Page 1

SCXI™-1102/B/C

User Manual

32-Channel Thermocouple Amplifier Modules

SCXI-1102/B/C User Manual

August 1997 Edition

Part Number 320975B-01

© Copyright 1995, 1997 National Instruments Corporation. All rights reserved.

Page 2

Internet Support

support@natinst.com

E-mail: info@natinst.com

FTP Site: ftp.natinst.com

Web Address: http://www.natinst.com

Bulletin Board Support

BBS United States: (512) 794-5422

BBS United Kingdom: 01635 551422

BBS France: 01 48 65 15 59

Fax-on-Demand Support

(512) 418-1111

Telephone Support (U.S.)

Tel: (512) 795-8248

Fax: (512) 794-5678

International Offices

Australia 03 9879 5166, Austria 0662 45 79 90 0, Belgium 02 757 00 20,

Canada (Ontario) 905 785 0085, Canada (Québec) 514 694 8521, Denmark 45 76 26 00,

Finland0972572511, France0148142424, Germany0897413130,

Hong Kong 2645 3186, Israel 03 5734815, Italy 02 413091, Japan 03 5472 2970,

Korea 02 596 7456, Mexico 5 520 2635, Netherlands 0348 433466, Norway 32 84 84 00,

Singapore 2265886, Spain 91 640 0085, Sweden 08 730 49 70, Switzerland 056 200 51 51,

Taiwan 02 377 1200, United Kingdom 01635 523545

National Instruments Corporate Headquarters

6504 Bridge Point Parkway Austin, TX 78730-5039 Tel: (512) 794-0100

Page 3

Important Information

Warranty

The SCXI-1102, SCXI-1102B, and SCXI-1102C modules are warranted against defects in materials and workmanship

for a period of one year from the date of shipment, as evidenced by receipts or other documentation. National

Instruments will, at its option, repair or replace equipment that proves to be defective during the warranty period. This

warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials an d work manship, f or a p eriod of 90 days f rom date of ship ment, as evidenced

by receipts or other documentation. National Instruments will, at its option, repair or replace software media that do

not execute programming instructions if National Instruments receives notice of such defects during the warranty

period. National Instruments does not warrant that the operation of the software shall be uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside

of the package before any equipment will be accepted for warranty work. National Instruments will pay the shipping

costs of returning to the owner parts which are covered by warranty.

National Instruments believes that the information in this manual is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments reserves

the right to make changes to subseq uent editio ns of th is do cum ent wi thout prio r not ice to ho lders of this edit ion. Th e

reader should consult National Instruments if errors are suspected. In no event shall National Instruments be liable for

any damages arising out of or related to this document or the information contained in it.

XCEPT AS SPECIFIED HEREIN

E

SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

USTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF NATIONAL

C

NSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER

I

WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR

CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF

Instruments will apply regardless of the form of action, whether in contract or tort, including negligence. Any action

against National Instruments must be brought within one year after the cause of action accrues. National Instruments

shall not be liable for any delay in performance due to causes beyond its reasonable control. The warranty provided

herein does not cover damages, defects, malfunctions, or service failures caused by owner’s failure to follow the

National Instruments installation, operation, or maintenance instructions; owner’s modification of the product;

owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of third parties, or

other events outside reasonable control.

ATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND

, N

.

ATIONAL INSTRUMENTS

. N

. This limitation of the liability of National

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical,

including photocopying, recording, storing in an information retrieval system, or translating, in whole or in part,

without the prior written consent of National Instruments Corporation.

Trademarks

LabVIEW®, NI-DAQ®, RTSI®, ComponentWorks™, CVI™, DAQCard™, DAQPad™, Measure™, SCXI™, and

VirtualBench

Product and company names listed are trademarks or trade names of their respective companies.

™

are trademarks of National Instruments Corporation.

WARNING REGARDING MEDICAL AND CLINICAL USE OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with components and testing intended to ensure a level of reliability

suitable for use in treatment and diagnosis of humans. Applications of National Instruments products involving

medical or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on the

part of the user or application designer. Any use or application of National Instruments products for or involving

medical or clinical treatment must be performed by properly trained and qualified medical perso nnel, and all traditi onal

medical safeguards, equipment, and procedures that are appropriate in the particular situation to prevent serious injury

or death should always continue to be used when National Instruments products are being used. National Instruments

products are NOT intended to be a substitute for any form of established process, procedure, or equipment used to

monitor or safeguard human health and safety in medical or clinical treatment.

Page 4

About This Manual

Organization of This Manual...........................................................................................ix

Conventions Used in This Manual...................................................................................x

National Instruments Documentation..............................................................................xi

Customer Communication...............................................................................................xii

Chapter 1

Introduction

About the SCXI-1102/B/C Modules................................................................................1-1

What You Need to Get Started ........................................................................................1-2

Software Programming Choices......................................................................................1-3

National Instruments Application Software......................................................1-3

NI-DAQ Driver Software.................................................................................. 1-4

Register-Level Programming ............................................................................1-5

Optional Equipment...................................................................... .................................. .1-5

Custom Cables.................................................................................................................1-6

Unpacking........................................................................................................................1-6

Table

of

Contents

Chapter 2

Configuration and Installation

Module Configuration......................................................................................................2-1

Digital Configuration.........................................................................................2-3

Analog Configuration........................................................................................2-4

Current-Loop Receivers......................................................................2-4

Hardware Installation.......................................................................................................2-6

Chapter 3

Signal Connections

Front Connector.............................................................. .................................................3-1

Front Connector Signal Descriptions................................................................3-3

Analog Input Signal Connections.......................................................3-3

Ground-Referencing Your Signals.......................................3-4

Cold-Junction Sensor Connection.....................................................................3-6

©

National Instruments Corporation v SCXI-1102/B/C User Manual

Page 5

Table of Contents

Rear Signal Connector..................................................................................................... 3-7

Rear Signal Connector Descriptions................................................................. 3-8

Chapter 4

Theory of Operation

Functional Overview.......................................................................................................4-1

Rear Signal Connector, SCXIbus Connector, and SCXIbus Interface............. 4-2

Digital Control Circuitry...................................................................................4-2

Analog Circuitry ...............................................................................................4-3

Chapter 5

Calibration

Overview .........................................................................................................................5-1

Calibration Procedure......................................................................................................5-1

Calibration Equipment Requirements...............................................................5-1

Gain and Offset Calibration..............................................................................5-2

Analog Output Signal Connections....................................................3-9

Digital I/O Signal Connections...........................................................3-9

Digital Timing Signal Connection......................................................3-10

Digital Signal Specifications ..............................................................3-10

Analog Input Channels.......................................................................4-3

Analog Bus Switch.............................................................................4-4

Appendix A

Specifications

Appendix B

Calibration Sample Program

Appendix C

Customer Communication

Glossary

Index

SCXI-1102/B/C User Manual vi

©

National Instruments Corporation

Page 6

Figures

Tables

Table of Contents

Figure 1-1. The Relationship between the Programming Environment,

NI-DAQ, and Your Hardware................................. ................................1-4

Figure 2-1. SCXI-1102/B/C Module Parts Locator Diagram (1102 shown).............2-2

Figure 2-2. Removing the SCXI Module Cover........................................................2-4

Figure 2-3. Bent and Trimmed Resistor.....................................................................2-5

Figure 3-1. SCXI-1102/B/C Module Front Connector Pin Assignments ..................3-2

Figure 3-2. Ground-Referenced Signal Connection...................................................3-5

Figure 3-3. Floating Signal Connection Referenced to Chassis Ground...................3-6

Figure 3-4. SCXI-1102/B/C Module Rear Signal Connector Pin Assignments........3-7

Figure 4-1. SCXI-1102/B/C Module Block Diagram................................................4-1

Table 2-1. Jumper Settings for Digital Signal Connection.......................................2-3

Table 3-1. SCXIbus to SCXI-1102/B/C Module Rear Signal Connector

to DAQ Device Pin Equivalencies..........................................................3-10

©

National Instruments Corporation vii SCXI-1102/B/C User Manual

Page 7

About

This

Manual

This manual describes the electrical and mechanical aspects of the

SCXI-1102 family of modules and contains information concerning

their installation and operation.

The SCXI-1102 family consists of the following modules:

• SCXI-1102

• SCXI-1102B

• SCXI-1102C

Unless otherwise noted, SCXI-1102/B/C will hereafter refer to all three

modules in the SCXI-1102 family.

The SCXI-1102/B/C modules are members of the National Instruments

Signal Conditioning eXtensions for Instrumentation (SCXI) Series for

the National Instruments data acquisition (DAQ) plug-in devices. Th ese

modules are designed for signal conditioning thermocouples, volt and

millivolt sources, and 4–20 mA sources or 0–20 mA process-current

sources. The SCXI-1102/B/C modules have 32 differential analog input

channels and one cold-junction sensor channel.

Organization of This Manual

The SCXI-1102/B/C User Manual is organized as follows:

• Chapter 1, Introduction, describes the SCXI-1102/B/C modules;

lists what you need to get started with your SCXI-1102/B/C

module, the optional software, optional equipment, and custom

cables; and explains how to unpack the SCXI-1102/B/C modules.

• Chapter 2, Configuration and Installation, describes how to

configure the SCXI-1102/B/C jumper, how to install current-loop

receivers, and how to install the SCXI-1102/B/C module into the

SCXI chassis.

• Chapter 3, Signal Connections, describes the input and output

signal connections to the SCXI-1102/B/C module via the module

front connector and rear signal connector. This chapter also

©

National Instruments Corporation ix SCXI-1102/B/C User Manual

Page 8

About This Manual

includes specifications and connection instructions for the signals

on the SCXI-1102/B/C connectors.

• Chapter 4, Theory of Operatio n , contains a functional overview of

the SCXI-1102/B/C module and explains the operation of each

functional unit making up the SCXI-1102/B/C module.

