MANUAL

MAGNET POWER SUPPLY

SYSTEM 9100

IMPORTANT!

This documentation contains information which

is the property of DANFYSIK A/S, Denmark.

It is submitted to you in confidence that it will not be

disclosed or transmitted to others without DANFYSIK=s

authorisation.

REV.

By

Date

Description

Pages

1.0

CSN

12.04.2010

Initial

All

2.0

CSN

18.06.2010

Chapter 2.5: Two or more SYSTEM 9100 in

parallel deleted

12

2.1

CSN

19.08.2010

Chapter 5: AC mains Connector X1. 208VAC pin

connections added

57

2.2

CSN

05.05.2011

Various

2.3

ESHA

19.12.2012

Address

MAGNET POWER SUPPLY SYSTEM 9100

3

DANFYSIK A/S - DENMARK.

Table of contents PAGE

1 INTRODUCTION AND SPECIFICATIONS ....................................................................................... 5

1.1 GENERAL INTRODUCTION ............................................................................................................... 5

1.2 SPECIFICATIONS .............................................................................................................................. 6

1.3 WARRANTY AND WARRANTY REPAIR. ............................................................................................ 9

2 UNPACKING AND INSTALLATION............................................................................................... 10

2.1 RECEIVING THE GOODS ................................................................................................................. 10

2.2 INSTRUCTIONS FOR UNPACKING .................................................................................................... 10

2.3 INSTALLATION REQUIREMENTS ..................................................................................................... 10

2.4 INSTALLATION ............................................................................................................................... 11

2.5 RS422 OR RS485 MULTIDROP CONFIGURATION ........................................................................... 12

3 OPERATING INSTRUCTIONS ......................................................................................................... 13

3.1 SWITCHING ON .............................................................................................................................. 13

3.2 OPERATING WITH THE MANUAL CONTROL PANEL ....................................................................... 13

3.2.1 Main power ON / OFF and interlock RESET ...................................................................... 14

3.2.2 Using the Manual Panel Menus ............................................................................................ 14

3.2.3 Front panel controls. ............................................................................................................. 16

3.2.4 The Display .......................................................................................................................... 17

3.2.5 Control Menus ...................................................................................................................... 20

3.2.6 Current setting ...................................................................................................................... 22

3.2.7 Polarity reversal .................................................................................................................... 22

3.3 OPERATING BY RS 232, RS422 OR RS 485 I/O ............................................................................. 24

3.3.1 Setting up the MPS via display board .................................................................................. 24

3.3.2 Data communication ............................................................................................................. 36

3.3.3 Termination using RS 422m or RS 485................................................................................ 37

3.3.4 Programming ........................................................................................................................ 38

3.3.5 Software Profile Programming ............................................................................................. 39

3.3.6 Arbitrary point ramp profile method .................................................................................... 40

3.3.7 Equal time slot ramp profile method .................................................................................... 41

3.3.8 Auto Slew Rate Ramp Profile method. ................................................................................ 42

3.3.9 SW limits .............................................................................................................................. 43

3.4 OPERATING IN ANALOG MODE ...................................................................................................... 47

3.4.1 Standard interface / Parallel interface ................................................................................... 48

4 THEORY OF OPERATIONS .............................................................................................................. 49

4.1 INTRODUCTION .............................................................................................................................. 49

4.2 M-PANEL ....................................................................................................................................... 52

4.3 I-LOOP, CONTROL, INTERLOCK PCB ............................................................................................ 52

4.3.1 Micro-processor .................................................................................................................... 52

4.3.2 DAC Circuit ......................................................................................................................... 52

4.3.3 ADC Control ........................................................................................................................ 53

4.3.4 Voltage reference.................................................................................................................. 53

4.3.5 DC/DC Converter ................................................................................................................. 53

4.3.6 Seriel Interface...................................................................................................................... 53

4.3.7 Current & Voltage loop ........................................................................................................ 54

4.3.8 Control .................................................................................................................................. 54

4.3.9 Soft start ............................................................................................................................... 54

4.3.10 Interlock ................................................................................................................................ 54

4.3.11 Peltier Control ...................................................................................................................... 55

MAGNET POWER SUPPLY SYSTEM 9100

4

DANFYSIK A/S - DENMARK.

4.4 EMC FILTER .................................................................................................................................. 55

4.5 AC INPUT FILTER MODULE ............................................................................................................ 55

4.5.1 Overcurrent breaker .............................................................................................................. 55

4.5.2 Rectifier 3 phase ................................................................................................................... 55

4.5.3 Soft Start Module ................................................................................................................. 55

4.5.4 Capacitor and DC link filter ................................................................................................. 55

4.6 OUTPUT MODULE........................................................................................................................... 56

4.6.1 Output and filter ................................................................................................................... 56

4.6.2 Transformer .......................................................................................................................... 56

4.6.3 PWM controller .................................................................................................................... 56

4.7 AUX POWER SUPPLY ...................................................................................................................... 56

4.7.1 AC line monitor .................................................................................................................... 56

4.7.2 Aux power loop & CPU ....................................................................................................... 56

4.7.3 Aux power FAN ................................................................................................................... 57

4.7.4 Aux power primary............................................................................................................... 57

4.8 DCCT TRANSDUCER ..................................................................................................................... 57

4.9 BIPOLAR OUTPUT STAGE (H-BRIGDE) ........................................................................................... 57

5 SYSTEM 9100 INTERFACE SPECIFICATION: .............................................................................. 58

AC Mains connector X1: ..................................................................................................................... 58

Output X24 and X25 ............................................................................................................................ 58

Analog X108 (D-SUB 25 Pole): .......................................................................................................... 59

SPI – Iset DAC interface X5 (HDMI 19- Pole): .................................................................................. 59

LOCAL CONTROL X6 (D-SUB 9 Pole): ........................................................................................... 60

REMOTE CONTROL X7 (D-SUB 25 Pole): ...................................................................................... 61

Connector X9 (pin 1-4) X8 (pin 6-10) X112 (pin 12-16): ................................................................... 61

Fuseholder F1: ...................................................................................................................................... 61

6 MAINTENANCE ................................................................................................................................ 62

6.1 INTRODUCTION .............................................................................................................................. 62

6.2 PREVENTIVE MAINTENANCE ......................................................................................................... 62

6.3 ADJUSTMENT AND CALIBRATION .................................................................................................. 62

7 TROUBLE SHOOTING ...................................................................................................................... 63

MAGNET POWER SUPPLY SYSTEM 9100

5

DANFYSIK A/S - DENMARK.

1 Introduction and specifications

1.1 General introduction

The System 9100 is a DC constant current output Power Supplies designed for applications

requiring very high stability and low noise combined with reliability and ease of operation.

The System 9100 is aimed at correction magnets in ion beam applications based on Danfysik´s

forty years of experience in delivering precision DC Power supplies to industrial and research

laboratory users around the world.

The System 9100 is the new generation of high performance Power Converters suitable for

many high current and voltage applications where size and cost are essential.

Power range of 3 kW, 6 kW, 9 kW and 12 kW , allowing the user to select the most

suitable solution

10ppm stability class using LEM Ultrastab high precision DCCT current transducer to

control the current stability in the power supply

Wide current range from 50 A to 200 A

Low output ripple, internal power modules are parallel connected in pairs with a 180º

phase angle, hereby reducing input and output ripple.

Remote controlled through a serial interface “RS232/RS422/RS485”

MAGNET POWER SUPPLY SYSTEM 9100

6

DANFYSIK A/S - DENMARK.

1.2 Specifications

AC INPUT

Mains, voltage: 400 VAC, 3 phase, 47 - 63 Hz.

Control voltage: 230 VAC, 47-63 Hz.

AC voltage variation: ±10%

See page 58 for connection to AC mains connector.

DC OUTPUT

Power Range up to 12 kW

Current: 50 A - 100 A - 150 A - 200 A versions

Voltage: 60 V

Regulation Topology: Constant current regulation

Converter Type: Primary switching type that operate after the Zero

voltage switch-mode principle

PERFORMANCE

Warm up time (cold): 30 min.

Warm up time (stand-by): 15 min

Drift (long term 8 hours): ±10ppm

Line regulation

± 10% slow, T > 1 min.: ±5ppm

± 1% fast, T > 3 m sec.: ±5ppm

Load regulation

± 10% resistance change: ±5ppm

Output ripple and noise

Voltage – peak to peak: < 100 mV @ 0-100 kHz

Load Range

Time Constant (L/R): 0 - 1 sec

Inductance (L): 0 - 1 H (standard)

Temperature coefficient

Ambient 15 – 40° C: 5ppm/°C

Ambient 15 – 30° C: 1ppm/°C

Current setting resolution: 20 bit DAC

Current reproducibility: ± 10ppm

Absolute current calibration: -0 / +400ppm

MAGNET POWER SUPPLY SYSTEM 9100

7

DANFYSIK A/S - DENMARK.

Current readback resolution: 16 bit ADC

Voltage readback resolution: 16 bit ADC

Current control range (setting range): 1 – 100%

Ramp speed (0 – 100%): 0.1 – 10 s (adjustable)*

Current loop bandwidth: 2 – 100 Hz

Voltage loop bandwidth: >200 Hz

*Ramp speed for the bipolar version is limited in the second and fourth quadrant. See page 22.

