Page 1

Retrofit Instructions

00825-0300-3240 , Rev AA

June 2022

Rosemount™ Gas Ultrasonic 3410 Series

Electronics Retrofit Instructions

Page 2

Retrofit Instructions June 2022

Safety and approval information

This Rosemount product complies with all applicable European directives when properly installed in

accordance with the instructions in this manual. Refer to the EU declaration of conformity for directives

that apply to this product. The EU declaration of conformity, with all applicable European directives,

and the complete ATEX Installation Drawings and Instructions are available on the internet at

www.emerson.com or through your local Emerson support center.

Information affixed to equipment that complies with the Pressure Equipment Directive, can be found

on the internet at http://www.emerson.com.

For hazardous installations in Europe, refer to standard EN 60079-14 if national standards do not apply.

Other information

Full product specifications can be found in the product data sheet. Troubleshooting information can be

found in the user manual. Product data sheets and manuals are available from the Emerson website at

http://www.emerson.com.

Return policy

Follow Emerson procedures when returning equipment. These procedures ensure legal compliance

with government transportation agencies and help provide a safe working environment for Emerson

employees. Emerson will not accept your returned equipment if you fail to follow Emerson procedures.

Return procedures and forms are available on our web support site at Emerson.com, or by phoning the

Emerson Customer Service department.

Emerson Flow customer service

Email:

• Worldwide: http://flow.support@emerson.com

• Asia-Pacific: http://APflow.support@emerson.com

Telephone:

North and South America

United States 800 522 6277 U.K. 0870 240 1978 Australia 800 158 727

Canada +1 303 527 5200 The

Mexico +41 (0) 41 7686

Argentina +54 11 4837 7000 Germany 0800 182 5347 Pakistan 888 550 2682

Brazil +55 15 3413 8000 Italy 8008 77334 China +86 21 2892 9000

111

Europe and Middle East Asia Pacific

Netherlands

France 0800 917 901 India 800 440 1468

Central &

Eastern

Russia/CIS +7 495 981 9811 South Korea +82 2 3438 4600

Egypt 0800 000 0015 Singapore +65 6 777 8211

Oman 800 70101 Thailand 001 800 441 6426

Qatar 431 0044 Malaysia 800 814 008

Kuwait 663 299 01

South Africa 800 991 390

Saudi Arabia 800 844 9564

+31 (0) 704 136

666

+41 (0) 41 7686

111

New Zealand 099 128 804

Japan +81 3 5769 6803

2 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 3

June 2022 Retrofit Instructions

North and South America Europe and Middle East Asia Pacific

UAE 800 0444 0684

Contents

Plan..............................................................................................................................................5

Install......................................................................................................................................... 16

Operate......................................................................................................................................31

Mark III RS-232 and RS-485 Serial communications setup...........................................................44

Summary table of communications/output settings.................................................................. 52

3410 Communication and Output settings................................................................................ 56

3410 Series engineering drawings..............................................................................................72

Retrofit Instructions 3

Page 4

Retrofit Instructions June 2022

4 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 5

June 2022 Retrofit Instructions

1 Plan

1.1 Introduction

1.1.1 General

Welcome to the Rosemount 3410 Series Ultrasonic Retrofit Instruction

Manual.

This manual has been designed to provide you with a step-by-step set of

instructions for retrofitting a meter with Mark III electronics to the new 3410

Series electronics.

NOTICE

Please read the “Before You Begin” section to make sure you have all the

components necessary to perform the before taking the meter out of

service.

Important

If retrofitting from Mark II electronics to 3410 Series electronics complete

Sections 3 and 4 in the Rosemount Ultrasonic Mark III Upgrade Kit

Instructions to determine the communications and output settings of the

Mark II electronics. Use those settings and the instructions in this manual to

configure the Series electronics.

Retrofit Instructions 5

Page 6

Retrofit Instructions June 2022

1.2 Before you begin

This section shows all of the parts and tools required to perform the

upgrade. Ensure that all of these items are available before taking the meter

out of service.

1.2.1 Tools required

Figure 1-1: Required Tools

A. ⅛-in. flat-blade screw driver

B. ¼-in. flat-blade screw driver

C. 3/8-in. drive ratchet wrench

D. 3/8-in. drive - extension - at least 3.5-in. long

E. 3/8-in. drive - 7/16-in. socket

F. Allen wrench - size 6 mm (included in Retrofit kit)

G. Crescent wrench for cable glands and electrical conduit

MeterLink™ is required to communicate with the meter electronics, access

information and collect the configuration in the meter and then convert and

download the configuration into the new 3410 Series electronics. Always

use the latest version of MeterLink™. Upgrades to the latest version are

available at: Emerson.com/Rosemount

6 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 7

June 2022 Retrofit Instructions

1.3 Before removing the Electronics

1.3.1 Procedure before removing the Mark III Electronics

Procedure

1. Before removing power from the meter being retrofitted software to

connect to the meter.

2. Use the Edit/Compare Configuration screen in MeterLink

to read the configuration from the meter and save it to a file on your

computer. An example for a file name might be “Meter Name, MkIII

Final Config, 3-4-2013 10-15-02 AM.cfg”. MeterLink will be used later

in this procedure (see Configure the 3410 Series Electronics) to

convert the configuration and download it to the 3410 Series

electronics.

™

CAUTION

Loss of set-up data

The current meter configuration file must be saved before beginning

the 3410 Series electronics retrofit.

Failure to save the current configuration file can result in the loss of

important set-up data.

3 through 8 provide more detailed instructions on obtaining the

required information with respect to the communications set-up of

the electronics, however, if these settings are already known, these

steps can be skipped. Step 8 is for Frequency and Diagnostic outputs.

For reference, the known values should be entered in the Summary

table of communications/output settings in Appendix B. This

information will be required in the setup of the Series electronics. For

any setting which is not known, the applicable step(s) for obtaining

that information can be used.

3. Use the File|Meter Directory menu path, then select the

<meter name> you want to retrofit.

a) Click the Direct button on the lower left corner of the Meter

Directory dialog box.

b) The Direct Connection Properties For dialog appears.

c) Obtain the Modbus ID (same as Comms Address).

Retrofit Instructions 7

Page 8

Retrofit Instructions June 2022

Figure 1-2: Accessing Modbus ID for Ports A and B

4. Based on the information contained in the connection properties

window, enter the values for the following parameters in the

Summary table of communications/output settings in Appendix B:

Port A and B: Modbus ID = _____(enter Comms Address).

5. Exit MeterLink and disconnect your PC from the meter electronics.

The remaining information required before doing the retrofit

upgrade, is based on the wiring terminations and the settings of

various switches on the boards that comprise the electronics.

6. Power down the electronics.

CAUTION

Equipment damage

Remove power from the meter electronics.

Failure to remove power from the meter electronics may result in

damage to the equipment.

7. Remove the end caps from the upper electronics housing of the

meter to access the electronic circuit boards. See Figure 1-4 for

board layout of the 3400 stacks. See Figure 3-4 for the 3410 Series

electronics for board layout.