• Chapter 5, Calibration, discusses the calibration procedures for the

SCXI-1102/B/C modules.

• Appendix A, Specifications, lists the specifications for the

SCXI-1102/B/C modules.

• Appendix B, Calibration Sample Program, contains a sample

program to help you calibrate your submodule.

• Appendix C, Customer Communication, contains forms you can

use to request help from National Instruments or to comment on our

products.

•The Glossary contains an alphabetical list and description of terms

used in this manual, including abbreviations, acronyms, metric

prefixes, mnemonics, symbols, and terms.

•The Index contains an alphabetical list of key terms and topics in

this manual, including the page where you can find each one.

Conventions Used in This Manual

The following conventions are used in this manual.

♦ The ♦ symbol indicates that the text following it applies only to specific

SCXI-1102 modules.

< > Angle brackets containing numbers separated by an ellipsis represent a

range of values associated with a port, b it, or signal name (f or example,

ACH<0..7> stands for the signals ACH0 through ACH7).

This icon to the left of bold italicized text denotes a note, which alerts

you to important information.

!

bold italic Bold italic text denotes a note, caution, or warning.

italic Italic text denotes emphasis, a cross reference, or an introduction to a

Lab board Refers to the boards that have Lab in their names, such as the Lab-LC

SCXI-1102/B/C User Manual x

This icon to the left of bold italicized text denotes a caution, which

advises you of precautions to take to avoid injury, data loss, or a

system crash.

key concept.

and the Lab-PC+.

©

National Instruments Corporation

Page 9

About This Manual

MIO board Refers to the multichannel I/O DAQ boards that have MIO in their

names, such as the AT-MIO-16 and the NEC-MIO-16E-4.

monospace Denotes text or characters that are to be literally input from the

keyboard, sections of code, programming examples, and syntax

examples. This font is also used for the proper names of disk drives,

paths, directories, programs, subprograms, subroutines, device names,

functions, variables, filenames, and extensions, and for statements and

comments taken from program code.

PC Refers to the IBM PC/XT, the IBM PC AT, and compatible computers.

SCXIbus Refers to the backplane in the chassis. A signal on the backplane is

referred to as the SCXIbus <signal name> line (or signal). The SCXIbus

descriptor may be omitted when the meaning is clear. Descriptions of

all SCXIbus signals are in Chapter 3, Signal Connections.

SCXI-1102/B/C Refers to all modules in the SCXI-1102 family unless otherwise noted.

modules

Slot 0 Refers to the power supply and control circuitry in the SCXI chassis.

Abbreviations, acronyms, metric prefixes, mnemonics, symbols, and

terms are listed in the Glossary.

National Instruments Documentation

The SCXI™-1102/B/C User Manual is one piece of the documentation

set for your data acquisition system. You could have any of several

types of manuals, depending on the hardware and s oftware in you r

system. Use the manuals you have as follows:

• Getting Started with SCXI—This is the first manual you should read.

It gives an overview of the SCXI system and contains the most

commonly needed information for the modules, chassis, and

software.

• Your SCXI hardware user manuals—Read these manuals next for

detailed information about signal connections and module

configuration. They also explain in greater detail how the module

works and contain application hints.

• Your DAQ hardware user manuals—These manuals have detailed

information about the DAQ hardware that plugs into or is

connected to your computer. Use these manuals for hardware

installation and configuration instructions, specification

information about your DAQ hardware, and application hints.

©

National Instruments Corporation xi SCXI-1102/B/C User Manual

Page 10

About This Manual

• Software documentation—Examples of software documentation

you may have are the LabVIEW and LabWindows

sets and the NI-DAQ documentation. After you set up your

hardware system, use either the application software

documentation or the NI-DAQ documentation to help you write

your application. If you have a large and complicated system, it is

worthwhile to look through the so ftware documentation b efore you

configure your hardware.

• Accessory installation guides or manuals—If you are using

accessory products, read the terminal block and cable assembly

installation guides. They explain how to physically connect the

relevant pieces of the system. Consult these guides when you are

making your connections.

• SCXI Chassis Manual—Read this manual for maintenance

information on the chassis and installation instructions.

Customer Communication

National Instruments wants to receive your comments on our products

and manuals. We are interested in the applications you develop with our

products, and we want to help if you have problems with them. To make

it easy for you to contact us, this manual contains comment and

configuration forms for you to complete. These forms are in

Appendix C, Customer Communication, at the end of this manual.

®

/CVI manual

SCXI-1102/B/C User Manual xii

©

National Instruments Corporation

Page 11

Chapter

Introduction

This chapter describes the SCXI-1102/B/C modules; lists what you

need to get started with your SCXI-1102/B/C module, the optional

software, optional equipment, and custom cables; and explains how to

unpack the SCXI-1102/B/C modules.

About the SCXI-1102/B/C Modules

♦ SCXI-1102

This module is for signal conditioning of thermocouples,

low-bandwidth volt and millivolt sources, 4 to 20 mA current sources,

and 0 to 20 mA process-current sources. The SCXI-1102 has

32 differential analog input channels and one cold-junction sensor

channel. On each channel, the SCXI-1102 has a three-pole lowpass

filter with a 2 Hz cutoff frequency to reject 60 Hz noise. Each channel

also has an amplifier with a selectable gain of 1 or 100. You can

multiplex the SCXI-1102 inputs to a single output, which drives a single

DAQ device channel.

♦ SCXI-1102B

This module is for the signal conditioning of thermocouples,

medium-bandwidth volt and millivolt sources, 4 to 20 mA current

sources, and 0 to 20 mA process-current sources. The SCXI-1102B has

32 different analog input channels and one cold-junction sensor

channel. On each channel, the SCXI-1102B has a three-pole lowpass

filter with a 200 Hz cutoff frequency. Each channel also has an

amplifier with a selectable gain of 1 or 100. You can multiplex the

SCXI-1102B inputs to a single output, which drives a single DAQ

device channel.

1

♦ SCXI-1102C

This module is for the signal conditioning of thermocouples,

high-bandwidth volt and millivolt sources, 4 to 20 mA current sources,

and 0 to 20 mA process-current sources. The SCXI-1102C has 32

different analog input channels and one cold-junction sensor channel.

On each channel, the SCXI-1102C has a three-pole lowpass filter with

a 10 kHz cutoff frequency. Each channel also has an amplifier with a

©

National Instruments Corporation 1-1 SCXI-1102/B/C User Manual

Page 12

Chapter 1 Introduction

selectable gain of 1 or 100. You can multiplex the SCXI-1102C inputs

to a single output, which drives a single DAQ device channel.

The SCXI-1102/B/C modules operate with full functionality with the

National Instruments MIO, Lab-PC+, PCI-1200, DAQCard-1200, and

SCXI-1200 modules. You can use the PC-LPM-16 board and the

DAQCard-700 with the SCXI-1102/B/C, but these devices cannot scan

the module; they can only perform single-channel reads. You can

multiplex several SCXI-1102/B/C modules and other SCXI modules

into a single channel on the DAQ device, greatly increasing the number

of analog input signals that you can digitize.

Detailed specifications of the SC XI-1102/B/ C modul es are listed in

Appendix A, Specifications.

What You Need to Get Started

To set up and use your SCXI-1102/B/C module, you will need the

following items:

❑ One of the following modules:

SCXI-1102

SCXI-1102B

SCXI-1102C

❑ SCXI-1102/B/C User Manual

❑ One of the following software packages and documentation:

ComponentWorks

LabVIEW for Macintosh

LabVIEW for Windows

LabWindows/CVI for Windows

Measure

NI-DAQ for Macintosh

NI-DAQ for PC Compatibles

VirtualBench

❑ Your computer

SCXI-1102/B/C User Manual 1-2

©

National Instruments Corporation

Page 13

Software Programming Choices

You have several options to choose from when programming your

National Instruments DAQ and SCXI hardware. You can use National

Instruments application software, NI-DAQ, or register-level

programming.

National Instruments Application Software

ComponentWorks contains tools for data acquisition and instrument

control built on NI-DAQ driver software. ComponentWorks provides

a higher-level programming interface for building virtual instruments

through standard OLE controls and DLLs. With ComponentWork s, you

can use all of the configuration tools, resource management utilities,

and interactive control utilities included with NI-DAQ.

LabVIEW features interactive graphics, a state-of-the-art user

interface, and a powerful graphical programming language. The

LabVIEW Data Acquisition VI Library, a series of VIs for using

LabVIEW with National Instruments DAQ hardware, is included with

LabVIEW. The LabVIEW Data Acquisition VI Library is functionally

equivalent to NI-DAQ software.

Chapter 1 Introduction

LabWindows/CVI features interactive graphics, state-of-the-art user

interface, and uses the ANSI standard C programming language. The

LabWindows/CVI Data Acquisition Library, a series of functions for

using LabWindows/CVI with National Instruments DAQ hardware, is

included with the NI-DAQ software kit. The LabWindows/CVI Data

Acquisition Library is functionally equivalent to the NI-DAQ so ftware.

VirtualBench features virtual instruments that combine DAQ products,

software, and your computer to create a stand-alone instrument with the

added benefit of the processing, display, and storage capabilities of

your computer. VirtualBench instruments load and save waveform data

to disk in the same forms that can be used in popular spreadsheet

programs and word processors.

Using ComponentWorks, LabVIEW, LabWindows/CVI, or

VirtualBench software will greatly reduce the development time

for your data acquisition and control application.

©

National Instruments Corporation 1-3 SCXI-1102/B/C User Manual

Page 14

Chapter 1 Introduction

NI-DAQ Driver Software

The NI-DAQ driver software is included at no charge with all National

Instruments DAQ hardware. NI-DAQ has an extensive library of

functions that you can call from your application programming

environment. These functions include routines for analog input

(A/D conversion), buffered data acquisition (high-speed A/D

conversion), analog output (D/A conversion), waveform generation,

digital I/O, counter/timer operations, SCXI, RTSI, self-calibration,

messaging, and acquiring data to extended memory.

