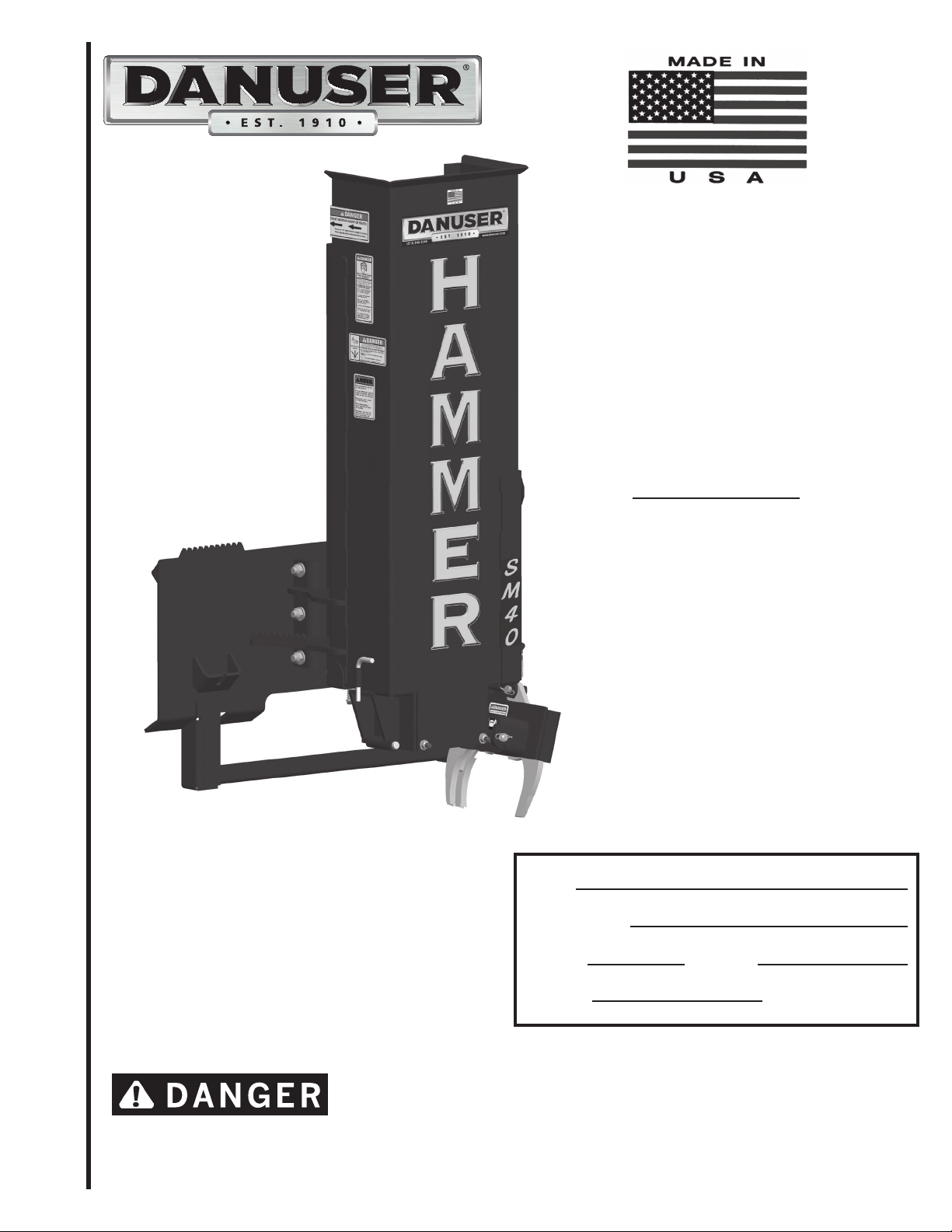

Page 1

Owner:

D A N G E R

HAMMER

SM40

Si no entiende ingles, se prefiere que

busque a alguien que interprete las

instrucciones para usted.

Date Purchased:

Model #: Serial #:

Manual #: 9MHAM2456252

Operator’s Manual

Danuser LLC

500 E. 3rd St.

P.O. Box 368

Fulton, MO 65251

Tel: (573) 642-2246 Fax: (573) 642-2240

E-mail: sales@danuser.com

Website: www.danuser.com

Page 2

Dear Owner/Operator,

Thank you for purchasing this Danuser Hammer. We appreciate your business.

Your safety as an operator of our product is very important to us. Therefore, before you

assemble, install, operate, maintain, service, remove, or move your Danuser Hammer, read and

understand this manual thoroughly. If there is anything you do not understand, immediately

contact your dealer, or contact our factory direct.

Phone: (573) 642-2246

Fax: (573) 642-2240

E-mail: sales@danuser.com

Your satisfaction in the performance and longevity of our product is also very important to us

and can be prolonged by proper assembly, installation, operation, maintenance, service, and

removal as instructed in this manual.

Thank you again for your business and for your trust in our product. Please feel free to contact

us at any time for further assistance.

Sincerely,

Danuser LLC

500 E. 3rd St., P.O. Box 368, Fulton, MO 65251

Tel: (573) 642-2246 Fax: (573) 642-2240

E-mail: sales@danuser.com Website: www.danuser.com

Page 3

Foreword

WARNING

D A N G E R

D A N G E R

Please read this manual thoroughly!

Before you assemble, install, operate, maintain, service, remove, or move your Danuser

Hammer, read this manual thoroughly. If there is anything you do not understand,

immediately contact your dealer, or call our factory direct at (573) 642-2246. Powered

equipment can be dangerous if not assembled, installed, operated, maintained, serviced,

removed, or moved properly.

Warranty Registration

To activate your warranty coverage and to provide you with efficient customer service,

please fill out your WARRANTY REGISTRATION FORM. This form is included in your

unit’s paperwork package. If you did not complete a WARRANTY REGISTRATION

FORM or did not receive one, please call Danuser LLC. Or, register online at

www.Danuser.com. Your satisfaction with our product and your safety as a user of our

product are both very important to us.

Symbols

Table of

Contents

This SAFETY ALERT symbol identifies important safety messages. Carefully read

each safety message that follows. Failure to understand and obey a safety message,

or recognize a safety hazard, could result in injury or death to you or others around you.

The operator is ultimately responsible for the safety of himself, as well as others, in the

operating area of the Hammer.

Symbol

This is important information for proper use of this

NOTE

Page

Letter to the Owner/Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hydraulic Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assembly & Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Removal & Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Decals & Safety Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Form No. 3269

equipment. Failure to comply may lead to premature

equipment failure.

Failure to follow these instructions may cause damage

to the implement or the vehicle, or minor personal

injury.

Failure to follow these instructions may result in

personal injury or death.

Immediate hazard! Failure to understand and obey this

warning is likely to result in personal injury or death.

Meaning

Improper operation of this Hammer can cause serious personal

injury or death. Operation of this Hammer should only be done by

a competent adult acting in compliance with the Operator's Manual.

Since Hammer operations are beyond our control, we disclaim all

liability for any damages, injuries or death which may result.

