Page 1

Pocket Guide

VLT® Soft Starter

– the single speed drive

Page 2

Page 3

Contents

Soft Starter Selection Guide

Warnings .................................................................................................................................... 5

Common Applications .......................................................................................................... 6

MCD Soft Starter Features and Specications ............................................................. 8

Current Ratings ........................................................................................................................11

Soft Starter Sizing ................................................................................................................. 13

FAQs

Adaptive Acceleration Control ......................................................................................... 14

AC53 Utilisation Codes ...................................................................................................... 15

Auto-Transformer Starters ............................................................................................... 16

Fault nding ............................................................................................................................. 16

Braking ....................................................................................................................................... 17

Bypass Contactor ................................................................................................................. 18

Cabling ..................................................................................................................................... 19

Extreme Conditions ............................................................................................................ 21

Flying Loads ........................................................................................................................... 22

Harmonics .............................................................................................................................. 22

IP Ratings ................................................................................................................................ 23

NEMA Ratings ........................................................................................................................ 24

Inside delta Connection .....................................................................................................25

Key Benets ........................................................................................................................... 26

Line Contac tor ...................................................................................................................... 27

Minimum Start Current ..................................................................................................... 28

Multiple Motors .................................................................................................................... 29

Power factor correction .................................................................................................... 30

Motor Thermal Capacity ................................................................................................... 30

Jog ............................................................................................................................................... 31

Reversing ................................................................................................................................ 31

Sealed Enclosures ................................................................................................................ 32

Primary Resistance Starters ............................................................................................. 32

Short Circuit Protection, Type 1 ...................................................................................... 33

Short Circuit Protection, Type 2 .......................................................................................34

Semiconductor Fuse Selection, Type 2 ........................................................................ 35

Slip-Ring Motors .................................................................................................................. 38

Soft Braking ........................................................................................................................... 39

Danfoss Drives · DKDD.PB.551.A1.02 | 3

Page 4

Star/Delta Starters ............................................................................................................... 40

Thermal Model Protection ............................................................................................... 42

Two Speed Motors .............................................................................................................. 43

Types of Soft Starter ........................................................................................................... 44

MCD Bus Options

MCD Bus Options – General Notes ................................................................................ 45

MCD 500 with MCD Remote Operator Option .......................................................... 46

MCD 500 Modbus Option ................................................................................................. 48

MCD 500 DeviceNet Option ............................................................................................. 49

MCD 500 PROFIBUS Option .............................................................................................. 50

MCD 500 USB Option ........................................................................................................... 51

MCD 200 with MCD Remote Operator Option .......................................................... 52

MCD 200 Modbus Option .................................................................................................. 53

MCD 200 DeviceNet Option .............................................................................................. 55

MCD 200 Probus Option .................................................................................................. 56

MCD 200 USB Option ........................................................................................................... 57

Glossary

Glossar y ....................................................................................................................................58

Abbreviations .........................................................................................................................63

4 | Danfoss Drives · DKDD.PB.551.A1.02

Page 5

Warnings

Soft starter selection requires information on the

intended application, the features required, and

the curre nt rating of the associated motor.

For applications with extreme or unusual conditions, consult the

relevant Design Guide and/or your supplier.

For example:

• High altitude installation (> 1000 m)

• High ambient temperatures (> 40˚ C)

• High and/or frequent operating overloads

• High start frequency

• Slip-ring motor operation

• Part speed operation

• Horizontal mounting of the starter

Danfoss Drives · DKDD.PB.551.A1.02 | 5

Page 6

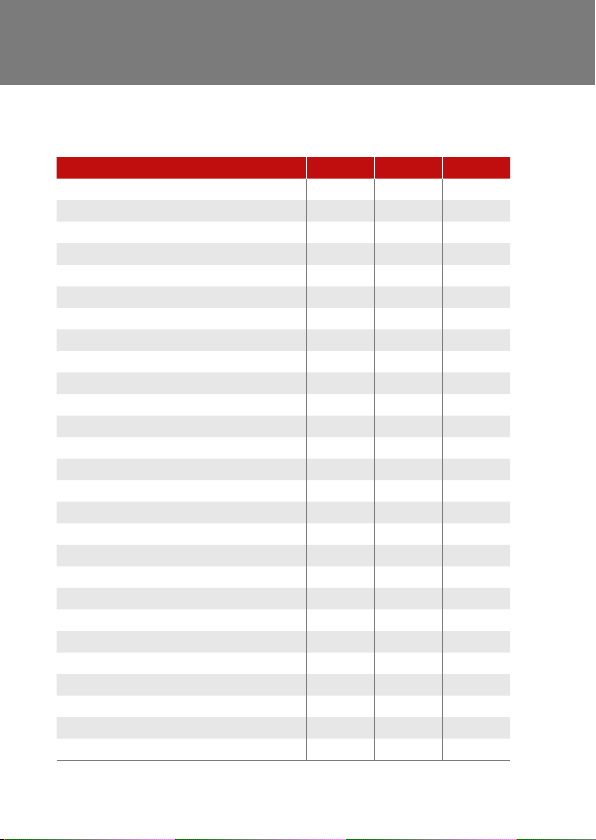

Common Applications

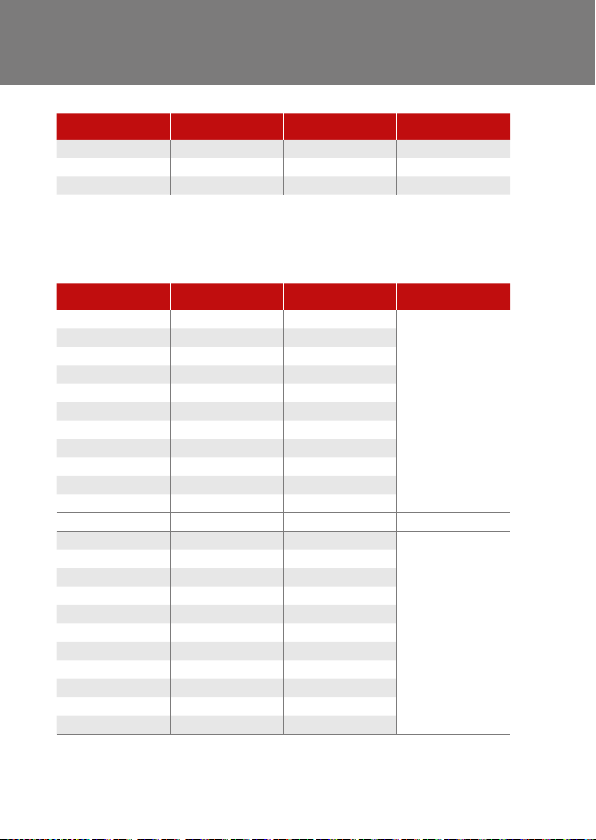

This table lists common applications for soft starters, and their

nominal duty ratings.

Application Normal Heavy Severe

Agitator •

Auger •

Blower (axial fan) •

Bottle Washer •

Centrifuge •

Chipper •

Compressor, centrifugal (rotary) •

Compressor (reciprocating, unloaded) •

Compressor (screw, unloaded) •

Conveyor (loaded) •

Conveyor (unloaded) •

Crusher, cone •

Crusher, jaw •

Crusher, rotary (unloaded) •

Debarker •

Drilling machine •

Dust collector •

Edger •

Escalator •

Fan, centrifugal (damped) •

Fan, centrifugal (undamped) •

Grinder •

Hydraulic power pack •

Mill, ball •

Mill, hammer •

Mill, roller •

Milliscreen •

6 | Danfoss Drives · DKDD.PB.551.A1.02

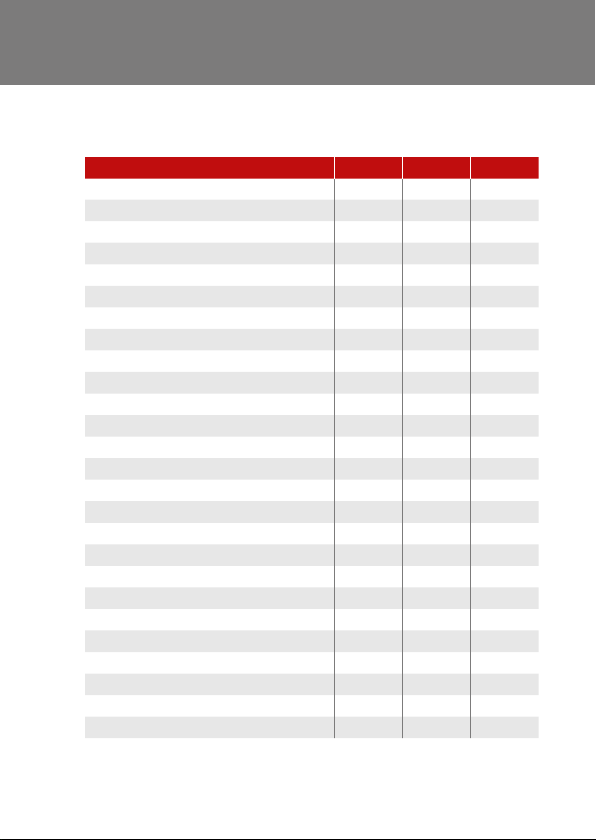

Page 7

Application Normal Heavy Severe

Mixer (low viscosity) •

Mixer (high viscosity) •

Pelletiser •

Planer •

Press •

Pump, bore •

Pump, centrifugal •

Pump, positive displacement •

Pump, slurry •

Pump, submersible •

Pump, vacuum •

Re-pulper •

Rotary table •

Sander •

Saw, band •

Saw, circular •

Shredder •

Separator, liquids •

Separator, solids •

Slabber •

Slicer •

Travelato r •

Tumbler/Dryer •

Vibrating screen •

Winch •

Wire draw machine (hydraulic) •

Danfoss Drives · DKDD.PB.551.A1.02 | 7

Page 8

MCD Soft Starter Features and Specications

MCD 500

• Soft start: Current limit, Current

ramp, Kickstart, AAC Adaptive

Acceleration Control

• Soft stop: Timed voltage ramp,

AAC Adaptive Control, DC brake

• Motor protection: Motor connection, Power loss, Phase loss, Mains

frequency, Current imbalance,

Motor thermistor, Motor overload

• System protection:

Phase sequence, Excess start time,

Undercurrent, Instantaneous

overcurrent, Bypass relay overload,

Heatsink temperature

• Metering: Current, Motor

temperature, Motor kW, motor kVA,

Motor pf

• Control option: Local control

panel plus remote inputs/outputs.