NI-DAQ also internally addresses many of the complex issues between

the computer and the plug-in device, such as programming interrupts

and DMA controllers. NI-DAQ maintains a consistent software

interface among its different versions so that you can change platforms

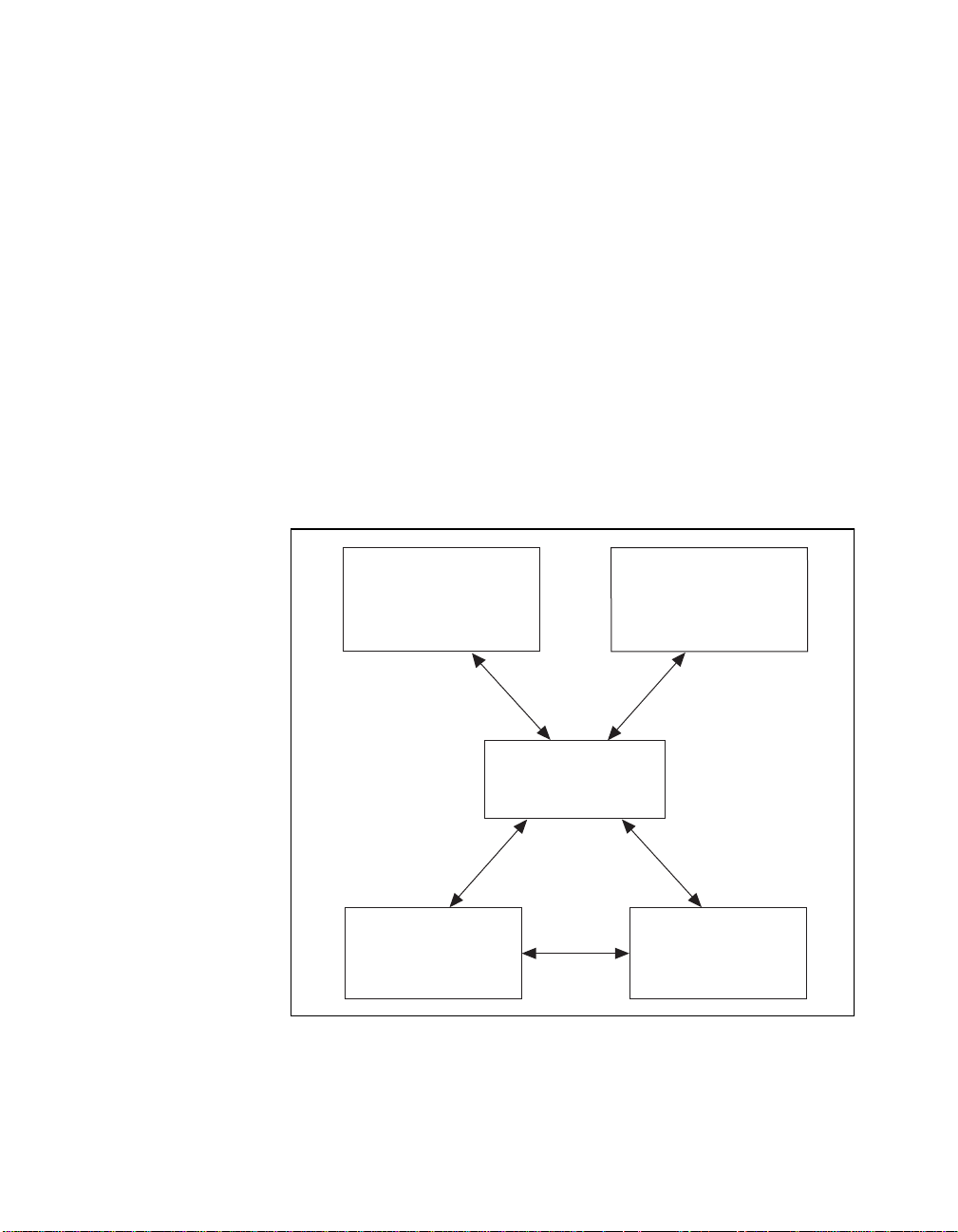

with minimal modifications to your code. Figure 1-1 illustrates the

relationship between NI-DAQ and your National Instruments

application software.

Conventional

Programming Environment

DAQ or

SCXI Hardware

Figure 1-1.

The Relationship between the Programming Environment,

NI-DAQ, and Your Hardware

ComponentWorks,

LabVIEW,

LabWindows/CVI, or

VirtualBench

NI-DAQ

Driver Software

Personal

Computer or

Workstation

SCXI-1102/B/C User Manual 1-4

©

National Instruments Corporation

Page 15

Register-Level Programming

The final option for programming any National Instruments DAQ

hardware is to write register-level software. Writing register-level

programming software can be very time-consuming and inefficient

and is not recommended.

Even if you are an experienced register-level programmer, consider

using NI-DAQ or other National Instruments application software to

program your National Instruments DAQ hardware. Using the

application software is easier than and as flexible as register-level

programming and can save weeks of development time.

Optional Equipment

National Instruments offers a variety of products to use with your

SCXI-1102/B/C module, as follows:

• Terminal blocks and 96-pin cables that allow you to attach input

signals to your module.

• SCXI process-current resistor kit

• Cables and cable assemblies, shielded and ribbon

Chapter 1 Introduction

For more specific information about these products, refer to your

National Instruments catalogue or call the office nearest you.

©

National Instruments Corporation 1-5 SCXI-1102/B/C User Manual

Page 16

Chapter 1 Introduction

Custom Cables

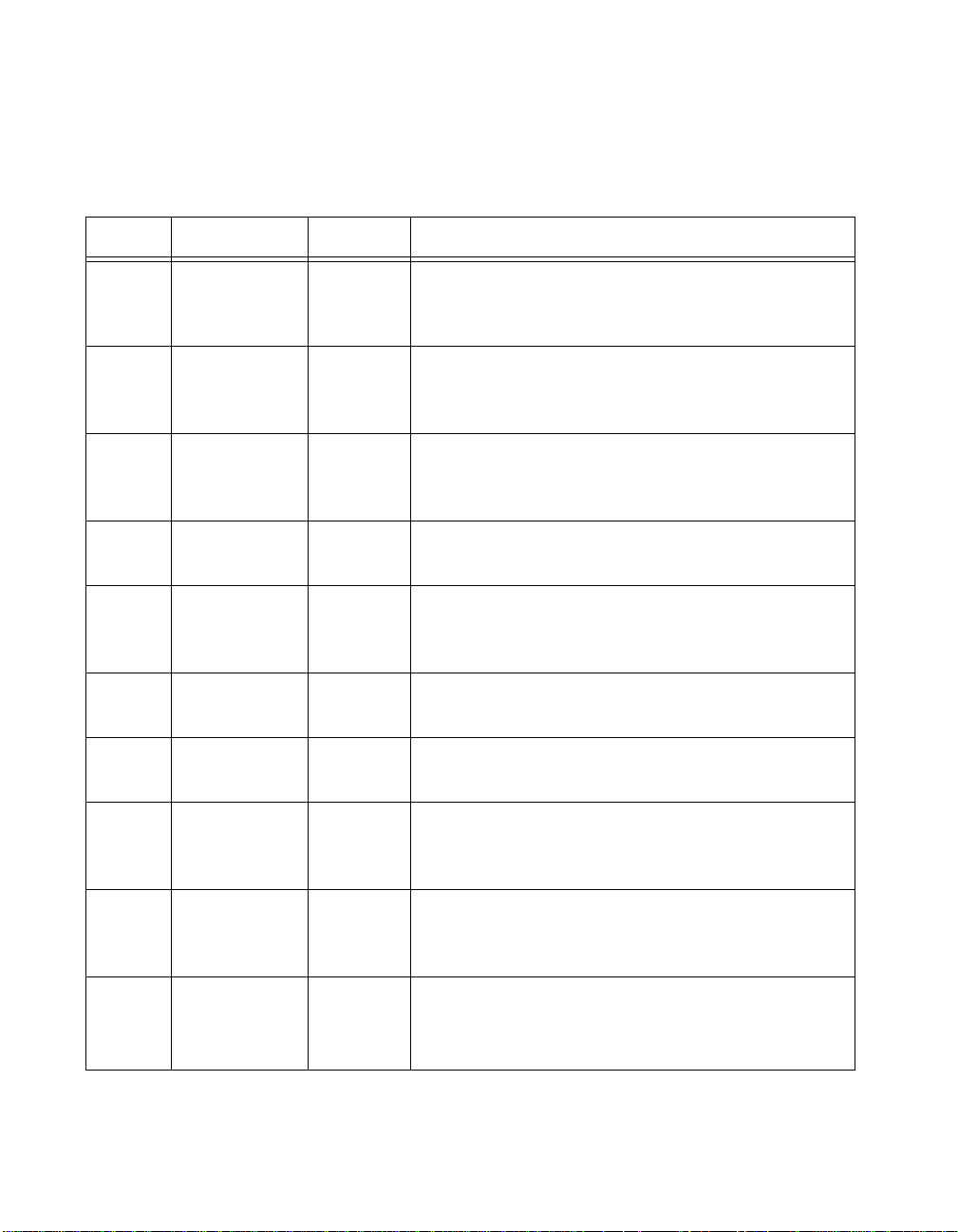

The following table summarizes the custom cable information.

Signal

Connector

Rear AMP Inc. (1-103310-0)

Front Harting Electronik Inc.