3

Page 4

Safety

WARNING

Working with unfamiliar equipment can lead to careless injuries. Read and understand

this manual and the manual for your vehicle before assembling, installing, operating,

maintaining, servicing, removing, or moving this Hammer. If there is anything in this

manual you do not understand, contact your dealer or Danuser LLC. The safe use of this

attachment is strictly up to you, the operator. If this attachment is used, loaned, or rented

by any other person, it is the owner's responsibility to make certain that the operator prior to

operating:

• Reads and understands the Operator's Manuals

• Is instructed in safe and proper use

• The Hammer is designed to be operated from the vehicle seat. Keep bystanders away

from the work area. Do not operate with another person in contact with any part of the

Hammer.

• All operators of this attachment must read and understand this entire manual, paying

particular attention to safety messages and operation instructions, prior to assembling,

installing, operating, maintaining, servicing, removing, or moving the Hammer.

• Please remember it is also important that you read, understand, and follow safety signs

on the attachment. Clean or replace all safety signs if they cannot be clearly read and

understood. They are there for your safety as well as the safety of others. Danuser LLC

will furnish new safety signs upon request at no charge.

• All things with moving parts are potentially hazardous. There is no substitute for a

cautious, safe-minded operator who recognizes potential hazards and follows reasonable

safety practices.

• Personal protection equipment including hard hat, safety glasses, safety shoes, gloves,

and ear plugs are recommended during assembly, installation, operation, maintenance,

service, removal, or movement of the attachment.

• When the use of hand tools is required to perform any part of assembly, installation,

operation, maintenance, or service of the attachment, be sure the tools used are designed

and recommended by the tool manufacturer for that specific task.

• Never check pressurized system for leaks with your bare hand. Wear proper hand and

eye protection and use wood or cardboard when searching for suspected leaks. Oil

escaping from pinhole leaks under pressure can penetrate skin and create a serious

medical emergency. If any fluid is injected into the skin, gangrene, blood poisoning,

even death may result. Obtain medical attention immediately.

• Always use two people to handle heavy, unwieldy components during assembly,

installation, maintenance, service, removal, or movement of the Hammer.

• Never place any part of your body where it would be in danger if movement should

occur during assembly, installation, operation, maintenance, service, removal, or

movement of the Hammer.

4

• Only properly trained people should operate this equipment. Do not allow anyone who

has not read this entire manual and understands the safety rules, safety signs, and

operation instructions to use this attachment.

• Never allow children to operate or be around the Hammer.

• Do not allow riders on the equipment at any time. There is no safe place for any riders.

Page 5

Safety

(continued)

• Never use alcoholic beverages or drugs which can hinder alertness or coordination

while operating this equipment. Consult your doctor about operating this equipment

while taking prescription medications.

• Consult local utility companies to make certain there are no buried gas lines, electrical

cables, etc., in the work area before beginning operation.

• Do not drive posts near underground utility lines.

• Stay away from power lines when transporting, raising, or operating the Hammer.

• Before you operate the attachment, check over pins and connections to be sure all are

securely in place. Make sure the Hammer is securely latched to the vehicle.

• Keep hands, feet, hair, jewelry, and clothing away from all moving and/or rotating parts.

• Never place yourself between the vehicle and the attachment.

• Never allow anyone under the attachment at any time.

• Keep clear of the Hammer while in operation. Never position, align, or support the post

by hand or with any tool when the Hammer is in operation.

• Do not exceed the vehicle's rated operating load. Use sufficient counterweights. Move

the vehicle slowly when the attachment is raised.

• Carry the load low. A heavy load can cause instability of the vehicle. Use extreme care

during travel. Slow down on turns and watch out for bumps. Use all safety devices,

including a seat belt, as recommended in the vehicle operator’s manual.

• Do not operate the Hammer on steep hillsides. When operating the Hammer on uneven

or hilly terrain, position the vehicle with the attachment uphill. With the attachment

downhill, the vehicle could tip when attempting to raise the attachment. Consult your

vehicle operator’s manual for maximum incline allowable.

• Always shut off the vehicle engine and remove the key before dismounting the vehicle,

adjusting the attachment, or servicing the Hammer. Never leave equipment unattended

with the vehicle running.

• Never attempt repairs or adjustments while the equipment is in operation.

• Before disconnecting hydraulic lines or fittings be sure to relieve all pressure by cycling

all hydraulic controls after shutdown. Remember hydraulic systems are under pressure

whenever the engine is running and may hold pressure after shutdown.

• Always use care when operating the Hammer. Most accidents occur because of neglect

or carelessness.

Safety is a primary concern in the design, manufacture, sale, and use of Hammers. Danuser

confirms to you, our customer, our concern for safety.

5

Page 6

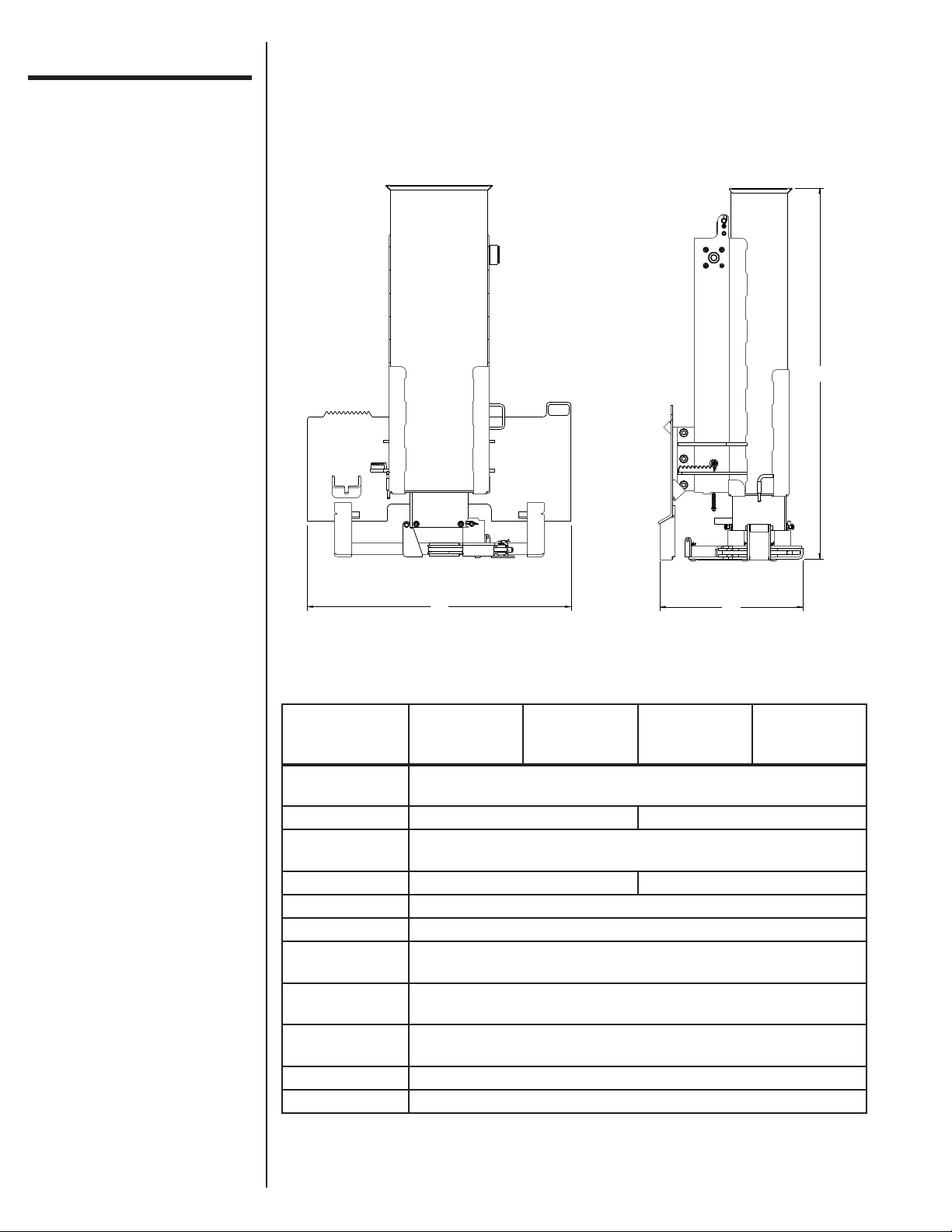

Specifications

A

C

Overall Length

(A)

