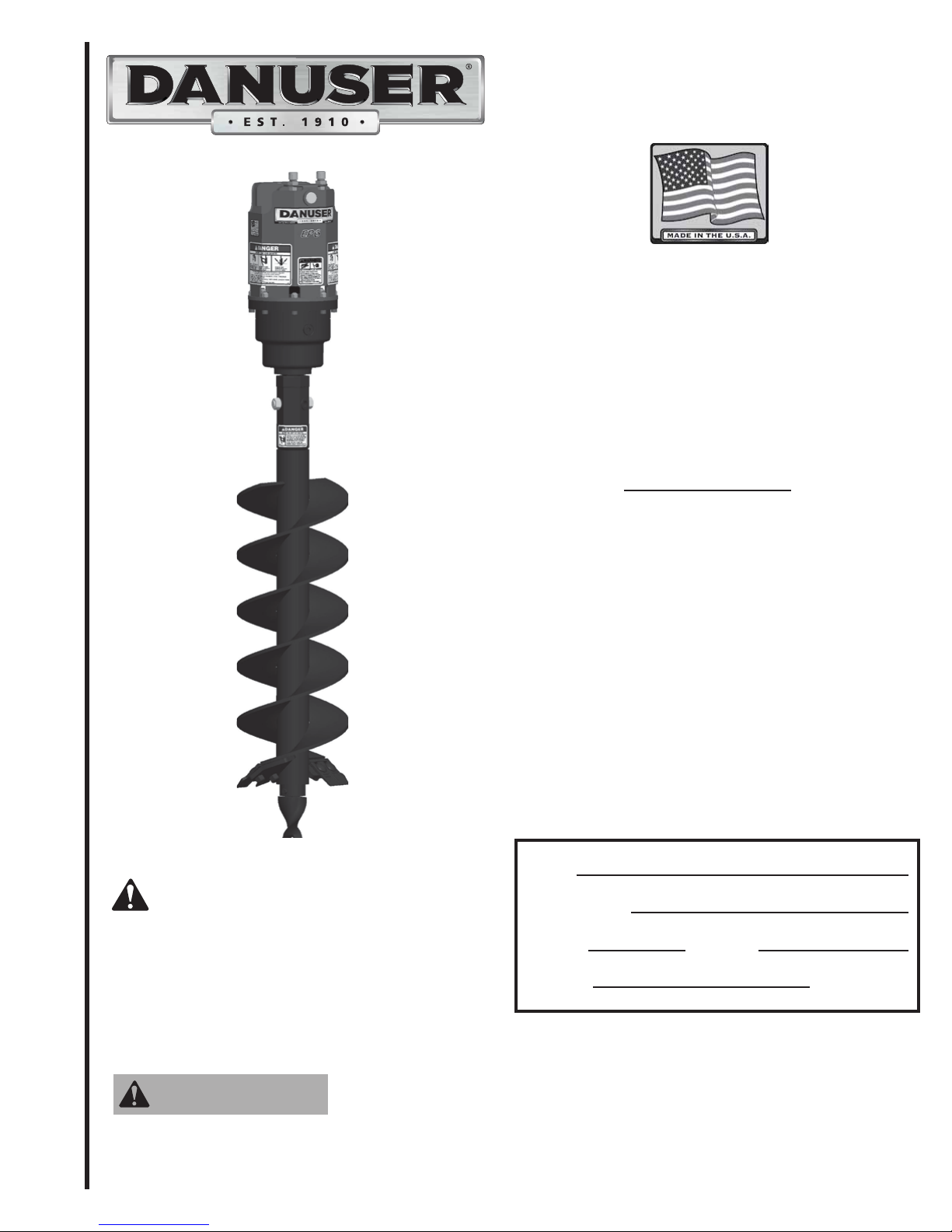

EP

HEAVY DUTY

AUGER SERIES

MODELS

Read this entire manual. This

safety alert symbol is used

throughout this manual to call your

attention to messages involving

your personal safety and the safety

of others. Failure to follow these

instructions can result in injury or

death.

WARNING

Si no entiende ingles, se prefiere que

busque a alguien que interprete las

instrucciones para usted.

EP6 Hex,

EP10 Hex,

EP15 Hex,

EP20 Hex,

Owner:

Date Purchased:

Model #: Serial #:

Manual #:

9MEP2457351

EP6 Round

EP10 Round

EP15 Round

EP20 Round

Operator’s Manual

Danuser LLC

500 E. 3rd St.

P.O. Box 368

Tel: (573) 642-2246 Fax: (573) 642-2240

Fulton, MO 65251

E-mail: sales@danuser.com

Website: www.danuser.com

Dear Owner/Operator,

Thank you for purchasing this Danuser Hydraulic Earth Auger. We appreciate your business.

The EP heavy-duty auger series is designed to meet the needs of farmers, ranchers, contractors,

landscapers, and municipalities. Various auger styles are available for drilling in light ground

conditions to harder ground conditions, such as rock, frozen ground, and more.

Your safety as an operator of our product is very important to us. Therefore, before you assemble,

install, operate, maintain, service, remove, or move your Danuser Earth Auger, read and understand

this manual thoroughly. If there is anything you do not understand, immediately contact your

dealer, or contact our factory direct.

Phone: (573) 642-2246

Fax: (573) 642-2240

E-mail: sales@danuser.com

Your satisfaction in the performance and longevity of our product is also very important to us and

can be prolonged by proper assembly, installation, operation, and maintenance as instructed in this

manual.

Thank you again for your business and for your trust in our product. Please feel free to contact us

at any time for further assistance.

Sincerely,

Danuser LLC

500 E. 3rd St.

P.O. Box 368

Fulton, MO 65251

Tel: (573) 642-2246 Fax: (573) 642-2240

E-mail: sales@danuser.com Website: www.danuser.com

Danuser provides this manual "as is" without warranty of any kind, either expressed or implied. Danuser assumes

no responsibility for errors or omissions. Danuser assumes no liability for damages resulting from the use of the

LQIRUPDWLRQFRQWDLQHGKHUHLQ'DQXVHUUHVHUYHVWKHULJKWWRUHYLVHDQGLPSURYHLWVSURGXFWVDVLWVHHV¿W7KLVPDQXDO

GHVFULEHVWKHVWDWHRIWKLVSURGXFWDWWKHWLPHRILWVSXEOLFDWLRQDQGPD\QRWUHÀHFWWKHSURGXFWLQWKHIXWXUH

Danuser is a registered trademark.

Foreword

Please read this manual thoroughly!

Before you assemble, install, operate, maintain, service, remove, or move your Danuser

Earth Auger, read this manual thoroughly. If there is anything you do not understand,

immediately contact your dealer, or call our factory direct at (573) 642-2246. Powered

equipment can be dangerous if not assembled, installed, operated, maintained, serviced,

removed, or moved properly.

Warranty Registration

To activate your warranty coverage and to provide you with efficient customer service,

please fill out your WARRANTY REGISTRATION FORM. This form is included in your

unit’s paperwork package. If you did not complete a WARRANTY REGISTRATION

FORM or did not receive one, please call Danuser LLC. Or, register online at

www.Danuser.com. Your satisfaction with our product and your safety as a user of our

product are both very important to us.

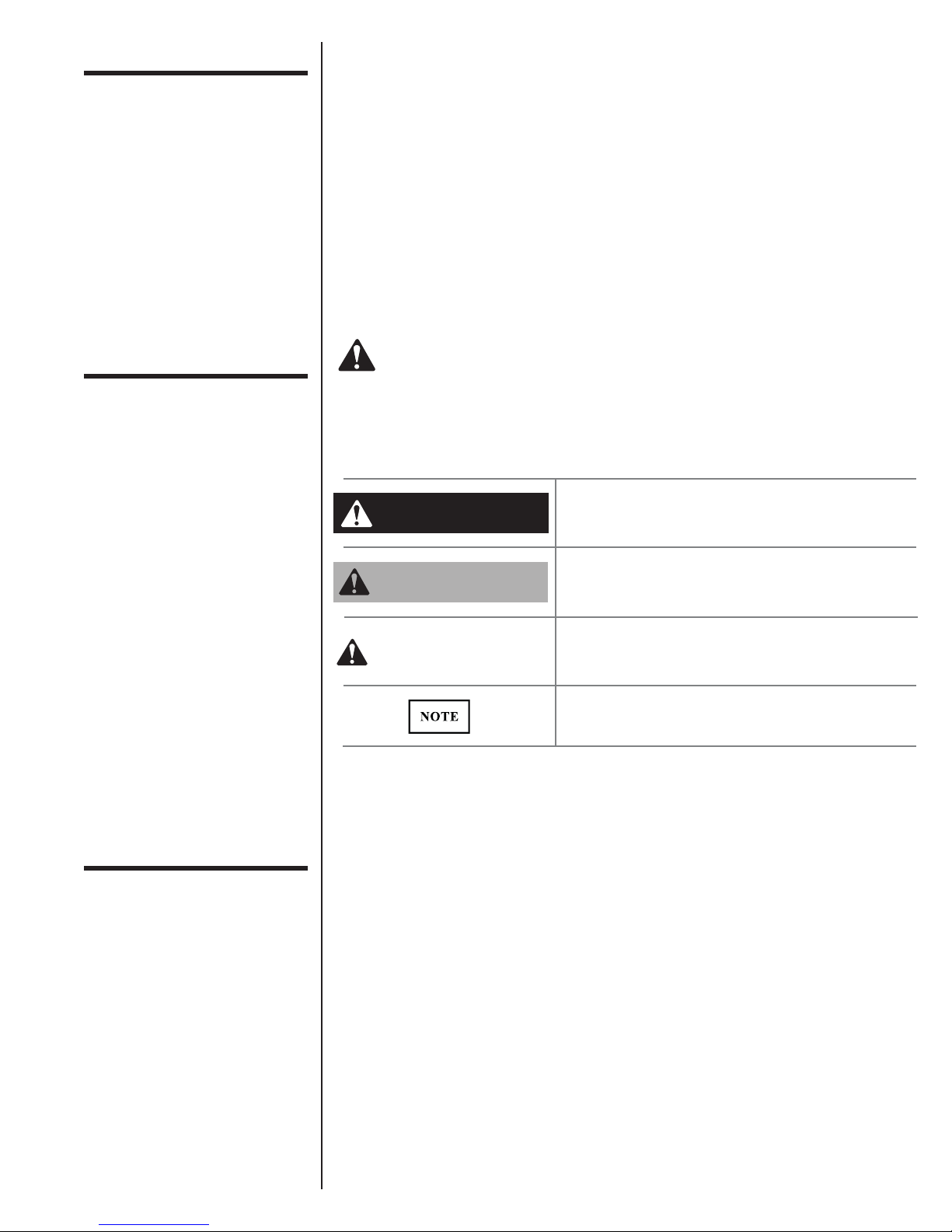

Symbols

This SAFETY ALERT symbol identifies important safety messages. Carefully read

each safety message that follows. Failure to understand and obey a safety message,

or recognize a safety hazard, could result in injury or death to you or others around you.