8 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 9

June 2022 Retrofit Instructions

Figure 1-3: Remove End Caps from the Upper Electronics

Enclosure

Figure 1-4: 3400 Electronics Assembly board layout

Retrofit Instructions 9

Page 10

Retrofit Instructions June 2022

Figure 1-5: 3410 Retrofit Electronics Assembly

A. End cap and security screw

B. O-ring

C. Desiccant packet

D. CPU module

E. Optional RS-232 I/O module

F. Optional RS-485 I/O module

G. Blanking cover

H. Guide plate

I. M20 reducer

J. Ground lug - external

K. Transmitter electronics enclosure

L. Power supply

M. I.S. barrier board

N. Standoffs

O. Backplane board

P. O-ring

Q. End cap and security screw

R. O-ring

S. Acquisition cable and roll pin

T. Acquisition module assembly

U. Base enclosure

V. Cable glands

W. Gasket, base enclosure

X. Acquisition cable clamp

10 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 11

June 2022 Retrofit Instructions

Y. Acquisition module

8. Remove the Mark III electronics CPU board, the HART Option Board,

and the Field Termination Board from the enclosure. Fill out the

Summary table of communications/output settings in Appendix B

based on the Field Connection Board wire terminations and/or switch

settings of the CPU board and Option Board, if installed. This

information will be used to configure the new 3410 Series electronics

later in this procedure.

Figure 1-6: Mark III CPU Board Showing Switch Settings

Retrofit Instructions 11

Page 12

Retrofit Instructions June 2022

Figure 1-7: Mark III CPU Board with I.S. Barrier Board PiggyBacked on CPU Board

1.4 Removing Mark III Electronics

1.4.1 Procedure to remove the Mark III Electronics

Procedure

1. Having obtained all the information related to the set-up of the 3400

Series electronics configuration and communications, all the

components related to the electronics can now be physically

removed from the meter. Unscrew all wiring from the Field

Termination Board. It may be helpful to label the wires to make it

easier to connect the 3410 Series electronics.

2. Remove any conduit and wiring attached to all six conduit ports.

3. Remove any ground wire attached to the ground lug on the outside

of the upper electronics housing. At this point there should be no

wires connected to the upper electronics housing.

12 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 13

June 2022 Retrofit Instructions

Figure 1-8: Ground Wire Removed

4. Use the 6mm Allen wrench (supplied with retrofit kit) to remove the

two bolts holding the base enclosure.

Figure 1-9: Remove Bolts from Base Enclosure Cover

5. Remove the upper electronics housing from the base enclosure.

a) Remove the Acquisition cable, which comes down from the

upper electronics to the Acquisition module in the base

enclosure.

Retrofit Instructions 13

Page 14

Retrofit Instructions June 2022

NOTICE

Figure 1-10 shows the Acquisition module for the 3400 Series

electronics.

b) Loosen the two screws on the ends of the Acquisition cable

connector, and disconnect it from the Acquisition module.

c) Set the upper electronics housing aside once the housing is

removed.

Figure 1-10: Remove the Acquisition Cable

6. Remove all the screws that hold the transducer wires in the terminal

blocks that attach the transducers to the Acquisition module.

a) Remove the screws from the ends of the two connectors.

b) Disconnect the connectors and remove each of the

transducer wires from the connector.

7. Loosen the cable glands on the base enclosure and pull all of the

transducer cables out of the base enclosure.

8. Unscrew the three screws holding the Acquisition module in the base

enclosure and remove the Acquisition module.

The four mounting bolts holding the enclosure cover to the meter

body are sealed with an RTV silicone adhesive/sealant.

14 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 15

June 2022 Retrofit Instructions

9. Remove the RTV with a flat blade screwdriver or utility knife around

the perimeter of the recessed opening and the RTV eases the

removal of the sealant.

a) Use the 7/16-in. socket wrench to remove the four mounting

bolts.

Figure 1-11: Remove Old RTV

10. Remove the base enclosure from the meter body.

11. If RTV silicone adhesive/sealant was used to seal the base enclosure

to the meter body, remove the adhesive/sealant so the 3410 base

enclosure will have a clean mounting surface.

The 3400 Series electronics should be completely removed from the

meter body at this time.

Retrofit Instructions 15

Page 16

Retrofit Instructions June 2022

2 Install

2.1 Installing the 3410 Series Electronics

2.1.1 Procedure to install the 3410 Series Electronics

Procedure

1. Remove the 3410 components from the packaging.

a) Use the 6 mm Allen wrench to remove the two screws from

the base enclosure cover.

Figure 2-1: Remove Bolts from Base Enclosure Cover

2. Lift the upper electronics housing from the base enclosure. The

acquisition cable connector from the upper electronics is attached to

the acquisition module with two screws. The cable is also secured by

a cable clamp to a mounting bolt.

a) Remove the screw securing the cable clamp and then loosen

the two screws on the acquisition cable connector and

disconnect the acquisition cable connector from the

acquisition module.

16 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 17

June 2022 Retrofit Instructions

Figure 2-2: Remove Acquisition Cable and Module

3. Unscrew the remaining two mounting screws from the acquisition

module in the base enclosure and remove the acquisition board.

4. Place an insulating gasket on the meter body where the electronics

will be mounted (see gasket in Figure 1-5).

5. Place the base enclosure on top of the meter body on top of the

insulating gasket. Note that the transducer port openings on the

base enclosure are labeled with transducer locations (i.e., A1, A2, B1,

B2, C1, C2, D1, D2).

a) Orient the base so that the A1 transducer port is closest to the

A1 transducer location on the meter body. The meter body

has the transducer location labels embossed in the body next

to each transducer boss. The ports on the base enclosure

must be oriented outward (towards the sides of the meter

body, perpendicular to meter axis).

Figure 2-3: Base Enclosure Orientation

6. Use the four ¼-in. bolts with stainless steel washers and nylon

shoulder washers to secure the base enclosure to the meter body.

a) Use a nut driver to tighten the bolts to a torque of 55 to 65

inch-lbs.

Retrofit Instructions 17

Page 18

Retrofit Instructions June 2022

Figure 2-4: Insert ¼-in. Bolts

7. Fill up the base enclosure wells with RTV adhesive/sealant around

and over the four ¼-in. bolts.

This will ensure a water-tight seal. Any excess sealant can be

removed by using a scraper to leave the sealant flush with the top of

the well. Excess sealant will adhere to the acquisition board when it is

installed, and make future removal of the board difficult.

Figure 2-5: Apply RTV Sealant Around Bolts

8. Insert the Acquisition board in the base enclosure and secure it with

the two screws as shown for now.

18 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 19

June 2022 Retrofit Instructions

Figure 2-6: Acquisition Module Attachment Screws

Figure 2-7: Acquisition Module Wiring

9. Route the transducer cables through the cable glands with the

correct label number (i.e. A1) which matches the label on the

transducer cable.

Figure 2-8: Base Enclosure Cable Glands Installation

10. Judge the proper length and cut off the excess.

Retrofit Instructions 19

Page 20

Retrofit Instructions June 2022

11. Strip the outer insulation, outer shield, and inner insulation using a

utility knife. Verify that insulation of individual wires was not cut

while removing outer layers. Strip each wire 0.28-in.

Figure 2-9: Transducer Cable Cut Instructions

12. Insert tubing over wires, inner insulation and under shield

approximately 1.5-in. of shield should overlap.

13. Insert and secure transducer cables through cable glands verify Line

Mark is as referenced in Figure 2-8.

Figure 2-10: Line Mark

14. Using a torque screwdriver set to 34 ±2 oz.-in., secure the wires to

the terminal plugs of the Acquisition Module.

15. Verify the cable lengths are still an appropriate length and if

necessary, cut the transducer cables to the correct length with

allowance for the wiring terminations and connector placement.

