Page 1

VXI-SC-1102 User Manual

32-Channel Multiplexer Amplifier Module

February 1997 Edition

Part Number 321385A-01

© Copyright 1997 National Instruments Corporation. All Rights Reserved.

Page 2

Internet Support

support@natinst.com

E-mail: info@natinst.com

FTP Site: ftp.natinst.com

Web Address: http://www.natinst.com

Bulletin Board Support

BBS United States: (512) 794 -5422

BBS United Kingdom: 01635 551422

BBS France: 01 48 65 15 5 9

Fax-on-Demand Support

(512) 418-1111

Telephone Support (U.S.)

Tel: (512) 795-8248

Fax: (512) 794-5678

International Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20,

Canada (Ontario) 905 785 0085, Canada (Québec ) 514 694 8521, Denmark 45 76 26 00,

Finland 09 527 2321, France 01 48 14 24 24, Ger many 089 741 31 30, H on g Kong 264 5 3186,

Israel 03 5734815, Italy 02 413091, Japan 03 5472 2970, K orea 02 596 7456,

Mexico 5 520 2635, Netherlands 0348 433466, Nor w ay 32 84 84 00, Singapore 22658 86,

Spain 91 640 0085, Sweden 08 730 49 70, Switzerland 056 200 51 51, Taiwan 02 377 1200,

U.K. 01635 523545

National Instruments Corporate Headquarters

6504 Bridge Point Parkw ay Austin, TX 78730-503 9 Tel: (512) 794-0100

Page 3

Important Information

Warranty

The VXI-SC-1102 is warranted agai nst defects in mater ials and workm anshi p fo r a period of one year from the date

of shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace

equipment that proves to be defective during the warranty per iod. This warrant y includes par ts and labor .

The media on which you receive National Instru ments software ar e warranted not to fail to execute pro grammi ng

instructions, due to defects in materials and workmanship, for a period of 90 days from date of shipment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace software media that do

not execute programming instructions if National Instruments receives notice of such defects during the warranty

period. National Instruments does not warr ant that t he operatio n of the softwar e shall be uni nte rrupt ed or erro r free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside

of the package before any equipment will be accepted for warranty work. Natio nal Instrum ents wil l pay the shippin g

costs of returning to the owner par ts whi ch are cov ered by w arranty .

National Instruments believes that the information in this manual is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves

the right to make changes to subsequent editi ons of this document without prior notice to holders of this edition. The

reader should consult National Instruments if errors are suspected. In no event shall National Instruments be liable for

any damages arising out of or related to this docum ent or the in format ion contai ned in it.

E

XCEPT AS SPECIFIED HEREIN

SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

C

USTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL

I

NSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER

WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR

CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF

Instruments will apply regardless of the form of action, whether in contract or tort, including negligence. Any action

against National Instruments must be brought within one year after the cause of action accrues. National Instruments

shall not be liable for any delay in performan ce due to causes beyo nd it s reasonable cont rol. The warranty pr ovided

herein does not cover damages, defects, malf unctio ns, or s ervice fai lures caused by owne r’s fail ure to fol low the

National Instruments in sta llat ion, o perat ion, or ma inte na nce instr uct ions; owner ’s modif icat ion of the p roduct;

owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or

other events outside reasonable control.

, N

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND

.

. N

ATIONAL INSTRUMENTS

. This limitatio n of the li abil ity of Natio nal

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, reco rding, storin g in an in format ion retr iev al system , or tra nslati ng, in wh ole or in par t,

without the prior written consent of Nation al Inst rument s Corpo ration .

Trademarks

LabVIEW®, NI-DAQ®, RTSI®, ComponentWorks™, CVI™, Measure™, SCXI™, and VirtualBench™ are

trademarks of Nationa l Ins trumen ts C orpor atio n.

Product and company names listed are trademarks or trade names of their respective companies.

WARNING REGARDING MEDICAL AND CLINICAL USE OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not design ed with comp onents and testing in tend ed to ensure a level o f reliabi lity

suitable for use in treatment and diag nosi s of humans . Appli cations of Nationa l Inst rument s prod ucts inv olving

medical or clinical treatment can create a potential for accidental injury caused by product failure, or by err ors on the

part of the user or application designer. Any use or applicati on of Nati onal Instrum ents pr oducts for or involvin g

medical or clinical treatment must be performed by properly trained and qualified medical personnel, and all traditional

medical safeguards, equipment, and procedures that are appropriate in the particular situation to prevent serious injury

or death should always continue to be used when National Instruments products are being used. National Instruments

products are NOT intended to be a substitute f or any for m of establ ished pr ocess, proce dure, or equi pmen t used to

monitor or safegua rd huma n he alth and sa fety in med ical or clin ical t reat ment .

Page 4

About This Manual

Organization of This Manual................................................ ...... ..... .............................ix

Conventions Used in This Manual................................................................................x

National Instruments Documentation.............................. ..... .................................. ......xi

Customer Communication............................................................................................xi

Chapter 1

Introduction

About the VXI-SC-1102...............................................................................................1-2

What You Need to Get Started.....................................................................................1-3

Software Programming Choices...................................................................................1-3

National Instruments Application Software...................................................1-3

NI-DAQ Driver Software...............................................................................1-4

VXIplug&play Instrument Driver..................................................................1-5

Optional Equipment......................................................................................................1-6

Unpacking.....................................................................................................................1-6

Table

of

Contents

Chapter 2

Installation

Current-Loop Receivers................................................................................................2-3

Installing Your Hardware .............................................................................................2-4

Chapter 3

Signal Connections

Front Connector............................................................................................................3-1

Signal Descriptions......................................................................................... 3-3

Channel Input Signal Connections.................................................................3-3

Ground-Referencing Your Signals...................................................3-4

Cold-Junction Sensor Connection..................................................................3-6

© National Instruments Corporation v VXI-SC-1102 User Manual

Page 5

Table of Contents

Chapter 4

Theory of Operation

Functional Overview....................................................................................................4-1

VXIbus Interface.......................................................................................................... 4-2

Digital Control Circuitry.............................................................................................. 4-2

Analog Circuitry........................................................................................................... 4-3

Analog Input Channels...................................................................................4-3

Analog Output................................................................................................ 4-3

Chapter 5

Calibration

Calibration Equipment Requirements................................................. .........................5-1

Gain and Offset Calibration................................................................. ...... ...... ............. 5-2

Sample Program for Calibration...................................................................................5-4

Appendix A

Specifications

Appendix B

Customer Communication

Glossary

Index

Figures

Figure 1-1. VXI Signal Conditioning System.......................................................... 1-1

Figure 1-2. The Relationship between the Programming Environment, Your

Instrument Driver, and Your VXI-DAQ Hardware .............................. 1-5

Figure 2-1. VXI-SC-1102 Parts Locator Diagram...................................................2-2

Figure 2-2. Bent and Trimmed Resistor................................................................... 2-3

Figure 3-1. VXI-SC-1102 Front Connector Pin Assignments................................. 3-2

Figure 3-2. Ground-Referenced Signal Connection.................................................3-5

Figure 3-3. Floating Signal Connection Referenced to Chassis Ground................. 3-6

VXI-SC-1102 User Manual vi © National Instruments Corporation

Page 6

Tables

Table of Contents

Figure 4-1. VXI-SC-1102 Block Diagram...............................................................4-1

Figure 5-1. Analog Bus Receptacle Pin Assignment ...............................................5-2

Table 3-1. Front Connector Signal Descriptions.....................................................3-3

© National Instruments Corporation vii VXI-SC-1102 User Manual

Page 7

This manual des cribe s the el ectri cal an d mech an ical a spect s of the

VXI-SC-1102 and contains informat io n concerning its installation and

operation. The VXI-SC-1102 is a signal conditioning submodule in the

VXI-data acquisition (VXI-DAQ) line of National Instruments

products. The VXI-SC-1102 is designed for signa l conditionin g of

thermocouples, volt and m illivolt sour c es, and 4 to 2 0 mA source s o r

0 to 20 mA pr ocess- c urren t sou rc es. T he V XI- SC-1 102 has 32

differential analog input channels and one cold-junction sensor channel.

Organization of This Manual

The VXI-SC-1102 U se r Ma nual is organized as follows:

• Chapter 1, Introduction, d escribe s th e V XI-SC -11 02, lists wha t

you need to get started, optional software and optional e quipment,

and explains how to u npac k th e V XI-SC- 110 2.

• Chapter 2, Installation, describes how to install cu rrent- loop

receivers on your VXI-SC-1102 and gives inform ation about

installing your VXI-SC-1102 submodule into the VXI -SC-1000

carrier module.

• Chapter 3, Signal Connections, de scribes the input signal

connections to the VXI-S C-1102 sub module via the front

connector.

• Chapter 4, Theory of Operation, contains a functional overview of

the VXI-SC-1102 and e xpl ains the op era tion o f each func tional

unit.

• Chapter 5, Calibration, discusses the ca libration procedures for the

VXI-SC-1102.

• Appendix A, Specifications, lists the specifications for the

VXI-SC-1102.

• Appendix B, Customer Communication, co ntains form s y ou ca n

use to request help from National Instruments or to comment on our

products.

About

This

Manual

©

National Instruments Corporation ix VXI-SC-1102 User Manual

Page 8

About This Manual

•The Glossary contains an alphabetical list and description of terms

used in this manual, including abbreviations, acronym s, metric

prefixes, mnemonics, symbols, an d general data acqu isition terms.

