Page 1

MAKING MODERN LIVING POSSIBLE

Programming Guide

VLT® AutomationDrive

Page 2

Contents

Contents

VLT® AutomationDrive Programming Guide

1 Introduction

1.1.1 Approvals 3

1.1.2 Symbols 3

1.1.3 Definitions 3

1.1.4 Electrical Wiring - Control Cables 8

2 How to Programme

2.1 The Graphical and Numerical Local Control Panels

2.1.1 The LCD-Display 12

2.1.3 Display Mode 14

2.1.4 Display Mode - Selection of Read-Outs 14

2.1.5 Parameter Set-Up 15

2.1.6 Quick Menu Key Functions 15

2.1.8 Main Menu Mode 18

2.1.9 Parameter Selection 18

2.1.10 Changing Data 19

2.1.11 Changing a Text Value 19

2.1.12 Changing 19

3

11

11

2.1.13 Infinitely Variable Change of Numeric Data Value 19

2.1.14 Value, Step-by-Step 19

2.1.15 Read-out and Programming of Indexed Parameters 20

2.1.16 Local Control Keys 21

2.1.17 Initialisation to Default Settings 21

3 Parameter Descriptions

3.2 Parameters: 0-** Operation and Display

3.3 Parameters: 1-** Load and Motor

3.4 Parameters: 2-** Brakes

3.5 Parameters: 3-** Reference/Ramps

3.6 Parameters: 4-** Limits/Warnings

3.7 Parameters: 5-** Digital In/Out

3.8 Parameters: 6-** Analog In/Out

3.9 Parameters: 7-** Controllers

3.10 Parameters: 8-** Communications and Options

3.11 Parameters: 9-** Profibus

3.12 Parameters: 10-** DeviceNet CAN Fieldbus

23

24

34

52

57

67

72

91

100

106

112

112

3.13 Parameters: 12-** Ethernet

3.14 Parameters: 13-** Smart Logic Control

3.15 Parameters: 14-** Special Functions

3.16 Parameters: 15-** Drive Information

MG33MF02 - VLT® is a registered Danfoss trademark

112

112

125

133

1

Page 3

Contents

VLT® AutomationDrive Programming Guide

3.17 Parameters: 16-** Data Read-outs

3.18 Parameters: 17-** Motor Feedb. Option

3.19 Parameters: 18-** Data Readouts 2

3.20 Parameters: 30-** Special Features

3.21 Parameters: 35-** Sensor Input Option

4 Parameter Lists

4.1.1 Conversion 154

4.1.2 Active/Inactive Parameters in Different Drive Control Modes 154

5 Troubleshooting

5.1.1 Warnings/Alarm Messages 192

Index

138

145

147

148

151

153

192

204

2 MG33MF02 - VLT® is a registered Danfoss trademark

Page 4

Introduction

VLT® AutomationDrive Programming Guide

1 Introduction

Programming Guide

Software

This Programming Guide can be used for all FC 300 frequency

converters with software version 6.7x.

The software version number can be seen from 15-43 Software

Version.

Table 1.1

version: 6.7x

1.1.1 Approvals

Table 1.2

1.1.2 Symbols

The following symbols are used in this manual.

WARNING

Indicates a potentially hazardous situation which, if not

avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided,

may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

CAUTION

Indicates

property-damage-only accidents.

NOTE

Indicates

with attention to avoid mistakes or operate equipment at

less than optimal performance.

1.1.3 Definitions

Frequency converter

I

VLT,

Maximum output current.

a situation that may result in equipment or

highlighted information that should be regarded

MAX

I

VLT

,N

Rated output current supplied by the frequency converter.

U

VLT, MAX

Maximum output voltage.

Input

Control command

and stop the connected motor by means of LCP and

Start

digital inputs.

Functions are divided into two groups.

Functions in group 1 have higher priority than functions in

group 2.

Group 1 Reset, Coasting stop, Reset and Coasting stop,

Quick-stop,

Group 2 Start, Pulse start, Reversing, Start reversing, Jog

and

Table 1.3

DC braking, Stop and the [OFF] key.

Freeze output

Motor

Motor Running

Torque

generated on output shaft and speed from zero

rpm to max. speed on motor.

f

JOG

Motor frequency when the jog function is activated (via

digital terminals).

f

M

Motor frequency.

f

MAX

Maximum motor frequency.

f

MIN

Minimum motor frequency.

f

M,N

Rated motor frequency (nameplate data).

I

M

Motor current (actual).

I

M,N

Rated motor current (nameplate data).

n

M,N

Rated motor speed (nameplate data).

n

s

Synchronous motor speed

2 ×

par

=

. 1 − 23 × 60

par

. 1 − 39

n

s

n

slip

s

Motor slip.

P

M,N

Rated motor power (nameplate data in kW or HP).

