Data sheet

Pressure operated water valve

Type WVFX and WVS

Pressure operated water valves types WVFX and

WVS are used for regulating the flow of water in

refrigeration plants with water-cooled

condensers.

The pressure operated water valves give

modulating regulation of the condensing

pressure within defined limits during operation.

When the refrigeration plant is stopped, the

cooling water flow is shut off automatically.

Pressure operated water valves can be used with

flammable refrigerants. Double sealing between

the refrigerant and the water line ensures that in

case the bellows damage and the refrigerant

leak, it cannot enter into the water. This severely

limits the safety implications. It means that the

valve can be used together with a double walled

heat exchanger and water circuit in such a

system does not need to be considered as a part

of the installation for flammable refrigerants

(EN378-1:2008, clause 4.4.2.2).

Features • Media: Fresh water and Neutral brine

• Refrigerants: HCFC, HFC and HC

• Needs no power supply – self acting

• Opens on rising condensing pressure

• Complete flow range from 1.4 – 300 m3/h

• Low flow version of WVFX – 0,63 m3/h,

(available on request)

• Insensitive to dirt

• WVFX 10 – 25 are available in stainless steel

housing

• Suitable for flammable refrigerants

• May be used in the following EX range:

Category 3 (Zone 2)

© Danfoss | DCS (az) | 2018.10

DKRCC.PD.DA0.3A.02 | 1

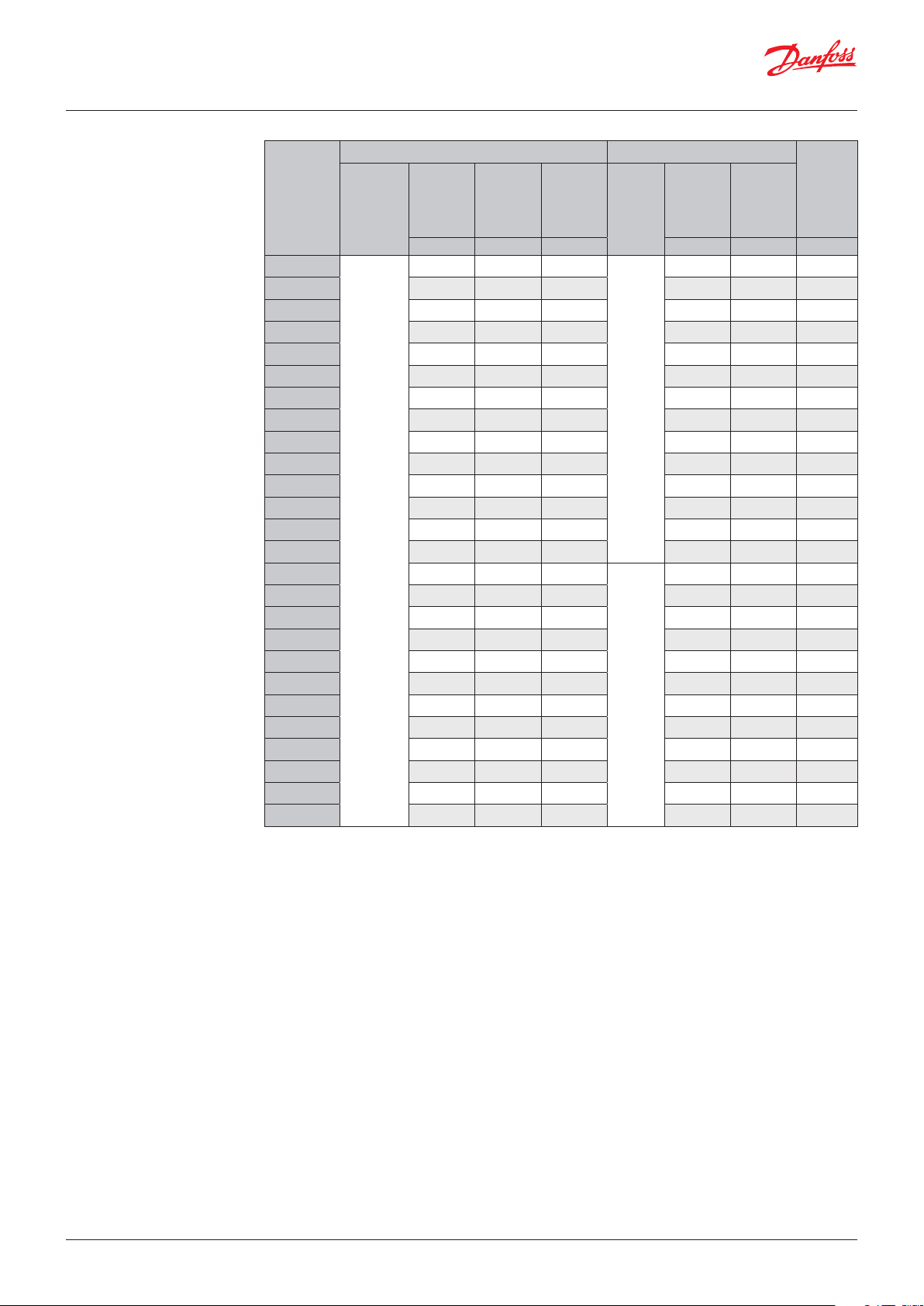

Data sheet | Pressure operated water valve, types WVFX and WVS

Technical data

Condenser side Liquid side

Typ e

Refrigerant

Control

press.

adjustable

opening