Dedicated output for MCD LCP 501

• Network communication: options

for DeviceNet, Modbus, PROFIBUS

and USB

• Bypass:

7.5 ~ 500 kW internally bypassed;

630 ~ 800 kW dedicated terminals

for external bypass connection

MCD 500

• Current: 7.5 kW ~ 800 kW @400 V

• Mains voltage: 200 ~ 690 VAC

• Supply frequency: 50/60 Hz

• Enclosure: 7.5 ~ 55 kW IP 20,

60 ~ 800 kW IP 00

Control Panel VLT® LCP 501

• Same user interface as

VLT® Soft Starter MCD 500

• Plug & play with MCD 500

• Copy/ paste of parameters

• Multiple monitoring setup

• Door-mount kit – 3 m cable

• IP 65 (NEMA 12)

8 | Danfoss Drives · DKDD.PB.551.A1.02

Page 9

MCD 2 01

• Soft start/stop:

Timed voltage ramp

• Motor protection: not included

• System protection:

not included

• Metering: not included

• Start/stop control: via inputs or via

optional controller

• Network communication: optional

• Bypass: Internally bypassed

MCD 202

• Soft start: Current limit

• Soft stop: Timed voltage ramp

• Motor protection:

Thermistor, Motor overload,

Phase imbalance

• System protection: Phase rotation,

Excess start time, Bypass overload

& Instantaneous overload

• Metering: optional extra

• Start/stop control: via inputs or via

optional controller

• Network communication: optional

• Bypass: Internally bypassed

MCD 201 and MCD 202

• Current: 7.5 kW ~ 110 kW @400 V

• Mains voltage: 200 ~ 575 VAC

• Supply frequency: 45 ~ 66 Hz

• Enclosure: 7.5 ~ 55 kW IP 20,

75 ~ 110 kW IP00

Danfoss Drives · DKDD.PB.551.A1.02 | 9

Page 10

MCD 100

• Micro Soft Start Controller for

motors up to 11 kW

• Extremely robust SCR design with

heavy ratings as standard

• Unlimited number of starts per hour

• Contactor style design for easy

selection, installation and commissioning

MCD 100

• Current: 1.5 kW ~ 11 kW @400 V

• Mains voltage: 208 ~ 600 VAC

• Control voltage: 24 – 480 VAC/VDC

• Enclosure: 1.5 ~ 11 kW IP 20

10 | Danfoss Drives · DKDD.PB.551.A1.02

Page 11

Current Ratings

These duty ratings dene the load requirements , not

the starter capabilities. Starter capability is specied

separately in User Manua ls, Product Guides and

WinStar t. Use these charts to select a soft starter for a

particular application.

Normal Heavy Severe

MCD 5-0 021B 21 (32) 17 (26) 15 (22)

MCD5 -0037B 37 (56) 31 (47) 26 (39)

MCD5-0043B 43 (65) 37 (56) 30 (45)

MCD5-0053B 53 (80) 46 (69) 37 (55)

MCD5-0 068B 68 (102) 55 (83) 47 (7 1)

MCD5-0084B 8 4 (126 ) 69 (10 4) 58 (87)

MCD5-0 089B 89 (134) 74 (112 ) 61 (92)

MCD5-0105B 105 (15 8) 95 (143) 7 8 (117 )

MCD 5-0131B 131 (197) 106 (159) 9 0 (136)

MCD5 -0141B 141 ( 212) 121 (181) 97 (14 6)

MCD5-0195B 195 (293) 160 ( 241) 134 (201)

MC D5- 0215B 215 (323) 178 (268) 149 (22 3)

MCD5-0245C 255 (383) 201 (302) 176 (264)

MCD5-0245B 245 (368) 19 4 (2 91) 169 (2 54)

MCD 5-0331B 331 (497 ) 266 (400) 229 (343)

MCD5-0360C 360 (540) 310 (465) 263 (395)

MCD5-0380C 380 (570) 359 (539) 299 (449)

MCD5- 0396B 396 (594) 318 (478) 27 3 (410)

MCD5-0428C 430 (645) 368 (552) 309 (4 63)

MCD5-0469B 469 (704) 383 (575) 326 (49 0)

MCD5-0525B 525 (787) 425 (637) 364 (546)

MCD5-0595C 620 (930) 540 ( 810) 434 (651)

MCD5 -0619 C 650 (975) 561 (8 42) 455 (683)

MCD5-0632B 632 (948) 512 (768) 438 (658)

MCD5-0790C 790 ( 1185 ) 714 (1072) 579 (869)

MCD5-0744B 744 (1116) 606 (910) 516 ( 774)

MCD5-0826B 826 (1239) 684 (1026) 571 (857)

MCD5-0927C 930 (1395) 829 (12 44) 6 61 (992 )

MCD5-09 61B 961 (14 41) 7 96 (119 4) 664 (997)

Danfoss Drives · DKDD.PB.551.A1.02 | 11

Page 12

Normal Heavy Severe

MC D5-12 00C 1200 (1800) 1200 (1800) 1071 (1607)

MCD5-1400C 1410 (2115) 1319 (197 9) 111 4 (16 71)

MCD5 -1600 C 1600 (2400) 1600 (2400) 13 53 (203 0)

All ratings are for bypassed operation.

Brackets denote ratings for inside delta connection.

Normal Heavy Severe

MCD 201-007 18 17

MCD 201-015 34 30

MCD 201-018 42 36

MCD 201-022 48 40

MCD 201-030 60 49

MCD 201-037 74 65

MCD 201-045 85 73

MCD 201-055 10 0 96

MCD 201-075 140 12 0

MCD 201-090 170 142

MCD 201-110 200 165

MCD 202- 007 18 17

MC D 202- 015 34 30

MCD 202-018 42 36

MCD 202- 022 48 40

MCD 202- 030 60 49

MCD 202-037 74 65

MCD 202- 045 85 73

MCD 202-055 10 0 96

MCD 202-075 140 12 0

MCD 202- 090 170 142

MCD 202- 110 200 165

Consult Danfoss

for suitability

Consult Danfoss

for suitability

12 | Danfoss Drives · DKDD.PB.551.A1.02

Page 13

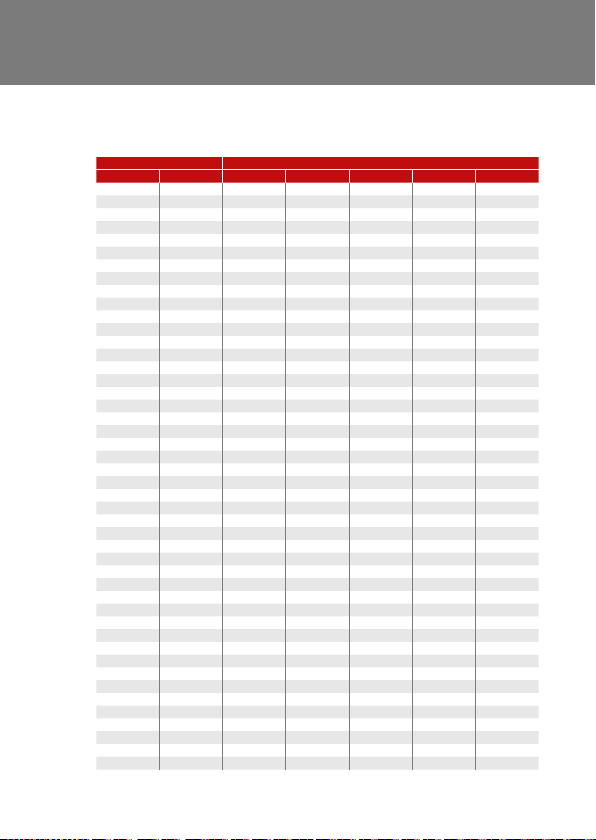

Soft Starter Sizing

• Th e soft start er’s current ratin g at the required st art duty must b e at least equal to th e

motor’s nameplate rating. If the motor’s nameplate rating is not available, approximate

information is available from the following table.

Motor Power Current rating at dierent voltages

kW HP 220-230 V 380- 400 V 4 40 V 500 V 660-690 V

7.5 10 27 15 .5 13.7 12 8.9

11 15 39 22 20.1 18.4 14

15 20 52 30 26.5 23 17. 3

18.5 25 64 37 32.8 28.5 21. 3

22 30 75 44 39 33 25.4

25 35 85 52 45.3 39.4 30.3

30 40 103 60 51.5 45 34.6

37 50 12 6 72 64 55 42

45 60 150 85 76 65 49

55 75 18 2 10 5 90 80 61

75 100 240 13 8 125 10 5 82

90 125 295 17 0 14 6 129 98

110 150 356 205 178 156 11 8

132 18 0 425 245 215 187 14 0

140 19 0 450 260 227 200 145

147 200 472 273 236 2 07 15 2

150 205 483 28 0 246 210 15 9

160 220 520 300 256 220 170

185 250 595 342 295 263 20 0

200 270 626 370 321 281 215

220 300 700 408 353 310 235

250 340 800 460 4 01 360 274

257 350 826 475 412 365 280

280 380 900 510 450 400 305

295 400 948 546 473 416 320

300 410 980 565 4 81 420 325

315 430 990 584 505 4 45 337

335 450 110 0 620 518 472 355

355 480 115 0 636 549 50 0 370

375 500 118 0 670 5 75 527 395

400 545 12 50 710 611 540 410

425 580 133 0 760 650 574 4 45

445 60 0 140 0 790 680 595 455

450 610 1410 800 690 608 460

475 645 149 0 850 730 645 485

500 680 15 70 900 780 680 515

560 76 0 1750 1000 860 760 570

600 800 1875 10 85 937 825 625

650 870 2031 1176 1015 894 67 7

700 940 2187 126 6 1093 962 729

750 1000 2343 1357 1172 1031 781

800 1070 2499 1447 12 50 110 0 833

850 114 0 2656 1537 1328 11 68 885

900 1250 2812 162 8 140 6 12 37 937

950 127 5 2968 1718 1484 13 06 989

1000 1340 3124 180 9 156 2 13 75 10 41

Note: Inform ation is based on a 4- pole motor

Danfoss Drives · DKDD.PB.551.A1.02 | 13

Page 14

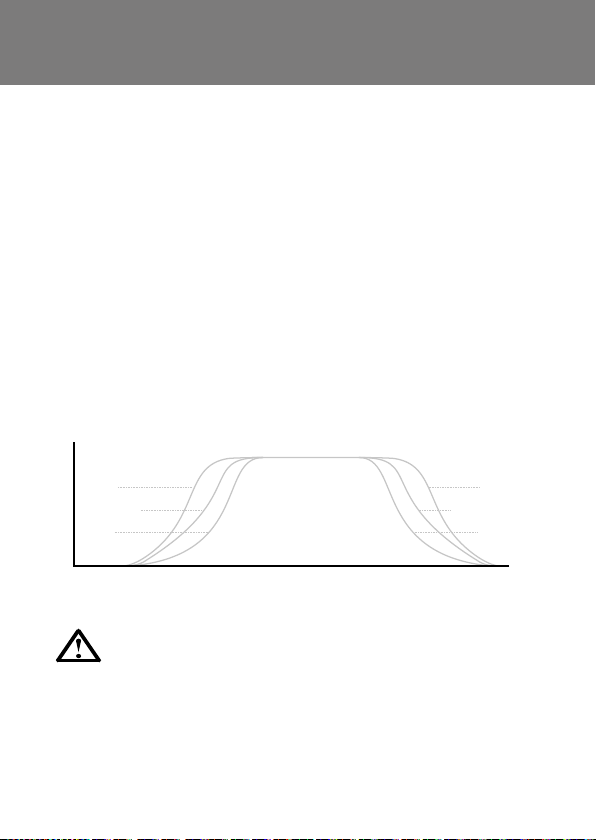

AAC: What is Adaptive Acceleration Control?

