Operations manual

00809-0800-3104, Rev AA

April 2022

Rosemount™ 3410 Series Gas Ultrasonic Flow

meters

Model 3418

Safety and approval information

This Rosemount product complies with all applicable European directives when properly installed in accordance with the

instructions in this manual. Refer to the EU declaration of conformity for directives that apply to this product. The EU declaration

of conformity, with all applicable European directives, and the complete ATEX Installation Drawings and Instructions are available

on the internet at www.emerson.com or through your local Emerson support center.

Information affixed to equipment that complies with the Pressure Equipment Directive, can be found on the internet at http://

www.emerson.com.

For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be found in the user manual.

Product data sheets and manuals are available from the Emerson website at http://www.emerson.com.

Return policy

Follow Emerson procedures when returning equipment. These procedures ensure legal compliance with government

transportation agencies and help provide a safe working environment for Emerson employees. Emerson will not accept your

returned equipment if you fail to follow Emerson procedures. Return procedures and forms are available on our web support site

at Emerson.com, or by phoning the Emerson Customer Service department.

Emerson Flow customer service

Email:

• Worldwide: http://flow.support@emerson.com

• Asia-Pacific: http://APflow.support@emerson.com

Telephone:

North and South America

United States 800 522 6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303 527 5200 The Netherlands +31 (0) 704 136 666 New Zealand 099 128 804

Mexico +41 (0) 41 7686 111 France 0800 917 901 India 800 440 1468

Argentina +54 11 4837 7000 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy 8008 77334 China +86 21 2892 9000

Europe and Middle East Asia Pacific

Central & Eastern +41 (0) 41 7686 111 Japan +81 3 5769 6803

Russia/CIS +7 495 981 9811 South Korea +82 2 3438 4600

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

UAE 800 0444 0684

2

Operations manual Contents

00809-0800-3104 April 2022

Contents

Chapter 1 Startup...................................................................................................................... 5

1.1 Checklist......................................................................................................................................5

1.2 Cybersecurity and network communications............................................................................... 6

Chapter 2 Communications........................................................................................................7

2.1 Setup meter communications..................................................................................................... 7

Chapter 3 Optional feature keys...............................................................................................15

3.1 General overview of the Optional feature keys...........................................................................15

3.2 Configure optional keys............................................................................................................. 16

Chapter 4 Measurement.......................................................................................................... 17

4.1 Flow measurement....................................................................................................................17

4.2 Signal processing.......................................................................................................................19

4.3 Acquisition mode.......................................................................................................................21

4.4 Chord gas and sound velocity measurements............................................................................ 21

4.5 Volumetric flow rate values........................................................................................................26

4.6 Rosemount 3410 Series gas flow meter characterizations......................................................... 31

Chapter 5 Configurations......................................................................................................... 33

5.1 Calibrate and configure the meter............................................................................................. 33

5.2 Calibrate analog inputs and outputs.......................................................................................... 45

5.3 Calibrate meter factors.............................................................................................................. 49

5.4 Configure frequency outputs.....................................................................................................54

5.5 Configure digital input/outputs................................................................................................. 56

5.6 Outputs test mode.................................................................................................................... 57

5.7 Configure meter corrections......................................................................................................58

5.8 Configure temperature and pressure......................................................................................... 59

5.9 Configure Gas Chromatograph parameters............................................................................... 62

Chapter 6 Directory..................................................................................................................79

6.1 Archive logs............................................................................................................................... 79

6.2 Smart Meter Verification..........................................................................................................120

Chapter 7 Commands.............................................................................................................127

7.1 Tools commands..................................................................................................................... 127

Appendix A Conversion factors................................................................................................. 145

A.1 Conversion factors per unit of measurement........................................................................... 145

Appendix B Miscellaneous equations........................................................................................ 147

B.1 K-Factor and Inverse K-Factor.................................................................................................. 147

B.2 Calculation of Chord "L" dimension...........................................................................................148

Rosemount Model 3418 GUSM 3

Contents Operations manual

April 2022 00809-0800-3104

Appendix C Troubleshooting comm., mech., and elec............................................................... 149

C.1 Communications troubleshooting...........................................................................................149

C.2 Mechanical/Electrical troubleshooting.....................................................................................150

Appendix D Flow Rate charts.....................................................................................................153

D.1 Summary charts for Flow rate..................................................................................................153

Appendix E Write-protected configuration...............................................................................157

E.1 Parameters for Write-protected configuration.........................................................................157

Appendix F Engineering drawings............................................................................................ 167

F.1 Rosemount™ 3410 Series engineering drawings.......................................................................167

4 Emerson.com/Rosemount

Operations manual Startup

00809-0800-3104 April 2022

1 Startup

1.1 Checklist

During meter startup, have the following equipment and information on hand:

Meter startup checklist

Site pipe and ID drawings with elevations

Site wiring diagrams

Rosemount Gas Ultrasonic Meter calibration data

Rosemount Gas Ultrasonic Meter manuals

Information and manuals for all other flow instrumentation - flow computers, pressure

and temperature transmitter data sheets, and wiring

Shutoff and control valve information, specifications, operation and setup data.

Ethernet (Cat 5 cables) or serial cables to link the laptop to the meter

Field service representative's telephone numbers for major components; valves, meter,

flow computer, communication gear, transmitters, site designers or integrators.

Check all ultrasonic meter wiring.

Check the settings of any bit switches on transmitter I/O cards.

Start MeterLink

Establish flow in the meter (at lease 3 feet per second to ensure good thermal mixing)

Save the meter configuration file - your "As Found" record of the meter. In MeterLink

select Tools → Edit/Compare Configuration.

Click the Read button and select File Save.

Open File → Program Settings and customize MeterLink™ user preferences.

Open Meter → Monitor and check the measurement paths or chords and that they agree

with each other to approximately 0.2%.

Check for alarms, open Meter → Monitor and click Check Status.

Check for good signal strength (usually shown as "SNR") or, Signal to Noise Ratio.

Check for reasonably correct flow profile

From the Logs/Reports menu, click Maintenance Logs/Reports, collect and save a

Maintenance Log to record the initial performance of your meter (this is your "as Found"

record).

™

™

From the Meter → Field Setup Wizard menu. Make any configuration adjustments, such

as setting the frequency output variable and frequency full scale.

Save another Maintenance Log (this is your "As Left" record).

Rosemount Model 3418 GUSM 5

Startup Operations manual

April 2022 00809-0800-3104

1.2 Cybersecurity and network communications

The 3410 electronics TCP/IP communications should be configured to mitigate

cybersecurity risks as follows:

1. MeterLink uses either FTP or HTTP protocols for Archive and Smart Meter

Verification log collection. It is recommended to disable the FTP protocol and leave

the HTTP protocol enabled. Both can be disabled for additional security, but log

collection will not be possible in this configuration.

2. Telnet port should be left disabled. This port is not required for any

communications to field devices or MeterLink.

3. Enabling the physical Write Protect switch will prevent metrology configuration

changes and firmware upgrades. It will also prevent enabling TCP/IP protocols such

as FTP, HTTP, and Telnet.

This transmitter:

1. Is not intended to be directly connected to an enterprise or to an internet facingnetwork without a compensating control in place.

2. Should be installed following industry best practices for cybersecurity.

6 Emerson.com/Rosemount

Operations manual Communications

00809-0800-3104 April 2022

2 Communications

2.1 Setup meter communications

After the installation of your Rosemount Ultrasonic Meter, install MeterLink™ on your PC or

laptop as described in the MeterLink Software for Gas and Liquid Ultrasonic Flow Meters Quick

Start Manual (00809-0100-7630) for your operating system ( Windows® 7 or Windows® 8,

Windows® 10), then configure the meter.

The MeterLink Software for Gas and Liquid Ultrasonic Flow Meters Quick Start Manual

(00809-0100-7630) is made available with the meter.

The MeterLink installation program is available for download from the Emerson website:

emerson.com/en-us/catalog/meterlink.

2.1.1

MeterLink utilities

MeterLink™ provides the following utilities to configure the meter's flow measurement

units, meter output parameters, communications settings, output tests and logs and

reports file management.

Field Setup Wizard

• Startup

• General

• Frequency/Digital Output Sources

• Frequency Outputs

• Meter Digital Outputs

• Analog Outputs

• HART® Outputs

• Meter Corrections

• Temperature and Pressure

• Gas Chromatograph Setup

• Gas Chromatograph Component Data

• AGA8

• Continuous Flow Analysis

• Alarm Limits

• Local Display

Tools

• Edit/Compare Configuration

• Waveform Viewer

Rosemount Model 3418 GUSM 7

Communications Operations manual

April 2022 00809-0800-3104

• SOS Calculator

• Outputs Test

• Transducer Swap-Out

• Transducer Type

• Velocity Estimation

• Locate Meter

• Baseline Wizard

• Program Download

• Warm Start Meter

• Communications Analyzer

Log/Reports

• Maintenance Logs and Reports

• Trend Maintenance Logs

• Meter Archive Logs

• Smart Meter Verification

• Create PDF from XML SMV Report

• Compare Excel® Meter Configurations

Calibration

• Analog Inputs Wizard

• Meter Factors

• Flow Calibration

• Zero Calibration

Setup the meter directory

Setup the connection properties for your meter. By default, the meter directory contains

only one record named New Meter, that is defaulted to connect to a Rosemount Gas

Ultrasonic meter configured as shipped from the factory.