SCXI–1102/B/C

Connector

50-pin male ribbon

cable header

(09-03-396-6921)

96-pin DIN C male

connector

Unpacking

Your SCXI-1102/B/C module is shipped in an antistatic package to

prevent electrostatic damage to the module. Electrostatic discharge can

damage several components on the module. To avoid such damage in

handling the module, take the following precautions:

• Ground yourself via a grounding strap or by holding a grounded

object.

• Touch the antistatic package to a metal part of your SCXI chassis

before removing the module from the package.

• Remove the module from the package and inspect the module for

loose components or any other sign of damage. Notify National

Instruments if the module appears damaged in any w ay. Do not

install a damaged module into your SCXI chassis.

• Never touch the exposed pins of connectors.

Mating

Connector

Electronic Products

Division/3M (3425-7650)

or T&B/Ansley Corp.

(609-5041CE) 50-position

polarized ribbon-socket

connector

AMP Inc. (535020;

right-angle pins) or Panduit

Corp. (100-096-434

straight-solder pins) 96-pin,

polarized, DIN C female

connector

Cable

Electronic Products

Division/3M (3365/50)

or T&B/Ansley Corp.

(171-50) 50-conductor,

28 AWG stranded

ribbon cable

N/A

SCXI-1102/B/C User Manual 1-6

©

National Instruments Corporation

Page 17

Configuration and

Chapter

Installation

This chapter describes how to configure your SCXI-1102/B/C jumper,

how to install current-loop receivers, and how to install your

SCXI-1102/B/C module into the SCXI chassis.

Module Configuration

The SCXI-1102/B/C contains one jumper, shown in Figure 2-1. Jumper

W1 connects a pullup resistor to the SERDATOUT signal on the rear

signal connector.

The remainder of the module configuration (gain, output signal

referencing, and so on) is software-programmable.

2

©

National Instruments Corporation 2-1 SCXI-1102/B/C User Manual

Page 18

Chapter 2 Configuration and Installation

1

2

3

4

5

6

7

1 RCL24-RCL31

2 RCL14-RCL23

3 RCL8-RCL13

4 Assembly Number

Figure 2-1. SCXI-1102/B/C Module Parts Locator Diagram (1102 shown)

SCXI-1102/B/C User Manual 2-2

5 RCL0-RCL7

6 Serial Number

7W1

©

National Instruments Corporation

Page 19

Digital Configuration

W1

PULLUP NO PULLUP

W1

PULLUP NO PULLUP

If you have a one-chassis system, you do not have to read this section.

You can skip to the next section, Analog Configuration.

Note: If nothing is cabled to the SCXI-1102/B/C module rear signal connector,

the position of jumper W1 is irrelevant.

The SCXI-1102/B/C modules have only one jumper—jumper W1—f or

communication between the DAQ device and the SCXIbus, shown in

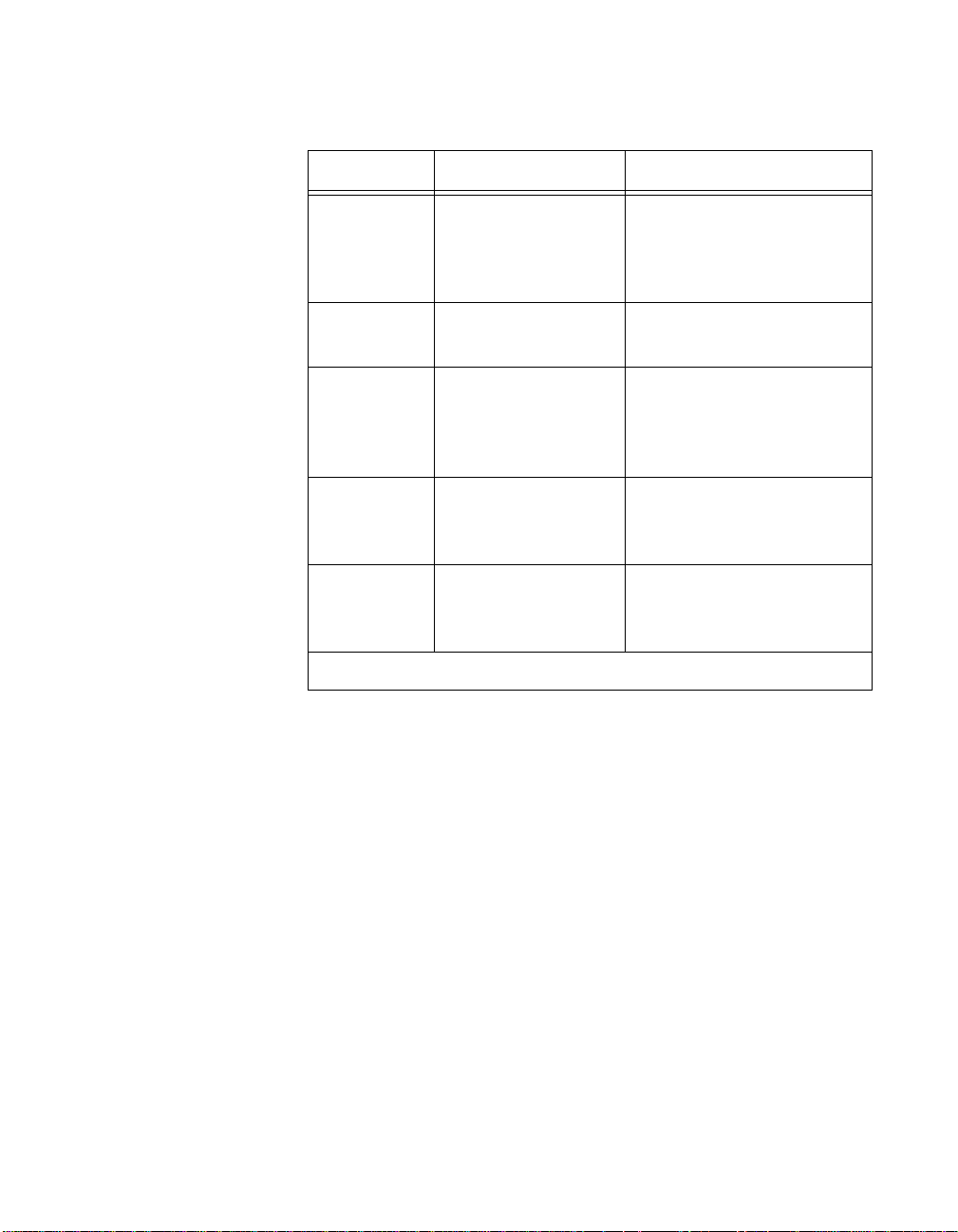

Table 2-1.

Chapter 2 Configuration and Installation

Table 2-1.

Jumper Settings for Digital Signal Connection

Jumper Description Configuration

Position PULLUP—Use this

setting for a single-chassis system

and for one cabled module in a

multi-chassis system. Connects a

2.2 kΩ pullup resistor to the

SERDATOUT line. (factory

setting)

Position NO PULLUP—Use this

W1

setting for additional chassis in a

multi-chassis system. No pullup

resistor is connected to the

SERDATOUT line.

All SCXI modules have a jumper that corresponds to jumper W1 on the

SCXI-1102/B/C module. Refer to the user manuals of the other SCXI

modules in your system to determine the designator and settings of this

jumper. In the pullup position, this jumper connects a pullup resistor to

the SERDATOUT line. This pullup resistor pulls the SERDATOUT

line high when its open-collector driver goes to a high-impedance state.

The SERDATOUT line on the SCXI-1102/B/C module reads the

Module ID Register, the Status Register, and the EEPROM.

©

When using a single-chassis system, set the jumper in the pullup

position on the SCXI module cabled to the DAQ device. When using

multiple chassis, set the jumper to the pullup position on only one of the

SCXI modules cabled to the DAQ device.

National Instruments Corporation 2-3 SCXI-1102/B/C User Manual

Page 20

Chapter 2 Configuration and Installation

If you want to change the W1 jumper setting, refer to Figure 2-2 as you

perform the following steps:

1. Ground yourself via a grounding strap or via a ground connected to

your SCXI chassis. Properly grounding yourself prevents damage

to your SCXI module from electrostatic discharge.

2. Remove the grounding screw of the top cover.

3. Snap out the top cover of the shield by placing a screwd river in the

groove at the bottom of the module and pushing down on the

screwdriver.

4. Change the W1 jumper setting.

5. Reinstall the top cover and grounding screw.

Removable Cover

Grounding

Screw

Figure 2-2. Removing the SCXI Module Cover

Analog Configuration

Current-Loop Receivers

The SCXI-1102/B/C modules have pads for transforming individual

channels to current-to-voltage converters. National Instruments offers

an SCXI process-current pack of four 249 Ω, 0.1%, 5 ppm, 1/4 W

resistors. The reference designators for the current loop resistors have

SCXI-1102/B/C User Manual 2-4

Front Connector

©

Top of Module

National Instruments Corporation

Page 21

Chapter 2 Configuration and Installation

the format: for input channel x, the resistor is RCLx. For example, the

resistor for channel 28 is RCL28.

Caution: Before installing the resistors in your module, make sure that there are no

!

signals connected to your module front connector.

Before installing your module in the SCXI chassis, you must install the

resistors by performing the following steps:

1. Ground yourself via a grounding strap or via a ground connected to

your SCXI chassis. Properly grounding yourself prevents damage

to your SCXI module from electrostatic discharge.

2. Remove the grounding screw of the top cover.

3. Snap out the top cover of the shield by placing a screwd river in the

groove at the bottom of the module and pushing down.

4. Remove the rear panel by unscrewing the two remaining screws.

5. Slide the module out of its enclosure.

6. Bend and trim the resistor lead as shown in Figure 2-3. Be sure that

the resistor does not extend more than 0.65 in. above the surface of

the circuit board.