TIME

AAC is the next evolution in soft starter technology.

Using AAC, the soft starter learns your motor’s performance during

start and stop, then adjusts control to optimize performance.

The soft starter estimates the motor’s speed throughout each

AAC start and stop, and adjusts power to the motor to provide the

selected acceleration or deceleration profile.

AAC is largely unaffected by changes in load, and is particularly

suitable for pumping situations.

AAC offers three starting and stopping profiles: early, constant and

late acceleration/deceleration.

EARLY

CONSTANT

SPEED

LATE

AAC is only available on MCD 500 soft starters.

14 | Danfoss Drives · DKDD.PB.551.A1.02

LATE

CONSTANT

EARLY

Page 15

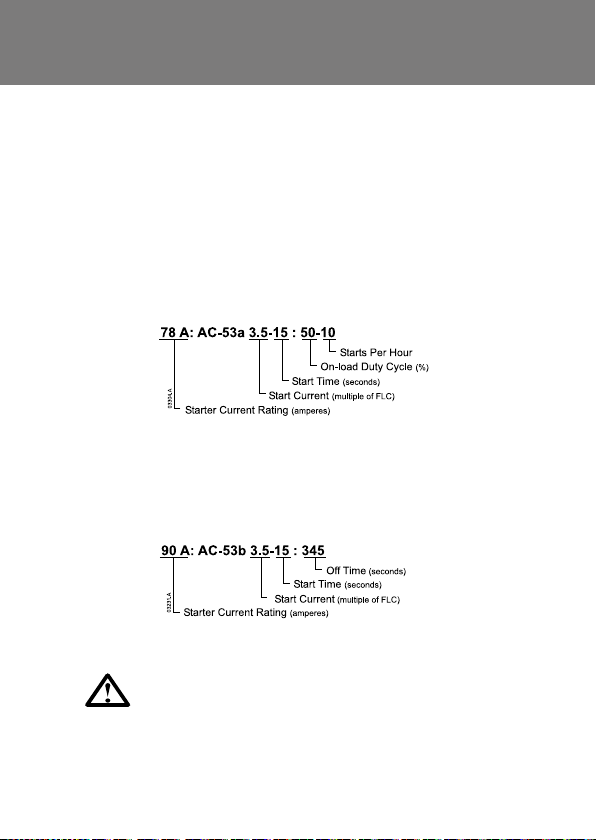

AC53 Utilisation Codes: What are AC53 Utilisation Codes?

AC53 utilisation codes describe the current rating for soft starters

under specied operating conditions.

The utilisation code determines the maximum motor size the

soft starter can be used with, under the specied conditions. The

current rating may change under dierent operating conditions.

AC53a: Non-bypassed soft starters

The rating depends on the number of starts per hour, the length

and current level of the start, and the percentage of the operating

cycle that the soft starter will be running (passing current).

AC53b: Bypassed soft starters

The rating depends on the number of starts per hour, the length

and current level of the start, and the amount of time the soft

starter will be o (not passing current) between starts.

Danfoss soft starters provide a relay output, which can

be used to control the main contactor. Ensure that the

inrush VA rating of the contactor coil does not exceed

the rating of the sof t starter’s relay input.

Danfoss Drives · DKDD.PB.551.A1.02 | 15

Page 16

Auto-Transformer Starters: How does soft start

compare to auto-transformer starting?

Soft starters are much more exible than auto-transformer starters

and provide a much smoother start, generally at a lower cost.

Auto-transformer starters cannot accommodate varying load

conditions (e.g. loaded or unloaded starts) and the start torque

cannot be freely adjusted to match motor and load characteristics.

Damaging torque and current transients still occur at the steps

between voltages, and auto-transformer starters are not capable

of providing soft stop. Auto-transformer starters are large and

expensive, especially if high start frequency is required.

Fault nding: What are the key questions?

To assist your service engineer, they require the following

information:

• Model and serial number of the soft starter

• Motor kW and FLC

• Main supply voltage and frequency

• Control voltage

• Application (e.g. pump, compressor)

• Time installed before failure

• Details of other soft starters on the supply bus. Are these failing?

• If the soft starter trips, details of the code and mode of operation

• The installation’s power and control schematic diagram

16 | Danfoss Drives · DKDD.PB.551.A1.02

Page 17

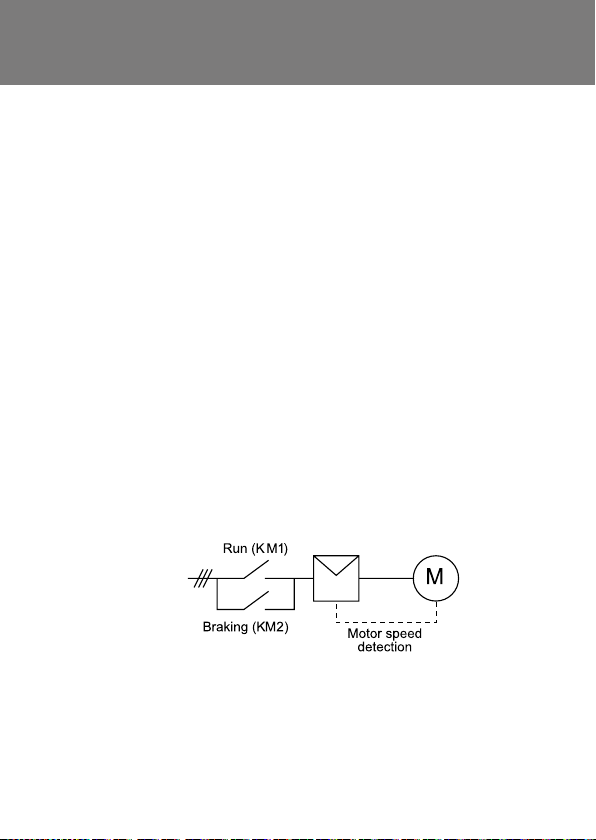

Braking:

What are DC braking and soft braking?

DC braking and soft braking both reduce motor stopping time,

unlike soft stopping which increases the stop time on frictional

loads.

DC braking uses DC injection to reduce the motor’s stopping time.

The soft starter slows the motor to approximately 70% of its full

running speed, then applies brake torque to stop the motor in the

selected braking time.

DC braking support is built into MCD 500 soft starters, and no

additional equipment is required. MCD 500 DC braking controls all

three phases, which reduces stress on the motor compared with

two phase braking solutions.

Soft braking uses reversing contactors on the input side of the

starter to start the motor in the reverse direction, which applies

braking torque to the load.

Soft braking causes less motor heating and provides more

braking torque for a given current than DC braking, and is better

for extremely high inertia loads (e.g. band saw and circular saw

applications).

Danfoss Drives · DKDD.PB.551.A1.02 | 17

Page 18

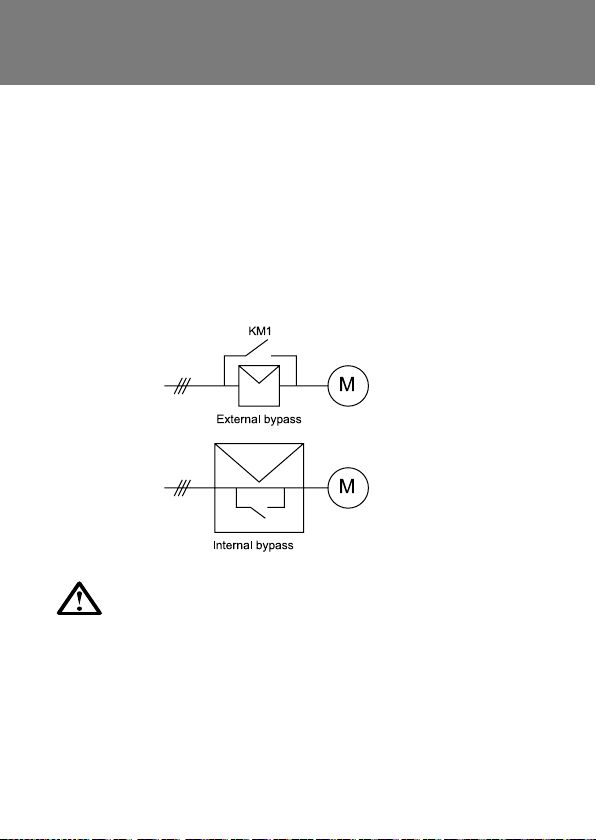

Bypass Contactors:

When should a bypass contactor be used?

Bypass contactors bridge out the SCRs when the motor is running

at full speed, eliminating heat dissipation during run. This allows

the soft starter to be installed in enclosures without the need for

forced-air cabinet ventilation.

If a soft starter is installed in a totally sealed enclosure (>IP 54) it

must be bypassed.

Bypass contactors should be AC1 rated for the motor FLC (the

bypass contactor does not carry start current).

Soft starters may be internally or externally bypassed:

MCD 200 sof t starters are i nternally bypas sed,

with built-in bypass relays.

MCD 500 sof t starters are i nternally bypas sed up to 500 kW.

Non-bypassed models include relay outputs to control an

external bypass contactor. Dedicated bypass terminals

mean moto r protection sti ll operates even when the sta rter

is bypassed.

18 | Danfoss Drives · DKDD.PB.551.A1.02

Page 19

Cabling: How is cable selected for

a soft starter installation?

Cable selection criteria depends on the circuit and the location of

the soft starter within the circuit.

1. Supply cable rating > nominal fuse/MCCB rating > motor FLC x 1.2

2. Inside delta motor circuit cable rating > motor FLC x 0.7

Installation factors (including grouping, ambient

temperature, method of installation and single or

parallel cabling) may aect the cable’s current rating.

Always follow the manufacturer’s guidelines and derate

appropriately.

Danfoss Drives · DKDD.PB.551.A1.02 | 19

Page 20

Cabling: What is the maximum allowable cable,

distance between a soft starter and the motor?

The maximum distance between the soft starter and motor

depends on the voltage drop and the cable capacitance.

Cable must be selected so that when the motor is running fully

loaded, the voltage drop at the motor terminals does not exceed

the limit specied in local electrical regulations.

For distances greater than 500 metres or when using parallel

cabling, cable capacitance may be a factor. If in doubt, please

contact Danfoss with details of the soft starter model, mains

voltage and frequency. If you want to use standard products, we

recommend using Line Reactors.