CONTROL PANEL

Alphanumeric LCD display:

Preset output current, 6 digits [A]

Actual output current, 5 digits [A]

Output voltage, 2 digits [V]

Interlock status text string

Push buttons and LED's

OFF [Button]/[LED]

Reset (interlock) [Button]/[LED]

ON [Button]/[LED]

Menu [Button]

Out of regulation [LED]

Remote control / interfacing

RS232 as standard (RS422 and RS485, or SPI are available on request)

The following status messages are available via the remote control interface:

ON/OFF command

Reset command

ON/OFF status

Remote status

Output current

Output voltage

Ambient temperature

Delta temperature

Internal power supply 15 V

Internal power supply 5 V

I set value

V set value

The following controls are available via the analog control interface:

Set current

Set voltage

Output current readback

Output voltage readback

MAGNET POWER SUPPLY SYSTEM 9100

8

DANFYSIK A/S - DENMARK.

Interlock status

Over voltage

Over current

Over temperature

Fan fault

Earth leakage

AC fault

Out of regulation

External interlock (ext. 1 – 4)

Summary interlock

COOLING

Water: 1 l/min @ max. Inlet temperature 35° C

Differential pressure: 1 bar

Test pressure: 15 bar

TEMPERATURE RATINGS

Operation Ambient temperature: 15 - 40° C

Storage temperature: -20 - 70° C, non-condensing

CABINET LAY-OUT

Material: Steel

Dimensions W x D x H: 482 mm x 550 mm x 132.5 (3U)

19 inch rack mount

Weight 32 kg (shipping weight 35 kg)

NORMS

Immunity for industries: EN/IEC 61000-6-2:2005

Emission for industries: EN/IEC 61000-6-4:2007

Harmonic Emission (single phase): EN/IEC 61000-3-2:2000

Harmonic Emission (three phase): EN/IEC 61000-3-12:2005

Electromagnetic compatibility: EN/IEC 61000-3-11:2000

Safety req. for electrical equipment: EN/IEC 61010-1:2001

MAGNET POWER SUPPLY SYSTEM 9100

9

DANFYSIK A/S - DENMARK.

1.3 Warranty and warranty repair.

DANFYSIK A/S warrants that the products manufactured by us will be free from defects in

material and workmanship that adversely would affect the normal functioning of the unit, for a

period of 24 months from the Date of Acceptance of the Equipment.

The exemptions to this are:

a) Parts not manufactured by DANFYSIK A/S which are covered by the original

equipment manufacturer's warranty.

b) Repair work, which is warranted for six (6) months from the date of shipment

from the DANFYSIK works.

DANFYSIK A/S will repair or replace either on site or at the factory, at option and without

charge, any equipment which proves to be defective within its warranty period.

In the case of warranty, DANFYSIK A/S will pay or reimburse lowest freight rate (two-way)

of any item returned to DANFYSIK or our designated agent/representative, provided that prior

written authorisation for such return has been given by DANFYSIK A/S.

This warranty shall not apply to any equipment, which has become defective or unworkable

due to mishandling, improper maintenance, incorrect use, radiation damage or any other

circumstance not generally acceptable for equipment of a similar type.

On standard products, DANFYSIK A/S reserves the right to make changes in design without

incurring any obligation to modify previously manufactured units.

The foregoing is the full extent of this warranty, and no other warranty is expressed or implied.

In no event shall Danfysik be liable for special damages arising from the delivery, late delivery

or use of the equipment.

If any fault develops, the following steps should be taken.

Notify DANFYSIK A/S, giving full details of the problems, and include Model-Type and

Serial number.

On receipt of these information, DANFYSIK A/S will give you either service information or

instructions for shipping.

All shipments of DANFYSIK equipment should be made according to our instructions and

shipped in the original or a similar container.

For smaller parts a carton will be sufficient, if the parts are wrapped in ESD bags and

surrounded with at least 10 centimetres of shock absorbing material.

MAGNET POWER SUPPLY SYSTEM 9100

10

DANFYSIK A/S - DENMARK.

2 Unpacking and installation

2.1 Receiving the goods

The Shipping container and the Power Supply should be thoroughly inspected for signs of

obvious physical damage immediately upon receipt.

All materials in the container should be checked against the enclosed packing list.

DANFYSIK A/S will not be responsible for shortages against the packing list unless notified

immediately.

2.2 Instructions for unpacking

The Power Supply is shipped in reinforced cardboard.

If the equipment is damaged in any way, a claim should be filed with the shipping agent, and a

full report of the damage should be forwarded to DANFYSIK A/S or our local agent/representative immediately.

Upon receipt of this report, you will be issued instructions for the repair, replacement or return

shipment.

Please include the Model no, Type no, Serial no, and Order no for the Power Supply on any

communication with DANFYSIK A/S or our representative.

2.3 Installation requirements

During installation of the Power Supply, local rules and regulations for electric power supplies

should be respected and the following conditions and installations should be available.

* A normal, dust free room with humidity not above 80 % and a room temperature within

15 to 40 centigrade.

* Three-phase Mains voltage switched and fused, + neutral and protective earth.

* Ground connection according to the local authority regulation and the requirements for

the equipment.

* If applicable, cooling water supply at a temperature within 15 to 35 centigrade.

Differential pressure: Min. 1 bar.

Max. inlet pressure: 12 bar.

Please see specification sheet chapter 1.2 in this manual for actual figures for this power

supply.

* For cooling of our power supplies and magnets we recommend the use of demineralised

water or pure water with an electrical conductivity of less than 10μS/cm. This reduces

the electrolytic corrosion to a minimum.

Adding pure ethylene glycol to cooling water with no other additives should not affect

the electrolytic corrosion. However, it will reduce the thermal conductivity of the

coolant. A percentage of 40% glycol reduces the conductivity by approximate 30%. We

would recommend not using more than 25% corresponding to an approximate reduction

of thermal conductivity of 17%. It may be necessary to increase the water flow in the

power supply.

MAGNET POWER SUPPLY SYSTEM 9100

11

DANFYSIK A/S - DENMARK.

No other additives should be used.

During operation, the conductivity of the coolant should be checked regularly. A few

days operation with water of poor quality can cause more corrosion damage than during

several years‟ operation with good quality water.

2.4 Installation

Before and during installation of the Power Supply, the following points should be checked /

carried out.

* Check that the main voltage and frequency matches to the specified and labelled

requirements.

* Check that screw connections from the output terminals are tightened.

* Check that all screws on D-sub connectors are tightened.

* If the magnet is provided with a thermal breaker connect the contacts to external

interlocks and +24 VGND (Ground for +24 V)

* Unused external interlocks shall be connected to +24V ground (Ground for +24 V pin

12, X112 or to pin 11 +24V_Ext_GND if +24V_Ext, pin X8 is used for interlock

supply)

MAGNET POWER SUPPLY SYSTEM 9100

12

DANFYSIK A/S - DENMARK.

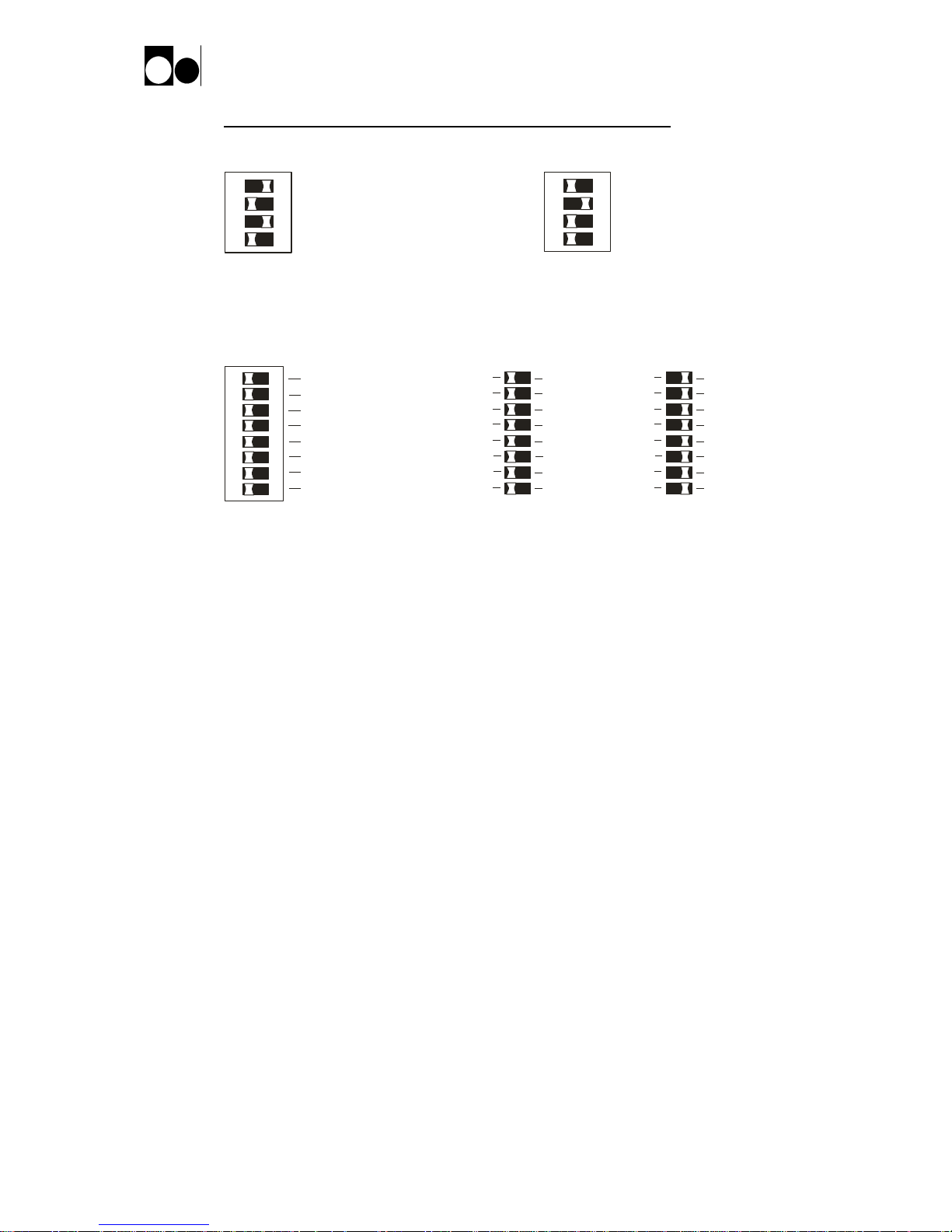

2.5 RS422 or RS485 Multidrop configuration

Up to 32 SYSTEM 9100 units can be connected in a RS422 or RS485 multidrop configuration.

