Page 1

Data sheet

Pressure operated water valve

Type WVO

Pressure operated water valve type WVO is used

for regulating the flow of water in refrigeration

plant with water-cooled condensers.

The pressure operated water valve gives

modulating regulation of the condensing

pressure and so keeps it constant during

operation. When the refrigeration plant is

stopped, the cooling water flow is shut off

automatically.

Pressure operated water valve can be used with

flammable refrigerants. Double sealing between

the refrigerant and the water line ensures that

in case the bellows damage and the refrigerant

leak, it cannot enter into the water. This severely

limits the safety implications.

It means that the valve can be used together with

a double walled heat exchanger and water circuit

in such a system does not need to be considered

as a part of the installation for flammable

refrigerants (EN378-1:2008, clause 4.4.2.2).

Features

y Compact valve

y Setting pressure done by factory (optional)

y HCFC, HFC and HC

y NPT threads on request

y Capillary tube available as option

y Stainless steel version available for request

y Suitable for flammable refrigerants

y May be used in the following EX range:

Category 3 (Zone 2)

© Danfoss | DCS (az) | 2018.03

DKRCC.PD.DA0.B8.02 | 1

Page 2

Data sheet | Pressure operated water valve, type WVO

Technical data

Water side Refrigerant side

Max. working pressure PS / MWP 16 bar / 232 psig 26.4 bar / 383 psig

Max. test pressure PT 24 bar / 350 psig 38 bar / 551 psig

R22, R1270, R134a, R290, R404A,

Media Fresh water and neutral brine

R407A, R407C, R407F, R448A, R449A,

R450A, R452A, R507A, R513A, R600,

R600a

Max. differential pressure 10 bar / 145 psi –

Temperature range -25 – 130 °C / -13 – 266 °F -25 – 130 °C / -13 – 266 °F

1

Typ e

[mm] [in] [m³ / h] [gal / min]

WVO 10 LF 10

WVO 10 10

WVO 15 15

WVO 20 20

Orifice size kv value

2

5

/

2

5

/

3

5

/

4

5

/

)

Cv value

0.63 0.7

1.4 1.6

1.9 2.2

3.4 3.9

WVO 25 25 1 5.5 6.4

1

The kv value is the flow of water in [m3 / h] at a pressure drop across valve of 1 bar, ρ = 1000 kg / m

2

The Cv value is the flow of water in [gal / min] at a pressure drop across valve of 1 psi, ρ = 10 lbs / gal

3

2

)