Calculation

The main point is to limit the di/dt so the SCR’s are not damage

with the inrush currents due to increase cable capacitance. The

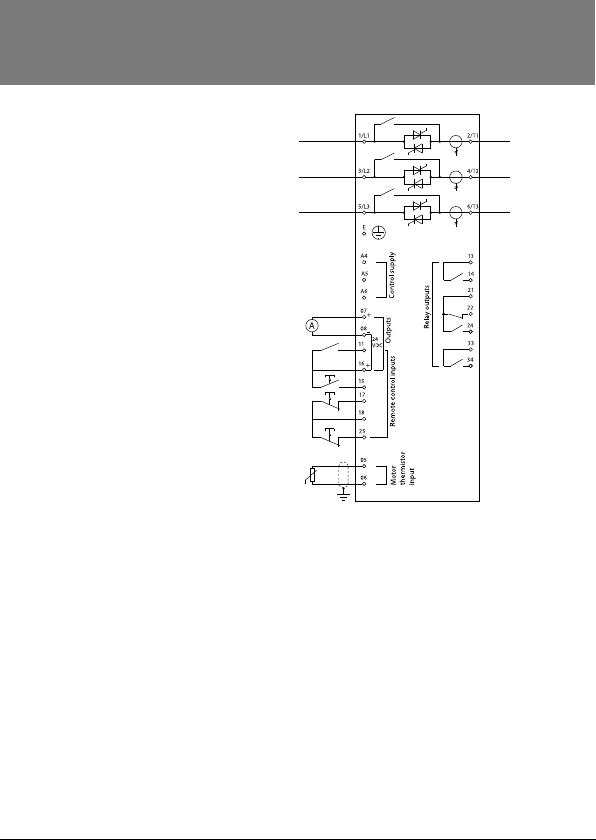

output inductors must be installed as close to the soft starter as

possible.

The output inductors must be smaller than the inductance of the

motor.

Minimum rated current of coil, is stated from start current.

(Soft starter selection and application, normally 3 – 4,5 x FLC)

V

p

< L

di

(

dt

)

Vp Vp = V

di

dt

V Motor supply voltage

Ilr Locked rotor current

ω 2 × π × frequency

L

Coil Inductance

coil

20 | Danfoss Drives · DKDD.PB.551.A1.02

V

coil

(√3 I

) ω

LR

× √2

rms

100 A

.

1 μS

Page 21

Example:

Compressor (Reciprocating, start unloaded), start current limited to

3,5 x FLC, motor: 132 kW, 400 V, In: 226 A, Ilr: 7,5 x In.

Mains Supply: 400 V, 50 Hz-

L

= Motor Inductance =

max

400 V × √2

L

=

min

10 0 A

(

1 μS

)

= 5,66 μH

(√3 x I

V

) ω

LR

400

(√3 x 1695) × (2 × π × 50)

= 0,434 mH=

Minimum rated current = 226 x 3,5 = 791 A

Extreme Conditions: How can soft starters be selected

for extreme conditions?

Soft starter ratings are based on specic operating conditions.

These generally specify start time, start current, starts per

hour, duty cycle and environmental factors such as ambient

temperature and altitude. If the soft starter will be used outside

these conditions, the rating must be revised according to the

manufacturer’s instructions.

Ratings for Danfoss soft starters are published in the

soft starter’s Operating Instructions. Alternatively,

WinStar t can be used to model requirements outside the

published ratings.

Danfoss Drives · DKDD.PB.551.A1.02 | 21

Page 22

Flying Loads: Are soft starters suitable for use

with a ying load?

Soft starters can be used with ying loads (motors that are already

rotating), without any special wiring or conguration.

As a general rule, the faster the motor is rotating in the forward

direction, the shorter the start time will be.

If the motor is rotating in the reverse direction, it will be slowed to

a standstill before accelerating in the forward direction. In this case

allow for the extended start time when rating the soft starter.

Harmonics: Are harmonics an issue for

soft starter applications?

Harmonics are voltages and currents that create unwanted heating

in motors, cables and other equipment. Harmonics may also

disrupt operation of other electrical and electronic equipment.

Soft starters generate very low levels of harmonics, only during

starting or soft stopping. According to IEC 60947-4-2 (8.3.2.1.1),

“harmonic emissions are of short duration during starting, and

there are no signicant emissions in the FULL-ON state”. No special

considerations or ltering are required for soft start applications.

All MCD soft star ters comply with the EMC directive on

radiofrequency emissions and immunity.

22 | Danfoss Drives · DKDD.PB.551.A1.02

Page 23

IP ratings

IEC 60529 species protection ratings for enclosures.

The rst number describes the protection against solid objects, the

second number describes the level of protection against entry of

liquids. Example IP 20 is highlighted below.

IP Solids

0 No protection No protection.

Protected agains t solid objects

1

greater tha n 50 mm (e.g.

accidental touching by hand).

Protected agains t solid objects

2

greater tha n 12 mm (e.g. ngers).

Protected agains t solid objects

3

greater tha n 2.5 mm

(e.g. tools or w ires)

Protected agains t solid objects

4

greater tha n 1 mm

(e.g. tools an d small wires).

Limited protection against dust

5

(some ingress but no har mful

deposit).

6 Complete protection against dust.

7

8

Examples

• MCD200- 007 ~ MCD200-055 is IP 20

• MCD200- 075 ~ MCD200-110 is IP 00

IP 20 with optional finger guard kit,

Order code 175G9007

• MCD5-0 021 ~ MCD5-0105 is IP 20

• MCD5-0131 ~ MCD5-1600 is IP 00

Liquids

Protected agains t vertically falling

drops of water (e.g. condensation).

Protected agains t direct sprays of

water up to 15° from vertical .

Protected agains t sprays of water

up to 60° from vertical.

Limited pr otection agains t water

sprayed fr om all directions (limited

ingress permitted).

Limited pr otection agains t low

pressure jets of water from all directions (limited ingress permitted).

Protected agains t strong jets of

water (limited ingress permitted).

Protected agains t the eects of

immersi on in water between 15 cm

and 100 cm.

Protected agains t extended

immersion in water under pressure.

Order codes for finger guard kits are:

MCD5-0131~0215: 175G5662

MCD5-0245: 175G5663

MCD5-0360~0927: 175G5664

MCD5-1200~1600: 175G5665

MCD5-0245~0396B: 175G5730

MCD5-0469~0961B: 175G5731

Danfoss Drives · DKDD.PB.551.A1.02 | 23

Page 24

NEMA ratings

NEMA 250 is a product standard for enclosure design and

performance.

NEMA Protection against solid objects Approx. IP equivalent

1 Indoor, protection from contact. IP 23

Indoor, limited protection from

2

dirt and water.

Outdoor, some protection from rain,

3

sleet, windblow n dust and ice.

Outdoor, some protection from rain,

3R

sleet and i ce.

Indoor or outdoor, some protection from

4

windblown dust, rain, splashing water,

hose-directed water and ice.

Indoor or outdoor, some protection

from corrosion, windblown dust, rain,

4X

splashing water, hose-directed water

and ice.

Indoor or outdoor, some protection from

6

ice, hose -directed water, entry of wa ter

when submerged at limited depth.

Indoor, protection from dust, falling dirt

12

and dripping non-corrosive liquids.

Indoor, protection from dust, spraying

13

water, oil and non-corrosive liquids.

Warning:

Conversion from NEMA to IEC (IP) degrees of enclosure not to be

used for converting from IEC to NEMA.

Please refer to NEMA publication 250, 2003.

IP 30

IP 64

IP 32

IP 66

IP 66

IP 67

IP 55

IP 65

24 | Danfoss Drives · DKDD.PB.551.A1.02

Page 25

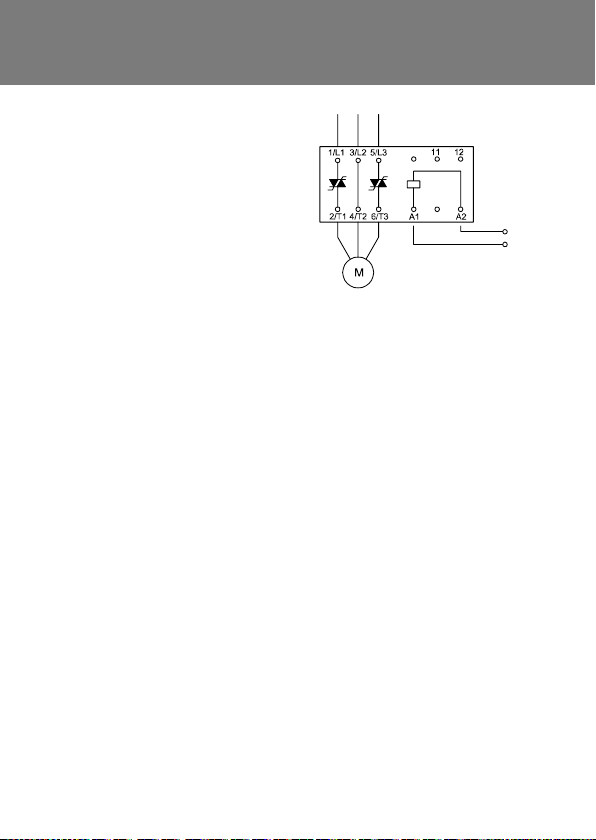

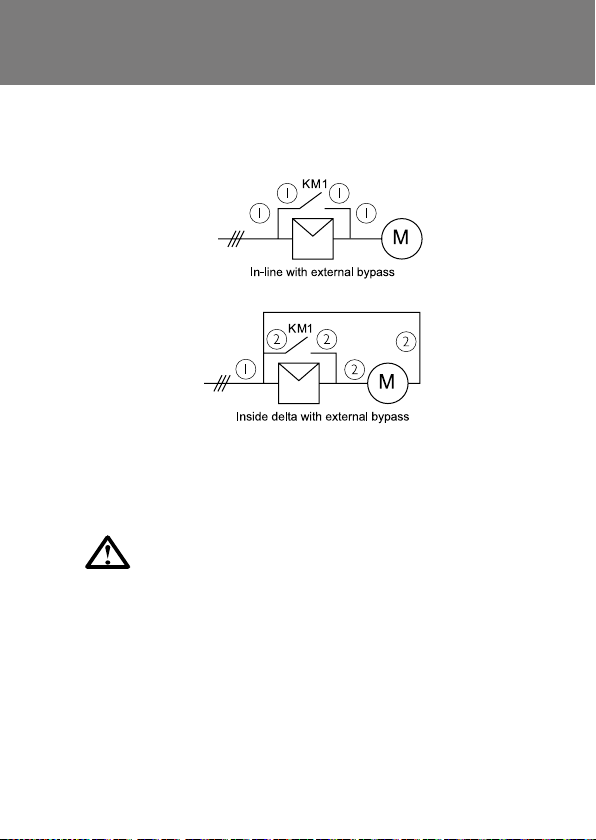

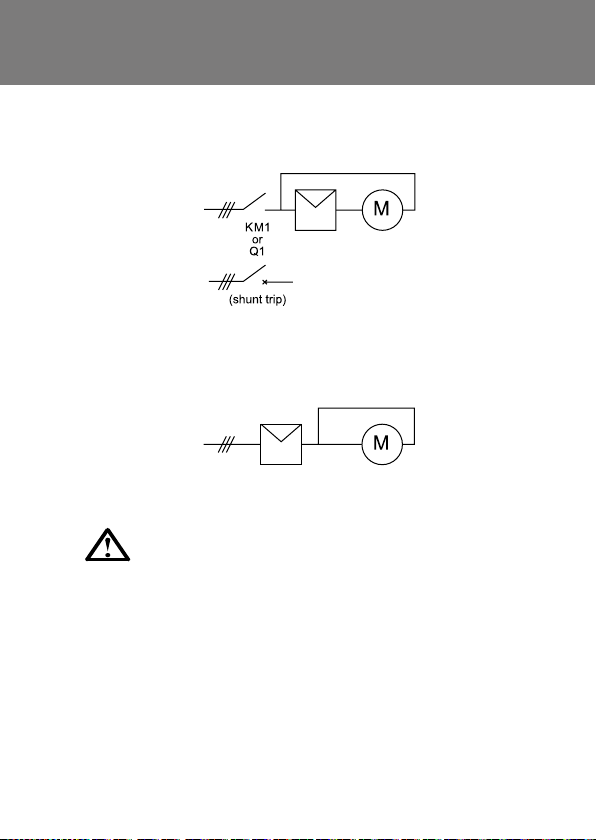

Inside delta Connection:

What is “inside delta” connection?

