Page 1

INSTALLATION MANUAL

CLOUD-BASED MONITORING SYSTEM

INSTALLATION MANUAL

Page 2

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS.................................................................................3

Safety Instructions ................................................................................................................. 3

FCC Compliance .................................................................................................................... 3

MONITORING SYSTEM...........................................................................................................4

PLC Box Overview ................................................................................................................. 4

Data Logger Overview .......................................................................................................... 5

Installing the PLC Box and Data Logger ........................................................................... 7

Registering the PV System .................................................................................................. 8

TROUBLESHOOTING ............................................................................................................ 12

Troubleshooting the PLC Box ........................................................................................... 12

Troubleshooting the Data Logger .................................................................................... 13

TECHNICAL SPECIFICATIONS ............................................................................................ 14

PLC Box ................................................................................................................................. 14

Data Logger .......................................................................................................................... 14

NOTES..................................................................................................................................... 15

Rev. 1 ©2017 Darfon Electronics Corp. 2 | Page

Page 3

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

IMPORTANT SAFETY INSTRUCTIONS

PLEASE READ INSTRUCTIONS BEFORE INSTALLING AND KEEP FOR FUTURE REFERENCE.

This manual contains important instructions for the installation and maintenance of Darfon’s Monitoring System.

Before installing, please read these safety instructions carefully. Take special care to follow the warnings indicated

on the unit itself as well as the safety instructions listed below.

Safety Symbols

To reduce the risk of injury and to ensure the continued safe operation of this product, the following safety

instructions and warnings are marked in this manual.

WARNING

This indicates the risk of electric shock. The presence of high voltage levels may constitute a risk of

injury or death to users and/or installers.

CAUTION

This indicates important information where failure to comply may result in safety hazards or cause

damage to this product.

Safety Instructions

• Read all instructions and cautionary marks in the manual carefully before starting the installation. Failure to

comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of

design, manufacture, and intended use of the device. The manufacturer assumes no liability for the customer’s

failure to comply with these requirements.

• Do not attempt to repair this product; it does not contain user-serviceable parts. Repairs and internal servicing

should only be performed by authorized service personnel.

• Do not tamper with or open this product. Opening this product may result in electric shock.

• Perform all electrical installations in accordance with all applicable local electrical codes and the National

Electrical Code (NEC), ANSI/NFPA 70.

• Only qualified electrical personnel should perform the electrical installation/wiring of this product.

• Switch off the circuit breakers before installation and wirings.

• For the safety of installation, remove all conductive jewelry or equipment during the installation or service of the

device parts, connector and/or wiring.

• Do not stand on a wet location while doing installation and wirings. Enclose the outer covering well before

switch on the circuit breakers.

FCC Compliance

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on,

you are encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by the party responsible for compliance may void the user’s

authority to operate the equipment.

Rev. 1 ©2017 Darfon Electronics Corp. 3 | Page

Page 4

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

FEATURE

FUNCTION

AC(PLC) Signal Input

Connects to the AC cable in the PV system.

DC Power Input

Plug the Power adapter to the DC Jack on the PLC Box.

Signal LEDs

The Signal LED will flash three times during normal startup.

Termination Resistor

If the distance between the Data Logger and PLC Box is greater than 50m, then the termination resistor

PLC signal Input

DC Power Input

Termination Resistor

Power LED

MONITORING SYSTEM

At this stage, the majority of the PV system is already installed: the PV modules and microinverters. The

following section list steps on how to install the monitoring system. Before installing, review and follow

all important safety instructions listed in the beginning of this manual.