press.

Max.

working

pressure

PS/MWP

Max.

test

pressure

P

e

Media

Max.

working

pressure

PS/MWP

Max.

test

pressure

Pe

Kv value 1)

[bar] [bar] [bar] [bar] [bar] [m3/h]

WV FX 10

3.5 – 16.0 26.4 29.0

16 24 1.4

WVFX 10 2) 4.0 – 23.0 26.4 29.0 16 24 1.4

WV FX 10 15.0 – 29.0 45.2 60.0 16 24 1.4

WVFX 15 3.5 – 16.0 26.4 29.0 16 24 1.9

WVFX 15 2) 4.0 – 23.0 26.4 29.0 16 24 1.9

WVFX 15 15.0 – 29.0 45.2 60.0 16 24 1.9

WVFX 20 3.5 – 16.0 26.4 29.0 16 24 3.4

WVFX 20 2) 4.0 – 23.0 26.4 29.0 16 24 3.4

WVFX 20 15.0 – 29.0 45.2 60.0 16 24 3.4

WVFX 25 3.5 – 16.0 26.4 29.0 16 24 5.5

WVFX 25 2) 4.0 – 23.0 26.4 29.0 16 24 5.5

WVFX 25 15.0 – 29.0 45.2 60.0 16 24 5.5

WVFX 32 4.0 – 17.0 24.1 26.5 10 10 11. 0

WVFX 40 4.0 – 17.0 24.1 26.5 10 10 11.0

WVS 32 2.2 – 19.0 26.4 29.0

WVS 32 15.0 – 29.0 45.2 60.0 10 16 12.5

WVS 40 2.2 – 19.0 26.4 29.0 10 16 21.0

WVS 40 15.0 – 29.0 45.2 60.0 10 16 21.0

R22 , R127 0,

R13 4a, R 29 0,

R404A,

R4 07A,

R407C,

R407 F,

R410A 4),

R448A,

R449A,

R450A,

R452A,

R507A,

R513A, R600,

R600a,

R717 5)

WVS 50 2.2 – 19.0 26.4 29.0 10 16 32.0

WVS 50 15.0 – 29.0 45.2 60.0 10 16 32.0

WVS 65 2.2 – 19.0 26.4 29.0 10 16 45.0

WVS 65 15.0 – 29.0 45.2 60.0 10 16 45.0

Fresh

water,

neutral

brine, sea

water 3)

10 16 12.5

Fresh

water,

neutral

brine

WVS 80 2.2 – 19.0 26.4 29.0 10 16 80.0

WVS 80 15.0 – 29.0 45.2 60.0 10 16 80.0

WVS 100 2.2 – 19.0 26.4 29.0 10 16 125.0

WVS 100 15.0 – 29.0 45.2 60.0 10 16 125. 0

1

The Kv value is the flow of water in [m3/h] at a pressure drop across valve of 1 bar, ρ = 1000 kg/m3.

2

Fully open valve requires 33% higher pressure than a WVFX, range 3.5 – 16 bar.