With inside delta (six wire connection), the soft starter SCRs are in

series with each motor winding so that the soft starter carries only

phase current, not line current. The soft starter can thus control a

motor with greater full load current than normal.

Inside delta connection is only possible with motors that allow

each end of all three motor windings to be connected separately,

and not all soft starters can be connected using inside delta. A line

contactor or shunt trip MCCB must always be used to disconnect

the motor and soft starter from the supply in the event of a trip.

Inside delta connection simplies replacement of star/delta starters

because the existing wiring can be used. In new installations,

inside delta connection may reduce the size and cost of the soft

starter, but there are additional costs for the line contactor/shunt

trip MCCB and extra cabling.

MCD 200 sof t starters cannot be installed using

inside delta connection.

MCD 500 sof t starters have built-in support for

inside delta connection.

Danfoss Drives · DKDD.PB.551.A1.02 | 25

Page 26

Key Benets: What are the key benets of soft start?

Soft start enhances motor start performance in many ways.

• The gradual application of voltage or current avoids the voltage

and current transients associated with electro-mechanical

reduced voltage starters.

• Acceleration is also smoother, as soft start avoids the torque

transients associated with electro-mechanical reduced voltage

starters.

• Constant current control gives higher torque as motor speed

increases, resulting in lower start currents and/or shorter start

times

• Start performance can be adjusted to suit the motor and load,

including exact control over the current limit.

• Soft starting provides reliable performance even with frequent

starts, or if load characteristics vary between starts (e.g. loaded

or unloaded).

Soft starters also provide a range of features not available from

other reduced voltage starters. This includes soft stop, which helps

eliminate water hammer and DC braking.

Other features such as built-in protection for the motor

and system, and metering and monitoring options, ca n

reduce the overall installed cost of the equipment and

reduce the long-term maintenance requirement.

26 | Danfoss Drives · DKDD.PB.551.A1.02

Page 27

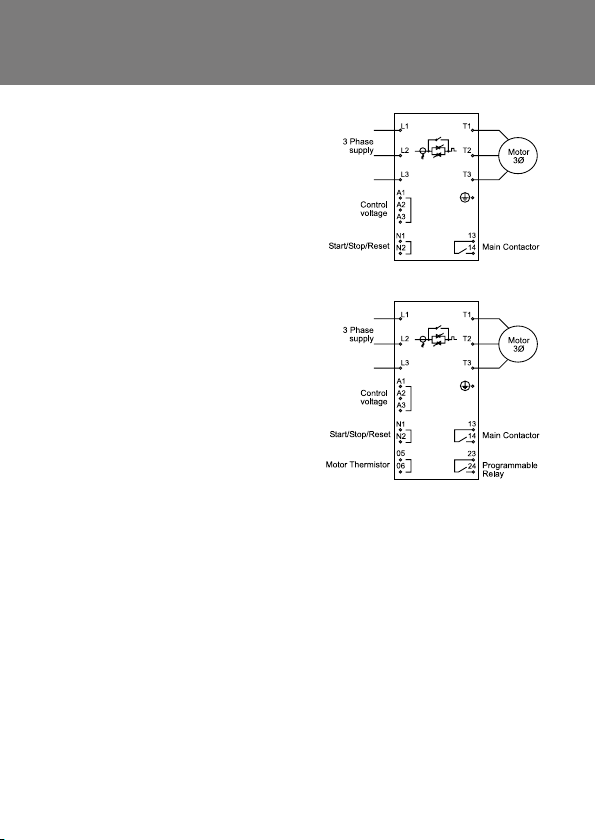

Line Contactors: When should a line contactor be used?

Soft starters can be installed with or without a line contactor.

A line contactor disconnects the SCRs from the supply when the

motor is not in use. This isolates the soft starter, and protects the

SCRs from damage due to severe overvoltage (e.g. lightning strikes)

– SCRs are most susceptible to overvoltage damage when in the o

state. The soft starter is also isolated from the supply in the event

of a trip.

A line contactor may be required by local electrical regulations and

should be AC3 rated for the motor FLC.

The line contactor can be controlled via the soft star ter’s

relay output. The inrush VA rating of the contactor coil

must not exceed the rating of the soft starter’s relay

output.

Danfoss Drives · DKDD.PB.551.A1.02 | 27

Page 28

Minimum Start Current: What is the minimum start

current required by a soft starter?

Soft starters can limit start current to any specied level, but the

practical minimum depends on the motor and load. Reducing

the start current reduces the torque produced by the motor, so

the load will stall if the start current is too low. In order to start

successfully, the motor must produce more acceleration torque

than the load requires throughout the start.

Successful start:

Unsuccessful start:

Start current can be estimated based on previous experience, or

the motor and load speed/torque curves can be analysed for a

precise calculation.

28 | Danfoss Drives · DKDD.PB.551.A1.02

Page 29

Multiple motors: Can one soft starter be used

to control multiple motors?

A single soft starter can be used to control multiple motors, either

in sequence or in parallel, provided the soft starter is correctly

selected for the application.

Motors in sequence

For two or more motors in sequence, the soft starter must be

capable of bearing the total start duty.

Installation requires additional wiring, plus separate overload

protection and line and bypass contactors for each motor. The additional installation costs may be greater than the cost of individual

soft starters.

* This control method is complex and would require the use

of a PLC or smart relay.

Danfoss Drives · DKDD.PB.551.A1.02 | 29

Page 30

Power factor correction: Can power factor correction

be used with soft starters?

Power factor correction (PFC) capacitors can be used with soft

starters, provided they are switched in using a dedicated contactor

when the motor is running at full speed. PFC must always be

installed on the input side of the soft starter; connecting PFC

capacitors to the output of a soft starter causes resonance between

the inductance of the motor and the power factor capacitance,

resulting in severe overvoltage and equipment failure.

The contactor should be AC6 rated for the motor full load current.

PFC capacitors can be sized using the following formula:

kVA (Cap) = √_3 x V

x 0.8 x motor no load current

line

1000

Motor thermal capacity: What is it?

Thermal capacity, also called “maximum locked rotor time” or

“maximum DOL start time”, describes the maximum time a motor

can run at locked rotor current from cold. This information is

usually available from the motor datasheet.

The MCD 202 overload protection can be set to match the motors

thermal capability using the motors locked rotor time (cold).

30 | Danfoss Drives · DKDD.PB.551.A1.02

Page 31

Jog: What is the jog function?

Jog runs the motor at reduced speed, to allow alignment of the

load or to assist servicing. The motor can be jogged in either

forward or reverse direction. The maximum available torque

for jog is approximately 50% - 75% of motor full load torque

(FLT) depending on the motor. Available jog torque in reverse is

approximately 50% - 75% of the jog torque in forward direction.

This is ideal for positioning of loads such as mixers or hopper bins

ready for unloading.

Reversing: Can soft starters be used

to reverse motor direction?

On their own, soft starters cannot run motors in reverse direction

at full speed. However, an arrangement of forward and reverse

contactors can be used to provide the same effect.

MCD 500 soft starters offer a part speed function that runs the

motor at slow speed in either forward or reverse direction, without

a reversing contactor. Reverse operation is limited to short periods

at a fixed slow speed.

Danfoss Drives · DKDD.PB.551.A1.02 | 31

Page 32

Sealed enclosures: Can soft starters be installed

in sealed enclosures?

Soft starters can be installed in sealed enclosures, provided the

ambient temperature within the enclosure will not exceed the soft

starter’s rated temperature.

All heat generated within the enclosure must be dissipated, either by

ventilation or through the enclosure’s walls. This includes heat not

only from the soft starter but also from other components such as

fuses, cabling and switchgear. Heating from the soft starter can be

minimised by installing the starter in a bypassed conguration. To

minimise external heating, protect the enclosure from direct sunlight.

WinStart includes a function to help design enclosure ventilation.

Primary Resistance Starters: How does soft start

compare to primary resistance starting?

Soft starters are more exible and reliable than primary resistance

starters.

Primary resistance starters cannot accommodate varying load

conditions (e.g. loaded or unloaded starts) and the start torque cannot

be ne-tuned to match motor and load characteristics. Performance

may vary with multiple starts in close succession, because the start

prole changes as the resistance heats up. Damaging torque and

current transients still occur at the steps between voltages, and

primary resistance starters are not capable of providing sof t stop.

Primary resistance starters are large and expensive, and liquid

resistance starters require frequent maintenance.

32 | Danfoss Drives · DKDD.PB.551.A1.02

Page 33

Short Circuit Protection: What is required for Type 1 short

circuit protection of a soft starter?

Type 1 protection requires that in the event of a short circuit on the

output of a soft starter the fault must be cleared without risk of injury to

personnel. The soft starter may or may not be operational af ter the fault.

Type 1 protection is provided by HRC fuses or a MCCB within the motor

branch circuit, which must be able to bear the required motor start current.

Typical selection criteria are as follows:

Rating (% Motor FLC),

Start Current

Starter

type

MCD 200

MCD 500

* Consult the manufacturer’s specication.

Protection Type < 350% FLC

15 seconds

Fuse (non time delayed) 175 % 200%

Fuse (time delayed) 15 0% 175%

MCCB* 150 – 200%

Fuse (non time delayed) 150%

Fuse (time delayed) 12 5%

MCCB* 150 – 200%

> 350% FLC

15 seconds

Maximum fuse ratings for Type 1 motor protection are specied in

UL and IEC standards.