•The Index contains a n alpha betica l list o f ke y term s and topic s in

this manual, including the page whe re you can fin d ea ch on e.

Conventions Used in This Manual

The following conventions are used in this manual.

< > Angle brackets containing numbers separated by an ellipsis represent a

range of values assoc iated wit h a port, bit, or signal nam e (for exam ple,

ACH<0..7> stands for the signals ACH0 through ACH7).

bold italic Bold italic text denotes a note, caution, or warning.

italic Italic text denotes emphasis, a cross reference, or an introduction to a

key concept.

monospace Denotes text or characters that are to be literally input from the

keyboard, sections of c ode, p rogra mmin g exa m ples, a nd synt ax

examples. This fo nt is also use d for the prope r n ame s of d isk d rive s,

paths, directories, pro gra ms , subp rog rams, su bro utines, de vice n ames ,

functions, variables, filenames, and extensions, and for statements and

comments taken from program code.

PC Refers to the IBM PC/XT, the IBM PC AT, and compatible computers.

VXI-MIO module Refers to any of the N ationa l Instrum ents V XI- MIO Se ries of p lug-in

data acquisition boards.

carrier module Refers to the VXI-SC-1000, which plugs directly into a VXI slot and on

which VXI-SC submodules are installed.

VXI-SC submodule Refers to VXI signal conditioning hardware that installs onto the carrier

module.

Abbreviations, acronyms, me tric prefixes, mnemonics, symbols, an d

terms are listed in the Glossary.

VXI-SC-1102 User Manual x

©

National Instruments Corporation

Page 9

National Instruments Documentation

The VXI-SC-1102 U se r Ma nual is one piece of the documenta tion set

for your VXI-DAQ s ystem . You co uld have any of seve ral type s of

documents, depending on the h ardw are and sof tware in yo ur syste m.

Use the different types of docu me nts you ha ve a s follow s:

• Your VXI-DAQ hardware user manuals—These manuals have

detailed information about the VXI-DAQ hardware that plugs into

or is connected to yo ur V XIbu s c hassis. Us e thes e ma nuals f or

hardware installation and configuration instructions, specification

information about your VXI-DAQ hardware, and application hints.

• Software documentation—You may have both application software

and driver software documentation. National Instruments

application software incl udes Com ponen tW ork s, LabV IEW,

LabWindows

Instruments driver software includes NI-DAQ and VXIplug&play

instrument drivers. After you set up y our ha rdw are system, use

either your application or driver softw are docume ntation to help

you write your application. I f you ha ve a lar ge, c omplica te d

system, it is worthwhile to look thr ough the software

documentation befo re yo u co nfigu re y our hard w are.

• Accessory installation guides or manuals—I f you are using

accessory products, read the terminal block and cable assembly

installation guides or accessory board user manuals. They explain

how to physically co nnec t the releva nt p ieces of the s ystem .

Consult these guides when you are mak ing your c onne ctions.

®

/CVI, Measure, and VirtualBench. National

About This Manual

Customer Communication

National Instruments wants to rece ive you r com ments o n ou r prod ucts

and manuals. We are interested in the applications you develop with our

products, and we want to help if you have problems with them. To make

it easy for you to contact us, this manual contains comment and

configuration forms for you to complete. These for ms are in

Appendix B, Customer Communication, at the end of this manual.

©

National Instruments Corporation xi VXI-SC-1102 User Manual

Page 10

Chapter

Introduction

This chapter describe s the VX I-SC -1102, lists wha t y ou need to get

started, optional soft w are and option al eq ui p m en t , an d explains ho w to

unpack the VXI-SC-1102.

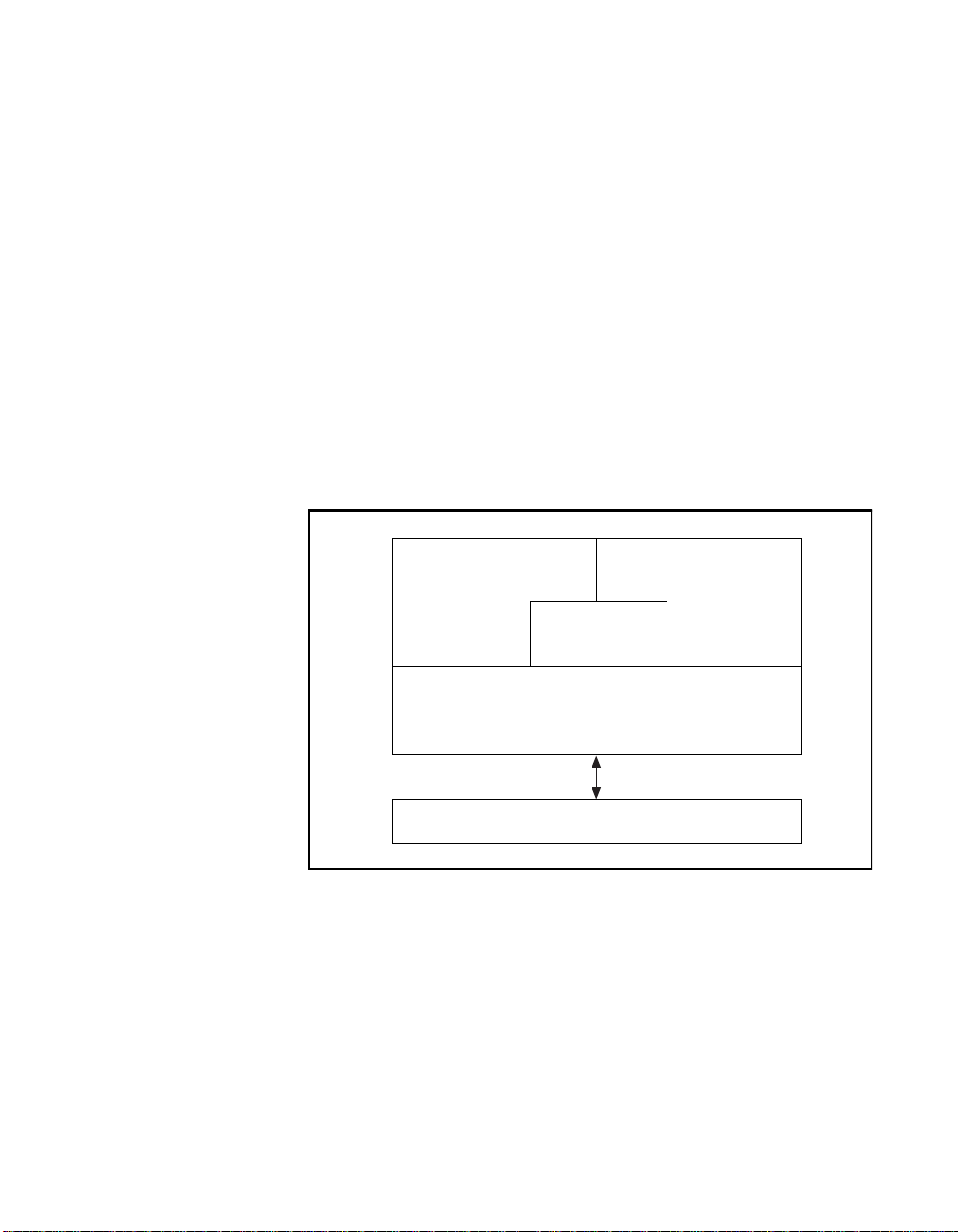

The VXI-SC-1102 is part of the VXI signal conditioning system, which

consists of a carrier m odu le and o ne or m ore V XI sign al con ditioning

submodules or filler panels as shown in Figure 1-1.

2

1

4

3

5

To VXIbus

Chassis

6

8

1

9

1 Analog Bus Receptacle

2SCMPs

3 SCMP Socket

©

National Instruments Corporation 1-13 VXI-SC-1102 User Manual

4 Address Switch

5 VXI-SC Subslot 1

6 VXI-SC Subslot 2

Figure 1-1.

7 VXI-SC Carrier Module

8 VXI-SC-1150 Submodule

9 VXI-SC Submodule

VXI Signal Conditioning System

7

Page 11

Chapter 1 Introduction

The VXI-SC-1000 is a carrier module that installs into a slot in a

VXIbus chassis and is po pulated w ith one or tw o submod ules. T he

VXI-SC-1102 is a submodule that installs into VXI-SC subslots on a

VXI-SC-1000 carrier module.

Your VXI-SC-1000 ca rrier modu le is shipp ed w ith a filler pane l

installed in one of the submodule sites. This filler panel is necessary for

the attachment of the front panel, so you should leave it in place until

you are ready to install a VXI-SC submodule.

About the VXI-SC-1102

The VXI-SC-1102 is a submodule for the signal conditio ning of

thermocouples, low-bandwidth volt and millivolt sources, 4 to 20 mA

current sources, a nd 0 to 2 0 mA p roce ss-curr en t sourc es . The

VXI-SC-1102 has 32 diffe rential analog inp ut cha nnels a nd o ne

cold-junction sensor channel. On each channel, the VXI-SC-1102 has a

three-pole lowpass filter with a 2 Hz cutoff frequency to reject 60 Hz

noise. Each channel also has an amplifier with a selectable gain of 1 or

100. You can multiplex the VXI-SC-1102 inputs to a single output,

which drives a single V XI-MIO boa rd c hanne l.