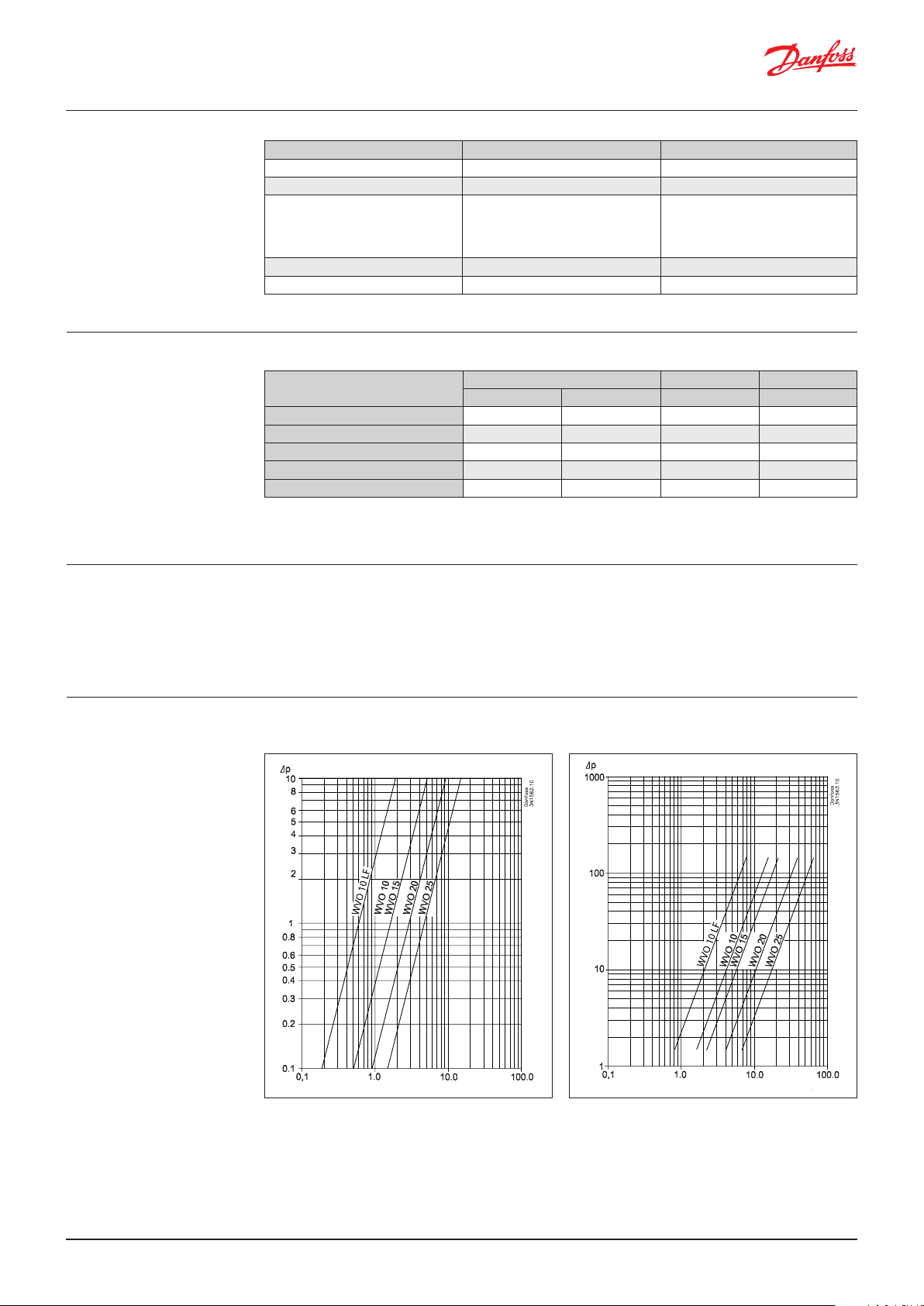

Capacity The capacity curves show the capacities of

the individual valves (water quantity in [m3 / h])

depending on the water pressure drop across the

valve.

SI unit US unit

[bar]

The capacity given apply at 85% valve opening

and are obtained with the offset shown on

page 4.

[bar]

© Danfoss | DCS (az) | 2018.03

[m3 / h]

[gal / min]

