

be mounted and secured to

two studs in the wall. The

backplate and inverter’s

brackets are secured to the

Unistrut using Unistrut lugs.

Step 3. Install the brackets onto each

side of the inverter.

Step 4. Hang the inverter onto the

backplate.

Step 2. Mount the backplate onto the wall.

Note: Use at least two screws, one on

the left the other on the right.

Step 5. Secure the brackets on

inverters to the wall.

Rev.1 ©2018 Darfon Electronics Corp. 5 | Page

Note: Use at least two screws,

one on each side of the

inverter.

INSTALLATION MANUAL H5001 HYBRID INVERTER

TERMINAL MARK

PV INPUT POWER

TYPICAL AMPERAGE

CABLE SIZE

TORQUE

BEST VMP

VMP RANGE

PV input 1

3.25kW

13A

12 AWG

1.4 - 1.6 Nm

360V

250V - 430V

PV input 2

3.25kW

13A

12 AWG

1.4 - 1.6 Nm

360V

250V - 430V

WARNING. Because this inverter is non-isolated, only two types of PV modules are acceptable: single crystalline and poly

current to the inverter. For example, non-grounded PV modules will cause leakage current to the inverter.

CAUTION. To reduce the risk of damage due to surge, Darfon recommends surge protection between the modules and

the inverter.

CAUTION. Exceeding the maximum input voltage can destroy the unit. Check the PV string voltage before wiring the

connection.

WARNING. Never touch the terminals of the inverter directly. It

at the array not at the inverter.