The operator is ultimately responsible for the safety of himself, as well as others, in the

operating area of the earth auger.

Symbol

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury,

including hazards that are exposed when guards are

removed.

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

This is important information for proper use of this

equipment. Failure to comply may lead to premature

equipment failure.

Meaning

Table of

Contents

Page

Letter to the Owner/Operator ............................................ 2

Foreword ............................................................ 3

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety............................................................... 4

Decals & Safety Signs.................................................. 7

Drive Unit Specifications ............................................... 9

Hydraulic Requirements ................................................ 10

Assembly & Installation ................................................ 11

Operation ............................................................ 19

Removal & Storage .................................................... 21

Troubleshooting....................................................... 22

Maintenance & Lubrication.............................................. 23

Torque Values Chart.................................................... 24

Drive Unit Parts....................................................... 25

Augers & Accessories .................................................. 26

Warranty................................................... Form No. 3387

3

Safety

WARNING

Working with unfamiliar equipment can lead to careless injuries. Read and understand this manual and

the manual for your vehicle before assembling, installing, operating, maintaining, servicing, removing, or

moving this earth auger. If there is anything in this manual you do not understand, contact your dealer or

Danuser LLC. The safe use of this machine is strictly up to you, the operator. If this unit is used, loaned,

or rented by any other person, it is the owner's responsibility to make certain that the operator prior to

operating:

• Reads and understands the Operator's Manuals

• Is instructed in safe and proper use

There is an entanglement risk if you replace the special auger retaining bolt with a bolt longer than

specified by Danuser LLC. This improper replacement occurs most often on machines that are loaned or

rented to someone who has not read the Operator's Manual and is not familiar with an earth auger.

• This earth auger is designed for one-man operation from the vehicle seat. It is the responsibility of

the operator to see that no one is within twenty-five feet (25') of the earth auger when it is started or

in use. Do not operate the earth auger with another person near or in contact with any part of the

drive unit or auger. Serious personal injury or death may result if any attempt is made to assist

drilling operation by hand.

• All operators of this attachment must read and understand this entire manual, paying particular

attention to safety messages and operation instructions, prior to assembling, installing, operating,

maintaining, servicing, removing, or moving the earth auger.

• Please remember it is also important that you read, understand, and follow the safety signs on the

attachment. Clean or replace all safety signs if they cannot be clearly read and understood. They are

there for your safety as well as the safety of others. Danuser LLC will furnish new safety signs upon

request at no charge.

• All things with moving parts are potentially hazardous. There is no substitute for a cautious,

safe-minded operator who recognizes potential hazards and follows reasonable safety practices.

• Personal protection equipment including hard hat, safety glasses, safety shoes, and gloves are

recommended during assembly, installation, operation, maintenance, service, removal, or movement

of the attachment.

• When the use of hand tools is required to perform any part of assembly, installation, maintenance,

service, removal, or movement of the earth auger, be sure the tools used are designed and

recommended by the tool manufacturer for that specific task.

• Never check pressurized system for leaks with your bare hand. Wear proper hand and eye protection

and use wood or cardboard when searching for suspected leaks. Oil escaping from pinhole leaks

under pressure can penetrate skin and create a serious medical emergency. If any fluid is injected into

the skin, gangrene, blood poisoning, even death may result. Obtain medical attention immediately.

• Always use two people to handle heavy, unwieldy components during assembly, installation,

maintenance, service, removal, or movement of the attachment.

• Never place any part of your body where it would be in danger if movement should occur during

assembly, installation, operation, maintenance, service, removal, or movement of the earth auger.

• Check clearances between vehicle and auger, as well as operator and auger, across the full range of

loader arms’ operating heights. Keep earth auger in cradle when not drilling.

• Only properly trained people should operate this equipment. Do not allow anyone who has not read

this entire manual and understood the safety rules, safety signs, and operation instructions to use this

attachment.

4

• Never allow children to operate or be around this earth auger.

Safety

(continued)

• Do not allow riders on the equipment at any time. There is no safe place for any riders.

• Never use alcoholic beverages or drugs which can hinder alertness or coordination while operating

this equipment. Consult your doctor about operating this equipment while taking prescription

or over-the-counter medications.

• Safe operation of equipment requires the operator's full attention. Avoid distractions such as radio

headphones, cell phones, etc. while operating.

• Contact with underground gas lines or electrical cables may result in serious injury or death from

explosion or electrical shock. Before operating, call 811 or the local number to locate underground

utilities.

• Do not drill near underground utility lines.

• Before beginning operation, clear the work area of objects which might be picked up and thrown by

or entangled in the auger.

• The earth auger must be securely latched to the vehicle. Ensure both locking handles are in the

locked position with pins fully seated. An improperly latched earth auger can fall without warning.

• Before you operate the attachment, check over all pins, bolts, and connections to be sure all are

securely in place. Replace any damaged or worn parts immediately.

• Never replace the auger retaining bolt with anything other than the specified length bolt in this

manual. A longer, or protruding, fastener is more likely to grab clothing or gloves, which can result

in serious injury or death.

• Keep all helpers and bystanders twenty-five feet (25') away from an operating earth auger.

• Keep hands, feet, hair, jewelry, and clothing away from all moving and/or rotating parts.

• Never place yourself between the vehicle and the attachment.

• Worn teeth or a slightly rounded point can seriously affect auger penetration. Check for wear before

each use, and replace as necessary.

• Never position the auger point by hand or with any tool when the vehicle is running.

• Never position the auger point by putting your hands on the auger or drive unit.

• Do not shovel dirt away from a rotating auger, as the shovel can be caught and thrown by the auger.

• Never transport with the drive unit out of the cradle or while the auger is rotating.

• A heavy load can cause instability of the vehicle. Use extreme care during travel. Slow down on

turns and watch out for bumps. Use all safety devices, including a seat belt, as recommended in the

vehicle operator’s manual.

• Do not operate the earth auger on steep hillsides. When drilling on uneven or hilly terrain, position

the vehicle with the earth auger uphill. With the earth auger downhill, the vehicle could tip when

attempting to raise the auger from its hole. Consult your vehicle operator’s manual for maximum

incline allowable.

• Always shut off the vehicle engine, remove the key, lower vehicle arms, and relieve all hydraulic

pressure before dismounting the vehicle. Never leave equipment unattended with the vehicle

running.

• Never attempt adjustments, service, or repairs while the equipment is in operation.

5

Safety

• Never work under equipment supported by hydraulics. Even with the vehicle shut off, equipment can

suddenly drop if controls are actuated or if hydraulic lines burst.

(continued)

• Before disconnecting hydraulic lines or fittings, be sure to relieve all pressure by cycling all hydraulic

controls after shutdown. Remember hydraulic systems are under pressure whenever the engine is

running and may hold pressure after shutdown.

• Store the attachment on a flat, level surface in an area where children do not play. Securely block

and support the attachment.

• Do not modify the attachment. Modifications may weaken the integrity of the attachment and may

impair the safety, function, life, and performance of the earth auger.

• When making repairs or servicing the earth auger, use only parts that meet original equipment

manufacturer's standards and requirements.

• Always use care when operating the earth auger. Most accidents occur because of neglect or

carelessness.

Safety is a primary concern in the design, manufacture, sale, and use of earth augers. Danuser confirms to

you, our customer, our concern for safety.

DANGER

Improper operation of this earth auger can cause serious

personal injury or death. Operation of this earth auger

should only be done by a competent adult acting in

compliance with the Operator's Manual. Since drilling

operations are beyond our control, we disclaim all liability

for any damages, injuries, or death which may result.