A

Model SM40

Model SM40

w/ Grapple

Model SM40

w/ Tilt

45.5"

B

Model SM40

w/ Tilt and

Grapple

Overall Width (B) 25" 25.5"

Overall Height

(C)

64"

Tilt (left or right) N/A 20°

Hammer Weight 300 lbs. (500 lbs. max.)

Length of Stroke 40"

Max. Strokes Per

Minute

Hydraulic

Requirements

Maximum

Post Size

35

1500-3000 PSI

Up to 30 GPM

8.5" x 9.25"

Impact Force 82000 lbs. @ 500 lb. weight

Impact Energy 1025 ft.-lbs. @ 300 lb. weight; 1709 ft.-lbs. @ 500 lb. weight

6

Page 7

Hydraulic

Filtration Requirements:

Requirements

• A filter of, at least, 25 micron filtration is required. A filter capable of 10 micron

filtration is preferred. The majority of paper type filters are 25 microns or better.

NOTE

• A low pressure type filter can be installed in the return line from the control valves to

• A high pressure type filter can be used between the pump and the control valves.

• If the source of the hydraulic power does not have a filter, it will be necessary to install

Pressure and Flow Requirements:

• The Hammer is designed to operate up to 30 GPM and 1500 – 3000 PSI.

The life of the hydraulic motor is almost entirely dependent upon cleanliness

of the oil. Instructions in your vehicle operator’s manual regarding filter and

oil changes should be carefully followed. Even small amounts of dirt in the

hydraulic oil can cause premature motor failure that is not covered by warranty.

the sump. A low pressure type filter can, also, be installed in the sump or pump intake

line, but must be sized large enough to avoid starving the pump.

one at some point in the system so, at least, part of the hydraulic oil is being filtered

whenever the system is operating. After a filter is installed and before attaching

the Hammer, the entire hydraulic system should be drained, filled with new oil, and

operated for 30 minutes or until the system is warm. During this run time, operate all

valves, cylinders, and hydraulic motors on the attachment.

Valve Requirements:

• The hydraulic system used to power the Hammer should be equipped with a four-way

valve large enough to carry full pump outlet without restricting flow and causing oil

heating.

• The four-way valve requires a relief valve which will open and relieve extreme

pressures between the Hammer and control valve, even when the control valve is in a

neutral position. This feature can be obtained by connecting two external relief valves

between the main lines running from the control valve to the Hammer in such a way

that high pressure in either line will be relieved to the other line.

Hydraulic Fluid Selection Requirements:

• Premium grade petroleum based fluids will provide the best performance.

• Fluids that contain anti-wear agents, rust inhibitors, anti-foaming agents, and oxidation

inhibitors are recommended.

• The viscosity of the fluid should never fall below 70 SUS (13 cST). The best

viscosity range of the Hammer is 100-200 SUS (20-43 cST).

7

Page 8

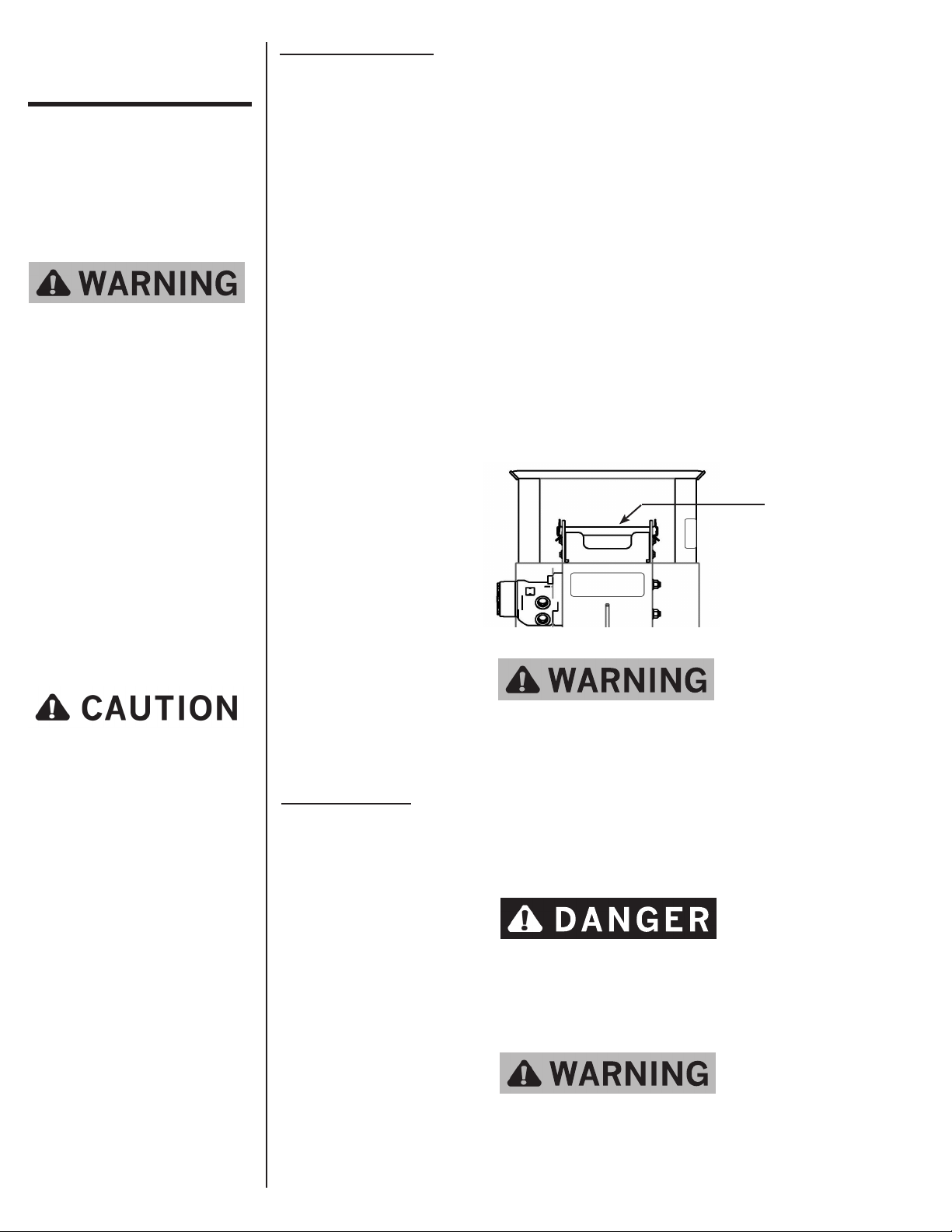

WARNING

D A N G E R

WARNING

Assembly &

WARNING

Installation

Add Additional Weight

For tough driving conditions or large posts, additional weight can be added up to 500

lbs. total hammer weight by purchasing a weight kit or by adding weight. Add weight in

a variety of ways: logging chain, metal punch slugs, lead tire weights, etc. Do not use

concrete or sand, as damage may result.

