Danfoss Electronics VLT HVAC Drive Catalog

MAKING MODERN LIVING POSSIBLE

VLT® HVAC Drive

For HVAC it has to be VLT®

1.5 mio

VLT® HVAC Drives

reliably perform tasks in HVAC systems.

Rely on proven VLT® technology – now

with PM motor control for e cient

control of EC and IEC standard motors.

56%

Energy use reduction

in Mumbai’s VSNL building. ‘Only by using

Variable Frequency Drives in the HVAC system

could we achieve this target’ – General

Manager VSNL, India.

VLT® HVAC Drive provides the lowest life-time cost

The VLT® HVAC Drive is the safe choice for fan,

pump or compressor applications.

It provides a high exibility with regard to the site

of installation, range of available bus systems,

broadest HVAC control intelligence and functionality, and respects the building environment by

o ering the best EMC and harmonics behaviour on

the market.

The HVAC Drive o ers the highest e ciency solution with both asynchronous motors and perma-

The VLT® HVAC Drive includes:

■ > 98% basic energy e ciency

■ Automatic Energy Optimisation

■ User-friendly operation

■ Programming in 27 languages

■ VLT® quality up to 1.4 MW

Save money

The modular design enables the user

greater exibility to select from a

range of functional performance

requirements to secure the best cost

advantage for their application needs.

nent magnet motors. It can log and record its own

energy load pro le for both the estimation and

validation of actual energy savings.

The VLT® HVAC Drive is a singular engineering

platform for all your variable speed needs, designed

to minimize the total applied system cost and

lifecycle cost.

In everything we do, Danfoss is a clean tech company.

Easy commissioning

■ Application menus

■ Quick menu

■ Motor Rotation Check

■ PID-auto tuning

2

High ambient temperature

The robust VLT® HVAC Drive is

design ed to work at maximum output

in an ambient temperature up to

50° C. At higher temperatures, the

drive will continue operation with

lower performance.

Automatic derating enables reduced

operation for a period of time at

higher ambient temperatures to

maintain operation of the HVAC

system.

Maintenance free

Due to a series of self-protecting

and monitoring features and a highly

durable mechanical design, the

VLT® HVAC Drive is maintenance free,

except for general cleaning.

No replacement of internal fans or

capacitors is required.

Save space

Due to its compact dimensions, the

VLT® HVAC Drive is easily mounted

inside an HVAC unit or panel, reducing

overall enclosure costs and freeing up

panel backspace for other devices.

Save energy

The energy consumption from HVAC

applications such as fans and pumps

rises with the cube of the ow.

That’s the reason why VLT® control of

such applications typically saves 48%

energy compared to on-o operation.

Fire Override Mode

Fire Override Mode helps keep re

escape routes free of smoke, overrides

the drive’s self-protecting features and

keeps the driven equipment running

as long as possible in the event of re.

Activating Fire Override Mode will

ensure the VLT® HVAC Drive ignores

“soft“ faults and alarms to continue

operation during essential services

such as a “ re” command.

Save cabinet

We o er a standard & integrated IP55/

Type 12 protection class equal to that

of the motor.

This eliminates the cost of a separate

enclosure and saves on the additional

installation costs associated with

installation in a remote location.

IP 66/Type 4x Indoor

for harsh environments

The IP 66/Type 4x enclosure option for

harsh environments can eliminate the

cost of a separate enclosure and

reduce the installation costs associated with remote installations.

EMC & network protection

Fully integrated EMC lters

eliminate the cost of installing

external EMC lters and secure

the highest integrity & fully tested

EMC performance.

All versions of VLT® HVAC Drive

comply as standard with EMC

limits according to the EN 61800-3

norm (page 13).

All A1 and B lter options are

available as factory built-in

options.

The standard integrated DC coils

also ensure low harmonic load on

the network within EN 61000-3-12

and increase the lifespan of the

DC link capacitors. They also

ensure that the drive can operate

motors to their full rated

performance.

For further protection against

harmonic disturbances of the

supply grid, Danfoss provides

passive solutions such as 12/18

pulse solutions and Advanved

Harmonic Filters (AHF).

Active solutions

Danfoss also provides active

solutions such as Low Harmonic

Drives, combining standard drives

with an active lter and standalone VLT® Advanced Active

Filters (AAF).

Proven reliability

The rst VLT® HVAC Drive – the VLT® 100 from 1983 – has proven the reliability

of VLT® drives. Original VLT® HVAC Drives installed in1983 are still functioning

reliably over 20 years later.

Global Marine

VLT®

Micro

Drive

VLT® 5 VLT® 100 VLT® 1000 VLT® 3000 HVAC VLT® 2000

196 8 1983 1988 1989 1993 199 6 1998 200 0 200 4 200 6-2 008

VLT® 3500 HVAC

VLT® 5000 book

VLT® 6000 HVAC VLT® 2800 VLT® FCD 300 VLT® AutomationD rive VLT® HVAC Drive

VLT® 5000

VLT® Drive Motor

FCM 300

VLT® AQUA Drive

Power Drives

VLT® High

VLT® Integrated

VLT® Decentral

Drive FCD 302

VLT®

VLT® OneGearDrive

12-P uls e Dri ve

VLT® Advanced

Active Filter

VLT® High Power

Drives up to 1.4 MW

2010 -2011 2013-

Servo Drive

3

VLT® HVAC Drives

make your building green

Expect optimisation

Danfoss’ long experience in applying

drives in HVAC systems has enhanced

its ability to o er a “Best in Class”

technical expertise in integrating the

drive into the overall system design.