The VXI-SC-1102 operates with full functionality with National

Instruments VXI-MIO modules. You can multiplex several

VXI-SC-1102 submodules an d oth er VX I signa l con ditioning

submodules into a single channel on the VXI-MIO module, greatly

increasing the number of analog input signals that you can digitize.

You can also use National Instruments terminal blocks, which have

screw terminals to which you attach the input signals for the

VXI-SC-1102. In addition, some of these terminal blocks have a

temperature sensor for thermocouple cold-junction compensation

(CJC). The VXI-SC-1102 multiplexes this cold-junction sensor with the

32 input channels during a h ardw are sc an . A N ational Instr uments

isothermal terminal block is recommende d for thermoc ouple

applications.

Detailed specifications of the VXI-SC-1102 ar e listed in Appendix A,

Specifications.

VXI-SC-1102 User Manual 1-14

©

National Instruments Corporation

Page 12

What You Need to Get Started

To set up and use y our VXI- SC-1 102 , you w ill need the follow ing

items:

❑ VXI-SC-1102 submodule

VXI-SC-1102 User Ma nua l

❑

❑ VXI-SC-1000 carrier module and documentation

❑ VXI-MIO module and documentation

❑ One of the following software packages and documentation:

ComponentWorks

LabVIEW for Windows

LabWindows/CVI fo r W indo ws

NI-DAQ for PC compatibles

VirtualBen ch

VXIplug&play instrumen t dr iver

Chapter 1 Introduction

❑ Your VXIbus system

Software Programming Choices

There are several op tions to choo se from whe n programm ing your

National Instruments VXI-DAQ hardw are. You c an use LabVIE W,

LabWindows/CVI, Comp one ntWorks, V irtu alBench, or o ther

application development enviro nments with eith er NI-DAQ or the

VXIplug&play instrument driver. Both NI-DAQ and the

VXIplug&play instrument driver access the VXI-DAQ hardware

through the VISA driver software.

National Instruments Application Software

LabVIEW features interactive graphics, a state-of-the-art user

interface, and a po werf ul g raphic al progr am ming langua ge. The

LabVIEW Data Acquisition VI L ibra r y, a se ries of V Is fo r using

LabVIEW with National Instruments DAQ hardware, is included with

LabVIEW. The LabVIEW D ata A cquisitio n VI Libr ar y is functiona lly

equivalent to the NI-DAQ software.

©

National Instruments Corporation 1-15 VXI-SC-1102 User Manual

Page 13

Chapter 1 Introduction

LabWindows/CVI features interactive graphics, a state-of-the-art user

interface, and uses th e ANSI standa rd C pr ogr am ming la nguage . The

LabWindows/CVI Data Ac quisition Lib rary, a se ries of fun ctions f or

using LabWindows/CVI with National Instruments DAQ hardware, is

included with the NI-DAQ software kit. The LabWindow s/CVI Data

Acquisition Library is functionally equivalent to the NI-D AQ sof twar e.

ComponentWorks con tains tools for data acq uisition and instr ument

control built on NI-DAQ driver softw are. Component Works provide s a

higher-level programming interface for building virtual instruments

through standard OLE controls and DLLs. With ComponentWorks, you

can use all of the configuration tools, resource management utilities,

and interactive control utilities included with NI-DAQ.

VirtualBench features VIs that combine DAQ products, software, and

your computer to create a standalone instrument with the added benefit

of the processing, display, and storage capabilities of your computer.

VirtualBench instruments lo ad and sa ve wav efor m data to disk in the

same forms that can be us ed in po pular sp readsh eet pr ogram s and wor d

processors.

Using LabVIEW, Lab Windo ws/C VI , Compon en tW ork s, or

VirtualBench software will greatly reduce the development time for

your data acquisition and control application.

NI-DAQ Driver Software

The NI-DAQ driver sof tware is included at no ch ar ge with all National

Instruments DAQ hardware. NI-DAQ is not packaged with accessory

products. NI-DAQ has an extensive library of functions that you can

call from your application progr amming environment. The s e functions

include routines for analog input (A/D conversion), buffered data

acquisition (high-speed A/ D c onver sion) , analog ou tput ( D/A

conversion), waveform generation, digital I/O, counter/timer

operations, SCXI, RTSI, self-calibration, messaging, and acquiring

data to extended memory.

NI-DAQ has both high-level DAQ I/O functions for maximum ease of

use and low-level DAQ I/O functions for maximum flexibility and

performance. Ex am ples of h igh- leve l func tions are stre aming data to

disk or acquiring a certain number of data po ints. An examp le of a

low-level function is writing directly to registers on the DAQ device.

NI-DAQ does not sacrifice the performance of National Instruments

VXI-SC-1102 User Manual 1-16

©

National Instruments Corporation

Page 14

VXI

plug&play

Chapter 1 Introduction

DAQ devices because it lets multiple devices operate at their peak

performance.

NI-DAQ maintains a consistent software interface among its different

versions so that you can cha nge p latfo rms w ith minimal mo dific ations

to your code.

Instrument Driver

National Instruments distributes VXIplug&play instrument drivers free

of charge. VXIplug&play instrument drivers are one leve l above the

NI-DAQ device driver and contain high-lev el software function s whose

architecture is specified by the VXIplug&play Systems Alliance. The

VXIplug&play standards increase interoperability with other vendors,

and ensure that drivers are designed and presented in a consistent

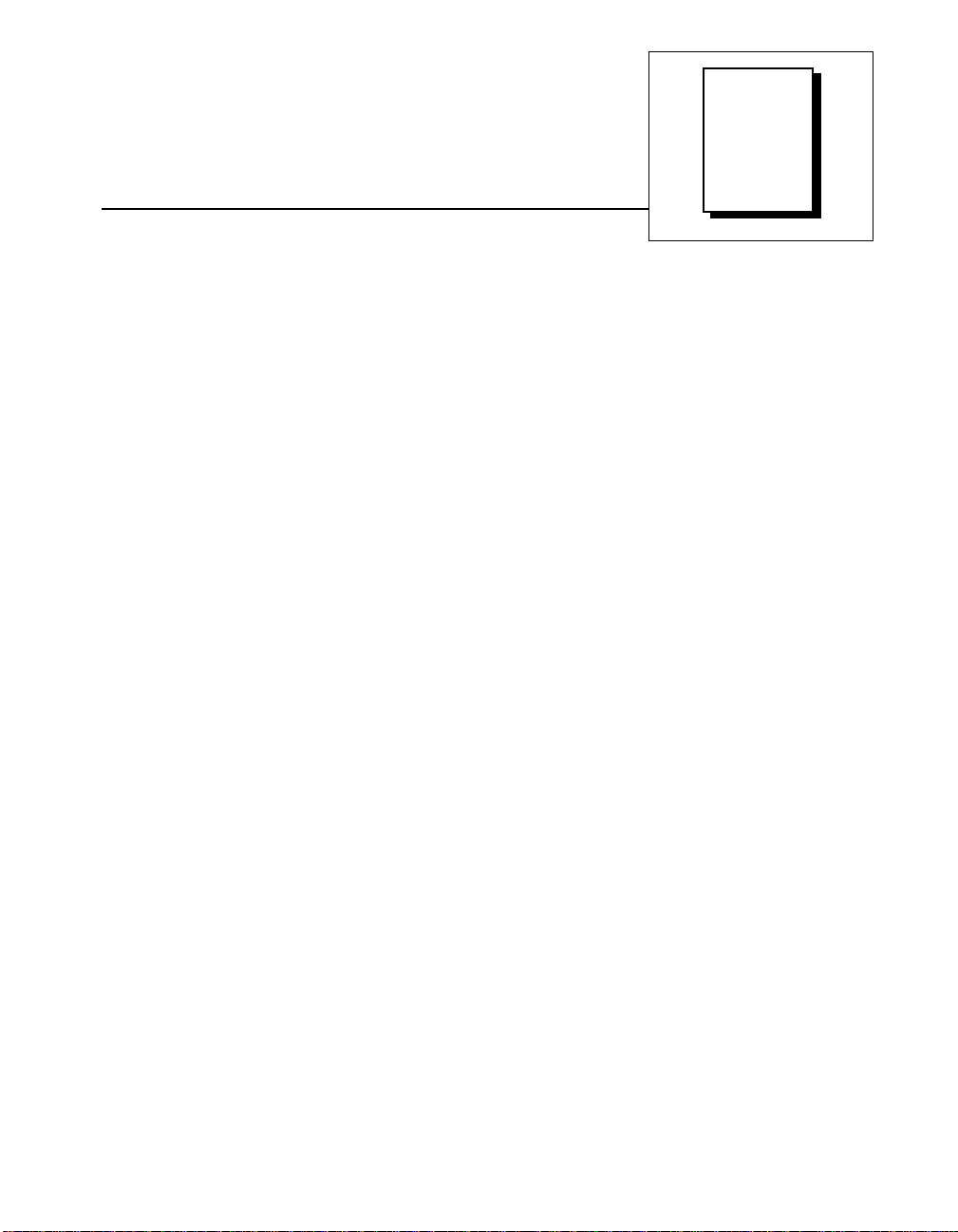

fashion that facilitates ease of use. Refer to Figure 1-2 to see the

relationship between your software components.

ComponentWorks,

LabVIEW, LabWindows/CVI,

or VirtualBench

Figure 1-2.