6

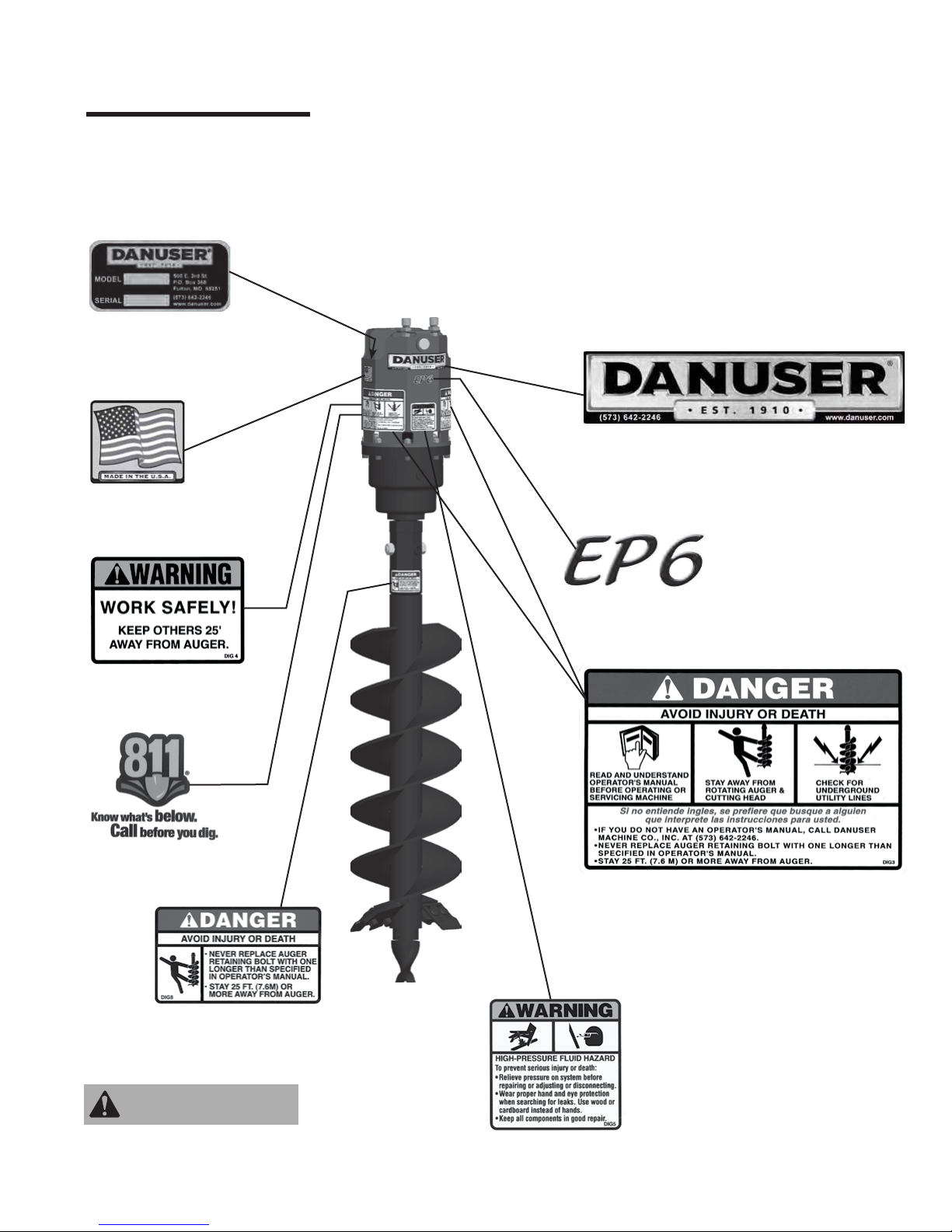

Decals &

Safety Signs

Model No. & Serial No.

Location: Drive unit,

inside right side

The earth auger comes equipped with all safety signs in place. Their locations are shown in

this section. Read and follow their instructions and ensure their care:

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing, illegible, or damaged.

• Ensure replacement parts installed during repair have safety signs attached.

To install new safety signs, follow these steps:

1. Clean the area where the safety sign is to be placed.

2. Spray a little soapy water on the surface where the safety sign is to be placed.

3. Peel the backing from the safety sign, and apply it in the position shown.

4. Firmly press the safety sign, and squeeze out the air bubbles with a straight edge (e.g., a

credit card).

PART NO. DANUSER100

Location: Drive unit, front

PART NO. 9875

Location: Drive unit, right side

PART NO. DIG4

Location: Drive unit, rear

PART NO. 20673

Location: Drive unit, rear

PART NO. 10981 (EP6)

PART NO. 10982 (EP10)

PART NO. 10983 (EP15)

PART NO. 20003 (EP20)

Location: Drive unit, front

PART NO. DIG3

Locations: Drive unit, left side;

Drive unit, right side

PART NO. DIG8

Location: Auger

WARNING

Clean or replace all safety

signs if they cannot be

clearly read and understood.

PART NO. DIG5

Location: Drive unit, front

7

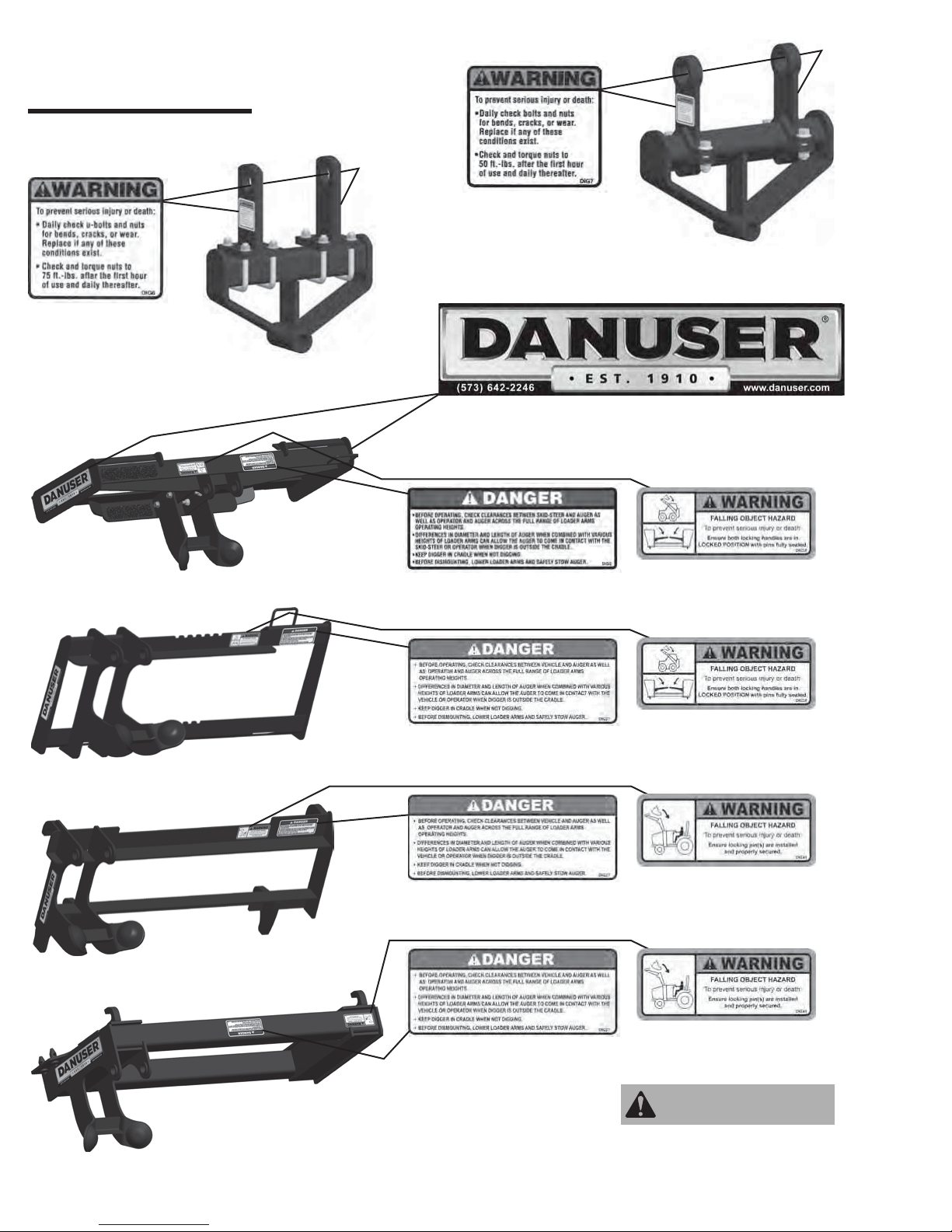

Decals &

Safety Signs

(continued)

PART NO. DIG6

Locations: Knuckle ear, left side;

Knuckle ear, right side

Mini-Excavator Knuckle

PART NO. DIG7

Locations: Knuckle ear, left side;

Knuckle ear, right side

TLB & Excavator Knuckle

PART NO. DANUSER101

Locations: Quick attach plate, left side;

Quick attach plate, right side

Skid-Steer Mount

Skid-Steer Offset Mount

Euro Offset Mount

PART NO. DIG2

Location: Quick attach plate, top

PART NO. DIG27

Location: Quick attach plate, top

PART NO. DIG27

Location: Quick attach plate, top

PART NO. DIG35

Location: Quick attach plate, top

PART NO. DIG35

Location: Quick attach plate, top

PART NO. DIG41

Location: Quick attach plate, top

John Deere 200/300/400/500 Series Mount

8

PART NO. DIG27

Location: Quick attach plate, top

PART NO. DIG41

Location: Quick attach plate, top

WARNING

Clean or replace all safety

signs if they cannot be

clearly read and understood.

Drive Unit

Specifications

Minimum Hydraulic Flow 6 GPM 10 GPM 15 GPM 20 GPM

Maximum Hydraulic Flow 15 GPM 20 GPM 30 GPM 35 GPM

Maximum Continuous Operating PSI 3000 PSI 3000 PSI 3000 PSI 3000 PSI

Maximum Auger Diameter 24 inches 30 inches 36 inches 36 inches

Output Spindle 2" Hex or 2" Hex or 2" Hex or 2" Hex or

EP6EP10EP15EP20

2-9/16" Round 2-9/16" Round 2-9/16" Round 2-9/16" Round

Model EP6

PSI TORQUE

2000 1014 Ft.-Lbs.

2500 1267 Ft.-Lbs.

3000 1520 Ft.-Lbs.

PSI TORQUE

2000 1874 Ft.-Lbs.

2500 2342 Ft.-Lbs.

3000 2811 Ft.-Lbs.

GPM RPM

636

848

10 60

12 73

14 85

15 91

GPM RPM

15 49

18 59

20 65

24 78

28 92

30 98

Model EP10

PSI TORQUE

2000 1270 Ft.-Lbs.

2500 1587 Ft.-Lbs.

3000 1904 Ft.-Lbs.

Model EP20Model EP15

PSI TORQUE

2000 2465 Ft.-Lbs.

2500 3081 Ft.-Lbs.

3000 3697 Ft.-Lbs.

GPM RPM

10 48

12 58

14 68

16 77

18 87

20 97

GPM RPM

20 50

24 60

28 70

30 75

32 80

35 87

Operator's Manual Direction Terminology

Front

Left

Rear

Right

Torque and output speed specifications are based on

theoretical values and are provided for comparative

purposes only.

9

Hydraulic

Requirements

Filtration Requirements:

• A filter of, at least, 25 micron filtration is required. A filter capable of 10 micron

filtration is preferred. The majority of paper type filters are 25 microns or better.

The life of the hydraulic motor is almost entirely dependent upon cleanliness of

the oil. Instructions in your vehicle operator’s manual regarding filter and oil

changes should be carefully followed. Even small amounts of dirt in the

hydraulic oil can cause premature motor failure that is not covered by warranty.