This extracts the maximum value

from your initial investment and

optimizes the operational savings

performance.

The 21st Century focus on energy

e ciency is not new with regard to

energy saving, but the emphasis on

the consequences of wasted energy

and the over-use of fossil fuels to

produce energy, is at the top of the

agenda.

Climate Change is seen as a cost to

the human race more than simply a

nancial cost.

Save energy

and CO2 emission

VLT® frequency converters save more

than 20 million MWh of energy

globally each year. This is equivalent

to the annual electricity consumption

of 5 million homes.

This energy saving reduces annual

CO2 emissions of over 12 million tons!

Makes the building perform

Today the prime focus is on the

overall performance of buildings

including design, construction,

e ciency, sustainability and the

environmental impact of these

buildings in the future.

Energy e cient products form part of

this overall plan. In most countries

around the world this is now realized

in the evaluation of high performance

buildings under the banner LEED.

We o er you a wealth

of knowledge

The various applications incorporated

within high performance buildings

are well understood by Danfoss and

as a global market leader, we have

built a wealth of knowledge and

understanding of the applications

and developed products and technology to ensure we meet and

determine future trends in this

industry. Our 40 years of experience

in this business have made the VLT®

HVAC Drive the industry benchmark.

Premier drive in the market

The e ciency of the VLT® HVAC Drive

and its built-in features make the VLT®

HVAC Drive the premier drive in the

market today.

Danfoss’ application and industry

knowledge will ensure that the

investment made in VLT® drives

provides a quali ed return.

Financial incentives are just as

important as moral incentives to

encourage people to choose energy

e cient solutions.

4

Reliable and cost e ective

Correct drive selection is critical to

reliability. Products that introduce

unacceptable levels of RFI or

harmonics into a building can prove

highly problematic and costly in

addition to breaking legislative

regulations.

Danfoss’ many years of experience in

the application of VLT® drives and in

the HVAC industry in particular, has

resulted in a global team focused on

delivering the best drives solution,

ensuring total security of your

investment.

Minimum impact

on the environment

Having chosen to t a VLT® drive as

part of the building control architecture, the lifetime sustainability of this

product is an important aspect.

New regulations are forcing manufacturers to look at how they manufacture, what they manufacture and with

what materials.