It is also possible to run a Master/Slave configuration within a multidrop system. To set up the

Master/Slave configuration, see chapter 2.5.

Connect parallel cables to all masters at the port REMOTE.

Address all the masters so each unit has a unique address. See chapter 3.3.1 for setup

address in local and remote mode.

MPS no. 1

addresse : X

MPS no. 2

addresse : X+1

MPS no. 3

addresse : X+2

MPS no. Y

addresse : X+(Y-1)

X :Start address

Y : The last unit of MPS on the

multdrop line

X108

AnalogREMOTE

+ OUT - OUT

16 POL

Analog

+ OUT - OUT

16 POL

Analog

+ OUT - OUT

16 POL

Analog

+ OUT - OUT

16 POL

REMOTE

REMOTE

REMOTE

Example of multidrop configuration

About the termination of RS422 or RS45, see chapter 3.3.3 “Termination using RS422 or

RS485”

MAGNET POWER SUPPLY SYSTEM 9100

13

DANFYSIK A/S - DENMARK.

3 Operating instructions

This chapter outlines the procedure and precautions for the operation in local and in remote

control mode.

It identifies and describes the controls and indicators on the M-Panel Graphical.

Also the programming of the remote lines is described.

Instructions for initial remote line set up are given in chapter 3.3.

3.1 Switching on

When precautions have been checked in accordance with chapter 2.3 and 2.4, the power supply

can be switched on.

Immediately after the Power Supply is switched on, a start up screen appears on the M-Panel

and displays which control module is connected and makes a self test and scans for a text table

has been downloaded or not.

After approximately 5sec., the panel is ready for use. The remote line is ready for use after

approximately 3 sec.

Make sure that the time between switching the control power - OFF and - ON again is at least 5

sec. to ensure a correct cold start (initialization of the Power Supply).

- Select LOCAL CONTROL mode at the CMD-menu. "LOC" text appears in the display

(1).

To turn the power supply ON for the first time, it is recommended to activate it in the

LOCAL CONTROL mode as this is the easiest way to get started.

- If any Interlocks are set, push the "Reset" button (8).

Remove the faults if the Interlocks are not reset.

- Set the desired output current by use of the SET-menu.

- Switch the Main power "ON" (3).

- The READY LED (6) illuminates, when the output current is equal to the preset value

within a given accuracy typically +/-200ppm.

- Switch the main power "OFF" (5).

3.2 Operating with the Manual Control Panel

The MANUAL CONTROL PANEL (M-Panel Graphical) is an interface module that are used

with several Danfysik Magnet Power Supplies including SYSTEM 9100.

The SYSTEM 9100 comes with a M-panel as standard. It can however also be delivered with a

display board. This has two 5 digit 7 segment displays for voltage and current. LED indicators

for POWER ON, FAULT and READY. With this display board, the System 9100 can be

operated remotely from a PC, or by connecting an M-panel to the local port situated on the

back side of the system 9100. The M-panel can be connected and disconnected from the Power

Supply without affecting the power supply operation. Communication between the Power

Supply and the M-Panel is by a serial link, and may be physically located at the Power Supply

or up to 400 meters away from it.

MAGNET POWER SUPPLY SYSTEM 9100

14

DANFYSIK A/S - DENMARK.

3.2.1 Main power ON / OFF and interlock RESET

The basic function on the M-panel is to turn the power supply ON / OFF and to RESET

pending interlocks. All controlled from a single button. For further information about the

button locations, see chapter 3.2.3 Front Panel Control.

Setting the output current is done through one of the pull down menus described in the next

chapter.

When the power supply is ON the LED in the button area will illuminate.

When the power supply is OFF the LED in the button area will illuminate.

If an interlock is present the LED inside the RESET button will illuminate.

Pressing the RESET button will clear the interlocks that are not due anymore.

Hint: If an interlock is present, it will also be represented on the display at the lower right

corner.

Hint: The color of the LEDs can be reprogrammed to illuminate green, red or

“orange”.

3.2.2 Using the Manual Panel Menus

This chapter shortly describes the use of the M-Panel Graphical. The menus themselves will be

described later.

The user interface of the M-Panel Graphical is based upon pull down menus. To display the

menus simply press the MENU button (if not already standing in the Menu window).

To prevent unnecessary hiding of the main display (set current, output current and voltage) the

pull down menus are always displayed left aligned. In other words, it is the menu bar that rolls

over the pull down region.

With visible menu bar, activating the “” or “” arrow buttons the menu bar always displaying

the selected pull down menu at the left side will rotate. At the bottom right is a help text,

showing what the selected pull down menu group is used for. To select one of the lower menu

items the “” or “” arrow buttons must be used. Also here a help text at the bottom right of

the display will tell what the selected menu will do. If a menu has a sub menu it will be shown

with a right arrow to the right of the menu text. This sub menu can be accessed by pressing the

right “” arrow. Having found the desired menu it can be entered by pressing the “” Enter

key (The selected menu is shown inversed). If the chosen menu has a parameter to be edited a

pop up window will be shown with the parameter (as the set current menu), if the menu only

contains data to be shown a pop up window will be displayed with the data (as in the Interlock

menus) or if the menu is a command (as the REMote or the LOCal) then the task will be

executed immediately and the cursor will stay at its position. A pop up window is exited by

pressing the “” Enter key again.

The above in short, one can say: The menu bar is entered with the MENU key end exited again

with the MENU key (back to default window). A pop up window is entered with the “”

Enter key and exited again with the “” Enter key. Just like parentheses in equations.

MAGNET POWER SUPPLY SYSTEM 9100

15

DANFYSIK A/S - DENMARK.

As usual any rule has exceptions and these are:

- If there is no need for parameters after activating the “” button “Stand alone menu” there

is no need to press the “” button again. [One ” ” equals “( )” ]

- Pressing the MENU button while editing a parameter will abort the operation. [Regret the

operation as an “ESC”]

- Remotely changing the command status to Remote will automatically abort any local

operation.

Hint: To ease the use, the “” Enter key may be used instead of one of the arrow keys in

some situations- i.e. if the action is given anyway. Eg. Standing on the top of a menu

the “” will do the same as the “” key or when standing in a menu containing a sub

menu the “” will do the same as the “” key. (Interferes a bit the mathematical

parentheses idea; but is fast to use in some cases)

Hint: Pressing the MENU key the first displayed menu will either be the SET or the INTL

menu. The last one if at least one interlock is present. This minimizes the number of

buttons to be pressed to “MENU”, “” , “” for setting the output current or the

same key sequence to se the active internal interlocks. Actually the three lowest

vertical keys pressed from bottom up.

Changing a parameter is done with the arrow keys. (See also the help text at the bottom right of

the display). A cursor, shown as the digit inverse, marks the digit to be manipulated. Pressing

the “Enter” key ends the editing.

Hint: Holding either the “” or the “” keys pressed when editing a number the auto

increment function will start.

If no menus have been used within 5 minutes, then the display will automatically be switched

back to the opening window aborting any current operation (security reason).

MAGNET POWER SUPPLY SYSTEM 9100

16

DANFYSIK A/S - DENMARK.

3.2.3 Front panel controls.

1. Graphic display 240*64

2. Main power is "ON" LED.

3. Main power "ON" push button.

4. Main power is "OFF" LED.

5. Main power "OFF" push button.

6. READY LED indicates when the

actual

output current is within a predefined

limit.

7. Control Power "ON". Back light is

lit.

8. Interlock "RESET" push button.

9. Sum Interlock LED.

10. MENU - Enter / Exit pull down

menus.

11. Navigation keys.

12. ENTER - Enter / Exit parameter

change.

A

R

E

D

Y

R

E

S

E

T

O

N

O

F

F

M

E

N

U

1 2

3

4

5

6

7 8 9

10

11 12

MAGNET POWER SUPPLY SYSTEM 9100

17

DANFYSIK A/S - DENMARK.

3.2.4 The Display

The display is a multi purpose graphic window to the user. The window can be divided into

three groups:

Default window:

The default window is shown below. If the Operator Control Panel is unused for 5 minutes, the

Operator Control Panel will automatically enter this state. This is for security reason. Escaping

from any menu back to this default window can be performed by pressing the “MENU” button

again. Any ongoing operation will be cancelled.

Scrolling menu bar

The upper part of the display is normally used for displaying the viable top menus. In the

default window, “------ DANFYSIK ------“ will be displayed. It is called “scrolling menu

bar” because contrary to normal Windows © pull down menus it is the top menus that

scrolls with the “” “” buttons.