Create a new meter record

Procedure

1. Select Insert, Insert Duplicate, or Add from the File pull-down menu to create a

new record.

2. Setup the record by entering a Meter Name, Short Desc, Meter Type, and select the

connection type(s) checkboxes Direct, Ethernet and Ethernet 2.

3. For each connection type selected, a button will be enabled at the bottom of the

dialog with the same name. Click these buttons to edit the connection properties

for that connection method. After choosing the connection properties, click OK

accept the changes or click Cancel to discard any changes and close the dialog.

8 Emerson.com/Rosemount

Operations manual Communications

00809-0800-3104 April 2022

a) Direct connection - to connect to the meter directly through one of the serial

ports on the meter using one of the serial ports on your computer. Click

Direct to set the following parameters.

• Protocol: TCP/IP is a read-only field and is the only protocol MeterLink

uses.

Note

Rosemount Ultrasonic meters still support Modbus ASCII and Modbus

RTU when talking to other applications or devices.

• Comms Address: Enter the communication address that is configured in

the meter hardware. The default address for meters from the factory is

32. For Rosemount Ultrasonic meters the valid range is from 1 to 247.

• Port: Select the available driver from the list of those installed on your

machine.

Note

For Windows® 7, you cannot use the Communications cable between two

computers at this time and must use the Rosemount Direct Connection

driver.

• Baud Rate: Select the serial port baud rate from the drop-down list for

which the meter hardware is configured. The default Baud Rates is 19200.

• Check Box labeled Route IP packets to connection to configure MeterLink

to automatically connect to both Transmitter heads of DualConfiguration meters when data sharing is enabled. This requires

Ethernet connection between the two heads.

b) Ethernet connection - Set the following properties to configure the

Rosemount ultrasonic meter hardware for Ethernet connectivity.

NOTICE

It is strongly recommended that the meter be configured using an

independent (off- network) single host computer. After configuration of the

meter, the DHCP option should be disabled.

• IP Address: Enter the IP Address for the meter's Ethernet port.

The factory set IP Address is 172.16.17.200 for Rosemount Gas Ultrasonic

meters or you can use 192.168.135.100 if DHCP is enabled in the meter

(see DHCP below for more details).

Dynamic Host Configuration Protocol (DHCP): Business PCs are usually

configured to work in a network environment where a DHCP server

assigns an IP address to each computer when they connect to the

network.

If a PC is configured to obtain an IP address from a DHCP server and it is

going to connect through the Ethernet Cable (1-360-01-596) to a

Rosemount meter that is not connected to a network, then the DHCP

server in the meter must be enabled so it can assign an IP address to the

PC when it connects.

Rosemount Model 3418 GUSM 9

Communications Operations manual

April 2022 00809-0800-3104

The DHCP server can be enabled on the meter by setting the DHCP switch

on the CPU module to the ON position.

When connecting to a meter with DHCP enabled, use the IP address of

192.168.135.100 to connect to the meter. In this mode you can create

just one Meter Directory record with this IP address to connect to all your

meters with DHCP enabled. When the connection is made, select to use

the Meter Name in the meter instead of the Meter Directory Name in

order to keep all log files and configurations separate from each meter.

Click OK to accept the changes or click Cancel to discard any changes and

return to the Meter Directory dialog box.

Meter groups

This dialog, available from the Meter Directory dialog, allows you to manage meter groups

for filtering the list of meters in the Connect to Meter dialog, exporting to other

MeterLink™ users and for filtering the list of meters in MeterLink™ Net Monitor’s main

window. There is a predefined meter group for “All meters,” otherwise meters can be

grouped together in any way that is useful to you, e.g. meters for geographic regions, or

meters that require daily monitoring.

User-defined meter groups can be added, edited and deleted in the dialog. The left side

displays a list of meter groups. The right side displays all available meters (meter directory

records) in the currently selected group and allows meters to be added to or removed

from the currently selected group using a checkbox next to each meter.

Ethernet initial connection steps

Procedure

1. Power up the meter.

2. Shutdown the PC.

3. Plug the Ethernet adapter cable Phoenix end into the meter Field Connection Board

connector J8 and connect the RJ-45 end into the PC Ethernet connector.

4. Enable the Ethernet LAN connector DHCP server on the CPU Module by moving the

DHCP (switch-1) to the ON position (see direction arrow on the CPU Module label).

5. Power up (boot) the PC and log in to the initial Windows logon prompt.

6. Verify the Ethernet connection status by the CPU Module “LINK” LED which should

be on solid green.

7. Launch MeterLink and create a new meter record.

Import a meter record

Procedure

1. Select File → Import from the Meter Directory drop-down menu or click Import.

2. The Import Meter Directory File dialog which allows you to select a meter

directory .DAT file to import the file into the currently used meter directory file.

If an identical meter record already exists and a duplicate is trying to be imported,

MeterLink inserts the duplicate meter record. The Import button performs the

same operation.

10 Emerson.com/Rosemount

Operations manual Communications

00809-0800-3104 April 2022

Export a meter record

Use the Export command to save the current meter directory to file. Select File → Meter

Directory from the Meter Directory drop-down menu or click Export.

Procedure

1. Enable the meter directory record checkbox you want to export or click Select All.

2. Click OK to begin exporting the meter record(s). Use the Export Meter Directory File

dialog to save the exported record to the default folder (C:\Ultrasonic Data) or enter

another location.

3. Click Save. If you have an existing METER_DIRECTORY_EXPORT.DAT file, you are

prompted to change the file name or replace the file. If changing the file name,

keep the .DAT extension to maintain functionality when importing the file to the

new machine.

4. Copy the exported file to the new machine.

5. Use the Import command to select this file and import it into the Meter directory.

Important

Due to limitations in the Microsoft® Dial-Up Networking, not all of the directory

information for Direct and Modem connection can be exported to the

METER_DIRECTORY.DAT file for Rosemount Ultrasonic meters. It will be able to

export the meter names, Comms Address, Interface, and Telephone numbers. It will

still be necessary to recheck the connection properties and verify the

communication parameters such as COM port, data bits, and parity are configured

correctly.

Connect to the meter

Procedure

1. From the menu bar, select Meter → Connect or click , the Connect icon, on the

toolbar.

2. The Connect to Meter dialog box displays a list of meters setup in MeterLink. Click

Direct, Ethernet next to the Meter Name to establish a connection with your

Rosemount Ultrasonic meter.

Collect “As Found” logs and reports

Use the MeterLink Logs/Reports menu and collect and save the logs and reports for a

historical record of the meter at several velocities within the operating range of the meter.

This will establish a baseline to be used for the trending of the meter diagnostics. Save the

following logs and reports for the "As Found" settings (factory default).

• Maintenance log

• System log

• Save your meter's configuration file

• Use the Tools → Edit/Compare Configuration menu to display the dialog. Enable the

View All or Metrology radio button and click Read.

Rosemount Model 3418 GUSM 11

Communications Operations manual

April 2022 00809-0800-3104

The All View displays the meter's extended configuration parameters. Grayed out

values are read-only, but help describe the configuration. The Metrology View displays

the path dimensions, pipe diameter, transducer delay parameters, zero flow calibration

coefficients, and flow calibration coefficients.

— Click the question mark icon, , for the data point to display additional information.

• Click Save to save the configuration file. By default, the file is saved to the Data Folder

setup in File → Program Settings.

Customize MeterLink settings

Open MeterLink and access File → Program Settings, then input the desired settings for

your meter. Your user name and company name is included on reports and logs generated

with MeterLink.

Figure 2-1: Program Settings

• User name

• Company name

• Data folder (where meter's data is stored)

• Select the checkbox to create a subfolder with the meter's name under Data folder for

saving and opening files for your meter

12 Emerson.com/Rosemount

Operations manual Communications

00809-0800-3104 April 2022

• Display units (of measurement); U.S. Customary or Metric for necessary unit

conversions read by the meter

• Meter volume units; gal, cubic feet, or bbl

• Prompt to save meter config (configuration) prompts you to save a copy of the meter

configuration after writing changes to the meter

• Run Connect dialog automatically after connecting

• Run Meter Monitor automatically after connecting

• Run Meter Monitor summary or detailed view after connecting

• Use FTP passive mode (client - server port communications)

• Allow backup upgrade mode connection - used to download firmware to Rosemount

Ultrasonic meters

• Tab from spreadsheet to next control instead of next cell

• TCP/IP meter connection database timeout - amount of time MeterLink waits to

respond to a request for data from the meter database (default 13 seconds)

• Override system default printer - used to change printer

2.1.2

• Product type preference - meter type you will most often connect, gas or liquid

HTTP file transfer

• Use HTTP for file transfer if available in the meter.

— A checkbox is enabled when selected.