Are products harmful to make? Are

they harmful to dispose of at their

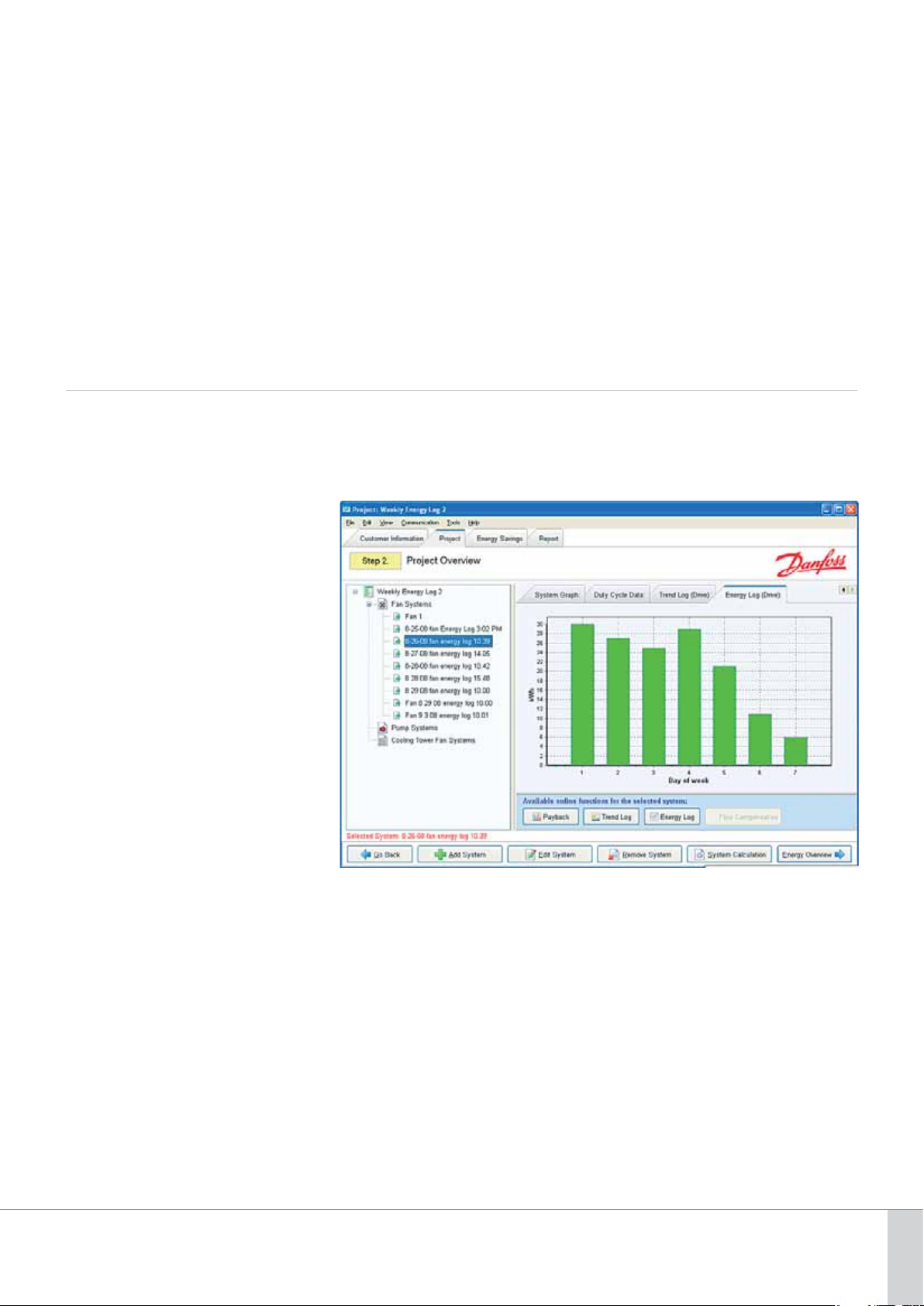

Energy documentation

VLT® Energy Box software is

the most modern and

advanced energy calculation

tool available.

end-of-life? Danfoss complies with

RoHS, WEEE Directives, ISO14001; all

standards and directives created to

ensure the minimum impact on the

environment.

Energy monitoring

The VLT® HVAC Drive provides a

complete range of energy consumption information. Choose to divide

absolute energy consumption into

hours, days or weeks or to monitor a

load pro le for the application.

It allows energy consumption calculations and comparisons of HVAC fans,

pumps and cooling tower applications

driven by Danfoss drives and alternative methods of ow control.

The program compares the total

operational costs of various traditional

systems to operation of the same

systems with a VLT® HVAC Drive.

With this program it is easy to evaluate

the savings by comparing a VLT® HVAC

Drive over other types of capa city

control systems in both new installations as well as retro t situations.

Complete nancial analysis

VLT® Energy Box provides a complete

nancial analysis including:

■ Initial cost for the drive system and

the alternative system

■ Installation and hardware costs

■ Annual maintenance costs and any

utility company incentives for

energy conservation products

■ Payback time and accumulated

savings

■ Upload of actual energy consump-

tion (kWh) and duty cycle from the

VLT® HVAC Drive

VLT® Energy Box makes it possible to

capture actual energy data from the

drives and monitor energy consumption and overall system e ciency.

Energy audit

The VLT® HVAC Drive coupled with

Energy Box software enables the

package to be used as the Energy

Audit equipment for both the estimation and validation of savings.

VLT® HVAC Drive can be interrogated

remotely for full energy data, making

it easy to monitor your energy savings

and return on investment. Monitoring

via eldbus often makes energy

meters omissible.

5

Danfoss VLT® HVAC Drive provides

lowest cost of ownership

Total Cost of Ownership is an

organization’s total cost of acquiring, operating and maintaining a

system through a given lifecycle.

Total Cost of Ownership includes

initial acquisition cost and operating

cost. Through its technology and

experience, Danfoss can transform

this into the “Bene t of Ownership”.

We understand the needs of our

customers, operating their facilities in

a competitive environment which

requires total system cost e ective -

Cost

Commissioning and installation

Purchase

Energy

Disposal

Time

ness and highest e ciency in daily

operations with environmental

sustainability.

Danfoss dedicated HVAC

organization at your side

Customer assurance stems from

Danfoss’ dedicated and highly

experienced HVAC support team.

It has the depth of understanding in

HVAC applications that ensures the

maximum bene t is extracted from

the customers’ investment in VLT®

drive systems.

Reducing acquisition costs

■ Fully integrated EMC & Harmonic

compliant solution

■ IP 21/55/66; Type 1/12/4x

■ Extensive HVAC functions to

reduce other system components

■ Extendable I/O to reduce total

BMS costs

■ Ease of installation and set-up

Total lifetime cost

Reducing operating costs

■ Minimum 98% e ciency

■ Energy metering

■ Automatic Energy Optimisation

■ Design lifetime of 10 years

■ Danfoss legacy and history in

HVAC applications

■ IP enclosures and optional

conformal coating to provide

robust & reliable performance in

the harshest of environments

■ 50° C ambient temperature

without derating

■ Auto derate functions above 50

■ Broadest range of drive

o

and motor protection

■ Maintenance free drive

■ System diagnostics

Enhanced advanced

monitoring

Enhanced advanced application

monitoring functionality for fans

allows you to also keep track of the

status of pumps and compressors.

This can mean increased lifetime,

reduced maintenance costs, and less

downtime.

