Page 1

MODEL 2500

INSTRUMENTATION

SYSTEM

__________________________________________

USER REFERENCE MANUAL

DANIEL MEASUREMENT AND CONTROL

HOUSTON, TEXAS

Part Number: 3-9000-591

Revision 5 Series

Revision H

NOVEMBER 1998

Page 2

Page 3

Year 2000 Warranty

The Company represents and warrants that computer programs in any medium, software,

firmware and combinations thereof (“Deliverables”) manufactured by the Company and

incorporated into or supplied by the Company for use with goods manufactured by the Company

will, under normal use and care:

i) recognize and accept dates falling on or after 1 January 2000;

ii) recognize and accept the year 2000 and every succeeding fourth year as leap

years;

iii) recognize and accept 29 February in the year 2000 and every succeeding fourth

year;

iv) record, store, process, sequence, present and output calendar dates and data related

to dates falling on or after 1 January 2000, in the same manner and with the same

functionality as they do on or before 31 December 1999 and without errors or

omissions; and

v) lose no functionality with respect to the introduction into them of dates or data

related to dates falling on or after 1 January 2000;

provided that, in the case of any non-conforming Deliverables that are returned to the Company

promptly following discovery of the non-conformity, the Company will, at its option and cost,

repair or replace such Deliverable or refund to the Purchaser the purchase price therefor. This

shall be the Purchaser's sole and exclusive remedy for breach of the foregoing warranty.

Notwithstanding the foregoing, the Company shall not, under any circumstances whatsoever, be

liable for any defects or errors caused by: materials or workmanship made, furnished or specified

by the Purchaser; non-compliance with the Company's installation or operation requirements;

failure to install any revisions and/or upgrades to the Deliverables deemed mandatory by the

Company; any modifications to Deliverables not previously authorized by the Company in

writing; the use by the Purchaser of any non-authorized spare or replacement parts in connection

with the goods used in conjunction with the Deliverables; or the use of the Deliverables with any

hardware or software not supplied by the Company. The Purchaser shall at all times remain

solely responsible for the adequacy and accuracy of all information supplied by it. Any third

party content in Deliverables shall carry only the warranty extended by the original manufacturer.

Page 4

THE FOREGOING CONSTITUTES THE COMPANY'S SOLE AND EXCLUSIVE

WARRANTY IN RELATION TO THE PERFORMANCE OF THE DELIVERABLES AS IT

RELATES TO THE CHANGE FROM YEAR 1999 TO YEAR 2000 OR THE OCCURRENCE

OF LEAP YEARS THEREAFTER, AND THE PURCHASER'S EXCLUSIVE REMEDY FOR

BREACH THEREOF. IN NO EVENT WILL THE COMPANY BE LIABLE FOR INDIRECT,

CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES, INCLUDING LOSS OF USE,

BUSINESS INTERRUPTION OR LOSS OF PROFITS, IRRESPECTIVE OF WHETHER THE

COMPANY HAD NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

The foregoing warranty shall remain valid until the later of December 31, 2000 or one year after

the date that the Deliverable was shipped.

Page 5

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

DANIEL INDUSTRIES, INC.

MODEL 2500 INSTRUMENTATION SYSTEM

USER REFERENCE MANUAL

NOTICE

DANIEL INDUSTRIES, INC.ANDDANIEL MEASUREMENT AND CONTROL ("DANIEL")

SHALL NOT BE LIABLE FOR TECHNICAL OR EDITORIAL ERRORS IN THIS MANUAL

OR OMISSIONS FROM THIS MANUAL. DANIELMAKES NO WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO THIS MANUAL

AND, IN NO EVENT, SHALL DANIEL BE LIABLE FOR ANY SPECIAL OR

CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF

PRODUCTION, LOSS OF PROFITS, ETC.

PRODUCT NAMES USED HEREIN ARE FOR MANUFACTURER OR SUPPLIER

IDENTIFICATION ONLY AND MAY BE TRADEMARKS/REGISTERED TRADEMARKS OF

THESE COMPANIES.

COPYRIGHT © 1998

BY DANIEL MEASUREMENT AND CONTROL

HOUSTON, TEXAS, U.S.A.

All rights reserved. No part of this work may be reproduced or

copied in any form or by any means - graphic, electronic or

mechanical - without first receiving the written permission of

Daniel Measurement and Control, Houston, Texas, U.S.A.

________________________________________________________________________________________________________________________________________

PREFACEPREFACE

i

Page 6

____________________________________________________________________________________________________________ MODELMODEL 25002500

WARRANTY

Daniel Measurement and Control ("Daniel") warrants all equipment manufactured by it to be free

from defects in workmanship and material, provided that such equipment was properly selected

for the service intended, properly installed, and not misused. Equipment which is returned,

transportation prepaid to Daniel within twelve (12) months of the date of shipment (eighteen (18)

months from date of shipment for destinations outside of the United States), which is found after

inspection by Daniel to be defective in workmanship or material, will be repaired or replaced at

Daniel’s sole option, free of charge, and return-shipped at lowest cost transportation. All

transportation charges and export fees will be billed to the customer. Warranties on devices

purchased from third party manufacturers not bearing a Daniel label shall have the warranty

provided by the third party manufacturer.

Extended warranty - Models 2470, 2480 and 2500 are warranted for a maximum of twenty-four

(24) months. The Danalyzer valves are warranted for the life of the instrument and the columns

for five years.

The warranties specified herein are in lieu of any and all other warranties, express or implied,

including any warranty of merchantability or fitness for a particular purpose.

Daniel shall be liable only for loss or damage directly caused by its sole negligence. Daniel’s

liability for any loss or damage arising out of, connected with, or resulting from any breach

hereof shall in no case exceed the price allocable to the equipment or unit thereof which gives

rise to the claim. Daniel’s liability shall terminate one year after the delivery of the equipment

except for overseas deliveries and extended warranty products as noted above.

In no event, whether as a result of breach of warranty or alleged negligence, shall Daniel be

liable for special or consequential damages, including, but not limited to, loss of profits or

revenue; loss of equipment or any associated equipment; cost of capital; cost of substitute

equipment, facilities or services; downtime costs; or claims of customers of the purchaser for

such damages.

________________________________________________________________________________________________________________________________________

ii

PREFACEPREFACE

Page 7

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

SECTION 1

INTRODUCTION ........................................ 1

MODEL 2500 HARDWARE ................................. 3

MODEL 2500 SOFTWARE ................................. 6

SECTION 2

CONTROL AND DISPLAY DEVICES ......................... 7

MODEL 2500 LED STATUS LIGHTS ......................... 8

MODEL 2500 DISPLAY SCREEN ............................ 9

MODEL 2500 KEYPAD ................................... 10

MODEL 2500 REMOTE FRONT PANEL ..................... 11

SECTION 3

STARTUP AND APPLICATION DOWNLOAD ................. 13

INITIALIZING SEQUENCE ............................... 14

TEST MALFUNCTIONS .................................. 15

FILE TYPES ........................................... 17

MEMORY RESIDENT SOFTWARE ......................... 18

HARD DRIVE USE ...................................... 19

DOWNLOADING INSTRUCTIONS .......................... 20

________________________________________________________________________________________________________________________________________

TABLETABLE OFOF CONTENTSCONTENTS

iii

Page 8

____________________________________________________________________________________________________________ MODELMODEL 25002500

SECTION 3

LOAD2500 - STAND-ALONE DOWNLOAD PROGRAM ......... 29

STAND-ALONE DOWNLOAD PROGRAM EXAMPLES .......... 30

SYSTEM READY ....................................... 32

DATA ENTRY SECURITY ................................. 32

SECURITY SWITCH .................................... 33

LOWER-LEVEL SECURITY PASSWORD .................... 34

RESTRICTED-USER PASSWORD .......................... 35

DATA ENTRY AT INITIAL STARTUP ....................... 36

PROCEDURE OF DATA ENTRY AT INITIAL STARTUP ........ 37

(continued)

TYPICAL START-UP DATA CHANGES ...................... 40

TIME-OF-DAY CLOCK CHIP ............................. 41

________________________________________________________________________________________________________________________________________

iv

TABLETABLE OFOF CONTENTSCONTENTS

Page 9

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

SECTION 4

MENU SELECTION ..................................... 43

MAIN MENU .......................................... 44

SUB-MENUS ........................................... 45

INPUT CHANNELS ................................. 46

OUTPUT CHANNELS ............................... 46

ALARMS ......................................... 47

OPERATOR ENTRY ................................ 47

CALCULATIONS ................................... 48

REPORTS ........................................ 48

TABLES .......................................... 49

TUBE SWITCHING ................................. 49

MODBUS MASTER ................................. 51

SERIAL PORTS .................................... 52

ARCHIVE ........................................ 56

SYSTEM COMMANDS .............................. 56

MENU DISPLAY AND SELECTION PROCEDURE ............. 60

________________________________________________________________________________________________________________________________________

TABLETABLE OFOF CONTENTSCONTENTS

v

Page 10

____________________________________________________________________________________________________________ MODELMODEL 25002500