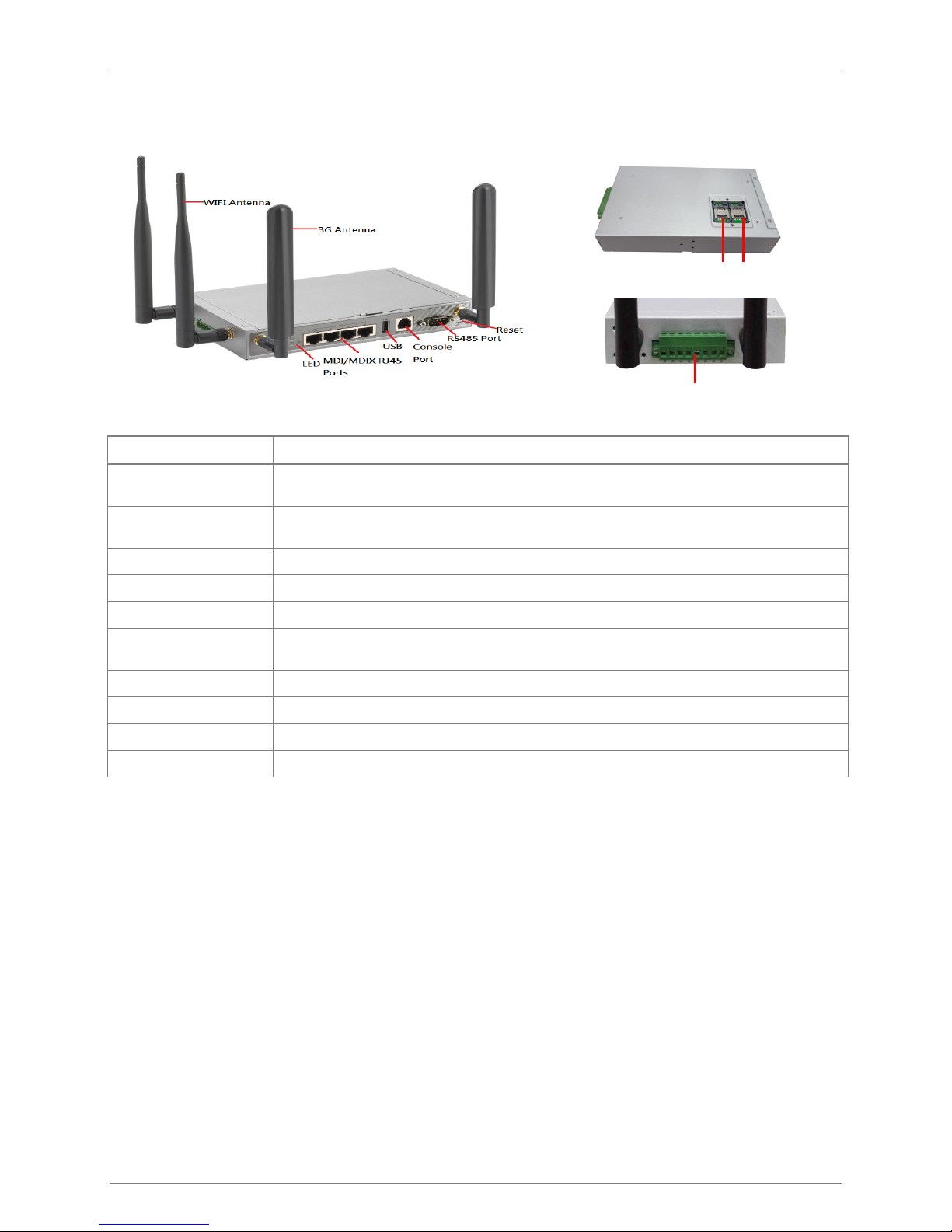

PLC Box Overview

Signal LEDs

(Input: AC 100-240V 50-60Hz, Output: DC+12V 1A)

Power LED The Power LED will be solid when on

Represents the strength of the signal. (1 LED - weak signal, 4 LEDs - strong signal.)

Weak Signal: Strong Signal:

switch on both the Data Logger and PLC Box should be switched ON. If the distance between the Data

Logger and PLC Box is less than 50m, then the termination resistor switch on both the Data Logger and

PLC Box should be switched OFF.

Rev. 1 ©2017 Darfon Electronics Corp. 4 | Page

Page 5

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

FEATURE

FUNCTION

Power Terminal Block

Plug the power adapter to the power terminal on the Data Logger.