16. Ensure that the contacts clamp on the bare wires and not on the wire

insulation when the wires are being terminated on the connector.

a) Leave the connector plugged into the Acquisition board while

terminating the individual wires.

b) Tighten the connector screws on the either end of the

connector after terminating all the wires on the applicable

connector.

c) Repeat this procedure for the transducer cables on the other

side of the meter.

20 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 21

June 2022 Retrofit Instructions

Figure 2-11: Install Cable and Secure Wires

17. Use the cable ties to dress the transducer cables. They should be

dressed in groups of two: A1 and C1, D1 and B1, A2 and C2, D2 and

B2. Install one cable tie at three inches from the base enclosure and

another about the point where the cables start to bend and separate

out to their respective port.

Retrofit Instructions 21

Page 22

Retrofit Instructions June 2022

Figure 2-12: Re-oriented and Secured Transducer Cables

18. Reconnect the acquisition cable connector to the acquisition module

and secure the cable connector by tightening the two screws.

19. Install the cable clamp on the Acquisition cable and secure it with the

final mounting screw for the Acquisition module.

22 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 23

June 2022 Retrofit Instructions

Figure 2-13: Installing the Acquisition Module Cable Clamp

A. Acquisition cable connector

B. Acquisition cable

C. Cable clamp and screw

20. Wrap the excess cable around the Acquisition Module and place the

electronics housing into position on the base enclosure.

21. Ensure the O-ring on the base of the upper enclosure is properly

seated. Position the upper enclosure housing so that it is in the

desired orientation for reattaching the electrical conduit.

22. Install the 3410 meter upper enclosure on the base enclosure once

the transducers are wired correctly.

23. Install the two screws with the 6 mm Allen wrench to secure the

upper enclosure to the base enclosure.

Retrofit Instructions 23

Page 24

Retrofit Instructions June 2022

Figure 2-14: Bolt the Upper Enclosure to Base Enclosure

24. Remove the end cap next to the conduit entries from the upper

enclosure. #unique_21/

unique_21_Connect_42_fig_B809C95392804A6EA94B366E5DF175

C4 shows the layout of the electronics.

24 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 25

June 2022 Retrofit Instructions

Figure 2-15: 3410 Series Electronics Layout

A. End cap and security screw

B. O-ring

C. Desiccant packet

D. CPU Module

E. Optional RS-232 I/O module

F. Optional RS-485 I/O module

G. Blanking cover

H. Guide plate

I. M20 reducer

J. Ground lug - external

K. Transmitter electronics enclosure

L. Power supply

M. I.S. Barrier board

N. Standoffs

O. Backplane board

P. O-ring

Q. End cap and security screw

R. O-ring

S. Acquisition cable and roll pin

T. Acquisition module assembly

U. Base enclosure

V. Cable glands

W. Gasket, base enclosure

X. Acquisition cable clamp

Y. Acquisition module

Retrofit Instructions 25

Page 26

Retrofit Instructions June 2022

The following table shows the default communications and output

settings for the 3410 electronics and configuration.

Table 2-1: 3410 Series Default Communications and Output

Settings

Communication

/output type

Serial port A Modbus ID = 32 Baud rate =

Frequency/

digital output 1

Frequency/

digital output 2

Frequency/

digital output 3

If the settings above are not consistent with those used in your

meter, then these parameters can be changed using MeterLink

Default setting Default setting Note

Port B and port C

are available if

optional RS-232

and RS- 485 I/O

modules are

installed

Frequency

output 1A is

configured for

uncorrected

forward flow

Frequency

output 2A is

configured for

uncorrected

forward flow

Digital output 1A

is configured for

validity status

Configured to

output frequency

1A

Configured to

output frequency

2A

Configured to

output digital

output 1A

19200

Drive mode =

open collector

Drive mode =

open collector

Drive mode =

open collector

™

software to reconfigure the communication ports and output ports

later in this procedure. 3410 Communication and Output settings of

this document contains additional details with respect to the wiring

related to the communications and discrete output signals.

Notice

MeterLink™ cannot communicate with 3410 meters over a halfduplex serial connection. As a result, for MeterLink to communicate

via a serial connection, that port on the 3410 electronics must be set

for RS-232-Full Duplex, or RS-485-Full Duplex (requires 4 conductor

cables).

25. Check the CPU module switches on the to ensure they are set

properly.

26 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 27

June 2022 Retrofit Instructions

Figure 2-16: CPU Switch Settings

A. WRITE PROT. switch

B. DHCP switch

C. Port A (override)

The DHCP switch enables or disables the DHCP server for Ethernet

communication. The WRITE PROT. switch enables or disables “write

protection” of the meter configuration.

Set the DHCP switch to the ON position to enable Ethernet

communication via the DHCP server. Set the WRITE PROT. switch to

the OFF position to allow configuration parameters to be written to

the meter. Only enable the DHCP server if the meter is not connected

to a network that may have a DHCP server already running. The

DHCP server is designed for use when a PC connects directly to the

meter and requires the meter to assign the PC an IP address.

26. Wire all of the electrical connections.

Retrofit Instructions 27

Page 28

Retrofit Instructions June 2022

Figure 2-17: Install Wiring Terminal Block Connectors to the CPU

Module (shown with Optional I/O Modules)

A. CPU lower terminal block

B. CPU upper terminal block and switches

C. CPU module

D. 24 VDC loop power

E. Optional RS-232 I/O module

F. 10.4 - 36 VDC power

G. Fuse

H. Optional RS-485 I/O module

I. Ethernet terminal block

J. Chassis ground

28 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 29

June 2022 Retrofit Instructions

Figure 2-18: Install Wiring Terminal Block Connectors to the CPU

Module (shown without optional I/O modules)

A. CPU lower terminal block

B. CPU upper terminal block and switches

C. CPU module

D. 24 VDC loop power

E. 10.4 - 36 VDC power

F. Guide plate blanking cover

G. Fuse

H. Guide plate blanking cover

I. Guide plate blanking cover

All of the terminations in the 3410 Series electronics are removable

terminal blocks. Removing the terminal blocks from the modules

before terminating wires to them makes wiring easier. 3410

Communication and Output settings of this document also includes

wiring tables and illustrations for each of the connectors in the

Retrofit Instructions 29

Page 30

Retrofit Instructions June 2022

electronics. Refer to the System Wiring Drawing in 3410 Series

engineering drawings.

27. Install a ground wire to the ground lug on the side of the upper

enclosure.

Figure 2-19: Transmitter Electronics Enclosure Ground Wire

28. Attach flex conduit to the conduit ports on the transmitter

electronics enclosure.

Before applying power to the meter, ensure the atmosphere is

proven safe using an intrinsically safe gas detector.

WARNING

EXPLOSION HAZARD

Do not apply power to the meter with the end caps removed unless

you are in a non-hazardous or explosive-free environment.

Failure to comply could result in death, serious injury and possible

equipment damage.

29. Apply the sealing compound to the conduit seal fittings and allow to

set in accordance with manufacturer specifications.

30. Apply electrical power to the system and verify the field connections

are working correctly.

31. Do not install end caps until you configure the meter.

This completes the installation of the hardware associated with the

3410 Series Electronics meter retrofit procedure.

30 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 31

June 2022 Retrofit Instructions

3 Operate

3.1 Configure the 3410 Series Electronics

1. Check all settings and wiring carefully.

2. Set up the Meter Directory, and start initial communication with the

3410 Series electronics.

The basic instructions for setting up the directory and initializing

communications are contained in the following text. Refer to the 3410

Series Gas Ultrasonic Flow Meter Installation Manual for more detailed

instructions. Use MeterLink v1.10 or later to make a connection to the

meter.