SECTION 4

MENU FLOW CHART DIAGRAMS ......................... 63

11 SUB-MENUS CHART ............................. 64

INPUT CHANNELS CHART .......................... 65

OUTPUT CHANNELS CHART ......................... 66

ALARMS CHART .................................. 67

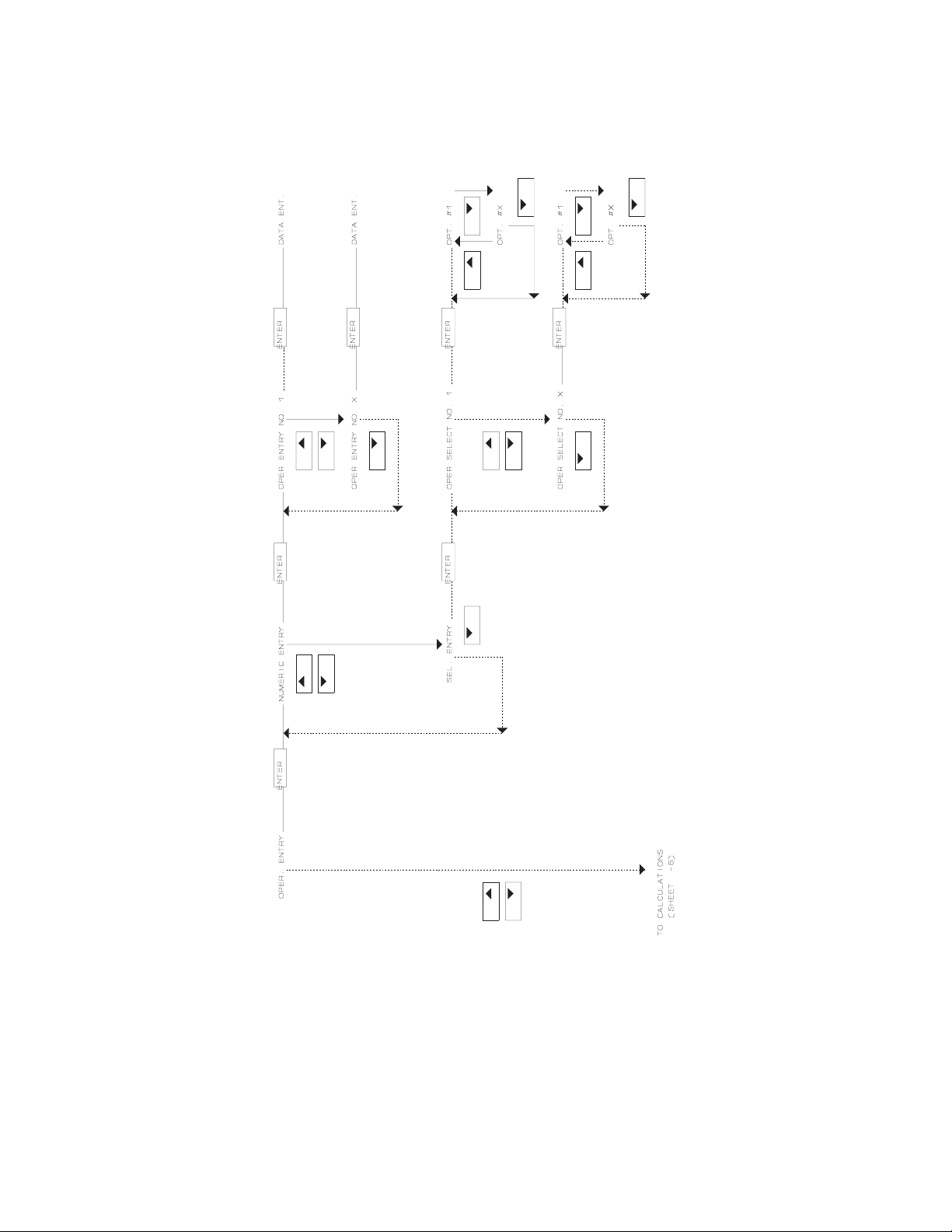

OPERATOR ENTRY CHART .......................... 68

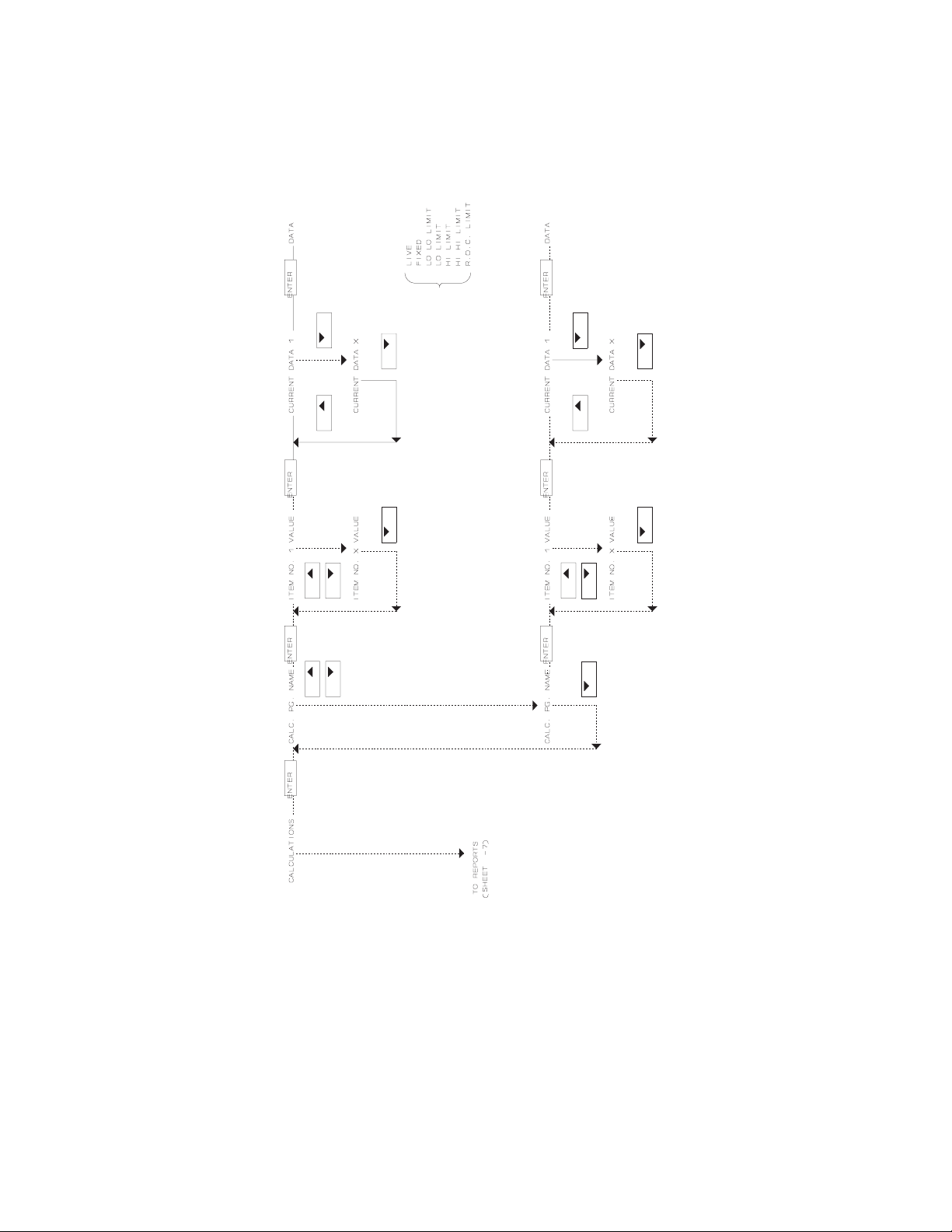

CALCULATIONS CHART ............................ 69

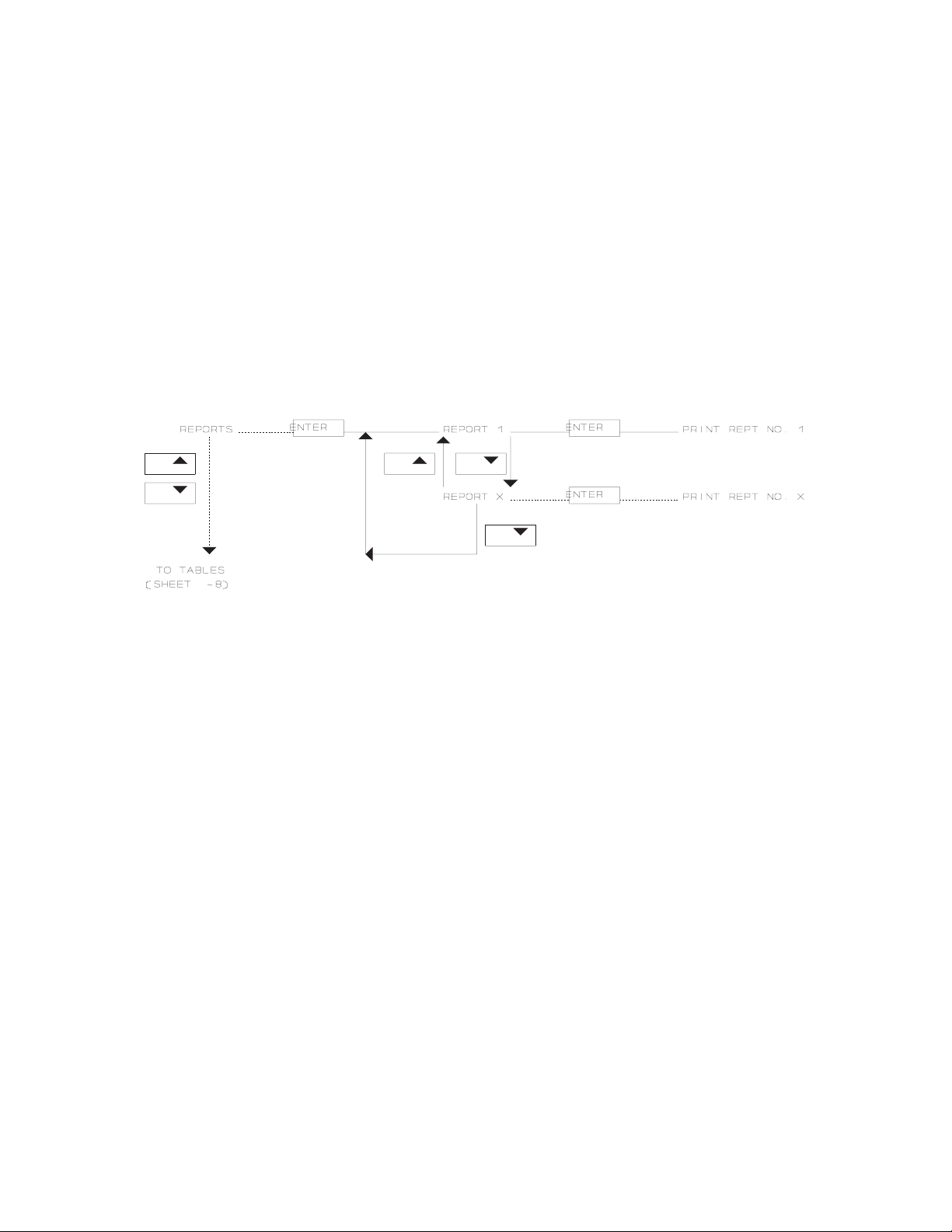

REPORTS CHART ................................. 70

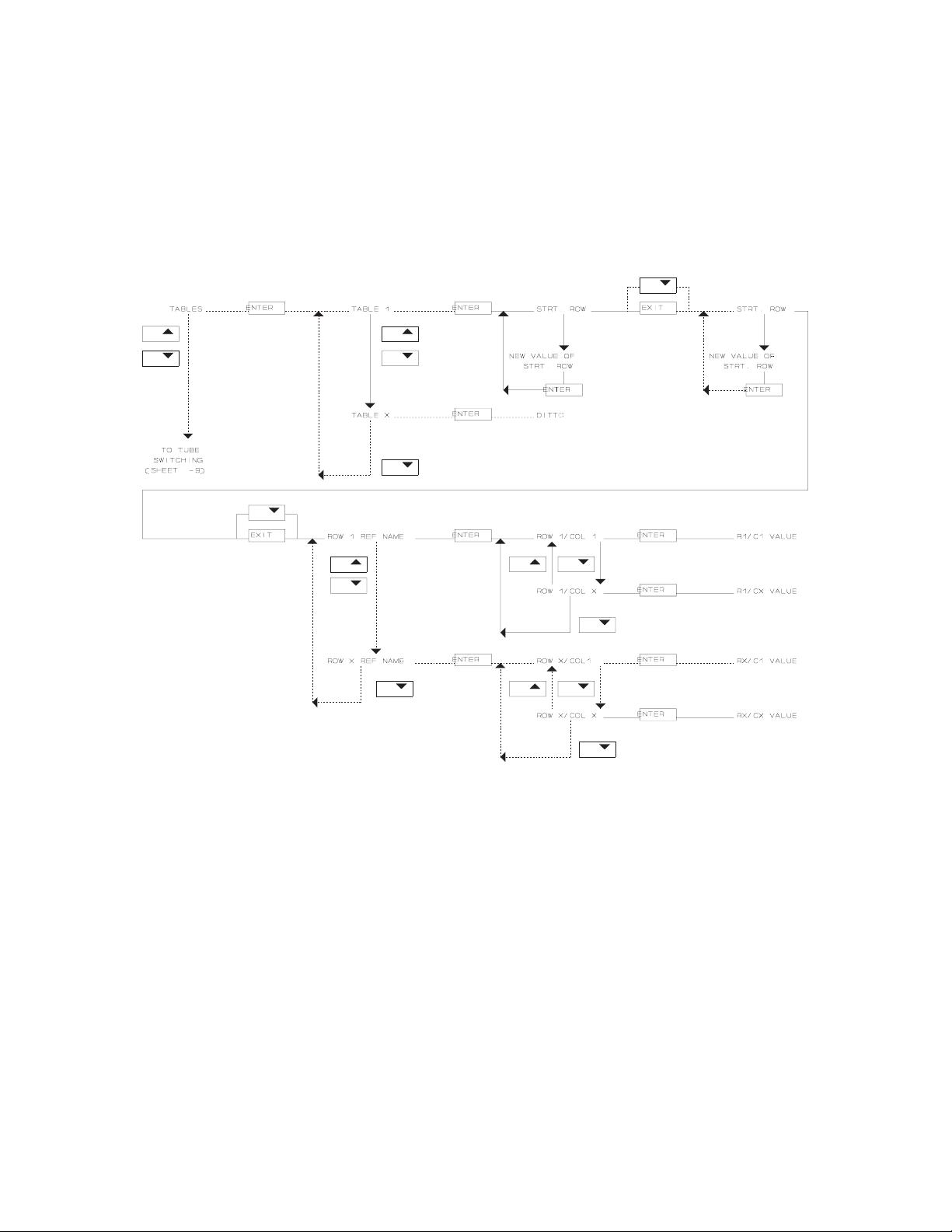