Personal protection

equipment including hard

hat, safety glasses, safety

shoes, gloves, and ear

plugs are recommended

during assembly,

installation, operation,

maintenance, service,

removal, or movement of

the attachment.

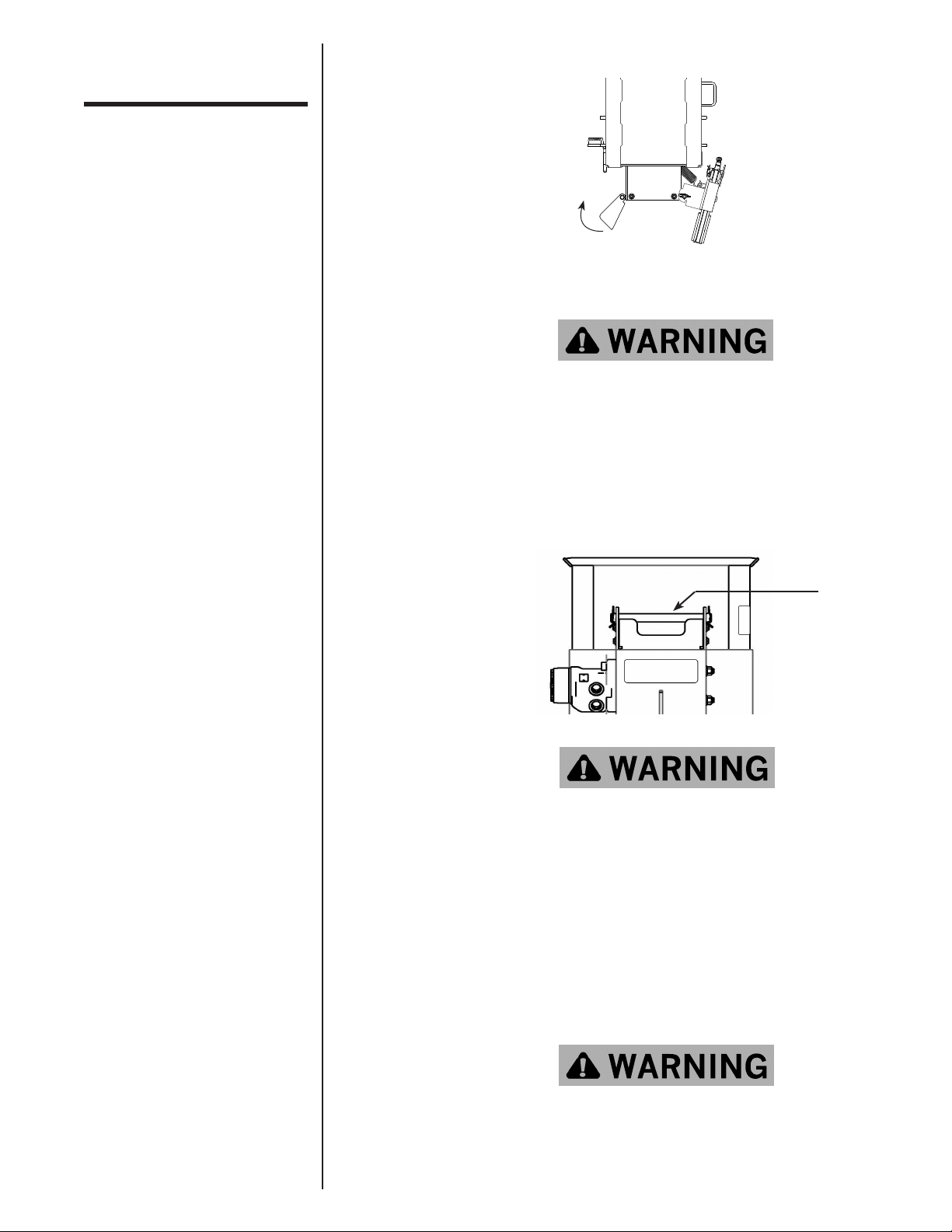

STEP 1:

STEP 2:

STEP 3:

STEP 4:

STEP 5:

STEP 6:

Make sure the hammer weight catch is visible through the viewing slots on the

back of the case.

Remove the retention pin from the top of the case. Insert a hook into the lifting

eye located on the top of the weight. Lift the weight out of the Hammer with a

hoist, forklift, or another vehicle. Set the weight on the ground.

Remove the weight cover by loosening the two lock nuts. It may be necessary to

use a hammer and punch in order to break the weight cover loose.

Place the additional weight into the cavity of the hammer weight until full.

Reinstall the weight cover using the two washers and lock nuts, making sure to

seal the cover with silicone sealant.

Lower the weight back into the Hammer and reinstall the retention pin.

Retention

Pin

Because of the weight

of some components,

and because some

components are difficult

to balance, two people are

required for safe

assembly and installation

of this equipment.

Do not tilt or operate the Hammer without the retention pin

in place. The hammer weight could slide out of the Hammer

and cause serious injury or death.

Prepare the Vehicle

Read and understand the manual for your vehicle before assembling or installing the

Hammer. The vehicle must be equipped with a universal quick attach hitch and auxiliary

hydraulics. The use of the Hammer may require the addition of counterweights to ensure

the attachment does not exceed the rated capacity of the vehicle.

Do not exceed the vehicle's rated operating load. If

necessary, use sufficient counterweights.

STEP 1:

Install the Hammer by following your vehicle operator's manual for installing an

attachment.

Make sure the Hammer is securely latched to the vehicle.

Failure to do so could result in separation of the attachment

from the vehicle.

8

Page 9

Assembly &

WARNING

WARNING

WARNING

Installation

(continued)

Raise the Hammer slightly, and latch the parking stand into the upright position.STEP 2:

STEP 3:

STEP 4:

Route the hydraulic hoses through the quick attach plate hose holder, and connect

the hydraulic hoses to the vehicle's auxiliary hydraulics.

Remember hydraulic systems are under pressure whenever

the engine is running and may hold pressure after

shutdown. Before connecting or disconnecting hydraulic

hoses, be sure to relieve all pressure by cycling all

hydraulic controls after shutdown.

Ensure the retention pin is in place. The retention pin prevents the hammer weight

from sliding out of the Hammer.

Retention

Pin

STEP 5:

STEP 6:

STEP 7:

Do not tilt or operate the Hammer without the retention pin

in place. The hammer weight could slide out of the Hammer

and cause serious injury or death.

Shut off the vehicle engine.

Oil the Hammer drive chain, and grease all zerks.