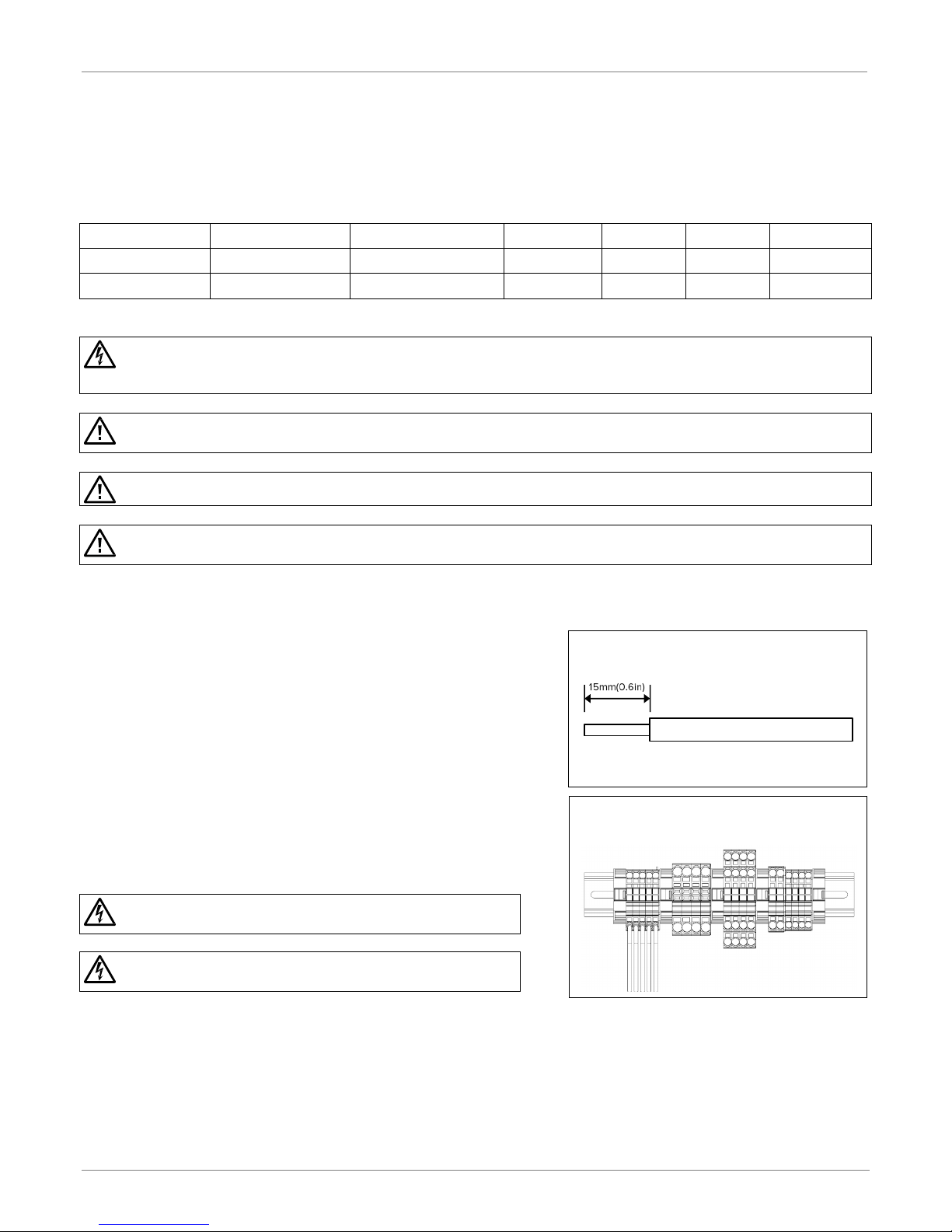

DC CABLE FOR PV CONNECTIONS

PV MODULE (DC) CONNECTION

There is a DC (PV) circuit breaker in the distribution box. This system can connect to two strings of PV modules with

MPPT control. Configure each PV input as recommended in the table below. Vmp is a PV panel’s max power point

voltage. The PV charging efficiency is maximized when the PV system’s voltage is close to Best Vmp.

crystalline with only Class A-rated. To avoid any malfunction, do not connect any PV modules with possibility of leakage

CAUTION. To reduce the risk of injury, use the proper cable size for PV module connection.

Connecting the PV Arrays

Step 1. For each PV input string, make sure the input voltage is between

250VDC and 430VDC, and the maximum current is 13A.

Note: The inverter can still be installed if you are only using

one PV input string.

Step 2. Make sure the circuit breaker is off.

Step 3. Strip 15mm(0.6in) of insulation from each PV cable (PV1+, PV1-, PV2+

and PV2-).

Step 4. Insert the PV cables into the PV quick connect terminals. Make sure

the polarity for each connection is correct; positive to positive and

negative to negative.

will cause lethal electric shock.