TABLES CHART ................................... 71

(continued)

TUBE SWITCHING CHART .......................... 72

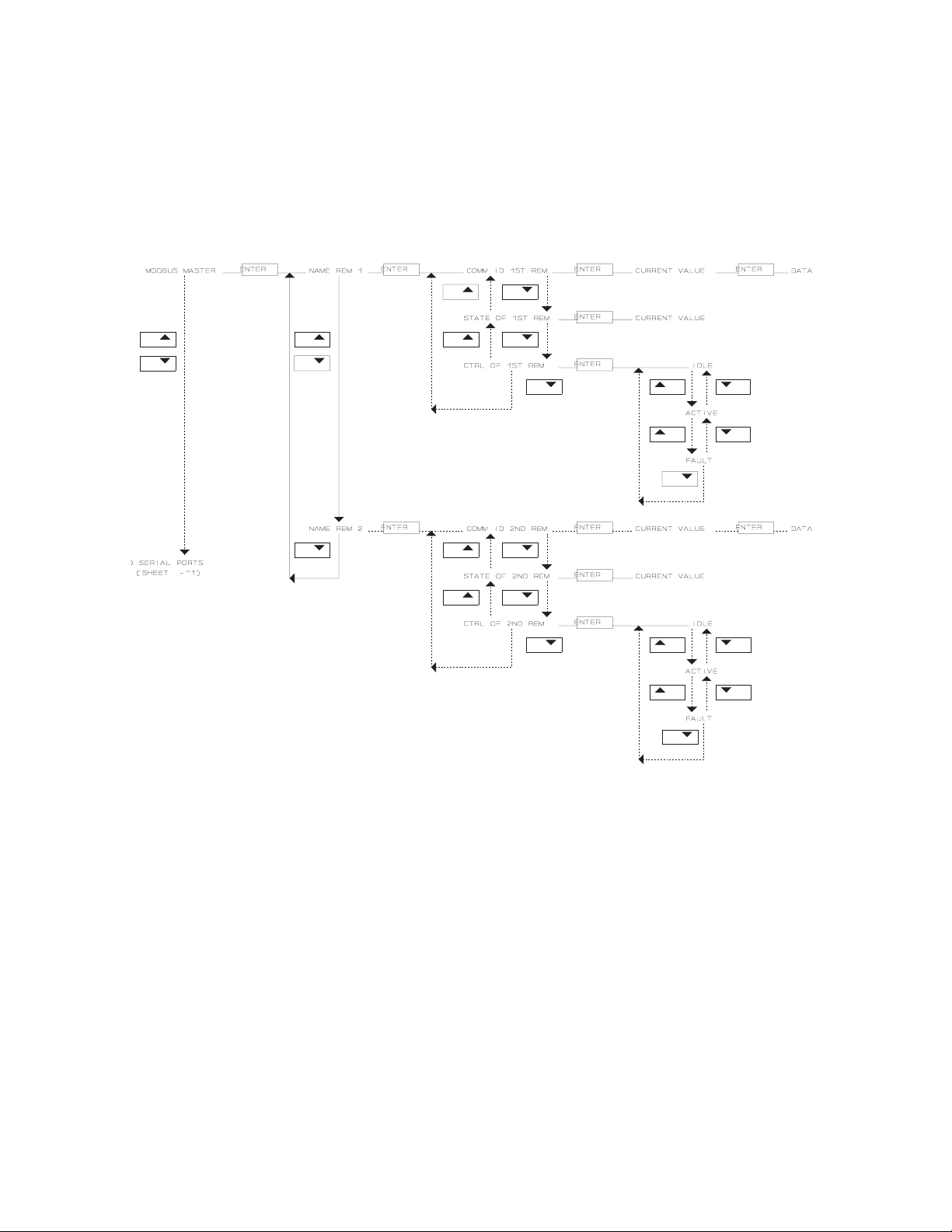

MODBUS MASTER CHART .......................... 73

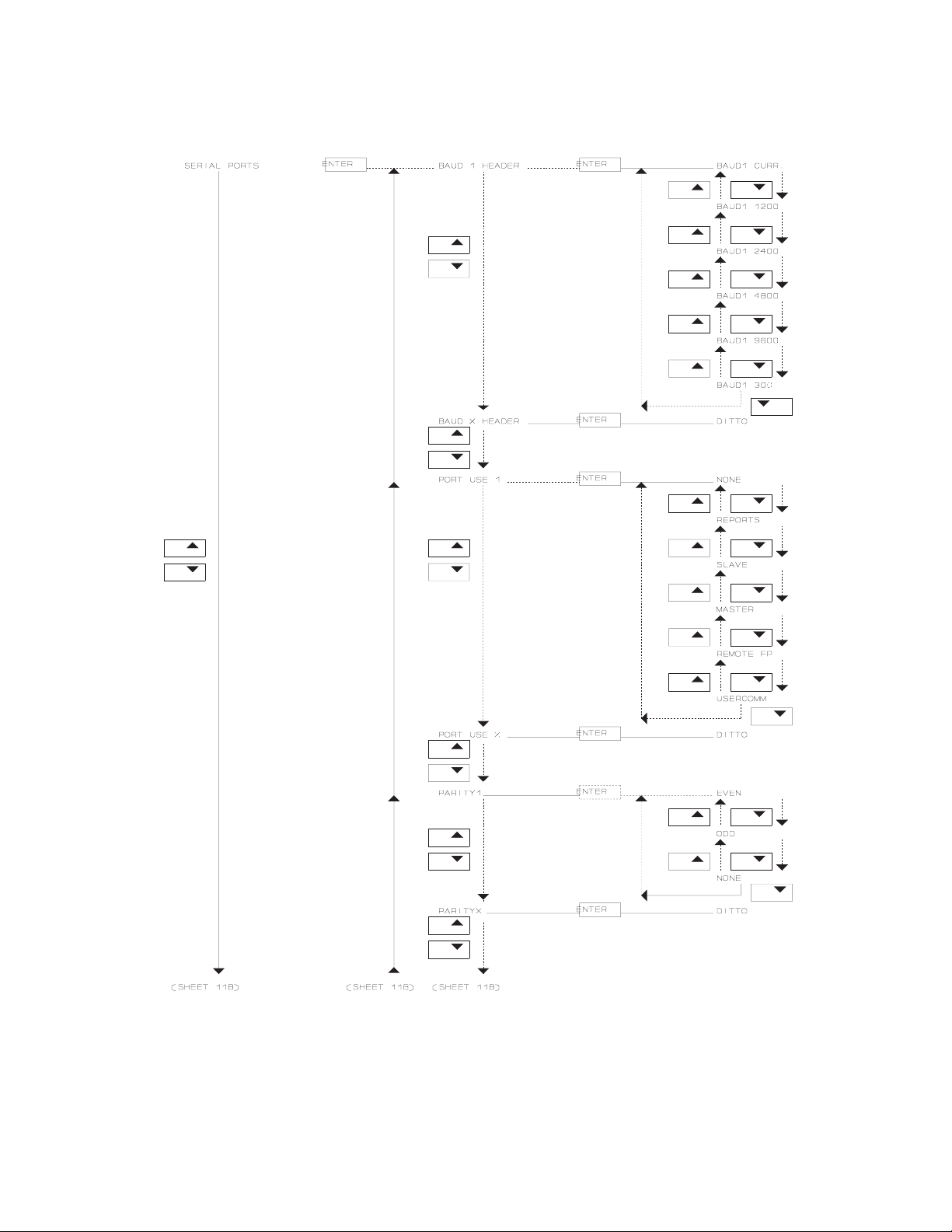

SERIAL PORTS CHART A ........................... 74

SERIAL PORTS CHART B ........................... 75

ARCHIVE CHART ................................. 76

SYSTEM COMMANDS CHART ....................... 77

________________________________________________________________________________________________________________________________________