1 1

MG33MF02 - VLT® is a registered Danfoss trademark

3

Page 5

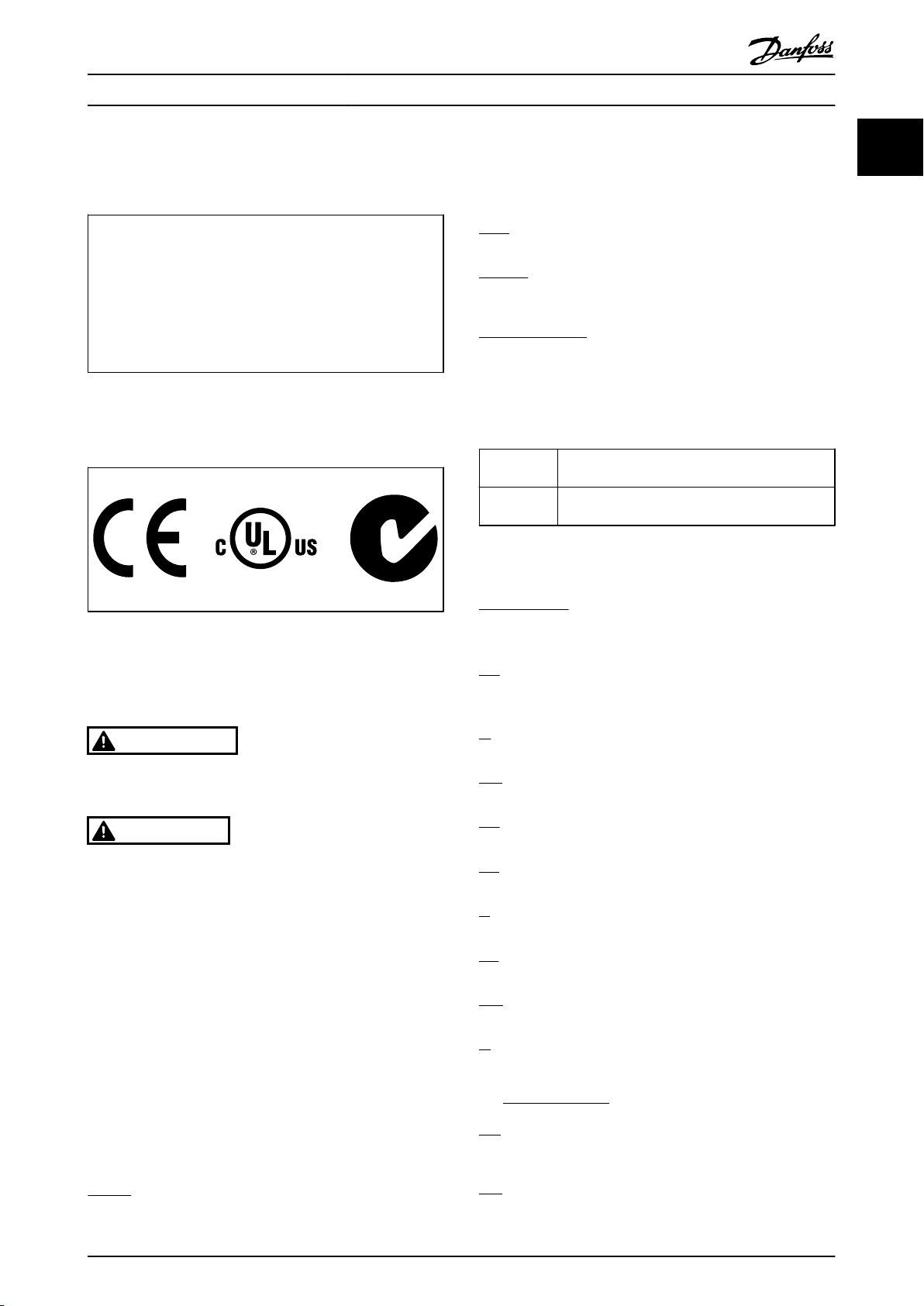

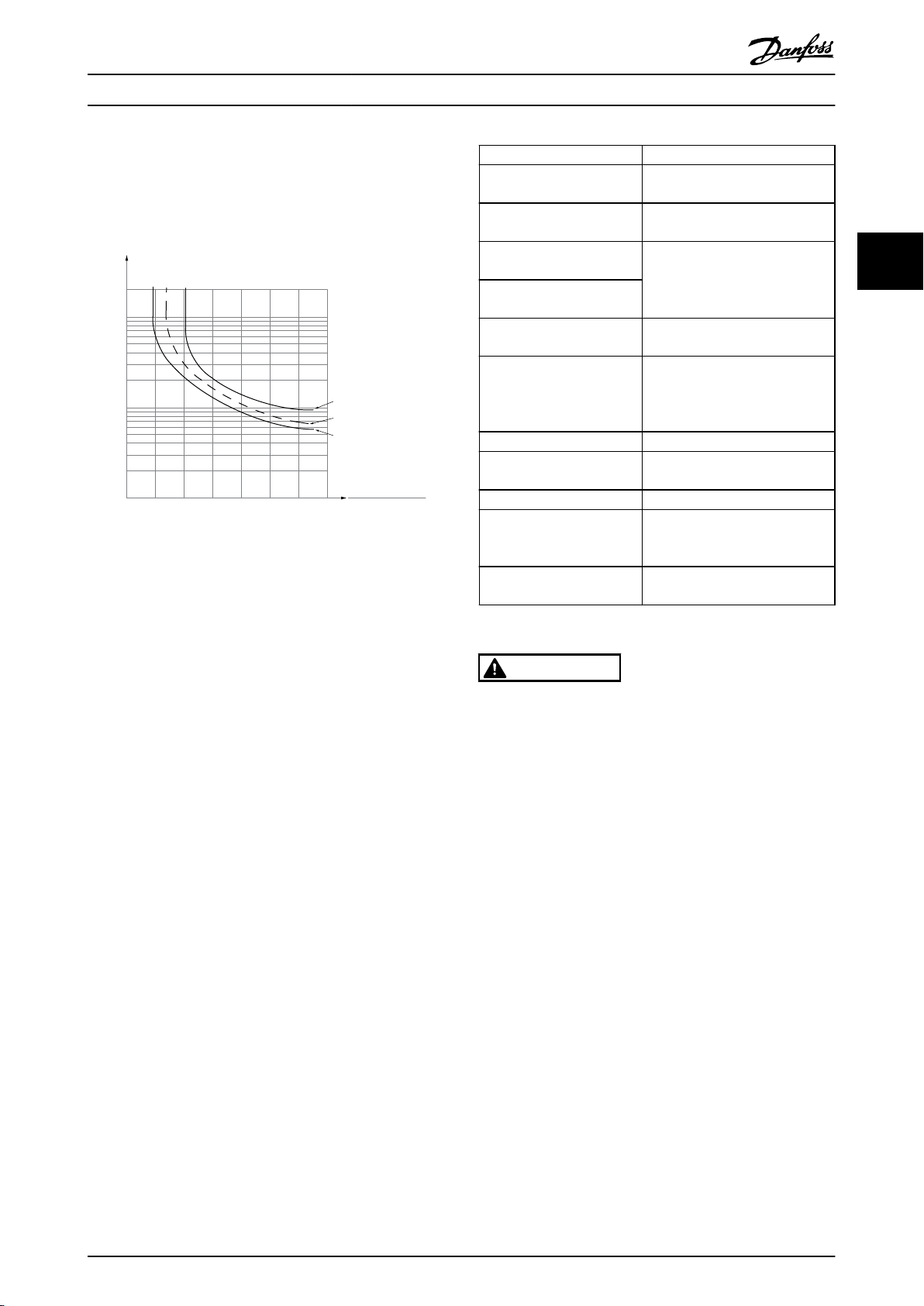

175ZA078.10

Pull-out

rpm

Torque

Introduction

VLT® AutomationDrive Programming Guide

11

T

M,N

Rated torque (motor).

Pulse Reference

pulse frequency signal transmitted to the digital inputs

A

(terminal 29 or 33).

U

M

Instantaneous motor voltage.

U

M,N

Rated motor voltage (nameplate data).

Break-away torque

Ref

MAX

Determines the relationship between the reference input

at

100% full scale value (typically 10 V, 20 mA) and the

resulting reference. The maximum reference value set in

3-03 Maximum Reference.

Ref

MIN

Determines the relationship between the reference input

0% value (typically 0 V, 0 mA, 4 mA) and the resulting

at

reference. The minimum reference value set in

3-02 Minimum Reference.

Miscellaneous

Analog Inputs

analog inputs are used for controlling various

The

functions of the frequency converter.

There are two types of analog inputs:

Current input, 0-20 mA and 4-20 mA

Voltage input, -10 to +10 V DC.

Analog Outputs

analog outputs can supply a signal of 0-20 mA, 4-20

The

mA.

Automatic Motor Adaptation, AMA

algorithm determines the electrical parameters for

AMA

Illustration 1.1

the connected motor at standstill.

Brake Resistor

brake resistor is a module capable of absorbing the

η

VLT

The efficiency of the frequency converter is defined as the

between the power output and the power input.

ratio

The

brake power generated in regenerative braking. This

regenerative braking power increases the intermediate

circuit voltage and a brake chopper ensures that the

power is transmitted to the brake resistor.

Start-disable command

stop command belonging to the group 1 control

A

commands - see this group.

Stop command

See

Control commands.

References

Analog Reference

A

signal transmitted to the analog inputs 53 or 54, can be

voltage or current.

Binary Reference

A

signal transmitted to the serial communication port.

Preset Reference

A

defined preset reference to be set from -100% to +100%

of the reference range. Selection of eight preset references

via the digital terminals.

CT Characteristics

Constant

torque characteristics used for all applications

such as conveyor belts, displacement pumps and cranes.

Digital Inputs

digital inputs can be used for controlling various

The

functions of the frequency converter.

Digital Outputs

frequency converter features two Solid State outputs

The

that can supply a 24 V DC (max. 40 mA) signal.

DSP

Signal Processor.

Digital

ETR

Electronic

Thermal Relay is a thermal load calculation

based on present load and time. Its purpose is to estimate

the motor temperature.

Hiperface

Hiperface®

®

is a registered trademark by Stegmann.

4 MG33MF02 - VLT® is a registered Danfoss trademark

Page 6

Introduction

VLT® AutomationDrive Programming Guide

Initialising

initialising is carried out (14-22 Operation Mode), the

If

frequency converter returns to the default setting.

Intermittent Duty Cycle

An intermittent duty rating refers to a sequence of duty

cycles. Each cycle consists of an on-load and an off-load

period. The operation can be either periodic duty or nonperiodic duty.

LCP

The Local Control Panel makes up a complete interface for

control and programming of the frequency converter. The

control panel is detachable and can be installed up to 3 m

from the frequency converter, i.e. in a front panel with the

installation kit option.

lsb

Least significant bit.

msb

Most significant bit.

MCM

Short for Mille Circular Mil, an American measuring unit for

cable cross-section. 1 MCM = 0.5067mm2.

On-line/Off-line Parameters

Changes

after the data value is changed. Changes to off-line

parameters are not activated until you enter [OK] on the

LCP.

Process PID

The

temperature, etc. by adjusting the output frequency to

match the varying load.

PCD

Process

Power Cycle

Switch

power on again.

Pulse Input/Incremental Encoder

An

information on motor speed. The encoder is used in

applications where great accuracy in speed control is

required.

RCD

Residual

Set-up

You

between the four parameter Set-ups and edit one Set-up,

while another Set-up is active.

SFAVM

Switching

Vector Modulation (14-00

to on-line parameters are activated immediately

PID control maintains the desired speed, pressure,

Control Data

off the mains until display (LCP) is dark – then turn

external, digital pulse transmitter used for feeding back

Current Device.

can save parameter settings in four Set-ups. Change

pattern called

Stator Flux oriented Asynchronous

Switching Pattern).

Slip Compensation

frequency converter compensates for the motor slip

The

by giving the frequency a supplement that follows the

measured motor load keeping the motor speed almost

constant.

Smart Logic Control (SLC)

SLC is a sequence of user defined actions executed

The

when the associated user defined events are evaluated as

true by the Smart Logic Controller. (Parameter group 13-**

Smart Logic Control (SLC).

STW

Status Word

FC Standard Bus

Includes RS-485 bus with FC protocol or MC protocol. See

8-30 Protocol.

Thermistor

temperature-dependent resistor placed where the

A

temperature is to be monitored (frequency converter or

motor).

Trip

state entered in fault situations, e.g. if the frequency

A

converter is subject to an over-temperature or when the

frequency converter is protecting the motor, process or

mechanism. Restart is prevented until the cause of the

fault has disappeared and the trip state is cancelled by

activating reset or, in some cases, by being programmed

to reset automatically. Trip may not be used for personal

safety.

Trip Locked

state entered in fault situations when the frequency

A

converter is protecting itself and requiring physical

intervention, e.g. if the frequency converter is subject to a

short circuit on the output. A locked trip can only be

cancelled by cutting off mains, removing the cause of the

fault, and reconnecting the frequency converter. Restart is

prevented until the trip state is cancelled by activating

reset or, in some cases, by being programmed to reset

automatically. Trip may not be used for personal safety.

VT Characteristics

Variable

VVC

If

Voltage Vector Control (VVC

and the stability, both when the speed reference is

changed and in relation to the load torque.

60° AVM

Switching

Modulation (14-00

Power Factor

The

torque characteristics used for pumps and fans.

plus

compared with standard voltage/frequency ratio control,

pattern called 60°

Switching Pattern).

power factor is the relation between I1 and I

plus

) improves the dynamics

Asynchronous Vector

RMS

.

1 1

MG33MF02 - VLT® is a registered Danfoss trademark

5

Page 7

Introduction

x U x I

cos

11

Power factor

=

3

x U x I

3

1

ϕ

RMS

The power factor for 3-phase control:

VLT® AutomationDrive Programming Guide

7. Please note that the frequency converter has

voltage sources than L1, L2 and L3, when

more

load sharing (linking of DC intermediate circuit)

or external 24 V DC are installed. Check that all

=

I1 x cos

I

RMS

ϕ1

=

I

RMS

I

1

since cos

ϕ1 = 1

The power factor indicates to which extent the frequency

converter imposes a load on the mains supply.