• A low pressure type filter can be installed in the return line from the control valves to

the sump. A low pressure type filter can also be installed in the sump or pump intake

line but must be sized large enough to avoid starving the pump.

• A high pressure type filter can be used between the pump and the control valves.

• If the source of the hydraulic power does not have a filter, it will be necessary to install

one at some point in the system so, at least, part of the hydraulic oil is being filtered

whenever the system is operating. After a filter is installed and before attaching the

drive unit, the entire hydraulic system should be drained, filled with new oil, and

operated for 30 minutes or until the system is warm. During this run time, operate all

valves, cylinders, and hydraulic motors on the machine.

Pressure and Flow Requirements:

• Models EP6, EP10, EP15, and EP20 Danuser Earth Augers are designed to operate

within the pressure range of 1500 to 3000 PSI.

• Operating flow rate is dependent on model: 6 to 15 GPM for Model EP6, 10 to 20

GPM for Model EP10, 15 to 30 GPM for Model EP15, and 20 to 35 GPM for Model

EP20.

Valve Requirements:

• The hydraulic system used to power the drive unit should be equipped with a four-way

valve large enough to carry full pump outlet without restricting flow and causing oil

heating.

• The four-way valve requires a relief valve which will open and relieve extreme

pressures between the drive unit and control valve, even when the control valve is in a

neutral position. This feature can be obtained by connecting two external relief valves

between the main lines running from the control valve to the drive unit in such a way

that high pressure in either line will be relieved to the other line.

Hydraulic Hose Requirements:

• High pressure hoses of, at least, 1/2 inch inside diameter connect four-way valve to the

hydraulic fittings on the top of the drive unit. If the drive unit is mounted 10 feet or

more from the hydraulic outlets on your unit, or the pump delivers 20 GPM or more,

hose size should be increased to 3/4 inch inside diameter.

• Working pressure of hydraulic hoses must be higher than the rated vehicle hydraulic

pressure.

• An abrasion sleeve is recommended on all hydraulic hoses.

• The hydraulic hoses should be equipped with a 45-degree fitting on the drive unit end.

• The hydraulic fittings on the top of the drive unit are #10 JIC male.

• Since the motor is reversible, hose connections to motor fittings are interchangeable.

• All hoses, pipes, and fittings used to connect the drive unit should be thoroughly

cleaned before use. Care should be taken to see that no thread sealer or metal chips are

forced to the inside of the joints when connections are being tightened.

Hydraulic Fluid Selection Requirements:

• Premium grade petroleum based fluids will provide the best performance.

• Fluids that contains anti-wear agents, rust inhibitors, anti-foaming agents,and oxidation

inhibitors are recommended.

• The viscosity of the fluid should never fall below 70 SUS (13 cST). The best

10

viscosity range for the drive unit is 100-200 SUS (20-43 cST).

Assembly &

Installation

Skid-Steer Mount

Drive unit and auger

1

4

exploded views and part lists

are detailed on separate pages

in this manual.

10

9

WARNING

Personal protection

equipment including

hard hat, safety glasses,

safety shoes, and gloves

are recommended during

assembly, installation,

operation, maintenance,

service, removal, or

movement of the earth

auger. Do not allow long

hair, loose fitting

clothing, or jewelry to be

around moving and/or

rotating parts.

= Safety Sign

Location

STEP 1:

STEP 2:

Bolt cradle assembly (2) to quick attach plate assembly (1) using bolts (3), and

secure with nuts (4). Nuts (4) must be torqued to 105 ft.-lbs.

After removing bucket or other attachment from vehicle, secure quick attach plate

assembly (1) to vehicle per vehicle manufacturer’s recommendations.

3

5

6

12

7

8

2

11

REF. NO. PART NO. DESCRIPTION QTY.

1 10488 Quick Attach Plate Assembly

(includes REF. NOS. 1-5 and 9-10)

2 10965 Cradle Assembly 1

3 10975 Bolt (1/2"

4 6196 Nut (1/2"

5 10198 Knuckle Assembly 1

6 ----- Drive Unit 1

7 10193 Pin (1-1/4" x 9-1/2") 1

8 20012 Lock Pin 1

9 9598 Pin (1-1/4" x 7-1/8") 1

10 1600 Klik Pin 2

11 10038 Special Retaining Bolt - 2" Hex

(3/4"

10039 Special Retaining Bolt - 2-9/16" Rd.

(7/8"

12 10041 Nut (3/4"

10042 Nut (7/8"

13 x 1-3/4", Gr. 8) 4

13) 4

10 x 4", Gr. 8, 3/4" of thread)

9 x 4-1/4", Gr. 8, 3/4" of thread)

10) - 2" Hex 1

9) - 2-9/16" Round

1

1

CAUTION

Because of the weight of

some components, and

because some

components are difficult

to balance, two people

are required for safe

assembly and installation

of this equipment.

STEP 3:

STEP 4:

WARNING

The earth auger must be securely latched to the vehicle.

Ensure both locking handles are in the locked position with

pins fully seated. An improperly latched earth auger can

fall without warning.

Attach knuckle assembly (5) to the drive unit (6) using pin (7). Secure pin (7)

with lock pin (8).

Attach knuckle assembly/drive unit to the quick attach plate assembly (1) using

pin (9). Secure pin (9) with klik pins (10).

Proceed to STEP 5 on page 18.

11

Assembly &

Installation

Offset Skid-Steer Mount

Drive unit and auger

exploded views and part lists

are detailed on separate pages

1

in this manual.

7

6

3

2

WARNING

Personal protection

equipment including

hard hat, safety glasses,

safety shoes, and gloves

are recommended during

assembly, installation,

operation, maintenance,

service, removal, or

movement of the earth

auger. Do not allow long

hair, loose fitting

clothing, or jewelry to be

around moving and/or

rotating parts.

= Safety Sign

Location

STEP 1:

5

4

9

8

REF. NO. PART NO. DESCRIPTION QTY.

1 20652 Offset Quick Attach Plate Assembly

(includes REF. NOS. 1-2 and 6-7)

2 10198 Knuckle Assembly 1

3 ----- Drive Unit 1

4 10193 Pin (1-1/4" x 9-1/2") 1

5 20012 Lock Pin 1

6 9598 Pin (1-1/4" x 7-1/8") 1

7 1600 Klik Pin 2

8 10038 Special Retaining Bolt - 2" Hex

(3/4"

10 x 4", Gr. 8, 3/4" of thread)

10039 Special Retaining Bolt - 2-9/16" Rd.

(7/8"

9 x 4-1/4", Gr. 8, 3/4" of thread)

9 10041 Nut (3/4"

10042 Nut (7/8"

After removing bucket or other attachment from vehicle, secure quick attach plate

assembly (1) to vehicle per vehicle manufacturer’s recommendations.

10) - 2" Hex 1

9) - 2-9/16" Round

1

1

WARNING

CAUTION

Because of the weight of

some components, and

because some

components are difficult

to balance, two people

are required for safe

assembly and installation

of this equipment.

12

STEP 2:

STEP 3:

The earth auger must be securely latched to the vehicle.

Ensure both locking handles are in the locked position with

pins fully seated. An improperly latched earth auger can

fall without warning.

Attach knuckle assembly (2) to the drive unit (3) using pin (4). Secure pin (4) with

lock pin (5).

Attach knuckle assembly/drive unit to the quick attach plate assembly (1) using

pin (6). Secure pin (6) with klik pins (7).

Proceed to STEP 5 on page 18.

Assembly &

WARNING

Installation

Offset Euro Mount

= Safety Sign

Location

Drive unit and auger

exploded views and part lists

are detailed on separate pages

1

in this manual.

7

6

3

2

9

5

4

8

Personal protection

equipment including

hard hat, safety glasses,

safety shoes, and gloves

are recommended during

assembly, installation,

operation, maintenance,

service, removal, or

movement of the earth

auger. Do not allow long

hair, loose fitting

clothing, or jewelry to be

around moving and/or

rotating parts.

STEP 1:

REF. NO. PART NO. DESCRIPTION QTY.

1 20653 Offset Euro Mount Assembly

(includes REF. NOS. 1-2 and 6-7)

2 10198 Knuckle Assembly 1

3 ----- Drive Unit 1

4 10193 Pin (1-1/4" x 9-1/2") 1

5 20012 Lock Pin 1

6 9598 Pin (1-1/4" x 7-1/8") 1

7 1600 Klik Pin 2

8 10038 Special Retaining Bolt - 2" Hex

(3/4"

10 x 4", Gr. 8, 3/4" of thread)

10039 Special Retaining Bolt - 2-9/16" Rd.

(7/8"

9 x 4-1/4", Gr. 8, 3/4" of thread)

9 10041 Nut (3/4"

10042 Nut (7/8"

After removing bucket or other attachment from vehicle, secure quick attach plate

assembly (1) to vehicle per vehicle manufacturer’s recommendations.

10) - 2" Hex 1

9) - 2-9/16" Round

1

1

WARNING

CAUTION

Because of the weight of

some components, and

because some

components are difficult

to balance, two people

are required for safe

assembly and installation

of this equipment.

STEP 2:

STEP 3:

The earth auger must be securely latched to the vehicle.

Ensure both locking pins are fully seated. An improperly

latched earth auger can fall without warning.

Attach knuckle assembly (2) to the drive unit (3) using pin (4). Secure pin (4) with

lock pin (5).

Attach knuckle assembly/drive unit to the quick attach plate assembly (1) using

pin (6). Secure pin (6) with klik pins (7).

Proceed to STEP 5 on page 18.

13

Assembly &

Installation

John Deere

200/300/400/500

Series Mount

1

Drive unit and auger

exploded views and part lists

are detailed on separate pages

in this manual.

7

6

WARNING

Personal protection

equipment including

hard hat, safety glasses,

safety shoes, and gloves

are recommended during

assembly, installation,

operation, maintenance,

service, removal, or

movement of the earth

auger. Do not allow long

hair, loose fitting

clothing, or jewelry to be

around moving and/or

rotating parts.

= Safety Sign

Location

STEP 1:

2

3

5

9

4

8

REF. NO. PART NO. DESCRIPTION QTY.