vi

TABLETABLE OFOF CONTENTSCONTENTS

Page 11

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

SECTION 5

DATA DISPLAY ........................................ 79

CONSTANT/VARIABLE NAME ............................ 80

CONSTANT/VARIABLE STATUS ........................... 81

CONSTANT/VARIABLE VALUE ........................... 82

CONSTANT/VARIABLE UNITS ............................ 83

TYPE OF DISPLAY ..................................... 84

ALARMS FOR VARIABLES AND CONSTANTS ............... 86

SECTION 6

OPERATING EXAMPLES ................................ 87

EXAMPLES FOR CHANGING AND DISPLAYING VARIABLES ... 88

DISPLAYING VARIABLES FROM THE MAIN MENU ...... 89

CHANGING THE STATUS OF A VARIABLE ............. 91

DISPLAYING A LIVE VALUE WHEN THE VARIABLE HAS

BEEN MANUALLY OVERRIDDEN ................. 93

CHANGING AND DISPLAYING A FIXED VALUE ........ 94

CHANGING AND DISPLAYING THE ZERO-SCALE VALUE

FOR A VARIABLE ............................. 95

________________________________________________________________________________________________________________________________________

TABLETABLE OFOF CONTENTSCONTENTS

vii

Page 12

____________________________________________________________________________________________________________ MODELMODEL 25002500

SECTION 6

CHANGING AND DISPLAYING THE FULL-SCALE VALUE

CHANGING AND DISPLAYING THE LOW-ALARM VALUE

CHANGING AND DISPLAYING THE HIGH-ALARM VALUE

EXAMPLES FOR FINDING, FIXING AND CHANGING

CALCULATIONS ................................... 99

FINDING THE CALCULATION ........................ 99

FIXING THE VALUE OF A CALCULATION ............. 102

CHANGING A FIXED VALUE ......................... 103

(continued)

FOR A VARIABLE ............................. 96

FOR A VARIABLE ............................. 97

FOR A VARIABLE ............................. 98

EXAMPLES FOR LOCATING AND ENTERING DATA TABLES ... 104

LOCATING A DATA TABLE .......................... 105

GAINING ACCESS TO THE DATA TABLE .............. 107

SELECTING A TABLE ROW .......................... 109

SELECTING A TABLE COLUMN ...................... 111

________________________________________________________________________________________________________________________________________

viii

TABLETABLE OFOF CONTENTSCONTENTS

Page 13

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

SECTION 7

REPORTS ............................................. 115

REPORT TYPES ........................................ 116

REPORT PRINTOUTS ................................... 120

AUTOMATIC REPORTS ................................. 121

OPERATOR COMMAND REPORTS ........................ 122

REMOTE TERMINAL OR COMPUTER REPORTS ............. 123

PRINTING REPORTS FROM A COMPUTER USING MACROS ... 124

APPENDIX A

GLOSSARY OF STANDARD VARIABLE NAMES .............. 125

APPENDIX B

GLOSSARY OF STANDARD UNIT ABBREVIATIONS ........... 133

APPENDIX C

GLOSSARY OF STANDARD SELECTION LIST OPERATOR

ENTRIES ......................................... 139

________________________________________________________________________________________________________________________________________

TABLETABLE OFOF CONTENTSCONTENTS

ix

Page 14

____________________________________________________________________________________________________________ MODELMODEL 25002500

This page intentionally left blank.

________________________________________________________________________________________________________________________________________

x

TABLETABLE OFOF CONTENTSCONTENTS

Page 15

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

INTRODUCTION

The DANIEL INDUSTRIES MODEL 2500 INSTRUMENTATION SYSTEM

MICROCOMPUTER is an advanced state-of-the-art, microprocessor-based

computer used to control and measure the numerous physical and dynamic

characteristics of fluids, such as liquids and gases. Compatible with most process

flowmeters and transmitters, the MODEL 2500 is a state-of-the-art instrument with

both a large input/output capacity and a powerful processor possessing the

programmable capabilities necessary for the hundreds of applications required for

a demanding environment.

The DANIEL INDUSTRIES MODEL 2500 software can be configured to:

- Perform a broad range of flow measurement and process applications

without compromising the exact needs of the application and without

the expense of a custom instrument.

- Monitor and read live transmitter inputs, both analog and digital.

- Produce multiple calculated outputs.

- Act as a controller for meter prover applications.

- Serve as a Remote Terminal Unit (RTU) furnishing calculated data on

demand to a "Host" computer or a Supervisory Control and Data

Acquisition (SCADA) system.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 11

1

Page 16

____________________________________________________________________________________________________________ MODELMODEL 25002500

The DANIEL INDUSTRIES MODEL 2500 INSTRUMENTATION SYSTEM

MICROCOMPUTER consists of the following:

- MODEL 2500 computer

- BASE25 operating system (resident in the EPROM of the MODEL

2500 microcomputer)

- Specialized application software that provides for customized

configuration of the microcomputer for specific tasks

________________________________________________________________________________________________________________________________________

2

SECTIONSECTION 11

Page 17

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

MODEL 2500 HARDWARE

The DANIEL INDUSTRIES MODEL 2500 INSTRUMENTATION SYSTEM

MICROCOMPUTER hardware comes in either a one-board system or a two-board

system. Both systems function identically with the same baseline and software.

The number of inputs and outputs required by the user will dictate whether a oneor a two-board system is needed.

Refer to Figures 1-1 and 1-2 for a graphic depiction of the differences between the

two systems. For more detailed specifications, refer to the MODEL 2500

Microcomputer Hardware Manual, Daniel P/N 3-9000-590.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 11

3

Page 18

____________________________________________________________________________________________________________ MODELMODEL 25002500

Figure 1-1

________________________________________________________________________________________________________________________________________

4

SECTIONSECTION 11

Page 19

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

Figure 1-2

________________________________________________________________________________________________________________________________________

SECTIONSECTION 11

5

Page 20

____________________________________________________________________________________________________________ MODELMODEL 25002500

MODELMODEL 25002500 SOFTWARESOFTWARE

The DANIEL INDUSTRIES MODEL 2500 specialized application software is

developed in conjunction with the CONFIG25 program. The CONFIG25 program

is designed to run on an IBM PC or compatible personal computer.

This manual provides the basic operational information to download and operate

software in the MODEL 2500, which contains a Revision 5.00 level or higher. The

new generation of BASE25 allows the user to download any Revision K.2 or

higher applications without requiring a new analysis of an application under a

different Config25.

Prior to Revision 5.00 baseline, applications had to be developed, analyzed, and run

on software that was of the same revision level. Revision 5.00 and higher

firmware (hereafter referred to as 5.nn), is designed to support applications

developed on multiple Daniel CONFIG25 software releases.

The following table lists the CONFIG25 software releases that are supported and

the baseline used for execution. The following compatibility rules are imposed by

the download routine.

Compatible BASE25 Revisions

CONFIG25

Revision

K.2 12/86 yes no no no yes

L.7 6/87 no yes yes yes yes

L.8 10/87 no yes yes yes yes

N 2/88 no no no yes yes

5.nn 12/89 no no no yes yes

Release

Date

K.2 L.7 L.8 N 5.nn

________________________________________________________________________________________________________________________________________

6

SECTIONSECTION 11

Page 21

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

MODEL 2500 CONTROL AND DISPLAY DEVICES

The DANIEL INDUSTRIES MODEL 2500 INSTRUMENTATION SYSTEM

MICROCOMPUTER operating commands and data are entered, changed, and

displayed on the instrument’s front panel as illustrated in Figure 2-1. The front

panel is composed of the following:

- Three status light-emitting diodes (LED)

- Backlighted, two-line liquid crystal display (LCD)

- 16-key keypad (symmetrically arranged in four columns with four

keys in each column)

Additionally, The MODEL 2500 instrument may be controlled from either the local

front panel on the instrument itself or from a remote front panel connected to the

MODEL 2500 by means of a serial port.

Figure 2-1

________________________________________________________________________________________________________________________________________

SECTIONSECTION 22

7

Page 22

____________________________________________________________________________________________________________ MODELMODEL 25002500

MODEL 2500 LED STATUS LIGHTS

The DANIEL INDUSTRIES MODEL 2500 INSTRUMENTATION SYSTEM

MICROCOMPUTER front panel has three LED status lights arranged horizontally

above the keypad and colored, from left to right, green, yellow, and red. The

different colors indicate different conditions or situations.

GREEN LIGHT Indicates that the correct password has been

properly entered (and not timed out), or that the

MODEL 2500 system will accept keyboard entries

for modifying application data and system

parameters.

YELLOW LIGHT Indicates that an alarm signal has been sensed, but

has not been acknowledged.

RED LIGHT Indicates that an alarm signal is currently active.

________________________________________________________________________________________________________________________________________

8

SECTIONSECTION 22

Page 23

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

MODEL 2500 DISPLAY SCREEN

The DANIEL INDUSTRIES MODEL 2500 INSTRUMENTATION SYSTEM

MICROCOMPUTER front panel has a LCD screen located at the top of the front

panel which is electro-luminescent backlighted for readability under various

ambient lighting conditions.

This screen displays two lines of alphanumeric characters with 16 characters in

each line, which provide for the readout of data, system command and prompts,

and computation results. Numeric values are displayed in appropriate engineering

units when applicable.

The display also has an adjustable viewing angle so that instruments, which are

mounted either at a relatively low or high height, may be adjusted for comfortable

viewing.

To adjust the LCD for comfortable viewing after installation:

- Release the catch located at the bottom of the panel

- Pull the display unit forward approximately one inch

- Locate the small potentiometer on the left hand side of the display

board in the center, approximately 1/2 " from the front, as illustrated

below. With a small screwdriver adjust the angle for the most

comfortable viewing.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 22

9

Page 24

____________________________________________________________________________________________________________ MODELMODEL 25002500

MODEL 2500 KEYPAD

The DANIEL INDUSTRIES MODEL 2500 INSTRUMENTATION SYSTEM

MICROCOMPUTER front panel has a 16-key keypad which gives the user the

ability to enter and change data and system commands. The keypad is located

approximately in the center of the panel, and is symmetrically arranged in four

columns of four keys each.