The lower the power factor, the higher the I

RMS

for the

same kW performance.

I

RMS

=

I

+

1

2

I

+

I

+ .. +

5

7

2

I

n

2

2

In addition, a high power factor indicates that the different

harmonic

currents are low.

The frequency converters' built-in DC coils produce a high

power factor, which minimizes the imposed load on the

mains supply.

Warning against unintended start

voltage sources have been disconnected and that

the necessary time has elapsed before

commencing repair work.

1. The motor can be brought to a stop by means of

digital commands, bus commands, references or

a local stop, while the frequency converter is

connected to mains. If personal safety considerations (e.g. risk of personal injury caused by

contact with moving machine parts following an

unintentional start) make it necessary to ensure

that no unintended start occurs, these stop

functions are not sufficient. In such cases the

mains supply must be disconnected or the Safe

WARNING

The voltage of the frequency converter is dangerous

whenever

motor, frequency converter or fieldbus may cause death,

serious personal injury or damage to the equipment.

Consequently, the instructions in this manual, as well as

national and local rules and safety regulations, must be

complied with.

Safety Regulations

connected to mains. Incorrect installation of the

1.

The mains supply to the frequency converter

must be disconnected whenever repair work is to

be carried out. Check that the mains supply has

been disconnected and that the necessary time

has elapsed before removing motor and mains

supply plugs.

2. [Off] does not disconnect the mains supply and

consequently it must not be used as a safety

switch.

3. The equipment must be properly earthed, the

user must be protected against supply voltage

and the motor must be protected against

overload in accordance with applicable national

NOTE

When using the Safe Stop function, always follow the

instructions in the section Safe Stop of the Design Guide.

Stop function must be activated.

2. The motor may start while setting the

parameters. If this means that personal safety

may be compromised (e.g. personal injury caused

by contact with moving machine parts), motor

starting must be prevented, for instance by use

of the Safe Stop function or secure disconnection

of the motor connection.

3. A motor that has been stopped with the mains

supply connected, may start if faults occur in the

electronics of the frequency converter, through

temporary overload or if a fault in the power

supply grid or motor connection is remedied. If

unintended start must be prevented for personal

safety reasons (e.g. risk of injury caused by

contact with moving machine parts), the normal

stop functions of the frequency converter are not

sufficient. In such cases the mains supply must be

disconnected or the Safe Stop function must be

activated.

and local regulations.

4. The earth leakage current exceeds 3.5 mA.

5. Protection against motor overload is not included

in the factory setting. If this function is desired,

set 1-90 Motor Thermal Protection to data value

ETR trip 1 [4] or data value ETR warning 1 [3].

6. Do not remove the plugs for the motor and

mains supply while the frequency converter is

4. Control signals from, or internally within, the

frequency

converter may in rare cases be

activated in error, be delayed or fail to occur

entirely. When used in situations where safety is

critical, e.g. when controlling the electromagnetic

brake function of a hoist application, these

control signals must not be relied on exclusively.

connected to mains. Check that the mains supply

has been disconnected and that the necessary

time has elapsed before removing motor and

mains plugs.

6 MG33MF02 - VLT® is a registered Danfoss trademark

Page 8

Introduction

VLT® AutomationDrive Programming Guide

WARNING

High Voltage

Touching

equipment has been disconnected from mains.

Also make sure that other voltage inputs have been

disconnected, such as external 24 V DC, load sharing

(linkage of DC intermediate circuit), as well as the motor

connection for kinetic back up.

Systems where frequency converters are installed must, if

necessary, be equipped with additional monitoring and

protective devices according to the valid safety regulations,

e.g law on mechanical tools, regulations for the prevention

of accidents etc. Modifications on the frequency converters

by means of the operating software are allowed.

NOTE

Hazardous

builder/ integrator who is responsible for taking necessary

preventive means into consideration. Additional

monitoring and protective devices may be included, always

according to valid national safety regulations, e.g. law on

mechanical tools, regulations for the prevention of

accidents.

the electrical parts may be fatal - even after the

situations shall be identified by the machine

1 1

NOTE

Lifts and Hoists:

Crane,

The controlling of external brakes must always have a

redundant system. The frequency converter can in no

circumstances be the primary safety circuit. Comply with

relevant standards, e.g.

Hoists and cranes: IEC 60204-32

Lifts: EN 81

Protection Mode

a hardware limit on motor current or dc-link voltage

Once

is exceeded the frequency converter will enter “Protection

mode”. “Protection mode” means a change of the PWM

modulation strategy and a low switching frequency to

minimize losses. This continues 10 s after the last fault and

increases the reliability and the robustness of the

frequency converter while re-establishing full control of the

motor.

In hoist applications “Protection mode” is not usable

because the frequency converter will usually not be able to

leave this mode again and therefore it will extend the time

before activating the brake – which is not recommendable.

The “Protection mode” can be disabled by setting

14-26 Trip Delay at Inverter Fault to zero which means that

the frequency converter will trip immediately if one of the

hardware limits is exceeded.

NOTE

is recommended to disable protection mode in hoisting

It

applications (14-26 Trip Delay at Inverter Fault = 0)