Figure 2-3. Bent and Trimmed Resistor

7. Insert the resistor into the appropriate pa d, labeled RCLx.

8. Solder the leads to the pad on the bottom side of the module.

9. Slide the module back into its enclosure.

10. Reinstall the rear panel.

11. Reinstall the top cover and grounding screw.

©

National Instruments Corporation 2-5 SCXI-1102/B/C User Manual

Page 22

Chapter 2 Configuration and Installation

Hardware Installation

You can install the SCXI-1102/B/C module in any available SCXI

chassis slot. After you have made any necessary changes and have

verified and recorded the jumper setting on the form in Appendix C,

Customer Communication, you are ready to install the SCXI-1102/B/C

module. The following are general installation instructions; consult the

user manual or technical reference manual of your SCXI chassis for

specific instructions and warnings:

1. Turn off the computer that contains the DAQ device or disconnect

it from your SCXI chassis.

2. Turn off the SCXI chassis. Do not insert the SCXI-1102/B/C

module into a chassis that is turned on.

3. Insert the SCXI-1102/B/C module into the module guides. Gently

guide the module into the back of the slot until the connectors make

good contact. If a cable assembly has already been installed in the

rear of the chassis, the module and cable assembly must be firmly

engaged; however, do not force the module into place.

4. Screw the front mounting panel of the SCXI-1102/B/C module to

the top and bottom threaded strips of your SCXI chassis.

5. If this module is to be connected to an MIO-16 DAQ device, attach

the connector at the metal end of the SCXI-1340 cable assembly to

the rear signal connector on the SCXI-1102/B/C module. Screw the

rear panel to the rear threaded strip. Attach the loose end of the

cable to the MIO-16 device.

Note: For installation procedures with other SCXI accessories and DAQ devices,

consult your cable installation guide.

6. Check the installation.

7. Turn on the SCXI chassis.

8. Turn on the computer or reconnect it to your chassis.

The SCXI-1102/B/C module is installed. You are now ready to install

and configure your software.

If you are using NI-DAQ or other National Instruments application

software, refer to the installation instructions in your documentation to

install and configure your software.

SCXI-1102/B/C User Manual 2-6

©

National Instruments Corporation

Page 23

Chapter

Signal Connections

This chapter describes the input and output signal connections to the

SCXI-1102/B/C module via the module front connector an d rear signal

connector. This chapter also includes specifications and connection

instructions for the signals on the SCXI-1102/B/C module connectors.

Caution:

!

Front Connector

Static electricity is a major cause of component failure. To prevent damage

to the electrical components in the module, observe antistatic techniques

whenever removing a module from the chassis or whenever working on a

module.

Figure 3-1 shows the pin assignments for the SCXI-1102/B/C module

front connector.

3

©

National Instruments Corporation 3-1 SCXI-1102/B/C User Manual

Page 24

Chapter 3 Signal Connections

CGND

NC

NC

NC

NC

NC

NC

NC

CGND

NC

NC

NC

NC

NC

NC

NC

CGND

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

CGND

CJSENSOR

CJSENSOR

CGND

+5 V

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

A

CH0CH1CH2CH3CH4CH5CH6CH7CH8-

CH9CH10CH11CH12CH13CH14-

CH15-

CH16CH17CH18CH19CH20CH21CH22-

9

8

7

6

5

4

3

2

1

CH23CH24CH25CH26CH27CH28CH29CH30CH31-

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

B

CH0+

CH1+

CH2+

CH3+

CH4+

CH5+

CH6+

CH7+

CH8+

CH9+

CH10+

CH11+

CH12+

CH13+

CH14+

CH15+

CH16+

CH17+

CH18+

CH19+

CH20+

CH21+

CH22+

CH23+

CH24+

CH25+

CH26+

CH27+

CH28+

CH29+

CH30+

CH31+

C

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

Figure 3-1. SCXI-1102/B/C Module Front Connector Pin Assignments

SCXI-1102/B/C User Manual 3-2

©

National Instruments Corporation

Page 25

Front Connector Signal Descriptions

Pin Signal Name Description

A1 +5 V +5 VDC Source—Used to

Chapter 3 Signal Connections

power the temperature sensor

on the terminal block. 0.2 mA

of source not protected.

A2, A5, A16,

A24, A32

A3, A4 CJSENSOR Cold-junction Temperature

B1–B32 CH31- through CH0– Negative Input Channels —

C1–C32 CH31+ through CH0+ Positive Input Channels 31

All other pins are not connected.

CGND Chassis Ground—Tied to the

SCXI chassis.

Sensor Input—Connects to

the temperature sensor of the

terminal block.

Negative side of differential

input channels.

through 0—Positive side of

differential input channels.

Analog Input Signal Connections

The signal terminals for the positive input channel are located in

column B of the connector. The signal terminal for each corresponding

negative input channel is located in column C of the connector. Each

input goes to a separate filter and amplifier that is multiplexed to the

module output buffer. The terminal block temperature sensor output—

connected to pins A3 and A4 (CJSENSOR)—is also filtered and

multiplexed to the module output buffer.

The differential input signal range of an SCXI-1102/B/C module input

channel is ±10 V/G, where G is the gain selected on the SCXI-1102/B/C

module input channel. This differential input range is the maximum

measurable voltage difference between the positive and negative

channel inputs. The common-mode input signal range of an

SCXI-1102/B/C module input channel is ±11 V. This common-mode

©

National Instruments Corporation 3-3 SCXI-1102/B/C User Manual

Page 26

Chapter 3 Signal Connections

Caution: Exceeding the input damage level (±42 VAC peak or VDC between input

!

channels and chassis ground) can damage the SCXI-1102/B/C module, the

SCXIbus, and the DAQ device. National Instruments is

injuries resulting from such signal connections.

Applying a voltage greater than ±42 VAC peak or VDC to the

SCXI-1102/B/C is an electrical shock hazard. National Instruments is

liable for any damages or injuries resulting from such voltage application.

Note: Exceeding the differential or common-mode input channel ranges results

in a distorted signal measurement.

input range for either positive or negative channel input is the maximum

input voltage which will result in a valid measurement. Each channel

includes input protection circuitry to withstand the accidental

application of voltages up to ±42 VAC peak or VDC.

liable for any

NOT

NOT

Ground-Referencing Your Signals

Your input signals can be either ground-referenced, as shown in

Figure 3-2, or floating, as shown in Figure 3-3. Before you connect

your thermocouple or any other signal, determine whether it is

floating or ground-referenced. If it is a floating signal, you must

ground-reference the signal in one of two ways. You can connect the

negative channel input to chassis ground as shown in Figure 3-3 or you

can use the clamping resistors on the SCXI-1303 terminal block. The

SCXI-1303 also has a resistor pack for pulling up the positive input s for

open-thermocouple detection. Consult the SCXI-1303 32-Channel

Isothermal Block Installation Guide for details.

Do not ground signals which are already ground-referenced; doing so

will result in a ground loop, which adversely affects your measurement

accuracy.

SCXI-1102/B/C User Manual 3-4

©

National Instruments Corporation

Page 27

Chapter 3 Signal Connections

CH0+

CH0-

+

-

+

V

s

CH1+

+

CH1-

+

-

V

cm

-

Connector

Front Signal

SCXI - 1102/B/C

Figure 3-2. Ground-Referenced Signal Connection

©

National Instruments Corporation 3-5 SCXI-1102/B/C User Manual

Page 28

Chapter 3 Signal Connections

CH0+

CH0-

Floating

Signal

Make This Connection

to Ground Reference

+

V

s

-

the Signal

Referenced to

Chassis Ground

CH1+

CH1-

Connector

Front Signal

CGND

Figure 3-3. Floating Signal Connection Referenced to Chassis Ground

Cold-Junction Sensor Connection

Pins A3 and A4 (CJSENSOR) connect the temperature sensor located

on the SCXI-1300 or SCXI-1303 terminal blocks to the SCXI- 1102/B/C

module. The CJSENSOR signal is measured relative to CGND. Pins A3

and A4 are connected within the SCXI-1102/B/C module so the

position of the MTEMP/DTEMP jumper on the SCXI-1300 or

SCXI-1303 does not matter. The input is overvoltage-protected to

15 VDC with power on and off.

+

-

+

-

SCXI - 1102/B/C

Caution: Exceeding the overvoltage protection on the CJSENSOR input can damage

!

the SCXI-1102/B/C module, the SCXIbus, and the DAQ device. National

Instruments is

liable for any damages or injuries resulting from such

NOT

signal connections.

SCXI-1102/B/C User Manual 3-6

©

National Instruments Corporation

Page 29

Rear Signal Connector

Note: If you are using the SCXI-1102/B/C module with a National Instruments

DAQ device and cable assembly, you do not need to read the remainder of

this chapter. If you are using the SCXI-1180 feedthrough panel, the

SCXI-1343 rear screw terminal adapter, or the SCXI-1351 one-slot cable

extender with the SCXI-1102/B/C module, read this section.

Figure 3-4 shows the SCXI-1102/B/C module rear signal connector pin

assignments.

Chapter 3 Signal Connections

AOGND

MCH0+

NC

NC

NC

NC

NC

NC

NC

OUTREF

NC

NC

SERDATIN

DAQD*/A

SLOT0SEL*

DGND

NC

NC

SERCLK

NC

NC

RSVD

NC

NC

NC

12

34

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

41 42

43 44

45 46

47 48

49 50

AOGND

MCH0NC

NC

NC

NC

NC

NC

NC

NC

NC

DGND

SERDATOUT

NC

NC

NC

NC

SCANCLK

NC

NC

NC

NC

RSVD

NC

NC

Figure 3-4.

©

National Instruments Corporation 3-7 SCXI-1102/B/C User Manual

SCXI-1102/B/C Module Rear Signal Connector Pin Assignments

Page 30

Chapter 3 Signal Connections

Rear Signal Connector Descriptions

The rear signal connector on the cabled module is the interface between

the DAQ device and all modules in the SCXI chassis.