6

Supporting software tool

Software tools are available to help

design a system with minimal

harmonics and best energy e ciency.

Protection mode

As soon as the system detects a critical

status, (e.g. over-current or overvoltage) the frequency of the VLT®

HVAC Drive will automatically be

reduced and the modulation process

adjusted.

Due to its ability to limit its switching

operations, the VLT® HVAC Drive is

extremely reliable and robust.

The protection mode will – if

allowable – end after 10 seconds and

the frequency will be restored under

control.

Minimum 98% e ciency

The VLT® HVAC Drive sets new

standards with a minimum 98%

e ciency at full load. This reduces

initial costs and operating costs due to

the smaller heat load/air conditioning

requirement in the switchroom/

plantroom, thereby maximizing

energy e ciency. Every kW of losses

requires another ~0.5 kW of energy to

remove the heat.

Installed in an air conditioned switchroom, lower losses can easily result in

operating cost savings >5% – 10% of

the cost of the drive every year (based

on a typical load pro le, with the drive

operating 24/7). Also energy

consumption and CO2 emissions are

reduced.

High Ambient

Temp er at ur es

VLT® HVAC Drive is designed to

operate in ambient temperatures

up to 50o C with an autoderate

capability for higher temperatures in

order to maintain reduced operation

in extreme climate conditions.

In most cases, the VLT® HVAC Drive

will handle abnormal situations

without needing attention.

VLT® HVAC Drive will manage the loss

of a mains phase or a high mains

imbalance by autoderating speed and

load to maintain a period of reduced

operation, enabling technicians to

respond to the situation.

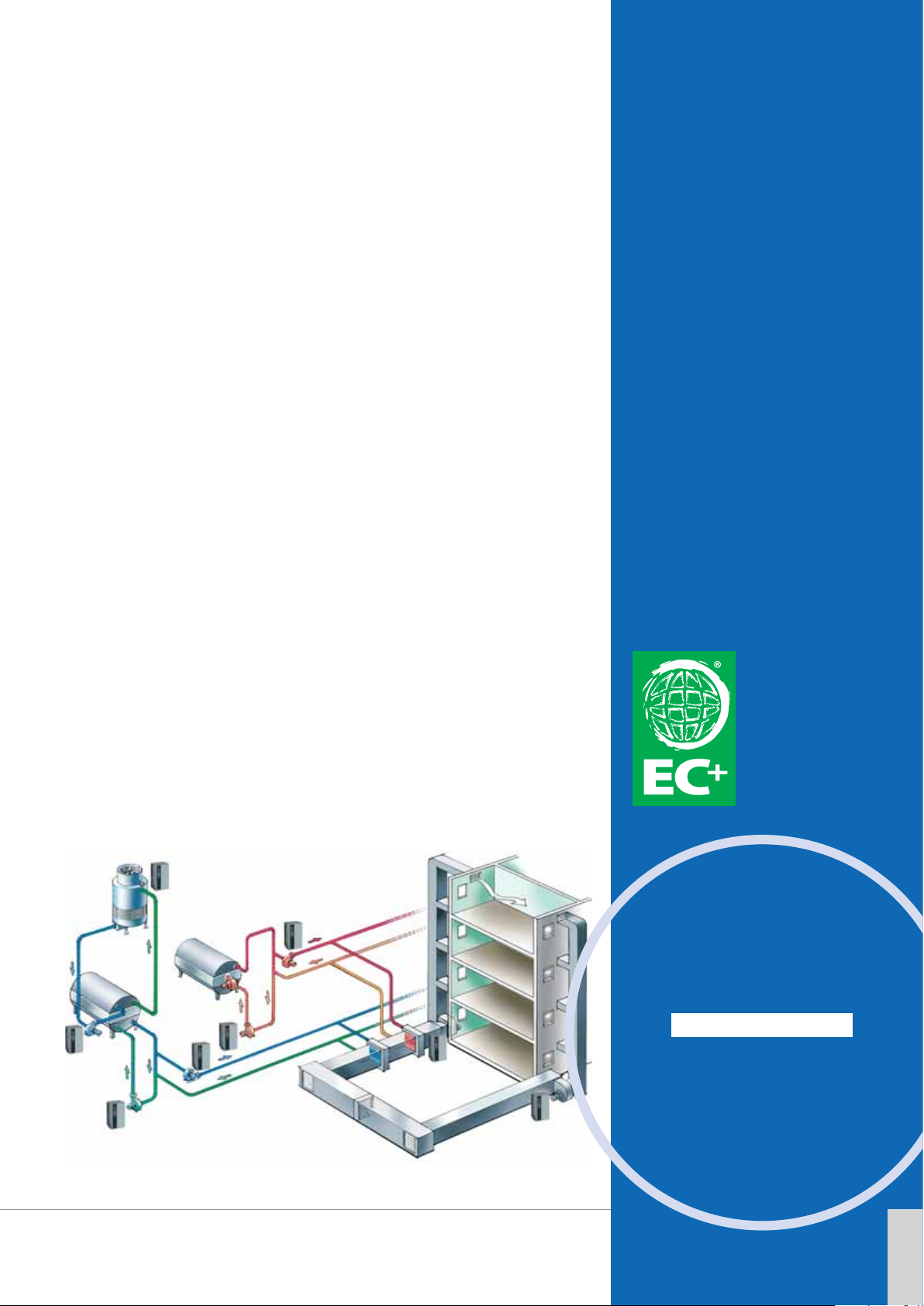

NEW!