MG33MF02 - VLT® is a registered Danfoss trademark

7

Page 9

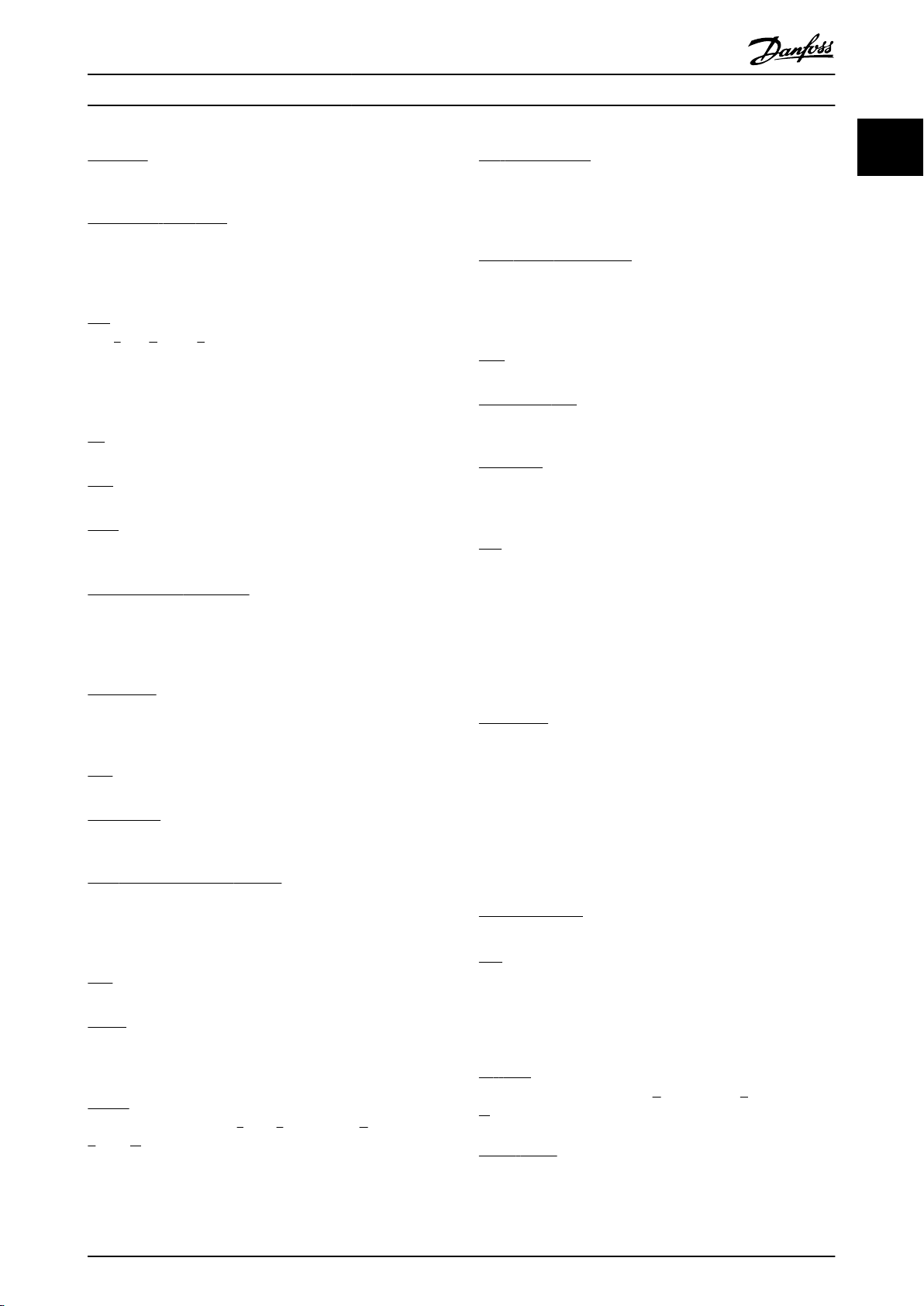

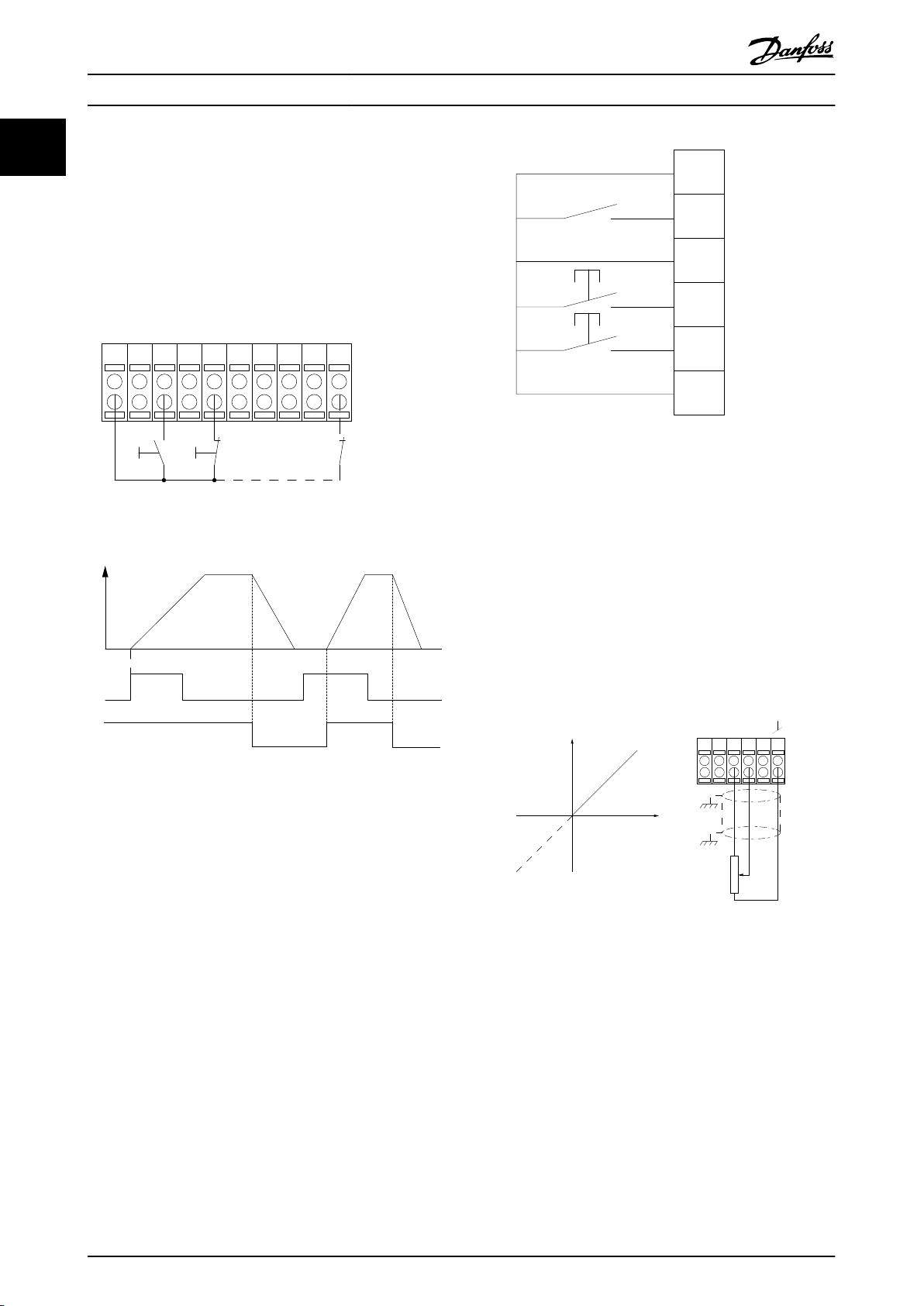

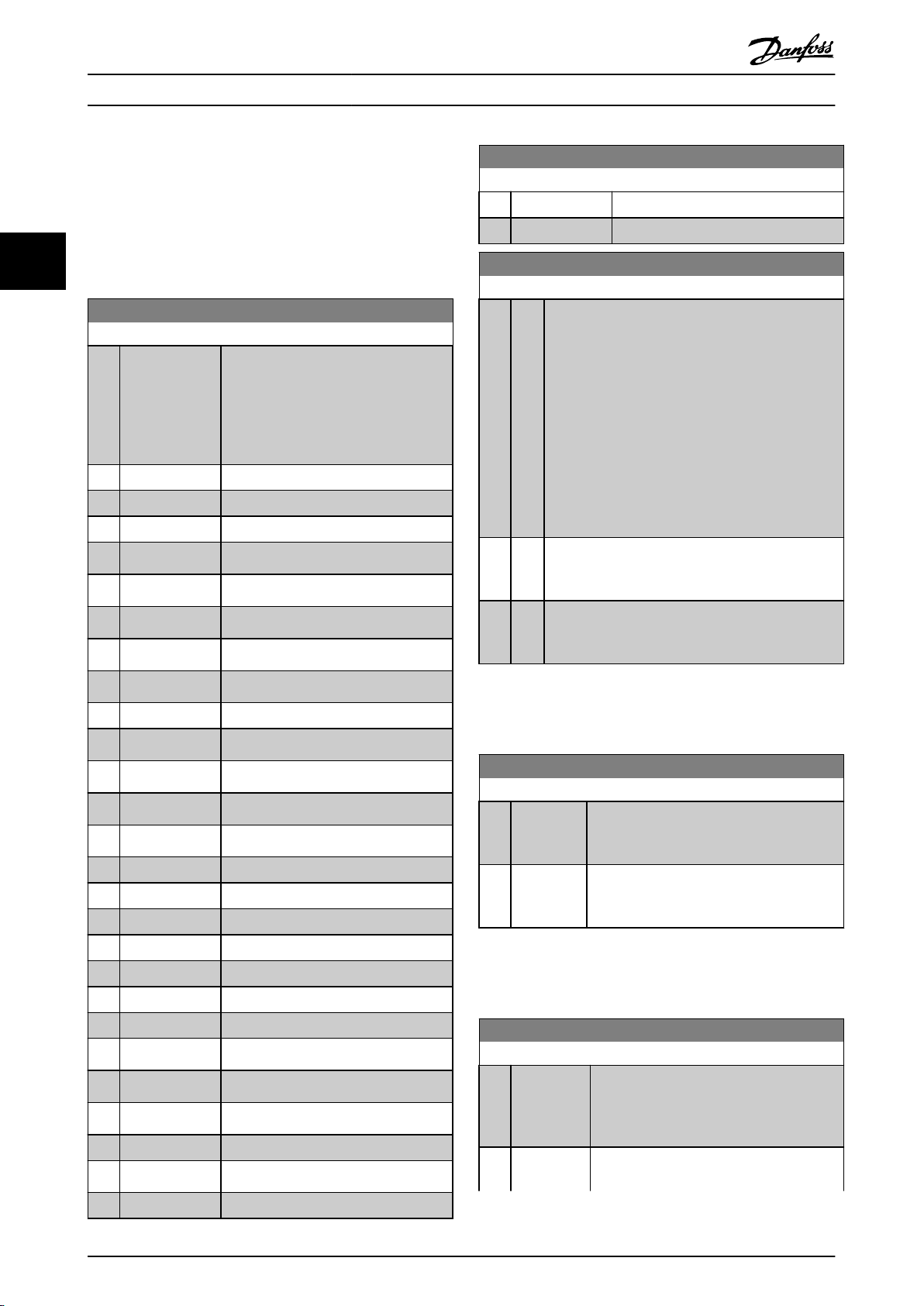

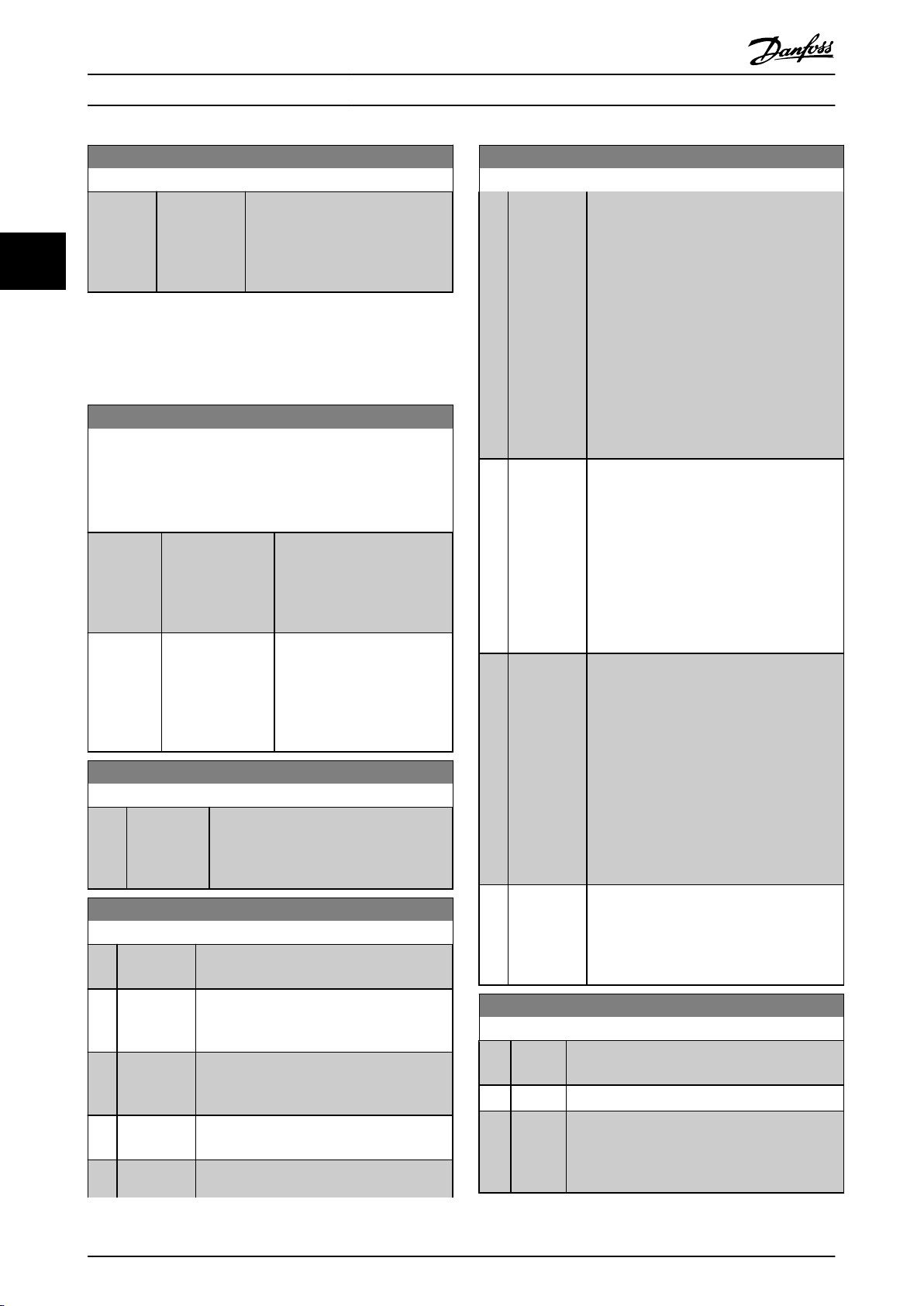