3

WVFX 15, WVFX 20 and WVFX 25 with stainless steel housing only.

4

) High pressure refrigerants version (45,2 MWP) only

5

) WVS, WVFX 10 – 25 and WVO with flare connection only; versions with capillary tube or with solder connections are not compatible

with R717. WVFX 32 and WVFX 40 are not compatible with R717

© Danfoss | DCS (az) | 2018.10

WVFX 10 – 40 are direct actuated valves.

WVS 32 – 100 are servo-operated valves.

Media temperature range

WVFX 10 – 25: -25 – 130 °C

WVFX 32 – 40: -25 – 90 °C

WVS: -25 – 90 °C

If a WVS is required with an opening differential

pressure of 1 – 10 bar, the valve servo spring

must be replaced.

See “Ordering”.

Opening differential pressure

WVFX 10 – 25: max. 10 bar

WVFX 32 – 40: max. 10 bar

WVS 32 – 40: min. 0.5 bar;

max. 4 bar

WVS 50 – 100: min. 0.3 bar;

max. 4 bar

Below 20% of max. capacity the WVS will act as

an on-off regulator.

DKRCC.PD.DA0.3A.02 | 2

Data sheet | Pressure operated water valve, types WVFX and WVS

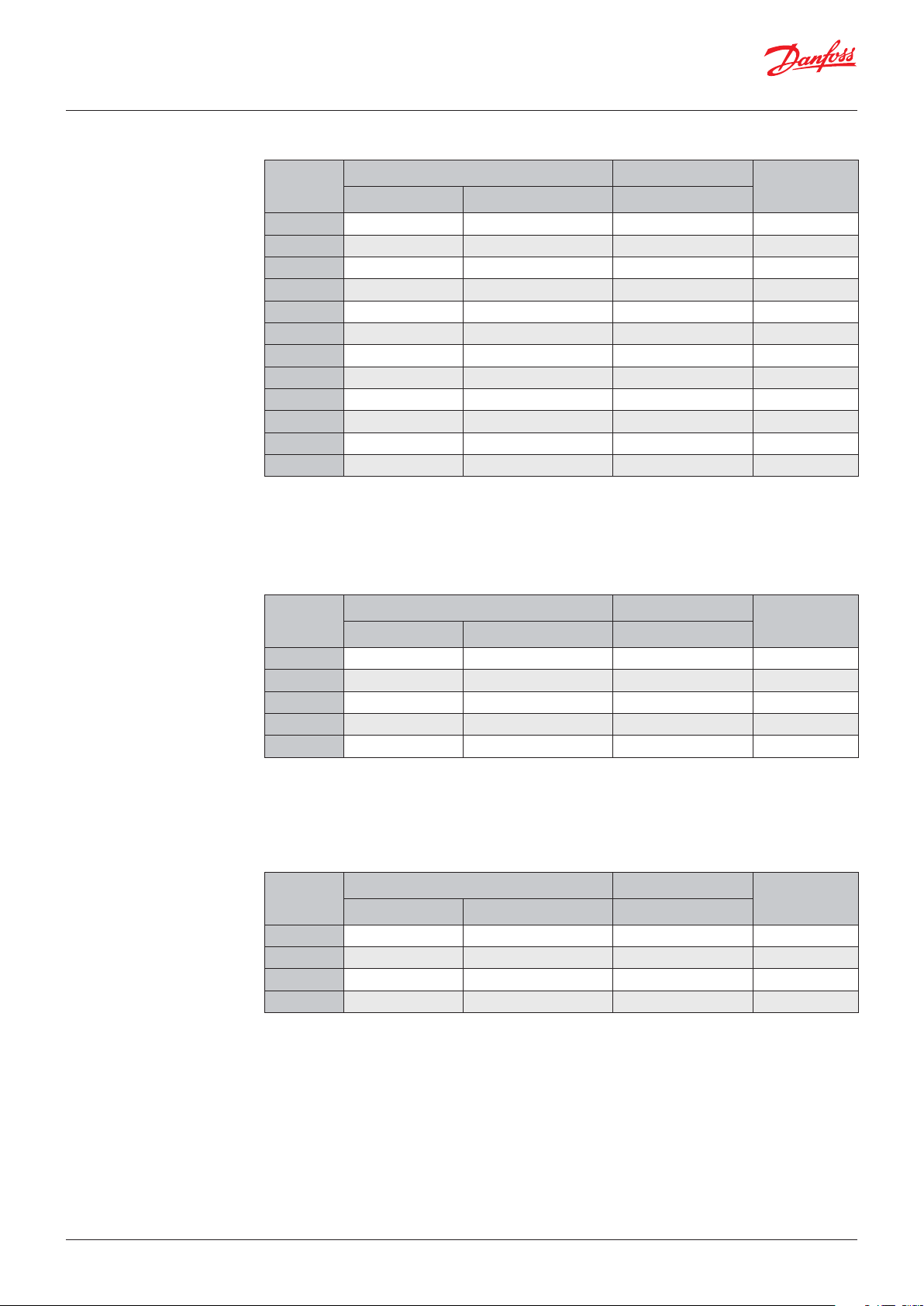

Ordering WVFX, commercial type

Typ e

Code no.

Water side Condenser side [bar]

WVFX 10 G ³⁄₈ ¼ in. / 6 mm flare 3.5 – 16 003N1100

WVFX 10 G ³⁄₈ ¼ in. / 6 mm flare 4.0 – 23 003 N110 5

WVFX 15 G ½ ¼ in. / 6 mm flare 3.5 – 16 003N2100

WVFX 15 G ½ ¼ in. / 6 mm flare 4.0 – 23 003N2105

WVFX 15 G ½ ¼ in. / 6 mm flare nut 4.0 – 23 003N2205 2)