(Input: AC 100-240V 50-60Hz, Output: DC+12V 2A)

LED Indicators

Power Source 1, Power Source 2, WLAN (WiFi), SIM A, SIM B, LAN 1, LAN 2, LAN 3,LAN 4, USB,

Serial Port, High 3G Signal, Low 3G Signal

WLAN Port

To connect to the internet (router).

LAN Port

To connect to the client device.

USB Port

To connect to a USB storage device.

Reset Button

To reset the data logger, press and hold the button for 10 seconds. The data logger will restart with

RS485 Port

To connect to the PLC Box.

WiFi Antenna

WiFi antenna is a device for sending or receiving WiFi waves.

3G Antenna

3G antenna is a device for sending or receiving 3G waves.

SIM Card Slot

Insert the SIM card to open 3G function.

Data Logger Overview

SIM A

SIM B

the default factory settings.

Power Terminal Block

Rev. 1 ©2017 Darfon Electronics Corp. 5 | Page

Page 6

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

LED ICON

INDICATION

LED COLOR

DESCRIPTION

Steady ON: Wireless radio is enabled

OFF: Wireless radio is disabled

Steady ON: Ethernet connection of LAN is established

Flash: Data packets are transferred

LED Indicators

Power Source 1 Green Steady ON: Device is powered on by power source 1

Power Source 2* Green Steady ON: Device is powered on by power source 2

~

* If both power source 1 and 2 are connected, the device will choose power source 1 first. The LED of power source 2 will remain

OFF at this condition.

WLAN (WiFi) Green

SIM A Green Steady ON: SIM card A is used

SIM B Green Steady ON: SIM card B is used

LAN 1 ~ LAN 4 Green

High 3G Signal Green Steady ON: The signal strength of 3G is strong

Low 3G Signal Green Steady ON: The signal strength of 3G is weak

USB Green Steady ON: If USB device is attached

Serial Port Green Steady ON: If serial device is attached

Flash: Data packets are transferred

Rev. 1 ©2017 Darfon Electronics Corp. 6 | Page

Page 7

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

CAUTION

the PLC box to the AC trunk cable or AC junction box.

Installing the PLC Box and Data Logger

Step 1: Install the PLC Box.

Connect DC power to the PLC Box through 12V/1A AC adaptor. Connect the AC wiring (PLC

Signal) from the PLC Box to the AC Trunk Cable or the AC Junction Box. The PLC Box will

need to be placed in and secured to the AC Junction Box. The wires in the AC trunk cable

are identified by color.

Disconnect the PV circuit from any grid power before installing

Step 2: Connect the Data Logger to the Router

Place the data logger near the router, then make a direct Ethernet connection. If the data

logger cannot be placed near the router, then the installer can add either a wireless access

port or a power line communication port (not supplied with the micro inverter).

Note: To mount the data logger, use the included wall-mount frame.

Step 3: Connect the Data Logger to the PLC Box

Insert the red/black wiring into the RS485 connectors, and then insert the connectors into

the Data Logger and PLC Box. (Ensure there is length of the red/black wiring is sufficient for

installation)

Note: Ensure the RS485 connectors are wired properly.

Data Logger RS485 D + PLC Box RS485 D +

Data Logger RS485 D – PLC Box RS485 D –

Note: If installing more than one PLC Box in the system, daisy-chain the PLC

Boxes together using RS485 cables. Then connect the last PLC Box in

the series to the Data Logger using the RS485 cable.

Rev. 1 ©2017 Darfon Electronics Corp. 7 | Page

Page 8

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

Step 4: Connect Power

Plug in the Data Logger into the AC outlet. (Be sure the adapter is connected to the Data

Logger before it is plugged into to the outlet.)

Registering the PV System

Step 1: Before Registering

Before registering the PV system, you will need the following information:

• Data logger serial number

• Installation map with microinverter location and serial numbers

Step 2: Installer Registration

In your web browser, go to http://portal.darfonsolar.com/register/ and complete the registration

process. (If you are already registered on the Darfon Solar Portal, go to step 4.)