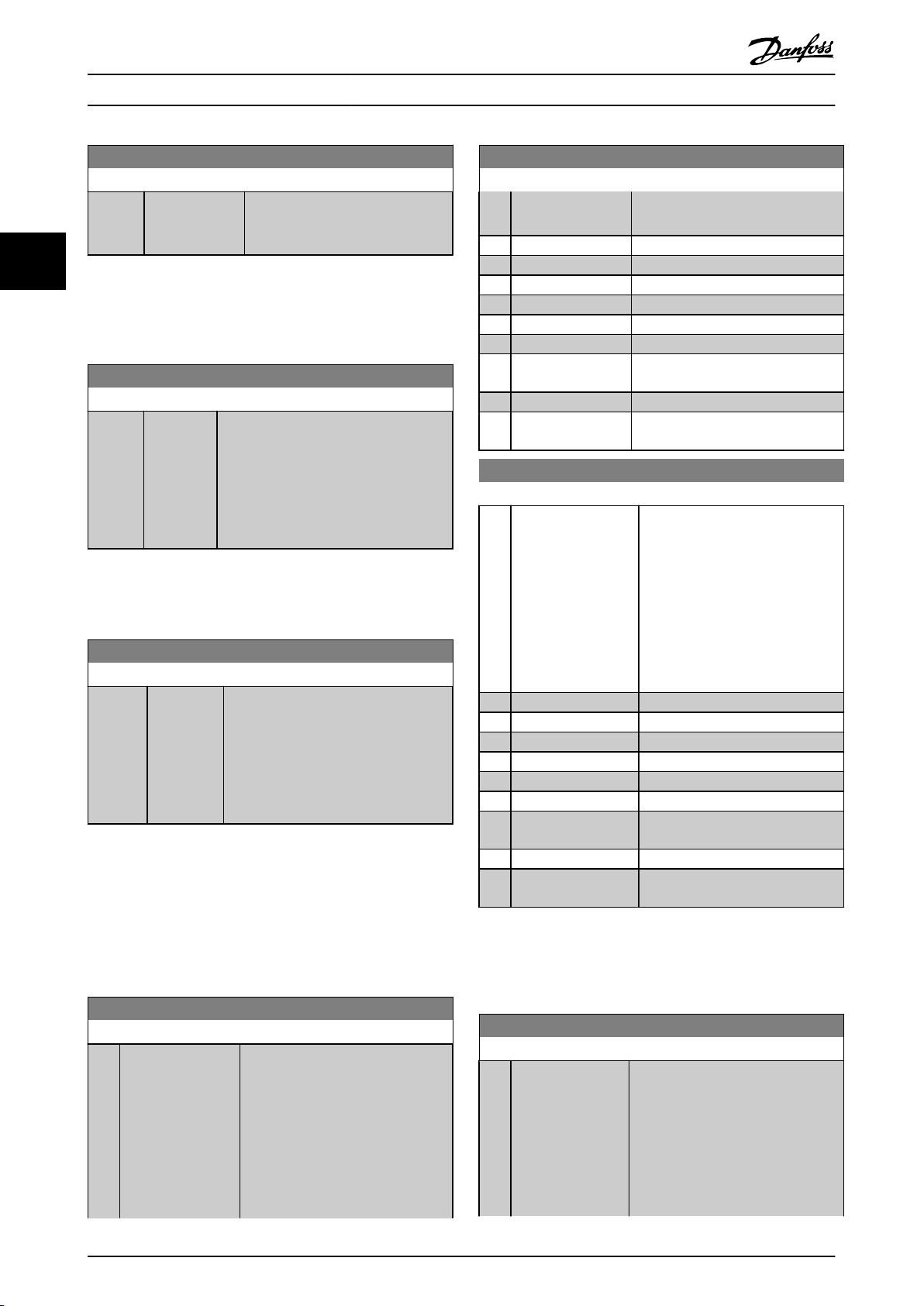

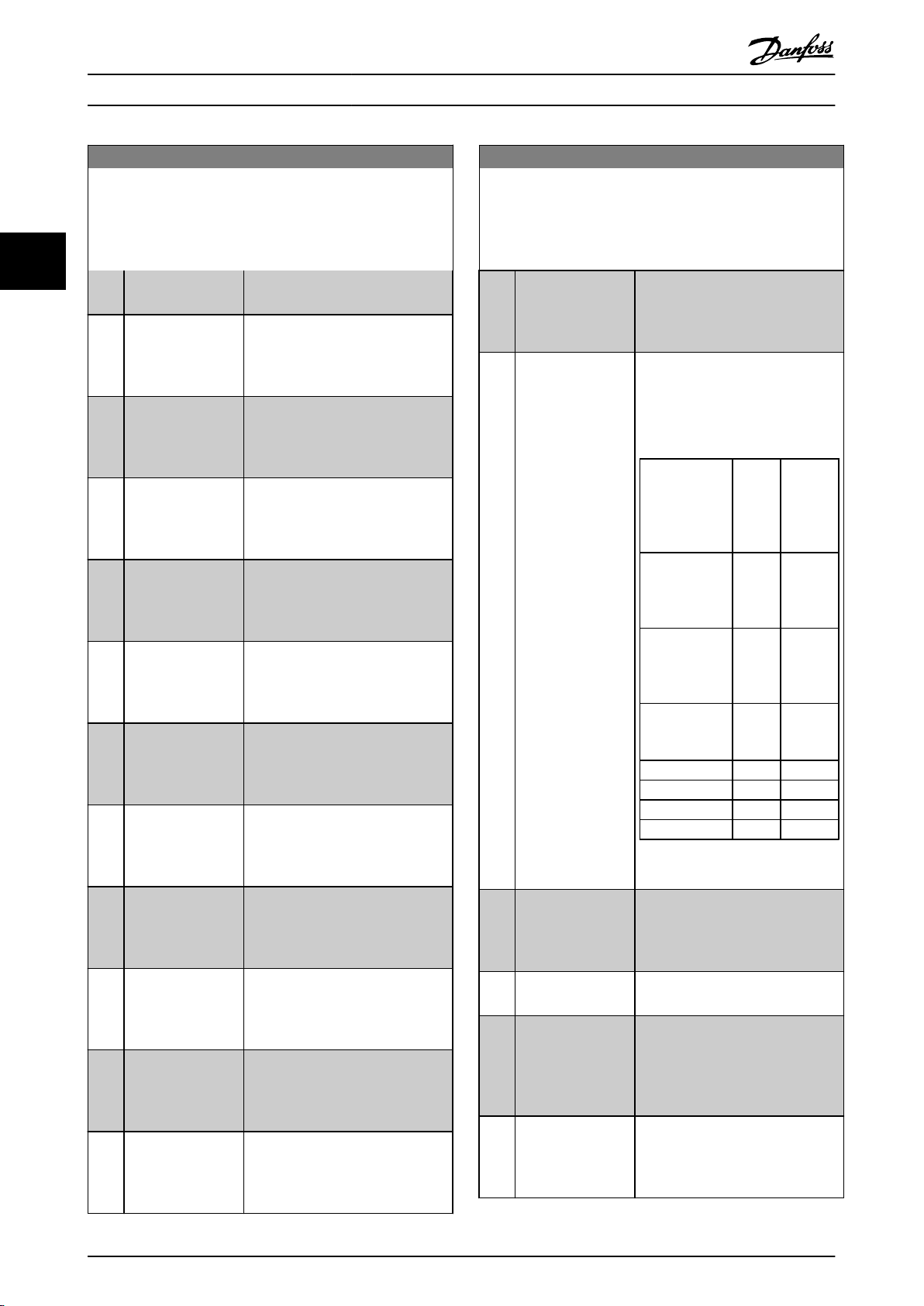

3 Phase

power

input

DC bus

Switch Mode

Power Supply

Motor

Analog Output

Interface

relay1

* relay2

ON=Terminated

OFF=Open

Brake

resistor

130BC931.10

91 (L1)