1 20659 John Deere 200/300/400/500 Series

Offset Mount Assembly

(includes REF. NOS. 1-2 and 6-7)

2 10198 Knuckle Assembly 1

3 ----- Drive Unit 1

4 10193 Pin (1-1/4" x 9-1/2") 1

5 20012 Lock Pin 1

6 9598 Pin (1-1/4" x 7-1/8") 1

7 1600 Klik Pin 2

8 10038 Special Retaining Bolt - 2" Hex

(3/4"

10 x 4", Gr. 8, 3/4" of thread)

10039 Special Retaining Bolt - 2-9/16" Rd.

(7/8"

9 x 4-1/4", Gr. 8, 3/4" of thread)

9 10041 Nut (3/4"

10042 Nut (7/8"

After removing bucket or other attachment from vehicle, secure quick attach plate

assembly (1) to vehicle per vehicle manufacturer’s recommendations.

10) - 2" Hex 1

9) - 2-9/16" Round

1

1

CAUTION

Because of the weight of

some components, and

because some

components are difficult

to balance, two people

are required for safe

assembly and installation

of this equipment.

14

STEP 2:

STEP 3:

WARNING

The earth auger must be securely latched to the vehicle.

Ensure both locking pins are fully seated. An improperly

latched earth auger can fall without warning.

Attach knuckle assembly (2) to the drive unit (3) using pin (4). Secure pin (4) with

lock pin (5).

Attach knuckle assembly/drive unit to the quick attach plate assembly (1) using

pin (6). Secure pin (6) with klik pins (7).

Proceed to STEP 5 on page 18.

Assembly &

Installation

Mini-Excavator Mount

Drive unit and auger

exploded views and part lists

are detailed on separate pages

in this manual.

5

7

REF. NO. PART NO. DESCRIPTION QTY.

1 ----- Drive Unit 1

2 10219 Knuckle Sub-Assembly 1

3 10193 Pin (1-1/4" x 9-1/2") 1

4 20012 Lock Pin 1

5 ----- Ear Assembly 2

6 10220 U-Bolt (1/2"

7 6196 Nut (1/2"

8 10038 Special Retaining Bolt - 2" Hex

(3/4"

10 x 4", Gr. 8, 3/4" of thread)

10039 Special Retaining Bolt - 2-9/16" Rd.

(7/8"

9 x 4-1/4", Gr. 8, 3/4" of thread)

9 10041 Nut (3/4"

10042 Nut (7/8"

13 x 3-3/4") 4

13) 8

1

10) - 2" Hex 1

9) - 2-9/16" Round

= Safety Sign

Location

2

6

4

1

3

WARNING

Personal protection

equipment including

hard hat, safety glasses,

safety shoes, and gloves

are recommended during

assembly, installation,

operation, maintenance,

service, removal, or

movement of the earth

auger. Do not allow long

hair, loose fitting

clothing, or jewelry to be

around moving and/or

rotating parts.

CAUTION

Because of the weight of

some components, and

because some

components are difficult

to balance, two people

are required for safe

assembly and installation

of this equipment.

STEP 1:

STEP 2:

STEP 3:

STEP 4:

9

8

Attach drive unit (1) to the knuckle sub-assembly (2) using pin (3). Secure pin

(3) with lock pin (4).

Remove bucket from dipperstick, and curl cylinder pin connections. The

dipperstick pin will be used to attach the knuckle assembly to the dipperstick.

The curl cylinder pin will not be required for drive unit installation.

Space the two ear assemblies (5) to the width of the dipperstick, and secure

them to the knuckle sub-assembly (2) using u-bolts (6) and nuts (7). The ear

assemblies should be spaced evenly from the center of the knuckle

sub-assembly and the safety signs should be facing out. Nuts (7) must be

torqued to 75 ft.-lbs. Nuts (7) should be checked and re-torqued after the first

hour of use.

Attach knuckle assembly/drive unit to the dipperstick using the dipperstick pin

removed from the bucket in STEP 2. Secure the bucket pin per vehicle

manufacturer’s recommendations.

Proceed to STEP 5 on page 18.

15

Assembly &

Installation

TLB & Excavator Mount

REF. NO. PART NO. DESCRIPTION QTY.

Drive unit and auger

exploded views and part lists

are detailed on separate pages

in this manual.

7

5

1 ----- Drive Unit 1

2 10247 Knuckle Sub-Assembly 1

3 10193 Pin (1-1/4" x 9-1/2") 1

4 20012 Lock Pin 1

5 ----- Ear Assembly 2

6 10242 Tube-Clamp 2

7 10243 Bolt (5/8"

8 3092 Nut (5/8"

9 10038 Special Retaining Bolt - 2" Hex

(3/4"

10039 Special Retaining Bolt - 2-9/16" Rd.

(7/8"

10 10041 Nut (3/4"

10042 Nut (7/8"

11 x 2", Gr. 5) 4

11) 4

10 x 4", Gr. 8, 3/4" of thread)

9 x 4-1/4", Gr. 8, 3/4" of thread)

10) - 2" Hex 1

9) - 2-9/16" Round

= Safety Sign

Location

WARNING

Personal protection

equipment including

hard hat, safety glasses,

safety shoes, and gloves

are recommended during

assembly, installation,

operation, maintenance,

service, removal, or

movement of the earth

auger. Do not allow long

hair, loose fitting

clothing, or jewelry to be

around moving and/or

rotating parts.

STEP 1:

STEP 2:

Attach drive unit (1) to the knuckle sub-assembly (2) using pin (3). Secure pin

(3) with lock pin (4).

Remove bucket from dipperstick, and curl cylinder pin connections. The

dipperstick pin will be used to attach the knuckle assembly to the dipperstick.

The curl cylinder pin will not be required for drive unit installation.

2

6

8

1

1

4

3

9

10

STEP 3:

CAUTION

Because of the weight of

some components, and

because some

components are difficult

to balance, two people

are required for safe

assembly and installation

of this equipment.

16

STEP 4:

Space the two ear assemblies (5) to the width of the dipperstick, and secure

them to the knuckle sub-assembly (2) using tube-clamps (6), bolts (7), and nuts

(8). The ear assemblies should be spaced evenly from the center of the

knuckle sub-assembly and the safety signs should be facing out. Nuts (8)

must be torqued to 50 ft.-lbs. Nuts (8) should be checked and re-torqued after

the first hour of use.

Attach knuckle assembly/drive unit to the dipperstick using the dipperstick pin

removed from the bucket in STEP 2. Secure the bucket pin per vehicle

manufacturer’s recommendations.

Proceed to STEP 5 on page 18.

Assembly &

Installation

Bolt-on Bucket Mount

Drive unit and auger

exploded views and part lists

are detailed on separate pages

in this manual.

6

7

5

4

10

WARNING

Personal protection

equipment including

hard hat, safety glasses,

safety shoes, and gloves

are recommended during

assembly, installation,

operation, maintenance,

service, removal, or

movement of the earth

auger. Do not allow long

hair, loose fitting

clothing, or jewelry to be

around moving and/or

rotating parts.

CAUTION

Because of the weight of

some components, and

because some

components are difficult

to balance, two people

are required for safe

assembly and installation

of this equipment.

1

2

9

8

3

STEP 1:

STEP 2:

STEP 3:

STEP 4:

= Safety Sign

Location

REF. NO. PART NO. DESCRIPTION QTY.

1 9591B Bucket Mount Assembly 1

2 10976 Knuckle Assembly 1

3 ----- Drive Unit 1

4 10193 Pin (1-1/4" x 9-1/2") 1

5 20012 Lock Pin 1

6 9595 Pin (1-1/4" x 6") 1

7 3041 Bolt (3/8"

8 2805 Self-locking Nut (3/8"

9 10038 Special Retaining Bolt - 2" Hex

(3/4"

10039 Special Retaining Bolt - 2-9/16" Rd.

(7/8"

10 10041 Nut (3/4"

10042 Nut (7/8"

Consideration must be given to the installation location of the bolt-on bucket

mount kit. The drive unit should be able to swing during normal operation without interference from the bucket. The bucket must be constructed with sufficient

strength to safely handle the loads generated during drilling. Position the drive

unit to allow space for the hydraulic hose connections and routing of hoses.

Drill four holes in the loader bucket to accommodate bucket mount assembly (1).

Bolt bucket mount assembly (1) to the left or right outside vertical surface of the

bucket. (See figure above.) Hardware to attach the mount assembly is not

included in the kit. You will need the following:

4 bolts (1/2" diameter, Grade 5 or greater)

4 lock washers (1/2")

4 nuts (1/2")

Attach knuckle assembly (2) to the drive unit (3) using pin (4). Secure pin (4)

with lock pin (5).

Attach knuckle assembly/drive unit to mount assembly (1) using pin (6). Secure

pin (6) with bolt (7) and nut (8).

16 x 3-1/2", Gr. 8) 1

16) 1

1

10 x 4", Gr. 8, 3/4" of thread)

9 x 4-1/4", Gr. 8, 3/4" of thread)

10) - 2" Hex 1

9) - 2-9/16" Round

17

Assembly &

Installation

(continued)

STEP 5:

Grease the inside of the auger collar liberally and attach the auger with the

retaining bolt and nut that came attached to the drive unit spindle. This is a

special thread length bolt - use genuine Danuser replacement parts only. For

hex spindle, use Danuser PN 10038 (3/4"

retaining bolt and nut PN 10041. NEVER use a bolt longer than 4". For round

spindle, use Danuser PN 10039 (7/8" 9 x 4-1/4", Gr. 8, 3/4" of thread)

special retaining bolt and nut PN 10042. NEVER use a bolt longer

than 4-1/4".

10 x 4", Gr. 8, 3/4" of thread) special

WARNING

Keep hands, feet, hair,

jewelry, and clothing

away from all moving

and/or rotating parts.

STEP 6:

STEP 7:

STEP 8:

Each time an auger or extension is attached to the drive unit, the inside of the

collar should be coated liberally with grease.