WVFX 20 G ¾ ¼ in. / 6 mm flare 3.5 – 16 003N3100

WVFX 20 G ¾ ¼ in. / 6 mm flare 4.0 – 23 0 03N3105

WVFX 20 G ¾ ¼ in. / 6 mm flare nut 4.0 – 23 003N3205 2)

WVFX 25 G 1 ¼ in. / 6 mm flare 3.5 – 16 003N4100

WVFX 25 G 1 ¼ in. / 6 mm flare 4.0 – 23 003N4105

WVFX 32 G 1 ¼ ¼ in. / 6 mm flare 4.0 – 17 0 03F12 32

WVFX 40 G 1 ½ ¼ in. / 6 mm flare 4.0 – 17 003F1240

Connection 1) Range

1

ISO 228-1

2

WVFX 15 with 1 m capillary tube and flare nut with valve depressor

WVFX, maritime type (stainless steel version)

Typ e

Water side Condenser side [bar]

WVFX 15 G ½ ¼ in. / 6 mm flare 3.5 – 16 003N2101

WVFX 15 G ½ ¼ in. / 6 mm flare 4.0 – 23 003N2104

WVFX 20 G ¾ ¼ in. / 6 mm flare 4.0 – 23 0 03N3104

WVFX 25 G 1 ¼ in. / 6 mm flare 3.5 – 16 003N 4101

WVFX 25 G 1 ¼ in. / 6 mm flare 4.0 – 23 003N4104

1

ISO 228-1

Connection 1) Range

Code no.

© Danfoss | DCS (az) | 2018.10

WVFX, commercial type (high pressure refrigerants, MWP 45.2 bar)

Typ e

Water side Condenser side [bar]

WV FX 10 G ³⁄₈ ¼ in. / 6 mm flare 15.0 – 29.0 003N1410

WVFX 15 G ½ ¼ in. / 6 mm flare 15.0 – 29.0 003N2410

WVFX 20 G ¾ ¼ in. / 6 mm flare 15.0 – 29.0 003N3410

WVFX 25 G 1 ¼ in. / 6 mm flare 15.0 – 29.0 0 03N4410

) ISO 228-1

Connection 1) Range

Code no.

DKRCC.PD.DA0.3A.02 | 3

Data sheet | Pressure operated water valve, types WVFX and WVS

Ordering

(continued)

WVS, commercial type

Code no.