Fuse Rating (% Motor FLC)

Fuse (non-time delayed) 300%

Fuse (time delayed) 175%

Danfoss Drives · DKDD.PB.551.A1.02 | 33

Page 34

Short Circuit Protection: What is required for Type 2

short circuit protection of a soft starter?

Type 2 protection requires that in the event of a short circuit on

the output of a soft starter the fault must be cleared without risk of

injury to personnel or damage to the soft starter.

Type 2 protection is provided by semiconductor fuses, which must

be able to carry motor start current and have a total clearing I2t

less than the I2t of the soft starter SCRs.

Semiconductor fuses for Type 2 circuit protection are additional

to HRC fuses or MCCBs that form part of the motor branch circuit

protection.

Refer to the soft starter’s Design Guide for semiconductor fuse

recommendations.

34 | Danfoss Drives · DKDD.PB.551.A1.02

Page 35

Semiconductor Fuse Selection: Type 2

• Semiconductor fuses may be used with MCD soft starters. Use

of semiconductor fuses will provide Type 2 coordination and

reduce the potential of SCR damage due to transient overload

currents and short circuits. MCD soft starters have been tested

to achieve Type 2 coordination with semiconductor fuses. The

following table provides a list of suitable Bussman fuses. If

selecting alternate brands ensure the selected fuse has a lower

total clearing I2t rating than the SCR, and can carry start current

for the full start duration.

MCD 200

MCD200-007 17 0M-1 314 63 FE 1150

MCD 200 -015 170 M-1317 160 FE E 8000

MCD2 00- 018 17 0M-13 18 160 FEE 10500

MCD20 0-022 170M -1318 180 F M 15000

MCD20 0-030 170M -1319 180 F M 18000

MCD20 0-037 170M -1321 250 FM 512 00

MCD20 0-045 170M -1321 250 FM 80000

MCD20 0-055 170M -1321 250 FM 97000

MCD20 0-075 17 0M- 1322 500 FM M 168000

MCD20 0-090 17 0M- 302 2 500 FM M 245000

MC D20 0 -110 170M -3 022 500 FMM 320000

Bussmann Fuse

Square Body (170M)

200 ~575 V

Bussmann Fuse

Britis h Style (BS88)

Danfoss Drives · DKDD.PB.551.A1.02 | 35

SCR I

(A

2

t

2

s)

Page 36

• Semiconductor fuses listed below are manufactured by Bussman

and should be ordered directly from Bussman or their local

supplier. Instruction for selection for alternative semi-conductor

fuses is available from Danfoss.

1.1.1. Bussman Fuses – Square Body (170M)

MCD 500 SCR I2t (A2s)

MCD 5-0 021B 1150 170M13 14 17 0M1314 17 0M1314

MCD5 -0037B 8000 17 0M1316 17 0M1316 170M 1316

MCD5-0043B 105 00 170 M1318 170M1318 170M1318

MCD5-0053B 15000 170 M1318 170 M1318 170M1318

MCD5-00 68B 15000 170M1319 17 0M1319 170M1318

MCD5-00 84B 512000 170M 1321 170M1 321 170 M1319

MCD5-00 89B 80000 170 M1321 170 M1321 170 M1321

MCD5 -0105B 125000 170M13 21 17 0M1321 17 0M132 1

MCD 5-0131B 125000 170M1 321 17 0M132 1 17 0M1321

MCD 5-0 141B 320000 170M2621 170M2621 170M2621

MCD5-0195B 320000 170M2621 170M2621 170M2621

MCD 5- 0215B 320000 170M2621 170M2621 170M2621

MCD5- 0245B 320000 170M2621 170M2621 170M2621

MCD 5-03 31B 20200 0 17 0M 5011 170 M5 011 ––

MCD5- 0396B 320000 17 0M 6011 –– ––

MCD5-0469B 320000 170M6008* –– ––

MCD5- 0525B 781000 170 M6 013 170 M601 3 17 0M6 013

MCD5- 0632B 781000 170M 5015 17 0M5 015 ––

MCD 5- 0744B 1200000 17 0M5 017 170 M60 17 ––

MCD5-0 826B 2530000 170 M60 17 17 0M6 017 ––

MCD 5-0 961B 2530000 170M 6018 170 M6 013* ––

MCD5- 0245C 320000 170M2621 170M2621 170M2621

MCD5-036 0C 320000 17 0M6 010 170 M60 10 170 M601 0

MCD5-038 0C 320000 170M 60 11 17 0M6 011 ––

MCD5-0428C 320000 170 M6 011 17 0M 6011 ––

MCD5-0595C 1200000 170 M601 5 170 M6 015 170 M60 14

MCD 5-0 619C 1200000 170 M60 15 17 0M6 015 170 M60 14

MCD5- 0790C 2530000 17 0M6 017 170 M60 17 17 0M6 016

MCD5- 0927C 4500000 17 0M6 019 170 M60 19 17 0M6 019

MC D5-120 0C 4500000 17 0M6 021 –– ––

MCD 5-1410C 6480000 –– –– ––

MCD 5-160 0C 12500000 17 0M6 019* –– ––

Supply Voltage

≤ 440 VAC

Supply Voltage

≤ 575 VAC

Supply Voltage

≤ 690 VAC

* Two parallel connected fuses required per phase.

36 | Danfoss Drives · DKDD.PB.551.A1.02

Page 37

1.1.2. Bussman Fuses – British Style (BS88)

MCD 500 SCR I2t (A2s)

MCD 5-0 021B 1150 63FE 63FE 63FE

MCD5 -0037B 8000 120 FEE 120F EE 12 0FE E

MCD5-0043B 105 00 12 0FE E 120 FEE 120F EE

MCD5-0053B 15000 200 FEE 200 FEE 20 0FEE

MCD5-00 68B 15000 200 FEE 20 0FEE 2 00FEE

MCD5-00 84B 512000 2 00FEE 200FEE 200FEE

MCD5-00 89B 80000 280FM 280FM 28 0FM

MCD5 -0105B 125000 280FM 28 0FM 280FM

MCD 5-0131B 125000 280FM 2 80FM 280FM

MCD 5-0 141B 320000 450FM M 450FMM 450FM M

MCD5-0195B 320000 450FM M 450FMM 450FM M

MCD 5- 0215B 320000 450FMM 450 FMM 450FMM

MCD5- 0245B 320000 450FMM 45 0FMM 450FMM

MCD 5-03 31B 20200 0 315FM * –

MCD5- 0396B 320000 400FMM* –– ––

MCD5-0469B 320000 450FMM* –– ––

MCD5- 0525B 781000 500FMM* 500FMM * 5 00FMM*

MCD5- 0632B 781000 630FM M* –

MCD 5- 0744B 1200000 –– –– ––

MCD5-0 826B 2530000 –– –– ––

MCD 5-0 961B 2530000 –– –– ––

MCD5- 0245C 320000 450FMM 450 FMM 450FMM

MCD5-036 0C 320000 – –– ––

MCD5-038 0C 320000 400FM M* 400 FMM 400 FMM*

MCD5-0428C 320000 – –– ––

MCD5-0595C 1200000 6 30FMM* 630 FMM* ––

MCD 5-0 619C 1200000 630FMM* 630FMM* ––

MCD5- 0790C 2530000 –– –– ––

MCD5- 0927C 4500000 –– –– ––

MC D5-120 0C 4500000 –– –– ––

MCD 5-1410C 6480000 –– –– ––

MCD 5-160 0C 12500000 –– –– ––

Supply Voltage

≤ 440 VAC

Supply Voltage

≤ 575 VAC

– ––

– ––

Supply Voltage

≤ 690 VAC

* Two parallel connected fuses required per phase.

Danfoss Drives · DKDD.PB.551.A1.02 | 37

Page 38

Slip-Ring Motors: Are soft starters suitable for use

with slip-ring motors?

Soft starters are suitable for use with slip-ring motors provided that

the motor can still deliver the torque required to accelerate the

load. Soft starters are not suitable if the load requires extremely

high start torque, or if the slip-ring motor is intended to provide

speed control. When considering a soft starter for slip-ring

applications, a trial should be conducted to verify the performance.

To develop starting torque, some resistance must remain in the

rotor circuit during motor starting. This resistance must be bridged

out using a contactor (AC2 rated for rotor current) once the motor

is running close to full speed.

Rotor resistance (R) can be sized using the following formula:

Where VR = open circuit rotor voltage

IR = full load rotor current

38 | Danfoss Drives · DKDD.PB.551.A1.02

Page 39

Soft Braking: What is soft braking?

Soft braking is a technique used by the soft starter to reduce

motor stopping time, unlike soft stopping which increases the stop

time on frictional loads. Soft braking requires the use of reversing

contactors.

When the soft starter receives a stop command, it operates the

reversing contactor connected on its input side to soft start the motor

in the reverse direction. This applies braking torque to the load.

Motor speed detection is required to shut down the braking at

motor standstill.

Soft starters can also use ‘DC braking’ to reduce the stopping time,

but soft braking causes less motor heating and provides more

braking torque for a given current, and is better for extremely high

inertia loads (e.g. band saw and circular saw applications).

Danfoss Drives · DKDD.PB.551.A1.02 | 39

Page 40

Star/Delta Starters: How does soft start compare

with star/delta starting?

Soft starters are much more flexible than star/delta starters and

provide a smooth start with no risk of transients.

Star/delta starters cannot accommodate varying load conditions

(e.g. loaded or unloaded starts) and the start torque cannot be

adjusted to match motor and load characteristics. In addition,

the open transition between star and delta connection causes

damaging torque and current transients. Star/delta starters are not

capable of providing soft stop.

However, star/delta starters may be cheaper than a soft starter and

they may limit the start current to a lower level than a soft starter

when used on an extremely light load. However, severe current

and torque transients may still occur.

40 | Danfoss Drives · DKDD.PB.551.A1.02

Page 41

Star/Delta Starters: Can soft starters be used

to replace star/delta starters?

If the soft starter supports inside delta connection, simply connect

it in place of the star/delta starter.

If the soft starter does not support inside delta connection,

connect the delta connection to the output side of the soft starter.

MCD 500 soft starters include built-in support

for inside delta connection.

Danfoss Drives · DKDD.PB.551.A1.02 | 41

Page 42

Thermal Model Protection: How is a motor thermal model

dierent from other forms of overload protection?

The motor thermal model used in MCD soft starters offers precise

motor protection normally only available from high-end motor

protection relays. The thermal model constantly models motor

temperature, based on information on the motor’s design

characteristics and actual operation. The thermal model accounts

for different heating and cooling rates when the motor is starting,

running or stopped. Accurate modelling allows the motor to be

used to its maximum potential without nuisance tripping.

The MCD 500 uses an advanced second order thermal

model, which models iron and copper losses separately.

This gives more prec ise modelling and provides greater

protection for the motor.

Compared with a motor thermal model, thermal overload relays

are less precise.