92 (L2)

93 (L3)

PE

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

0/4-20 mA

12 (+24V OUT)

13 (+24V OUT)

37 (D IN)

18 (D IN)

20 (COM D IN)

10Vdc

15mA 130/200mA

+ - + -

(U) 96

(V) 97

(W) 98

(PE) 99

(COM A OUT) 39

(A OUT) 42

(P RS-485) 68

(N RS-485) 69

(COM RS-485) 61

0V

5V

S801

0/4-20 mA

RS-485

RS-485

03

+10Vdc

0/-10Vdc -

+10Vdc

+10Vdc

0/4-20 mA

0/-10Vdc -

240Vac, 2A

24Vdc

02

01

05

04

06

240Vac, 2A

24V (NPN)

0V (PNP)

0V (PNP)

24V (NPN)

19 (D IN)

24V (NPN)

0V (PNP)

27

24V

0V

(D IN/OUT)

0V (PNP)

24V (NPN)

(D IN/OUT)

0V

24V

29

24V (NPN)

0V (PNP)

0V (PNP)

24V (NPN)

33 (D IN)

32 (D IN)

1 2

ON

S201

ON

21

S202

ON=0/4-20mA

OFF=0/-10Vdc +10Vdc

95

400Vac, 2A

P 5-00

21

ON

S801

(R+) 82

(R-) 81

*

*

: Chassis

: Earth

**

Introduction

VLT® AutomationDrive Programming Guide

11

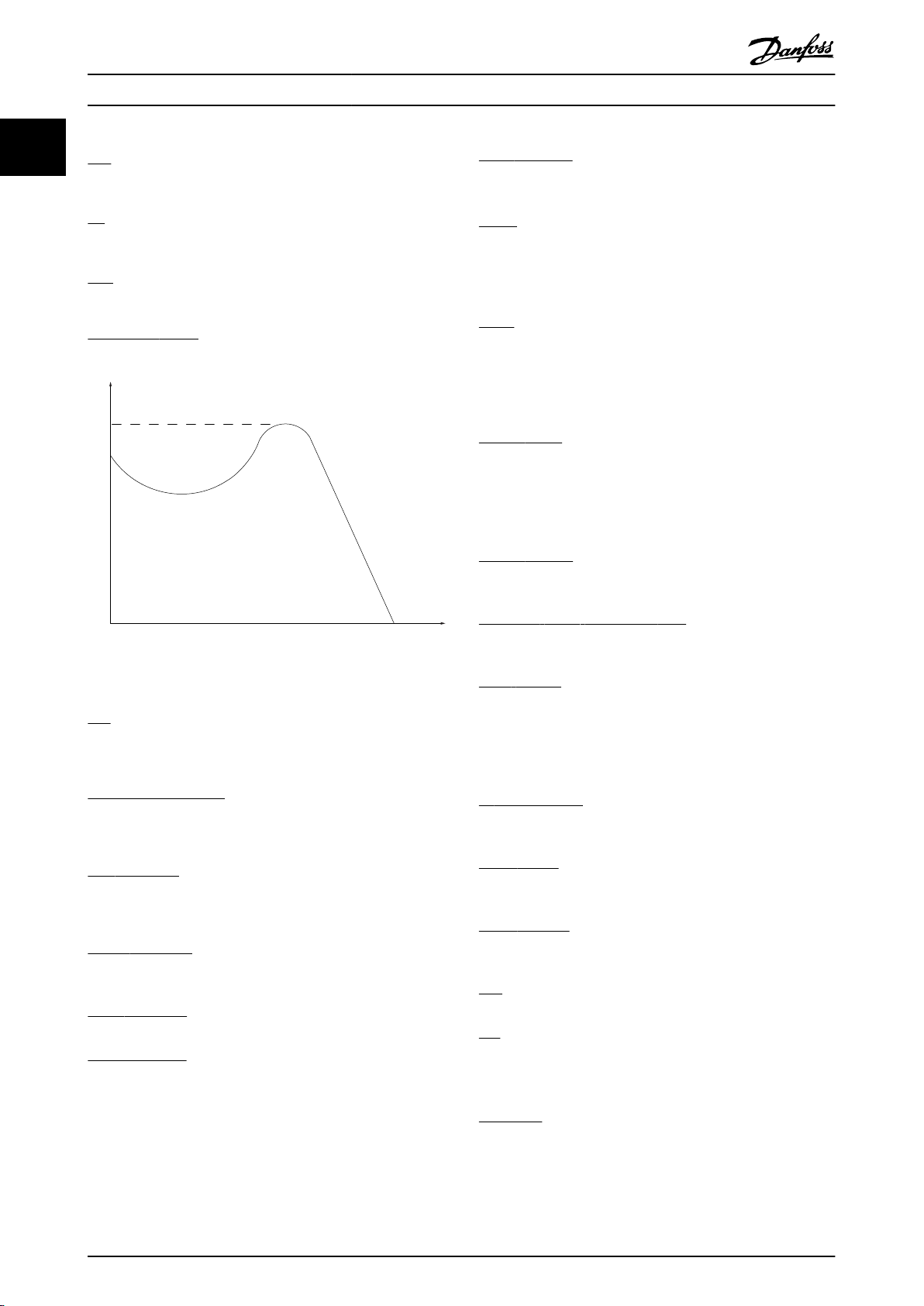

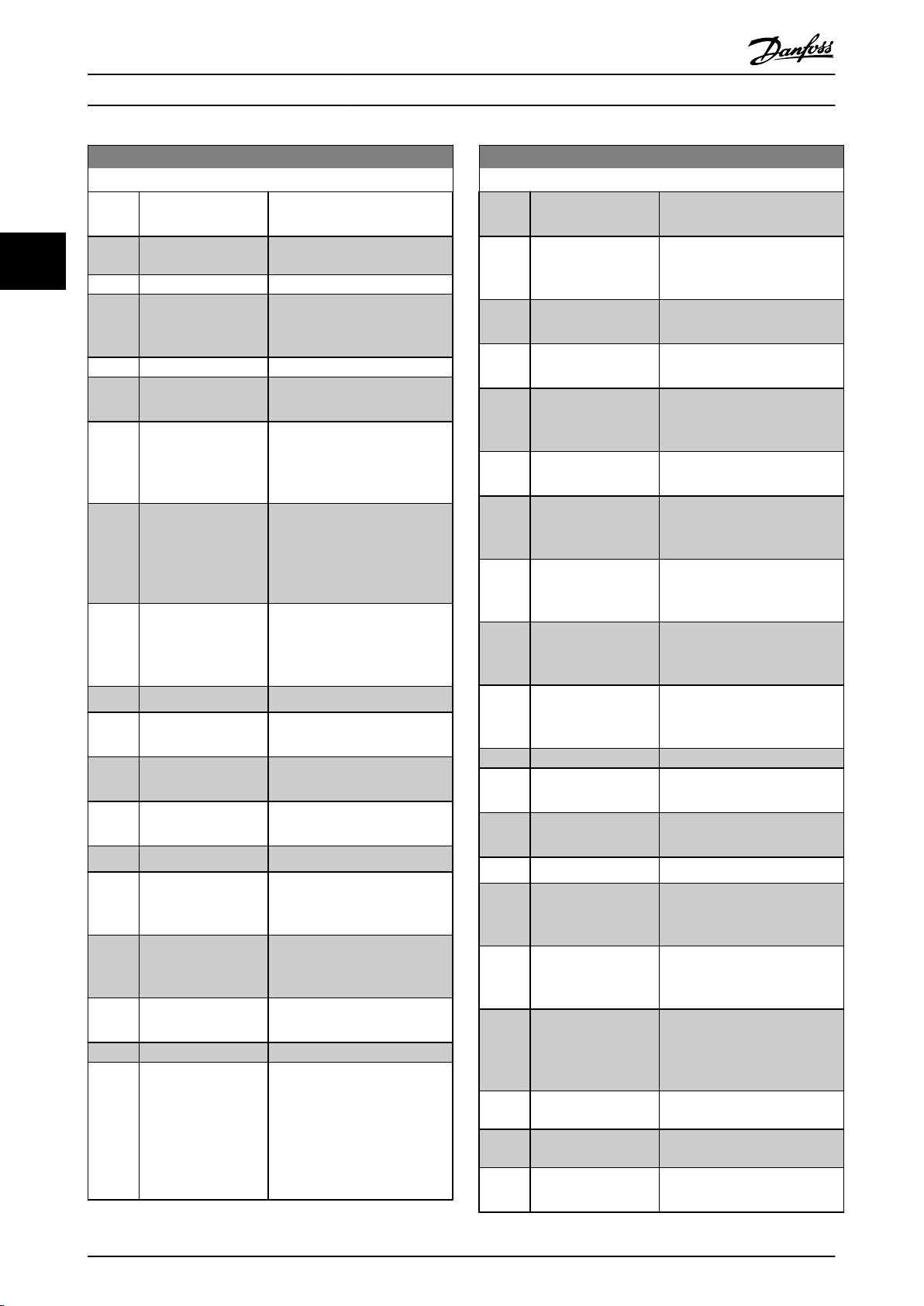

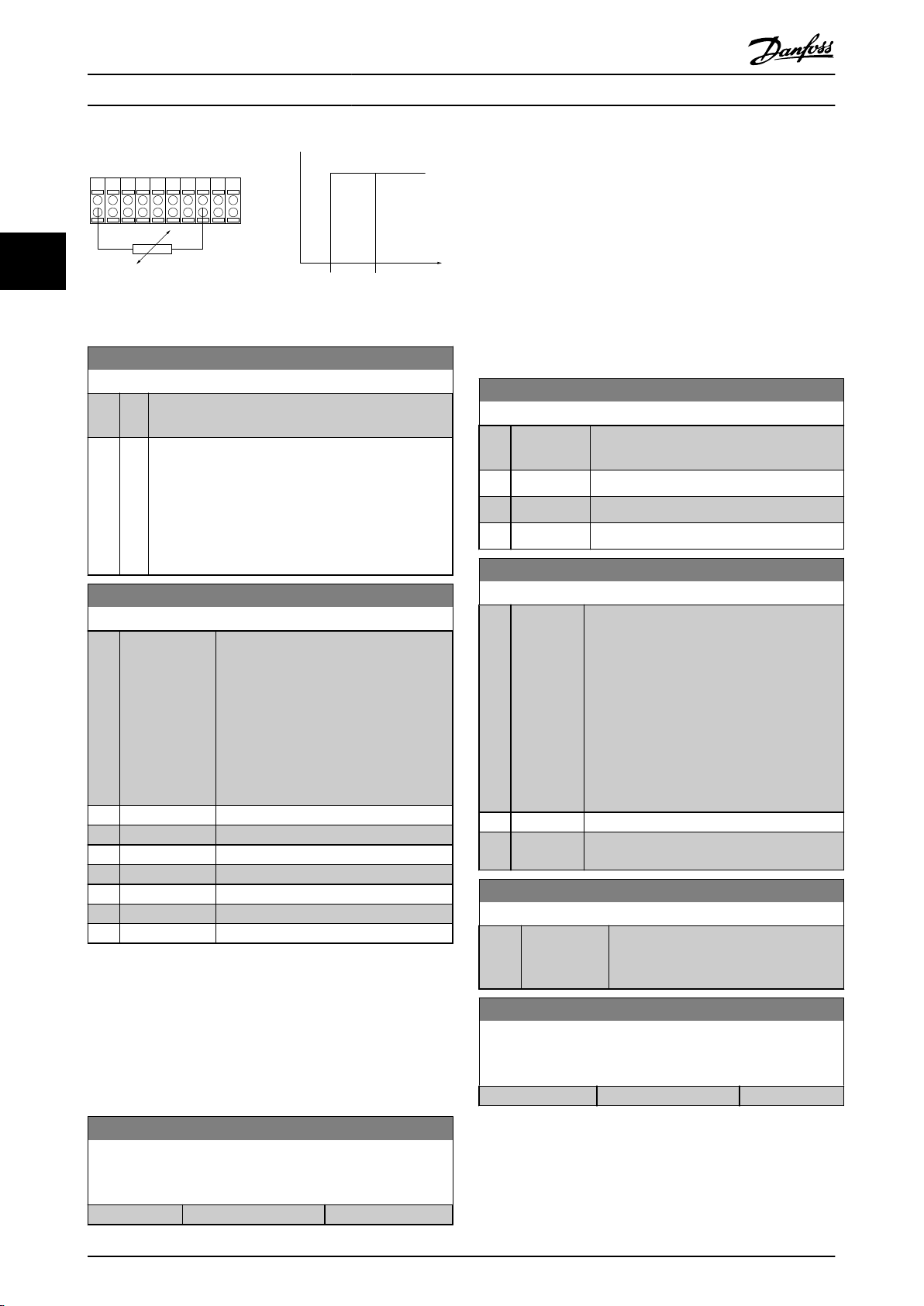

1.1.4 Electrical Wiring - Control Cables

Illustration 1.2 Basic Wiring Schematic Drawing.

A=Analog, D=Digital

Terminal

* Terminal 37 is not included in FC 301 (except frame size A1). Relay 2 and terminal 29 have no function in FC 301.

** Do not connect cable screen.

Very long control cables and analog signals may in rare cases and depending on installation result in 50/60 Hz earth loops

37 is used for Safe Stop. For Safe Stop installation instructions, refer to the Design Guide.

due to noise from mains supply cables.

If this occurs, it may be necessary to break the screen or insert a 100 nF capacitor between screen and chassis.

The digital and analog inputs and outputs must be connected separately to the common inputs (terminal 20, 55, 39) of the

frequency converter to avoid ground currents from both groups to affect other groups. For example, switching on the

digital input may disturb the analog input signal.