The Relationship between the Programming Environment, Your

Instrument Driver, and Your VXI-DAQ Hardware

Other Application

Development Environments

VXI

plug&play

Instrument Driver

NI-DAQ Driver Software

VISA

VXI-DAQ Hardware

©

National Instruments Corporation 1-17 VXI-SC-1102 User Manual

Page 15

Chapter 1 Introduction

Optional Equipment

National Instruments offers a v ari ety of pr oducts to u se with your

VXI-SC-1102 module, as follows:

• Terminal blocks and 96-pin cables that allow you to attach input

signals to your submodule

• SCXI Process Current Resistor Kit

For more specific information about these products, refer to your

National Instruments catalogue or c all the of fice near est you .

Unpacking

Your VXI-SC-1102 subm odule is sh ippe d in a n antistatic p acka ge to

prevent electrostatic damage to the submodule. Electrostatic discharge

can damage severa l com pon ents on the su bm odu le. To a vo id su ch

damage in handling the submodule, take the following prec autions.

• Ground yourself via a ground ing strap or by holdin g a grounded

object.

• Touch the antistatic package to a me tal part of your VXIbus chassis

before removing the su bmo dule from th e pa ck ag e.

• Remove the submodule from the package and inspect the

submodule for loose components or any othe r sign of damage .

Notify National Instruments if the module appears damaged in any

way. Do not install a damaged submodule into your VXIbus

chassis.

• Never touch the exposed pins of connectors.

VXI-SC-1102 User Manual 1-18

©

National Instruments Corporation

Page 16

Chapter

Installation

2

This chapter describes how to install current-loop receivers on your

VXI-SC-1102 and gives information abou t installing your

VXI-SC-1102 submodu le into the VXI -SC-1000 c arrie r mod ule .

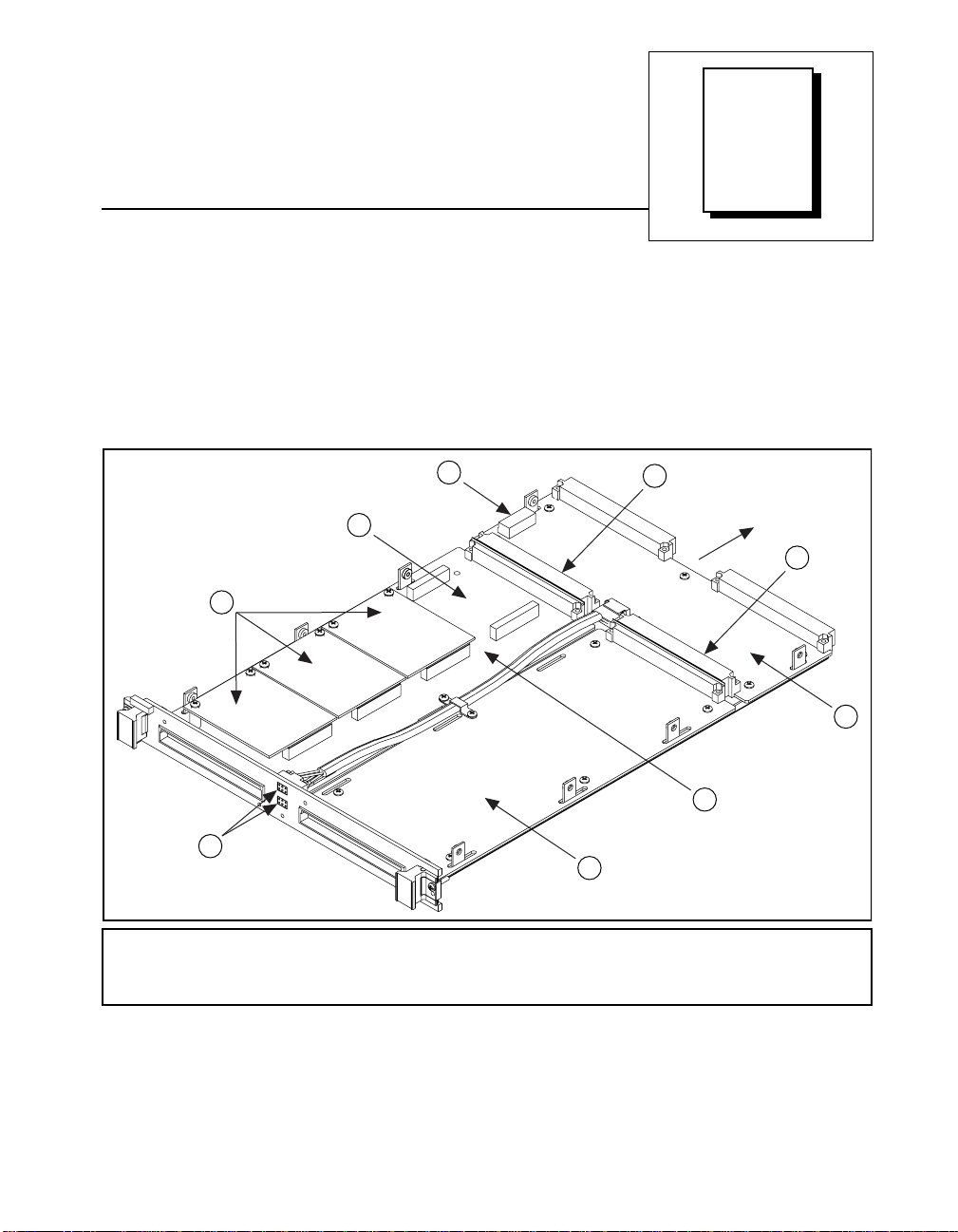

Refer to Figu re 2-1, VXI -SC-11 02 Parts Locator Di agram, for

information as you read the instructions in this chapter.

©

National Instruments Corporation 2-19 VXI-SC-1102 User Manual

Page 17

Chapter 2 Installation

2

3

1

4

1 Serial Number 2 Product Name 3 Assembly Number 4RCLx Pads

©

VXI-SC-1102 User Manual 2-20

National Instruments Corporation

Page 18

Current-Loop Receivers

The VXI-SC-1102 has pads fo r tran sforming ind ividua l cha nnels to

current-to-vo ltage co nvert ers. Na tional Instr umen ts offers an SCXI

Process Current Resistor Kit of four 249 Ω, 0.1%, 5 ppm, 1/4 W

resistors. The reference designators for the cu rrent loop resistors have

the following format: for input channel x, the resistor is RCLx. For

example, the resistor for chann el 28 is RCL28.

Warning: Before installing the resistors in your submodule, make sure that there are

no signals connected to your submodule front connector.

Install the resistors by performing the following steps:

1. Follow the instructions in the VXI-SC-1000 Carrier Module

Installation Guide to remove the VXI-SC-1102 submodu le from

the carrier assembly.

2. Bend and trim the resistor lead as shown in Figure 2-2. Be sure that

the resistor does no t extend more th an 0.6 5 in. ab ove the su rfac e of

the circuit board.

Chapter 2 Installation

Figure 2-1. VXI-SC-1102 Parts Locator Diagram

Figure 2-2. Bent and Trimmed Resistor

3. Insert the resistor into the appropriate pad, labeled RCLx.

4. Solder the leads to the pad on the bottom side of the module.

5. Follow the instructions in the VXI-SC-1000 Carrier Module

Installation Guide to replace the VXI-SC-1102 submod ule in the

carrier assembly.

©

National Instruments Corporation 2-21 VXI-SC-1102 User Manual

Page 19

Chapter 2 Installation

Installing Your Hardware

Follow the instructions in the VXI-SC-1000 Carrier Module Installation

Guide to replace the VXI-SC-110 2 submo dule and to install th e

assembled VXI-SC carrier module in the VXIbus chassis.

VXI-SC-1102 User Manual 2-22

©

National Instruments Corporation

Page 20

Chapter

Signal Connections

This chapter describes the analog input signal connections to the

VXI-SC-1102 submodule via the front connecto r.

Caution:

!

Front Connector

Static electricity is a major cause of comp onent failure. To pre vent damage

to the electrical components in the module, observe antistatic techniques

whenever removing a module from the chassis or whenever working on a

module.

Figure 3-1 sh ows the pin assign ments f or the VX I-SC-1 102 front

connector.

3

©

National Instruments Corporation 3-23 VXI-SC-1102 User Manual

Page 21

Chapter 3 Signal Connections

CGND

NC

NC

NC

NC

NC

NC

NC

CGND

NC

NC

NC

NC

NC

NC

NC

CGND

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

CGND

CJSENSOR

CJSENSOR

CGND

+5 V

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

A

CH0CH1CH2CH3CH4CH5CH6CH7CH8CH9-

CH10-

CH11-

CH12CH13CH14-

CH15-

CH16CH17CH18CH19CH20CH21CH22-

9

8

7

6

5

4

3

2

1

CH23CH24CH25CH26CH27CH28CH29CH30CH31-

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

B

CH0+

CH1+

CH2+

CH3+

CH4+

CH5+

CH6+

CH7+

CH8+

CH9+

CH10+

CH11+

CH12+

CH13+

CH14+

CH15+

CH16+

CH17+

CH18+

CH19+

CH20+

CH21+

CH22+

9

8

7

6

5

4

3

2

1

CH23+

CH24+

CH25+

CH26+

CH27+

CH28+

CH29+

CH30+

CH31+

C

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Figure 3-1. VXI-SC-1102 Front Connector Pin Assignments

VXI-SC-1102 User Manual 3-24

©

National Instruments Corporation

Page 22

Signal Descriptions

Chapter 3 Signal Connections

Table 3-1.