DKRCC.PD.DA0.B8.02 | 2

Page 3

Data sheet | Pressure operated water valve, type WVO

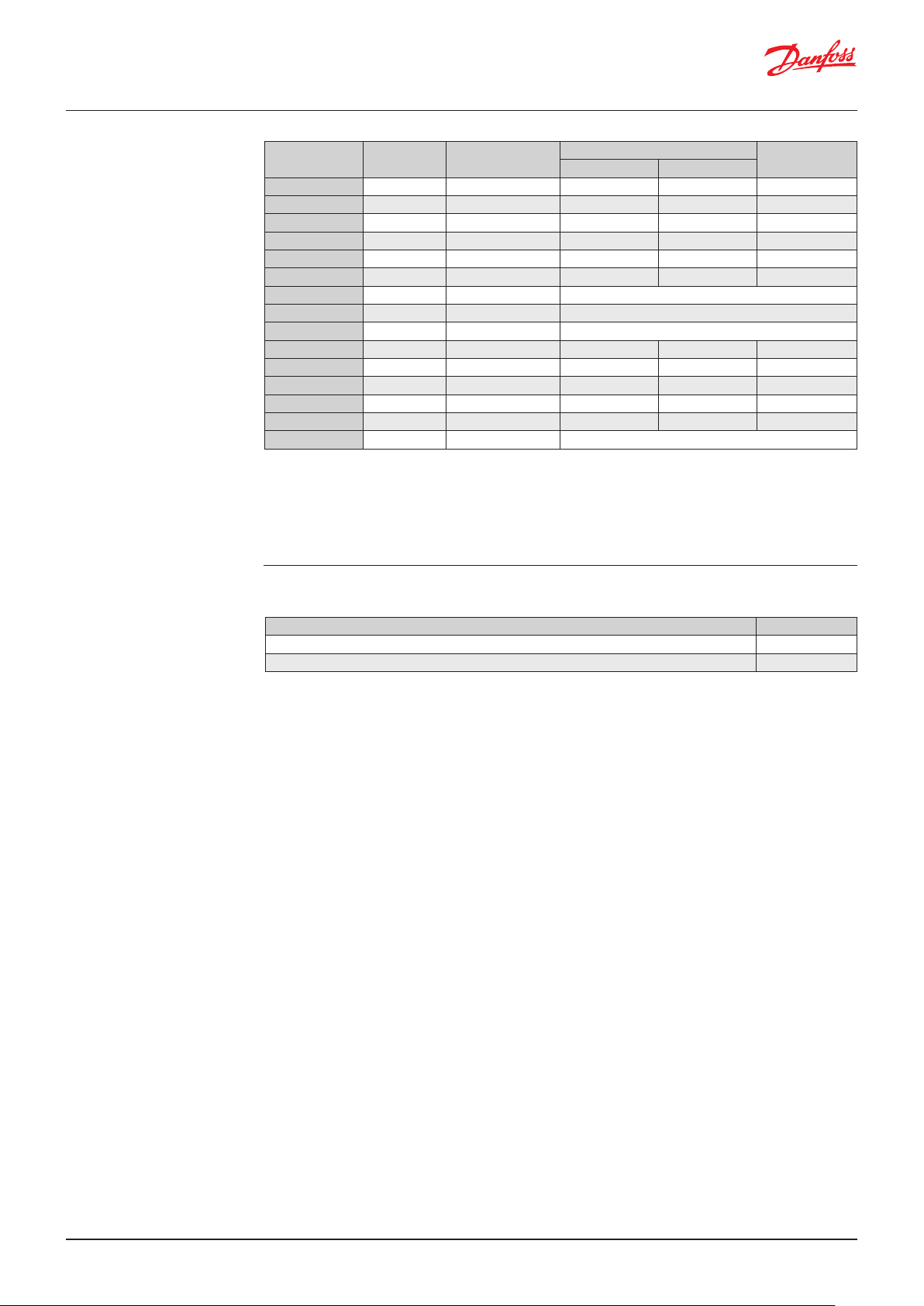

Ordering

Typ e

Connection

type

WVO 10 LF G 3/

WVO 10 LF G 3/

WVO 10 G 3/

WVO 10 G 3/

WVO 10 G 3/

WVO 10 G 3/

WVO 15 G 1/

WVO 20 G 3/

Connection

standard

8

8

8

8

8

8

2

4

ISO 228–1 8 – 12 115 – 175 003N8053

ISO 228–1 14 – 18 200 – 260 003N8054

ISO 228–1 8 – 12 115 – 175 003N5203

ISO 228–1 14 – 18 200 – 260 003N5206

ISO 228–1 16 – 20 232 – 290 003N5207

ISO 228–1 16 – 22 232 – 320 003N6220

ISO 228–1 Available on request

ISO 228–1 Available on request

Pressure range

[bar] [psig]

Code no.

WVO 25 G 1 ISO 228–1 Available on request

WVO 10 NPT 3/

WVO 10 NPT 3/

WVO 15 NPT 1/

WVO 15 NPT 1/

WVO 20 NPT 3/

8

ANSI/ASME B1.20.1 6 – 10 85 – 145 003N8052

8

ANSI/ASME B1.20.1 14 – 18 200 – 260 003N8056

2

ANSI/ASME B1.20.1 6 – 10 85 – 145 003N8062

2

ANSI/ASME B1.20.1 14 – 18 200 – 260 003N8066

4

ANSI/ASME B1.20.1 14 – 18 200 – 260 003N8076

WVO 25 NPT 1 ANSI/ASME B1.20.1 Available on request

) with 0.8 m capillary tube and valve opener

) WVO 10 low flow version with kv value: 0,63 m³⁄h

Codes for valve with prefabricated factory setting, other sizes and pressure ranges are available on

request.