3.1.1 Initial communication connection using Ethernet Ethernet initial connection material checklist

The following materials and information are required:

• 3410 Ethernet adapter cable

• Personal computer (PC) configured as follows:

— MeterLink software installed (version 1.10 or later)

— Ethernet LAN adapter

— Configured to automatically obtain IP address (via DHCP)

• Desired 3410 Series meter(s) communication configuration parameters:

— IP address

— Serial communication parameters such as baud rate and Modbus ID

(if desired)

Ethernet initial connection steps

Procedure

1. Power up the 3410 Series meter and wait two minutes for the meter

to startup.

2. Ensure that the Ethernet DHCP server is enabled on the 3410 CPU

Module by setting DHCP switch to the ON position.

3. Plug the Ethernet adapter cable into the meter CPU Module and

connect the RJ45 end into the PC Ethernet connector.

4. Verify the Ethernet connection status by the 3410 CPU Module LINK

LED which should be solid green.

5. Start MeterLink™ on the PC. The Connect to Meter dialog displays.

a) Click the Edit Meter Directory button.

Retrofit Instructions 31

Page 32

Retrofit Instructions June 2022

b) Click the Add button (below the Meter Directory file

operations field). MeterLink inserts the New Meter record in

the last field in the Meter Directory table.

6. Create a new meter directory record with the following parameters:

a) Enter a name for the meter.

b) Select Meter Type as Gas or Liquid as appropriate.

c) Check the Ethernet box and uncheck the Direct and Modem

boxes.

d) Set the Ethernet IP address to 192.168.135.100.

e) Close the Meter Directory window.

7. Use the Meter|Connect menu path and click the Ethernet

connection for the meter record established in the previous step.

MeterLink™ will now connect to the meter using the user-specified

Ethernet settings.

3.1.2 Initial communication connection using RS-232 Serial Communications settings and Field Setup Wizard

RS-232 Serial initial connection material checklist

The following materials and information are required:

• Ultrasonic serial cable.

• Personal computer (PC) with MeterLink™ software version 1.10 (or later)

• Desired 3410 meter(s) communication configuration parameters:

— IP address (if desired)

— Serial communication parameters such as baud rate and Modbus ID

RS-232 Serial initial connection steps

Procedure

1. Power up the 3410 meter and PC.

2. Plug the DB-9 end of the cable directly into the PC running

MeterLink. The three wires on the other end of the cable connect to

RX, TX, and COM terminals on the CPU Module. The Digital Out wire

goes to RX, the Digital In wire goes to TX, and the COMMON wire

goes to COM.

32 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 33

June 2022 Retrofit Instructions

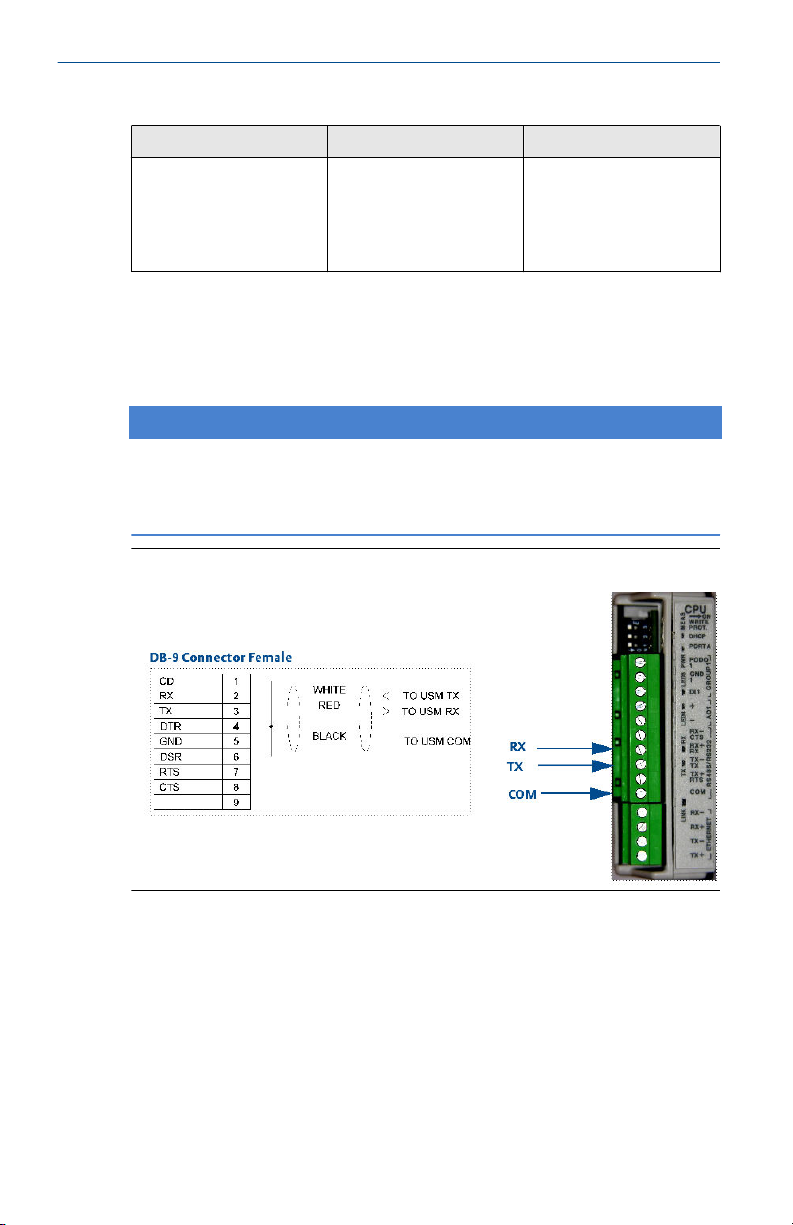

Figure 3-1: CPU RS-232 serial connection

Table 3-1: CPU RS-232/RS-485 wire colors

CPU Wire colors

R X Red

T X White

C O M Black

3. Start MeterLink™ on the PC and create a new Meter Directory record

with the following parameters:

Retrofit Instructions 33

Page 34

Retrofit Instructions June 2022

a) Enter a name.

b) Select Meter Type as Gas or Liquid as appropriate.

c) Check the Direct box and uncheck the Modem and Ethernet

boxes.

d) Set the Direct connection properties for Baud Rate of 19200

and Comms Address (Modbus ID) of 32.

4. Use the Meter|Connect menu path and click Direct connection for

the meter record established above. MeterLink™ will now connect to

the meter using the user-specified serial communication settings.

34 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 35

June 2022 Retrofit Instructions

Follow the instructions in LINK HERE to write the converted

configuration file to the meter.

Meter Communications Settings

Procedure

1. Use the Meter|Communications Settings menu path to

access the Communications dialog.

This dialog displays the communications parameters for the 3410

Series electronics and is used to adjust the Baud Rate and Comms

Address (i.e. Modbus ID) for the serial ports.