— MeterLink uses HTTP protocol for file transfer with meter if it is supported by

firmware.

— Rosemount 3410 Series Firmware v1.50 and later supports HTTP protocol for file

transfer for Program Download, Collect Archive Logs, Collect XML SMV Report and

cache database configuration XML file when connecting to meter for the first time.

— Alternatively, Rosemount 3410 Series Firmware also supports FTP protocol for file

transfer for Program Download, Collect Archive Logs, Collect XML SMV Report and

cache database configuration XML file when connecting to meter for the first time.

Setup Modbus communications

Rosemount 3410 Gas Ultrasonic Flow Meters support RS-232 or RS-485 4-wire or 2-wire

half duplex serial interface to an external system (e.g., flow computer) using Modbus ACSII

protocol with the following parameters:

Setting

Value

Baud rate 19200

Data bits 7

Stop bits 1

Parity even

Rosemount Model 3418 GUSM 13

Communications Operations manual

April 2022 00809-0800-3104

Setting Value

Protocol Modbus ACSII

Refer to your flow computer user manual to set I/O settings required to allow serial

communication with the Rosemount 3410 Gas Ultrasonic Flow Meters.

The Rosemount 3410 Gas Ultrasonic Flow Meters supports ASCII and RTU Modbus

communication. For ASCII Modbus, both 7E1 and 7O1 are supported. For RTU Modbus,

8N1 is supported. The communication ports provide automatic protocol detection - only

the baud rate and Modbus ID need to be specified. Also, refer to the Rosemount website

and select the Product page for the model of your meter:

emerson.com/en-us/automation/emerson

14 Emerson.com/Rosemount

Operations manual Optional feature keys

00809-0800-3104 April 2022

3 Optional feature keys

3.1 General overview of the Optional feature keys

Rosemount 3410 Series Gas Ultrasonic Flow Meters offer many industry-leading features

including Chapter 21-compliant data log access, gas chromatograph (GC) interface,

AGA10 sound velocity calculation (with comparison to measured sound velocity) and

Continuous Flow Analysis diagnostics.

With Mark XX v1.50 Firmware or later, features keys will be generated on meter start up

and this enables all optional features available. All keys are unique to the CPU board's serial

number, so a key from one meter will not work in another meter.

The Continuous Flow Analysis optional feature is enabled via a software "key" value that is

specific to the meter's CPU Board. This software feature key consists of 16 characters

divided into four hyphen-separated, 4-character groups (such as 1234-5678-90AB-CDEF).

This dialog is only available while connected to a meter with firmware that contains option

keys to enable.

3.1.1

3.1.2

In MeterLink, access the Key Manager to view key statuses, add keys or change the key

values.

Obtaining optional keys

If you do not have a valid key to enter to enable a feature, you must have the CPU board

serial number available, which displays in the Meter → Key Manager dialog and the Meter

Menu → Meter Information dialog, when you contact Rosemount to obtain the key. The

keys can be given verbally over the phone or they can be e-mailed in a Key file for easy

entry.

• E-mail: tech.service@emersonprocess.com

• Web: http://www.emerson.com/en-us/support

• Also see, MeterLinkHelp → Technical_Support

GC interface key

The optional GC interface feature allows the meter to read gas property data (composition

and heating value) from a Rosemount gas chromatograph.

The meter can use the gas composition data to:

1. Calculate AGA8 compressibilities for converting volumetric flow rate and volumes

to standard (base) condition

2. Calculate AGA8 density for calculating mass rate and mass totals

3. To optionally calculate the AGA10 sound velocity (see AGA10 key (sound velocity

calculation)). The meter uses the GC-reported gas heating value to calculate the

energy rate and totalized energy rate values. This feature is enabled/disabled via the

GCKey data point.

Rosemount Model 3418 GUSM 15

Optional feature keys Operations manual

April 2022 00809-0800-3104

3.1.3 AGA10 key (sound velocity calculation)

The optional AGA10 sound velocity calculation feature allows the meter to calculate the

predicted sound velocity based upon the gas composition and compare this value to the

measured average sound velocity. The gas composition can be either specified via data

points or optionally read live from a GC (see above). This feature is enabled or disabled via

the AGA10Key data point.

3.1.4 Continuous Flow Analysis (CFA) key

The Continuous Flow Analysis key enables all optional features and provides extensive

diagnostics for the meter's operational health.

3.2 Configure optional keys

Procedure

1. Open MeterLink and connect to your meter.

2. Use the Meter Menu drop-down list and click Key Manager. MeterLink displays the

Key Manager dialog.

3. Enter the key you obtained in the appropriate field in the Key Manager dialog.

The field turns yellow indicating a change was made and the status will be updated.

When at least one change is made and none of the keys are Invalid, the Write to

Meter button is enabled so the changes can be written to the meter.

The Status column indicates if the key you entered is a Valid key.

4. Click Write to Meter to write the keys to the meter. After the keys are written

successfully, the Key Manager dialog closes.

If for any reason, one or more keys were not written successfully, before the Key

Manager closes, a message displays stating which keys could not be written to the

meter. This could occur if communications to the meter is lost between entering

the Key Manager dialog and clicking Write to Meter.

5. If desired, on the Field Setup Wizard-Startup page, enable the View Gas

Chromatograph setup and View Continuous Flow Analysis setup checkboxes to

display these pages later in the Field Setup Wizard. The Gas Chromatograph Setup

page provides the serial port configuration option to collect live gas compositions.

The Continuous Flow Analysis Setup page allows you to configure the SOS

comparison, liquid detection, abnormal profile detection, blockage detection, and

internal bore buildup detection features.

16 Emerson.com/Rosemount

Operations manual Measurement

00809-0800-3104 April 2022

4 Measurement

4.1 Flow measurement

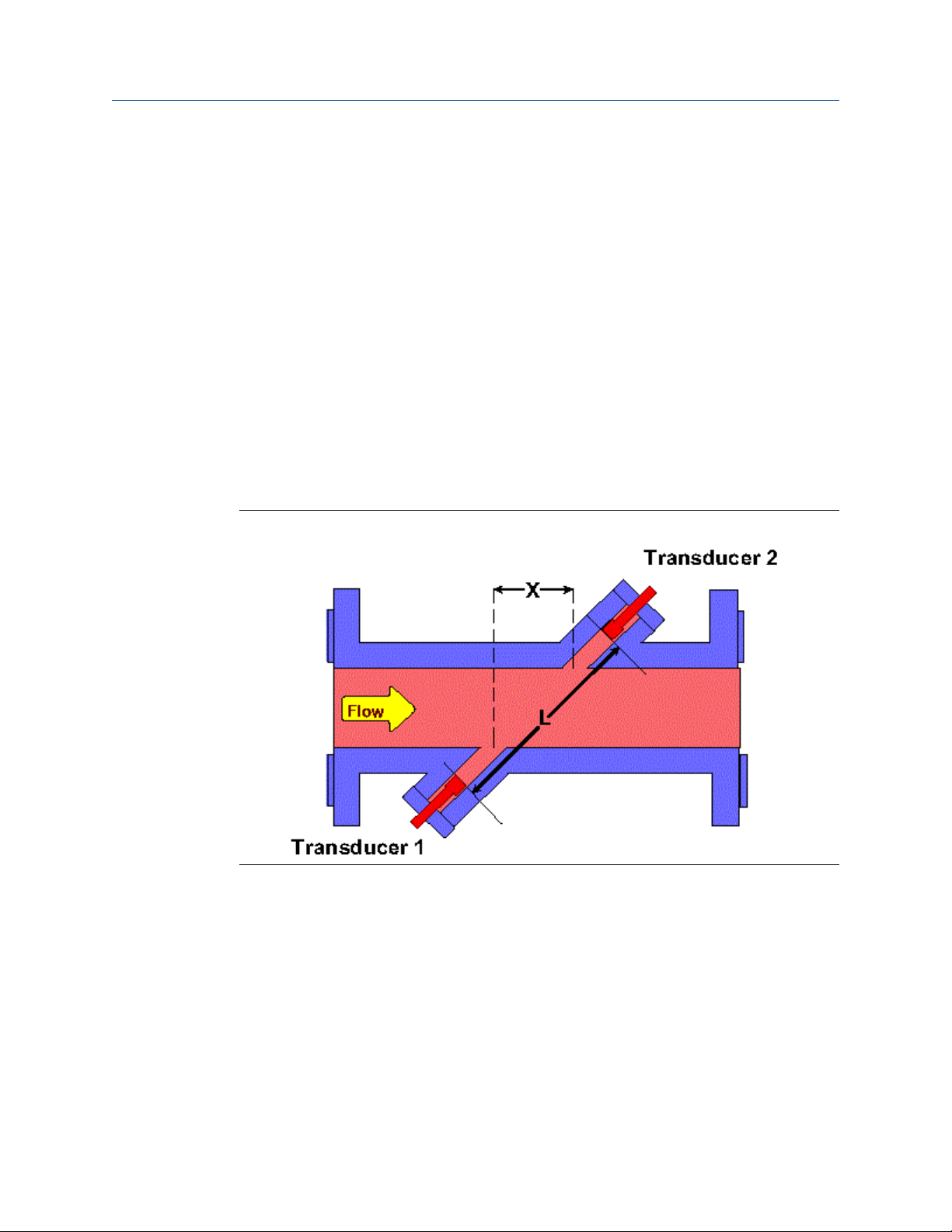

Rosemount 3410 Gas Ultrasonic Flow Meters measure the transit times of ultrasonic

pulses passing through the medium on two parallel planes. The measurement paths (also

referred to as "chords") are angled to the pipe axis, and each chord has two transducers

acting alternately as transmitter and receiver as shown in Figure 4-1. This permits the

transit times to be measured both with and against the flow (upstream and downstream).