Pin Signal Name Description

A1 +5 V +5 VDC Source—Powers the

A2, A5, A16,

A24, A32

A3, A4 CJSENSOR Cold-Junction Temperature

B1–B32 CH31-

C1–C32 CH31+

All other pins are not connected.

Front Connector Signal Descriptions

temperature sensor on the terminal

block. 0.2 mA of source not

protected.

CGND Chassis Ground—Tied to the

VXIbus chassis.

Sensor Input—Connects to the

temperature sensor of the terminal

block.

Negative Input Channels 31–0

through

CH0-

through

CH0+

—Negative side of differential

input channels.

Positive Input Channels 31–0

—Positive side of differential

input channels.

Channel Input Signal Connections

The signal terminals for the positive input channels are located in

column C of the connector. The signal terminal for each corresponding

negative input channel is locat ed in column B of the connector . Each

input goes to a separate filte r and a mplifier that is m ultiplexed to the

module output buffer. Th e ter mina l b lock tempe ratur e sensor

output—connected to p ins A 3 and A4 (CJSE NSOR) —is al so fi ltere d

and multiplexed to the module output buffer.

The differential input sign al range of a VX I-SC-11 02 input ch annel is

±10 V/G, where G is the gain selec ted on the VXI-SC-1 102 input

channel. Th is di ff er en tia l i np ut r an ge is th e ma ximu m me asu ra bl e

voltage difference between the positive and negative channel inputs.

The common-mode input signal range of a VXI-SC-1102 input channel

©

National Instruments Corporation 3-25 VXI-SC-1102 User Manual

Page 23

Chapter 3 Signal Connections

Warning: Exceeding the input damage leve l (±42 VAC peak or VD C be tween inp ut

!

channels and chassis ground) can damage the VXI-SC-110 2, the VXIbus,

and the VXI-MIO module. National Instruments is

injuries resulting from such signal connections.

Applying a voltage greater than ±42 VAC peak or VDC to the VXI-SC-1102

is an electrical shock hazard. National Instruments is

damages or injuries resulting from suc h voltage a pplication.

Note: Exceeding the differential or common-mode input channel ranges results

in a distorted signal measurement.

is ±11 V. This common-mode input range for either positive or negative

channel input is the maximum input voltage (relative to CGND) that

will result in a valid measurement. Each channel includes input

protection circuitry to withstand the accidental application of voltages

up to ±42 VA C peak or VD C.

NOT

liable for any

NOT

liable for any

Ground-Referencing Your Signals

Your input signals can be e ith er g rou nd-re fe renc ed, as sho wn in

Figure 3-2, or floating, as s how n in Figure 3-3. B efore y ou c onnec t

your thermocouple or any other signal, de termine wh ether it is

floating or ground-referen ce d. I f it is a f loating sign al, yo u m ust

ground-reference the sig nal in one o f two w ays. You ca n conne ct the

negative channel input to chassis ground as shown in Figure 3-3 or you

can use the clamping resistors on a VXI-TB Series terminal block. The

VXI-TB Series terminal block may also have a resistor pack for pulling

up the positive inputs for open-thermocouple detec tion. Consult the

terminal block installation guide for d etails.

Do not ground signals w hich ar e alr eady gr oun d-ref ere nced; doin g so

will result in a ground loop, which adversely affects your measurement

accuracy.

VXI-SC-1102 User Manual 3-26

©

National Instruments Corporation

Page 24

Chapter 3 Signal Connections

CH0 +

CH0 -

+

V

diff

-

+

V

cm

-

CH1 +

CH1 -

Connector

Front Signal

+

-

+

-

VXI-SC-1102

Figure 3-2. Ground-Referenced Signal Connection

©

National Instruments Corporation 3-27 VXI-SC-1102 User Manual

Page 25

Chapter 3 Signal Connections

CH0 +

CH0 -

Floating

Signal

Make this connection to

ground reference the signal.

+

V

s

-

Reference to

Chassis Ground

CH1 +

CH1 -

Front Signal

CGND

Figure 3-3. Floating Signal Connection Referenced to Chassis Ground

Cold-Junction Sensor Connection

Pins A3 and A4 (CJSENSOR) connect the temperature sensor located

on the National Instruments VXI-T B Series term inal block to the

VXI-SC-1102. The CJSENSOR signal is measured relative to CGND.

Pins A3 and A4 are connected within the VXI-SC-1102 so the position

of the MTEMP/DTEMP switch on the VX I-TB Series ter minal block

does not matter. The input is overvoltage-protected to 15 VDC with the

power on and off.

+

-

+

-

Connector

VXI-SC-1102

Warning: Exceeding the overvoltage protection on the CJSENSOR input can damage

!

the VXI-SC-1102, the VXIbus, and the VX I-M IO bo ard. N ational

NOT

Instruments is

liable for any damages or injuries resulting from such

signal connections.

VXI-SC-1102 User Manual 3-28

©

National Instruments Corporation

Page 26

Chapter

Theory of Operation

This chapter contains a function al overview of the VXI-SC -1102 an d

explains the operation o f ea ch f unctiona l unit.

Functional Overview

The block diagram in Figure 4-1 illustrates the key functional

components of the VXI-SC-1102.

CH 0 +

CH 0 –

+

Inst.

Amp

–

Input Protection

and Lowpass Filter

Gain 0

Lowpass

Filter

Buffer

4

Buffer

Mux

32-to-1 Mux

CH 31+

CH 31 –

Front Signal Connector

CJSENSOR

©

National Instruments Corporation 4-29 VXI-SC-1102 User Manual

+

Inst.

Amp

–

Input Protection

and Lowpass Filter

Input Protection

and Lowpass Filter

Gain 31

Lowpass

Filter

Lowpass

Filter

Buffer

Buffer

Figure 4-1.

Switch

Switch

Gain

Register

Calibration EEPROM

Digital

Control

VXI-SC-1102 Block Diagram

Analog Bus +

Analog Bus -

Connector to Carrier Module

Page 27

Chapter 4 Theory of Operation

The major components of the VXI-SC -1102 are a s follows:

• VXIbus interface

• Digital control circuitry

• Analog circuitry

The VXI-SC-1102 consists of 32 multiplexed input channels, each with

a software-progra mmab le gain of 1 or 100. E ach inpu t cha nnel ha s its

own lowpass filter with a cutoff frequency of 2 Hz. The V XI-SC-110 2

also has digital control circuitry for automatic control of channel

scanning, temperature sen sor se lect ion, a nd gain sele ction .

VXIbus Interface

The VXI-DAQ module controls the VXI-SC-1102 over the VXIbus.

The VXI-SC-1000 carrier module serves as an interface from the

VXI-SC-1102 to the VXIbus.

Digital Control Circuitry

The digital control c ircu itry co nsists of the ad dress handle r and the

following registers: Module ID, Configuration, Status, EEPROM, Gain,

and Channel. The address ha ndler controls w hich register is being

addressed. The Module ID Register contains the module ID 42 decimal,

a code unique to the VX I-S C-1102 . The Conf igur ation Re giste r

configures the VXI -SC-110 2 f or the d esired scan ning mo de a nd

connection to the rear signal connector. The Status Register indicates

whether the input channels have settled after a change in the gains. The

EEPROM Register is the addr ess for inte rf acing with the subm odule ’s

EEPROM, which contains calibration information. The Gain Register

selects between gain s of 1 o r 1 00 fo r e ach o f the 32 ch anne ls . The

Channel Register selects a channel for a single measurement or a start

channel for a sca n. Ref er to Software Programming Choices in

Chapter 1, Introduction, of this manual to learn about options fo r

programming the control circuitry.

VXI-SC-1102 User Manual 4-30

©

National Instruments Corporation

Page 28

Analog Circuitry

The analog circuitry per ch anne l consists of a lowpass fi lter and an

amplifier with a software -sele ctable gain of 1 or 100 . The C JSEN SO R

channel also has a buffered low pass filter but has no amp lifier. The

channels and CJSENSOR are multiplexed to a single output buffer.

Analog Input Channels

Each of the 32 analog input channels dr iv es a sepa ra te amp lifier with a

programmable gain of 1 or 100. Th en the signal passes thr ough a

three-pole lowpass filter with a cutoff frequency of 2 Hz.

Note: Because of the 2 Hz bandwidth of the input channels, you must wait

approximately 3 s after changing the gains before the channels settle and

you can take an accurate measurement. NI-DAQ au tomatically reads the

Status Register to determine when the module output has settled.

The temperature sensor consists of a thermistor located on a National

Instruments VXI terminal block. The tempera tur e sen sor is for

cold-junction compensation of thermocouples. The CJSENSOR

channel also passes through a 2 Hz lowpass filter to reject unwa nted

noise. Along with the other 32 input channels, the CJSENSO R is

multiplexed to the output buffer, where it can be read by the VXI-MIO

module.

Chapter 4 Theory of Operation

For a measurement accurac y of 0.0 12% of fu ll scale, th e minimum scan

interval is 3 µs. This is the smallest interval in which you can switch

between analog channels on the submodule and still measure accurate

voltages. The 3 µs scan interval gives you a maximum sampling rate of

333 kHz. Because each VXI-SC-1102 channel contains a 2 Hz lowpass

filter, the 333 kHz sample rate allows you to sample multiple channels

without undersampling any c hann el.