Step 3: Account Activation

After completing registration, a confirmation email with an activation link will be emailed to you.

Click the link to activate your account.

Rev. 1 ©2017 Darfon Electronics Corp. 8 | Page

Page 9

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

Step 4: Log into the Darfon Solar Portal

Go to http://portal.darfonsolar.com. Enter your email and password, then click “Login”.

Step 5: Click “New Installation”

Select the installer and enter the data logger’s serial number.

Step 6: Enter the homeowner and site information

Be sure to select the correct time zone for the site and then click “Save & Continue”.

Rev. 1 ©2017 Darfon Electronics Corp. 9 | Page

Page 10

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

Step 7: Create an Array

7.1 Enter the number of rows and columns in the array.

7.2 Drag and drop each PV modules onto the array. For each module, select/assign the

microinverter serial number, enter the module manufacturer and model, then click “Done”.

7.3 Enter in a name for the array, the tilt and the azimuth.

If you have more than one array, click “+Add More Arrays” and repeat the process.

If all the PV modules and the microinverters have been assigned, click “Next”.

Rev. 1 ©2017 Darfon Electronics Corp. 10 | Page

Page 11

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

Step 8: Arrange the Arrays

Arrange the arrays to match the layout of the PV system and click the “Save” button.

Note: Uploading a background image is not required.

Step 9: Account Activation

Scroll down to the Account Activation section. Select the Send Activation Notification to

homeowner option and click “Save & Continue”.

Step 10: Completion Confirmation

The PV System registration has been completed and your screen should display the following

confirmation page.

Rev. 1 ©2017 Darfon Electronics Corp. 11 | Page

Page 12

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

LED STATUS

DESCRIPTION

Power LED

No Light

No Input Power

●

Solid Green

Operating

Signal LED

No Light

No Signal from Microinverters

●●●●

One Solid Green

Weak Signal from Microinverters

●●●●

Four Solid Green

Strong Signal from Microinverters

TROUBLESHOOTING

Troubleshooting the PLC Box

If the monitoring system is not operating correctly, use the steps below to troubleshoot the problem. If

the issue cannot be resolved using these steps, please contact inverter maker’s technical services.

●

Power LED

Signal LED(x4)

RS485

Termination Resistor

DC Power Input

If the Power LED status shows no light:

• Verify the Power Adaptor is securely connected to the PLC Box

• Verify the AC source connected to Power Adaptor is turned on

If the RS485 LED status shows no light:

• Check the RS485/CAT5 connection between the PLC Box and Data Logger

• Verify the Data Logger has power

•

If the Signal Strength LEDs status shows no lights or only one solid green LED:

• Check the connections and cable distances between the PLC Box and micro inverters

• Place the PLC Box as close to the micro inverters as possible. Maximum cable distance is 164ft (50m)

If the Signal Strength LEDs status shows 3 or 4 solid green lights, but there is no communication:

• Turn the PLC Box termination resistor on

●●●●

Rev. 1 ©2017 Darfon Electronics Corp. 12 | Page

Page 13

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

Troubleshooting the Data Logger

If the monitoring system is not operating correctly, use the steps below to troubleshoot the problem. If

the issue cannot be resolved using these steps, please contact inverter maker’s technical services.

3G Antennas

WiFi

Antennas

LED

Indicators

Auto MDI/MDIX RJ-45 Ports

4x FE LAN to connect local devices

USB

Port

Console

Port

Power LED did not turn on:

• Verify that the Power adapter is connected to the Data Logger and the AC outlet.

• Verify that there is power in the AC outlet.

Serial Port LED did not turn on:

• Check the RS485 connection between the Data Logger and the PLC Box.

• Verify the PLC Box has power.

WLAN LED did not turn on:

• Check the WLAN connection between the Data Logger and the router (Internet).

• Verify the router has power.