The transducers are mounted on the meter body at accurately known locations for each

pipe size so the distance L between opposing transducers and the angle are precisely

defined for the measurement path.

The 3418 combines the power of two interlocked 4-path British Gas design meters in one

flowmeter body. The second set of chords is the mirror image of the first, which allows the

meter to cancel out the effects of swirl and cross flow.

4.1.1

Figure 4-1: Direct path transit-time measurement principle

Transducer timing control

The following terms are used in explaining the effects of transducer timing control, the

performance of batch data collection and calculation updates in Rosemount 3410 Gas

Ultrasonic Flow Meters.

Rosemount Model 3418 GUSM 17

Measurement Operations manual

April 2022 00809-0800-3104

Figure 4-2: Signal Analyzer - update rate, stack size, filter and emission rate

Terminology

• Sequence - a complete cycle of firing all enabled transducers in a single round of

transducer operation.

• Stacking - the process of modifying a sequence so that each individual transducer is

fired "x" times (where x equals the stack size) before the next transducer in the

sequence is fired.

• Stack size - the multiple of times each transducer is fired before the next transducer

within the sequence is fired. (When stacking is absent or disabled, the stack size is

actually 1, because each enabled transducer is fired once during the sequence. When

stacking is applied or enabled, it is applied increments of 2, 4, 8, and 16 and are the

only stack size choices, so that each enabled transducer is fired 2, 4, 8, or 16 times

before the next transducer in the sequence is fired.)

• Emission rate - the time elapsed before the next transducer in a sequence is fired,

regardless of stack size (minimum emission rate is 2 milliseconds with the Filter ON or

OFF). We recommend the default Filter setting, which is the OFF position.

• Stack emission rate - the time elapsed before a single transducer is re-fired when

stacking is enabled (minimum stack emission rate is 2 milliseconds with the Filter OFF).

• Chords inactive or active - the exclusion or inclusion of a chord-forming pair of

transducers in the sequence of transducer operation.

• Update time - the time elapsed, in seconds, between each processing, or recalculation

of data that is collected from sequences of transducer firings.

• Batch period, or batch cycle - synonymous with Update time, as defined above.

18 Emerson.com/Rosemount

Operations manual Measurement

00809-0800-3104 April 2022

• Sample - refers to one point on the waveform as in samples per cycle. The data that is

collected from one Sequence of transducer operation. (This term is displayed in the

MeterLink™ Signal Analyzer screen, and is nearly synonymous with Sequence, as

defined above. That is, Samples/update, as displayed in the MeterLink™ Signal Analyzer

Wizard, could be interpreted as Sequences/update.) This shows the average number of

new samples collected during an update period.

4.2 Signal processing

The signal at the receiving transducer is amplified, digitized and processed digitally to

provide accurate transit time measurement.

A measure of the signal "quality" is the signal-to-noise ratio (SNR). The higher the SNR, the

better the signal. In general there are two types of noise: "white" noise and "colored" noise.

White noise is noise that occurs across the frequency spectrum and is asynchronous to the

transmitted signal. Colored noise is concentrated around a particular frequency and can

be synchronous with the transmitted signal. The meter provides two methods for

improving the received signal waveform SNR by reducing the noise energy: Stacking and

Filtering.

4.2.1

4.2.2

Stacking

Stacking is a method of firing a transducer multiple times and averaging the received

signals on a point-by-point basis.

Stacking is effective on asynchronous noise such as is typically seen with valve noise. This

method is not useful for removing synchronous noise and should not be used when there

is a great deal of signal "jitter." Meters are configured by default with a stack size of 1 (no

stacking).

Care should be taken when turning on stacking and it is recommended to consult with

Emerson Customer Support if you are unsure of how stacking a signal can affect the

meter's operation. Refer to Technical Support under the Help menu of MeterLink for

contact information.

The number of consecutive times to fire each transducer is specified via the StackSize data

point. Available stack sizes are 1 (None), 2, 4, 8, and 16. A stack size of 1 selects no

stacking (i.e., stacking disabled). Stacking is only available when the standard update rate

is selected (see Batch update period).

Filtering

Filtering applies a bandpass filter that removes noise that is above and below the

transducer frequency.

Filtering is effective on noise outside of the frequency passband of the filter (e.g., filtering

works on any noise outside of the passband of the filter).

Filtering is enabled/disabled via the Filter data point (TRUE=enable filtering, FALSE=disable

filtering). Meters are configured by default with filtering disabled. The minimum emission

rate for the gas meter is 2 milliseconds with the filter ON or OFF. We recommend the

default Filter setting, which is the OFF position.

Rosemount Model 3418 GUSM 19

Measurement Operations manual

April 2022 00809-0800-3104

Care should be taken when enabling/disabling filtering and it is recommended to consult

with Flow Lifecycle Services for Rosemount products if you are unsure of how this change

can affect the meter's operation. Refer to Technical Support under the Help menu of

MeterLink™ for contact information.

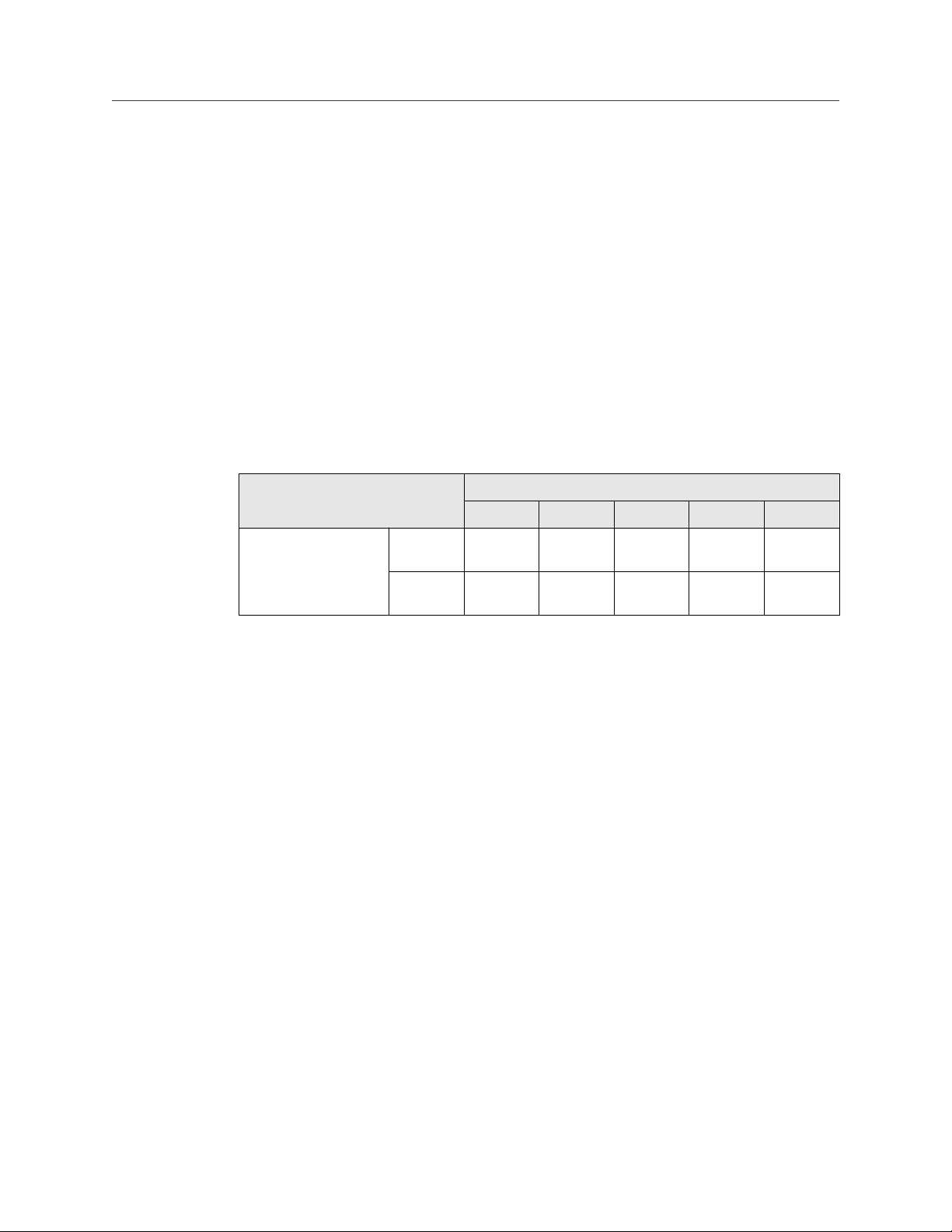

4.2.3 Batch cycle processing

Batch update period

Calculation updates performed by the meter, for deriving volume and velocity, are based

on batches of data samples collected from sequences of transducer firings. The batch

update period is dependent upon the user specified batch update period

(SpecBatchUpdtPeriod) and the stack size (StackSize) as shown in Table 4-1. The

Standard batch update period is the default. The actual batch update period is readable via

the BatchUpdatePeriod data point.