Analog Output

The 32 input channels and the CJSENSOR are multiplexed into one

output. This output is passed to the VXI-SC-1000 carrier module, where

it is connected to the Analog Bus for measurement by a VXI-MIO

module.

©

National Instruments Corporation 4-31 VXI-SC-1102 User Manual

Page 29

Chapter

Calibration

This chapter di scusses th e calib ratio n pr oced ures fo r the VXI-SC -110 2.

Using the procedure described in this chapter , you will be able to

calculate the gain error and voltage offset on a per channel per gain

basis. You can store these constants in the onboard EEPROM for future

use and for automatic calibra tion when you are using National

Instruments software. The V XI-SC -11 02 come s f rom the fa ctor y with

factory-determined calibration constants in the EEPROM. However,

National Instruments recomme nd s that y ou reca librate your

VXI-SC-1102 at least once per year or when you operate the submodule

outside the 20° to 30° C temperature range. If you are not using National

Instruments software to store the calibration data in the EEPROM, refe r

to the VXI-SC-1102 Reg ister- Lev el Pro gramme r Ma nual for a more

detailed description of the EEPROM.

In order to calibrate the VXI-SC-1102, you will need to apply precision

voltages to the channel inputs and/or ground the channel inputs.

Calibration Equipment Requirements

5

According to standard practice, the equipment you use to calibrate the

VXI-SC-1102 should be 10 times as accurate as the VXI-SC-11 02.

Calibration equipment with four times the accuracy of the

VXI-SC-1102 is generally considered acceptable. To calibrate the

VXI-SC-1102, you need a voltmeter with the following specifications:

• Accuracy ±6 ppm sta ndar d readin g

±15 ppm sufficient reading

• Range ±10 V

• Resolution 8.5 digits

A multiranging 8.5-digit digital multimeter (DMM) can perform the

necessary calibrations.

To make sure that the DMM does not introduce an additional offset, you

can determine the offset error of the DMM by shorting its leads together

©

National Instruments Corporation 5-33 VXI-SC-1102 User Manual

Page 30

Chapter 5 Calibration

and reading t h e meas ure d va lu e. T his valu e, t he DM M o ffs et , mu s t be

subtracted from all subseq uent m easur eme nts.

Measure the submodule’ s output at the analog bus rece ptacle (se e

Figure 1-1 for the location of this receptacle). Refer to Figure 5-1 to

connect the positive DMM input to MUX+ and the negative DMM input to

MUX-.

MUX+ MUX- CAL- CAL+

MUX- MUX+ CAL+ CAL-

Figure 5-1. Analog Bus Receptacle Pin Assignment

Gain and Offset Calibration

To determine the of fse t a nd ga in ca libra tion f act ors o f th e

VXI-SC-1102 for a g iven gain, per for m th e follo wing ste ps for a

two-point calibration. For two-point calibration, it is best to use input

voltages that correspond to the signal range of interest. For example, to

measure bipolar v oltages over the subm odule’s fu ll input rang e, choose

-9.9 V/G (negative full-scale) and +9.9 V/G (positive full-scale) as your

two input voltages.

1. Se lec t the desir ed channel. Set the channel gain to the desired gain.

2. Apply the input for the first calibration point. To select negative

full scale as the calibration point, apply -9.9 V/G for an input

voltage.

a. Apply the input voltage to the channel selected in Step 1.

VXI-SC-1102 User Manual 5-34

©

National Instruments Corporation

Page 31

Chapter 5 Calibration

Note: To make one of your calibration points the zero point, connect the positive

and negative channel leads to one of the chassis ground pins on the front

connector or terminal block.

b. Measure the input voltage with the DMM. Call the measured

voltage input1.

Note: If you are using a calibrator that supplies accurate voltages, you can

simply use the known applied voltage for

input1

instead of measuring.

c. Measure the mo dule o utput at the a nalog bus rece pta cle wit h

the DMM. Call the measured voltage

output1

.

3. Repeat Step 2, applying the input for the seco nd calibra tion p oint.

Call the measured voltages

input2

and

output2

. To select

positive full scale as the calibration point, repeat Step 2 and apply

+9.9 V/G.

4. You now have two pairs of voltages (

(

input2, output2

). Each pair consists of an input voltage and an

input1, output1

) and

output voltage.

5. Convert the output vo ltages from volt un its to you r VX I-M IO

module binary unit. You must take into consideration the polarity

of your VXI-MIO module, its resolution (12 bi ts or 16 bits), and

gain. For example, if you are using the 12-bit VXI-MIO-64E-1 in

bipolar mode with the gain set to G

, your output voltage s f or

MIO

the autozeroing option will be represented in binary units as given

by the following formula:

Binary

=

Output

-----------------5 V

12

G

•

•

2

MIO

For other VXI-MIO modules, refer to the user manual to determine

the appropriate formula.

6. You now have a new set of pairs referred to as voltage binary pairs

(

input1, bin_output1

pairs to the

SCXI_Cal_Constants

) and (

input2, bin_output2

function or VI as described in

). Pass these

your software us er do cu me ntation .

Note: When you use 0 V and positive full-scale for your two calibration points,

you elimin ate t he e rro r a t 0 V an d at p os it ive f ull - sca le vo lta g e. H ow e ver ,

because of nonlinearity, the error at the negative full-scale voltage will be

two times the nonlinearity error. This is also true for the positive full-scale

voltage if you use the negative full-scale voltage and 0 V as your two

calibration points.

©

National Instruments Corporation 5-35 VXI-SC-1102 User Manual

Page 32

Chapter 5 Calibration

When you make a me asurem ent us ing L abV IEW, C omp onentWo rks, or

VirtualBench, the driver automatically uses the calibration constants to

correct the measured voltages.

When you use application development environments other than

LabVIEW, ComponentWorks, or VirtualBench, you have the option to

apply the calibration constants to measured voltages through the NI-DAQ

API.

Sample Program for Calibration

The following sample C program will help you calibrate the

VXI-SC-1102. The calibration constants are stored only in NI-DAQ

memory. The (input, o utput) vo ltage pair s read by a DMM must be

entered by hand. Before this program is run, the NI-DAQ Configuration

Utility must be run to configure the VXI-SC chassis and to configure

the DAQ board which will be used to communicate with the

VXI-SC-1102.

The program is written to work for a DAQ board, such as the

VXI-MIO-64E-1, with a 5 V full-scale input.

#include <stdio.h>

#include <math.h>

#include <dataacq.h >

#define MIO_FULL_SC ALE 5.0 /* valid for VXI- MIO -64E-1 */

#define N_VXI_SC_SL OTS 24

#define NIDAQMEM 0

#define ALL -1

int

enterInt (char *pro mpt)

{

short

ret;

int

value;

©

VXI-SC-1102 User Manual 5-36

National Instruments Corporation

Page 33

do

{

fputs(prompt, stdo ut);

fflush(stdin);

ret = scanf("%d", &value );

} while (!ret);

return (value);

}

double

enterFloat (char *p rompt)

{

short

ret;

double

value;

do

{

fputs(prompt, std out);

fflush(stdin);

ret = scanf("%lf" , &val ue) ;

} while (!ret);

return (value);

}

Chapter 5 Calibration

void

main()

{

int

vxiChassisID,

commPath,

moduleSlot, /* slot of module to calibr ate */

moduleChan;

short

dummyRangeCode = 0,

dummyDAQboard,

dummyDAQchan = 0,

dummyDAQgain = 1,

dummyDAQrange; /* These dummy varia ble s would be

used if the measu rement act ual ly

came from a DAQ b oard a nd n ot an

external DMM. */

©

National Instruments Corporation 5-37 VXI-SC-1102 User Manual

Page 34

Chapter 5 Calibration

double

scale,

gain,

vInput1,

vOutput1,

vInput2,

vOutput2,

binOutput1,

binOutput2,

binOffset,

gainerr,

offset;

do

{

vxiChassisID = enterInt ("\nEnter chassis ID of the VXI-SC chassis:");

} while (vxiChassisID < 1);

do

{

moduleSlot = enterInt ("E nter s lot of the VX I-S C-1102: " );

} while (moduleSlo t < 1 | | N _VX I_SC_SL OTS < mod uleS lot );

do

{

commPath = enterInt ("Enter device number of th e DAQ b oar d"

"controlling the chassis: ");

} while (commPath < 0);

dummyDAQboard = commPath;

dummyDAQrange = MIO_FULL_SCALE / d umm yDAQgai n;

scale = pow(2.0, 12.0) * dumm yDAQ gai n / 10 ;

/* factor for converting to format

of 12-bit bipolar DAQ b oard */

SCXI_Reset (vxiCha ssisID, mo dul eSlot);

SCXI_Single_Chan_S etup (vxiChas sisID, mod uleSlo t, 0, dummyDAQbo ard);

/* This is necessary o nly so tha t

SCXI_Change_Chan wo n't ret urn

an error. */

for (gain = 1; gai n <= 10 0; gai n = gai n + 99)

{

SCXI_Set_Gain (vx iChassi sID , m oduleS lot, ALL, gai n);

/* Set the gain on all channels. */

for (moduleChan = 0; modul eCh an < 32 ; m odu leChan+ +)

{

SCXI_Change_Chan ( vxiCha ssi sID , modul eSl ot, mod ule Cha n);