Pull down menu area

The pulls down menus are always shown in this area. If a pull down menu has sub menus

they will advance to the right. The second submenu will overwrite the “ Set and Output”

area.

Power supply Set and Output

Upper line displays the output current setting with six digits. After a cold start it displays

"SET 000000 ppm". When full output current is set, it displays "Iset 999999 ppm", which is

to be read as 99.9999 % of full scale. If required a setting in Ampere with six digits and a

decimal point can be adapted. This will be set at Danfysik during test or by Danfysik service

personnel.

The middle line display the actual output current with two digits. E.g. "Iout 54 %" means

that the current is 54 % of full scale. This reading is made by the internal 8 Bit bipolar ADC.

If a more accurate read out is required, the Control module can be added with a 16 Bit ADC.

The current will then be automatically displayed by six digits where the last digit always

will be zero. That is with five significant digits. E.g. "Iout 346340 ppm" means that the

current is 34.634 % of full scale. If required an output reading in Ampere with two or five

digits can be adapted. This will be set at Danfysik during test or by Danfysik service

personnel.

The lower line displays the actual output voltage with two digits. E.g. "Vout 45 %" means

that the current is 45 % of full scale. This reading is made by the internal 8 Bit bipolar ADC.

If required an output reading in Volt with two digits can be adapted. This will be set at

Danfysik during test or by Danfysik service personnel.

Bar graph

Status

area

Scrolling menu bar

Pull down

menu area

Power supply

Set and Output

MAGNET POWER SUPPLY SYSTEM 9100

18

DANFYSIK A/S - DENMARK.

Bar Graph

The bar graph is an analog representation of the actual output current. The output current is

100 % when the bar-graph is full. The minor tics are for 5% steps and the major tics for 10%.

Each pixel represents therefore 0.5%.

Status area

The status area shows for a quick view the present control status of the power supply

These are:

- Control mode. LOCal or REMote Remote is shown inversed.

- Regulation status. ReaDY or not Ready is shown inversed and not ready as three bars.

- Main power. ON or OFF. OFF is shown inversed.

- The controlling address in a multi drop configuration. Blank if not enabled

Information area

The bottom right corner of the display is used for displaying other information. These are:

- The time taken from the SMD Control module is shown if nothing else is to be

displayed.

- INTERLOCK present if an interlock is pending. (In default window)

- STATUS present if a particular Status is pending, normally 1 transistor fault.

- Help text on the menus.

MAGNET POWER SUPPLY SYSTEM 9100

19

DANFYSIK A/S - DENMARK.

Menu Window:

Pressing the MENU button the

Menu window will appear. The

picture to the right shows the

opening window if no interlock is

present and after the “” button is

pressed once.

Editing Window:

If a value needs editing a cursor, shown as an inverted character, will occur somewhere in the

value. Somewhere because the cursor can remember its last used position. Move the cursor to

the desired position and change its

value with the “” or “” keys.

Holding the keys pressed will

initiate an auto increment /

decrement operation.

Pop Up Window:

The picture to the right shows a pop up window displaying many interlocks. The bar at the

bottom indicates that there is no further information downwards, and the arrow at the top

indicates that pressing the “”

button will display the above

listed interlocks. If a pop up

window contains values to be set,

the line to be changed will be

displayed inversed (cursor over

the line). Use the “” “” buttons

to change the value. “” & “”

scrolls between the lines. (Eg.

LED Color setup menu).

History Window:

The history window can be seen as

an oscilloscope screen with auto

scaling.

The picture to the right shows an

example history window set to

absolute scale with visible scale

units. The indicates one pixel unit.

MAGNET POWER SUPPLY SYSTEM 9100

20

DANFYSIK A/S - DENMARK.

3.2.5 Control Menus

The table below lists the standard menus. (Horizontal pop up layout)

Scroll

menu

Sub menu 1

Sub menu 2

Sub menu 3

Comment

SET

Setting of output current

CURRENT

Set output current immediately

CURRENT d

elayed

Set output current after

MEM

Memory function

RCL

Reg 0 9

Recalls one memory

STO

Reg 0 9

Stores to a memory

MAX/MIN

Set current to one end.

0%

Set current to zero

100%

Set current to max

CMD

Control Command line

REM

Set to Remote Control

LOC

Set to Local control

ADR

Select a multidrop address

INTL

Display Interlocks / Status

INT

Internal Interlocks

CROWBAR OFF

DC OVERCURRENT (OCP)

DC OVERVOLTAGE (OVP)

15VP OK

PHASE FAILURE

EARTH LEAKAGE FAILURE

FAN

MPS OVERTEMPERATURE

See also the list below the tables.

EXT

External interlocks

EXTERNAL INTERLOCK 0

EXTERNAL INTERLOCK 1

EXTERNAL INTERLOCK 2

EXTERNAL INTERLOCK 3

POL

Change output polarity

POS +

Set polarity to +

NEG -

Set polarity to -

+<>-

Invert output polarity

MAGNET POWER SUPPLY SYSTEM 9100

21

DANFYSIK A/S - DENMARK.

Scroll

menu

Sub

me

nu

1

Sub menu 2

Sub menu 3

Comment

LIMITS

Value limitations

I

SE

T

Current value limitations

POS

Positive limit

NEG

Negative limit

AD-CHAN

CHN 0-8

A/D Channels 0 to 8

Output current

Field Input

Vout

Internal +15V

Internal -15V

Internal +5V

Delta Temperature

I Set Value

Optional Iout 16 bit resolution

Output current 3 significant digits

Hall-probe required.

Output Voltage 0 - 120%

Internal control voltage

Internal control voltage

Internal control voltage

Delta temperature inside regulated area

Output setting current

Output current 5 significant digits

CHN 9-17

A/D Channels 9 to 18

Iout

Not Used

Output current for display

Output voltage for display

Not Used

Not Used Not

Used Not

Used Iset

value

Output current for bar graph

Output current for display, in ampere

Output voltage for display, in voltage

Output setting current

DA-CHAN

Setting of D/A Channels

SETUP

Sets working conditions

BA

UD

Operator Control Panel Baud rate setting

1200,

2400,

9600,

19200,

38400

57600

76800

115200

Communication may be lost when changing

the baud rate.

CO

LO

UR

LED Color

Interlock

PSU ready

Power ON

Power OFF

Set to RED, GREEN or

“YELLOW”

SOUND

Buzzer ON or OFF

DEFAULT

Set to factory default

OP

TIO

N

ADR

Multidrop Address enable

HISTORY

OPEN LOG

Se chapter for further information.

MAGNET POWER SUPPLY SYSTEM 9100

22

DANFYSIK A/S - DENMARK.

3.2.6 Current setting

The output current may be set immediately as a potentiometer “SET CURRENT” or first preset

and thereafter accepted with the Enter ” ” button “SET CURRENT”.

Setting the output current choose the “SET CURRENT” menu, position the cursor above the

digit to alter and adjust the digit with the “” or “” button.

When the output current is within a predefined limit of the set value the "READY" LED will

turn ON.

It is also possible to set the output current to a predefined value, either using the storage

registers (STO, RCL in the MEM menu), to maximum current (=100% ) or to zero (=0%).

The maximum allowed set value can be limited through the LIMITS menu. This separates for

the positive and the negative set values. That is, if it is not possible to adjust the current above

a certain value, then check the limits.

The storage and the limit registers are saved within the M-Panel and can therefore not be used

in remote control. When using multidrop configuration e.g. all power supplies will share the

same limit.

3.2.7 Polarity reversal

If a polarity reversal switch is installed, a sign will be shown in front of the set value. (+ is

NOT reversed).

A polarity reversal procedure can be initiated either through the “POL” menu or simply by

putting the cursor above the sign in the “SET CURRENT” menu and changing the sign with

either the “” or “” button.

Please be aware that the system 9100 power supply is designed to work mainly in the first and

third quadrant, i.e. either positive output voltage and current or negative output voltage and

current. Working in the second or fourth quadrant is limited to the safe operating area of the

polarity switch transistors. The safe operating area of these transistors can be seen in the

picture on the next page. The Vds voltage on the horizontal axis is the drain to source voltage

of the transistors and is equal to the output voltage in the second and fourth quadrant. The Id

on the vertical axis is the drain current of the transistors. There are two transistors in parallel so

the actual allowed output current is equal to twice the drain current indicated on the graph.

The graph should be interpreted as follows:

If the output voltage of the 9100 during ramping down the current in an inductive load

becomes negative, say -10V, the current in one transistor must not exceed approx. 35 A i.e. the

output current must not exceed 70A.

The curves used in this example are the solid lines which should be used for DC operation.

The ramp time of the system 9100 bipolar version has been factory set to 3 sec., i.e. ramping

down from 150A to 0 takes 3 seconds, and from 0 to -150A also 3 seconds. Other ramp times

can be set by the user, see software manual for detailed description, but this must only be done

if the safe operating area is not exceeded. A lower ramp time i.e. ramping the current down

faster in an inductive load gives a higher negative voltage on the output (second quadrant

operation) and therefore the output current must be smaller so that the safe operating area is not

exceeded.

MAGNET POWER SUPPLY SYSTEM 9100

23

DANFYSIK A/S - DENMARK.

MAGNET POWER SUPPLY SYSTEM 9100

24

DANFYSIK A/S - DENMARK.

3.3 Operating by RS 232, RS422 or RS 485 I/O

The Control-Module uses standard serial interfaces compatible with many computers, PC and

terminals.

Two data communication lines are available:

- A REMOTE LINE, with either RS232, RS422 or RS485 communication.

- A LOCAL LINE, with either RS422 or RS 485 communication.