2

)

2

)

1

)

Accessories

Description Code no.

1 m (39 in) capillary tube ¼ in. (6 mm) flare coupling nuts at each end 060- 007166

Bracket 003N0388

© Danfoss | DCS (az) | 2018.03

DKRCC.PD.DA0.B8.02 | 3

Page 4

Data sheet | Pressure operated water valve, type WVO

Sizing When sizing and selecting water regulating

valves it is most important to ensure that the

valve at any time is able to give the necessary

quantity of cooling water.

To select a suitable size of valve it is necessary

to know the precise amount of cooling required.

On the other hand, to avoid the risk of unstable

regulation (hunting) the valve should not

be oversized. In general, the aim should be

to select the smallest valve capable of giving

the required flow .

To obtain a precise control it can be

recommended to only use 85% of the capacity.

Offset

Water Capacity

Below 85% the ratio between flow and

condensing difference pressure is linear. Above

85% the ratio is no longer linear. To reach a 100%

capacity the WVO needs significant increase of

condensing pressure. See table at the bottom of

the page.

Valve size

offset

∆p

Typ e

WVO 10 LF 1.6 23

WVO 10 2.0 30

WVO 15 2.5 35

WVO 20 3.0 43

WVO 25 3.5 50

[bar] [psi]

∆p offset

The following data is used when selecting

the size of WVO:

y Cooling capacity of condenser,

y Temperature rise in cooling media,

y Differential pressure across valve,

y Condensing temperature,

y Specific heat capacity of cooling media,

y Refrigerant.

Condensing

pressure

© Danfoss | DCS (az) | 2018.03

DKRCC.PD.DA0.B8.02 | 4

Page 5

Data sheet | Pressure operated water valve, type WVO

Calculating size in SI Unit Example 1:

y Condenser capacity Q0: 30 kW

y Condensing temperature t0: 35 °C

y Refrigerant: R404A

y Cooling media: water

Necessary mass flow

Volume flow

Selecting size

∆p [bar]

y Specific heat capacity of water

Cp: 4.19 kj / (kg*K)

y Water inlet temperature t1: 15 °C

y Water outlet temperature t2: 25 °C

y Pressure drop across valve p: max. 1.0 bar

Q

·

m =

c

· 3600 =

30

Cp · (t2 t1) 4.19 · (25 - 15)

·

·

m = 2577

V =

≈ 2.6 m3 / h

ρ 1000

· 3600 = 2577 kg / h

© Danfoss | DCS (az) | 2018.03

[m3 / h]

Selecting WVO 20 code number

The saturated pressure for R404A

Tc = 35 °C Pc = 7.9 barg

Choose a WVO 20 with 6 – 10 barg range

DKRCC.PD.DA0.B8.02 | 5

Page 6

Data sheet | Pressure operated water valve, type WVO

Calculating size in SI Unit

(continue)

Example 2:

y Condenser capacity Qc: 20 kW

y Condensing temperature tc : 35 °C

y Refrigerant: R134a

y Cooling media: Brine

y Density of brine ρ: 1015 kg / m

Necessary mass flow

Volume flow

kv value

Selecting size of WVO 20

y Specific heat capacity of brine

Cp : 4.35 kj (kg*K)

y Brine inlet temperature t1: 20 °C

y Brine outlet temperature t2: 25 °C

y Pressure drop across valve p: max. 2.0 bar

3

Q

·

m =

c

· 3600 =

Cp · (t2 t1) 4.35 · (25 - 20)

·

·

m = 3310

V =

≈ 3.26 m3 / h

ρ 1015

·

kv ≥

V

3.26

=

1000 · p 1000 · 2.0

ρ 1015

Code number

20

· 3600 = 3310 kg / h

= 2,32 m3 / h

kv ≥ 2.32 m3 / h WVO 20

WVO 20 has kv = 3.4 m3 / h and the necessary

capacity is below 85% of full capacity.