The hydraulic fittings on the top of the drive unit are #10 JIC male. Install 1/2"

Danuser Hose Kit if your unit delivers less than 20 GPM. Install 3/4" Danuser

Hose Kit if your unit delivers 20 GPM or more. Danuser Hose Kits include

abrasion sleeves. Since the motor is reversible, hose connections to motor fittings

are interchangeable.

The hydraulic hoses should be equipped with a 45-degree fitting on the drive unit

end.

All hoses and fittings used to connect the earth auger should be thoroughly

cleaned before use. Care should be taken to see that no thread sealer or metal

chips are forced to the inside of the joints when connections are being tightened.

If you did not purchase quick couplers with your unit, you must obtain and install

the proper hydraulic quick couplers for your particular vehicle.

Fittings must be compatible with the fittings on your vehicle. Be sure the threads

match on the hydraulic quick couplers you are using.

After you have tightened the drive unit connections, run the hoses through the

hose holder on the quick attach plate and plug them into your auxiliary hydraulic

outlets.

18

STEP 9:

STEP 10:

WARNING

Before connecting or disconnecting hydraulic lines or

fittings, be sure to relieve all pressure by cycling all

hydraulic controls after shutdown. Remember hydraulic

systems are under pressure whenever the engine is

running and may hold pressure after shutdown.

Test the vehicle to make sure you have enough hose length to perform the full

range of the loader arms’ operating heights.

Hose routing is the responsibility of the operator. Pinched and/or stretched hoses

are not covered under the warranty.

Check the hydraulic system for leaks.

WARNING

Never check pressurized system for leaks with your bare

hand. Wear proper hand and eye protection and use wood

or cardboard when searching for suspected leaks. Oil

escaping from pinhole leaks under pressure can penetrate

skin and create a serious medical emergency. If any fluid

is injected into the skin, gangrene, blood poisoning, even

death may result. Obtain medical attention immediately.

Operation

DANGER

This earth auger is

designed for one-man

operation from the

vehicle seat. It is the

responsibility of the

operator to see that no

one is within twenty-five

feet (25') of the earth

auger when it is started

or in use. Do not operate

the earth auger with

another person near or

in contact with any part

of the drive unit or auger.

Serious personal injury

or death may result if any

attempt is made to assist

drilling operation by

hand.

DANGER

Contact with underground gas lines or electrical cables may

result in serious injury or death from explosion or electrical

shock. Before operating, call 811 or the local number to

locate underground utilities. Do not dig near underground

utility lines.

WARNING

Differences in diameter and length of auger when combined

with various heights of loader arms can allow the auger to

come into contact with skid-steer or operator when earth

auger is outside of cradle.

Before operating, check clearances between skid-steer and

auger, as well as operator and auger, across the full range

of loader arms’ operating heights.

WARNING

Keep earth auger in cradle when not drilling. To reduce the

risk of personal injury, never transport with the drive unit

out of the cradle or while the auger is rotating.

WARNING

Personal protection

equipment including

hard hat, safety glasses,

safety shoes, and gloves

are recommended during

assembly, installation,

operation, maintenance,

service, removal, or

movement of the earth

auger. Do not allow long

hair, loose fitting

clothing, or jewelry to be

around moving and/or

rotating parts.

WARNING

Safe operation of

equipment requires the

operator's full attention.

Avoid distractions such

as radio headphones,

cell phones, etc. while

operating.

DANGER

STEP 1:

STEP 2:

STEP 3:

STEP 4:

STEP 5:

WARNING

Before you operate the earth auger, check over all pins,

bolts, and connections to be sure all are securely in place.

Make sure the earth auger is securely latched to the vehicle.

Contact local utility companies to make certain there are no buried gas lines,

electrical cables, etc., in the work area. Clear area of objects that could wrap

around the auger or might be thrown. Check for ditches, stumps, holes, or other

obstacles that could cause the vehicle to roll.

Layout and mark where you want to drill your holes.

Lower the auger point slowly to the ground with the auger not powered.

Skid-steer mounted earth augers should not come in contact with the cradle during

drilling maneuvers. Drill with the quick attach plate in the horizontal position.

With the auger point lowered to the ground and before engaging the auger, move

the vehicle slowly left, right, forward, or backward as needed until the auger

appears vertical to the ground.

Actuate the hydraulics to start the auger’s rotation in the clockwise direction and

increase the speed as required so dirt is conveyed from the hole.

The hydraulic actuation lever connected to the earth auger will have three

positions: clockwise rotation, stop (neutral), and counter-clockwise rotation. The

clockwise and counter-clockwise positions may be changed by switching the hose

connections.

Do not allow riders on the

equipment at any time.

There is no safe place for

any riders.

DANGER

Never position the auger point by hand or with any tool

when the vehicle is running. Never position the auger point

by putting your hands on the auger or the drive unit.

19

Operation

(continued)

STEP 6:

The hydraulic flow rate or pressure should not exceed the earth auger’s specified

maximums. The hydraulic minimums must be met to deliver satisfactory

performance. Use only enough down pressure to assure positive penetration of

the auger into the ground. Ease up on down pressure if auger rotation slows

down drastically or stalls. Excessive down pressure will cause the auger to

frequently stall. See Hydraulic Requirements section for filtration, pressure, and

flow rate specifications.

If you have difficulty penetrating hard ground, refer to the Troubleshooting

section.

DANGER

To prevent injury, keep

an area of at least

twenty-five feet (25’)

around the auger clear of

bystanders and all other

people.

DANGER

Do not shovel dirt away

from a rotating auger, as

the shovel can be caught

and thrown by the auger.

STEP 7:

STEP 8:

STEP 9:

STEP 10:

STEP 11:

When the auger has been lowered about 24 inches into the ground, raise the auger

almost out of the hole to clear the dirt, then drill deeper and raise the auger again.

Repeat this procedure until the desired hole depth is reached.

The earth auger should be raised and lowered by changing the elevation and not

the tilt of the quick attach plate.

When the auger has reached the full depth required, allow the auger to dwell

momentarily at this depth at a slower speed to assist in cleaning out the hole.

Deactivate the earth auger, and raise it from the hole.

For “heavy” soil conditions, allow the auger to turn at slow speed while raising it

to the top of the hole.

Move away from the hole, then remove loose dirt from the auger by momentarily

actuating the earth auger and spinning it at a faster speed than used for drilling.

If necessary, repeat STEPS 8 and 9 to obtain a cleaner hole.

In some soil conditions, or when excessive down pressure is applied, the auger

may screw itself into the ground and become stuck, causing the earth auger to

stall. Do not attempt to pull the auger out of the ground. Instead, reverse the

auger rotation (counter-clockwise), and slowly raise the auger. Once unstuck,

continue operation.

If the auger becomes lodged under rocks, roots, or other large obstructions, do not

attempt to pull the auger out of the ground. If this happens, reverse the auger

rotation (counter-clockwise), and slowly raise the auger. Once unstuck, continue

operation.

WARNING

Replace a broken,

damaged, or missing

auger retaining bolt

ONLY with an authorized

factory replacement. An

auger retaining bolt that

is too long increases the

possibility of personal

injury. The auger

retaining bolt must be of

the proper size and grade

to function properly.

STEP 12:

20

Since the earth auger uses a Grade 8 retaining bolt, all vehicles must be protected

with relief valves or some other means of protection against excessive pressures.

Failure of the retaining bolt is a possible indication of excessive pressure.

Replacement of the retaining bolt should be as follows:

a) Shut off the vehicle engine, and remove the vehicle key.

b) Install a new Danuser retaining bolt. This is a special thread length bolt -

use genuine Danuser replacement parts only. For hex spindle, use Danuser

PN 10038 (3/4"

PN 10041. NEVER use a bolt longer than 4". For round spindle, use

Danuser PN 10039 (7/8"

bolt and nut PN 10042. NEVER use a bolt longer than 4-1/4".

c) Tighten the retaining bolt and nut securely.

Deactivate the auger and place the drive unit in the cradle when moving between

holes.

Frequently check the condition of the auger teeth and point, and replace them

when wear is detected. Always keep spare parts on hand for replacements to

avoid damage to the auger head and auger flighting.

10 x 4", Gr. 8, 3/4" of thread) special retaining bolt and nut

9 x 4-1/4", Gr. 8, 3/4" of thread) special retaining

Removal &

Storage

Before storage, the earth auger should be thoroughly cleaned, washing off all dirt and grime.

Make sure the hydraulic system is properly sealed against contaminants entering the unit.

Always store the earth auger in a dry, covered location.

DANGER

Never allow anyone under

the attachment at any

time.

WARNING

Personal protection

equipment including

hard hat, safety glasses,

safety shoes, and gloves

are recommended during

assembly, installation,

operation, maintenance,

service, removal, or

movement of the earth

auger. Do not allow long

hair, loose fitting

clothing, or jewelry to be

around moving and/or

rotating parts.

STEP 1:

STEP 2:

STEP 3:

STEP 4:

STEP 5:

/RZHUWKHHDUWKDXJHURQWRDÀDWOHYHOVXUIDFHLQDQDUHDZKHUHFKLOGUHQGRQRW

play.

Disconnect the hydraulic hoses from the vehicle's auxiliary hydraulics.

WARNING

Before disconnecting hydraulic lines or fittings, be sure

to relieve all pressure by cycling all hydraulic controls

after shutdown. Remember hydraulic systems are under

pressure whenever the engine is running and may hold

pressure after shutdown.

Connect the quick couplers together to prevent contaminants from entering the

earth auger's hydraulic system.

Follow your vehicle operator's manual for removing an attachment. Securely

block and support the attachment.

Tighten any loose nuts, bolts, and hydraulic components.

Replace any damaged or missing safety signs.

CAUTION

Because of the weight of

some components, and

because some

components are difficult

to balance, two people

are required for safe

assembly and installation

of this equipment.