The Danfoss EC+ concept...

... enables the use of PM motors in

IEC-standard sizes with Danfoss

VLT® frequency converters.

After entering the relevant motor

data, you bene t from the high

e ciency of EC technology in all

applications.

The necessary control algorithm

has been embedded in dedicated

VLT® series drives.

Bene ts of the EC + concept:

■ Free choice of motor tech-

nology: PM or asynchronous

with the same frequency

converter

■ Operation and installation of

the VLT® drive remain the same

■ Vendor-independent selection

of all components

■ Best system e ciency by

combining e ciency-optimized

components

■ Retro t of existing plant

■ Supports a broad range of

standard and PM motors

GOAL

e ciency

Our goal is the highest e ciency

with the lowest energy consumption and with the lowest overall

system cost for our customers

= ‘The Bene t of Ownership’.

7

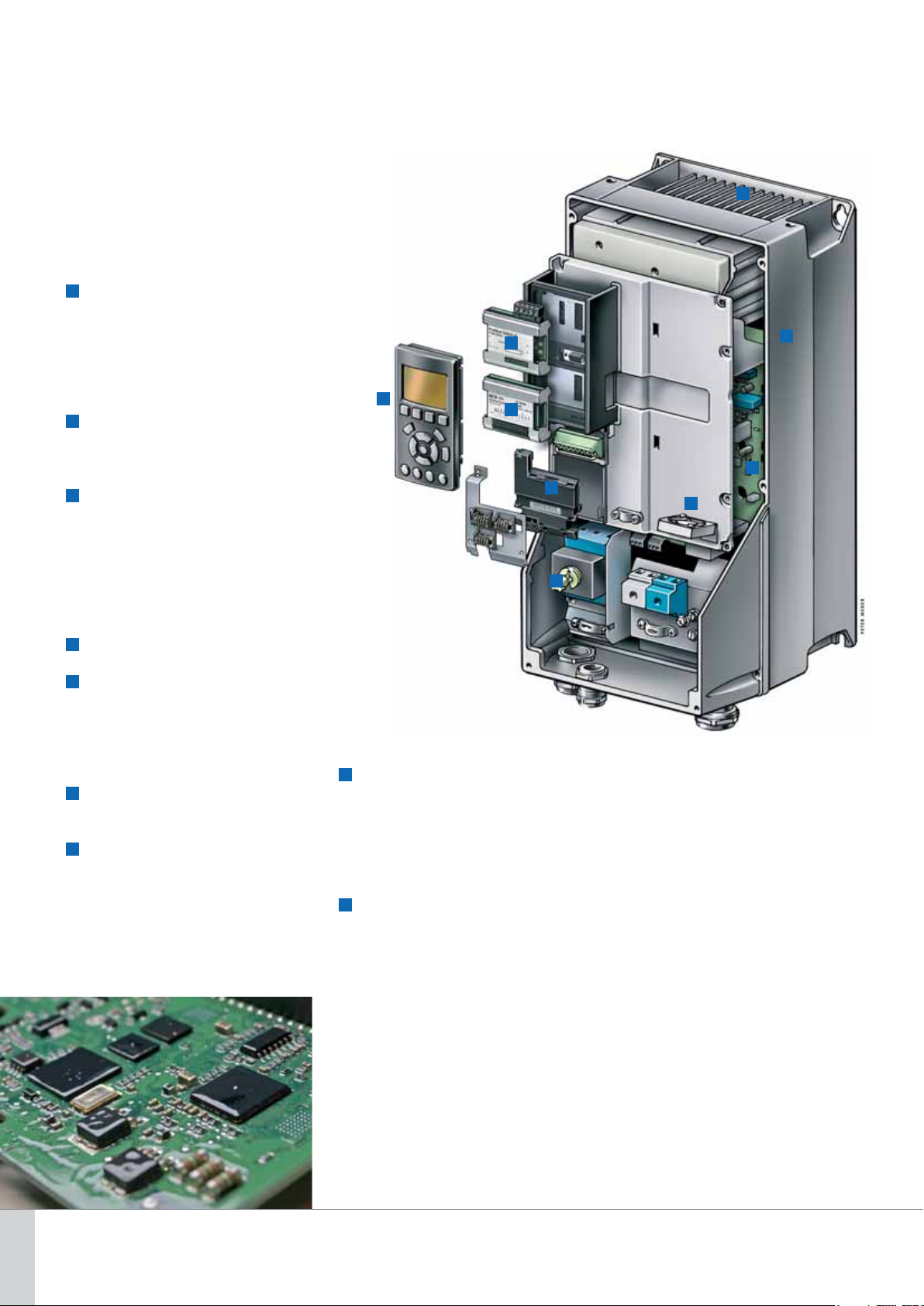

The modular VLT® HVAC Drive

– not too much – nor too little

The VLT® HVAC Drive is built on

Danfoss’ modular concept. Real

plug-and-play adding and

exchanging of options. Just upgrade

instead of buying a new drive.