They do not account for iron loss or for different cooling rates at

different stages of motor operation, and cannot be adjusted to

match the characteristics of the individual motor because the mass

of the bimetal strips is fixed. The bimetal strips are also affected by

their own ambient temperature, which may be different from the

motor’s ambient temperature.

Thermal modelling is also superior to inverse time-current and

I2T electronic overloads, which do not account for iron loss or for

different cooling rates at different stages of motor operation. They

offer only limited adjustment and the trip curves do not closely

match motor heating. Inverse time-current protection also does

not allow for motor temperature before the overload.

42 | Danfoss Drives · DKDD.PB.551.A1.02

Page 43

Two-Speed Motors: Are soft starters suitable for use

with two-speed motors?

Soft starters are suitable for use with Dahlander and dual winding

motors, provided that separate motor protection is used for both

low and high speed operation.

Dual-winding motors have one shaft with two separate pole

congurations (e.g. 4 pole and 8 pole), providing two dierent

speeds. The speed is selected using external contactors (AC3

rated).

Dahlander motors are often used for two-speed compressor or

fan applications. The motor windings are externally congured

using contactors for high speed (dual star) and low speed (delta)

operation.

MCD 201 soft starters are designed for use with external

motor protection devices and are ideal for two-speed

motor applications. MCD 202 soft starters have motor

protection built in and are less suitable for two-speed

applications.

Danfoss Drives · DKDD.PB.551.A1.02 | 43

Page 44

Types of Soft Starter: What are the dierent types

of soft starters?

There are three dierent types of soft starter which oer dierent

features and control the motor in dierent ways.

1. Torque controllers control only one phase during start. This

reduces the torque shock at start but does not reduce start

current. Torque controllers must be used in conjunction with a

direct on-line starter.

2. Soft starters which control two phases can reduce start current

as well as eliminating torque transients, and are suitable for

normal and heavy duty loads, but not severe loads. The start

current on the uncontrolled phase is slightly higher than the two

controlled phases.

3. Soft starters which control all three phases provide the

maximum level of soft start control and are the only soft start

solution that is suitable for severe duty applications.

44 | Danfoss Drives · DKDD.PB.551.A1.02

Page 45

MCD Bus Options – General Notes

All bus options have the ability to:

• Control the soft starter

• Monitor the soft starter status

• Monitor the soft starter trip state

• Monitor the soft starter current (not available on MCD 201)

• Monitor the soft starter thermal model overload temperature

(not available on MCD 201)

Parameters can also be uploaded to or downloaded from MCD 500

soft starters on Modbus, DeviceNet or PROFIBUS networks.

In order for the MCD 500 to accept commands from the serial

network, the soft starter must be in Auto On mode and links must

be fitted to terminals 17 and 25 to 18. In Hand On mode, the starter

will not accept commands from the serial network but the starter’s

status can still be monitored.

The following information is a general guide to MCD 500 and MCD

200 bus options. Refer to the relevant installation instructions and

users manual for more detail.

Danfoss Drives · DKDD.PB.551.A1.02 | 45

Page 46

MCD 500 with Control Panel VLT® LCP 501

The VLT® LCP 501, Cat. No. 175G0096 ensures seamless plug and

play communication and control of VLT® Soft Starter MCD 500.

Full control and monitoring

The screen view set-up is selected from 7 standard views and one

user programmable.

Language selection:

English, Chinese, German, Spanish, Portuguese, French, Italian,

Russian.

The VLT® LCP 501 is connected to the MCD 500 by using a 3 m cable

using 9 pin (D-sub) plug and 3m cable provided with the IP 65

(NEMA 12) door-mount kit.

Control Panel VLT® LCP 501

• Same user interface as VLT® Soft Starter MCD 500

• Plug & play with MCD 500

• Copy/ paste of parameters

• Multiple monitoring setup

• Door-mount kit – 3 m cable

• IP 65 (NEMA 12)

The MCD LCP 501 (Cat. No: 175G0096) can be connected directly to

the dedicated output on MCD 500 (v10 and later). The LCP 501 can

be mounted up to 3 metres away from the starter, for control and

monitoring. The starter can be controlled and programmed from

either the remote LCP or the LCP on the starter. Both displays show

the same information.

46 | Danfoss Drives · DKDD.PB.551.A1.02

Page 47

MCD500

(Auto On mode)

Cat. No: 175G0096

Notes

• MCD LCP 501 includes one LCP and complete mounting kit (3

metre cable, gasket, screws).

• No set-up or configuration is required for the Control Panel VLT®

LCP 501. No external power is required.

• Control Panel VLT® LCP 501 can be used to transfer parameters

between multiple starters with the same software version.

• Control Panel VLT® LCP 501 is not compatible with MCD 200 soft

starters.

• Upgrade kit is available to enable use with MCD 500 v9 and

earlier.

Danfoss Drives · DKDD.PB.551.A1.02 | 47

Page 48

MCD 500 Modbus Option

This requires an MCD Modbus Module which clips onto the side of

the MCD 500 (Cat. No: 175G9000).

MCD

MCD500

(Auto On mode)

Notes:

• A single Modbus Module is required for each MCD 500.

• Modbus Module settings are provided using two 8-way DIP

switches on the module.

• Up to 31 Modbus Modules can be used as Modbus slave devices

on a single Modbus RTU network.

• The Modbus Module is powered by the MCD 500.

• For more information about operating the MCD Modbus Module,

refer to the Installation Instructions (MG.17.Fx.02), located at

www.danfoss.com/drives.

Modbus

Module

-

B6

GND

B7

+

B8

Cat. No: 175G9000

RS485

connection

onto a

Modbus

RTU

network

48 | Danfoss Drives · DKDD.PB.551.A1.02

Page 49

MCD 500 DeviceNet Option

This requires an MCD DeviceNet Module which clips onto the side

of the MCD 500 (Cat. No: 175G9002).

MCD

MCD500

(Auto On mode)

Notes

• A single DeviceNet Module is required for each MCD 500.

• DeviceNet node address (MAC ID) and data rate are selected

using three rotary switches on the DeviceNet Module.

• Up to 63 DeviceNet Modules can be used as DeviceNet slaves on

a single DeviceNet network.

• The DeviceNet Module is powered via the network cable.

• The MCD DeviceNet Module is ODVA tested and certified.

• For more information on the MCD DeviceNet Module, refer to the

Installation Instructions (MG.17.Hx.02), located at

www.danfoss.com/drives.

DeviceNet

Module

(V+)

RD

(CAN-H)

WH

(SHIELD)

(CAN-L)

BU

(V-)

BK

Cat. No: 175G9002

Standard 5-wire

connection onto a

DeviceNet network.

120 termination

resistors are required

at end of each end

of the network cable.

Danfoss Drives · DKDD.PB.551.A1.02 | 49

Page 50

MCD 500 Probus Option

This requires an MCD PROFIBUS Module which clips onto the side

of the MCD 500 (Cat. No: 175G9001).

MCD

MCD500

PROFIBUS

Module

Standard

DB9

connection

Cat. No: 175G9001

PROFIBUS DP

network cable

Notes:

• A single PROFIBUS Module is required for each MCD 500.

• The PROFIBUS node address is selected using two rotary

switches. Data rate is automatically detected.

• Up to 31 PROFIBUS Modules can be used as PROFIBUS slaves on a

single PROFIBUS DP network.

• The PROFIBUS Module requires an external 24 VDC auxiliary

supply.

• The MCD PROFIBUS Module is PROFIBUS tested and certified.

• For more information on the MCD PROFIBUS Module, refer to the

Installation Instructions (MG.17.Gx.02) at www.danfoss.com/

drives

50 | Danfoss Drives · DKDD.PB.551.A1.02

Page 51

MCD 500 USB Option

This is achieved using the MCD USB Module

(Cat. No: 175G9009).

MCD500

MCD

USB

Module

USB cable

Cat. No: 175G9009

Notes

• A single USB Module is required for each MCD 500

• The USB Module acts as a physical interface when using PC based

Master software such as WinMaster V4.x or MCT 10

• Driver software must be installed before the USB Module can be

used (supplied with the module on CD-ROM).

• For more information on the MCD USB Module, refer to the

Installation Instructions (MI.17.Cx.02) located at www.danfoss.

com/drives

PC

Danfoss Drives · DKDD.PB.551.A1.02 | 51

Page 52

MCD 200 with MCD Remote Operator Option

Cat. No: 175G9004

This requires an MCD Serial Interface Module which clips onto the

side of the MCD 200. It is supplied with the MCD Remote Operator

when ordering Cat. No: 175G9004.

MCD Remote Operator

RS485

Starter

-

GND GND

+

RS485

Network

B1

B2

B3

B6

B7

B8

-

+

MCD200

MCD

Serial

Interface

Module

69

GND

61

+

68

-

Notes

• A single MCD Remote Operator and MCD Serial interface Module

is required for each MCD 200.

• No set-up or conguration is required for operation.

• If two Remote Operators are required, the RS485 Network side

of the rst Remote Operator (terminals B6, B7, B8) must be connected to the RS485 Starter side of the second Remote Operator

(terminals B1, B2, B3). The rst Remote Operator is ordered using

Cat. No: 175G9004 and the second Remote Operator is ordered

using Cat. No: 175G3061.

• The Serial Interface Module is powered by the MCD 200. The

Remote Operator requires an external 18-30 VAC/DC auxiliary

supply.

• For more information on the MCD Remote Operator, refer to the

User Manual (MG.17.Ex.02)) located at www.danfoss.com/drives.

52 | Danfoss Drives · DKDD.PB.551.A1.02

Page 53

Cat. No: 175G9000

MCD 200 Modbus Option

There are two options to connect an MCD 200 to a Modbus network.

Option 1: Using an MCD Modbus Module (Cat. No: 175G9000)

MCD

MCD200

Notes

• A single Modbus Module is required for each MCD 200.

• Modbus Module settings are provided using two 8-way

DIP switches on the module.

• Up to 31 Modbus Modules can be used as Modbus slave devices

on a single Modbus RTU network.

• The Modbus Module is powered-up by the MCD 200.

• For more information about operating the MCD Modbus Module,

refer to the Installation Instructions (MG.17.Fx.02), located at

www.danfoss.com/drives.

Modbus

Module

-

B6

GND

B7

+

B8

RS485

connection

onto a

Modbus

RTU

network

Danfoss Drives · DKDD.PB.551.A1.02 | 53

Page 54

MCD 200 Modbus Option

Option 2: Using the MCD Remote Operator as a Modbus RTU

Gateway device (Cat. No: 175G9004)

MCD Remote Operator

RS485

Starter

B1

GND GND

B2

+

B3

Cat. No: 175G9004

RS485

Network

B6

B7

B8

-

+

RS485

connection

onto a

Modbus

RTU

network

MCD200

MCD

Serial

Interface

Module

69

GND

61

68

-

+

Notes:

• A single Remote operator and Serial Interface Module

is required for each MCD 200.

• Parameters 1 to 5 of the Remote Operator are used to set it up

as a Modbus slave device.