Pin Signal Name Direction Description

1, 2 AOGND Output Negative Module Analog Output—With software, you

can configure these pins to connect to the analog

reference.

3 MCH0+ Output Positive Module Analog Output—This pin connects to

the positive side of the differential analog input channel

0 of the DAQ device.

4 MCH0- Output Negative Module Analog Output—In the reset state of

the module, this pin is configured to connect to the

analog reference.

19 OUTREF Output Negative Module Analog Output—With software, you

can configure this pin to connect to the analog reference.

24, 33 DGND — Digital Ground—These pins supply the reference for

DAQ device digital signals and are tied to the module

digital ground.

25 SERDATIN Input Serial Data In—The DAQ device uses this signal to

program modules in all slots.

26 SERDATOUT Output Serial Data Out—A cabled module uses this signal to

return data from any module to the DAQ device.

27 DAQD*/A Input DAQ Device Data/Address Line—The DAQ device

asserts this signal to indicate to the module whether the

incoming serial stream is data or address information.

29 SLOT0SEL* Input Slot 0 Select—The DAQ device asserts this signal low

to indicate that the SERDATIN line information is going

to the Slot 0 controller instead of a module.

36

SCANCLK Input Scan Clock—A rising edge indicates to the scanned

SCXI module that the DAQ device has taken a sample

and causes the module to advance channels.

SCXI-1102/B/C User Manual 3-8

©

National Instruments Corporation

Page 31

Chapter 3 Signal Connections

Pin Signal Name Direction Description

37

43, 46

All other pins are not connected.

SERCLK Input Serial Clock—This signal clocks the data on the SER-

DATIN and SERDATOUT lines.

RSVD Input Reserved

The signals on the rear signal connector are analog output signals,

digital I/O signals, or digital timing signals. The following section

contains signal connection guidelines for each of these groups.

Analog Output Signal Connections

Pins 1 through 4 and pin 19 of the rear signal connector are analog

output signal pins. Pins 1 and 2 are AOGND signal pins, pin 4 is the

MCH0- pin, and pin 19 is the OUTREF pin. With software, you can

configure pin 1, 2, 4 or 19 to connect to the module’s analog ground

(AGND). You can use the pin that is connected to AGND as a general

analog power ground tie point to the SCXI-1102/B/C module, if

necessary.

Caution: The SCXI-1102/B/C module analog outputs are not overvolta ge-protected.

!

Applying external voltages to these outputs can damage the

SCXI-1102/B/C module. National Instruments is

damages resulting from such signal connections.

liable for any

NOT

Note: The SCXI-1102/B/C module analog outputs are short-circuit protected.

Digital I/O Signal Connections

Pins 24 through 27, 29, 33, 36, 37, 43, and 46 constitute the digital I/O

lines of the rear signal connector.

The SCXI-1102/B/C module digital input and output signals match the

digital I/O lines of the MIO-16 boards. When used with an SCXI-1341,

SCXI-1342, or SCXI-1344 cable assembly, the SCXI-1102/B/C module

signals match the digital lines of the Lab-NB/PC+, the PC-LPM-16, and

©

National Instruments Corporation 3-9 SCXI-1102/B/C User Manual

Page 32

Chapter 3 Signal Connections

the Lab-LC boards, respectively. Table 3-1 l ists th e equi vale nc ies . For

more detailed information, consult your cable installation guide.

Table 3-1.

SCXIbus

Line

SCXIbus to SCXI-1102/B/C Module Rear Signal Connector to DAQ Device Pin Equivalencies

SCXI-1102/B/C

MIO-16 Lab Boards PC-LPM-16

Rear Signal

Connector

MOSI SERDATIN ADIO0 PB4 DOUT4

D*/A DAQD*/A ADIO1 PB5 DOUT5

INTR* SLOT0SEL* ADIO2 PB6 DO UT6

SPICLK SERCLK EXTSTROBE* PB7 DOUT7

MISO SERDATOUT BDIO0 PC1 DIN6

Digital Timing Signal Connection

The SCXI-1102/B/C module uses pin 36, SCANCLK, to increment to

the next channel after each DAQ device conversion during scanning.

Digital Signal Specifications

The following specifications and ratings apply to the digital signals:

• Absolute max voltage input rating 5.5 V with respect

to DGND

• Digital input specifications (referenced to DGND)

–V

–V

–I

• Digital output specifications (referenced to DGND)

–V

–V

input logic high voltage 2 V min

IH

input logic low voltage 0.8 V max

IL

input current leakage ±1 µA max

I

output logic high voltage 3.7 V min at 4 mA max

OH

output logic low voltage 0.4 V max at 4 mA max

OL

SCXI-1102/B/C User Manual 3-10

©

National Instruments Corporation

Page 33

Chapter

Theory of Operation

This chapter contains a functional overview of the SCXI-1102/B/C

module and explains the operation of each fun ctional unit making up the

SCXI-1102/B/C module.

Functional Overview

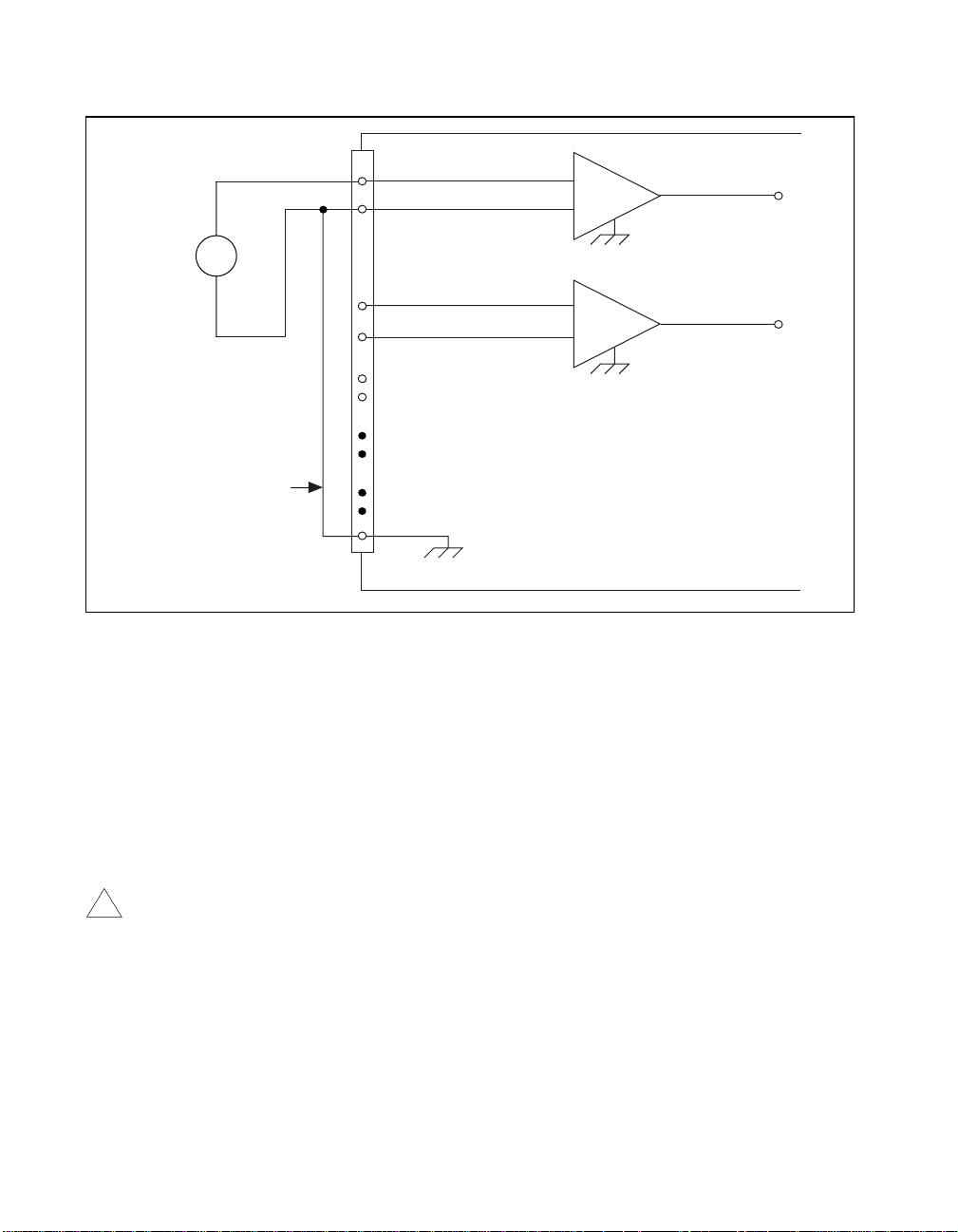

The block diagram in Figure 4-1 illustrates the key functional

components of the SCXI-1102/B/C module.

CH 0 +

CH 0 –

+

Inst.

Amp

–

Input Protection

and Lowpass Filter

Gain 0

Lowpass

Filter

Buffer

32-to-1 Mux

Mux

Buffer

Switch

Switch

Switch

4

Mux

MCH0+

MCH0-

AOGND

OUTREF

Rear Signal Connector

CH 31+

CH 31 –

Front Signal Connector

CJSENSOR

©

National Instruments Corporation 4-1 SCXI-1102/B/C User Manual

+

Inst.

Amp

–

Input Protection

and Lowpass Filter

Input Protection

and Lowpass Filter

Lowpass

Gain 31

Lowpass

Filter

Filter

Buffer

Buffer

Figure 4-1.