Ten of the 16 keys are marked with the numbers 0 through 9, arranged in

descending order. The remaining keys are marked with a decimal point, a minus

sign, an UP arrow, a DOWN arrow, and the command words of EXIT and ENTER.

The UP arrow, DOWN arrow, EXIT and ENTER keys have been assigned specific

functions. The keys and their functions are defined below:

UP/DOWN

Arrow Keys Sequences the front panel display forward or backward

through a menu or sub-menu. The display can be

changed one step at a time by depressing a key

repeatedly, or it can be sequenced rapidly by holding

down a key.

EXIT Key Moves the display to the next higher menu.

ENTER Key Selects the sub-menu displayed on the front panel, enters

the data that has been keyed-in on the display, and

initiates a printout of a report when the name of the

report is displayed on the front panel.

A further discussion of the keypad is provided later when operation of the

instrument is explained in greater detail.

________________________________________________________________________________________________________________________________________

10

SECTIONSECTION 22

Page 25

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

MODEL 2500 REMOTE FRONT PANEL

The DANIEL INDUSTRIES MODEL 2500 INSTRUMENTATION SYSTEM

MICROCOMPUTER remote front panel is an external terminal connected to the

MODEL 2500 by means of a serial port. The same functions that are possible on

the front panel of an on-site MODEL 2500 are also possible with the remote front

panel. However, only one front panel may be active at a given time.

Activation of the remote front panel is made possible by assigning it to a serial port

using one of the PORTUSE selections in the Serial Ports sub-menu. Control is

returned to the front panel of the on-site unit from the remote front panel by

changing the PORTUSE selection to an option other than the remote front panel.

Selecting the remote front panel or returning control to the front panel of the

on-site unit may take as long as 30 seconds before the operation is complete. The

remote front panel responds more slowly than the front panel of the on-site unit to

both keyboard entry and display refreshing.

When the remote front panel is selected, the LCD screen of the on-site unit

displays the following message:

REMOTE FRONT

PANEL SELECTED

_________________________________________________________

NOTE! If the remote front panel fails when the remote unit is

in control or if for some other reason, communications

is lost between the on-site unit and the remote front

panel, control can be returned to the front panel of the

on-site unit by simultaneously pressing the zero,

decimal, and minus keys.

_________________________________________________________

________________________________________________________________________________________________________________________________________

SECTIONSECTION 22

11

Page 26

____________________________________________________________________________________________________________ MODELMODEL 25002500

This page intentionally left blank.

________________________________________________________________________________________________________________________________________

12

SECTIONSECTION 22

Page 27

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

STARTUP AND APPLICATION DOWNLOAD

After the DANIEL INDUSTRIES MODEL 2500 INSTRUMENTATION SYSTEM

has been mechanically and electrically installed, startup and application download

procedures can begin. For instructions, refer to Daniel Industries Manual, P/N 39000-590.

Unless the MODEL 2500 has been supplied with a resident program at the factory,

there must be a computer available (IBM PC or equivalent), which is connected to

the communications port on the Model 2500. If the MODEL 2500 has been

supplied with a resident program at the factory, a computer (IBM PC or equivalent)

will not be necessary.

Your software is delivered on 360 KB diskette(s) or on 3.5" diskette(s) archived

in a compressed format which cannot be directly executed until properly installed.

In most cases the installed software on the hard disk will be the working copy and

the distribution diskette will serve as a backup. The following instructions enable

you to install your software on a hard drive or on another diskette.

a. Insert the distribution diskette in drive A and type:

A: < <ENTER>

b. A:\>INSTALL < <ENTER>

c. Follow the instructions on your screen.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

13

Page 28

____________________________________________________________________________________________________________ MODELMODEL 25002500

INITIALIZING SEQUENCE

After power is applied to the DANIEL INDUSTRIES MODEL 2500

INSTRUMENT SYSTEM, it automatically performs an initializing sequence,

whether the startup is considered to be a "cold" or "warm".

In a "cold" startup, power is switched on to the MODEL 2500, and the initializing

sequence:

- Determines if the instrument is configured for a specific application

- Performs a series of self-diagnostic tests

The self-diagnostic tests ensure that all internal circuitry and devices in the

instrument are operational.

In a "warm" startup, which occurs after the power supply has been briefly

interrupted or a "watchdog" message has indicated a problem in the program, the

initializing sequence, again:

- Determines if the instrument is configured for a specific application

- Performs a series of self-diagnostic tests

During a "warm" startup, the front panel displays a copyright message and

copyright date for several seconds before performing the initializing sequence.

However, during a "cold" startup, the copyright message does not appear.

________________________________________________________________________________________________________________________________________

14

SECTIONSECTION 33

Page 29

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

TEST MALFUNCTIONS

In the case of an internal malfunction detected within the MODEL 2500:

- Alarm contact is actuated and the red LED glows on the front panel.

- Unit automatically ceases operation and no longer accepts data from

the keypad.

- Cause of the failure is displayed in English on the LCD screen.

Malfunctions indicating failure in the self-diagnostic test, or a specific application

are illustrated below:

1. The following illustrated message of the MODEL 2500 LCD screen indicates

that a memory test of the Random Access Memory (RAM) has failed. The

characters XXXX indicate the RAM integrated circuit where the error

occurred.

MEMORY ERROR

BLOCK XXXX

2. The following illustrated message of the MODEL 2500 LCD screen indicates

that a required programmable read-only memory (PROM) is not installed in

the unit, or is improperly installed.

PROM MISSING

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

15

Page 30

____________________________________________________________________________________________________________ MODELMODEL 25002500

3. The following illustrated message of the MODEL 2500 LCD screen indicates

that a PROM has been changed since installation, or is being read

improperly. The message on line 2 (XXXX) is the location of the error.

CHECKSUM ERROR

XXXX

4. If the MODEL 2500 is not configured for an application:

- Alarm contact closure inside the case can be heard opening and

closing.

- Red LED light on the front panel flashes on and off.

- Following illustrated message of the MODEL 2500 LCD screen is

displayed.

AWAITING CONFIG

PX BXXXX IDXXX

Line 2 of the display message indicates:

- PX is the Port (for example, P2 or Port 2).

- BXXXX is the baud rate (for example, B2400 or 2400 baud).

- IDXXX is the COMMID (for example, ID001 or COMMID

001).

If this message is displayed when power is applied to the MODEL

2500, the instrument must be configured before proceeding.

________________________________________________________________________________________________________________________________________

16

SECTIONSECTION 33

Page 31

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

FILE TYPES

Each application for the MODEL 2500 has three files composed of an application

name and a file name extension, indicated by the three letters following the file

name and separated by a dot or decimal point, to indicate the type of information

contained in the file. The extensions are defined in the following table.

EXTENSION DEFINITION

This file contains a configuration and should

.CFG

.BTA

.LST

not be erased unless the configuration is no

longer needed.

This file contains an analyzed configuration in

a format that is ready to be downloaded to a

MODEL 2500 microcomputer.

This file contains documentation that describes

a configuration in a format that can be listed

on a printer. Listing a .LST file on a printer

provides a hard copy record of the

configuration.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

17

Page 32

____________________________________________________________________________________________________________ MODELMODEL 25002500

MEMORY RESIDENT SOFTWARE

Frequently, utility software packages such as "Sidekick" and "Prokey" are loaded

by the user and remain resident in the Random Access Memory (RAM) of a

PC-compatible computer when the computer is booted (activated). Usually these

resident utilities do not interfere with running the DANIEL IPL25 program.

However, if the resident utility software package requires an excessive amount of

memory or a utility software package with serial communications, which causes

problems when downloading a configuration to a MODEL 2500 instrument, then

both of these problems may be corrected by removing the user’s resident utility

software package(s).

________________________________________________________________________________________________________________________________________

18

SECTIONSECTION 33

Page 33

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

HARD DRIVE USE

When using an IBM PC (or compatible computer) equipped with a hard drive,

standard practice suggests that regularly used programs should be grouped in a

sub-directory which is separate from the data sub-directory. The DANIEL

application program IPL25 supports this practice and all the files on the distribution

disk for IPL25 should be copied to the program sub-directory on the hard drive.

However, to do this proper MS-DOS PATH commands must be used to indicate

the sub-directory where the files for IPL25 are located. If necessary, refer to the

applicable computer manuals for details on the proper use of PATH commands.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

19

Page 34

____________________________________________________________________________________________________________ MODELMODEL 25002500

DOWNLOADING INSTRUCTIONS

The application software may be downloaded with the DANIEL program on the

application diskette, designated as IPL25. The IPL25 program, which is a new

window’s program, invokes the LOAD2500 program that can also be used directly.

Before attempting to download the application to the MODEL 2500, the user

should complete the following preliminary procedures:

- Activate both the PC and the MODEL 2500.

- Make certain the communications link between the PC and the Model

2500 is established. If necessary, refer to the Hardware Manual, Daniel

P/N 3-9000-590, for system wiring diagrams.

- Ensure that the MODEL 2500 has the proper communication ports and

baud rates installed and that a communications identification number

is designated.

- Make a working copy of the application diskette(s).

- Copy the application diskette(s) onto the hard drive, if the PC has a

hard drive installed.

_________________________________________________________

NOTE! Since diskette(s) wear out over time, file copies should

be made and stored in safe place.

_________________________________________________________

________________________________________________________________________________________________________________________________________

20

SECTIONSECTION 33

Page 35

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

Once these preliminary procedures have been completed, the user should perform

the following steps to download the application.

1. Place the working copy of the application diskette into the A drive.

2. From the A:\> prompt, type IPL25 and press the ENTER key.

The following MAIN MENU screen will appear on the PC monitor.

3. At the MAIN MENU, use the arrow keys to highlight the EDIT

CONFIGURATION and press the ENTER key.

To escape back to the MAIN MENU, press the ESC (escape) key twice.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

21

Page 36

____________________________________________________________________________________________________________ MODELMODEL 25002500

At the MAIN MENU, when the EDIT CONFIGURATION is selected and entered,

the following screen appears.

4. Highlight the desired COMMPORT selections with the arrow keys.

COMMPORT refers to the PC communications port used for serial data

transfer, which is Port 1 or Port 2.

5. After selecting the correct COMMPORT port press the ENTER key.

The reference screen at the bottom will indicate the selection. This reference

screen, which shows default entries, now indicates that the user will be loading the

Model 2500 on COM1. Other default entries on this reference screen indicate a

baud rate of 2400 with a COMMID of 1.