Figure 3-2: Communications Settings dialog

2. Use the

Driver selection pull-down menu if communication settings

require RS-485

Retrofit Instructions 35

Page 36

Retrofit Instructions June 2022

Figure 3-3: Change driver selection for RS-485 half duplex or full

duplex communication

3.1.3 Write the converted configuration file to the meter

Important

If the Mark III electronics contained keys, the user needs to ensure the same

keys are enabled in the 3410 electronics prior to writing the convereted

configuration. Otherwise, some configuration points may not be able to be

written.

Writing the converted configuration file to the meter

Procedure

1. With communication to the meter established, use the Tools|Edit/

Compare Configuration menu path to access the Edit/Compare

Configuration dialog.

36 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 37

June 2022 Retrofit Instructions

2. Click Open and the Open Configuration File dialog

displays.

Figure 3-4: Edit/Compare Configuration Dialog

a) Select the final configuration file created in Step 2 of

Procedure before removing the Mark III Electronics of this

document (i.e., “Meter Name, MKIII Final Config, 3-4-2005

10-15-02 AM.cfg”).

b) Click Open. The file opens and you returned to the Edit/

Compare Configuration dialog.

Figure 3-5: Open Configuration File Dialog

c) Click Convert (see Figure 3-6). MeterLink™ reads the 3410

configuration from the meter and modifies it with the 3410

configuration.

Retrofit Instructions 37

Page 38

Retrofit Instructions June 2022

Figure 3-6: Edit/Compare Configuration Dialog with

Active Convert Button

If the meter supports HART, check the 2nd variable

parameter setting using the Field Setup Wizard|

Current Outputs dialog. A reminder dialog prompts you

to set this parameter.

Figure 3-7: HART Parameter Settings

For Gas ultrasonic meters, the HART Secondary Variable

options are:

• Uncorrected flow rate

• Corrected flow rate

• Average flow velocity

• Average sound velocity

• Energy flow rate

• Mass flow rate

All data points shown in yellow have been modified from the

3400 configuration.

38 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 39

June 2022 Retrofit Instructions

Figure 3-8: Converted Configuration with Highlighted

Changes

d) Click Write Checked to write the converted configuration to

the meter (see Figure 3-8). If an error occurs, MeterLink™ will

display a message indicating the nature of the problem.

Manually edit the parameter(s) with errors to successfully

complete the download.

e) Click Write Checked again after modifying the parameter(s).

Repeat this until the write occurs with no errors.

f) Save the 3400 Series electronics configuration file to your PC.

g) With the converted configuration still displayed, from the

Edit/Compare Configuration dialog, click the Meter radio

button, located next to the Compare button (see Figure 3-8).

h) Compare the file to verify that this saved configuration

matches the meter configuration. If an error occurs, go back

to the beginning of the Step 2 and try again until no errors are

reported.

3. Use the Meter|Monitor menu path to display the Monitor

window and verify that the meter is operating correctly.

Retrofit Instructions 39

Page 40

Retrofit Instructions June 2022

Figure 3-9: Meter Monitor Dialog

3.1.4 Configure the meter using the Field Setup Wizard Configuring the meter using the Field Setup Wizard

Procedure

1. Use the Meter|Field Setup Wizard menu path to access the

Field Setup Wizard Startup dialog.

a) Verify that all settings (options) are correct (e.g.,

temperature, pressure, meter connections and meter

outputs).

b) In the Meter name field insert a name for the meter (this

name displays on MeterLink™ main window and the

Maintenance logs and Reports files).

c) Ensure the 3410 Series Electronics digital outputs are

configured appropriately. The 3410 Series Electronics also

supports, and may be configured for, the AGA8 Detailed

Method.

40 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 41

June 2022 Retrofit Instructions

Figure 3-10: Field Setup Wizard Startup Dialog

2. Setup the Frequency and Digital Output Sources parameters from

the Field Setup Wizard Frequency/Digital Outputs Sources Page.

Figure 3-11: Field Setup Wizard Frequency and Digital Output

Sources Page

Retrofit Instructions 41

Page 42

Retrofit Instructions June 2022

The meter has user-configurable selections for either a frequency

output or digital status (FODO). Use the pull-down menus to edit

these parameters.

(3) Frequency/Digital Outputs:

• FODO1 (four possible output configurations)

• FODO2(eight possible output configurations)

• FODO3(eight possible output configurations)

Frequency or Digital Outputs (FODO 1) source selections:

• FO1A, DO1A, FO1B, DO1B

Frequency or Digital Outputs (FODO 2) source selections:

• FO1A, DO1A, FO1B, DO1B, FO2A, DO2A, FO2B, DO2B

Frequency or Digital Outputs (FODO 3) source selections:

• FO1A, DO1A, FO1B, DO1B, FO2A, DO2A, FO2B, DO2B

Mode options:

• Open Collector (requires external excitation supply voltage and

pull-up resistor)

• TTL (internally powered by the meter 0-5 VDC signal)

Channel B Phase options:

• Lag forward, Lead reverse (Phase B lags Phase A while reporting

forward flow, leads Phase A while reporting reverse flow)

• Lead forward, Lag reverse (Phase B leads Phase A while reporting

forward flow, lags Phase A while reporting reverse flow)

Phase A and Phase B output (based on flow direction):

• Reverse flow - output only reports flow in the reverse direction.

For frequency outputs, Phase B of the output is 90 degrees out of

phase with Phase A.

• Forward flow - output only reports flow in the forward direction.

For frequency outputs, Phase B of the output is 90 degrees out of

phase with Phase A.

• Absolute - output reports flow in both directions. For frequency

outputs, Phase B of the output is 90 degrees out of phase with

Phase A.

• Bidirectional - output reports flow on Phase A only in the forward

direction and on Phase B only in the reverse direction.

Maximum frequency for the frequency outputs:

42 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 43

June 2022 Retrofit Instructions

• 1000 Hz

• 5000Hz

3. If changes were made in the Field Setup Wizard, choose to save the

configuration when MeterLink™ prompts you after the changes are

written to the meter. Click Finish in the Field Setup Wizard dialog to

write any changes to the meter.

4. You have successfully completed upgrading your3400 electronics to

3410 Series electronics.

5. Save your configuration file for the meter's parameters you just set as

the “As Left Settings”.

Retrofit Instructions 43

Page 44

Retrofit Instructions June 2022

A Mark III RS-232 and RS-485 Serial

communications setup

A.1 Mark III RS-232 Full Duplex

Figure A-1: Port A Settings

Figure A-2: Port B Settings

44 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 45

June 2022 Retrofit Instructions

A.2 Mark III RS-485 Half Duplex

Figure A-3: Port A Settings (Factory Default Switch Settings for Port A)

Figure A-4: Port B Settings

A.3 Mark III Discrete output switch settings

Figure A-5: Group 1 Frequency and Digital Outputs

Retrofit Instructions 45

Page 46

Retrofit Instructions June 2022

Figure A-6: Group 2 Frequency and Digital Outputs

Figure A-7: Series 100 Option Board (If Installed)

46 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 47

June 2022 Retrofit Instructions

A.4 Mark III RS-232 Full Duplex

Figure A-8: Port C Settings

A.5 Mark III RS-485 Half Duplex

Figure A-9: Port C Settings

A.6 Mark III Series 100 option board (if installed)

Figure A-10: Analog Output 1

Retrofit Instructions 47

Page 48

Retrofit Instructions June 2022

Figure A-11: Analog Input 1 (Temperature)

Figure A-12: Analog Input 2 (Pressure)

Figure A-13: Series 100 Plus HART Option Board (If Installed)

48 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 49

June 2022 Retrofit Instructions

A.7 Mark III RS-232 Full Duplex

Figure A-14: Port C Settings

A.8 Mark III RS-485 Half Duplex

Figure A-15: Port C Settings

A.9 Mark III Series 100 plus HART option board (if installed)

Figure A-16: Analog Output 1

Retrofit Instructions 49

Page 50

Retrofit Instructions June 2022

Figure A-17: Analog Output 2 (HART capable)

Figure A-18: Analog Input 1 (Temperature)

Figure A-19: Analog Input 2 (Pressure)

50 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 51

June 2022 Retrofit Instructions

Retrofit Instructions 51

Page 52

Retrofit Instructions June 2022

B Summary table of communications/output

settings

Based on switch position on the 3400 CPU board and Option board if

installed, indicate the appropriate configuration for each communication/

output parameters on the 3400 electronics. Use these parameters to

configure the 3410 Series electronics.