8 MG33MF02 - VLT® is a registered Danfoss trademark

Page 10

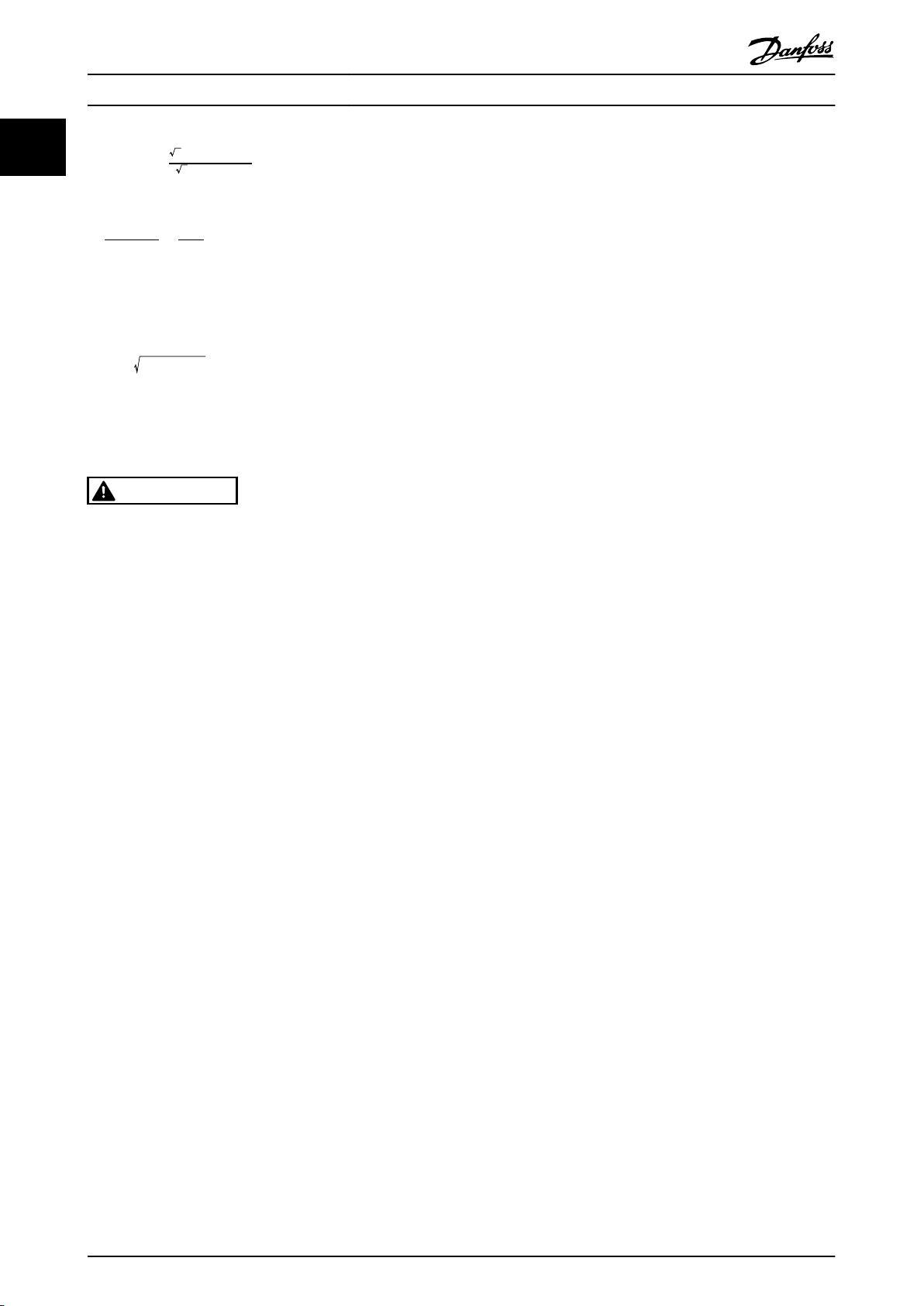

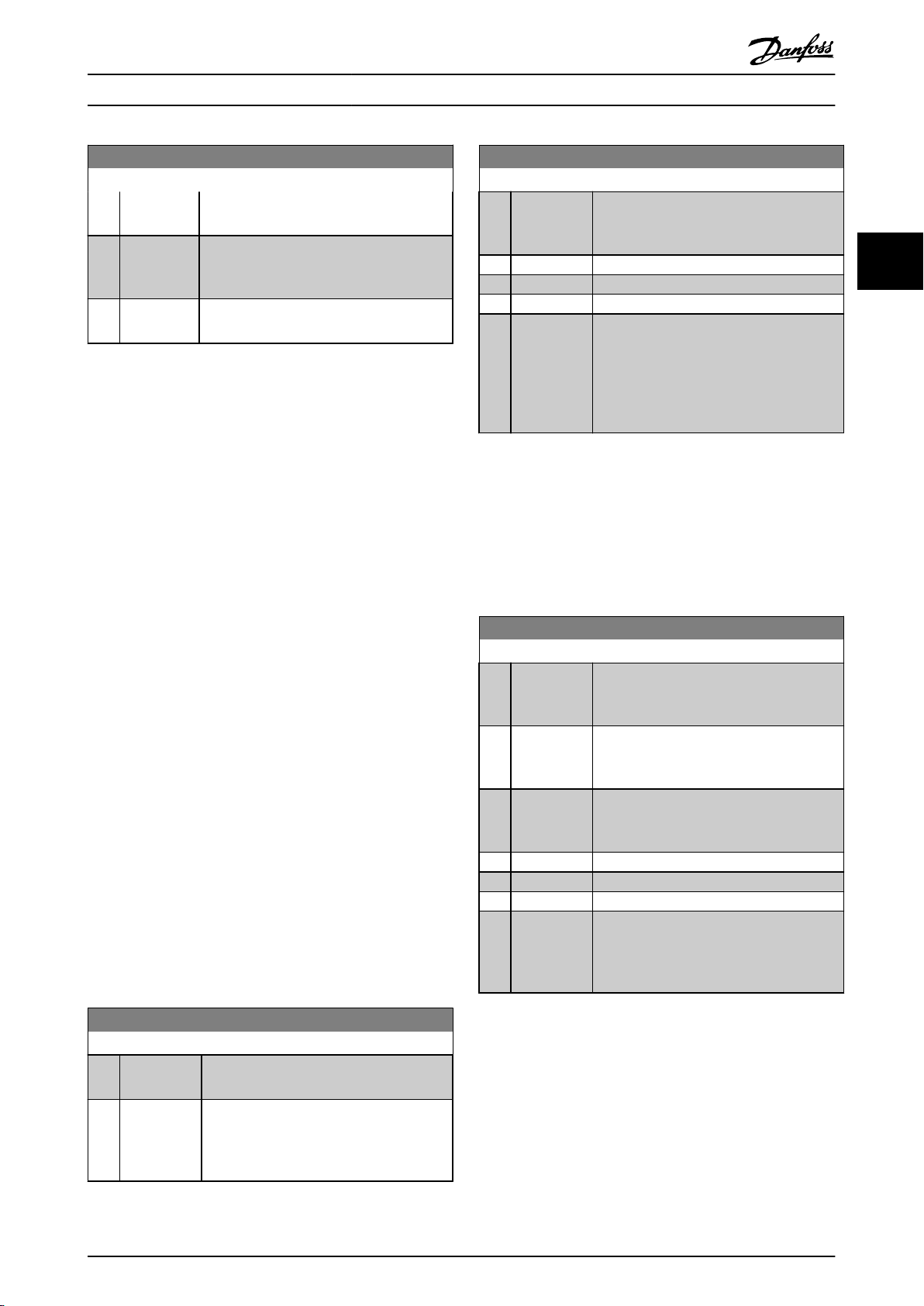

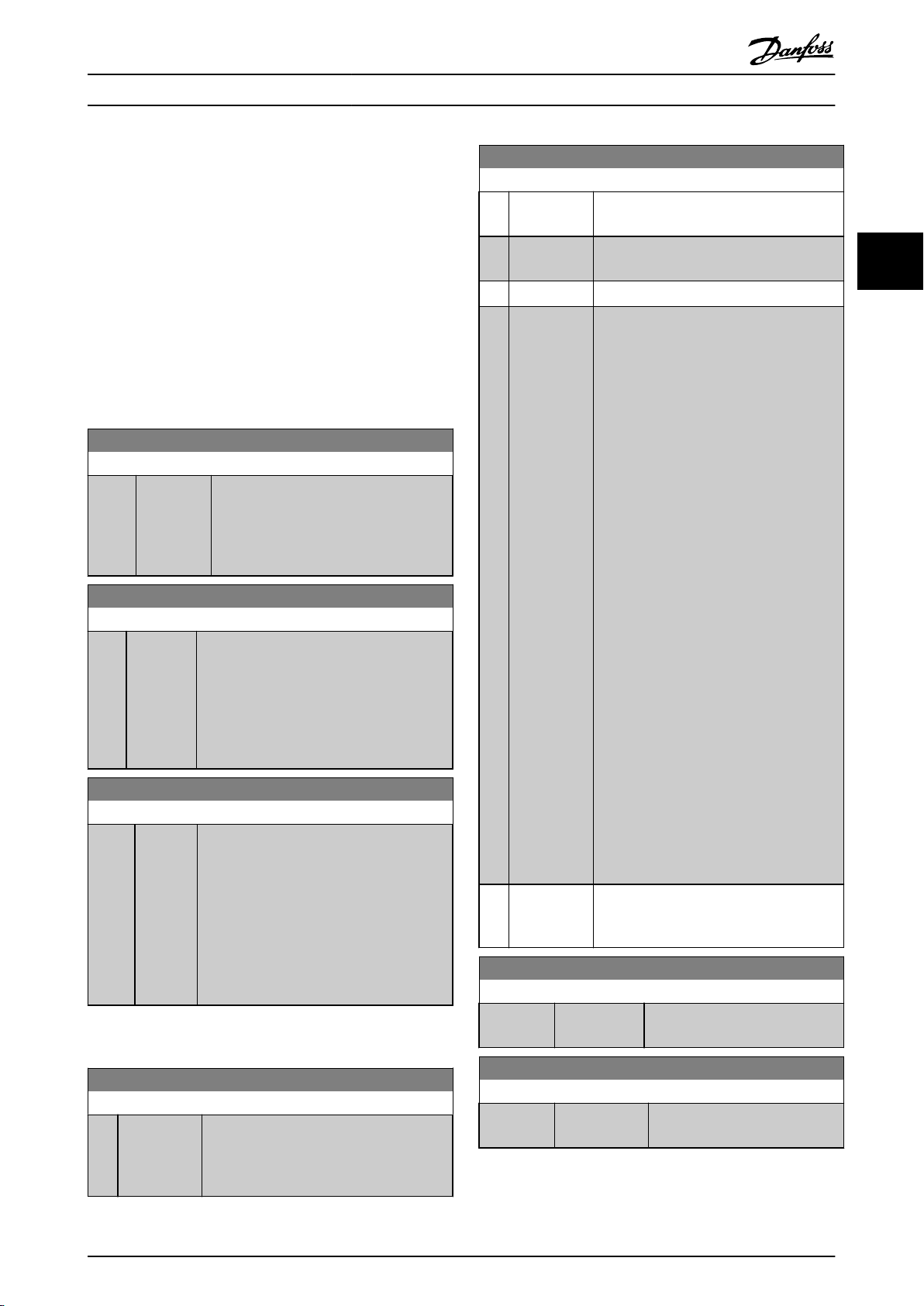

12 13 18 19 27 29 32 33 20 37

+24 VDC

0 VDC

130BT106.10

PNP (Source)

Digital input wiring

NPN (Sink)

Digital input wiring

12 13 18 19 27 29 32 33 20 37

+24 VDC

0 VDC

130BT107.11

130BA681.10

12 13 18 37

130BA155.12

322719 29 33 20

P 5-12 [0]

P 5-10 [8]

Start/Stop

+24V

Speed

Safe Stop

Start/Stop

[18]

Introduction

VLT® AutomationDrive Programming Guide

Input polarity of control terminals

Illustration 1.3

1 1

Illustration 1.5

1.1.5 Start/Stop

Illustration 1.4

NOTE

Control cables must be screened/armoured.

See section on earthing of screened/armoured control

in the Design Guide for the correct termination of

cables

control cables.

Terminal 18 = 5-10

Terminal 18 Digital Input [8] Start

Terminal 27 = 5-12 Terminal 27 Digital Input [0] No

operation (Default coast inverse)

Terminal 37 = Safe stop (where available)

Illustration 1.6

MG33MF02 - VLT® is a registered Danfoss trademark

9

Page 11

12 13 18 37

130BA156.12

322719 29 33 20

P 5 - 12 [6]

P 5 - 10[9]

+24V

Speed

Start Stop inverse Safe Stop