21

Troubleshooting

Problem Possible Cause Solution

/RZÀRZ

Fittings or connections are too small or

incompatible

Slow speed

Auger will not drill

Lacks drilling power Low system pressure (PSI)

Oil leaks

Line restrictions Clear lines

'LUW\RLORURLO¿OWHU

Hydraulic pump worn or damaged See your dealer for repairs

Worn teeth or point Replace with new ones

Ground too hard and dry Order hardfaced or carbide teeth and point

Fittings loose or damaged 7LJKWHQRUUHSODFH¿WWLQJV

Hoses loose or damaged Tighten or replace hoses

Hydraulic motor seals worn or damaged See your dealer for repairs

&KHFNZLWKÀRZPHWHUDQGLIORZ

investigate the cause

5HSODFHZLWKSURSHU¿WWLQJV

&KDQJHRLODQGRLO¿OWHUDFFRUGLQJWRYHKLFOH

manufacturer's recommendation

Check with pressure gauge, and if low,

investigate the cause

Oil over heating

Hydraulic hose failure

Low quantity of hydraulic oil

Improper oil Replace with proper oil

'LUW\RLORURLO¿OWHU

Fittings loose or damaged 7LJKWHQRUUHSODFH¿WWLQJV

Hoses loose or damaged Tighten or replace hoses

Improper hose size

Hydraulic relief pressure setting too high

Hoses worn and damaged Replace hoses

Hose rating too low for hydraulic system

pressure

Hoses pinched Reroute hoses

For additional assistance, please call your dealer or contact Danuser direct:

Fill reservoir to proper level and/or

increase reservoir storage capacity

&KDQJHRLODQGRLO¿OWHUDFFRUGLQJWRYHKLFOH

manufacturer's recommendation

Check hose diameter and length requirements

Adjust vehicle hydraulic relief pressure

VHWWLQJWRZLWKLQGULYHXQLWVSHFL¿FDWLRQV

Replace with hoses with working pressure

rated higher than vehicle hydraulic pressure

22

Tel: (573) 642-2246

Fax: (573) 642-2240

E-mail: sales@danuser.com

Maintenance &

Lubrication

Proper servicing and maintenance are key to the long life of any attachment. Careful

inspection and routine maintenance helps avoid costly downtime and repair. Do not use the

earth auger with any damaged parts.

WARNING

DANGER

Never allow anyone under

the attachment at any

time.

WARNING

Personal protection

equipment including

hard hat, safety glasses,

safety shoes, and gloves

are recommended during

assembly, installation,

operation, maintenance,

service, removal, or

movement of the earth

auger. Do not allow long

hair, loose fitting

clothing, or jewelry to be

around moving and/or

rotating parts.

30

OIL LEVEL

Never check pressurized system for leaks with your bare

hand. Wear proper hand and eye protection and use wood

or cardboard when searching for suspected leaks. Oil

escaping from pinhole leaks under pressure can penetrate

skin and create a serious medical emergency. If any fluid is

injected into the skin, gangrene, blood poisoning, even

death may result. Obtain medical attention immediately.

WARNING

Do not modify the attachment. Modifications may weaken

the integrity of the attachment and may impair the safety,

function, life, and performance of the earth auger.

CAUTION

When making repairs or servicing the earth auger, use

only parts that meet original equipment manufacturer's

standards and requirements.

Maintenance Interval

Inspect the attachment for any damage, worn parts, or

cracked welds. Repair or replace as necessary.

Check for damaged or missing safety signs. Replace as

necessary.

Coat the inside diameter of the auger or extension collar

with grease.

Check all fasteners. Ensure they are tight and secure.

(See Torque Values Chart.) Replace as necessary.

Check all hydraulic components for leaks or wear.

Repair or replace as necessary.

Check planetary gear oil level to assure proper

lubrication is maintained. Check by removing the front

¿OOSOXJZLWKWKHGULYHXQLWDQJOHGDSSUR[LPDWHO\

degrees from vertical.

Check for clean hydraulic oil. At all times, keep dirt and

other contaminants from entering the hydraulic

system during connecting and disconnecting the

hydraulic system. Always use dust caps and plugs on all

quick disconnects when not in use.

&KDQJHSODQHWDU\JHDUUHGXFWLRQRLODIWHU¿UVWKRXUV

of operation or 6 months, then every 2000 hours or 12

PRQWKVZKLFKHYHUFRPHV¿UVW8VHKHDY\GXW\H[WUHPH

SUHVVXUHOXEULFDQW$3,*/:IRU¿OOLQJWKH

planetary gear reduction. Approximate oil capacity is

.90 quarts (.85 liters).

Before each use

Before each use

Each time an auger or extension

is attached

Daily

Daily

Daily

Daily

After 1st 500 hours, then every

2000 hours or yearly

23

Torque Values

Chart

%ROW+HDG,GHQWL¿FDWLRQ

Torque Values Chart

%ROW+HDG,GHQWL¿FDWLRQ

Bolt Size

(inches)

in

tpi

1/4”

20

1/4”

28

5/16”

18

5/16”

24

3/8”

16

3/8”

24

7/16”

14

7/16”

20

1/2”

13

1/2”

20

9/16”

12

9/16”

18

5/8”

11

5/8”

18

3/4”

10

3/4”

16

7/8”

9

7/8”

14

1”

8

1”

12

1-1/8”

1-1/8”

1-1/4”

1-1/4”

1-3/8”

1-3/8”

1-1/2”

1-1/2”

7RUTXHWROHUDQFHRIWRUTXHYDOXHV8QOHVVRWKHUZLVHVSHFL¿HGXVHWRUTXHYDOXHVOLVWHGDERYH

7

12

7

12

6

12

6

12

Grade 2

Nm ft.-lbs. Nm ft.-lbs. Nm ft.-lbs. mm x pitch Nm ft.-lbs. Nm ft.-lbs. Nm ft.-lbs.

7.4 5.6 11 8 16 12

8.5 613101814

15 11 24 17 33 25

17 13 26 19 37 27

27 20 42 31 59 44

31 22 47 35 67 49

43 32 67 49 95 70

49 36 75 55 105 78

66 49 105 76 145 105

75 55 115 85 165 120

95 70 150 110 210 155

105 79 165 120 235 170

130 97 205 150 285 210

150 110 230 170 325 240

235 170 360 265 510 375

260 190 405 295 570 420

225 165 585 430 820 605

250 185 640 475 905 670

340 250 875 645 1230 910

370 275 955 705 1350 995

480 355 1080 795 1750 1290

540 395 1210 890 1960 1440

680 500 1520 1120 2460 1820

750 555 1680 1240 2730 2010

890 655 1990 1470 3230 2380

1010 745 2270 1670 3680 2710

1180 870 2640 1950 4290 3160

1330 980 2970 2190 4820 3560

Grade 5

Grade 8

Bolt Size

(Metric)

M5 x 0.8

M6 x 1

M8 x 1.25

M8 x 1

M10 x 1.5

M10 x 0.75

M12 x 1.75

M12 x 1.5

M12 x 1

M14 x 2

M14 x 1.5

M16 x 2

M16 x 1.5

M18 x 2.5

M18 x 1.5

M20 x 2.5

M20 x 1.5

M24 x 3

M24 x 2

M30 x 3.5

M30 x 2

M36 x 3.5

M36 x 2

in

tpi = nominal thread diameter in inches threads per inch

Nm = Newton-meter

ft.-lbs. = foot pounds

mm x pitch = nominal thread diameter in millimeters by thread pitch

5.8 8.8

Class 5.8

436597

751181511

17 12 26 19 36 27

18 13 28 21 39 29

33 24 52 39 72 53

39 29 61 45 85 62

58 42 91 67 125 93

60 44 95 70 130 97

90 66 105 77 145 105

92 68 145 105 200 150

99 73 155 115 215 160

145 105 225 165 315 230

155 115 240 180 335 245

195 145 310 230 405 300

220 165 350 260 485 355

280 205 440 325 610 450

310 230 650 480 900 665

480 355 760 560 1050 780

525 390 830 610 1150 845

960 705 1510 1120 2100 1550

1060 785 1680 1240 2320 1710

1730 1270 2650 1950 3660 2700

1880 1380 2960 2190 4100 3220

10.9

Class 8.8 Class 10.9

KEY:

24

Drive Unit

Parts

= Safety Sign

Location

1

15

13

5

14

2

3

4

7

6

8

9

16

10

12

17

REF. NO. PART NO. DESCRIPTION QTY. MODELS

1 10180 (H) 20180 (R) Drive Unit 1 EP6 Hex or Rd.

10181 (H) 20181 (R) Drive Unit 1 EP10 Hex or Rd.

10182 (H) 20182 (R) Drive Unit 1 EP15 Hex or Rd.

20001 (H) 20184 (R) Drive Unit 1 EP20 Hex or Rd.

2 10197 Nut (7/16"

3 20186 Housing Assembly 1 EP6, EP10, EP15, EP20

4 20190 Hose Assembly 2 EP6, EP10, EP15, EP20

5 20034 #10 O-ring #8 JIC Elbow 2 EP6, EP10, EP15, EP20

6 10184 Hydraulic Motor 1 EP6

10185 Hydraulic Motor 1 EP10

10186 Hydraulic Motor 1 EP15

10964 Hydraulic Motor 1 EP20

7 10482 Socket Head Bolt (M12 x 1.75 x 35mm) 4 EP6, EP10, EP15, EP20

8 10979 O-ring 1 EP6, EP10, EP15, EP20

9 10183 Planetary Gear Reduction 1 EP6, EP10, EP15, EP20 Hex

20183 Planetary Gear Reduction 1 EP6, EP10, EP15, EP20 Rd.

10 10196 Socket Head Bolt (7/16"

11 10038 Special Retaining Bolt - 2" Hex

(3/4"

10039 Special Retaining Bolt - 2-9/16" Rd.

(7/8"

12 10041 Nut (3/4"

10042 Nut (7/8"

13 20191 Nut (7/8"

14 10193 Pin (1-1/4" x 9-1/2") 1 EP6, EP10, EP15, EP20

15 20012 Lock Pin 1 EP6, EP10, EP15, EP20

16 10980 Output Seal 1 EP6, EP10, EP15, EP20

17 10996 Output Spindle - 2" Hex 1 EP6, EP10, EP15, EP20 Hex

10997 Output Spindle - 2-9/16" Round EP6, EP10, EP15, EP20 Rd.

14) 8 EP6, EP10, EP15, EP20

14 x 2") 8 EP6, EP10, EP15, EP20

1 EP6, EP10, EP15, EP20 Hex

10 x 4", Gr. 8, 3/4" of thread)

EP6, EP10, EP15, EP20 Rd.