SCXIbus

Interface

Gain

Register

Calibration EEPROM

Digital

Control

SCXI-1102/B/C Module Block Diagram

AB0+

AB0-

SCXIbus Connector

Page 34

Chapter 4 Theory of Operation

The major components of the SCXI-1102/B/C modules are as follows:

• Rear signal connector

• SCXIbus connector

• SCXIbus interface

• Digital control circuitry

• Analog circuitry

The SCXI-1102/B/C modules consist of 32 multiplexed input channels,

each with a software-programmable gain of 1 or 100. Each input

channel has its own lowpass filter. The SCXI-1102/B/C modules also

have a digital section for automatic control of channel scan ning,

temperature sensor selection, and gain selection.

Rear Signal Connector, SCXIbus Connector, and SCXIbus Interface

The SCXIbus controls the SCXI-1102/B/C module. The SCXIbus

interface connects the rear signal connector to the SCXIbus, allowing a

DAQ device to control the SCXI-1102/B/C module and the rest of the

chassis.

Digital Control Circuitry

The digital control circuitry consists of the Address Handler and the

following registers: Module ID, Configuration, Status, EEPROM, Gain,

and Channel. The Address Handler controls which register is being

addressed. The Module ID Register contains a code unique to each type

of SCXI-1102 module:

♦ SCXI-1102—The Module ID is 30 decimal.

♦ SCXI-1102B—The Module ID is 31 decimal.

♦ SCXI-1102C—The Module ID is 62 decimal.

The Configuration Register configures t he SCXI-1102/B/C modules for

the desired scanning mode and connection to the rear signal connector.

The Status Register indicates whether the input channels have settled

after a change in the gains. The EEPROM Register is the address for

interfacing with the module EEPROM, which contains calibration

information. The Gain Register selects between gains of 1 or 100 for

each of the 32 channels. The Channel Register selects a channel for a

single measurement or a start channel for a scan. Refer to

SCXI-1102/B/C User Manual 4-2

©

National Instruments Corporation

Page 35

Analog Circuitry

Note: Because of the 2 Hz bandwidth of the SCXI-1102 module input channels,

Chapter 4 Theory of Operation

Software Programming Choices in Chapter 1, Introduction, to learn

about options for programming the control circuitry.

The analog circuitry per channel consists of a lowpass filter and an

amplifier with a software selectable gain of 1 or 100. The CJSENSOR

channel also has a buffered lowpass filter but has no amplifier. The

channels and CJSENSOR are multiplexed to a single output buffer.

Analog Input Channels

Each of the 32 analog input channels feeds to a separate amplifier with

a programmable gain of 1 or 100. Then the signal passes through a

three-pole lowpass filter.

you must wait approximately 3 s after changing the gains before the

channels settle and you can take an accurate measurement. NI-DAQ

automatically reads the Status Register to determine when the module

output has settled. For the SCXI-1102B and SCXI-1102C modules, this

time is approximately 100 ms and 1 ms, respectively.

The temperature sensor consists of a thermistor located on the

SCXI-1300 or SCXI-1303 terminal block. The temperature sensor is for

cold-junction compensation of the SCXI-1102/B/C thermocouples. The

CJSENSOR channel also passes through a 2 Hz lowpass filter to reject

unwanted noise on the SCXI-1102/B/C. Along with the other 32 input

channels, the CJSENSOR is multiplexed to the output buffer, where it

can be read by the DAQ device.

For measurement accuracy of 0.012% of full scale, the minimum scan

interval is 3 µs. This is the smallest interval in which you can switch

between analog channels on the module and still measure accurate

voltages. The 3 µs scan interval gives you a maximum sampling rate of

333 kHz. Because this rate is higher than the bandwidth of a single

SCXI-1102/B/C channel, you can sample multiple channels on mu ltiple

SCXI modules without undersampling one of the SCXI-1102/B/C

channels.

©

National Instruments Corporation 4-3 SCXI-1102/B/C User Manual

Page 36

Chapter 4 Theory of Operation

Analog Bus Switch

The SCXI-1102/B/C modules contain switches to place their analog

output on the SCXIbus to pass the output to the SCXI module cabled to

the DAQ device. The SCXI-1102/B/C modules also contain switches to

receive a signal placed on the SCXIbus by another SCXI module. The

output buffer of the cabled module drives a received signal onto the

MCH0+ line of the rear signal connector so that the DAQ device can

read it. When a signal passes on the SCXIbus from the scanned SCXI

module to the cabled SCXI module, the measurement is known as

indirect scanning.

SCXI-1102/B/C User Manual 4-4

©

National Instruments Corporation

Page 37

Chapter

Calibration

Overview

5

This chapter discusses the calibration procedures for the

SCXI-1102/B/C modules.

Using the procedure described in this chapter, you will be able to

calculate the gain error and voltage offset on a per channel per gain

basis. You can store these constants in the onboard EEPROM for future

use and for automatic calibration when you are us ing National

Instruments software. The module comes from the factory with

factory-determined calibration constants in the EEPROM. However, it

is recommended that you recalibrate a module at least once per year or

when you operate the module outside of the 20° to 30° C temperature

range.

In order to calibrate the SCXI-1102/B/C modules, you will need to

apply precision voltages to the channel inputs and/or ground the

channel inputs.

Calibration Procedure

Calibration Equipment Requirements

According to standard practice, the equipment you use to calibrate the

SCXI-1102/B/C module should be 10 times as accurate as the

SCXI-1102/B/C module. Calibration equipment with four times the

accuracy of the SCXI-1102/B/C is generally considered acceptable.

©

National Instruments Corporation 5-1 SCXI-1102/B/C User Manual

Page 38

Chapter 5 Calibration

To calibrate the SCXI-1102/B/C module, you need a voltmeter with the

following specifications:

• Accuracy ±6 ppm standard reading

±15 ppm sufficient reading

• Range –10 to +10 V

• Resolution 8.5 digits

A multiranging 8.5-digit digital multimeter (DMM) can perform the

necessary calibrations.

To make sure that the DMM does not introdu ce an additional offset, you

can determine the offset error of the DMM by shorting its leads together

and reading the measured value. This value, the DMM offset, must be

subtracted from all subsequent measurements.

You will need to measure the module’s output between MCH0+ and

MCH0–. To access these pins, connect a 50-pin ribbon cable from the

CB-50 I/O connector block to the module rear signal connector or to the

rear signal adapter. Then connect to MCH0+ and MCH0– on the CB-50

pins 3 and 4, respectively.

Gain and Offset Calibration

To determine the offset and gain calibration factors of the

SCXI-1102/B/C module for a given gain, perform the following steps

for a two-point calibration. For two-point calibration, it is best to use

input voltages that correspond to the signal range of interest. For

example, if you are planning to measure bipolar voltages over the

module’s full input range, choose –9.9 V/G (negative full-scale) and

+9.9 V/G (positive full-scale) as your two input voltages.

1. Select the desired channel. Set the channel gain to the desired gain.

2. Apply the input for the first calibration point. To select negative

full scale as the calibration point, apply –9.9 V/G for an input

voltage.

a. Apply the input voltage to the channel selected in step 1.

Note: To make one of your calibration points the zero poi nt, connect the positive

and negative channel leads to one of the chassis ground pins on the front

connector or terminal block.

b. Measure the input voltage with the DMM. Call the measured

voltage

SCXI-1102/B/C User Manual 5-2

input1.

©

National Instruments Corporation

Page 39

Chapter 5 Calibration

Note: If you are using a calibrator that supplies accurate voltages, you can simply

use the known applied voltage for

input1 instead of measuring.

c. Measure the module output between MCH0+ and MCH0–

with the DMM. Call the measured voltage

output1

.

3. Repeat step 2, applying the input for the second calibration point.

Call the measured voltages

input2 and output2. To select

positive full scale as the calibration point, repeat step 2 and apply

+9.9 V/G.

4. You now have two pairs of voltages (

(

input2, output2

). Each pair consists of an input voltage and an

input1, output1

) and

output voltage.

5. Convert the output voltages from volt units to your DAQ device

binary unit. You must take into consideration the polarity of your

DAQ device, its resolution (12 bits or 16 bits), and gain. For

example, if you are using the 12-bit AT-MIO-16E-2 in bipolar

mode with the gain set to G

, your output voltages for the

MIO

autozeroing option will be represented in binary units as given by

the following formula:

Binary

=

Output

----------------- 5 V

12

2

•

•

G

MIO

For other DAQ devices, refer to your DAQ device user manual to

determine the appropriate formula.

6. You now have a new set of pairs referred to as voltage binary pairs

input1, bin_output1) and (input2, bin_output2). Pass these

(

pairs to the

SCXI_Cal_Constants function or VI as described in

your software documentation.

Note: When you use 0 V and positive full-scale for your two calibration points,

you eliminate the error at 0 V and at positive full-scale voltage. However,

because of nonlinearity, the error at the negative full-scale voltage will be

two times the nonlinearity error. This is also true for the positive full-scale

voltage if you use the negative full-scale voltage and 0 V as your two

calibration points.

When you make a measurement using National Instruments software, the

driver automatically uses the calibration constants to correct the measured

voltages.

For an example of how to calibrate your module, refer to Appendix B,

Calibration Sample Program.

©

National Instruments Corporation 5-3 SCXI-1102/B/C User Manual

Page 40

Appendix

Specifications

This appendix lists the specifications for the SCXI-1102/B/C modules.

These specifications are typical at 25° C unless otherwise noted.