• Up to 31 Remote Operators can be used as Modbus slave devices

on a single Modbus network.

• The Serial Interface Module is powered via the MCD200. The

Remote Operator requires an external 18-30 VAC/DC auxiliary

supply.

• For more information about operating the MCD Remote Operator

as a Modbus RTU gateway, refer to the Installation Instructions

(MG.17.Fx.02), Appendix A, located at www.danfoss.com/drives.

54 | Danfoss Drives · DKDD.PB.551.A1.02

Page 55

MCD 200 DeviceNet Option

This requires an MCD DeviceNet Module which clips onto the side

of the MCD 200 (Cat. No: 175G9002).

MCD

MCD200

Notes

• A single DeviceNet Module is required for each MCD 200.

• DeviceNet node address (MAC ID) and data rate are selected

using three rotary switches on the DeviceNet Module.

• Up to 63 DeviceNet Modules can be used as DeviceNet slaves

on a single DeviceNet network.

• The DeviceNet Module is powered via the network cable.

• The MCD DeviceNet Module is ODVA tested and certied.

• For more information on the MCD DeviceNet Module, refer to the

Installation Instructions (MG.17.Hx.02), located at

www.danfoss.com/drives.

DeviceNet

Module

(V+)

RD

(CAN-H)

WH

(SHIELD)

(CAN-L)

BU

(V-)

BK

Cat. No: 175G9002

Standard 5-wire

connection onto a

DeviceNet network.

120 termination

resistors are required

at end of each end

of the network cable.

Danfoss Drives · DKDD.PB.551.A1.02 | 55

Page 56

MCD 200 Probus Option

This requires an MCD Probus Module which clips onto the side of

the MCD 200 (Cat. No: 175G9001).

MCD

MCD200

Profibus

Module

Standard

DB9

connection

Cat. No: 175G9001

Profibus DP

network cable

Notes:

• A single Probus Module is required for each MCD 200.

• Probus node address is selected using two rotary switches.

Data rate is automatically detected.

• Up to 31 Probus Modules can be used as Probus slaves

on a single Probus DP network.

• The Probus Module requires and external 24 VDC auxiliary supply.

• The MCD Probus Module is Probus tested and certied.

• For more information on the MCD Probus Module, refer to the

Installation Instructions (MG.17.Gx.02) at www.danfoss.com/drives.

56 | Danfoss Drives · DKDD.PB.551.A1.02

Page 57

MCD 200 USB Option

This is achieved using the MCD USB Module

(Cat. No: 175G9009).

MCD200

MCD

USB

Module

USB cable

Cat. No: 175G9009

Notes

• A single USB Module is required for each MCD 200

• The USB Module acts as a physical interface

when using PC based Master software such as

WinMaster V4.x or MCT10

• Driver software must be installed before the USB

Module can be used (supplied with the module

on CD-ROM).

• For more information on the MCD USB Module,

refer to the Installation Instructions (MI.17.Cx.02)

located at www.danfoss.com/drives

PC

Danfoss Drives · DKDD.PB.551.A1.02 | 57

Page 58

Glossary

AAC – Adaptive Acceleration Control. A new soft start control

technique that allows the soft starter to estimate the motor’s speed

and control it to match a selected acceleration or deceleration profile.

AC53 Utilisation Code – The specification of a soft starter’s

current rating and intended operating conditions.

Auger – a device which uses a screw-like mechanism to move

material or liquid, similar to the process that drives shavings up a

drill bit and out of a hole during drilling.

Blower – see Fan.

Bow thruster – a steering mechanism in large ships which uses

an impeller to force water through a tunnel in the bow below the

waterline, causing the ship to turn.

Centrifuge – a machine which separates materials of different

densities (e.g. solids from liquids or liquids from liquid mixtures).

Chipper – a machine which cuts large pieces of wood into chips.

Compressor, centrifugal – a machine which accelerates gas

through a housing then converts the velocity energy to pressure

energy. Normally used in heavy industrial applications.

Compressor, positive displacement – see Compressor, reciprocating.

Compressor, piston – see Compressor, reciprocating.

Compressor, reciprocating – a machine which compresses gas using

pistons driven by a crankshaf t. Small reciprocating compressors (up

to 30 HP) are suitable for intermittent use and are commonly found in

automotive applications. Larger units (up to 1000 HP) may be used for

large industrial applications.

Compressor, screw – a machine which forces gas into a smaller

space, using two meshed rotating positive-displacement screws.

Crusher – a machine which crushes material into smaller pieces.

Crusher, cone – a crusher consisting of two cones inside each other.

Material is fed into the top of the large, outer cone and is broken into

progressively smaller pieces by the rotation of the inverted inner cone.

58 | Danfoss Drives · DKDD.PB.551.A1.02

Page 59

Glossary

Crusher, jaw – a crusher with one fixed side and one moving “jaw”. The

crusher is wider at the top than the bottom, and material is fed in at the

top and moves down as it is broken into progressively smaller pieces.

Crusher, roller – a crusher with two horizontal rollers which rotate

in opposite directions, crushing the material into smaller pieces.

Current limit – (1) a method of soft starting a motor by limiting the

maximum amount of current the motor can draw during the start.

(2) The maximum amount of current the soft starter will allow a

motor to draw during a current limit start.

Current ramp – a method of soft starting a motor by gradually

increasing the amount of current from a specified point to the

current limit.

Debarker – a machine that strips bark from logs.

Decanter – a type of centrifuge.

Edger – a machine that cuts large pieces of timber into usable sizes.

Escalator – a type of conveyor which is used to move people up or

down, much like a moving staircase.

Fan, axial – a fan with blades that turn around a shaft, forcing air

along the shaft and across the axis of the fan.

Fan, centrifugal – a fan which pulls air in near the shaft and forces

it out through an opening in the outer edge of the fan casing. A

centrifugal fan produces more pressure for a given air volume than

an axial fan.

Fan, radial – see Fan, centrifugal.

Full load current – the amount of current a motor will draw when

operating fully loaded and at full speed.

Full load torque – the amount of torque a motor will produce

when operating fully loaded and at full speed.

Grinder – a machine which reduces the size of small particles

through compression and attrition. For machines operating on

larger items, see Crusher.

Danfoss Drives · DKDD.PB.551.A1.02 | 59

Page 60

Glossary

Gyratory crusher – see Crusher, cone.

Hydraulic power pack – A hydraulic pump which is used to supply

pressurised hydraulic fluid.

IP rating – a description of the soft starter’s level of physical

protection, according to IEC 60529.

Kickstart – a method of soft starting a motor which uses a high

level of current for a short period at the beginning of a current limit

or current ramp start.

Locked rotor current – the amount of current a motor will draw in

locked rotor situations, including full voltage starts. Locked rotor

current is described as a percentage of full load current.

Locked rotor time – the maximum amount of time a motor can

safely run at locked rotor current.

Locked rotor torque – the amount of torque a motor will produce

at locked rotor current (such as a full voltage start). Locked rotor

torque is described as a percentage of full load torque.

Mill, ball – a machine which grinds or mixes materials such as

ores, chemicals, ceramics and paints. The machine consists of a

horizontal cylinder which is rotated, causing the grinding medium,

commonly stainless steel balls, to repeatedly crush the material

inside into a powder.

Mill, hammer – a machine which crushes material into smaller

pieces. Hammers attached to rotating disks repeatedly strike the

material until it is small enough to fall through openings at the

bottom of the mill.

Mill, roller – a machine which crushes material into smaller pieces.

Material is passed between two horizontal rollers which rotate in

opposite directions, crushing the material into smaller pieces.

Milliscreen – a machine which separates solids from slurry, using

an inclined rotating drum with perforated sides.

Mixer – a machine which combines ingredients.

60 | Danfoss Drives · DKDD.PB.551.A1.02

Page 61

Glossary

Nameplate rating – See Full load current.

NEMA – a description of the soft starter’s physical format, accord-

ing to the National Electrical Manufacturers’ Association standard.

Pelletiser – a machine which turns powders into pellets.

Planer – a machine which draws boards over a cutting head to

reduce them to a specified thickness.

Press – a machine which changes the shape and internal structure

of metals (usually steel).

Pump – a machine which moves fluids.

Pump, bore – a submersible pump with a small diameter, suitable

for operation down bores.

Pump, centrifugal – a pump with an impeller which causes fluid

to rotate and move from the inlet to the outlet under its own

momentum. The fluid’s velocity increases as it progresses through

the impeller passage. Diffuser, ring or volute cavities reduce the

velocity of the fluid and convert the energy into pressure energy.

Pump, positive displacement – a pump which reduces the

volume of the pump chamber to cause the fluid to move. Positive

displacement pumps may be used for viscous fluids, and include

rotary (lobe, screw or gear pump) and reciprocating (piston or

diaphragm pump) types.

Pump, slurry – a centrifugal pump for pumping slurry.

Pump, submersible – a pump which is submerged in the fluid to

be pumped. The sealed motor is close-coupled to the pump body.

Pump, vacuum – a pump which removes gas from a sealed

chamber in order to create a partial vacuum. Multiple vacuum

pumps may be used together for a single application.

Re-pulper – a machine which re-pulps raw product for further

processing.

Rotary table – a large rotating table which is used to sort or move

material.

Danfoss Drives · DKDD.PB.551.A1.02 | 61

Page 62

Glossary

Sander – a machine which smooths raw material by abrading the

surface.

Saw – a machine which uses a serrated edge to cut materials.

Saw, band – a saw where the cutting edge is a long, thin strip of

metal with teeth on one side, commonly used for ripping lumber.

Saw, circular – a saw where the cutting edge is a large rotating

disk with teeth on the outer edge.

Screw feed – see Auger.

Separator – a type of centrifuge.

Shredder – a machine that tears objects such as paper, plastic or

wood into smaller pieces.

Slabber – a machine consisting of several saws, which cuts edged

logs into smaller pieces before further processing.

Slicer – a machine that slices materials, normally using more than

one blade.

Travelat or – a type of conveyor which is used to move people

along a flat or inclined surface.

Tumbler – a machine which rotates to turn material over during

drying or other processes.

Vibrating screen – a machine which separates particles of different sizes by vibrating horizontally. Smaller particles fall through

gaps in the plane.

Winch – a machine which winds ropes or cables.

Wire draw machine – a machine which draws metal wire through

progressively narrower dies to create finer wire.

62 | Danfoss Drives · DKDD.PB.551.A1.02

Page 63

Abbreviations

AC – Alternating Current

DC – Direct Current

DOL – Direct On Line

FLC – Full Load Current

FLT – Full Load Torque

HRC – High Rupturing Capacity

IP – Ingress Protection

kW – Kilowatt

LRC – Locked Rotor Current

MCCB – Moulded Case Circuit Breaker

PFC – Power Factor Correction

SCR – Silicon Controlled Rectier

TVR – Time Voltage Ramp

Danfoss Drives · DKDD.PB.551.A1.02 | 63

Page 64

Loading...

Loading...