The two channels are galvanic isolated from all other internal voltages through opto couplers

but are supplied from the same voltage source.

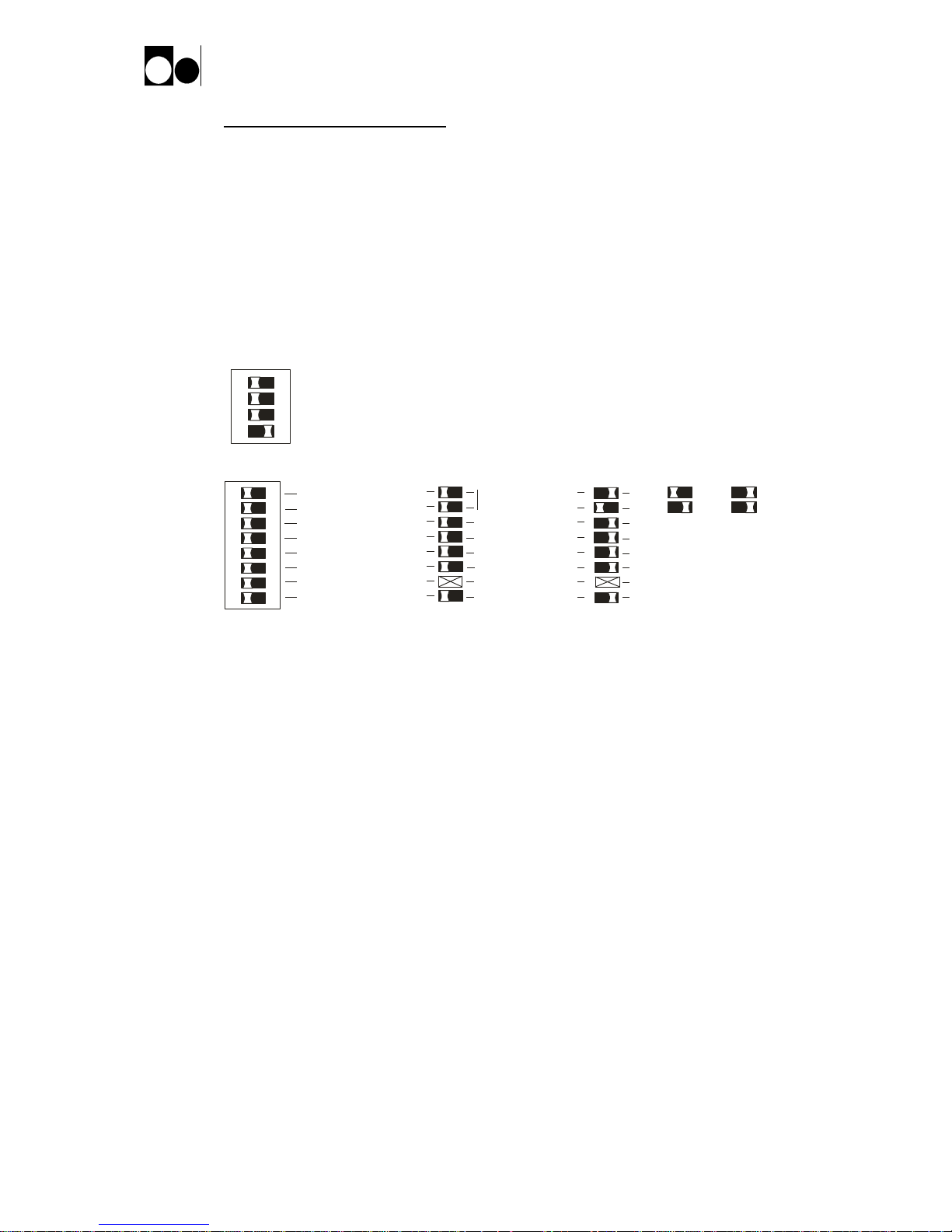

3.3.1 Setting up the MPS via display board

The set up of the MPS is done by two dip switches SW3 and SW4 together with the push

button S4 (SETUP), or through SW commands. Please refer to the “ESC” commands in the

SW appendix chapter for further information.

The two dip switches are configured as a multi function port, which will be validated by the

CPU upon pressing the button S4.

The four levers on SW3 instruct what parameters to set up, and the eight levers on SW4

delivers the actual parameters for this set up.

The parameters are first acknowledged after pressing the SETUP switch S4.

The SW3 switch position can also be seen as a binary number. The following table to the right

shows the SW3 number position and which parameters it controls.

Leaving all levers in the OFF position will disable the SETUP switch and enable Interlock

status mode. 8 LEDs will illuminate and

indicate which interlocks have occurred.

Therefore please leave all dip switches

in the OFF position as default.

If the one of the set up modes are

selected, the yellow LED D24 below

switch SW3 will illuminate and indicate

that set up port is activated. The eight

red LEDs, D13-D20 below switch SW4

will show the present parameter of

selected mode. Changing SW4 has no

effect, first after pressing S4 SETUP the

red LEDs (D13 to D20) will take the

same indication as SW4.

SW3

position

Number

Parameter

0 {0000}

Interlock Status Mode

1 {0001}

REM_UART_SETUP

2 {0010}

REM_LINE_SETUP

3 {0011}

REM_ADR_SETUP

4 {0100}

LOC_UART_SETUP

5 {0101}

LOC_LINE_SETUP

6 {0110}

LOC_ADR_SETUP

7 {0111}

COLDBOOT_SETUP

8 {1000}

AUX_SETUP

9 {1001}

NOT USED

10 {1010}

NOT USED

11 {1011}

NOT USED

12 {1100}

POLARITY_DELAY_PULSE

13 {1101}

NOT USED

14 {1110}

AD_AUTO_SCALE

15 {1111}

DA_AUTO_SCALE

MAGNET POWER SUPPLY SYSTEM 9100

25

DANFYSIK A/S - DENMARK.

Be aware when changing the Baud rates. Wrong setting may cause communication loss.

Modifying a baud rate with the HW switches or through the appropriate SW command, will

first take effect after a reset. At the remote line, use command ESC<CPURESET to make a

reset.

For switch settings following terminology will be used.

SW 4

ON

SIGNATURE USED:

OFF

DON‟T CARE

DON‟T CHANGE

SW 3

ON

ON

1

2

3

4

1

2

3

4

5 678

D13 - D20

D24 - D30

Setup

SETUP

S

Reset

Interlock LED indications (Mode 0)

red LED

LED

13

LED

14

LED

15

LED

16

LED

17

LED

18

LED

19

LED

20

Status

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

NO interlocks

ON Overvoltage

ON

Overcurrent

ON Phase failure

ON

Fault UV/Temp

ON Ground Leak

ON

Fan

ON External interlock 1&2

ON

External interlock 3&4

If all interlocks occur, all 8 red LEDs will illuminate.

When the interlocks are removed, the interlock LED indications can be reset by pressing the

RESET button on the display board which means that the red LEDs turn off.

MAGNET POWER SUPPLY SYSTEM 9100

26

DANFYSIK A/S - DENMARK.

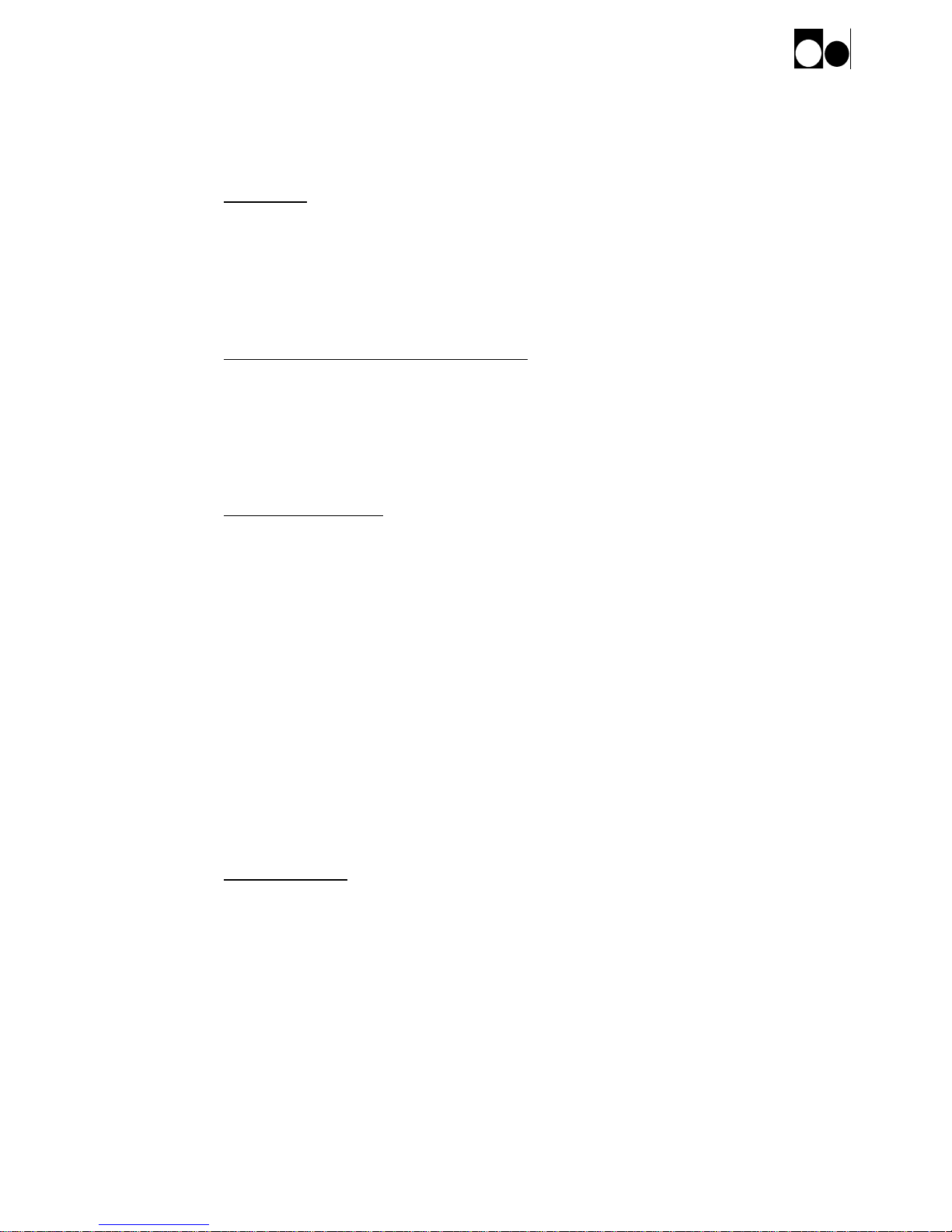

UART HW SET UP (Esc<BAUD)

In the “UART HW SETUP” mode the baud rate and associated parameters for the serial lines

can be set.