Start the vehicle. Engage the auxiliary hydraulics. Note the direction of the chain

rotation (visible from the operator’s seat). The hammer weight catch should be

rotating from the top to the bottom. If the chain is not rotating at all, reverse the

hydraulic hoses.

Remember hydraulic systems are under pressure whenever

the engine is running and may hold pressure after

shutdown. Before connecting or disconnecting hydraulic

hoses, be sure to relieve all pressure by cycling all

hydraulic controls after shutdown.

9

Page 10

Assembly &

NOTE

WARNING

Installation

STEP 8:

Check the hydraulic system for leaks.

(continued)

Never check pressurized system for leaks with your bare

hand. Wear proper hand and eye protection and use wood

or cardboard when searching for suspected leaks. Oil

escaping from pinhole leaks under pressure can penetrate

skin and create a serious medical emergency. If any fluid

is injected into the skin, gangrene, blood poisoning, even

death may result. Obtain medical attention immediately.

Tilt Option

If the Hammer is equipped with Tilt, follow the instructions below.

STEP 9:

STEP 10:

STEP 11:

STEP 12:

Grease the grease zerk on the tilt pivot boss.

Route the wires along the hydraulic hoses to the vehicle, and secure them with

zip-ties.

Route the control portion of the wiring harness along the loader arm of the vehicle

and into the cab, and secure the wiring with zip-ties. Mount the switch out of the

way of other controls.

Keep wiring a safe distance from hot components such as a heater or exhaust.

Connect the remainder of the wiring harness to a 12 volt power supply. If

necessary, consult your dealer.

10

Page 11

D A N G E R

D A N G E R

D A N G E R

D A N G E R

D A N G E R

D A N G E R

NOTE

WARNING

Operation

SM40

Before you operate the attachment, check over pins and

connections to be sure they all are securely in place. Make

sure the Hammer is securely latched to the vehicle.

Consult local utility companies to make certain there are

no buried gas lines, electrical cables, etc., in the work

area before beginning operation. Do not drive posts near

underground utility lines.

The Hammer is designed

to be operated from

the vehicle seat. Keep

bystanders away from the

work area. Do not operate

with another person in

contact with any part of

the Hammer.

Stay away from power

lines when transporting,

raising, or operating the

attachment.

STEP 1:

STEP 2:

STEP 3:

Without the Grapple, the Hammer requires a second person to position the post.

This person will set the post at the desired location and grasp the post securely,

making sure his hands are at least 30 inches (30") from the top of the post.

When using a second person, do not turn on the auxiliary

hydraulics until the second person is clear from the work

area.

After the post is in position, move the vehicle with the arms raised, and position

the Hammer directly over the top of the post.

Lower the Hammer onto the top of the post, ensuring the post is inside of the lower

portion of the Hammer. Continue lowering the Hammer until the oating anvil has

moved up and the weight of the Hammer is supported by the post.

After the post is in position, the second person must move

away from the Hammer and vehicle.

Personal protection

equipment including hard

hat, safety glasses, safety

shoes, gloves, and ear

plugs are recommended

during assembly,

installation, operation,

maintenance, service,

removal, or movement of

the attachment.

STEP 4:

STEP 5:

STEP 6:

STEP 7:

STEP 8:

After the second person has cleared the area, place the loader arms in the oat

position. If the vehicle is not equipped with oat, the loader arms should be

lowered, applying down force to the post.

Move the vehicle slowly left, right, forward, or backward as needed until the post

appears vertical to the ground.

The Hammer can now be activated by turning the auxiliary hydraulics to the

forward position. If you are not using the loader oat position, the loader arms

should be lowered as the post is driven into the ground.

Drive the post to the desired depth.

As soon as the weight is released (starts to drop), shut off the auxiliary hydraulics,

raise the Hammer until the post is cleared, and move to the next post.

When stopping the Hammer, the hammer weight catch should be visible through

the viewing slots on the back of the case. Never stop the Hammer with the

hammer weight partially raised.

11

Page 12

Operation

D A N G E R

D A N G E R

D A N G E R

D A N G E R

NOTE

WARNING

SM40 w/ Grapple

The Hammer is designed

to be operated from

the vehicle seat. Keep

bystanders away from the

work area. Do not operate

with another person in

contact with any part of

the Hammer.

STEP 1:

STEP 2:

STEP 3:

STEP 4:

STEP 5:

Before you operate the attachment, check over pins and

connections to be sure they all are securely in place. Make

sure the Hammer is securely latched to the vehicle.

Consult local utility companies to make certain there are

no buried gas lines, electrical cables, etc., in the work

area before beginning operation. Do not drive posts near

underground utility lines.

Raise the Hammer approximately two feet (2') off the ground with the Hammer

tilted slightly forward so the grapple jaws are visible.

Drive the vehicle forward and position the grapple jaws around the post,

approximately four inches (4") from the top of the post.

Activate the auxiliary hydraulics in the reverse direction for two (2) seconds or

until the grapple jaws are rmly clamped around post.

Raise the loader arms until the bottom of the post is above the ground.

Position the post in desired location and lower the Hammer until the post is inside

the lower portion of the Hammer.

Stay away from power

lines when transporting,

raising, or operating the

attachment.

Personal protection

equipment including hard

hat, safety glasses, safety

shoes, gloves, and ear

plugs are recommended

during assembly,

installation, operation,

maintenance, service,

removal, or movement of

the attachment.

STEP 6:

STEP 7:

STEP 8:

STEP 9:

STEP 10 :

STEP 11:

STEP 12:

Intermittently activate auxiliary hydraulics in the forward direction to release the

grapple jaws from the post. The Grapple will rotate up and away from the post.

Continue lowering the Hammer until the oating anvil has moved up and the

weight of the Hammer is supported by the post.

Place the loader arms in the oat position. If the vehicle is not equipped with

oat, the loader arms should be lowered, applying down force to the post.

Move the vehicle slowly left, right, forward, or backward as needed until the post

appears vertical to the ground.

The Hammer can now be activated by turning the auxiliary hydraulics to the

forward position. If you are not using the loader oat position, the loader arms

should be lowered as the post is driven into the ground.

Drive the post to the desired depth.

As soon as the weight is released (starts to drop), shut off the auxiliary hydraulics,

raise the Hammer until the post is cleared, and move to the next post.

When stopping the Hammer, the hammer weight catch should be visible through

the viewing slots on the back of the case. Never stop the Hammer with the

hammer weight partially raised.

12

Page 13

Operation

D A N G E R

D A N G E R

D A N G E R

D A N G E R

WARNING

SM40 w/ Tilt and Grapple

The Hammer is designed

to be operated from

the vehicle seat. Keep

bystanders away from the

work area. Do not operate

with another person in

contact with any part of

the Hammer.

Before you operate the attachment, check over pins and

connections to be sure they all are securely in place. Make

sure the Hammer is securely latched to the vehicle.

Consult local utility companies to make certain there are

no buried gas lines, electrical cables, etc., in the work

area before beginning operation. Do not drive posts near

underground utility lines.

Remove the tilt lock pin.STEP 1:

Tilt Lock Pin

Stay away from power

lines when transporting,

raising, or operating the

attachment.

Personal protection

equipment including hard

hat, safety glasses, safety

shoes, gloves, and ear

plugs are recommended

during assembly,

installation, operation,

maintenance, service,

removal, or movement of

the attachment.