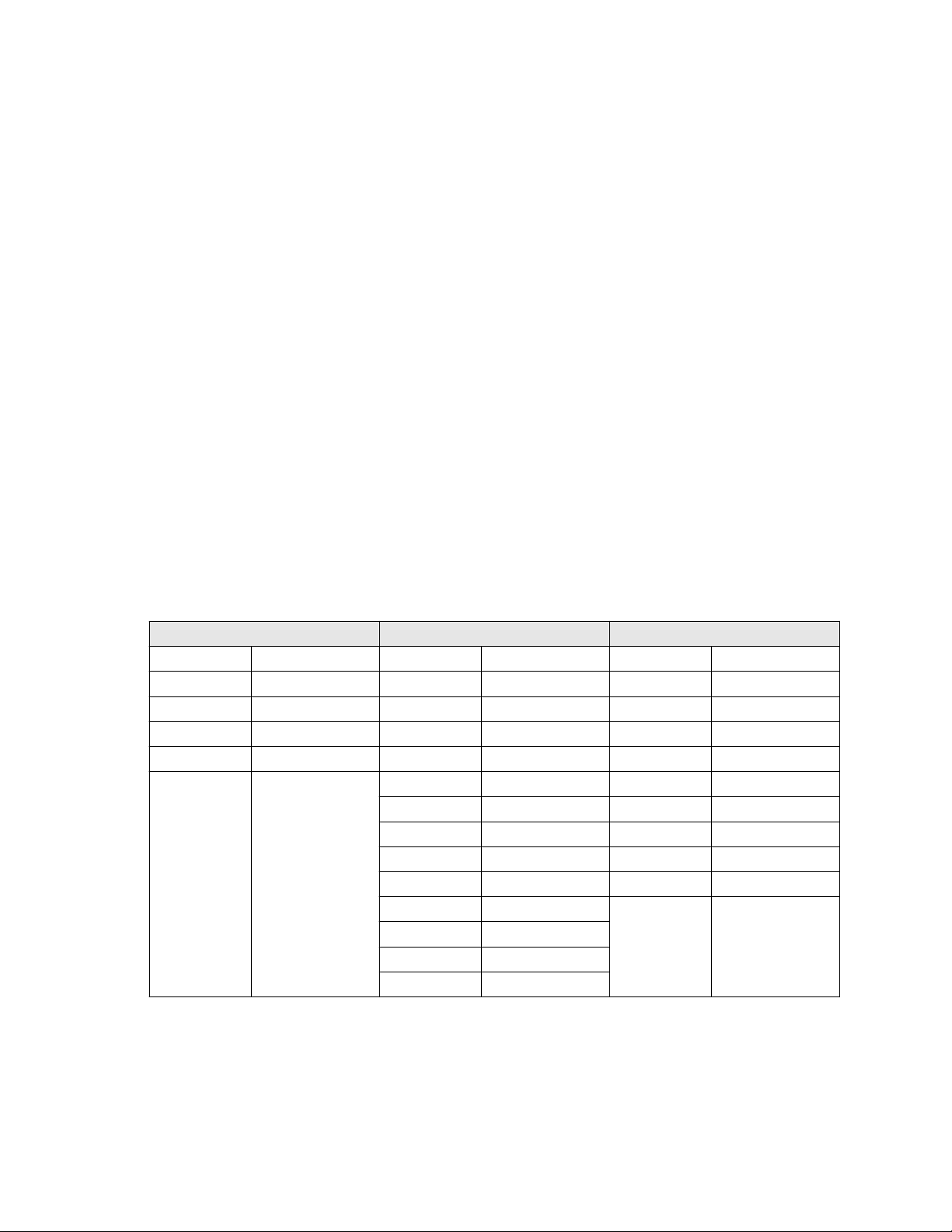

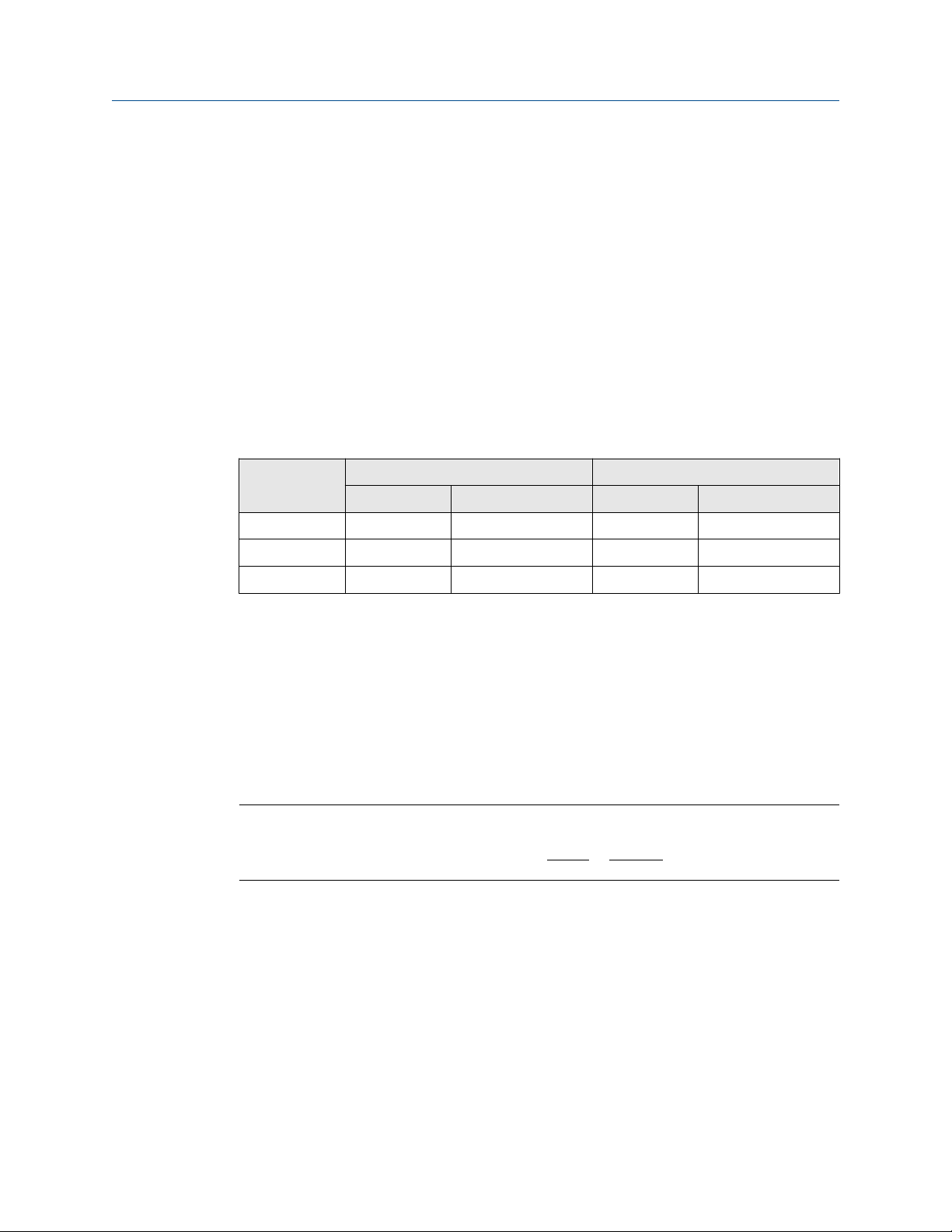

Table 4-1: Actual meter update period

Stack size

1 (None) 2 4 8 16

SpecBatchUpdtPeriod

Rapid

(250 ms)

0.25 sec N/A N/A N/A N/A

4.2.4

Standard

(1000 ms)

Emission rates

The emission rate is the period between firing two different transducers. The stacked

emission rate is the period between consecutive firings of a single transducer when

stacking is used (i.e., the stack size is not set to None).

The actual emission rates used (readable via the EmRateActual and StackEmRateActual

data points) are functions of the desired emission rates, meter type, firing sequence, stack

size, and pipe diameter.

1 sec 1 sec 1.5 sec 3 sec 5 sec

Smoothing

The Rosemount 3410 Series Gas Ultrasonic Flow Meter applies a method for smoothing

the output (particularly the frequency output) by averaging times collected from past

batch periods with new times for the current batch period.

Smoothing can be applied in the following increments: 0 (i.e., smoothing is disabled), 20,

40, 60, or 80%.