/* Select the ch ann el. */

VXI-SC-1102 User Manual 5-38

©

National Instruments Corporation

Page 35

Chapter 5 Calibration

printf("Apply inpu t volt age fo r point 1, chann el % d, gain % .0f. \n"

moduleChan, gain);,

vInput1 = enterFloat ("Ente r VXI- SC-1 102 input vo ltage: ") ;

/* User enters vI npu t1. */

vOutput1 = enterFloat ("En ter VX I-SC -11 02 out put voltag e: ") ;

/* User enters vOutput1. */

printf("Apply inpu t volt age fo r point 2, chann el % d, gain

%.0f.\n",moduleChan , gain );

vInput2 = en ter Float ( "En ter VX I-SC -11 02 inp ut voltage : ");

/* User enters vInpu t2. */

vOutput2 = enterFloat ("En ter VX I-SC -11 02 out put voltag e: ") ;

/* User enters vO utp ut2. */

binOutput1= v Outp ut1*sc ale ;

binOutput2= v Out put2*sc ale ; /* Convert to DAQ bo ard's f orm at. */

SCXI_Cal_Constants (vxi Cha ssisID , mo dul eSlot, mo duleCha n,

2, NIDAQMEM, dummyRangeCo de, gain,

dummyDAQboard, dumm yDAQch an, dum myDAQg ain , 1,

vInput1, binOutput1 , vInp ut2, bi nOutpu t2,

&binOffset, &gainer r);

/* Calculate o ffset & ga in error. */

offset = binOffset/scale ; /* C onve rt from D AQ board f orm at. */

printf("Calculated offse t % f V , gain rat io (ac tual /id eal) % f"

"and stored in NI -DAQ m emo ry. \n\n", off set, g aine rr) ;

}

}

}

©

National Instruments Corporation 5-39 VXI-SC-1102 User Manual

Page 36

Appendix

Specifications

This appendix lists the specifications for the VXI-SC-1102. These

specifications are typical at 25° C unless otherwise noted.

Analog Input

Input Characteristics

Number of channels...............................32 differential

Input signal ranges.................................±10 0 mV (gain = 100) or ±10 V

Max working voltage

(signal + common mode).......................Each input should remain

Input damage level.................................±42 VAC peak or VDC

Inputs protected...............................CH<0..31>, CJSENSOR

Transfer Characteristics

A

(gain = 1)

within ±10 V of CGND

Nonlinearity ........................................ ...0.005% FSR

Offset error

Gain = 1

After calibration.......................150 µV max

Before calibration....................600 µV

Gain = 100

After calibration.......................15 µV max

Before calibration....................100 µV

Gain error (relative to calibration reference)

Gain = 1

After calibration.......................0.015% of reading max

Before calibration....................0.04% of reading

©

National Instruments Corporation A-41 VXI-SC-1102 User Manual

Page 37

Appendix A Specifications

Gain = 100

After calibration .......................0.017% of reading max

Before calibration .....................0.1% of reading

Amplifier Characteristics

Input impedance

Normal powered on.........................> 1 GΩ

Powered off .....................................10 kΩ

Overload..........................................10 kΩ

Input bias current....................................±0.5 nA

Input offset current.................................±1.0 nA

CMRR

50 to 60 Hz, either gain...................110 dB

0 Hz, gain 1......................................75 dB min

0 Hz, gain 100..................................100 dB min

Output range...........................................±10 V

Output impedance...................................91 Ω

Dynamic Characteristics

Bandwidth...............................................2 Hz

Scan interval (per channel, any gain)

0.012%.............................................3 µs

0.0061%...........................................10 µs

System noise (related to input

Gain = 1............................... ...... ......50 µVrms

Gain = 100.......................................5 µVrms

Filters

Cutoff frequency (-3 dB)........................2 Hz

NMR (60 Hz)..........................................40 dB

VXI-SC-1102 User Manual A-42

©

National Instruments Corporation

Page 38

Stability

Physical

Appendix A Specifications

Step response (either gain)

To 0.1%...........................................1 s

To 0.01%.........................................10 s

Recommended warm-up time................ 20 min.

Offset temperature coefficient

Gain = 1 ..........................................20 µV/°C

Gain = 100 ......................................1 µV/°C

Gain temperature coefficient..................10 ppm/°C

Dimensions.............................................115 by 273 mm

(4.54 by 10.75 in.)

I/O connector..........................................50-pin male ribbon cable

rear connector

96-pin male DIN C front

connector

Environment

Operating temperature............................0° to 50° C

Storage temperature ...............................-55° to 150° C

Relative humidity...................................5% to 90% noncondensing

Power Requirements

5 V supply..............................................15 mA max

±15 V supply (regulated

from ±24 V supply)................................150 mA max

©

National Instruments Corporation A-43 VXI-SC-1102 User Manual

Page 39

Appendix

Customer Communication

For your convenience, this appendix contains forms to help you gather the information necessa ry

to help us solve your te ch nical p rob lems a nd a fo rm yo u ca n use to co mm ent on the p rod uct

documentation. When yo u con tac t us, we nee d the inf ormation on the Te ch nical Su ppo rt Fo rm

and the configuration form, if your ma nual contains one , about yo ur system configu ration to

answer your questions a s q uickly as possible .

National Instruments has techn ica l assistan ce thr ou gh electronic , fa x, a nd telepho ne sys tems to

quickly provide the informa tion you ne ed. Ou r el ectronic servic es inc lude a bulle tin bo ard

service, an FTP site, a Fax-on-Demand system, and e-mail support. If you have a hardware or

software problem, first try the electronic suppo rt systems. If the inform ation available on these

systems does not answer your questions, we offer fax and telephone support through our technical

support centers, which are staffed by ap plications en gineers.

B

Electronic Services

Bulletin Board Support

National Instruments has BBS and FTP sites dedicated for 24-hou r support with a collection of

files and documents to answer most common customer questions. From these sites, you can also

download the latest instrument drivers, updates, and example programs. For recorded instructions

on how to use the bulletin board and FTP services and for BBS automated infor mation, call

(512) 795-6990. You ca n ac cess thes e servic es at:

United States: (512) 7 94-5422

Up to 14,400 bau d, 8 da ta bits, 1 sto p b it, n o p arity

United Kingdom: 0 163 5 55 1422

Up to 9,600 baud , 8 d ata b its, 1 stop bit, no parity

France: 01 48 65 15 59

Up to 9,600 baud , 8 d ata b its, 1 stop bit, no parity

FTP Support

To access our FTP site, log on to our Internet host, ftp.natinst.com, as anonymous an d use

your Internet address, such as joesmith@anywhere.com, as your password. The support files

and documents are located in the /support directories.

©

National Instruments Corporation B-1 VXI-SC-1102 User Manual

Page 40

Fax-on-Demand Support

Fax-on-Demand is a 24-hour information retrieval system containing a library of documents on a

wide range of technical information . You can access Fax- on-Dema nd from a touch-ton e

telephone at (512) 418-1111 .

E-Mail Support (currently U.S. only)

You can submit technical suppor t questions to the applicatio ns engineer ing team through e- mail

at the Internet address li sted below. R emember to incl ude your n ame, ad dress, and phone nu mber

so we can contact you with solutions and suggestions.

support@natinst.com

Fax and Telephone Support

National Instruments has branch offices all over the world. Use the list below to f ind the technical

support number for your country. If there is no National Instruments off ice in your co untry,

contact the source from which yo u purchase d your softwar e to obtain support.

Telephone Fax

Australia 03 9879 5166 03 9879 6277

Austria 0662 45 79 90 0 0662 45 79 90 19

Belgium 02 757 00 20 02 757 03 11

Canada (Ontario) 90 5 785 0085 905 785 0086

Canada (Quebec) 514 694 8521 51 4 694 4399

Denmark 45 76 26 00 45 76 26 02

Finland 09 527 232 1 09 502 2930

France 01 48 14 24 24 01 48 14 24 14

Germany 08 9 741 31 30 089 714 60 35

Hong Kong 2645 3186 2686 8505

Israel 03 5734815 03 5734816

Italy 02 413091 02 41309215

Japan 03 5472 2970 03 5472 2977

Korea 02 596 7456 02 596 7455

Mexico 5 520 2635 5 520 3282

Netherlands 0348 433466 0348 430673

Norway 32 84 84 00 32 84 86 00

Singapore 2265886 2265887

Spain 91 640 0085 91 640 0533

Sweden 08 730 49 70 08 730 43 70

Switzerland 056 200 51 51 056 200 51 55

Taiwan 02 377 1200 02 737 4644

U.K. 01 635 52 354 5 01635 523154

Page 41

Technical Support Form

Photocopy this form and update it each time you make changes to your software or hardware, and

use the completed copy of this form as a reference for yo ur curr ent config uration. Completing

this form accurately before contacting National Instruments for technical support helps our

applications engineers answer you r questions more efficiently .

If you are using any National Instrume nts hardware or software products related to this problem,

include the configuration f orms f rom th eir user manu als. Inc lude add itio nal pa ges if nec essary .