SCXI-1102/B/C

Analog Input

Input Characteristics

Number of channels............................32 differential

Input signal ranges................................±100 mV (gain = 100) or

Max working voltage

(signal + common mode) ....................Each input should remain

A

±10 V (gain = 1)

within ±10 V of CGND

Input damage level ...............................±42 VAC peak or VDC

Inputs protected............................CH<0..31>, CJSENSOR

Transfer Characteristics

Nonlinearity........................................0.005% FSR

Offset error

Gain = 1

After calibration .................... 300 µV max

Before calibration..................600 µV

Gain = 100

After calibration .................... 15 µV max

Before calibration..................100 µV

©

National Instruments Corporation A-1 SCXI-1102/B/C User Manual

Page 41

Appendix A Specifications

Gain error (relative to calibration reference)

Gain = 1

After calibration.................... 0.015% of reading max

Before calibration ................. 0.04% of reading

Gain = 100

After calibration.................... 0.020% of reading max

Before calibration ................. 0.1% of reading

Amplifier Characteristics

Input impedance

Normal powered on ..................... >1 GΩ

Powered off................................. 10 kΩ

Overload ...................................... 10 kΩ

Input bias current...................................±0.5 nA

Input offset current................................±1.0 nA

CMRR

50 to 60 Hz, either gain 110 dB 90 dB 90 dB

DC, gain 1 75 dB min 75 dB min 75 dB min

DC, gain 100 100 dB min 100 dB min 100 dB min

Output range ..........................................±10 V

Output impedance ..............................91 Ω

Dynamic Characteristics

Bandwidth.......................................... 2 Hz (1102)

Scan interval (per channel, any gain)

0.012% ........................................ 3 µs

0.0061% ......................................10 µs

SCXI-1102/B/C User Manual A-2

1102 1102B 1102C

200 Hz (1102B)

10 kHz (1102C)

©

National Instruments Corporation

Page 42

Filters

Appendix A Specifications

System noise (related to input)

1102 1102B 1102C

Gain = 1 50 µVrms 50 µVrms 70 µVrms

Gain = 100 5 µVrms 5 µVrms 10 µVrms

Cutoff frequency (–3 dB)....................2 Hz (1102)

200 Hz (1102B)

10 KHz (1102C)

NMR (60 Hz)......................................40 dB (1102)

Step response (either gain)

1102 1102B 1102C

To 0.1% 1 s 10 ms 200 µs

To 0.01% 10 s 100 ms 1 ms

Stability

Recommended warm-up time..............20 min.

Offset temperature coefficient

Gain = 1 .......................................20 µV/°C

Gain = 100 ...................................1 µV/°C

Gain temperature coefficient ............... 10 ppm/ °C

Physical

Dimensions.........................................115 by 273 mm

(4.54 by 10.75 in.)

I/O connector......................................50-pin male ribbon cable

rear connector

96-pin male DIN C front

connector

©

National Instruments Corporation A-3 SCXI-1102/B/C User Manual

Page 43

Appendix A Specifications

Environment

Operating temperature ........................ 0° to 50° C

Storage temperature ........................... –55° to 150° C

Relative humidity............................... 5% to 90% noncondensing

Power Requirements

5 V supply .......................................... 15 mA max

±15 V supply (regulated

from ±24 V supply)............................ 150 mA max

SCXI-1102/B/C User Manual A-4

©

National Instruments Corporation

Page 44

Appendix

Calibration Sample Program

This appendix contains a sample program to help you calibrate your

submodule.

B

Sample Program for Calibration

The following is a sample C program that implements the procedure

discussed in the Gain and Offset Calibration section and

SCXI_Cal_Constants in Chapter 5, Calibration:

/* This sample program assists the user in calibrating the SCXI-1102. The

calibration constants are stored only in NI-DAQ memory. The (input, output)

voltage pairs read by a DMM must be entered by hand. Before running this

programed must run the NI-DAQ Configuration Utility to set up the DAQ board

that will communicate with the SCXI-1102.

This program is written for the four-slot SCXI-1000 chassis. The program

prompts for all required configurati on information a bout the SCXI c hassis. */

#include <ansi_c.h>

#include <dataacq.h>

#define SCXI1102 30 /* the SCXI-1102 module ID */

#define TWOPOINT 2

#define NIDAQMEM 0

void main()

{

char entry[4];

int SCXI_Chassis_ID,

moduleSlot, /* chassis slot of module

moduleChan;

long modulesPresent[] = {-1, -1, -1, -1};

short operatingModes[] = {0, 0, 0, 0},

connectionMap[] = {0, 0, 0, 0},

commPath, /* DAQ board that communicates with

dummyRangeCode = 0,

dummyDAQboard,

dummyDAQchan = 0,

dummyDAQgain = 1,

to calibrate */

SCXI chassis */

©

National Instruments Corporation B-1 SCXI-1102/B/C User Manual

Page 45

Appendix B Calibration Sample Program

dummyDAQrange, /* These dummy variables would be used

if the measurement actually came

from a DAQ board and not an external

DMM. */

ret;

double scale,

gain,

vinput1,

voutput1,

vinput2,

voutput2,

bin_output1,

bin_output2,

bin_offset,

gainerr,

offset;

do

{

printf("Enter the slot of the SCXI-1102: ");

fflush(stdin);

ret = scanf("%d", &moduleSlot);

} while (!ret || moduleSlot < 1 || moduleSlot > 4);

modulesPresent[moduleSlot - 1] = SCXI1102;

do

{

printf("Enter the chassis ID of the chassi s containing the SCXI-1102: ");

fflush(stdin);

ret = scanf("%d", &SCXI_Chassis_ID);

} while (!ret);

commPath = SCXI_Chassis_ID;

do

{

printf("Enter the device number of the DAQ board communicating \n");

printf("with the chassis (default %d): ", SCXI_Chassis_ID);

fflush(stdin);

fgets(entry, 3, stdin);

if (strlen(entry) - 1) commPath = atof(entry);

} while (!commPath);

dummyDAQboard = connectionMap[moduleSlot - 1] = commPath;

/* Since the DAQ board is not

used to acquire data, the

connectionMap does not need to

dummyDAQrange = 5.0 / dummyDAQgain;

scale = pow(2.0, 12.0) * dummyDAQgain / 5; /* factor for converting to

SCXI_Set_Config(SCXI_Chassis_ID, 0, 0, 1, commPath, 4,

modulesPresent, operatingModes, connectionMap);

be accurate. */

format of 12-bit bipolar DAQ

board with 5 V full scale*/

/* Set up communication path to

module. */

SCXI-1102/B/C User Manual B-2

©

National Instruments Corporation

Page 46

Appendix B Calibration Sample Program

SCXI_Reset(SCXI_Chassis_ID, moduleSlot);

/* In reset state, the module

SCXI_Single_Chan_Setup(SCXI_Chassis_ID, moduleSlot, 0, dummyDAQboard);

for (moduleChan = 0; moduleChan < 31; moduleChan++)

{

for (gain = 1; gain <= 100; gain = gain + 99)

{

SCXI_Change_Chan(SCXI_Chassis_ID, moduleSlot, moduleChan);

SCXI_Set_Gain(SCXI_Chassis_ID, moduleSlot, moduleChan, gain);

printf("Apply input voltage for point 1, channel %d, gain %.0f.\n",

moduleChan, gain);

do

{

printf("Enter SCXI-1102 input voltage: ");

fflush(stdin);

ret = scanf("%lf", &vinput1);/* User enters vinput1. */

} while (!ret);

do

{

printf("Enter SCXI-1102 output voltage: ");

fflush(stdin);

ret = scanf("%lf", &voutput1);/* User enters voutput1. */

} while (!ret);

will drive the MCH0+ output */

/* This is necessary only so that

SCXI_Change_Chan won't return

an error. */

/* Select the channel and gain. */

printf("Apply input voltage for point 2, channel %d,

gain %.0f.\n", moduleChan, gain);

do

{

printf("Enter SCXI-1102 input voltage: ");

fflush(stdin);

ret = scanf("%lf", &vinput2);/* User enters vinput2. */

} while (!ret);

do

{

printf("Enter SCXI-1102 output voltage: ");

fflush(stdin);

ret = scanf("%lf", &voutput2);/* User enters voutput2. */

} while (!ret);

bin_output1 = voutput1 * scale;

bin_output2 = voutput2 * scale; /* Convert to format of DAQ

board. */

©

National Instruments Corporation B-3 SCXI-1102/B/C User Manual

Page 47

Appendix B Calibration Sample Program

SCXI_Cal_Constants(SCXI_Chassis_ID, moduleSlot, moduleChan,

offset = bin_offset / scale; /* Convert from DAQ board

printf("Calculated offset %f V, gain error %f%% ", offset,

gainerr);

printf("and stored in NI-DAQ memory.\n\n");

}

}

}

TWOPOINT, NIDAQMEM, dummyRangeCode, gain,

dummyDAQboard, dummyDAQchan, dummyDAQgain, 1,

vinput1, bin_output1, vinput2, bin_output2,

&bin_offset, &gainerr);

/* Calculate offset and gain

error. */

format. */

SCXI-1102/B/C User Manual B-4

©

National Instruments Corporation

Page 48

Appendix

Customer Communication

For your convenience, this appendix contains forms to help you gather the information necessary to

help us solve your technical problems and a form you can use to comment on the product

documentation. When you contact us, we need the information on the Technical Support Form and the

configuration form, if your manual contains one, about your system configuration to answer your

questions as quickly as possible.

National Instruments has technical assistance through electronic, fax, and telephone systems to

quickly provide the information you need. Our electronic services include a bulletin board service,

an FTP site, a fax-on-demand system, and e-mail support. If you have a hardware or software

problem, first try the electronic support systems. If the information available on these systems

does not answer your questions, we offer fax and telephon e support through our technical sup port

centers, which are staffed by applications engineers.

C

Electronic Services

Bulletin Board Support

National Instruments has BBS and FTP sites dedicated for 24-hour support with a collection of files

and documents to answer most common customer questions. From these sites, you can also download

the latest instrument drivers, updates, and example programs. For recorded instructions on how to use

the bulletin board and FTP services and for BBS automated information, call (512) 795-6990. You can

access these services at:

United States: (512) 794-5422

Up to 14,400 baud, 8 data bits, 1 stop bit, no parity

United Kingdom: 01635 551422

Up to 9,600 baud, 8 data bits, 1 stop bit, no parity

France: 01 48 65 15 59