Typ e Connection 1)

Valve body Pilot unit 3)

WVS 32 G 1 1⁄2 1) 016D5032 016D1017 016D1018 – 016D1327

WVS 40 G 1 1⁄2 1) 016D5040 016D1017 016D1018 – 016D0575

WVS 50 2 in. weld flange 016D5050 2) 016D1017 016D1018 027N3050 016D0576

WVS 65 2 1⁄2 in. weld flange 016D5065 2) 016D1017 016D1018 027N3065 016D0577

WVS 80 3 in. weld flange 016D5080 2) 016D1017 016D1018 027N3080 016D0578

WVS 100 4 in. weld flange 016D5100 2) 016D1017 016D1018 027N3100 016D0579

) ISO 228–1

) Parts included: valve body, flange gaskets, flange bolts and screws for pilot valve.

) Parts included: control element and spring housing.

) Parts included: 2 flanges

Pilot unit for

R410A and

R744 3)

Flange set 4)

Servo spring for

differential

pressure range

of 1 – 10 bar

Accessories

Description Code no.

1 m capillary tube 1⁄4 in. (6 mm) flare coupling nuts at each end 06 0- 01716 6

Bracket for WVFX 10 – 25 003N0388

Installation WVS and WVFX 32, WVFX 40 is to be fitted in the

cooling water inlet with flow in the direction of

the arrow and with the bellows element facing

upwards. Horizontal mounting is a must.

WVFX 10, WVFX 15 and WVFX 25 can be

mounted in any position. Horizontal mounting is

not required.

© Danfoss | DCS (az) | 2018.10

DKRCC.PD.DA0.3A.02 | 4

Data sheet | Pressure operated water valve, types WVFX and WVS

Capacity

[bar]

Standard servo spring type WVS

Special servo spring type WVS

Water Valves Offset – rise in condensing pressure

Typ e [bar] p

WV FX 10 2.0

WVFX 15 2.5

WVFX 20 3.0

WVFX 25 3.5

WVFX 32 40 3.0

WVS 32 0.6

WVS 40 0.7

WVS 50 80 0.8

WVS 100 0.9

The capacity curves show the capacities of

individual valves (water quantity in [m3/h])

depending on the pressure drop across valves.

The capacities given apply at 85% valve opening

and are obtained with the following offset

(rise in condensing pressure).

[m3/h]

© Danfoss | DCS (az) | 2018.10

DKRCC.PD.DA0.3A.02 | 5

Data sheet | Pressure operated water valve, types WVFX and WVS

Design / Function

1. Handwheel

2. Spring housing

3. Spindle guide

4. Spring retainer

5. O-ring

6. Guide bush

7. Diaphragm

8. Valve cone

9. Thrust pad

10. Bellows element

Condensing pressure impulses are transmitted

via the bellows element to the valve cone so that

the valve – even at very small pressure

variations – is able to adapt the quantity of water

required by the condenser.

The valves are pressure-relieved in such a way

that a variation in the water pressure will not

affect their setting.

To protect the refrigeration plant against high

head pressures in the event that the water

supply to the condenser fails, a safety switch

type KP or RT should be fitted on the high

pressure side.

WVFX 10 – 25

Water side connections are internal BSP

and the compressor discharge side connection

is ¼ in. / 6 mm flare.

The valve body WVFX 10 – 25 is made of

hot-stamped brass and for WVFX 32 – 40 of cast

iron. WVFX 15, WVFX 20 and WVFX 25 can also

be supplied in stainless steel housing.

All metal external valve parts are surface-treated

to resist corrosion from condensate, etc.

It is possible to order reverse acting WVFX valve,

which opens on refrigerant pressure decrease.

Reverse acting valve are mostly used in bypass

lines and heat pump applications.

The valve cone (8) is a brass plate with a

vulcanized layer of artificial rubber to form an

elastic seal against the valve seat. The valve is

externally sealed by the diaphragms (7).

The top and bottom of the valve plate holder are

extended by a guide that is fitted with O-rings

(5) to ensure the internal operating parts move

correctly. These O-rings, fitted in conjunction

with the diaphragms, also provide extra

protection against external leakage.

The valve seat is made of stainless steel

and is pressed to the valve body.

The spring housing (2) is of aluminium and has a

guide slot for the spring holder that is extended

in the form of an indicating pointer.

An associated indicator label is riveted to the

housing and is graduated from 1 – 5.