________________________________________________________________________________________________________________________________________

22

SECTIONSECTION 33

Page 37

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

6. Press the F1 function key.

As indicated on the screen below, this causes a HELP screen to be overlaid

in a window at the upper right portion of the screen being viewed.

7. At this point, the user may select and highlight the desired choice on the

HELP screen with the arrow keys, press the ENTER key, or press the ESC

(escape) key to exit from the HELP screen.

By using this procedure, a HELP screen is available whenever the user needs to

refer to it.

8. After removing the HELP screen, use the arrow keys to move from the

COMMPORT option window at the top of the screen to the DISK-DRIVE

option window, and press the ENTER key.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

23

Page 38

____________________________________________________________________________________________________________ MODELMODEL 25002500

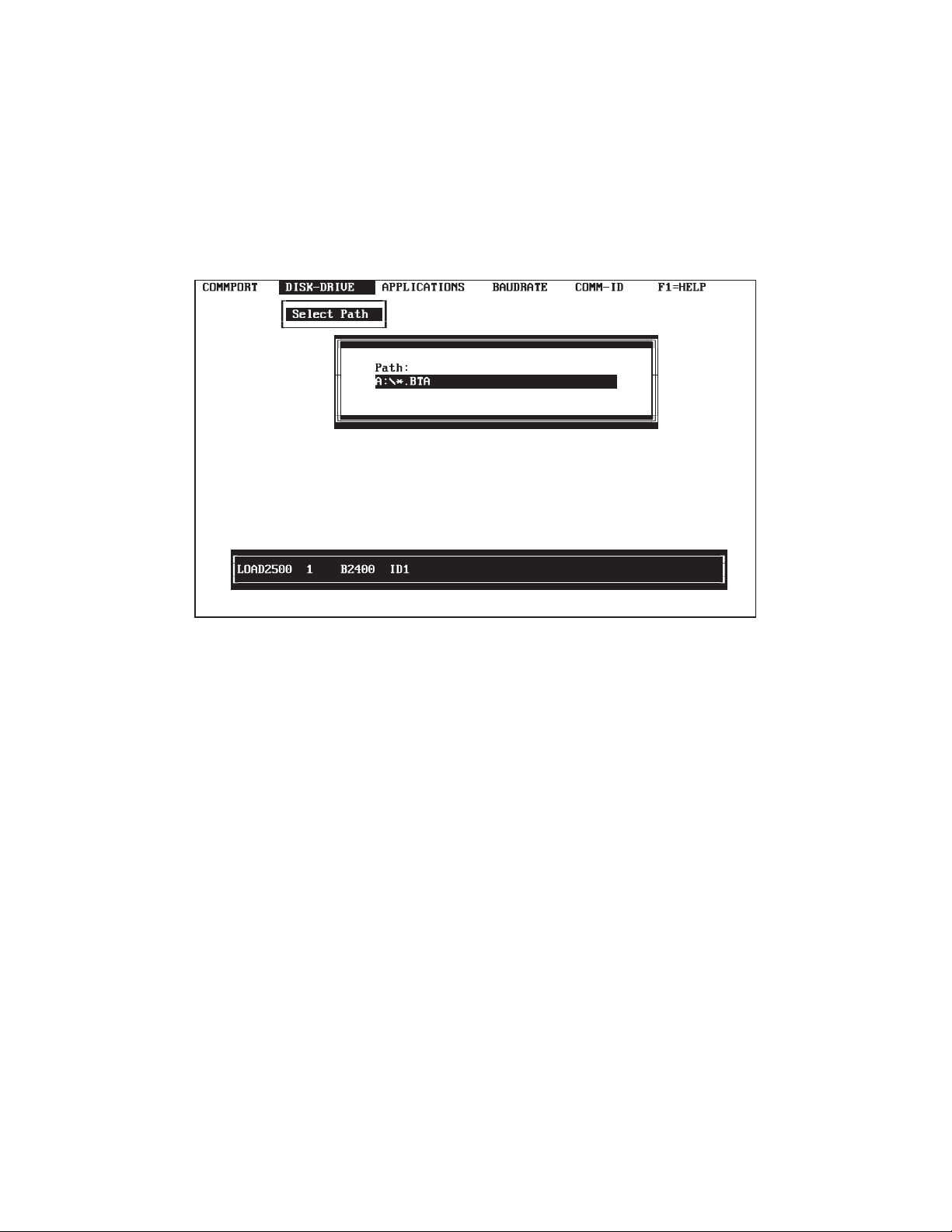

As indicated in the illustrated screen below, this causes a PATH screen to be

overlaid in a window in the right center portion of the screen being viewed. This

is a valid path if this IPL25 program is maintained on a diskette and not transferred

to the hard drive.

If the IPL25 program is transferred to the hard drive, the user will need to add a

directory\subdirectory to the program path.

9. At the PATH screen create a program path similar to

C:\"directory"\"subdirectory"\*.BTA

and press the ENTER key.

A reference window at the bottom of the screen will indicate whether the newly

created program path is a "Valid Path" or an "Invalid Path".

________________________________________________________________________________________________________________________________________

24

SECTIONSECTION 33

Page 39

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

10. Once the reference window indicates a "Valid Path" has been created, use

the arrow keys to move from the DISK-DRIVE option window at the top of

the screen to the APPLICATIONS option window and press the ENTER key.

As indicated in the illustrated screen below, this causes a FILES screen to be

overlaid in a window in the center portion of the screen being viewed. One or more

files may be listed with the BTA extension, which means that they can be

downloaded to the Model 2500. Also, there may be two or more diskettes,

depending on the number of applications and their size.

11. At the FILES screen, select the desired application to be downloaded and

press the ENTER key. The selected application will be displayed in the path

number in the bottom reference screen.

12. Once the desired application has been selected and entered, use the arrow

keys to move from the APPLICATIONS option window at the top of the

screen to the BAUDRATE option window. Select the desired baud rate and

press the ENTER key.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

25

Page 40

____________________________________________________________________________________________________________ MODELMODEL 25002500

If the Model 2500 has no configuration program, its default baud rate is normally

2400. If the downloaded application replaces a resident program, the baud rate

must match the slave baud rate on the Model 2500 receiving the application.

As indicated in the illustrated screen below, this causes a baud rate list to be

overlaid in a window beneath the BAUDRATE option window at the top of the

screen.

If the user selects a baud rate different than 2400, a "b" prefix, which is a code that

changes the baud rate in the Model 2500, will appear just before the baud rate

number in the reference screen. At this point, the user should press the ENTER

key.

13. Once the desired baud rate has been selected and entered, use the arrow keys

to move from the BAUDRATE option window at the top of the screen to the

COMMID option window and press the ENTER key.

________________________________________________________________________________________________________________________________________

26

SECTIONSECTION 33

Page 41

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

As indicated in the screen below, this causes a COMMID number screen to be

overlaid in a window beneath the COMMID option window at the top of the

screen.

The default COMMID number is 1, but a communications identification number

from 1 through 247 may be assigned. However, if an active program is resident in

the user’s Model 2500, the number assigned must match the COMMID number as

indicated in the System Command Menu.

14. When changing the COMMID number, the user must type in the number

assigned and press the ENTER key.

The following rules apply when changing the COMMID number:

- Do not place a "0" in front of one or two digit numbers.

- Delete mistakes by using the delete function or by typing over the

error.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

27

Page 42

____________________________________________________________________________________________________________ MODELMODEL 25002500

- Correct erroneously entered numbers by pressing the ENTER key

again and re-entering the number.

At this point, the user must check all entries in the reference window at the bottom

of the screen. If all entries are correct, the user is ready to download the application

to the Model 2500.

15. When all entries are correct, the user must press the ESC (escape) key twice

to return to the MAIN MENU.

16. If the MODEL 2500 is set up and ready, at the MAIN MENU use the arrow

keys to select and highlight the LOAD 2500 option and press the ENTER

key to load the application.

If a problem occurs, recheck the communications link, COMMPORT, COMMID,

etc., and the steps described above for loading the application.

17. When the downloading of the application is complete, use the arrow keys to

select and highlight the EXIT option and press the ENTER key to leave the

program.

________________________________________________________________________________________________________________________________________

28

SECTIONSECTION 33

Page 43

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

LOAD 2500 - STAND-ALONE DOWNLOAD PROGRAM

A stand-alone utility program, LOAD2500, is provided on the DANIEL software

diskette to download configurations into the DANIEL INDUSTRIES MODEL

2500.

After the MODEL 2500 has been activated and the system prompt appears, the

LOAD2500 program is invoked by using the command line illustrated and

explained below.

Command line: LOAD2500 n cccccccc [ Byyyy IDzzz A ]

n Number of the computer communications port

cccccccc BTA file name of the configuration, with the possible

subdirectory location. The file extension is not entered.

Byyyy Optional entry to set the baud rate to yyyy. Valid baud rates are

300, 1200, 2400, 4800, and 9600. If the baud rate is omitted or

entered incorrectly in the command line, LOAD2500 defaults to

a 2400 baud rate.

IDzzz Optional entry to set Comm ID to zzz. Comm ID is valid from

1 to 247. If the Comm ID is omitted or entered incorrectly,

LOAD2500 defaults to 1.

A Optional entry required only for loading a configuration created

with Revision G of CONFIG25.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

29

Page 44

____________________________________________________________________________________________________________ MODELMODEL 25002500

STAND-ALONE DOWNLOAD PROGRAM EXAMPLES

Following are several examples of the command line for the downloading of

LOAD2500 configurations:

- LOAD2500 1 D533011B B1200 ID12

This example illustrates the downloading of application number

D533011B through communications port 1, at a 1200 baud rate, and

sets the Comm ID to 12.

- LOAD2500 2 D533011B ID24

This example illustrates the downloading of application number

D533011B through communications port 2, at the default baud rate of

2400, and sets the Comm ID to 24.

- LOAD2500 1 C511009A B300

This example illustrates the downloading of application number

C511009A through communications port 1, at a 300 baud rate, and

sets the Comm ID to the default value of 1.

_________________________________________________________

NOTE! If all of the preceding steps have been properly

executed and the MODEL 2500 does not accept the

new program, make certain that the revision level of

the BASE25 EPROMs matches the revision level of the

Config25 program used to build the BTA file.

_________________________________________________________

________________________________________________________________________________________________________________________________________

30

SECTIONSECTION 33

Page 45

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

The following table lists the CONFIG25 software releases that are supported and

the baseline used for execution. The following compatibility rules are imposed by

the download routine.