Table B-1: Communications/Output Settings Summary Table

Output

type

Serial

port A

Serial

port B

Serial

port C

Digital

output

1A

Digital

output

1B

Frequen

cy

output

1A

Digital

output

2A

Digital

output

2B

(Check electronics switch settings and circle appropriate box for

each output)

Not

used (if

J6 not

used)

Not

used (if

J7 not

used)

Not

used (if

J16 not

used)

Not

used (if

J4-2 not

used)

Not

used (if

J4-1 not

used)

Not

used (if

J4-1 not

used)

Not

used (if

J5-2 not

used)

Not

used (if

J5-2 not

used)

RS-232 (if S3 is set

to RS232)

RS-232 (if S4 is set

to RS232)

RS-232 (if S10 is

set to RS232)

TTL (if S8-1 is set

to TTL)

TTL (if S8-2 is set

to TTL)

TTL (if S8-3 is set

to TTL)

TTL (if S9-1 is set

to TTL)

TTL (if S9-2 is set

to TTL)

RS-485 Half

Duplex (if S3 is set

to RS-485 and S5-1

is set to Half

RS-485 Half

Duplex (if S4 is set

to RS482 and S5-2

is set to Half)

RS-485 Half

Duplex (if S10 is

set to RS-485)

Open Collector (if

S8-1 is set to OC)

Open Collector (if

S8-2 is set to OC)

Open Collector (if

S8-3 is set to OC)

Open Collector (if

S8-1 is set to OC)

Open Collector (if

S9-2 is set to OC)

RS-485 Full Duplex

(if S3 is set to

RS-485 and S5-1 is

set to Full

RS-485 Full Duplex

(if S4 is set to

RS-485 and S5-2 is

set to Full)

52 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 53

June 2022 Retrofit Instructions

Table B-1: Communications/Output Settings Summary Table

(continued)

Output

type

Frequen

cy

output

1B

Frequen

cy

output

2A

Frequen

cy

output

2B

Analog

input 1

Analog

input 2

Analog

output

1

Analog

output

2 (HART

Capable

)

(Check electronics switch settings and circle appropriate box for

each output)

Not

used (if

J5-1 not

used)

Not

used (if

J5-6 not

used)

Not

used (if

J5-5 not

used)

Not

used (if

J12-1

not

used)

Not

used (if

J12-3

not

used)

Not

used (if

J11 not

used)

Not

used (if

J10 not

used)

TTL (if S8-4 is set

to TTL)

TTL (if S9-3 is set

to TTL)

TTL (If S9-4 is set

to TTL)

Source (if S12 is

set to SRC)

Source (if S13 is

set to SRC)

Source (if S14 is

set to SRC)

Source (if S15 is

set to SRC)

Open Collector (if

S8-4 is set to OC)

Open Collector (if

S9-3 is set to OC)

Open Collector (if

S9-4 is set to OC)

Sink (if S12 is set to

SINK)

Sink (if S13 is set to

SINK)

Sink (if S14 is set to

SINK)

Sink (if S15 is set to

SINK)

Enter the results of the 3400 Summary Table of Communications/output

settings in the table below as a quick reference to setup the 3410 Series

meter configuration parameters.

Table B-2: Communications/Output Settings Summary Table Results

Output type Enter communications and

Serial port A

Retrofit Instructions 53

output settings

Page 54

Retrofit Instructions June 2022

Table B-2: Communications/Output Settings Summary Table Results

(continued)

Output type Enter communications and

Serial port B

Serial port C

Digital output 1A

Digital output 1B

Frequency output 1A

Digital output 2A

Digital output 2B

Frequency output 1B

Frequency output 2A

Frequency output 2B

Analog input 1

Analog input 2

Analog output 1

Analog output 2 (HART Capable)

(1)

(1)

output settings

54 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 55

June 2022 Retrofit Instructions

Retrofit Instructions 55

Page 56

Retrofit Instructions June 2022

C 3410 Communication and Output settings

C.1 3410 Wiring and I/O

Refer to the 3410 Series Ultrasonic Gas Flow Meter Installation Manual for

more wiring details.

Figure C-1: 3410 Upper Electronics with Optional I/O Modules

56 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 57

June 2022 Retrofit Instructions

Figure C-2: CPU Module Labeling and LED Indicators

Table C-1: CPU Module Labeling and LED Functions

CPU Module label or LED Function Switch position indicator

WRITE PROT. Write-protect mode - with

switch in the ON position

(default setting) protects

configuration and

firmware overwrites. To

write configuration

changes or download

firmware to the meter

change the switch to the

OFF position

or LED

Switch position

• ON - (default setting)

enables writeprotection of the

configuration and

firmware

• OFF - enables writing

configuration changes

or downloading

firmware

Retrofit Instructions 57

Page 58

Retrofit Instructions June 2022

Table C-1: CPU Module Labeling and LED Functions (continued)

DHCP Dynamic Host Protocol

Server - enables you to

communicate with a

Rosemount™ Ultrasonic

meter that is not

connected to a network.

When the CPU Module

switch is in the ON

position, the meter is

enabled to act as a DHCP

server for a single DHCP

client connected to the

Ethernet port using a

crossover cable. This

should be used for peer to

peer connections only.

When the connection is

made, select to use the

Meter Name in the meter

instead of the Meter

Directory Name in order to

keep all log files and

configurations separate

from each meter.

PORT A PORT A override - RS-232

serves as an override

during meter

commissioning to

establish communications

and in the event the user

cannot communicate with

the meter due to an

inadvertent

communication

configuration change. The

override period is for two

minutes. Supports:

• auto-detected ASCII

(Start bit 1, Data Bit 7,

Parity Odd/Even, Stop

Bit 1)

• RTU (Start Bit 1, Data

Bit 8, Parity none,

Stop Bit 1).

• Modbus protocols

RS-232 Baud

rate=19,200 Modbus

ID=32

Switch position

• ON - the meter is

enabled to act as a

DHCP server for a

single DHCP client

• OFF - disables the

DHCP server

Switch position

• ON - enables RS-232

PORT A override

• OFF - (default setting)

disables RS-232 PORT

A override

58 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 59

June 2022 Retrofit Instructions

Table C-1: CPU Module Labeling and LED Functions (continued)

MEAS System color indicates

metrology mode

Acquisition mode

Measurement mode

PWR 3.3V Power Indicator Solid Green

LED 4 Not used

LED 5 Not used

RX RX signal (Port A for RS485

or RS232)

communication) receiving

data

TX TX signal (Port A for

RS485; 2-wire or 4-wire) or

RS232 communication)

transmitting data

LINK ETH1Link user Ethernet

connection

LED status

• Red flashing LED

• Solid red the

Acquisition Module is

not communicating

with the CPU Module

• Green flashing LED

Flashing green (when

receiving data)

Flashing green (when

transmitting data)

Solid green

Optional RS-232 Module Wiring

Use the table in MISSING LINK HERE to wire the Optional RS-232 module.