For example, setting Smoothing to 20% means that of the samples used for the current

update, 20% will be from previously collected samples and 80% will be from the newly

collected samples. Thus, if eight new samples are collected, then those eight samples

along with the last two previous samples would be used together for the current update

period calculations.

Meters are configured by default for Smoothing of 0% (only new samples are used for the

Current Update period).

20 Emerson.com/Rosemount

Operations manual Measurement

00809-0800-3104 April 2022

4.3 Acquisition mode

Rosemount 3410 Gas Ultrasonic Flow Meters have two modes of normal operation:

Acquisition and Measurement. The Acquisition mode is used to acquire the ultrasonic

signals. This mode is entered when power is applied to the meter.

Once the ultrasonic signals are acquired, the Measurement mode is entered and the flow

velocity is measured. The meter remains in the Measurement mode as long as at least one

chord is operational.

If while in the Measurement mode all chords fail, then the meter re-enters the Acquisition

mode. If the VelHold data point is set to a value greater than zero, then, while in the

Acquisition mode, the meter holds the average weighted flow velocity to the last good

value for up to the VelHold number of batches before setting the velocity to zero. The

VelHold default value is 0.

The Acquisition mode uses the chords' "L" dimensions (LA…LH as appropriate to the meter

type) and the specified minimum and maximum sound velocities (SSMin and SSMax)

determines the signal search range. MinHoldTime and MaxHoldTime are also used to

determine the signal search range. The meter uses the more restrictive of SSMin/

MaxHoldTime and SSMax/MinHold time.

4.3.1

Re-acquisition

When fewer than MinChord (default 1) chords are good, then the meter re-enters the

Acquisition mode. If MinChord is set to the number of active chords, the meter will

reacquire on the first time a chord is failed for a batch.

Note that failed for a batch is different from hard failed. A chord fails for a batch when PctGood[A1..H2] is less than MinPctGood.

Hard fails occur after AlarmDef number of batches in a row.

4.4 Chord gas and sound velocity measurements

At each batch update period, each firing path's transit time measurements are averaged.

The average (mean) value for each path is available via data points MeanTmA1...

MeanTmH2 (as appropriate for the meter type).

NOTICE

The data point names often use a "short-hand" way of identifying the receiving transducer.

The last two characters identify the chord (A...H) and the transducer (1=upstream,

2=downstream). For example, MeanTmA1 is the mean transit time for the chord A

upstream transducer.

The difference between a chord's average upstream transit time and average downstream

transit time is the average delta time. The chord's average times and the chord "X" and "L"

dimensions are used to calculate the gas velocity and sound velocity measured by the

chord as shown in Equation 4-1 and Equation 4-2.

Rosemount Model 3418 GUSM 21

Measurement Operations manual

April 2022 00809-0800-3104

Equation 4-1: Chord Gas Velocity

2

V

chord

L

=

2X

chord

chord

t1‐t

t1t

2

2

and

Equation 4-2: Chord Sound Velocity

C

chord,classic

C

=C

chord

L

=

chord,classic

t1+t

chord

2

t1t

2

2

×PortAngleFactor

where the PortAngleFactor is a dimensionless factor that is dependent upon the chord port

angle with respect to the meter body:

For 60 degree port angles,

PortAngleFactor= 1+ 0.5•

2

V

chord

2

C

chord,classic

•

2

X

chord

2

L

chord

•tan260°

For 75 degree port angles,

PortAngleFactor= 1+ 0.5•

2

V

chord

2

C

chord,classic

•

2

X

chord

2

L

chord

•tan275°

For all other port angles,

PortAngleFactor=1

where

V

= chord average gas velocity (m/s) (FlowVelA ... FlowVelH)

chord

C

= chord average sound velocity (m/s) (SndVelA ... SndVelH)

chord

L

= chord "L" dimension (m) (LA ... LH)

chord

X

= chord "X" dimension (m) (XA...XH)

chord

t1 = chord average transit time in the upstream direction (s) (MeanTmA1 ...

MeanTmH1)

t2 = chord average transit time in the downstream direction (s) (MeanTmA2 ...

MeanTmH2)

Important

Note that a positive chord gas velocity indicates flow in the forward direction whereas a

negative chord gas velocity indicates flow in the reverse direction.

4.4.1

Average sound velocity

The Average Sound Velocity is calculated as the average of the active chord sound velocity

measurements as shown in the equation below:

22 Emerson.com/Rosemount

Operations manual Measurement

00809-0800-3104 April 2022

Equation 4-3: Average sound velocity

C

∑

C

ActiveChords

=

Avg

NumActiveChords

chord

where

C

= average sound velocity (m/s) (AvgSndVel)

Avg

C

= chord average sound velocity (m/s) (SndVelA... SndVelH)

chord

NumActiveChords = number of active chords

4.4.2 Optional AGA10 sound velocity calculation and comparison

The Rosemount 3410 Series Gas Ultrasonic Flow Meter offers an option to calculate the

sound velocity (using AGA10 equations and gas property data) and compare the result to

the meter- measured sound velocity on an hourly basis.

This feature is enabled via the AGA10 Key (see AGA10 key (sound velocity calculation)).

The gas property data required for using this feature can be specified via data points or

optionally read from a Rosemount GC (Configure Gas Chromatograph parameters). The

AGA8 Detail Method or GERG-2008 must be selected (via the HCH_Method data point,

Configure Gas Chromatograph parameters) in order for the AGA10 calculations to be

performed.

Every five seconds the meter updates the AGA10-calculated sound velocity. This value is

readable via the AGA10SndVel data point and the calculation status value is readable via

the AGA10SndVelStatus data point. The status values are as listed in the table below:

Table 4-2: Status of AGA speed of sound calculation

AGA10SndVelStatus value Description

0 Calculation OK (no errors)

1 Calculation not performed as the feature is not enabled .

AGA10SndVel is set to zero.

2 Calculations not performed as the AGA8 method (HCH_Method)

is not the Detail Method or GERG-2008. AGA10SndVel is set to

zero.

3 Calculations not performed as the AGA8 calculations are invalid.

AGA10SndVel is set to zero.

4 Calculations not performed due to encountered division by zero.

AGA10SndVel is set to zero.

Over the course of an hour (starting from the top of the hour), the meter calculates the

average measured sound velocity (the average of the average weighted sound velocity)

and the average AGA10-calculated sound velocity. At the end of the hour, the two

averages are compared; the comparison error (%) is readable via the SndVelCompErr data

point.

Rosemount Model 3418 GUSM 23

Measurement Operations manual

April 2022 00809-0800-3104

Note that the comparison error is only calculated at the end of the hour when there is at

least 75% of a log hour worth of valid flow data during the hour. A valid flow data means

that all of the following are true:

• no AGA10 sound velocity calculation errors occurred (i.e., AGA10SndVelStatus always

equal to 0),

• the measured average flow velocity (AvgFlow) is between the diagnostic flow analysis

limits (FlowAnalysisLowFlowLmt and FlowAnalysisHighFlowLmt), and

• the measured sound velocity was always valid (as indicated by the QMeterValidity data

point).

4.4.3 Average weighted gas flow velocity

When all active chords are non-failed, the average weighted gas flow velocity is a weighted

sum of the chord velocity measurements as shown in Equation 4-4 where the chord

weights are determined by the meter geometry.

Equation 4-4: Average weighted gas flow velocity

4.4.4

where

V

Wtd

V

AvgWtd

=

ActiveChords

V

= average weighted gas flow velocity (m/s) (AvgWtdFlowVel)

AvgWtd

= chord weight (dimensionless) (WtA ... WtH)

chord

= chord average gas velocity (m/s) (FlowVelA ... FlowVelH)

chord

∑

Wt

chordVchord

Average weighted flow velocity using chord proportions

In the event of one or more chord failure(s), the meter operation is dependent upon the

number of non-failed chords. If there is at least one operating chord, then the meter uses a

velocity estimation method described in the following paragraphs.

If all chords fail, then the meter re-enters the Acquisition mode as described in the Re-

acquisition section.

The meter partitions the velocity range (for forward and reverse flow) into ten

consecutive, non- overlapping "bins" (where the velocity range is as specified via the

MeterMaxVel data point).

The meter maintains a set of bins for each active chord where each bin contain three data

values: (1) the chord's average velocity (within the bin's velocity range), (2) the chord's

average proportion value, and (3) an indicator that the value is still the default (Is[Fwd/

Rev]Prop[A..H]DfltBin[1..10]). A chord proportion value is the ratio of the chord velocity

to the average weighted flow velocity as shown in Equation 4-5 below. The default

indicator is used to determine if a bin's velocity and proportion data values have been

updated from their initialized values. The bins are initialized with the average velocity over

the bin's range and meter-geometry-dependent proportion values. All default indicators

are initialized to TRUE. The bin data is stored in non-volatile memory.