1

Fieldbus option

– Advanced BACnet

– LonWorks

– Pro bus

– PROFINET

– DeviceNet

2

Local Control Panel (LCP)

Choose numerical,

graphical or no display

3

I/O option

– General Purpose I/O

(3DI + 2AI + 2DO + 1AO)

– Analog I/O option

(3AI (0 – 10 V / PT1000 /

NI 1000) + 3AO (0 – 10 V))

– Relay output (3 x relays)

4

24 V supply option

5

RFI lter

Built-in RFI lter for long

motor cables compliant with

the IEC 61800-3 and EN 55011

standards.

6

AC mains disconnect

(Factory mounted option)

7

Input mains option

Various input plate con gurations

are available including mains

switch (disconnect), or RFI lter.

Input plates are eld adaptable if

options need to be added after

installation.

1

2

The modula r design of the

VLT® HVAC Drive allows even h ighly

customised drives to be m ass

produced and fa ctory tested.

Plug-and -play options make

upgradin g easy and

ensure exibility.

8

Unique cooling concept

3

4

6

– No ambient air ow over the

electronics up to 90 kW

– Above 90 kW, designed with back

channel cooling (85% heat

dissipated via back channel)

9

Durable in aggressive

environments

In some HVAC applications, it is

recommended to protect the drive

with coated PCB’s. VLT® HVAC

Drive is designed for level 3C2

according to IEC 60721-3-3.

Protection level 3C3 is optionally

delivered from factory.

8

5

9

7

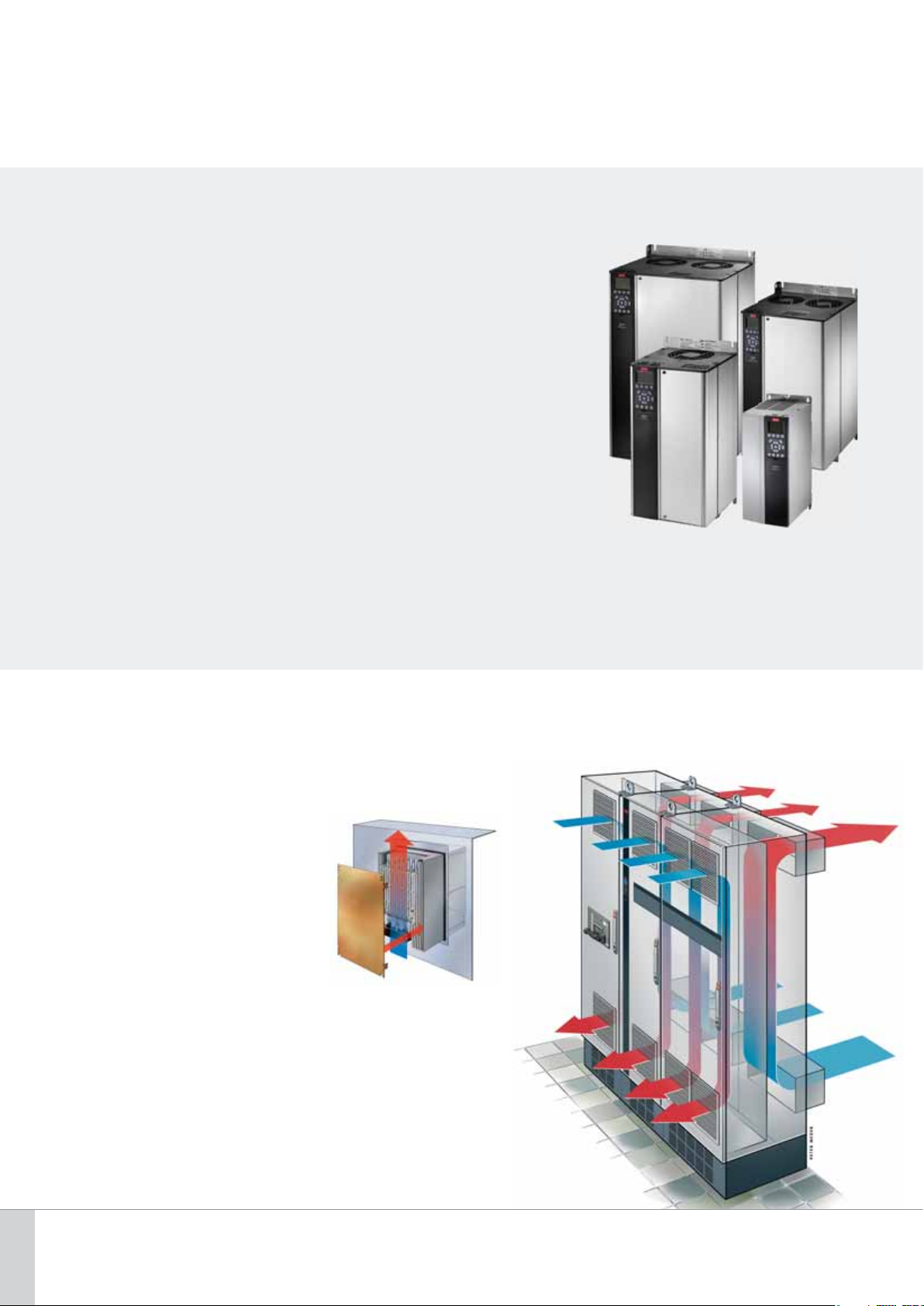

VLT® quality up to 1.4 MW

The VLT® HVAC Drive is available

from 1.1 kW to 1.4 MW.