WARNING. The final connection for DC strings should be done

CONNECTING TO PV MODULE

Rev.1 ©2018 Darfon Electronics Corp. 6 | Page

INSTALLATION MANUAL H5001 HYBRID INVERTER

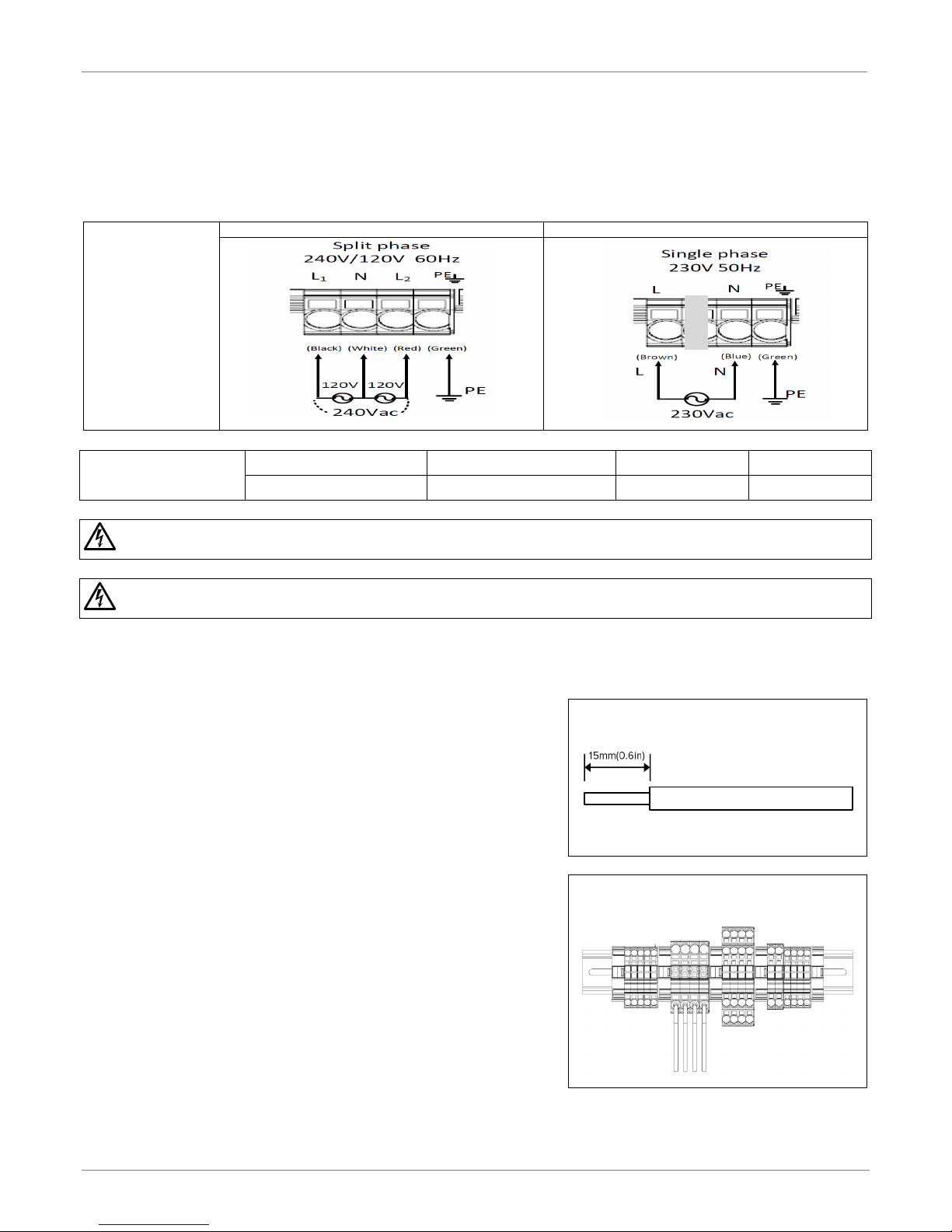

USA: 240V/120V SPLIT-PHASE SYSTEM

EURO: 230V SINGLE PHASE SYSTEM

GRID RATED POWER

NOMINAL VOLTAGE

WIRE SIZE

TORQUE

5KW

230/240 VAC

8 AWG

0.82 Nm

efficient operation to use the appropriate wire for grid (utility) connection.

WARNING. To prevent the risk of electric shock, make sure the ground wire is properly earthed before operating this unit

whether the grid is connected or not.

CONNECTIN G TO AC UTILITY TERMINAL

AC WIRE FOR GRID CONNECTION

GRID (UTILITY) CONNECTION

There is an AC (Grid) circuit breaker in the distribution box. This will ensure the inverter can be safely disconnected

during maintenance and is fully protected from overcurrent of AC input.

AC GRID

UTILITY

TYPE

GRID CONNECTION

WIRING REQUIREMENTS

WARNING. To reduce the risk of injury, use the recommended wire size above. It is very important for system safety and

Connecting to the Grid/Utility

Step 1. Check the grid voltage and frequency with an AC voltmeter. It

should be within the operation AC voltage range of the product’s

specifications.

Step 2. Make sure the circuit breaker is off.

Step 3. For each AC wire, strip 15mm(0.6in) of isolation.

Step 4. Connect the AC wires to the inverter according to the labels

indicated on the terminal block or your grid utility type.

Note: The PE protective conductor (Ground) should be the

first to be connected.

Rev.1 ©2018 Darfon Electronics Corp. 7 | Page

INSTALLATION MANUAL H5001 HYBRID INVERTER

BATTERY POWER

TYPICAL AMPERAGE

BATTERY CAPACITY

CABLE LENGTH

CABLE SIZE

TORQUE VALUE

5KW

104A

200 to 600AH

< 3m (one-way)

2 AWG

2 to 3Nm (18 to 26 in-lb)

WARNING. To reduce the risk of injury, use the recommended cable size above. It is very important for system safety and

WARNING. Shock Hazard. Installation must be performed with

care due to high battery current.

CAUTION. Before making the final DC connection or closing DC

CAUTION. Do not apply anti-oxidant substance on the terminals

before terminals are connected tightly.

CAUTION. Do not place anything between the flat part of the inverter terminal and the ring terminal. Otherwise,

overheating may occur.

CABLES FOR BATTERY CONNECTION

CONNECTING TO BATTERY TERMINAL

BATTERY CONNECTION AND CHARGING REQUIREMENTS

There is a DC (Battery) circuit breaker in the distribution box. Before connecting the batteries, please have the

battery specifications on hand.

Notes: 1. For lead acid batteries, Flooded, Gel or AGM can be used. Please check maximum charging voltage and current

when first using this inverter.

2. If using Lithium batteries, consult with the battery manufacturer for details.

efficient operation to use the appropriate cable for battery connection.