1. Bellows element

2. Upper pressure spindle

3. Top plate

4. Guide bush gland

5. Guide bush

6. T-ring

7. Valve cone

8. O-ring

9. Lower pressure spindle

10. Spring retainer

11. Spring housing

12. Regulating spring

13. Regulating spindle

14. Spring holder

© Danfoss | DCS (az) | 2018.10

The valve cone (7) is made of brass with

a T-ring (6) of artificial rubber forming a flexible

seal against the valve seat. The O-rings (8) are

external seals for the cooling water.

The valve cone guide bushes (5) are specially

treated to counteract lime deposits from the

cooling water inside the cylinder, and also

to reduce friction in the valve to a minimum.

The valve seat is made of stainless steel

and is pressed to the valve body.

The regulating spindle (13) is mounted

in a guide in the spring housing which has

a notch for the spring holder (14). The spring

holder also acts as an indicator.

WVFX 32 – 40

DKRCC.PD.DA0.3A.02 | 6

Data sheet | Pressure operated water valve, types WVFX and WVS

Design / Function

(continued)

1. Pressure connection

(flare nipple)

2. Pressure connection

(weld nipple)

3. Bellows element

4. Push rod

5. Regulating nut

6. Spring housing

6a. Cover

7. Pilot assembly

8. Spindle for pilot cone

9. Teflon sleeves

10. Insulating gasket

10a. Gasket

11. O-ring

12. Valve cover

13. O -ring

14. O -ring

15. Servo piston

16. Bottom screw

17. Drain plug

18. Gasket

19. Strainer assembly,

complete

20. Self-cleaning strainer

assembly

21. Pilot orifice

22. Gasket

23. O -ring

24. Servo spring

WVS 32

WVS 50 – 100

WVS 40

© Danfoss | DCS (az) | 2018.10

WVS 32 – 40 valves have internal BSP

connections, while WVS 50 – 100 can be supplied

with either BSP connections or weld flanges.

Connection to the plant condenser can be made

by copper tube or steel tube, the valves being

supplied with both a flare nipple for 1⁄4 in. (6 mm)

copper tube and a weld nipple

for ø6 mm / ø10 mm steel tube.

The valve consists of three main components:

1. Main valve with servo piston

The main valve body is made of cast iron

with a pressed-in bronze seat. The servo piston is

of gun metal and has a sleeve and a profiled

rubber seal ring.

2. Pilot valve

The pilot valve is made of gun metal, the pilot

cone and seat of stainless steel and the pilot

orifice of brass. These materials are particularly

resistant to water corrosion. However, the valve

is not resistant to sea water.

The strainer ahead of the pilot orifice is made of

nickel gauze.

The degree of opening of the pilot valve (which

corresponds to the increase in condensing

pressure above the set opening pressure)

determines the degree of opening of the main

valve and thereby amount of the water flow.

3. Bellows unit with connection to condenser

The bellows unit is made of aluminium

and corrosion-proofed steel.

DKRCC.PD.DA0.3A.02 | 7

Data sheet | Pressure operated water valve, types WVFX and WVS

Sizing

Offset

When sizing and selecting water regulating valves it

is most important to ensure that the valve at any

time is able to give the necessary quantity of

cooling water.

To select a suitable size of valve it is necessary

to know the precise amount of cooling required.

On the other hand, to avoid the risk of unstable

regulation (hunting) the valve should not be

oversized.

Water Capacity

In general, the aim should be to select the

smallest valve capable of giving the required

flow.

To obtain a precise control it can be

recommended to only use 85% of the capacity.

Below 85% the ratio between flow and

condensing difference pressure is linear. Above

85% the ratio is no longer linear. To reach a 100%

capacity the water valve needs significant

increase of condensing pressure. See fig. below.