STEP 2:

STEP 3:

STEP 4:

STEP 5:

STEP 6:

STEP 7:

STEP 8:

STEP 9:

STEP 10:

Raise the Hammer approximately two feet (2') off the ground with the Hammer

tilted slightly forward so the grapple jaws are visible.

Drive the vehicle forward and position the grapple jaws around the post,

approximately four inches (4") from the top of the post.

Activate the auxiliary hydraulics in the reverse direction for two (2) seconds or

until the grapple jaws are rmly clamped around post.

Raise the loader arms until the bottom of the post is above the ground.

Position the post in desired location and lower the Hammer until the post is inside

the lower portion of the Hammer.

Intermittently activate auxiliary hydraulics in the forward direction to release the

grapple jaws from the post. The Grapple will rotate up and away from the post.

Continue lowering the Hammer until the oating anvil has moved up and the

weight of the Hammer is supported by the post.

Place the loader arms in the oat position. If the vehicle is not equipped with

oat, the loader arms should be lowered, applying down force to the post.

Move the vehicle slowly left, right, forward, or backward as needed until the post

appears vertical to the ground.

STEP 11:

STEP 12:

Activate the electrical control switch.

Tilt the Hammer to a vertical position. Activate the auxiliary hydraulics to tilt the

Hammer clockwise up to 20 degrees (20°). Activating the auxiliary hydraulics in

reverse will tilt the Hammer counter-clockwise up to 20 degrees (20°).

13

Page 14

D A N G E R

WARNING

D A N G E R

NOTE

Operation

WARNING

STEP 13:

Deactivate the electrical control switch.

(continued)

Removal &

Storage

STEP 14:

STEP 15:

STEP 16:

The Hammer can now be activated by turning the auxiliary hydraulics to the

forward position. If you are not using the loader oat position, the loader arms

should be lowered as the post is driven into the ground.

Drive the post to the desired depth.

As soon as the weight is released (starts to drop), shut off the auxiliary hydraulics,

raise the Hammer until the post is cleared, and move to the next post.

When stopping the Hammer, the hammer weight catch should be visible through

the viewing slots on the back of the case. Never stop the Hammer with the

hammer weight partially raised.

Before disconnecting the Hammer from the vehicle, tilt to a

vertical position and reinstall the tilt lock pin. Failure to do

so will cause the Hammer to become unstable in the freestanding position.

Before storage, the Hammer should be thoroughly cleaned, washing off all dirt and grime.

If you have a Grapple or Tilt, coat the exposed portions of the cylinder rod with grease.

Lubricate the drive chain, and grease all zerks. Make sure the hydraulic system is properly

sealed against contaminates entering the unit. Always store the Hammer in a dry, covered

location.

Personal protection

equipment including hard

hat, safety glasses, safety

shoes, gloves, and ear

plugs are recommended

during assembly,

installation, operation,

maintenance, service,

removal, or movement of

the attachment.

STEP 1: Lower the parking stand by pulling up on the lock pin.

STEP 2: Lower the Hammer onto a at, level surface. If the Hammer is equipped with a

Grapple, lower the Hammer until the end of the Grapple jaws touch the ground.

Shift the vehicle to the left while lowering the Hammer in order to rotate the

Grapple to the horizontal position.

NOTE

Always store the Hammer with the Grapple horizontal.

Never allow anyone under the attachment at any time.

STEP 3: Shut off the vehicle engine, lower the arms, relieve all hydraulic pressure (by

activating the vehicle controls), and remove the vehicle key before leaving the

vehicle seat.

Before disconnecting hydraulic lines or fittings be sure

to relieve all pressure by cycling all hydraulic controls

after shutdown. Remember hydraulic systems are under

pressure whenever the engine is running and may hold

pressure after shutdown.

14

STEP 4: Disconnect the hydraulic hoses from the vehicle's auxiliary hydraulics.

NOTE

STEP 5: Follow your vehicle operator's manual for removing an attachment.

Connect the quick couplers together to prevent contaminants from entering the

Hammer hydraulic system.

Page 15

Troubleshooting

PROBLEM POSSIBLE CAUSE SOLUTION

Floating anvil falls out

or gets jammed

a. Weight is not down after

driving

b. Post too small Use T-post adapter when driving

When nished driving, make sure

weight is down and/or catch is visible

through viewing slots. Refer to

Operation section of manual.

small posts.

Weight is dropping

unexpectedly

Vehicle battery is dead a. Tilt switch was activated

Weight not cycling a. No post loaded in

Motor will not operate a. Motor damaged Contact Danuser.

Chain jumps a. Incorrect chain tension Adjust chain tension.

a. Weight is not down after

driving

too long

Hammer

b. Broken or missing shaft

key

c. Channel is not lubricated Grease the inside of the Hammer case.

d. Motor damaged Contact Danuser.

b. Incorrect hose routing Refer to Hydraulics section of manual

b. Sprockets or chain are

worn

When nished driving, make sure

weight is down and/or catch is visible

through viewing slots. Refer to

Operation section of manual.

Deactivate tilt switch when Hammer

is not in use.

A post must be pushed up inside the

Hammer until it stops before the

weight will cycle.

Replace key.

for proper hose routing.

Replace worn item(s).

Oil over heating a. High ow activated Ensure vehicle is not in high ow

mode.

b. Low oil level Fill reservoir to proper level.

c. Dirty oil or oil lter Change oil and lter.

Tilt feature not

working

Tilt or grapple

cylinder not working

For additional assistance, please call your dealer or contact Danuser direct:

a. No power to solenoid Check electrical connections. Ensure

switch is activated.

b. Blown fuse Check inline fuse in electrical

harness. Check vehicle's fuses.

c. Solenoid not working Contact Danuser.

d. Tilt lock pin in place Remove tilt lock pin. Refer to

Operation section of manual.

a. Air in hydraulic system Cycle hydraulics until both cylinders

have completely extended and

retracted (fully cycled).

b. Incorrect hose routing Refer to Hydraulics section of manual

for proper hose routing.

c. Tilt or Grapple

obstruction

d. Cylinder damaged Contact Danuser.

Phone: (573) 642-2246

Fax: (573) 642-2240

E-mail: sales@danuser.com

Ensure tilt and grapple mechanisms

can move freely.

15

Page 16

Maintenance

WARNING

Personal protection

equipment including hard

hat, safety glasses, safety

shoes, gloves, and ear

plugs are recommended

during assembly,

installation, operation,

maintenance, service,

removal, or movement of

the attachment.

DAILY

CHECK FOR CLEAN HYDRAULIC OIL

The majority of all hydraulic component failures are caused by contamination of the

hydraulic oil. At all times, keep dirt and other contaminates from entering the hydraulic

system during connecting and disconnecting the hydraulic system. Always use dust caps

and plugs on all quick disconnects when not in use.

CHECK ALL HYDRAULIC HOSE ASSEMBLIES

Check for cracked or brittle hoses. Replace hoses immediately if cracked or brittle.

Replacement of hoses before failure will prevent loss of hydraulic oil, hydraulic oil

contamination, and component damage caused by cavitation.

CHECK ATTACHMENT AND ALL ACCESSORIES

Check all bolts and fasteners for tightness. Visually inspect the attachment for damage.