Name __________________________________________________________________________

Company _______________________________________________________________________

Address ________________________________________________________________________

_______________________________________________________________________________

Fax (___ )___________________ Phone (___ ) ________________________________________

Computer brand ________________ Model ________________ Processor___________________

Operating system (include version number)____________________________________________

Clock speed ______MHz RAM _____MB Display adapter __________________________

Mouse ___yes ___no Other adapters installed _______________________________________

Hard disk capacity _____MB Brand _____________________________________________

Instruments used _________________________________________________________________

_______________________________________________________________________________

National Instrument s hard war e produ c t mode l__________ Revision ____________ ___ _______

Configuration _____________________________________ ___ ___ _________________ ___ __ __

National Instrument s sof t war e produ ct___________________________ _ Version ____________

Configuration _____________________________________ ___ ___ _________________ ___ __ __

The problem is: __________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

List any error messages: ___________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

The following steps reproduce the problem:____________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

Page 42

VXI-SC-1102 Hardware and Software

Configuration Form

Record the settings a nd re vision s o f your h ardw are a nd softwa re on th e line to th e righ t of e ach

item. Complete a new copy of this form each time you rev ise your softw are or hardw are

configuration, and use this form as a refer ence for your c urren t configuration. Completing this

form accurately before con tact ing Na tional I nstrume nts for tec hnica l sup port he lps our

applications engineers answer you r questions more efficiently .

National Instruments Products

Application Software Version ____________________________ _______ _________ _______

PCMCIA Software Version ______________ _______ _________ _______ ______ ______ ____

Other Products

Computer make and model __ _______ ______ _______ _________ _______ ______ ______ ____

Microprocessor _______________________________________________________________

Clock frequency ________ ___ ____ ___ ______ ___ ____ ___ ______ ___ ____ ___ ______ ___ ____

Type of video bo ard installe d _____________ ___ _______ ___ ___ ___ _______ ___ ___ ___ ____

Operating system ______________________ _______ ___ ___ ___ _______ ___ ___ ___ _______

Operating system vers io n _______ ___ ___ ______ ____ ___ ___ ______ ____ ___ ___ ______ ____

Programming language _______________ __________ ______ ______ _______ _________ ____

Programming language vers ion ________ __________ ______ ______ _______ _________ ____

Other boards in system _______________ ___ ___ ____ ______ ___ ___ ____ ______ ___ ___ ____

Base I/O address of o ther b oards __________________________ ___ ____ ___ ______ ___ ____

DMA channels of other boards _______________ _______ ______ __________ ______ _______

Interrupt level of other boards _______________ __________ ______ _______ ______ _______

Page 43

Documentation Comment Form

National Instruments encourages you to comment on the documentation supplied with our

products. This information helps us provide quality products to meet your needs.

Title:

Edition Date:

Part Number:

Please comment on the completeness, clarity, and organization of the manual.

_______________________________________________________________ ________________

_______________________________________________________________ ________________

_______________________________________________________________ ________________

_______________________________________________________________ ________________

_______________________________________________________________ ________________

_______________________________________________________________ ________________

_______________________________________________________________ ________________

If you find error s in the m an ual, plea se r ecor d the pa ge nu mbe rs and descr ibe the e rr ors.

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

VXI-SC-1102 User Ma nua l

February 1997

321385A-01

Thank you for y our he lp.

Name _________________________________________________________________________

Title __________________________________________________________________________

Company _______________________________________________________________________

Address ________________________________________________________________________

_______________________________________________________________________________

Phone (___ )__________________________ Fax (___ ) _________________________________

Mail to:

Technical Publications

National Instruments Corporation National Instruments Corporation

6504 Bridge Point Parkway (512) 794-5678

Austin, TX 78730-5039

Fax to:

Technical Publications

Page 44

Prefix Meaning Value

Glossary

p- pico- 10

n- nano- 10

µ-micro-10

m- milli- 10

k- kilo- 10

M- mega- 10

G- giga- 10

Numbers/Symbols

+5 V +5 volt signal

° degrees

Ω ohms

% percent

± plus or minus

-12

-9

-6

-3

3

6

9

A

AC alternating current

A/D analog-to-digital

©

National Instruments Corporation G-1 VXI-SC-1102 User Manual

Page 45

Glossary

ADC analog-to-digital converter–an electronic device, often an integrated

circuit, that converts an analog voltage to a digital number

amplification a type of signal conditioning that improves accuracy in the resulting

digitized signal and reduces noise

API application programming interface

B

bus the group of conductors that interc onn ect ind ividua l circ uitry in a

computer. Typ ica l ly, a bu s is th e ex pa nsi on vehi c le to w hi ch I/ O o r

other devices are connec ted. Examp les of PC buse s are the AT bus ,

NuBus, Micro Channel, a nd EI SA bu s.

C

CCelsius

CGND chassis gr ound signal

channel pin or wire lead to which you apply or from which you read the analog

or digital signal. Analog signals can be single-ended or differential. For

digital signals, you group channels to form ports. Por ts usually consist

of either four or eight digital channels.

CH<0..31> - negative input ch annels 0 through 31

CH<0..31>+ positive input channels 0 through 31

CJSENSOR cold-junction sensor

cold-junction a method of compensating for inaccu racies in the rmocouple ci rcuits

compensation

D

DAQ data acquisition–(1) collecting and measuring electrical signals from

sensors, transducers, and test probes or fixtures and inputting them to a

computer for pro cessing ; (2 ) collecting a nd mea surin g the sam e kinds

of electrical signals w ith A /D and/or DI O board s p lugge d into a

VXI-SC-1102 User Manual G-2

©

National Instruments Corporation

Page 46

Glossary

computer, and possibly generating control signals with D/A and/or DIO

boards in the same computer

DC direct current

DIFF differentia l c onfigur ation

differential input an analog input consisting of two terminals, both of which are isolated

from computer g rou nd, w ho se diff eren ce is mea sure d

drivers/driver software software that controls a specific hardware device such as a DAQ board

F

filtering a type of signal conditioning that allows you to filter unwanted signals

from the signal you are trying to measure

G

G gain—the factor by which a signal i s amplified , sometimes expr essed in

decibels

H

hex hexadecimal

Hz hertz

I

in. inches

input impedance the measured resistance and capacitance between the input terminals of

a circuit

instrument driver a set of hig h-leve l sof tware functions that contr ols a s pecific VX I or

RS-232 programmable instrument or a specific plug-in DAQ board.

Instrument drivers are available in seve ral forms, rang ing from a

function callable language to a virtual instrument (VI) in LabVIEW.

©

National Instruments Corporation G-3 VXI-SC-1102 User Manual

Page 47

Glossary

L

logical address An 8-bit number that uniquely identifies each VXIbus device in a

system. It defines the A16 register addresses of a device, and indicates

Commander and Servant relationships.

LSB least significant bit

M

mainframe The chassis of a VXIbus sy stem that mechanically contains VXI

modules inserted into the backplane, ensuring that connectors fit

properly and that adjacent modules do not contact each other. It also

provides cooling airflow , an d ensu res tha t m odu les do no t dise ngage

from the backplane due to vibration or shock.

MB megabytes of memo ry

MIO multifunction I/O

MSB most significant bit

mux multiplexer—a switching device with multiple inputs that sequentially

connects each of its inputs to its output, typically at high speeds, in

order to measure several signals with a single analog input channel

N

NC not connected (signal)

noise an undesirable electrical signal—Noise comes from external sources

such as the AC power line, motors, generators, transformers,

fluorescent lights, soldering irons, CRT displays, computers, electrical

storms, welders, radio transmitters, and internal sources such as

semiconductors, resistors, and capacitors. Noise corrupts signals you

are trying to send or receive.

R

RMA Return Material Authorization

VXI-SC-1102 User Manual G-4

©

National Instruments Corporation

Page 48

Glossary

rms root mean square

S

S/s samples per se co nd

signal conditioning the manipulation of signals to prepare them for digitizing

slot A po sition w here a mod ule c an be inser ted into a V XIbu s bac kplane.

Each slot provides the 96-pin J connectors to interface with the board

P conn ec tors. A slot c an hav e on e, two, or thr ee co nnecto rs.

T

thermocouple a temperature sens or create d by joining two dissimilar me tals. The

junction produces a small voltage as a function of the temperatur e.

transducer excitation a type of signal conditioning that uses external voltages and currents to

excite the circuitry of a signal conditioning system into measuring

physical phenomena

V

V volts

V

em

VDC volts, direct current

V

diff

VI virtual instrument

V

IH

V

IL

V

in

VISA a new driver softw are arc hitect ure de velo ped b y Nationa l Instru me nts

©

National Instruments Corporation G-5 VXI-SC-1102 User Manual

common-mode voltage

differentia l v ol tage

volts, input high

volts, input low

volts in

to unify instrumentation software GPIB, DA Q, and VXI . It has been

accepted as a standar d for VXI by the VXI plug&pla y Systems Allian ce.

Page 49

Glossary

V

OH

V

OL

volts, output high

volts, output low

VXIbus VMEbus eXtensions for Instrumentation

VXIplug&play A group of VXI developers de dicated to m aking VX I de vices as

Systems Alliance easy to use as possible, primarily by simplifying software development

W

waveform a time-vary ing physica l phenomeno n, often me asured in voltag e

VXI-SC-1102 User Manual G-6

©

National Instruments Corporation

Page 50

Index

Numbers

+5 V signal (table), 3-3

A

address handler, 4-2

analog circuitry, 4-3

analog input channels, 4-3

analog output, 4-3

analog input specifications, A-1 to A-2

amplifier characteristics, A-2

dynamic characteristics, A-2

input characteristics, A-1