Condensing

pressure

Typ e p offset [bar]

WVFX 10 2.0

WVFX 15 2.5

WVFX 20 3.0

WVFX 25 3.5

WVFX 32 – 40 3.0

WVS 32 0.6

WVS 40 0.7

WVS 50 – 80 0.8

WVS 100 0.9

Valve size

The following data is used when selecting

the size of the water valve:

y Cooling capacity of condenser

y Temperature rise in cooling media

y Differential pressure across valve

Sizing Examples Example 1:

Condenser capacity Q0: 30 kW

Condensing temperature t0: 35 °C

Refrigerant: R404A

Cooling media: water

y Condensing temperature

y Specific heat capacity of cooling media

y Refrigerant

Specific heat capacity of water Cp: 4.19 kj/(kg*K)

Water inlet temperature t1: 15 °C

Water outlet temperature t2: 25 °C

Pressure drop across valve p: max. 1.0 bar

© Danfoss | DCS (az) | 2018.10

Necessary mass flow

Volume flow

·

m =

Qc

· 3600 =

30

Cp · (t2 t1) 4.19 · (25 – 15)

·

·

m = 2577

V =

≈ 2.6 m3/h

ρ 1000

· 3600 = 2577 kg/h

DKRCC.PD.DA0.3A.02 | 8

Data sheet | Pressure operated water valve, types WVFX and WVS

Selecting size

[bar]

Standard servo spring type WVS

Special servo spring type WVS

Selecting WVFX 20 Code number

The saturated pressure for R404A

Tc = 35 °C => Pc = 15.5 barg

Choose a WVFX 20 with 4 – 23 barg range

Example 2:

Condenser capacity QC: 20 kW

Condensing temperature tC: 35 °C

Refrigerant: R134a

Cooling media: Brine

Specific heat capacity of water Cp: 4.35 kj/(kg*K)

Water inlet temperature t1: 20 °C

Water outlet temperature t2: 25 °C

Pressure drop across valve p: max. 2.0 bar

Density of brine ρ: 1015 kg/m3

Q

Necessary mass flow

Volume flow

Kv value

·

m =

c

· 3600 =

Cp · (t2 t1) 4.35 · (25 – 20)

·

·

m = 3310

V =

≈ 3.26 m3/h

ρ 1015

·

V

Kv ≥

=

1000 · p 1000 · 2.0

ρ 1015

3.26

20

· 3600 = 3310 kg/h

= 2,32 m3/h

[m3/h]

© Danfoss | DCS (az) | 2018.10

Selecting size of WVFX 20

Kv ≥ 2.32 m3/h => WVFX 20

WVFX 20 has Kv = 3.4 m3/h and the necessary

capacity is below 85% of full capacity

Code number

The saturated pressure for R134a

Tc = 35 °C Pc = 7.9 barg

Choose a WVFX 20 with 3.5 – 16 barg range

DKRCC.PD.DA0.3A.02 | 9

16D03.14 FW

Data sheet | Pressure operated water valve, types WVFX and WVS

Dimensions [mm]

and weights [kg]