Retrofit Instructions 59

Page 60

Retrofit Instructions June 2022

Figure C-3: Optional RS--232 Module Wiring

Optional RS-485 Module Wiring

Use the table in MISSING LINK HERE to wire the Optional RS-485 module.

Figure C-4: Optional RS-485 Module Wiring

60 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 61

June 2022 Retrofit Instructions

C.2 Ethernet cable to PC communication

The Ethernet port IP address, subnet mask, and gateway address are

software-configurable. In addition, a meter can be configured to act as a

DHCP (Dynamic Host Configuration Protocol) server to assign an IP address

to a PC or laptop running MeterLink. The DHCP server facility is not intended

to act as a general purpose DHCP server for a wider network. To this end, no

user control is provided over the class or range of IP addresses the unit

provides. A standard twisted pair (Cat-5) cable should be used for Ethernet

wiring.

It is strongly recommended that the meter be configured using an

independent (off-network) single host. After configuration of the 3410

Series Gas Ultrasonic Flow Meter, the DHCP option must be turned off if

used on a LAN/WAN.

NOTICE

RESTRICTED ETHERNET AND SERIAL CONNECTIVITY USAGE

Failure to restrict Ethernet and communication access to the 3410 Series Gas

Ultrasonic Flow Meter can result in, among other things, unauthorized

access, system corruption, and/or data loss.

User is responsible for ensuring that physical access and Ethernet or

electronic access to the 3410 Series Gas Ultrasonic Flow Meter is

appropriately controlled and any necessary security precautions are

implemented; such as, establishing a firewall, setting password permissions

and/or implementing security levels.

Retrofit Instructions 61

Page 62

Retrofit Instructions June 2022

Table C-2: Ethernet Communication

Ethernet

Wire color CPU/EXP

White with green Stripe TX+

Solid green TX-

White with orange stripe RX+

Solid orange

Note

Wiring colors for TX+/TXand RX+/RX- can be

switched as ethernet ports

will automatically detect

crossover vs. straight

connection. Connections

shown are straight

through cable.

RX-

Ethernet Communication

Use ethernet cable, to connect the PC to the meter.

A DIN 41612 48-pin connector is the interface from the CPU Module to the

Backplane (male end located on the back of the Backplane Board).

C.3

Input and output connections

The Rosemount 3410 Series Ultrasonic Flow Meter provides the Analog

inputs for pressure and temperature, Analog output 2 and frequency and

digital outputs on the CPU Module lower terminal block.

62 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 63

June 2022 Retrofit Instructions

Figure C-5: CPU Module Lower Terminal Block I/O Connections

A. Frequency/Digital output 2 (FODO 2)

B. Frequency/Digital output 2 (FODO 2) Gnd

C. Frequency/Digital output 2 (FODO 2) Gnd

D. Frequency/Digital output 3 (FODO 3)

E. Analog output 2 + (4-20mA output)

F. Analog output 2 - (4-20mA output)

G. Analog in (Temperature) +

H. Analog in (Temperature) -

I. Analog in (Pressure) +

J. Analog in (Pressure) -

Possible configurations for Frequency and Digital Outputs are shown in the

following figure.

Retrofit Instructions 63

Page 64

Retrofit Instructions June 2022

Figure C-6: Frequency/Digital Output

Output for FODO1 and Digital Output1 (Group 1 on the CPU Module upper

terminal block) share a common ground and have 50V isolation. FODO2 and

FODO3 (Group 2 on the CPU Module lower terminal block) share a common

ground and have 50V isolation. This allows an output to be connected to a

different flow computer. The outputs are opto-isolated from the CPU

Module and have a withstand voltage of at least 500V rms dielectric.

64 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 65

June 2022 Retrofit Instructions

Figure C-7: CPU Module - Frequency/Digital Outputs Common Ground Type 2

A. FODO1 and Digital input1 - shared common ground (Group1)

B. FODO2 and FODO3 - shared common ground (Group2)

Retrofit Instructions 65

Page 66

Retrofit Instructions June 2022

Figure C-8: CPU Module - Frequency/Digital Outputs Common Ground Type 4

A. FODO1 and DI1/FODO6 - shared common ground - Type 4 CPU Module

(Group 1)

B. FODO2, FODO3, FODO4 and FODO5 - shared common ground - Type 4

CPU Module (Group 2)