SW3 indicates witch line to set up.

Hint: Selecting SW3 will immediately display the present setting on the red LEDs below SW4.

SW3 FOR LOCAL LINE

SW3 FOR REMOTE LINE

ON

ON

1

2 3

4

1

2

3

4

4

1

Parameters

PARITY

7 / 8 Bits

8 Bits

1½

2

7 Bits

STOP Bits

OFF

OFF

ON

ODD/EVEN

EVEN

ODD

BAUD

RATE

ON

1.200 2.400

9.600 19.200 38.400

57.600 76.800 115.200

1 2

3

4 5 6 7 8

SW4

Default setting after “COLD BOOT”

Local Line: 9600Baud, No party, 8 Bits, 2 Stop bits

Remote Line: 115200Baud, No party, 8 Bits, 1 Stop bits

MAGNET POWER SUPPLY SYSTEM 9100

27

DANFYSIK A/S - DENMARK.

ADDRESS LINE SET UP (Esc<ADR)

When using the RS422 or RS485 standard for the serial communication Remote or Local, it is

possible to attach a specific address to the line for multi drop connection.

The LOCAL line addressing can be used for controlling more power supplies through one

Operator Control Panel. (SW nr. 4 in the OPERATOR CONTROL PANEL must be ON).

Grounding problems has to be taken into consideration to avoid communication problems due

to noise and high differential voltages that may jam the input signals.

The REMOTE line addressing can be used for controlling more power supplies through one

serial line (one PC). Grounding problems has to be taken into consideration to avoid

communication problems due to noise and high differential voltages that may jam the input

signals.

SW3 FOR LOCAL LINE

SW3 FOR REMOTE LINE

ON

ON

1

2 3

4

1

2 3

4

6 3

Parameters

SW4

0 1

254

2

3

255

#1

#1

#1: Selecting address 0 or 255 equals allways addressed channel.

ADDR. 2

3

ADDR. 2

2

ADDR. 2

1

ADDR. 2

0

ADDR. 2

5

ADDR. 2

6

ADDR. 2

7

ADDR. 2

4

ON

1

2 3

4 5 6

7

8

Default setting after “COLD BOOT”

Local Line: Address 0

Remote Line: Address 0

MAGNET POWER SUPPLY SYSTEM 9100

28

DANFYSIK A/S - DENMARK.

LINE FUNCTION PROTOCOL SETUP (Esc<LINE)

SW3 FOR LOCAL LINE

SW3 FOR REMOTE LINE

ON

ON

1

2 3

4

1

2 3

4

5

2

The “LINE FUNCTION PROTOCOL SETUP” is for setting up serial line protocols.

Parameters:

SW4

„OK‟ ANSWER MODE

DISABLED ENABLED

RS 485 LINE TURN AROUND

DISABLED ENABLED

RS 485 LINE TURN AROUND

DISABLED ENABLED

RS 485 COMMUNICATION

DISABLED ENABLED

NOT USED

DISABLED ENABLED

XON/XOFF PROTOCOL

DISABLED ENABLED

NOT USED

BOOT CHARACTER

SEND “FF” Hex SEND “R”

ON

1

2 3

4 5 6

7

8

DISABLED

ENABLED

Default setting after “COLD BOOT”

Remote Line: RS485 Communication: Disabled

(=0) RS485 Line turn around time: Disabled Line turn around set bit 0

RS485 Line turn around time: Disabled Line turn around set bit 1

OK Answer mode: Disabled

BOOT character: "FF" / "R"

NU Disabled

XON/XOFF Protocol: Disabled

NU Disabled

Local Line: RS485 Communication: Disabled

(=1) RS485 Line turn around time: Disabled Line turn around set bit 0

RS485 Line turn around time: Disabled Line turn around set bit 1

OK Answer mode: Disabled

BOOT character: "FF" / "R"

NU Disabled

XON/XOFF Protocol: Disabled

NU Disabled

Line turn around set bit:

2, 3: 0, 0 Delay = 0

2, 3: 1, 0 Delay = 1ms approx.

2, 3: 0, 1 Delay = 2ms approx.

2, 3: 1, 1 Delay = 3ms approx.

The line turn around time setting includes RS422 as well.

MAGNET POWER SUPPLY SYSTEM 9100

29

DANFYSIK A/S - DENMARK.

COLD BOOT SETUP (Esc<COLDBOOT)

After power up or reset the power supply can wake up in different control conditions. The

switch settings shown below describe the possible Wake up conditions.

Parameters:

SW3 FOR COLD BOOT INITIAL SETUP

ON

1

2 3

4

7

Default setting after “COLD BOOT”

SW4

#1

#1: Local line is allways in auto answer mode.

#2: Using ACK/NACK protocol with or without error code will overide this setting.

#2

REMOTE AUTO ANSWER

DISABLED

¤1: “?”-BELL, Without further information.

¤2: “?”-BELL, Followed by error in code.

¤3: “?”-BELL, Followed by error in text.

ENABLED

¤1 ¤2 ¤3 ¤3

DEFAULT LINE IN

REMOTE LOCAL

LOCAL ADDRESSING

ENABLED DISABLED

REMOTE ADDRESSING

ENABLED DISABLED

Wake to 0%/100%

NOT USED

ERROR RESPONSE

ON

1

2 3

4 5 6

7

8

#3

0% at power up 100% at power up

#3: Default is 0% output current at power up. [From SW version SCS109]

Remote addressing: Disabled

Local addressing: Disabled

Default line in: Local

Remote Auto answer: Disabled

Error response: “?”-BELL only

Wake up output current: 0%

MAGNET POWER SUPPLY SYSTEM 9100

30

DANFYSIK A/S - DENMARK.

AUX SETUP (Esc<AUX)

Special options can be initiated with the auxiliary switch set up 1.

Setting of bit 16 and 17 is intended for Offset DAC use. That is a 16 bit setting between 88 and

96% (Bit16=0 & BIT 17=1) or between 92% and 100% output current (Bit16=1 & BIT 17=1).

For linear DAC settings please set bit 16 & 17 to transparent mode.

Using the “WA” command a leading zeroes or trailing zeroes input format can be chosen.

- For leading zeroes: “WA 123" equals “WA 000123"

- For trailing zeroes: “WA 123" equals “WA 123000"

SW3 FOR AUXILIARY SETUP 1

ON

1

2 3

4

8

SW4

WA ZEROES

TRALING

A / V

%

LEADING

INTERLOCK CLEAR

CLEAR

OFF & CLEAR

DAC 17

TRANSPARENT

->0

->1

->1

DAC 16

->1

->0

->1

CAMAC TEST

NOT USED

UNI/BI-POLAR

DISPLAY UNITS

ON

1

2 3

4 5 6

7

8

#1

#1 AD Scaling factor must be set accordingly.

DISABLE {Hi Z}

ENABLE AS OUTPUT

UNIPOLAR

BIPOLAR

Parameters:

Default setting after “COLD BOOT”

DAC 16 & 17: Transparent

Interlock clear: OFF & CLEAR resets interlocks

“WA” Zeroes: WA command uses trailing zeroes.

( ): UNIPOLAR

Notice that UNI/BI-polar is a read-only parameter and cannot be changed by dip switch setting

nor by software. The mode is detected automatically.

MAGNET POWER SUPPLY SYSTEM 9100

31

DANFYSIK A/S - DENMARK.

POLARITY DELAY TIME SETUP (Esc<POLDELAY)

A time delay can be inserted between the OFF state and the activation of the polarity change

over switch. The range of the time delay can be set from 0 to 25.5 seconds, (in steep of 100ms)

this for letting the rest energy in the magnet to decay.

The time delay is only inserted, if the power supply was ON before invoking the POL +/command. That is, when just changing the polarity in the power OFF mode, no time delay will

be inserted.

SW3 FOR POLDELAY

ON

1

2 3

4

12

SW4

0 0.1

25.4

0.2

0.3

25.5

#2

#2: Zero defaults to no delay

#1: Time is in 0.1 sec steps.

TIME 2

3

TIME 2

2

TIME 2

1

TIME 2

0

TIME 2

5

TIME 2

6

TIME 2

7

TIME 2

4

ON

1

2 3

4 5 6

7

8

#1

Parameters:

Default setting after “COLD BOOT”

No polarity delay.