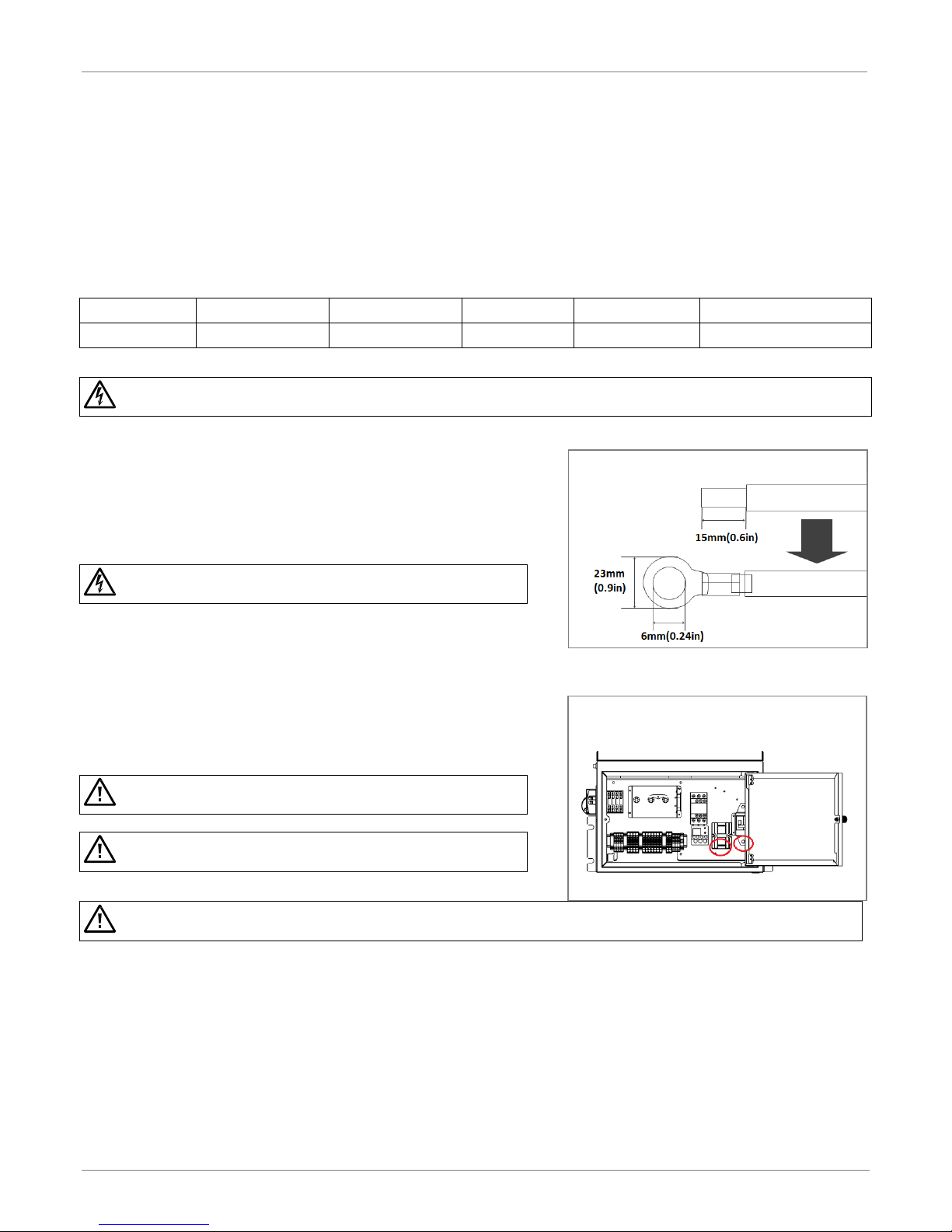

Connecting the Batteries

Step 1. Make sure the circuit breaker is off.

Step 2. Make sure the nominal voltage for the batteries is 48VDC.

Step 3. Strip 15mm(0.6in) of insulation from each battery cable and insert it

into a ring lug.

Step 4. Connect the battery ring lugs to the battery terminals. Make sure the polarity for each connection is correct; positive to

positive and negative to negative.

RED cable to the positive terminal (+);

BLACK cable to the negative terminal (-).

breaker, make sure the connections have the correct polarity.

Step 5. Update AP registers as needed. Please refer to the remote setting (Page 28).

Rev.1 ©2018 Darfon Electronics Corp. 8 | Page

INSTALLATION MANUAL H5001 HYBRID INVERTER

Charging Parameter

Default Value

Floating Charging Voltage

54Vdc

Charging process based on default setting.