EVERY 40 HOURS

GREASE ZERKS

Grease the zerk on the drive chain bearing. Grease the zerk on the bottom chain sprocket

shaft. If equipped with Tilt, grease the zerk on the tilt pivot boss.

LUBRICATE ATTACHMENT

Grease the inside of the Hammer case. Lubricate the drive chain with a high quality

commercial grade chain lubricant.

CHECK ATTACHMENT AND ACCESSORIES

Visually inspect all welds for cracks. Check the chain catch for wear. Check all bolts and

fasteners for tightness.

CHECK CHAIN TENSION

Inspect the chain tensioning springs. Springs should be preloaded but not entirely collapsed.

16

Page 17

Service

D A N G E R

WARNING

NOTE

WARNING

Never attempt repairs or adjustments while the equipment

is in operation.

Replacing the Drive Chain

STEP 1:

Make sure the hammer weight catch is visible through the viewing slots on the

back of the case.

Personal protection

equipment including hard

hat, safety glasses, safety

shoes, gloves, and ear

plugs are recommended

during assembly,

installation, operation,

maintenance, service,

removal, or movement of

the attachment.

Because of the weight

of some components,

and because some

components are difficult

to balance, two people are

required for servicing of

this equipment.

STEP 2:

STEP 3:

STEP 4:

STEP 5:

STEP 6:

STEP 7:

STEP 8:

STEP 9:

STEP 10:

Remove the retention pin from the top of the case. Insert a hook into the lifting

eye located on the top of the weight. Lift the weight out of the Hammer with a

hoist, forklift, or another vehicle. Set the weight on the ground.

Carefully lay down the Hammer on its front side.

Remove the top and bottom chain covers.

Remove the retaining ring fastened to the lower sprocket shaft assembly, and pull

out the shaft from the opposite side of the Hammer.

Remove the tensioning rods and shim(s). Slide chain slack to the top of the

Hammer.

Find the chain catch and two pins that secure it. Remove the clips that retain the

pins, and remove the pins.

Install new chains over the upper sprocket shaft assembly. Make sure open ends

of the chain are at equal links away from sprockets.

Reinstall the chain catch and pins through the open ends of the new chain. Install

clips on the pins.

Slide chain slack to the bottom of the Hammer, and insert the lower sprocket shaft

assembly into the chain.

1.5"

Tighten tensioning nuts until

springs are adequately preloaded

STEP 11

STEP 12:

STEP 13:

STEP 14:

Shim(s) must be inserted between the tensioning rods and the lower sprocket shaft

assembly to maintain proper sprocket location.

Insert the lower sprocket shaft through the side of the Hammer and through the

tensioning rods and sprockets.

Install shim(s) and retaining ring on the end of the sprocket shaft.

Install bottom chain guard and tensioning springs. Tighten tensioning nuts until

the springs are adequately preloaded but not entirely collapsed.

Install the top chain cover, stand Hammer upright, reinstall weight, and install the

retention pin.

Do not tilt or operate the Hammer without the retention pin

in place. The hammer weight could slide out of the Hammer

and cause serious injury or death.

17

Page 18

Parts

= Safety Sign

Location

7

8

26

25

27

24

23

1

22

2

3

21

20

4

28

5

29

6

19

18

17

18

7

16

8

12

30

14

13

31

10

11

15

9

Page 19

Parts

(continued)

REF. NO. PART NO. DESCRIPTION QTY.

1 10195 Toplock Nut (1/4" 20) 4

2 21056 1/4" Flat Washer 4

3 21055 Bolt (1/4" 20 x 1") 4

4 21137 Hydraulic Manifold 1

5 21169 Foot 1

6 21079 Pin 1

7 10268 3/4" Flat Washer 8

8 10267 Toplock Nut (3/4" 10) 8

9 21062 Grapple Assembly 1

10 21148 Grapple Spring 1

11 21124 Floating Anvil 1

12 6156 Socket Head Bolt (1/2" 13 x 1-1/2") 4

13 21156 1/2" Flat Washer 8

14 10125 Toplock Nut (1/2" 13) 4

15 21105 Bolt (3/4" 10 x 2-1/4" Gr. 5) 6

16 21086 Quick Attach Plate 1

17 21093 Quick Attach Plate w/ Tilt 1

18 21157 Bolt (3/8" 16 x 1") 2

19 2178 3/8" Flat Washer 2

20 21026 Case 1

21 21133 Cover 1

22 21118 Retention Pin 1

23 21078 Rue Clip 6

24 21045 Weight 1

25 21051 Cover 1

26 21054 Stud (3/4" 10 x 3-1/4") 2

27 21044 Weight Assembly (consists of items 7, 8,

24, 25, and 26)

1

28 21207 Pin 1

29 21208 Parking Stand 1

30 21206 Pin 1

31 2164 Drive Screw 1

19

Page 20

Parts

Drive Assembly

= Safety Sign

Location

6

5

REF.

NO.

PART

NO.

DESCRIPTION

QTY.

3

1 21119 Connecting Link 2

2

1

4

8

7

9

10

11

12

13

2 21024 Chain Pin 2

3 21025 Roller Chain #80, 1" Pitch 2

4 21122 Catch Weight 1

5 21126 Socket Head Bolt

(1/2" 13 x 2")

6 21113 Hydraulic Motor 1

7 21114 Upper Sprocket Shaft

Assembly

8 21156 1/2" Flat Washer 2

9 10125 Toplock Nut (1/2" 13) 2

10 21043 Bearing 1

11 2489 7/16" Flat Washer 4

12 10197 Toplock Nut (7/16" 14) 4

13 21057 Bolt (7/16" 14 x 1-1/2") 4

14 21040 Sprocket Shaft 1

15 21080 Lower Sprocket Shaft

Assembly

16 21125 Shim 2

17 21083 Tensioning Rod 2

18 10267 3/4" Flat Washer 1

19 2172 Retaining Ring 1

20 21123 Spring 2

21 2178 3/8" Flat Washer 2

22 10412 Toplock Nut (3/8" 16) 2

23 21110 Cover Assembly 1

2

1

1

20

14

15

20

21

22

16

23

17

18

19

Page 21

Parts

Hydraulics

= Safety Sign

Location

1

2

6

3

5

4

7

REF. NO. PART NO. DESCRIPTION QTY.

1 10040 45° Elbow 2

2 21142 Motor-Manifold Hydraulic Hose 2

3 21141 #6 O-ring Plug 2

4 10049 Female Coupler 1

5 21155 Vehicle-Manifold Hydraulic Hose 1

6 10048 Male Coupler 1

7 21139 Vehicle-Manifold Hydraulic Hose 1

21

Page 22

Parts

Tilt Hydraulics

= Safety Sign

Location

1

2

3

4

6

5

9

10

8

7

REF. NO. PART NO. DESCRIPTION QTY.

1 21164 Diverter-Cylinder Hydraulic Hose 2

2 21154 Restrictor 2

3 21103 Hydraulic Cylinder 1

4 21147 Diverter-Manifold Hydraulic Hose 1

5 21153 #10 O-ring #6 JIC Fitting 2

6 21128 Diverter Valve 1

7 21145 Vehicle-Diverter Hydraulic Hose 2

8 21146 Diverter-Cylinder Hydraulic Hose 1

9 10049 Female Coupler 1

10 10048 Male Coupler 1

22

Page 23

Parts

Grapple Hydraulics

= Safety Sign

Location

1

3

2

REF. NO. PART NO. DESCRIPTION QTY.