MAGNET POWER SUPPLY SYSTEM 9100

32

DANFYSIK A/S - DENMARK.

AD AUTO ADJUSTMENT (Gain & Offset) (Esc<ADSET)

The scaling factors for the AD channels can automatically be adjusted with this setting.

SW3 FOR ADSET

ON

1

2 3

4

14

Parameters

SW4

0 1 302

3

31

#1

#1: Not all channels are implemented.

CH_No. 2

3

CH_No. 2

2

CH_No. 2

1

CH_No. 2

0

NOT USED

FUNC

MODE

CH_No. 2

4

ON

1

2 3

4 5 6

7

8

OFFSET GAIN

USE

RESTORE

OFFSET adjustment

The OFFSET adjustment can automatically be executed if the value lies between 0 and 255 of

the AD channel resolution.

To activate the automatic OFFSET adjustment following steps must be preformed:

- Select SW3 as above. “setting number14"

- Select the desired channel number “lever 1 to 5" on SW4

- Set lever 8 on SW4 to OFF (The LEDs will display the present Offset value)

- Ensure that the AD input signal is set to zero. Grounded or turned OFF in any way.

- Press the Setup Button

- To restore the Offset value to default factory setting (Zero), please set lever 7 to one

before pressing the Setup Button.

CHANNEL VALUE CHANNEL VALUE

0 Output current 1 Field input

2 Output Voltage 3 Internal +15V sup.

4 Internal -15V sup. 5 Internal +5V sup.

6 Delta Temperature 7 I set value

8 Optional Iout (16 Bit) 9 Iout (16 Bit)(Crtl panel).

10 Not used 11 Output current for display

12 Output voltage for display 13 Not used

14 Not used 15 Not used

16 Internal +5Vana. 17 I set value

18 Spare

MAGNET POWER SUPPLY SYSTEM 9100

33

DANFYSIK A/S - DENMARK.

GAIN adjustment

The GAIN adjustment can automatically adjust the scaling factor of the selected channel to

only nines. That is e.g. 99999 for the 16 bit output current reading. This adjustment is only

useful for the output current and voltage read back (CH0, CH2, CH8, CH11 and CH12) Please

do not use this feature if the output reading is in Volts and Amps and for not applicable

channels.

To auto adjust to a specific value, please use the “Esc”ADSET command.

To activate the automatic GAIN adjustment following steps must be preformed:

- Select SW3 as above. “setting number14"

- Select the desired channel number “lever 1 to 5" on SW4

- Set lever 8 on SW4 to ON

- Ensure that the AD input signal is set to 100%

- Press the Setup Button

- To restore the Gain value to default factory setting, please set lever 7 to one before

pressing the Setup Button.

MAGNET POWER SUPPLY SYSTEM 9100

34

DANFYSIK A/S - DENMARK.

DA AUTO ADJUSTMENT (Gain & Offset) (Esc<DASET)

The scaling factors for the DA channels can automatically be adjusted with this setting. This

feature is specially designed for “non calibrated”

SW3 FOR ADSET

ON

1

2 3

4

15

Parameters

SW4

0 1

30

2

3

31

#1

#1: Not all channels are implemented.

CH_No. 2

3

CH_No. 2

2

CH_No. 2

1

CH_No. 2

0

NOT USED

FUNC

MODE

CH_No. 2

4

ON

1

2 3

4 5 6

7

8

OFFSET GAIN

USE RESTORE

OFFSET adjustment.

The OFFSET adjustment can automatically be executed if the value lies between 0 and 255.

To activate the automatic OFFSET adjustment following steps must be preformed:

- Select SW3 as above. “setting number15"

- Select the desired channel number “leaver 1 to 5" on SW4

- Set lever 8 on SW4 to OFF and leaver 7 to OFF (The SW1 LED‟s will display the

present Offset value)

- Set the AD channel value (WA for “DA 0") to a value that gives a zero output.

- Press the Setup Button. A given “DA 0 0" or “WA 0” will now produce a zero output at

the DA channel. Due to the unipolar operation of the DAC‟s only positive offset values

can be added.

- To restore the Offset value to default factory setting (Zero), please set lever 7 to one

before pressing the Setup Button.

GAIN adjustment.

The GAIN adjustment can automatically adjust the scaling factor of the selected channel to

only nines. That is eg. 999999 for the WA command.

To auto adjust to a specific value, please use the “Esc”DASET command. (DAC setting in

Amps)

To activate the automatic GAIN adjustment following steps must be preformed:

- Select SW3 as above. “setting number15"

- Select the desired channel number “lever 1 to 5" on SW4

- Set on SW4 lever 8 to ON and lever 7 to OFF.

- Set the output signal to 100% with the DA or the WA command

- Press the Setup Button.

- To restore the Gain value to default factory setting, please set lever 7 to one before

MAGNET POWER SUPPLY SYSTEM 9100

35

DANFYSIK A/S - DENMARK.

pressing the Setup Button.

CHANNEL VALUE DA channel spec. Equal to

0 Output current 16 bit WA range as default

1 Not used

2 Not used

3 Not used

4 Output voltage 16 bit

MAGNET POWER SUPPLY SYSTEM 9100

36

DANFYSIK A/S - DENMARK.

3.3.2 Data communication

The SYSTEM 9100 uses the standard serial interface RS 232 which is compatible with many

computers and terminals. Beside RS232, SYSTEM 9100 supports RS422 and RS485.

The connectors for the serial interface ports “REMOTE CONTROL” and “LOCAL

CONTROL” are found at the back of the power supply.

Pin description for RS232 and RS422 for the connector DB25S at the back of the power supply

is as follow.

REMOTE CONTROL

DB25

LOCAL CONTROL

DB9

RS422/RS485

RS232

RS422/RS485

Pin No.

Signal

Signal

Pin No.

Signal

2 TX

2

/TX_LOC

3 RX

3

TX_LOC

7

RETURN

RETURN

4

/RX_LOC

9

TX_REM

5

RX_LOC

10

/TX_REM

6-7

+15V

11

RX_REM

8-9

-15V

12

/RX_REM

13

Vcc

Vcc

Rx : Signals received by the Control Module from its host.

Tx : Signals transmitted by the Control Module to its host.

NOTE! The selection between RS232, RS422 and RS485 is selected through solder straps on

the Control Board.

Serial interface

in REMOTE mode

Strap

REMOTE CONTROL

DB25

RS232

ST330 : Close

ST 324 : Open

ST 325 : Open

Pin 2 TX

Pin 3 RX

2-Wire RS485

ST324 : Close

ST325 : Open

ST330 : Open

Pin 9 TX_REM

Pin 11 RX_REM

4-Wire RS422/RS485

ST325 : Close

ST324 : Open

ST330 : Open

Pin 9 TX_REM

Pin 10 /TX_REM

Pin 11 RX_REM

Pin 12 /RX_REM

Serial interface

in LOCAL mode

Strap

LOCAL CONTROL

DB9

2-Wire RS485

ST334 : Close

ST339 : Open

Pin 3 TX_REM

Pin 5 RX_REM

4-Wire RS422/RS485

ST339 : Close

ST334 : Open

Pin 3 TX_REM

Pin 2 /TX_REM

Pin 5 RX_REM

Pin 4 /RX_REM

MAGNET POWER SUPPLY SYSTEM 9100

37

DANFYSIK A/S - DENMARK.

The default serial setting is:

8 BIT DATA, NO PARITY AND 1 STOPBIT and baud rate 115200.

The communication is done by transmitting characters in ASCII code terminated by

CARRIAGE RETURN.

The termination characters from the Power Supply are CARRIAGE RETURN and LINE

FEED.

An ERROR message includes a "?BELL". (Bell = ASCII 7.)

NOTE! None of the serial lines has control signals.

3.3.3 Termination using RS 422m or RS 485

As standard there is no termination resistors connected inside the M-panel. An external

termination resistor of 100 Ohm must therefore be added at the end of the communication

cable or the internal 100 Ohm resistor must be enabled (short-circuiting strap ST2). This

applies for both the local and the remote line.

The external resistor is preferable.

Hint. This resistor can be placed inside the last DB 25 plug for the remote line and the DB9

plug for the Local line.

When using the RS 485 or the RS 422 line in the multi drop configuration, it is very important

during an address transfer to leave the lines at the "SPACE" state when tri stated. That is when

the line is not driven by any transmitters at all. The "SPACE" state can be utilized by adding

1K Ohm resistors to +5 V(non inverting) and GND (inverting) on both the transmit and the

receive lines. The control module can provide this by short circuiting ST318-ST321 and

ST326-ST329 for the remote line and ST335-ST338 and ST340-ST343 for the local line (use a

thin soldering iron). The 1K resistors increase the noise immunity eliminating noise to be

treated as commands thereby flawing the first character after being addressed.

NOTE! None of the two serial lines have control signals (hand checking). Use the

XON/XOFF protocol if necessary.

MAGNET POWER SUPPLY SYSTEM 9100

38

DANFYSIK A/S - DENMARK.

3.3.4 Programming

The power supply communication protocol is built upon plain ASCII characters where each

command or reply is delimited by a "Carriage Return" <CR> character. However replies have

a “Line Feed” <LF> character added before the <CR> for a friendlier display when using a

terminal. <LF> characters on commands will be ignored.

Hint. Actually the protocol allows full control of the power supply from a "dumb" terminal. In

case of a service- debug- situation a terminal can be used to tap the communication

transfer by a simple parallel connection.