Compatible BASE25 Revisions

CONFIG25

Revision

K.2 12/86 yes no no no yes

L.7 6/87 no yes yes yes yes

L.8 10/87 no yes yes yes yes

N 2/88 no no no yes yes

5.nn 12/89 no no no yes yes

Release

Date

K.2 L.7 L.8 N 5.nn

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

31

Page 46

____________________________________________________________________________________________________________ MODELMODEL 25002500

SYSTEM READY

If the results of the automatic initializing sequence have been satisfactory, the

MODEL 2500 LCD screen gives a message similar to the following illustration,

which indicates that front-panel operation can begin.

53301510

13-JAN-89 08:34

Line 1 of the display (in this example, 53301510) is the designation for the

alphanumeric configuration that has been downloaded to the Model 2500. Line 2

gives the current date and time.

DATA ENTRY SECURITY

Data entry security is provided by:

- Three-position security switch

- Two-level password system consisting of a lower-level password and

a restricted-user password

The lower-level password provides for changing constants and variable values that

are not designated as limited-access variables. The restricted-user password

provides access for changing the limited-access variables. Functioning of the

passwords is controlled by the three-position security switch.

________________________________________________________________________________________________________________________________________

32

SECTIONSECTION 33

Page 47

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

SECURITY SWITCH

A three-position security switch controls operator changes to variables in the

system through the front panel. The switch is located at the rear of CPU I/O

board.

The three selections provided by the switch are defined in the table below.

POSITION DEFINITION

DOWN Lower-level security password entry is not required to change

data. Restricted-user password entry may be required.

CENTER Password entry is allowed and required to change data.

UP Password entry is not allowed. Data cannot be changed at the

front panel of the instrument.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

33

Page 48

____________________________________________________________________________________________________________ MODELMODEL 25002500

LOWER-LEVEL SECURITY PASSWORD

If the security switch, which is located at the rear of CPU I/O board, is in the

center position, an operator must enter the lower-level security password before

entering or changing variable values in the system. The lower-level security

password remains active for five minutes after the last key is pressed. The system

command "Unit Lock" disables the unit password and the password must be entered

again in order to change data.

When the instrument is downloaded, the default lower-level password is eight 1s,

(11111111). Installing a new, user-originated, lower-level password at the initial

startup of the MODEL 2500 system, is recommended.

________________________________________________________________________________________________________________________________________

34

SECTIONSECTION 33

Page 49

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

RESTRICTED-USER PASSWORD

The restricted-user password provides an additional level of security for

user-specified, limited-access variables. The restricted-user password may not be

entered until the lower-level password is activated.

Until the restricted-user password is entered, limited-access variables can be

displayed, but cannot be changed, regardless of the state of the lower-level

password. After the restricted-user password is entered, limited-access variables

can be changed.

If the three-position security switch is in the center position, the restricted-user

password remains active for five minutes after the last key is pressed. In this

switch position, the system command "Unit Lock" disables the restricted-user

password and the lower-level password.

If the three-position security switch is in the up position, the restricted-user

password will not automatically time-out after five minutes, and must be disabled

using the "Unit Lock" command.

The factory-installed restricted-user password is "11111111". A new,

user-originated, restricted-user password should be entered at initial startup.

_________________________________________________________

CAUTION! Since neither the standard-unit password, nor the

restricted-user password can be retrieved after

being entered, a record of each should be kept in

a secure location for future reference. However,

the standard unit password may be over-written

if the security switch is in the down position.

_________________________________________________________

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

35

Page 50

____________________________________________________________________________________________________________ MODELMODEL 25002500

DATA ENTRY AT INITIAL STARTUP

Before a DANIEL INDUSTRIES MODEL 2500 INSTRUMENTATION SYSTEM

is placed in service, constants and variables for the application must be entered in

the microcomputer memory, or changed if this data differs from factory-installed

values. Data entry is made through the MODEL 2500 front panel keypad.

The following occurs when a MODEL 2500 system is configured for a specific

application:

- Default value for each constant and variable required for that

configuration is stored in the computer memory.

- Variables are stored in either a fixed or a dynamic mode, depending

on how the values are specified when the Model 2500 is initially

configured with CONFIG25.

- Variables will remain as configured until modified.

- All variables and constants are named and are available for display in

real time on the front panel.

- Calculation variables are displayed only if units for the variables are

assigned.

- Calculation variables can be changed manually only if units for the

variables were assigned the first time the variables were defined.

________________________________________________________________________________________________________________________________________

36

SECTIONSECTION 33

Page 51

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

PROCEDURE OF DATA ENTRY AT INITIAL STARTUP

The procedural steps for entering data during initial startup of the DANIEL

INDUSTRIES MODEL 2500 INSTRUMENTATION SYSTEM are as follows:

1. Turn on the MODEL 2500 and ensure that the normal start-up message,

which is illustrated below, is displayed.

D513024A

13-JAN-89 08:34

2. Unlock the front panel for data entry by pressing the DOWN arrow on the

front panel keypad several times until the message "SYSTEM

COMMANDS" appears on the lower text line of the LCD screen display.

_________________________________________________________

NOTE! Continuously holding down the key, rather than

pressing it several times will cause the display to

scroll rapidly through the MAIN MENU and may

result in overshooting the SYSTEM COMMANDS

sub-menu. If this occurs, continue to press the

DOWN arrow one step at a time until the message

SYSTEM COMMANDS reappears.

_________________________________________________________

3. Press the ENTER key once.

4. Press the DOWN arrow one step at a time until the message "UNIT

PASSWORD" appears.

5. Pressing the ENTER key once.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

37

Page 52

____________________________________________________________________________________________________________ MODELMODEL 25002500

6. Press the number 1 key 8 times, which will cause the default password,

"11111111" to appear on the LCD screen,

7. Press the ENTER key. This will cause the green LED on the front panel to

glow.

_________________________________________________________

NOTE! The password may be changed at this time by keying in

eight numbers on the front panel keypad. (The MODEL

2500 accepts prefixed zeros as discrete, which means the

instrument requires all eight digits of a number such as

00000004 in order to interpret the number 4 as the

password.) When the new password has been keyed in,

press the ENTER key. The keyboard now can be

unlocked for data entry only with the new password.

The password cannot be retrieved once entered, and

should be recorded in a secure location.

_________________________________________________________

8. Scroll to the desired sub-menu and lower sub-menu by pressing the arrow

keys.

9. Key in new or revised data, and enter the data by pressing the ENTER key.

_________________________________________________________

CAUTION! Changing values in the Model 2500 system may

activate alarms, which must be cleared before

placing the unit in service.

_________________________________________________________

10. Press the arrow keys when data entry is complete to find the lower sub-menu

UNIT LOCK located in the sub-menu SYSTEM COMMANDS.

________________________________________________________________________________________________________________________________________

38

SECTIONSECTION 33

Page 53

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

11. Press the ENTER key when the message "UNIT LOCK" appears on the LCD

screen.

_________________________________________________________

NOTE! After approximately five minutes with no keyboard

activity, the MODEL 2500 automatically disables the

keyboard for data entry until the password is re-entered.

_________________________________________________________

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

39

Page 54

____________________________________________________________________________________________________________ MODELMODEL 25002500

TYPICAL START-UP DATA CHANGES

The following list represents data that is often changed from the factory-installed

default values at the initial start-up of a MODEL 2500 configured for a specific

application:

- Measured or hand-entered values of process variables

- Definitions of the metering arrangement, including:

- Flange or pipe-tap differential pressure transmitters

- Upstream or downstream static pressure transmitters

- Single or dual-range differential pressure transmitters

- Settings for zero (4 mA) and full-scale (20 mA) values (in engineering

units) of transmitter inputs

- Desired multipliers for readouts of flow rates and flow accumulators

- High and low alarm limits

- Calibration units for frequency-type densitometers

- Base values for temperature and pressure

- Barometric pressure for the measurement site

- Unit ID number for printout identification

- Time and date

- Contract hour and time period between printouts

________________________________________________________________________________________________________________________________________

40

SECTIONSECTION 33

Page 55

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

TIME-OF-DAY CLOCK CHIP

DANIEL INDUSTRIES MODEL 2500 microcomputer units that have a

time-of-day clock chip will continue to provide the time even when the unit is

without power either because of a power failure or because the instrument is in

storage.

When the MODEL 2500 is in operation, the clock chip is updated several times a

day as follows:

- Approximately two-hour intervals

- Shortly after midnight each day

- Whenever the time of day is changed

The clock chip is additional and secondary to the time of day maintained by the

software clock, which is an integral part of the MODEL 2500 operating system.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 33

41

Page 56

____________________________________________________________________________________________________________ MODELMODEL 25002500

This page intentionally left blank.

________________________________________________________________________________________________________________________________________

42

SECTIONSECTION 33

Page 57

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

MENU SELECTION

The DANIEL INDUSTRIES MODEL 2500 INSTRUMENTATION SYSTEM

microcomputer enters, changes and displays operating commands and data by

making selections from various menus displayed on the LCD screen located on the

front panel of the instrument.

Individual menus, which are organized into groups of related data and functions,

are configured for each specific application, and only appear on the display screen

when required by the specific application.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 44

43

Page 58

____________________________________________________________________________________________________________ MODELMODEL 25002500

MAIN MENU

The highest level menu in the MODEL 2500 is the MAIN MENU, which is

activated after the completion of diagnostic testing and when the "TIME and

DATE" message is displayed on the LCD screen.

Depending on the MODEL 2500 configuration, the MAIN MENU contains up to

11 sub-menus, each of which either provides a functional category for accessing

system data or for controlling the instrument.

________________________________________________________________________________________________________________________________________

44

SECTIONSECTION 44

Page 59

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

SUB-MENUS

The MAIN MENU’s 12 possible sub-menus are listed below with those menus that

appear in all system configurations marked with an asterisk (*).

- INPUT CHANNELS

- OUTPUT CHANNELS

- ALARMS*

- OPERATOR ENTRY

- CALCULATIONS*

- REPORTS

- TABLES

- TUBE SWITCHING

- MODBUS MASTER

- SERIAL PORTS*

- ARCHIVE

- SYSTEM COMMANDS*

When required by an application, each sub-menu may have one or more lower

sub-menus that provides for specific data entry, or system control in the category

covered by that sub-menu.