Bulk FloatingAbsorption

time

U

time

I

Bulk Voltage

Float Voltage

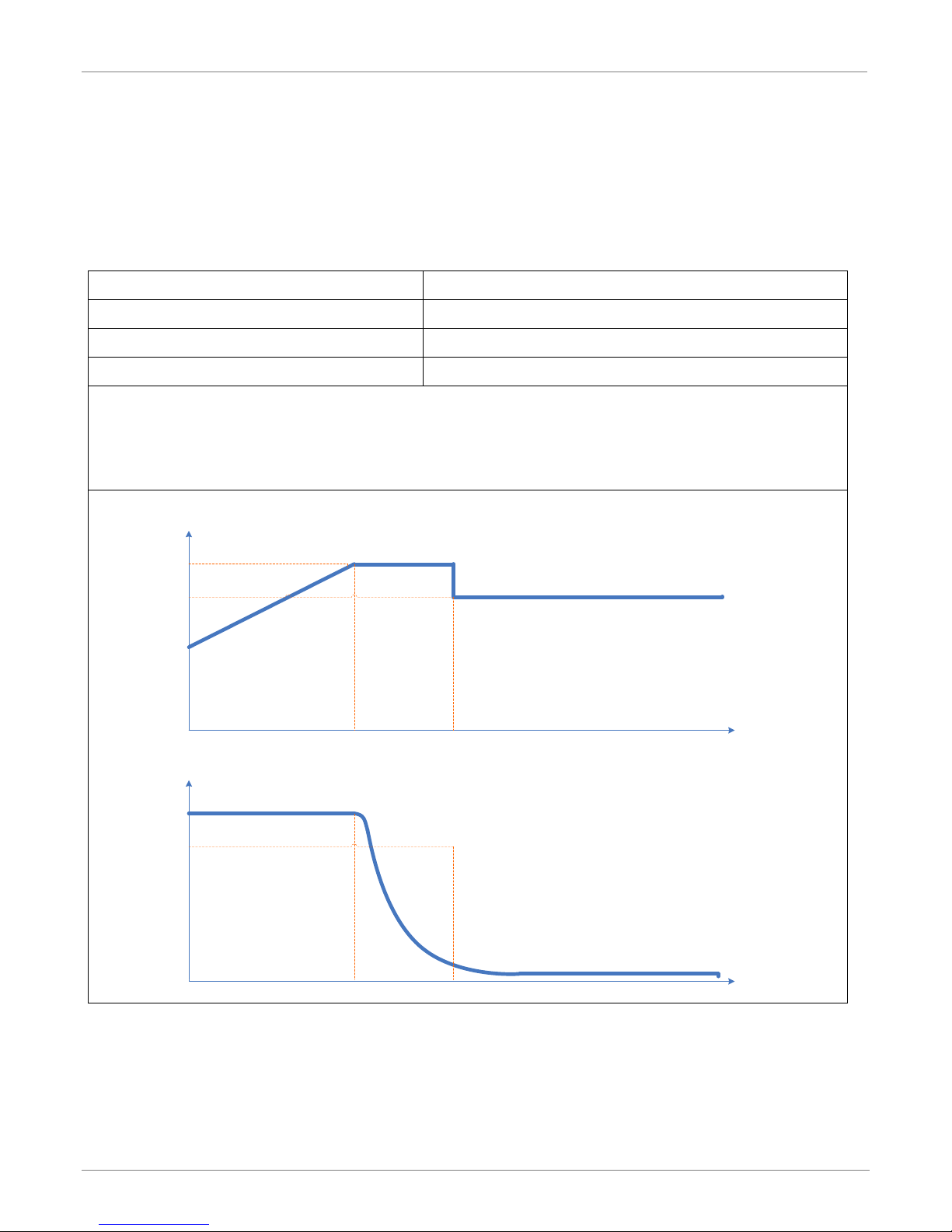

Battery Charging Requirements

The default charging parameters are shown below. Use this as a reference to make sure the battery selected is

compatible with H5001 inverter. It is recommended that you use a deep cycle battery when the mode of operation

is not set as one of the two back-up modes. If you want to change battery charging parameters, please refer to the

remote setting on page 25.

1. Lead-Acid Battery Charging Characteristics(include non-conmunication batteries)

Max. Charging Current 60A

Absorption Charging Voltage 56Vdc

The three stages:

First - charging voltage increases to 56V.

Second- charging voltage will maintain at 56V until charging current is down to 2 Amp.

Third- go to floating charging at 54V.