Hint: When debugging, the "ERRT" command enables error messages to be given as a read

able text.

More commands may be transmitted in a chain but each single command must be trailed

individually with the delimiter character <CR>. The power supply is able to execute up to 200

commands a second depending of the complexity of each command.

Ps. Issuing short commands faster than the time to transmit the answer e.g. “S1" will

overload the internal transmit buffer regardless of the selected baud rate.

All commands can be divided into three sections.

a) Directive commands. Eg. the "N" command that turns the power supply ON

b) Status commands. Eg. the "S1" that returns the power supply status

Status commands delivers always a reply whereas directive- and setup- commands only

responds with an error message if the command couldn‟t be understood or if the given

parameters are incorrect. It is possible to set the power supply to always generate an

answer; this feature is very useful when using RS485 protocol.

Hint. When using the "Always Answer" mode a re-transmission of the last given command

can be performed if no answer or an error message is received. The System 9100

respond time is around 5ms after receiving the last bit of the termination character.

Answer scheme if set to “Always Answer” mode.

c) Directive commands. Answer: - No answer

- ERROR message

- OK if set to always answer mode (ab SW ver. SCY

2.xx)

d) Status commands . Answer: - Data

- ERROR message

e) Set up commands. Answer: - No answer

- ERROR message

- OK if set to always answer mode (ab SW ver. SCY

2.xx)

Below is an example written in BASIC on how to turn ON the power supply and read the status

without and with acceptance answer:

MAGNET POWER SUPPLY SYSTEM 9100

39

DANFYSIK A/S - DENMARK.

Turning the power supply ON and reading/evaluating the status with always answer disabled.

LPRINT "N"+CHR$(13) :REM Turns the power supply on

LPRINT "S1" :REM Issues the status command

LINPUT S1$ :REM Read the MPS reply

IF LEFT$(S1$,1) = CHR$(?) :REM Is it an error message reply?

GOTO ERROR_HANDLING :REM Yes then go to error module

ENDIF

J=1

DO :REM evaluate status reply

IF MID$(S1$,J,1)="!"

GOSUB STATUS(J)_ACTIVE :REM set this status bit active

ELSE

GOSUB STATUS(J)_ACTIVE :REM set this status bit inactive

ENDIF

J=J+1

UNTIL J=24

Turning the power supply ON with always answer enabled

J=0 :ERROR$=”“

DO

J=J+1 :REM Counter for maximum attempts

LPRINT "N"+CHR$(13) :REM Turns the power supply on

LINPUT RE$ :REM Read the MPS reply with 0.1 Sec. time out

IF LEFT$(RE$,1) = CHR$(?) :REM Is it an error reply?

ERROR$=RE$ :REM Mark the error code

ELSEIF RE$=”OK” :REM Is it a good reply

BRAKE :REM then exit DO loop

ELSEIF J=6 :REM Try only six times

IF LEFT$(ERROR$,1) = CHR$(?) :REM Was it error reply?

GOTO ERROR_HANDLING :REM Yes then go to error module

ELSEIF

GOTO NO_COMMUNICATION :REM Yes then go to “No answer” error module

ENDIF

ENDIF

UNTIL -1 :REM loop endless

Ps. An ERROR message includes a "?BELL". (Bell = ASCII 7.)

3.3.5 Software Profile Programming

SYSTEM 9100 is delivered with the software ramp profile option.

With the ramp profile SW it is possible to down load and run a predefined ramp sequence that

the output current must follow. The ramp sequence can be programmed in two quite different

methods.

A- Arbitrary point method; B- Equal timeslot method.

Arbitrary point method and Equal timeslot method are both available, but only one method can

be used at a time.

The examples below are shown for a unipolar power supply. For bipolar supplies, the output

current may also be set as negative.

MAGNET POWER SUPPLY SYSTEM 9100

40

DANFYSIK A/S - DENMARK.

3.3.6 Arbitrary point ramp profile method

With the ”Arbitrary point method” it is possible to download up to fifteen independent points

each generating a ramp line (through interpolation). This profile must be stored in one of the

15 available stacks.

Each ramp point consists of a stack number, a starting point (current set value, normally the

previous end point), an end point (current set value) and a time value for reaching the given

end point.

E.g. Command: WSA' sp' stack, start, stop, time 'cr'

To use the arbitrary point method at least the following steps must be preformed:

- Clear the stack “CSS [parameter]”,- Program the stack “WSA [parameter]”,- Set the speed

“SPEED [parameter]”, -Set the attenuator “MULT [parameter]”, -Start the stack “TS

[parameter]”, -Read the status of the running stack “S2".

Please refer to the software manual about “SW2 Ramp Profile Commands” for full

instructions.

The figure shows an example of one ramp profile stack. (Ps. not all 15 points need to be

programmed empty, entries will be ignored.)

The SW will after the start (Trig) command update the output current every 1.25ms in the

FAST and in the SLOW mode (Step Time). This enables us to calculate the stair case size

(interpolating step size) according to the formulae below:

Where “START” and “END” are the set values in ppm. The “Step Time” is 1.25ms. , Δt in

seconds and the “Step. Size” will come out as ppm value.

In-between the 1.25ms step time a second HW interpolation counter will update the set value

for every 78μs (fast ramp times) to about 78μs (slow ramp times).

Starting the ramp is done with the trig command “TS (stack no.)”.

T1 T2 T3 T4 T5 T6 T7

Output

Current

Time

From

TRIG

Software Ramp Profile

No1

No2

No3

No4

No5

No6

No7

Relative

Arbitrary Point Method

MAGNET POWER SUPPLY SYSTEM 9100

41

DANFYSIK A/S - DENMARK.

If synchronization to an eternal event is required, it is possible to arm the ramp sequence first

with the synchronization command “SYNC (stack no.), [trigger delay]”. A hardware signal on

the trigger input X9 pin 1&2 (10 to 24V) or a TS command will start the sequence. If a trig

delay is entered, the sequence will first start after the delay time has elapsed.

If more power supplies have to be synchronized, one of the supplies has to be appointed as

master. Connecting the master trig output X9 pin 3&4 to the other supplies trig input will start

the other supplies when the master is triggered. A maximum skew of 5μs between the supplies

may be expected. (an external 15V auxiliary supply is needed, as the trig output is an open

collector and the trig input is an optocoupler input.)

3.3.7 Equal time slot ramp profile method

With the ”Equal time slot method” it is possible to download up to 1000 current set values and

a single time slot value, that will be used for all set values. Only one stack is available.

This profile method is especially useable for faster and more accurate curves fitting profiles

e.g. as a function generator.

To use the Equal time slot method at least the following steps must be preformed:

- Clear and set the stack “RAMPSET [parameter]”,- Program the stack “R [parameter]”, -Start

the stack “RAMP [parameter]”, -Read the status of the running stack “RAMP".

PS. A difference in the value parameters setting comparing to the “Arbitrary point method”

is, that all values must be given as a floating point number scaled to “1.000000". That is;

1.25ms must be entered as 0.00125 and 19.54% output current as 0.1954.

Please refer to the Software manual about Ramp Profile Commands for full instructions.

The figure below shows an example of one ramp profile stack. (Ps. not all 1000 points need to

be programmed empty entries will be ignored.)

The time slot

must be given as a multiple of 1.25ms. Between 1.25ms to 1 second. Any value in-between

will automatically be rounded according to formula:

{time slot}=frac({time}/0.00125)*0.00125

Time Slots

Output

Current

Time

From

TRIG

Software Ramp Profile

1

2

3

4

15

20

26

27

Incremental

5

25

10

Equal Time Slot Method

MAGNET POWER SUPPLY SYSTEM 9100

42

DANFYSIK A/S - DENMARK.

The SW will after the start command update the output current every 1.25ms. By means of

interpolation regardless of the programmed time slot value:

The ramp can be set up to run as a single shot “RAMP R”, auto iteratively (auto loop) “RAMP

RL” or HW triggered auto armed “RAMP TW”. For a full documentation on controlling the

“Equal time slot method” please refers to the software manual about Ramp Profile Commands.

If synchronization to an external event is required, it is possible to arm the ramp sequence first

with the synchronization command “RAMP T”. A hardware signal on the trigger input X9 pin

1&2 (10 to 24V) or a “RAMP R” command will start the sequence.

If more power supplies have to be synchronized, one of the supplies has to be appointed as

master. Connecting the master trig output X9 pin 3&4 to the other supplies trig input will start

the other supplies when the master is triggered. A maximum skew of 1.25ms between the

supplies may be expected. (an external 15V auxiliary supply is needed, as the trig output is an

open collector and the trig input is an optocoupler input.)

3.3.8 Auto Slew Rate Ramp Profile method.

With the”Auto Slew Rate Ramp Profile Method” an automatic ramp profile will be generated

and executed when issuing a new current set point. In other words, this feature acts like a

software driven slew rate controller.

Two shapes can be preselected. A cosines and a square shape. Which shape is selected, is

given by the Aux2 setting bit 4. 0 = Cosines & 1 = Square

Example: If the power supply is at 10% output current, the slew rate is set to 1 second

(„esc‟<slopetime 1.1) and a set command “da 0.600000" is given the power supply will

start at 10% and run to 60% within ½ a second with the selected shape.

The positive and negative slew rate value can be set individually. Please refer to the SW

manual describing the “„esc‟< slopetime „val1',‟val2'” for further information.

The two ramp profile shapes has both its benefit and draw backs. The cosines shape is smooth

all the way but has a higher di/dt in the middle and results in a sinus output voltage shape on an