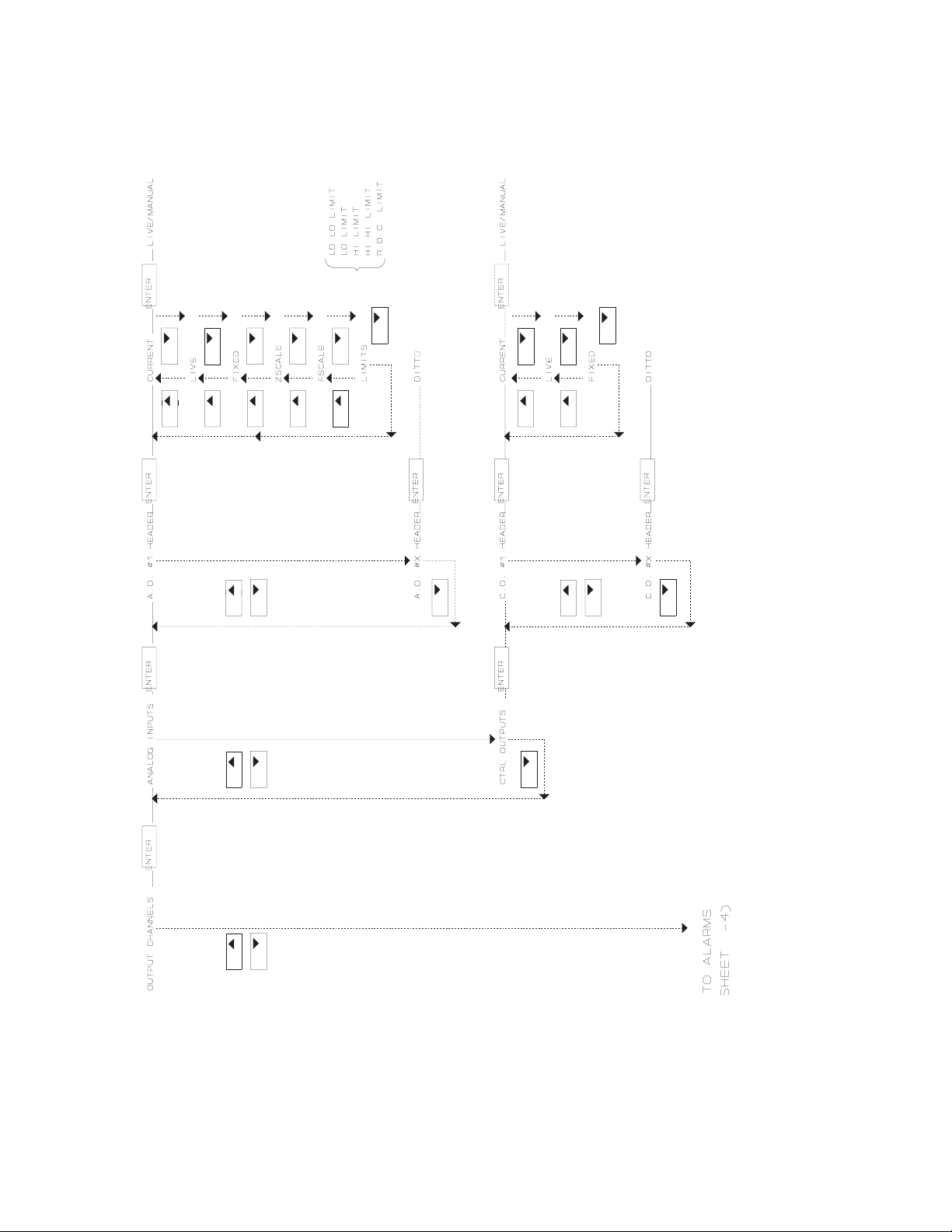

The following flow-chart graphically illustrates how to enter and exit each of the

11 sub-menus, and refers the user to other diagrams, which are listed at the end of

this section, that illustrate the lower level sub-menus within the 11 main submenus.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 44

45

Page 60

____________________________________________________________________________________________________________ MODELMODEL 25002500

The following is a detailed explanation of the MAIN MENU’s 12 sub-menus.

INPUT CHANNELS

The INPUT CHANNELS sub-menu, which is the first selection listed on the MAIN

MENU, has three lower level sub-menus. They are:

ANALOG INPUTS The ANALOG INPUTS lower level sub-menu

displays the variable names, values, units, alarm

limits, scaling factors, and default values of the

analog input channels.

STATUS INPUTS The STATUS INPUTS lower level sub-menu

provides for changing the states of status (discrete)

input channels, and for displaying the variable

names, states, and units.

PULSE INPUTS The PULSE INPUTS lower level sub-menu allows

the values of the pulse input channels to be

changed, and displays the channel variable names,

values, and units.

OUTPUT CHANNELS

The OUTPUT CHANNELS sub-menu, which is the second selection on the Main

menu, has two lower level sub-menus. They are:

ANALOG OUTPUTS The ANALOG OUTPUTS lower sub-menu

provides for changing the values of the analog

output channels and for displaying the variable

names, values, units, alarm limits, and scaling

factors of the channels.

________________________________________________________________________________________________________________________________________

46

SECTIONSECTION 44

Page 61

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

CONTROL OUTPUTS The CONTROL OUTPUTS lower level sub-menu

provides for changing the values of the control

output channels and for displaying the variable

names, values, and units.

ALARMS

The ALARMS sub-menu, which is the third selection on the MAIN MENU, has

two lower sub-menus. They are:

UNACKED ALARMS The UNACKED (unacknowledged) ALARMS

lower level sub-menu displays all alarms that have

not been acknowledged by the operator.

CURRENT ALARMS The CURRENT ALARMS lower level sub-menu

displays currently active alarms.

OPERATOR ENTRY

The OPERATOR ENTRY sub-menu, which is the fourth sub-menu on the MAIN

MENU, has two lower sub-menus. They are:

NUMERIC ENTRIES The NUMERIC ENTRIES lower level sub-menu

allows the values of numeric operator entries to be

changed and displays the names, values, units, and

alarm limits of the entries. Typical numeric entries

for a MODEL 2500 configuration, which measures

orifice mass and volume of a liquid, are the

specific gravity of the liquid, the hour when daily

reports are printed, base temperature and pressure

for calculations, and pipe and orifice diameters.

________________________________________________________________________________________________________________________________________

SECTIONSECTION 44

47

Page 62

____________________________________________________________________________________________________________ MODELMODEL 25002500

SELECTION

ENTRIES The SELECTION ENTRIES lower level sub-menu

displays the name, units, and startup selection of

selection list operator entries, and allows for

changing the startup selections. For example, in a

MODEL 2500 configured to measure orifice mass

and volume, selection list operator entries are

typically the type and location of orifice taps.

Startup selections for tap type are pipe and flange.

Startup selections for tap location are upstream and

downstream.

CALCULATIONS

The CALCULATIONS sub-menu, which is the fifth sub-menu on the MAIN

MENU, has the names of individual calculation sheets as lower level sub-menus.

Individual calculation sheets provide programming instructions for data processing

by the MODEL 2500. Representative calculation sheets include those that:

- Perform initialization routines

- Process status inputs

- Process operator entries

- Process timer functions

- Perform flow rate, volume, and mass calculations

- Process report scheduling

REPORTS

The REPORTS sub-menu, which is the sixth sub-menu on the MAIN MENU, has

lower level sub-menus composed of each report produced by a MODEL 2500

configuration.

A complete report can be printed by pressing the ENTER key when the report

name is displayed on the front panel.

________________________________________________________________________________________________________________________________________

48

SECTIONSECTION 44

Page 63

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

_________________________________________________________

NOTE! Applications in which report lengths are in excess of

one page require a printer with an 8k buffer capacity,

or the baud rate of the printer output signal must be

lowered to 300, and the RPTGAP lower level sub-menu

must be set to SPACES.

_________________________________________________________

TABLES

The TABLES sub-menu, which is the seventh sub-menu on the MAIN MENU, has

a lower level sub-menu for each data table defined in the configuration.

TUBE SWITCHING

The TUBE SWITCHING sub-menu, which is the eighth sub-menu on the MAIN

MENU, provides the following list of variables that define common switching

parameters for all tube sets and individual switching parameters for each tube in

a set.

Common switching parameters for all tube sets:

Time delay variable The time delay variable is a user-entered interval

that allows time for a valve to change position, and

for the position change to affect the differential

pressure across the tube set before the position of

the next valve in the set is changed. The default

value for this variable is 120 seconds.

Verify DP variable The verify DP variable enables or disables

automatic verification of the differential pressure

________________________________________________________________________________________________________________________________________

SECTIONSECTION 44

49

Page 64

____________________________________________________________________________________________________________ MODELMODEL 25002500

level after a valve position change is ordered by the

MODEL 2500. When the variable is OFF, no

verification is performed.

Verify level variable The verify level variable specifies the cutoff value

for differential pressure across a tube set to be used

in verifying a valve position change. The default

value of this variable is 2.

Control number

variable The control number (#) variable displays the

number of the tube assigned as the current control

tube.

Individual tube switching parameters are listed for the first tube in a set in the

following order and repeat in that same order for each subsequent tube. Tubes are

listed in the desired sequence for switching the valves.

DP name Differential pressure name is the analog input variable

with a value that represents the current differential

pressure transmitted.

Low Low differential pressure switchpoint (expressed in

engineering units) across a tube when the valve

controlling the tube is closed. The default value for this

variable is 2.

High High differential pressure switchpoint (expressed in

engineering units) across a tube when the valve

controlling the tube is opened. The default value for this

variable is 98.

State Operational status of the tube being displayed (i.e.,

enabled, disabled, fault). The default status of this

variable is "enabled".

________________________________________________________________________________________________________________________________________

50

SECTIONSECTION 44

Page 65

MODELMODEL 2500_______________________________________________________2500_______________________________________________________

Open Boolean variable that opens the valve when set

Close Boolean variable that closes the valve when set

MODBUS MASTER

The MODBUS MASTER sub-menu, which is the ninth sub-menu on the MAIN

MENU, has a lower level sub-menu for defining two remote units. The remote unit

definition sub-menu provides for identifying or changing the remote name ID, the

communications address and state variable, and the control option for each of the

two remote units.

Name Identifies the remote unit

Communications

Address Integer variable for the communications address of the

slave unit. If a communications address is not entered,

the default variable is zero. When the communications

address is zero, communications with the remote unit is

disabled.

State Integer variable that contains the current MODBUS

function code transmitted and received for the remote

unit. The state entry provides a means of monitoring the

activity between the master and remote units. Error

conditions are also visible by means of this variable.

Control Three options available here are:

IDLE Indicating no communications in progress

ACTIVE Indicating communications in progress