WVFX 10 – 25

Danfoss

3N1573.10 FW

Bracket for WVFX 10 – 25

15

22

40

WVFX 32 – 40 WVS 32 – 40

Danfoss

3-193.15 FW

9

56

50

Ø4

Ø7.15

25

62

Danfoss

3N200.11

Danfoss

16D69.14 FW

© Danfoss | DCS (az) | 2018.10

WVS 50 – 100

Danfoss

DKRCC.PD.DA0.3A.02 | 10

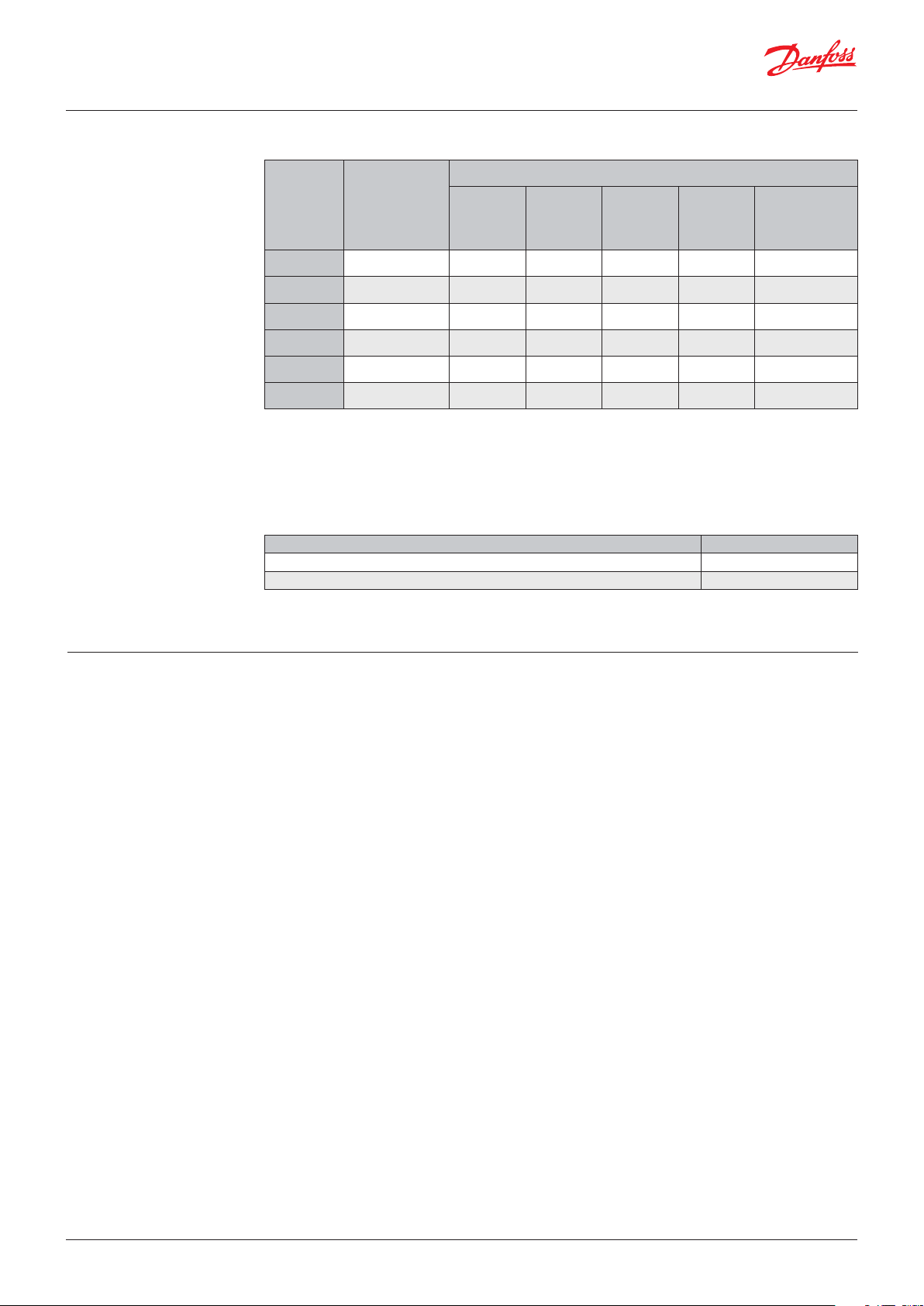

Dimensions [mm]

and weights [kg]

(continued)

Pressure operated water valve

Typ e H

1

WVFX 10 91 133 – 72 11 – 55 1.0

WVFX 15 91 133 – 72 14 – 55 1.0

WVFX 20 91 133 – 90 16 – 55 2.0

WVFX 25 96 138 – 95 19 – 55 2.0

WVS 32 42 243 234 138 20 85 – 4.0

WVS 40 72 271 262 19 8 30 100 – 7.0

WVS 50 78 277 268 315 218 – 165 19.0

WVS 65 82 293 284 320 224 – 185 24.0

WVS 80 90 325 316 370 265 – 200 34.0

WVS 100 100 345 336 430 315 – 220 44.0

H

2

H

3

L L

1

B ø

weight

Pressure operated water valve, type WVS - high pressure refrigerants

Typ e H

1

WVS 32 42 259 250 138 20 85 – 4.0

WVS 40 72 287 278 19 8 30 10 0 – 7. 0

WVS 50 78 293 2684 315 218 – 165 19.0

WVS 65 82 309 300 320 224 – 185 24.0

WVS 80 90 341 332 370 265 – 200 34.0

WVS 100 100 361 352 430 315 – 220 44.0

H

2

H

3

L L

1

B ø

weight

Net

Net

© Danfoss | DCS (az) | 2018.10

DKRCC.PD.DA0.3A.02 | 11

Loading...

Loading...