Danfoss’ drive experience since 1968

lies behind the intelligent design of

VLT® drives.

All enclosures are mechanically

designed with focus on:

– Robustness

– Easy access and installation

– Intelligent cooling

– High ambient temperatures

This option o ers signi cantly

improved protection against

chlorine, hydrogen sulphide,

ammonia and other corrosive

environments.

8

The VLT® HVAC Drive is

hooked-up on your net

The VLT® HVAC Drive integrates and

communicates seamlessly with all

HVAC devices, mastered by Building

Management Systems via the eldbus.

HVAC-speci c features make it

economical, exible and user-friendly

and make HVAC operation simple.

Improve system performance

VLT® HVAC Drive uses limited network

bandwidth, and requires less

resources in the DDC controller due to

the support of alarm and event

noti cation.

This can reduce tra c by more than

50% compared to other drives.

With VLT® HVAC Drive it is possible to

read all the inputs and control all the

outputs on I/O options.

This means that when integrating a

VLT® HVAC Drive into the control

system it is possible to save by

requiring fewer physical I/O points.

Detailed information about

warnings and alarms

VLT® HVAC Drive has outputs giving

detailed information about alarms and

warnings. DDC controllers can

monitor these and see when an alarm

or warning occurs and why it

occurred.

Embedded eldbuses

■ Native BACnet

■ Modbus RTU (std.)

■ FC protocol

■ N2 Metasys

■ FLN Apogee

Optional eldbuses

■ Advanced BACnet

■ LonWorks

■ Pro bus

■ Devicenet

NEW!

■ Ethernet

Have BACnet your way

VLT® HVAC Drive comes with an

embedded BACnet protocol that

makes it suitable for most smaller

plants.

For larger plants, more system

performance is required.

The VLT® BACnet option is a plug-andplay solution that optimizes the use of

VLT® HVAC Drive together with

building management systems using

the BACnet® eldbus.

VLT® HVAC Drive has objects de ned

to accept 3 separate feedbacks

transmitted over BACnet.

This option makes it easy to control or

monitor points required in typical

HVAC applications.

Listed by BTL

The option has passed comprehensive

and long-lasting tests at the BTL

laboratories, which ensures that the

function will work together with any

other BLT-listed equipment.

9

VLT® HVAC drives

– optimized for installation in panels

IP 20/Type 1 enclosures

The installation volume and/or the

mounting surfaces are reduced by up

to 60% compared to the previous

VLT® series.

The functionality nevertheless ful lls

the highest requirements even for

applications with high overload, long

motor cables and ambient temperatures up to 50° C (55° C with derating).

Optimized design

Optimized e ciency and intelligent

cooling technology make for a

compact and service-friendly design.

Supplementary equipment such as

EMC lters, harmonics suppression

and brake modules are integrated

into the enclosure.

Save installation time

The IP20/NEMA 1 series is designed

for easy accessibility and time-saving

installation. Mechanical fastening

points are easy to access from the

front even with automatic tools.

All terminals are su ciently dimensioned and clearly marked. One need

only loosen a few screws to get to the

terminals.

Accessories for bonding screened

cables are included. The compact

enclosures are easier to install. This is

important especially within existing

installations with limited accessibility.

An extensive range of options and

accessories are available, optimizing

the drive for the respective

application.

Intelligent heat management

– variable cooling methods for di erent bene ts

Total separation between cooling air

and electronics protects the electronics and allows for installation

where heat is removed from outside

of the cabinets.

With the VLT® HVAC Drive, a anged

heat sink kit is available for mounting

the drive in the backplate of a cabinet,

separating the heatsink air ow from

the electronics.

Eliminating air ow over the electronics increases drive lifetime as

contaminants are excluded from the

drive.

Back channel cooling minimizes heat

loss increasing energy e ciency, a

signi cant bene t for high power

drives.

10

High reliability in any environment

All VLT® HVAC Drive versions have

manganese phosphor rear bodies.

IP66/Type 4x enclosed drives are

suitable for installation in demanding

environments (e.g. cooling towers).

Cooling air is kept outside the device

to prevent any pollution of the

electronics. The surfaces are smooth

and easily cleaned.

The IP55/66, Type 4x series are

designed for easy accessibility and

time-saving installation.

Furthermore, all components such as

EMC lters for compliance with

EN 55011, class A1/B, as well as the

DC coils, are protected inside the

drive.

NEW! Type 4x Indoor

VLT® HVAC Drive comes in the

extremely tight Type 4x enclosure.