24 Emerson.com/Rosemount

Operations manual Measurement

00809-0800-3104 April 2022

Equation 4-5: Chord proportion calculation

V

Prop

chord

=

chord

V

AvgWtd

where

Prop

V

chord

V

AvgWtd

= chord proportion (dimensionless)

chord

= chord velocity (m/s) (FlowVelA ... FlowVelH)

= average weighted gas flow velocity (m/s) (AvgWtdFlowVel)

When the meter has operated for a user-specified number of consecutive batches without

any chord failures, the meter updates each chord's data values for the bin containing the

chord velocity as shown in Equation 4-6 and sets the bin's default indicator to FALSE. The

PropUpdtBatches data point, configurable via the MeterLink Edit/Compare Configuration

screen, specifies the number of consecutive failure-free batches required for updating the

bin data (range: [1, 1000], default: 24). The NumVals data point (that determines how

quickly an average value changes) is also configurable via the Edit/Compare

Configuration screen (range: [1, 1000], default: 10).

Equation 4-6: Updating chord proportion bin data values

AvgVel

AvgProp

ChordBin

ChordBin

n+1

n+1

=

AvgVel

=

ChordBin

AvgProp

ChordBin

NumVals‐1 +V

•

n

NumVals

NumVals‐1 +Prop

•

n

NumVals

chord

chord

where

AvgVel

AvgVel

ChordBin

ChordBin

= chord bin (n+1)st average velocity (m/s)

n+1

= chord bin nth average velocity (m/s)

n

NumVals = update factor data point (dimensionless) (NumVals)

V

= chord velocity (m/s) (FlowVelA ... FlowVelH)

chord

AvgProp

AvgVel

Prop

chord

ChordBin

ChordBin

= chord proportion (dimensionless)

= chord bin (n+1)st average proportion value (dimensionless)

n+1

= chord bin nth average proportion value (dimensionless)

n

In the event of a chord failure with at least one operating chord, the meter's average

weighted flow velocity is estimated as shown in Equation 4-7.

Equation 4-7: Estimating average flow velocity using proportion values

V

chord

∑

V

AvgWtd

est

Non‐FailedChord(s)

=

InterpProp

∑

Non‐FailedChord(s)

chord

where

V

AvgWtd

V

Chord

InterProp

Rosemount Model 3418 GUSM 25

= estimated average weighted flow velocity (m/s) (AvgWtdFlowVel)

est

= (non-failed) chord velocity (m/s) (FlowVelA ... FlowVelH)

= (non-failed) chord interpolated proportion value (dimensionless)

chord

Measurement Operations manual

April 2022 00809-0800-3104

For each non-failed chord, the interpolated proportion value used in Equation 4-7 is

calculated as follows:

• If the chord's velocity is surrounded by non-default (average velocity, average

proportion) data pairs, then the interpolated proportion is the linear interpolation

between the two data pairs.

• If the chord's velocity has a non-default (average velocity, average proportion) data

pair on one side of it but not the other, then the interpolated proportion is the data pair

average proportion.

• If there are only default (average velocity, average proportion) data pairs, then the

interpolated proportion is the corresponding bin's default average proportion value.

4.5 Volumetric flow rate values

The Rosemount 3410 Series Gas Ultrasonic Flow Meter meter provides three volumetric

flow rate values: raw, (expansion-corrected and/or profile-effect corrected) flowcondition, and base- condition. Note that a positive volumetric flow rate indicates flow in

the forward direction whereas a negative volumetric flow rate indicates flow in the reverse

direction.

4.5.1

4.5.2

Raw volumetric flow rate

The "raw" volumetric flow rate is calculated from the average gas flow velocity (wetcalibration gas flow velocity) as shown in Equation 4-8.

Equation 4-8: Raw volumetric flow rate

2

Q

= V

Raw

where

Q

= “raw” volumetric flow rate (m3/h) (QMeter)

Raw

V

= wet-calibration gas flow velocity (m/s) (AvgFlow)

WetCal

π = geometric constant, pi (dimensionless) (3.14159...)

D = pipe inside diameter (m) (PipeDiam)

WetCal

πD

⋅

⋅ 3600 s/ℎ

4

Flow-condition volumetric flow rate

The flow-condition volumetric flow rate is the result of applying expansion correction and

flow- profile correction to the raw volumetric flow rate as shown in Equation 4-9 subject to

the low- flow cut-off. If the resulting value is below the low-flow cut-off value, it is set to

zero. The low-flow cut-off volumetric flow rate (QCutOff) is the specified low-flow velocity

threshold (ZeroCut) converted to a volumetric flow rate.

Equation 4-9: Flow-condition volumetric flow rate

Q

= Q

Flow

where

26 Emerson.com/Rosemount

ExpCorrPExpCorrTCorrFctr

Raw

Operations manual Measurement

00809-0800-3104 April 2022

Q

= flow-condition volumetric flow rate (m3/h) (QFlow)

Flow

Q

= “raw” volumetric flow rate (m3/h) (QMeter)

Raw

ExpCorrP = expansion correction factor due to pressure (dimensionless)

(ExpCorrPressure) calculated as shown in Equation 4-10.

ExpCorrT = expansion correction factor due to temperature (dimensionless)

(ExpCorrTemperature) calculated as shown in Equation 4-12.

CorrFctr = profile-effect correction factor (CorrectionFactor) calculated as shown in

Equation 4-11.

4.5.3 Pressure-effect expansion correction

The meter is capable of correcting the raw volumetric flow rate for the effect of pipe

expansion due to pressure changes.

Note that for the pressure-effect expansion correction factor to be calculated, the

correction must be enabled (via the EnableExpCorrPress data point) and the flowcondition pressure must be available (i.e., the EnablePressureInput data point must be set

to 'Live'(1) or 'Fixed'(2), see Configure the pressure parameters for the meter. The

pressure-effect calculation is shown in Equation 4-10. If the pressure-effect expansion

correction factor is not calculated, it is set to 1.0.

Equation 4-10: Pressure-effect expansion correction

ExpCorrP= 1 + 3 × β × P

abs, f

− P

ref

where

ExpCorrP = expansion correction factor due to pressure (dimensionless)

(ExpCorrPressure)

ß = pipe linear expansion coefficient due to temperature (MPaas-1)

(StrainPerUnitStress) calculated as shown in Equation 4-8.

P

= flow-condition absolute pressure (MPaa) (AbsFlowPressure) calculated as

abs,f

shown in Equation 4-13

P

= reference absolute pressure (MPaa) (0.101325MPaa) reference temperature for

ref

the pipe linear expansion coefficient (K)

Equation 4-11: Pressure-effect strain per unit stress

β=

2

D

out

1+υ + D

E× D

2

out

‐D

2

in

2

in

1‐2υ

where

β = pipe strain per unit stress (MPaa-1) (StrainPerUnitStress)

D

= outside diameter of the meter or pipe (m) (PipeOutsideDiameter)

out

Din = inside diameter of the meter or pipe (m) (PipeDiam)

ʋ = Poisson’s Ratio (dimensionless) (PoissonsRatio)

E = Young’s Modulus of elasticity (MPaa) (YoungsModulus)

Rosemount Model 3418 GUSM 27

Measurement Operations manual

April 2022 00809-0800-3104

4.5.4 Temperature-effect expansion correction

The meter is capable of correcting the raw volumetric flow rate for the effect of pipe

expansion due to temperature changes.

Note that for the temperature-effect expansion correction factor to be calculated, the

correction must be enabled (via the EnableExpCorrTemp data point) and the flowcondition temperature must be available (i.e., the EnableTemperatureInput data point

must be set to 'Live'(1) or 'Fixed'(2), see Temperature expansion correction . The

temperature-effect calculation is shown in Equation 4-12. If the temperature-effect

expansion correction factor is not calculated, it is set to 1.0.

Equation 4-12: Temperature-effect expansion correction

4.5.5

ExpCorrT= 1 + 3 × α × Tf− T

ref

where

ExpCorrT = expansion correction factor due to temperature (dimensionless)

(ExpCorrTemperature)

α = pipe linear expansion coefficient due to temperature (K-1) (LinearExpansionCoef)

Tf = flow-condition temperature (K) (FlowTemperature)

T

= reference temperature for the pipe linear expansion coefficient (K)

ref

(RefTempLinearExpCoef)

Base-condition volumetric flow rate

The base-condition volumetric flow rate is the result converting the flow-condition

volumetric flow rate to the base pressure-temperature condition.

This conversion requires (1) AGA8 calculations to be either performed internally (i.e., by

the meter) or externally (with the resulting compressibilities specified to the meter via the

SpecZFlow and SpecZBase data points), and (2) the flow-condition temperature and

pressure to be live or fixed. If AGA8 calculations are not performed (i.e., neither internally

nor externally) or the flow-condition temperature and/or pressure are/is not enabled, then

the base-condition volumetric flow rate is set to zero. The base-condition volumetric flow

rate is calculated as shown in Equation 4-13.

Equation 4-13: Base-condition volumetric flow rate

Q

Base

= Q

Flow

P

abs, f

P

abs, b

T

Z

b

b

T

Z

f

f

where

Q

= “raw” volumetric flow rate (m3/h) (QMeter)

Base

Q

= flow-condition volumetric flow rate (m3/h) (QFlow)

Flow

P

= flow-condition absolute pressure (MPaa) (AbsFlowPressure) calculated as

abs,b

shown in Equation 4-10.