9 x 4-1/4", Gr. 8, 3/4" of thread)

10) - 2" Hex 1 EP6, EP10, EP15, EP20 Hex

9) - 2-9/16" Round EP6, EP10, EP15, EP20 Rd.

14) 2 EP6, EP10, EP15, EP20

11

25

Augers &

Accessories

= Safety Sign

Location

AUGER COLLAR

DESCRIPTION PART NO.

2Ǝ Hex 10328

2-9/16Ǝ Rd. 10329

DRIVE

UNIT

2Ǝ Hex to 2-9/16Ǝ Rd. 10921

2Ǝ Hex to 2Ǝ5G 10922

2-9/16Ǝ Rd. to 2Ǝ Hex 10923

2-9/16Ǝ Rd. to 2Ǝ5G 10924

2Ǝ Hex to 2-9/16Ǝ Rd. *20211

2-9/16Ǝ Rd. to 2-9/16Ǝ Rd. *20212

2Ǝ Hex to 2Ǝ5G *20214

2-9/16Ǝ Rd. to 2Ǝ5G *20215

AUGER ADAPTERS

AUGER

COLLAR

PART

NO.

*Allows attachment of augers with 1/2" diameter bolt.

VARIABLE LENGTH EXTENSIONS

LENGTH

12Ǝ ---- 10903

24Ǝ 10900 10904

48Ǝ 10901 10905

72Ǝ 10902 10906

2Ǝ HEX 2-9/16Ǝ RD.

FIXED LENGTH EXTENSIONS

LENGTH

2Ǝ HEX 2-9/16Ǝ RD.

26

12Ǝ 10910 10914

24Ǝ 10911 10915

48Ǝ 10912 10916

72Ǝ 10913 10917

Augers &

Accessories

"FAB" AUGERS - 4ƍ LENGTH

DIA.

NO. OF

TEETH

2Ǝ

HEX

2-9/16Ǝ

RD.

(continued)

FISHTAIL POINT

Dirt 10331

Hardfaced 10332

Chunky Carbide 10335

Nut 10412

Bolt 10413

4Ǝ diameter auger below

Dirt 10333

Hardfaced 10334

Chunky Carbide 10336

Nut 10412

Bolt 10416

TEETH BOLT & NUT

Carriage Bolt 10410

Nut 10411

4Ǝ 0 10600 10601

6Ǝ 2 10603 10604

8Ǝ 2 10606 10607

9Ǝ 3 10609 10610

10Ǝ 3 10612 10613

12Ǝ 4 10615 10616

15Ǝ 5 10618 10619

16Ǝ 5 10621 10622

18Ǝ 6 10624 10625

20Ǝ 6 10627 10628

24Ǝ 8 10630 10631

30Ǝ 9 10633 10634

36Ǝ 11 10636 10637

Please call Danuser for 3ƍ, 5ƍ, or 6ƍ requests.

"TREE" AUGERS - 4ƍ LENGTH

DIA.

18ƎƎ 7 10639 10640

24ƎƎ 10 10642 10643

30ƎƎ 11 10645 10646

36ƎƎ 13 10648 10649

NO. OF

TEETH

2Ǝ

HEX

2-9/16Ǝ

RD.

GAGE TOOTH

Dirt 10340

Hardfaced 10341

WISDOM TOOTH

Dirt 10337

Hardfaced 10338

Carbide 10339

CHISEL TOOTH

Dirt 10342

Hardfaced 10343

Carbide 10344

= Safety Sign

Location

"CAST" AUGERS - 4ƍ LENGTH

DIA.

6Ǝ 2 10657 10658

8Ǝ 4 10660 10661

9Ǝ 4 10663 10664

10Ǝ 4 10666 10667

12Ǝ 4 10669 10670

15Ǝ 6 10672 10673

16Ǝ 6 10675 10676

18Ǝ 6 10678 10679

20Ǝ 6 10681 10682

24Ǝ 8 10684 10685

30Ǝ 10 10687 10688

36Ǝ 12 10690 10691

Please call Danuser for 3ƍ, 5ƍ, or 6ƍ requests.

NO. OF

TEETH

2Ǝ

HEX

2-9/16Ǝ

RD.

27

Augers &

Accessories

(continued)

"BULLET" ROCK

Pilot 10758

Tooth 10759

Tooth Holder 10760

"BULLET" ROCK AUGERS

4ƍ LENGTH

DIA.

4.5Ǝ 4 10700 10701

6Ǝ 6 10703 10704

7Ǝ 8 10706 10707

8Ǝ 8 10709 10710

9Ǝ 8 10712 10713

10Ǝ 10 10715 10716

12Ǝ 12 10718 10719

15Ǝ 15 10740 10741

18Ǝ 18 10727 10728

24Ǝ 22 10730 10731

30Ǝ 24 10733 10734

36Ǝ 30 10736 10737

NO. OF

TEETH

= Safety Sign

Location

2Ǝ

HEX

2-9/16Ǝ

RD.

28

WOBBLE AUGERS - 4ƍLENGTH

DIA.

4" N/A 20600 20601

6" N/A 20603 20604

9" N/A 20606 20607

The Wobble Auger pushes through dirt, sand,

clay, asphalt, compacted rock, and embedded

rock. The 9Ǝ Wobble Auger should be used on

a skid-steer with an Operating Load or Rated

Operating Capacity of 2250 lbs. or greater,

utilizing an auger drive with 2000 ft. lbs. of

torque or greater.

See patent at danuser.com/patents.

NO. OF

TEETH

HOSE KITS & COUPLERS

1/2Ǝ+RVH.LWZLWKIODWIDFHFRXSOHUV 10050

3/4Ǝ+RVH.LWZLWKIODWIDFHFRXSOHUV 10051

1/2Ǝ+RVH.LWLQFOXGHVILWWLQJV127FRXSOHUV 10043

3/4Ǝ+RVH.LWLQFOXGHVILWWLQJV127FRXSOHUV 10044

3/4Ǝ)URQW(QG/RDGHU+RVH.LWORQJZLWK

flat face couplers and Pioneer couplers.

Mounting bracket included for bolting or welding.

Male Hydraulic Coupler 10048

Female Hydraulic Coupler 10049

21350

2Ǝ

HEX

2-9/16Ǝ

RD.

FLAT FACE ISO

COUPLERS

This page is intentionally blank.

Warranty

DANUSER

Model #

LIMITED WARRANTY

Danuser LLC (“Danuser”) warrants its products, under normal use and maintenance, to be free from defects in material and

workmanship for period(s) specified below from the purchase date from an authorized Danuser Dealer. Start of the warranty period

is determined by purchase date given on your returned WARRANTY REGISTRATION FORM. Proof of purchase may be

required. This Limited Warranty is extended only to the original purchaser of Danuser products.

EP Drive Units - 3 Years Mountings - 1 Year Augers - 1 Year

Lifetime Warranty Covering EP Drive Unit Output Pull Out

Wear Items Not Covered Under Warranty - Hydraulic Hoses, Seals, Auger Teeth, and Auger Point

1. During the applicable warranty period, Danuser, at its option, will repair or replace any part determined by Danuser to be

defective. Such repair or replacement shall take place at Danuser’s factory or a location designated by Danuser. Under no

circumstances shall Danuser be obligated for the cost of any repair or replacement by anyone other than Danuser without its

express written consent.

2. Parts may not be returned without written authorization from Danuser.

3. Some purchased components, including but not limited to hydraulic motors, planetary gears, and augers, are subject to the

inspection and warranty of the respective manufacturer. Thus, delays in a warranty determination can be expected while

Danuser awaits their decision.

4. This warranty is void if any attempt is made to make field repairs to hydraulic motors or planetary gears. To qualify for

warranty inspection, the complete drive unit must be returned in its original “failed” condition.

Serial #

5. To make a claim under this warranty, first contact your authorized Danuser Dealer. The Danuser Dealer shall complete the

Warranty Claim Form and obtain written authorization from Danuser to return parts. All warranty claims must include

detailed information regarding make and model of vehicle on which the Danuser product was mounted, hours of use,

description of events that led up to the failure, and any other information helpful in reviewing the warranty claim. All

warranty returns must be prepaid. Shipments arriving at our factory on a freight collect basis will be refused by our

receiving department. The freight charge will be credited if the parts are determined by Danuser to be defective, and the

associated freight costs in returning those parts will be prepaid by Danuser. NOTE: Hydraulic motors must arrive with all

ports sealed from dirt and moisture. If a motor arrives with open ports, the warranty is void and no inspection will be made.

6. Products or parts thereof which, as determined by Danuser’s examination, show wear from normal use, have been

improperly operated, damaged by accident or negligence, field repaired, altered or modified are not considered defective in

material and workmanship and are not covered by this warranty. This warranty does not apply to parts subject to normal

wear ("Wear Items") or to damage caused by the failure to perform recommended maintenance or to replace worn parts.

This warranty shall not obligate Danuser to bear any cost of labor for field repair, replacement, testing, or adjustment nor for

damage caused by accident, abuse, misuse, or environmental elements.

7. Any parts or labor required to repair or replace parts not covered under this warranty will be charged to the customer. Parts

repaired or replaced by Danuser are then covered by this warranty only for the remainder of the original warranty as if such

parts were original parts.

8. Danuser reserves the right to change its specifications and designs at any time.

This warranty is exclusive and in lieu of all other express warranties, if any, including the implied warranties of merchantability

and fitness for a particular purpose. It shall not extend beyond the duration of the expressed warranty provided herein and the

remedy for violations of any implied warranty shall be limited to repair or replacement of the defective part pursuant to the terms

contained herein. No employee, dealer, salesman, or representative is authorized to change this warranty in any way or grant any

other warranty. Danuser shall not be liable for any consequential, incidental, or punitive damages, losses, or expenses, including

those resulting from or caused by any defects.

Danuser LLC Tel: (573) 642-2246

500 E. 3rd St. Fax: (573) 642-2240

P.O. Box 368 E-mail: sales@danuser.com

Fulton, MO 65251 Website: www.danuser.com

Form No. 3387

Loading...

Loading...