RS-485

Port

Reset

Button

Rev. 1 ©2017 Darfon Electronics Corp. 13 | Page

Page 14

INSTALLATION MANUAL CLOUD- BASED MONITORING SYSTEM

COMMUNICATION

Serial Port

DB9 RS485 for Data Logger1

Number of Devices

Up to 24 Microinverters

Transmission Distance2

Up to 164ft (50m)

MEMORY

Internal Memory

Flash ROM 16kb

MECHNICAL DATA

Operating Temperature

-10 to 50°C (14 to 122°F)

Dimensions (WxHxD)

70 x 70 x 20mm

Weight

57.1g (2oz),

Adaptor 65.3g (2.3oz)

Protection Rating

IP20 (Indoor Use Only)

Compliance

UL60950-1,

FCC Part 15 Class B

POWER

Power Consumption

7.2W (Maximum)

Power Supply Input

12VDC, 600mA

DEVICE INTERFACE

Uplink

Embedded 3G (Dual SIM), RJ45 FE

LAN

4x RJ45 FE, 11n 2T2R (WiFi)

Serial Port

DB9 RS485 (Up to 3 PLC Boxes)

Management Port

RJ12 RS232 (Console)

Storage & Log

USB 2.0 (32G Max.)

Cellular Band³ (EURO)

UMTS(WCDMA): 2100/1900/900 MHz

GSM: 1900/1800/850/900 MHz

Cellular Band (US)

UMTS(WCDMA): 2100/1900/850 MHz

Antenna (Detachable)

2x 5dBi (WiFi), 2x 3dBi (3G)

WAN FUNCTIONS

WAN

Multiple WANs, Failover/Load Balance,

Configurable Ethernet/3G

Cellular

2G/3G IPv4/IPv6, IP Pass-through

Ethernet

Dynamic IP, Static IP, PPPoE, PPTP, L2TP

IPv6

Dual Stack, 6-in-4, 6-to-4

BASIC FUNCTIONS

Ethernet

LAN IP, Subnet Mask

WiFi System

802.11n 2T2R MIMO 300Mbps (2.4GHz)

WiFi Operation

AP Router

Modes

Multi-SSID, WPS, WMM

WiFi Security

WEP, WPA,WPA2, WPA-PSK, WPA2-PSK,

VLAN

Port-based, Tag-based

NAT

ALG, Special AP, DMZ Host, Virtual Server/

Computer, PPTP/L2TP/IPSec Pass-Through

Routing

Static, Dynamic: RIP1/RIP2, OSPF, BGP

MECHNICAL DATA

Operating Temp.

-10 to 50°C (14 to 122°F)

Dimensions (WxHxD)

7.4 x 4.3 x 1.2 in (187 x 110 x 31mm)

Weight

1.5 lbs (0.67kg)

Protection Rating

IP20 (Indoor Use Only)

Compliance

UL60950-1, FCC Part 15B, Part 15C

POWER

Power Supply Input

Dual 12VDC, 2A Max.

TECHNICAL SPECIFICATIONS

PLC Box

¹ The maximum distance between the Data Logger

and PLC Box is 1312ft (400m).

² The distance from the PLC Box to the microinverter

at the farthest end of the AC branch.

³ Supported cellular band is dependent upon regional

hardware version.

3G and Wi-Fi performance will be degraded if

device's ambient temperature is above 55°C.

Data Logger

GSM: 1900/1800/850/900 MHz

802.1x

Rev. 1 ©2017 Darfon Electronics Corp. 14 | Page

Page 15

NOTES

Manufactured by:

Darfon Electronics Corp.

167 Shan-ying Road, Gueishan

Taoyuan 333, Taiwan, (R.O.C.)

Tel: +886 3 2508800

©2017 Darfon Electronics Corp. All rights reserved. All specifications are subject to change without prior notice.

Darfon and the Darfon logo are trademarks of Darfon Electronics Corp. All other trademarks are the property of the respective owners.

USA Office:

Darfon America Corp.

103A Pioneer Way

Mountain View, CA 94041

Tel: +1.650.316.6300

For more information:

www.darfonsolar.com

Loading...

Loading...