Rev.1 ©2018 Darfon Electronics Corp. 9 | Page

INSTALLATION MANUAL H5001 HYBRID INVERTER

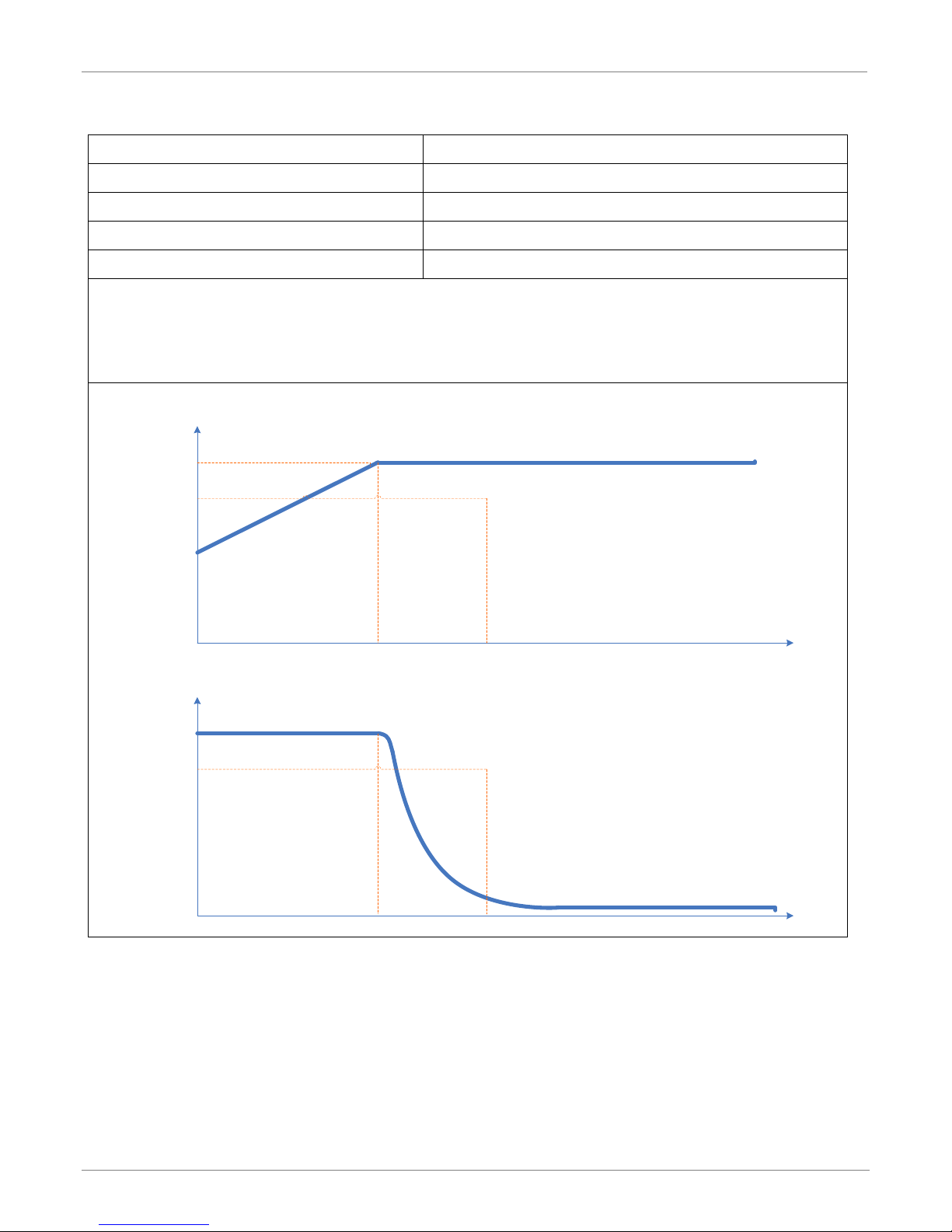

Charging Parameter

Default Value

Max. Charging Current

60A

Darfon Battery Charging Voltage

57.4Vdc

Charging process based on default setting.

Bulk Absorption

time

U

time

I

Bulk Voltage

Float Voltage

2. Lithium Battery Charging Characteristics

Golden Crown Battery Charging Voltage 56Vdc

Panasonic Battery Charging Voltage 52Vdc

The three stages:

First - charging voltage increases to Charging voltage.

Second- charging voltage will maintain until battery SOC is 99%.

Third- stop charging after 1 hour.

Rev.1 ©2018 Darfon Electronics Corp. 10 | Page

Loading...

Loading...