C.4

66 Rosemount Gas Ultrasonic 3410 Series Electronics

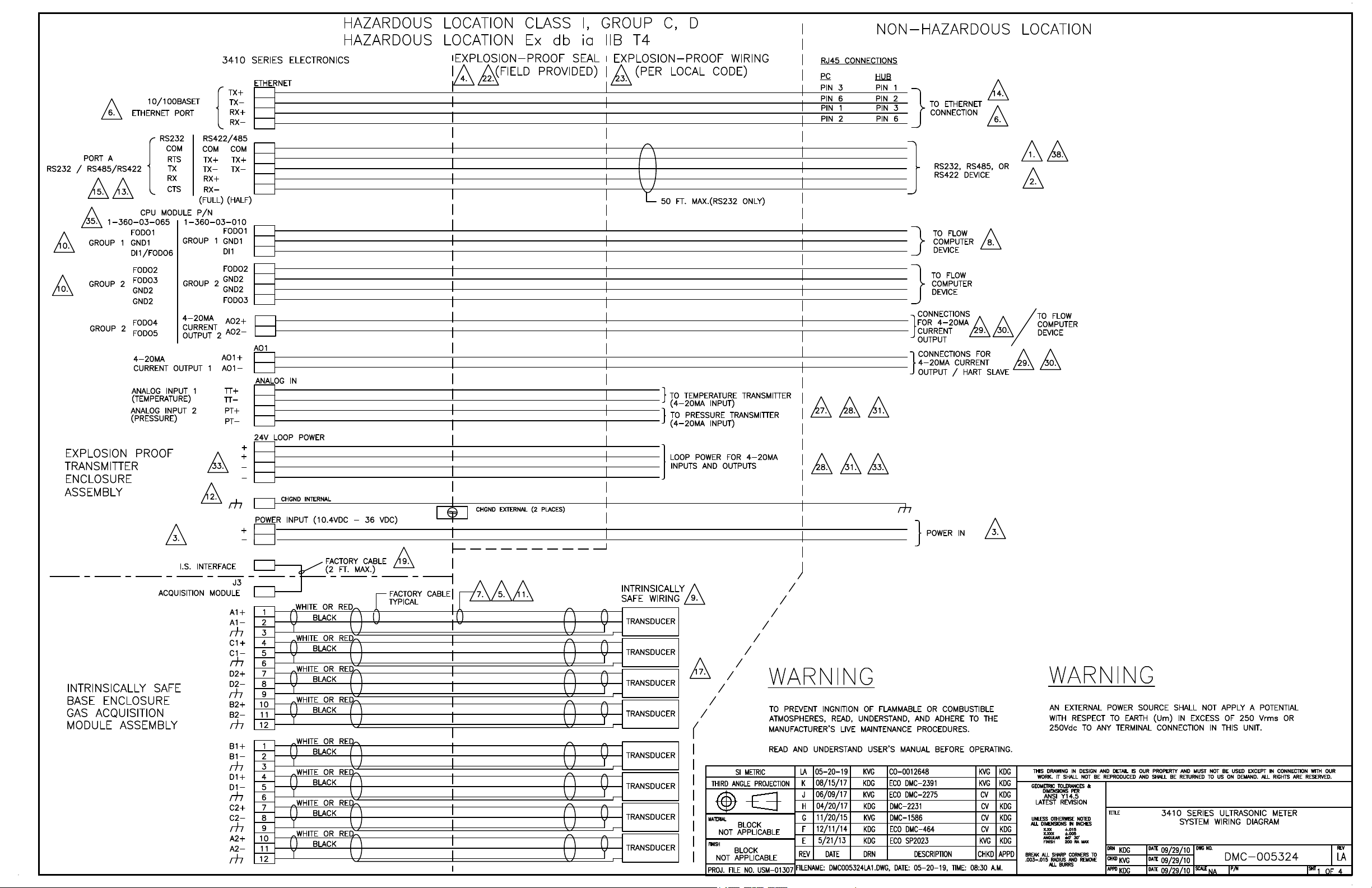

Serial communications

Use a serial cable, to connect to a PC running MeterLink™. The cable is

designed for RS-232 communications which is the serial Port A default

configuration (see 3410 Series engineering drawings Systems Wiring

Diagram, Drawing DMC - 005324).

The DB-9 end of the cable plugs directly into the PC running MeterLink. The

three wires on the other end of the cable connect to the CPU Module

RS-485/RS-232 terminals. The RED wire goes to RX, the WHITE wire goes to

TX, and the BLACK wire goes to COM (see Table 3-5 for Port A wiring).

RS-485, 2-wire connection on Port A, uses TX+ and TX- on the CPU Module

and has a ground wire.

When Belden wire No. 9940 or equivalent is used, the maximum cable

length for RS-232 communications at 9600 bps is 88.3 meters (250 ft.) and

the maximum cable length for RS-485 communication at 57600 bps is 600

meters (1970 ft.).

Page 67

June 2022 Retrofit Instructions

Port A supports a special override mode which forces the port to use known

communication values (19200 baud, address 32, RS-232). Note that the

protocol is auto-detected. This mode is expected to be used during meter

commissioning (to establish initial communication) and in the event that the

user cannot communicate with the meter (possibly due to an inadvertent

communication configuration change). Alternately, when using MeterLink

with an Ethernet port, use Ethernet cable, to connect the PC.

Table C-3: Serial Port Parameters

Port/communication Description Common features

• Port A (Standard)

• RS-232

• RS-485 Half Duplex

• RS-485 ( 2-wire

communication on

(1)

Port A.)

• Typically used for

general

communications with

a flow computer, RTU

(Modbus slave) and

radios.

• RS-485 - 2-wire (Half

Duplex) connected to

TX + and TX -

• Special override mode

to force port

configuration to

known settings.

• Supports RTS/CTS

handshaking with

software-configurable

RTS on/off delay

times.

• Factory default is

RS-232, Address 32,

19200 baud.

• Communications via

MeterLink using

RS-232 or RS-485 Full

Duplex

• Software configurable

Modbus Address

(1-247)

• Auto-detects TCP/IP

and ASCII or RTU

Protocol

• ASCII Protocol:

— Start Bits = 1, Data

Bits = 7

(2)

— Parity: odd or

even 1, Stop Bits =

(3)

1

— Baud Rates: 1200,

2400, 9600,

19200, 38400,

57600, 115000

bps

—

• RTU Protocol: Start

Bits = 1, Data Bits =

(4)

8

— Parity: none, Stop

Bits = 1

(5)

— Baud Rates: 1200,

2400, 9600,

19200, 38400,

57600, 115000

bps

Retrofit Instructions 67

Page 68

Retrofit Instructions June 2022

Table C-3: Serial Port Parameters (continued)

Port/communication Description Common features

Ethernet Preferred port for

diagnostic

communication via

MeterLink

10 Mbps/100 Mbps

(1) RS-485 2-wire connections use TX+ and TX - on the CPU Module

(2) Denotes auto-detected protocols

(3) Denotes auto-detected protocols

(4) Denotes auto-detected protocols

(5) Denotes auto-detected protocols

Modbus TCP/IP, Modbus

TCP

NOTICE

If not using Ethernet, a full duplex serial connection is necessary for

MeterLink to communicate with a Rosemount 3410 Series Ultrasonic Flow

Meter.

Figure C-9: PC to Meter Serial Connection Wiring

C.5 Analog input settings

The Rosemount 3410 Series Ultrasonic Flow Meter has the capability to

sample analog temperature (Analog Input 1) and pressure (Analog Input 2)

with 4-20 mA signals. These analog input signals are configured to sink. The

two independent analog input circuits are configured for conventional 4-20

mA service. Also, 24VDC isolated power supply connection is provided for an

external power source. Refer to the System Wiring Diagram in 3410 Series

engineering drawings.

68 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 69

June 2022 Retrofit Instructions

C.6 Analog output settings

The Rosemount 3410 Series Ultrasonic Flow Meter provides two 4-20 mA

analog output signals that are software configurable for either sink or source

current. Refer to the System Wiring Diagram in 3410 Series engineering

drawings.

Full HART® functionality is provided so that any commercially available HART

transmitter which meets the specifications of the HART Communications

Foundation can be connected to a Rosemount 3410 Series Ultrasonic Flow

Meter.

C.7 Digital Input

The Rosemount 3410 Series Ultrasonic Flow Meter provides one digital input

that can be used as a general purpose input. The digital input must be

configured via the MeterLink™ Tools|Edit/Compare

Configuration screen.

C.8 External power source connection and fuse

Located on the CPU Module are connections for a user-provided external

power source, a 2 Amp fuse and a 24V loop power connection for ultrasonic

meter analog outputs, temperature transmitter or pressure transmitter

devices. The current is limited to 88mA.

Retrofit Instructions 69

Page 70

Retrofit Instructions June 2022

Figure C-10: CPU Module Power Source Connections

A. 24V Loop power

B. Power in connector (main power source)

C. 2 Amp fuse (used for main power input)

70 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 71

June 2022 Retrofit Instructions

Retrofit Instructions 71

Page 72

Retrofit Instructions June 2022

D 3410 Series engineering drawings

DMC-005324 3410 Series Ultrasonic Meter System

Wiring Diagram

72 Rosemount Gas Ultrasonic 3410 Series Electronics

Page 73

Page 74

≥

≥

≥

≥

≥

≥

Page 75

WARNING

WARNING

3/4 NPT

3/4 NPT

US

C

LISTED

90Y1

·

·

·

·

TELEMETERING

EQUIPMENT

FOR HAZ. LOC.

Page 76

≥

≥

≥

≥

≥

≥

≥

≥

≥

≥

≥

≥

Page 77

June 2022 Retrofit Instructions

Retrofit Instructions 75

Page 78

* 00825-0300-3240 *

Retrofit Instructions

00825-0300-3240 , Rev. AA

June 2022

For more information:

©

2022 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo

is a trademark and service mark of

Emerson Electric Co. Rosemount is a mark

of one of the Emerson family of

companies. All other marks are the

property of their respective owners.

Emerson.com

Loading...

Loading...