1 21140 #6 O-ring 1/4" Pipe Elbow 2

2 21143 Manifold-Grapple Hydraulic Hose 1

3 21144 Manifold-Grapple Hydraulic Hose 1

23

Page 24

Parts

Grapple

= Safety Sign

Location

7

1

5

3

4

2

6

REF. NO. PART NO. DESCRIPTION QTY.

1 21063 Case 1

2 21070 Right Jaw 1

3 21073 Left Jaw 1

4 21077 Clevis Pin 3

5 21078 Rue Clip 4

6 21134 Clevis Pin 1

7 21167 Hydraulic Cylinder 1

24

Page 25

Parts

= Safety Sign

Location

Tilt

10

6

12

5

8

4

2

3

9

14

1

13

11

15

16

7

8

17

REF. NO. PART NO. DESCRIPTION QTY.

1 6339 5/16" Flat Washer 2

2 10267 3/4" Flat Washer 2

3 10268 Toplock Nut (3/4" 10) 2

4 21078 Rue Clip 1

5 21094 Quick Attach Plate 1

6 21100 Tilt Bracket 1

7 21103 Hydraulic Cylinder 1

8 21106 Bolt (3/4" 10 x 2-3/4") 2

9 21107 5/8" Large Flat Washer 4

10 21108 Flange Bolt (5/8" 11 x 1-1/4", Gr. 8) 4

11 21128 Diverter Valve 1

12 21134 Clevis Pin 1

13 21158 Socket Head Bolt (5/16" 18 x 3") 2

14 21159 Toplock Nut (5/16" 18) 2

15 21162 Wiring Harness 1

16 21220 Wiring Harness 8-Pin 1

21221 Wiring Harness 14-Pin

21222 Wiring Harness 14-Pin Deere

17 21223 Cigarette Lighter Adapter 1

25

Page 26

Decals &

WARNING

Safety Signs

PART NO. DIG21

Location: Unit, left side

(5 7 3) 642 -22 4 6 www.danuser.com

PART NO.

DANUSER101

Location: Unit, front

PART NO. 9875

Location:

Drive Unit, front

PART NO. DIG13

Location: Unit, left side

PART NO. DIG16

Location: Unit, left side

HAMMER DECAL

Location: Unit, front

SM40

DECAL

Location:

Unit, front

PART NO. DIG14

Location: Unit, left side

26

Clean or replace all safety

signs if they cannot be

clearly read and understood.

PART NO. DIG26

Location: Grapple,

top & bottom

Page 27

Decals &

WARNING

Safety Signs

(continued)

Model No. & Serial No.

Location: Unit, rear

PART NO. DIG22

Location: Unit, rear shelf

PART NO. DIG23

Location: Unit, rear

PART NO. DIG5

Location:

Unit, right side

PART NO. PHDC6

Location: Unit, inside rear

PART NO. DIG24

Location: Unit, rear

Clean or replace all safety

signs if they cannot be

clearly read and understood.

PART NO. DIG25

Location: Tilt plate

27

Page 28

Accessories

= Safety Sign

Location

Tilt

PN 21005

Wiring Harness Options

PN 21220 - 8 Pin

PN 21221 - 14 Pin

PN 21222 - 14 Pin Deere

PN 21223 - Cigarette Lighter Adapter

28

Page 29

Accessories

(continued)

= Safety Sign

Location

Grapple

PN 21004

T-Post Adapter

PN 21149

Additional Weight Kit (not shown)

PN 21163

29

Page 30

Warranty

DANUSER

Model #

LIMITED WARRANTY

Danuser LLC (“Danuser”) warrants its products, under normal use and maintenance, to be free from defects in material and

workmanship for periods specified below from the purchase date from an authorized Danuser Dealer. Start of the warranty period

is determined by purchase date given on your returned WARRANTY REGISTRATION FORM. Proof of purchase may be required.

This Limited Warranty is extended only to the original purchaser of Danuser products.

Hammer - 1 Year

1. During the applicable warranty period, Danuser, at its option, will repair or replace any part determined by Danuser to be

defective. Such repair or replacement shall take place at Danuser’s factory or a location designated by Danuser. Under no

circumstances shall Danuser be obligated for the cost of any repair or replacement by anyone other than Danuser without its

express written consent.

2. Parts may not be returned without written authorization from Danuser.

3. Some purchased components, including but not limited to hydraulic components are subject to the inspection and warranty of

the respective manufacturer. Thus, delays in a warranty determination can be expected while Danuser awaits their decision.

4. This warranty is void if any attempt is made to make field repairs to hydraulic components. To qualify for warranty inspection,

the “failed” part must be returned in its original “failed” condition.

5. To make a claim under this warranty, first contact your authorized Danuser Dealer. The Danuser Dealer shall complete the

Warranty Claim Form and obtain written authorization from Danuser to return parts. All warranty claims must include

detailed information regarding make and model of vehicle on which the Danuser product was mounted, hours of use,

description of events that led up to the failure, and any other information helpful in reviewing the warranty claim. All

warranty returns must be prepaid. Shipments arriving at our factory on a freight collect basis will be refused by our receiving

department. The freight charge will be credited if the parts are determined by Danuser to be defective, and the associated

freight costs in returning those parts will be prepaid by Danuser. NOTE: Hydraulic motors must arrive with all ports sealed

from dirt and moisture. If a motor arrives with open ports, the warranty is void and no inspection will be made.

Serial #

6. Products or parts thereof which, as determined by Danuser’s examination, show wear from normal use, have been improperly

operated, damaged by accident or negligence, field repaired, altered or modified are not considered defective in material and

workmanship and are not covered by this warranty. This warranty does not apply to parts subject to normal wear or to damage

caused by the failure to perform recommended maintenance or to replace worn parts. This warranty shall not obligate Danuser

to bear any cost of labor for field repair, replacement, testing, or adjustment nor for damage caused by accident, abuse, misuse,

or environmental elements.

7. Any parts or labor required to repair or replace parts not covered under this warranty will be charged to the customer. Parts

repaired or replaced by Danuser are then covered by this warranty only for the remainder of the original warranty as if such

parts were original parts.

8. Danuser reserves the right to change its specifications and designs at any time.

This warranty is exclusive and in lieu of all other express warranties, if any, including the implied warranties of merchantability and

fitness for a particular purpose. It shall not extend beyond the duration of the expressed warranty provided herein and the remedy

for violations of any implied warranty shall be limited to repair or replacement of the defective part pursuant to the terms contained

herein. No employee, dealer, salesman, or representative is authorized to change this warranty in any way or grant any other

warranty. Danuser shall not be liable for any consequential, incidental, or punitive damages, losses, or expenses, including those

resulting from or caused by any defects.

Danuser LLC Tel: (573) 642-2246

500 E. 3rd St. Fax: (573) 642-2240

P.O. Box 368 E-mail: sales@danuser.com

Fulton, MO 65251 Website: www.danuser.com

Form No. 3269

Loading...

Loading...