The saturated pressure for 134a

T

= 35 °C Pc = 7.9 barg

c

Choose a WVO 20 with 6 – 10 barg range

© Danfoss | DCS (az) | 2018.03

DKRCC.PD.DA0.B8.02 | 6

Page 7

Data sheet | Pressure operated water valve, type WVO

Calculating size in US Unit

Example 1:

y Condenser capacity Qc: 5 TR

y Condensing temperature tc: 95 °F

y Refrigerant: R404A

y Cooling media: water

Necessary water flow

Selecting size

V =

500 (t2 - t1) 500 · (75 - 60)

∆p [psi]

y Water inlet temperature t1: 60 °F

y Water outlet temperature t2: 75 °F

y Pressure drop across valve p: max. 15 psi

Qc 15000 = 5 15000

= 10 GPM

© Danfoss | DCS (az) | 2018.03

[gal / min]

Selecting WVO 20 code number

The saturated pressure for R404A

Tc = 95 °F PC = 115 psig

Choose a WVO 20 with 85 – 145 psig range

DKRCC.PD.DA0.B8.02 | 7

Page 8

Data sheet | Pressure operated water valve, type WVO

Design / Function

1. Screw for setting pressure

2. Spring housing

3. Spindle retainer

4. Spring retainer

5. O-ring

6. Guide bush

7. Diaphragm

8. Valve plate

9. Thrust pad

10. Bellows element

Installation

Condensing pressure impulses are transmitted

via the bellows element to the valve cone so that

the valve - even at very small pressure variations is able to adapt the quantity of water required by

the condenser.

If fluorinated refrigerants are to be used

a capillary tube connection is required, 1 m

capillary tube with ¼ in. / 6 mm flared union nuts

at either end can be supplied.

The valves are pressure-relieved in such a way

that a variation in the water pressure will not

affect their setting.

To protect the refrigeration plant against high

head pressures - in the event that the water

supply to the condenser should fail - a safety

switch type KP or RT should be fitted on the high

pressure side.

Between the flare connection of the pressure

operated water valve and the pipe

line / compressor Danfoss recommends to use

capillary tube to avoid fatigue error due to the

vibration from the compressor.

The valve plate (8) is a brass plate with

a vulcanized layer of special rubber to form

an elastic seal against the valve seat. The valve

is externally sealed by the diaphragms (7).

The top and bottom of the valve plate holder

is extended by a guide that is fitted with

O-rings (5) to ensure the internal operating

parts move correctly. These O-rings, fitted in

conjunction with the diaphragms, also provide

extra protection against external leakage.

The valve seat is made of stainless steel and

is swaged to the valve body.

The installation of an MESH 40 filter ahead of the

valve is recommended.

If a mounting bracket is used it must always be

between valve body and setting section.

© Danfoss | DCS (az) | 2018.03

DKRCC.PD.DA0.B8.02 | 8

Page 9

Dimensions and weights

Bracket

15

22

9

56

50

40

Ø4

Ø7.15

25

62

Danfoss

3N200.11

Typ e

H

1

[mm] [in] [mm] [in] [mm] [in] [mm] [in] [kg] [lbs]

H

2

L L

1

Net weight

WVO 10 91 3.58 89 3.50 72 2.83 11 0.43 1. 0 2.20

WVO 15 91 3.58 89 3.50 72 2.83 14 0.55 1.0 2.20

WVO 20 91 3.58 89 3.50 90 3.54 16 0.63 2.0 4.40

WVO 25 96 3.78 94 3.70 96 3.74 19 0.75 2.0 4.40

© Danfoss | DCS (az) | 2018.03

DKRCC.PD.DA0.B8.02 | 9

Loading...

Loading...