Because of the high-density integration, the tight housings of the VLT®

HVAC Drive are signi cantly smaller

when compared to other drives of the

same performance.

Motor and power cables are mounted

securely through glands in the base

plate.

The VLT® HVAC Drive

is also available w ith

a mains switch

option. This switch

interrupts the m ains

supply and has a f ree

useable auxil iary

contact.

An external

watertight USB pl ug

connected to th e

control card inside I P

55/66 enclosures

makes USB access

easy.

11

The real e ect of VLT® HVAC drives is

– money-saving right through the chain

12

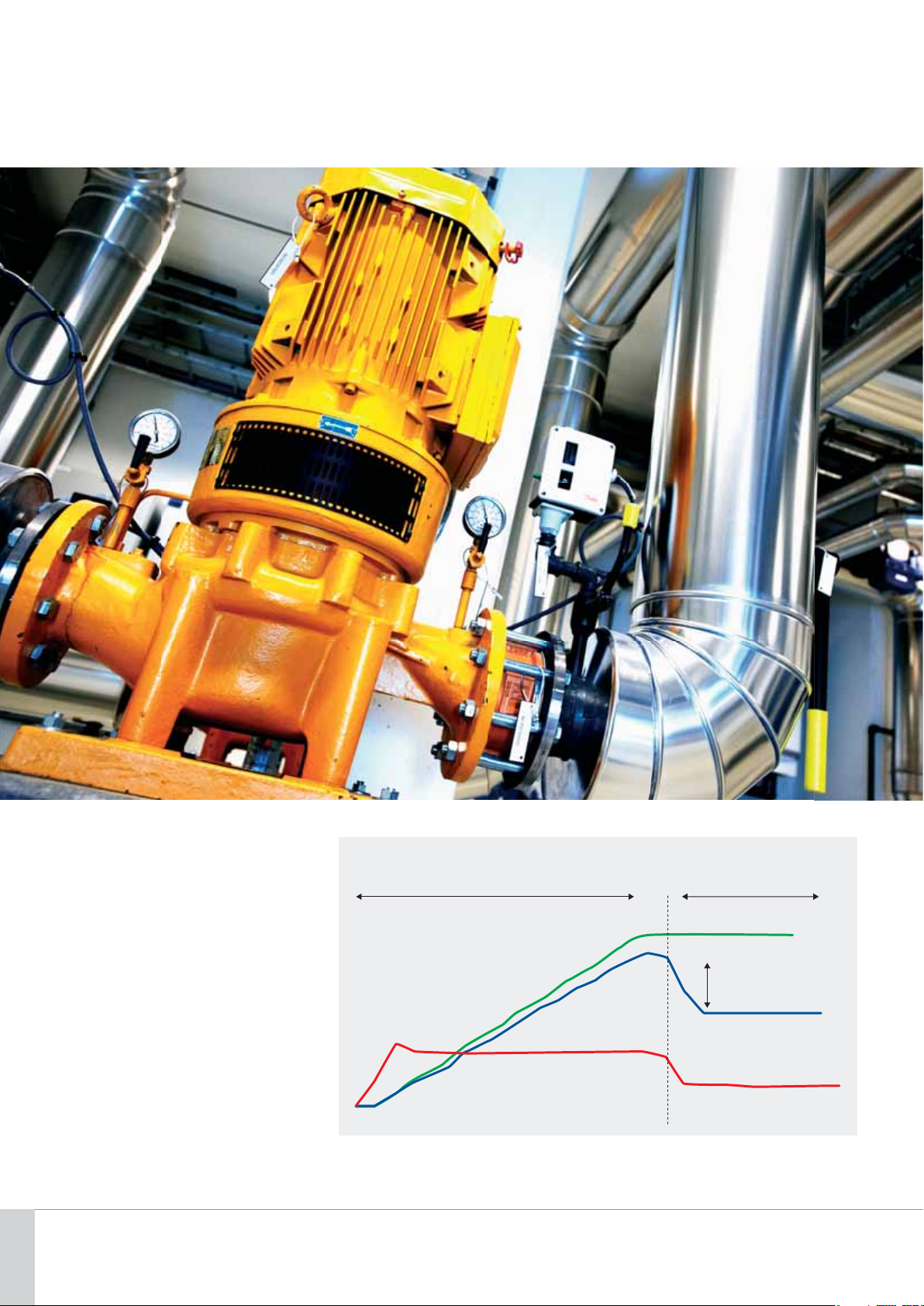

Automatic Energy

Optimisation

The standard AEO feature provides

optimized motor magnetization at all

speeds and loads.

This optimization program increases

the energy savings gained by applying

variable speed control.

Automatic Motor Adaptation

Enter the name plate data, and VLT®

HVAC Drive automatically adjusts to

the motor.

Suitable for ‘follower’

operation

The drive’s modular structure makes it

suitable for ‘follower’ operation

mastered by BMS, PLC’s or DDCs.

Automatic Energy Optimisation

AEO-adjustmentStart with high acceleration

Speed

Automatic load

adjustment

Motor voltage

Motor current

Loading...

Loading...