Tb = base-condition temperature (K) (TBase)

Tf = flow-condition temperature (K) (FlowTemperature)

Zb = base-condition compressibility factor (ZBase)

28 Emerson.com/Rosemount

Operations manual Measurement

00809-0800-3104 April 2022

Zf = flow-condition compressibility factor (ZFlow)

4.5.6 Volume

The Rosemount 3410 Series Gas Ultrasonic Flow Meter provides forward and reverse

volume accumulators for each of the three volumetric flow rate values: raw, flowcondition (raw with expansion and/or profile correction), and base-condition.

Each volume accumulator is actually stored as a data pair: (64-bit unsigned integer

portion, 32-bit floating point fractional portion). For example, a volume of 12345.750 m

is stored as 12345 m3 for the integer portion and 0.750 m3 as the fractional portion. Note

that while a volumetric flow rate can be positive (indicating forward flow) or negative

(indicating reverse flow), the volume accumulators are always positive values.

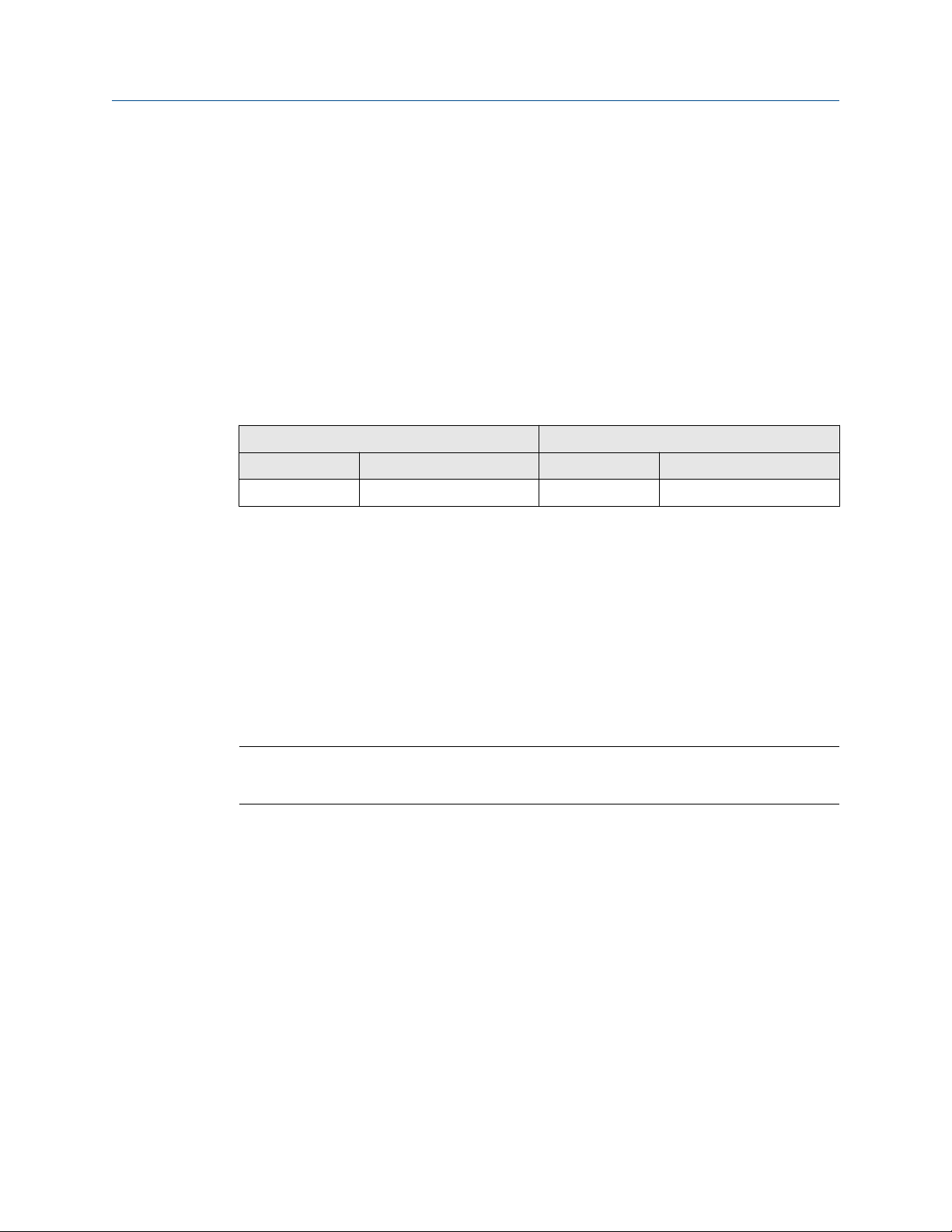

The non-volatile volume accumulator data points are as listed in the table below:

Table 4-3: Volume accumulation data points

Volumetric

flow rate type

Raw

Flow-condition

Base-condition

Forward Direction Reverse direction

Integer Fraction Integer Fraction

PosVolUncorr PosVolUncorrFrac NegVolUncorr NegVolUncorrFrac

PosVolFlow PosVolFlowFrac NegVolFlow NegVolFlowUncorr

PosVolBase PosVolBaseFrac NegVolBase NegVolBaseUncorr

4.5.7 Energy rate and totals

These calculations require that the flow-condition pressure and temperature are available

(either fixed or optional analog inputs, Flow-condition pressure and temperature, the gas

property data (composition and heating value) are available (either fixed or optionally read

from a GC, Flow-condition pressure and temperature), and the AGA8 calculations are

performed (internally by the meter or externally with the results written to the meter,

Flow-condition pressure and temperature).

3

The energy rate is calculated as shown in Equation 4-14

Equation 4-14: Energy rate

QE= Q

Base

× HV ×

1MJ

1000kJ

×

1000dm

3

1m

3

where

QE = energy rate (MJ/h) (EnergyRate)

Q

= base-condition volumetric flow rate (m3/h) (QBase)

Base

HV = "in-use" heating value (kJ/dm3) (HeatingValueInUse)

The sign of the energy rate indicates the flow direction: a positive value indicates flow in

the forward direction, a negative value indicates flow in the reverse direction.

The energy rate validity is indicated by the EnergyRateValidity data point TRUE(1)

indicates valid). The energy rate is valid if the base-condition volumetric flow rate is valid

Rosemount Model 3418 GUSM 29

Measurement Operations manual

April 2022 00809-0800-3104

(indicated by QBaseValidity where TRUE(1) indicates valid) and if the in-use gas properties

are valid (indicated by AreGasPropertiesInvalidInUse where FALSE(0) indicates valid).

The energy rate is accumulated into the corresponding direction energy total regardless of

the energy rate validity.

The forward and reverse direction energy totals are each stored in non-volatile memory as

a data pair: a 64-bit unsigned integer portion and a 32-bit floating point fractional portion.

For example, an energy total of 12345.750 MJ is stored as 12345 MJ for the integer portion

and 0.750 MJ as the fractional portion. Note that while the energy rate can be positive

(indicating forward flow) or negative (indicating reverse flow), the energy totals are always

positive values.

The non-volatile energy total data points are as listed in the table below:

Table 4-4: Energy total data points

Forward direction Reverse direction

Integer Fraction Integer Fraction

PosEnergy PosEnergyfrac NegEnergy NegEnergyFrac

4.5.8 Mass rate and totals

The Rosemount 3410 Series Gas Ultrasonic Flow Meter meter calculates the mass rate and

mass totals (forward and reverse).

These calculations requires that the flow-condition pressure and temperature are available

(either fixed or optional analog inputs, Gas properties), the gas composition is available

(either fixed or optionally read from a GC, Gas property data), and the AGA8 calculations

are performed (internally by the meter or externally with the results written to the meter,

Configure Gas Chromatograph parameters).

The mass rate is calculated as shown in Equation 4-15

Equation 4-15: Mass rate

MassRate = mass rate (kg/h) (MassRate)

Q

= flow-condition volumetric flow rate (m3/h) (QFlow)

Flow

ρ

= "in-use" flow-condition gas mass density (kg/m3) (RhoMixFlow)

Flow

The sign of the mass rate indicates the flow direction: a positive value indicates flow in the

forward direction, a negative value indicates flow in the reverse direction.

The mass rate validity is indicated by the MassRateValidity data point (TRUE(1) indicates

valid). The mass rate is valid if the flow-condition volumetric flow rate is valid (indicated by

QFlowValidity where TRUE(1) indicates valid) and if the AGA8 flow-condition calculation is

valid (indicated by AGA8FlowCalcValidity where TRUE(1) indicates valid).

MassRate = Q

Flow

× ρ

Flow

The mass rate is accumulated into the corresponding direction mass total regardless of

the mass rate validity.

The forward and reverse direction mass totals are each stored in non-volatile memory as a

data pair: a 64-bit unsigned integer portion and a 32-bit floating point fractional portion.

30 Emerson.com/Rosemount

Loading...

Loading...