Start (18)

Start (27)

12

18

27

29

32

37

+24V

Par. 5-10

Par. 5-12

Par. 5-13

Par. 5-14

130BA021.12

130BA154.11

555039 42 53 54

Speed RPM

P 6-15

1 kΩ

+10V/30mA

Ref. voltage

P 6-11 10V

Introduction

VLT® AutomationDrive Programming Guide

11

1.1.6 Pulse Start/Stop

Terminal 18 = 5-10

Terminal 18 Digital InputLatched start,

[9]

Terminal 27= 5-12 Terminal 27 Digital InputStop inverse, [6]

Terminal 37 = Safe stop (where available)

Illustration 1.8

1.1.8 Potentiometer Reference

Voltage reference via a potentiometer

Reference

Terminal 53, Low Voltage = 0 V

Terminal 53, High Voltage = 10 V

Terminal 53, Low Ref./Feedback = 0 RPM

Terminal 53, High Ref./Feedback = 1500 RPM

Switch S201 = OFF (U)

Source 1 = [1] Analog input 53 (default)

Illustration 1.7

1.1.7 Speed Up/Down

Terminals 29/32 = Speed up/down

Terminal

[9] (default)

Terminal 27 = 5-12 Terminal 27 Digital Input

Freeze reference [19]

Terminal 29 = 5-13 Terminal 29 Digital Input

Speed up [21]

Terminal 32 = 5-14 Terminal 32 Digital Input

Speed down [22]

NOTE

29 only in FC x02 (x=series type).

Terminal

18 = 5-10 Terminal 18 Digital Input Start

Illustration 1.9

10 MG33MF02 - VLT® is a registered Danfoss trademark

Page 12

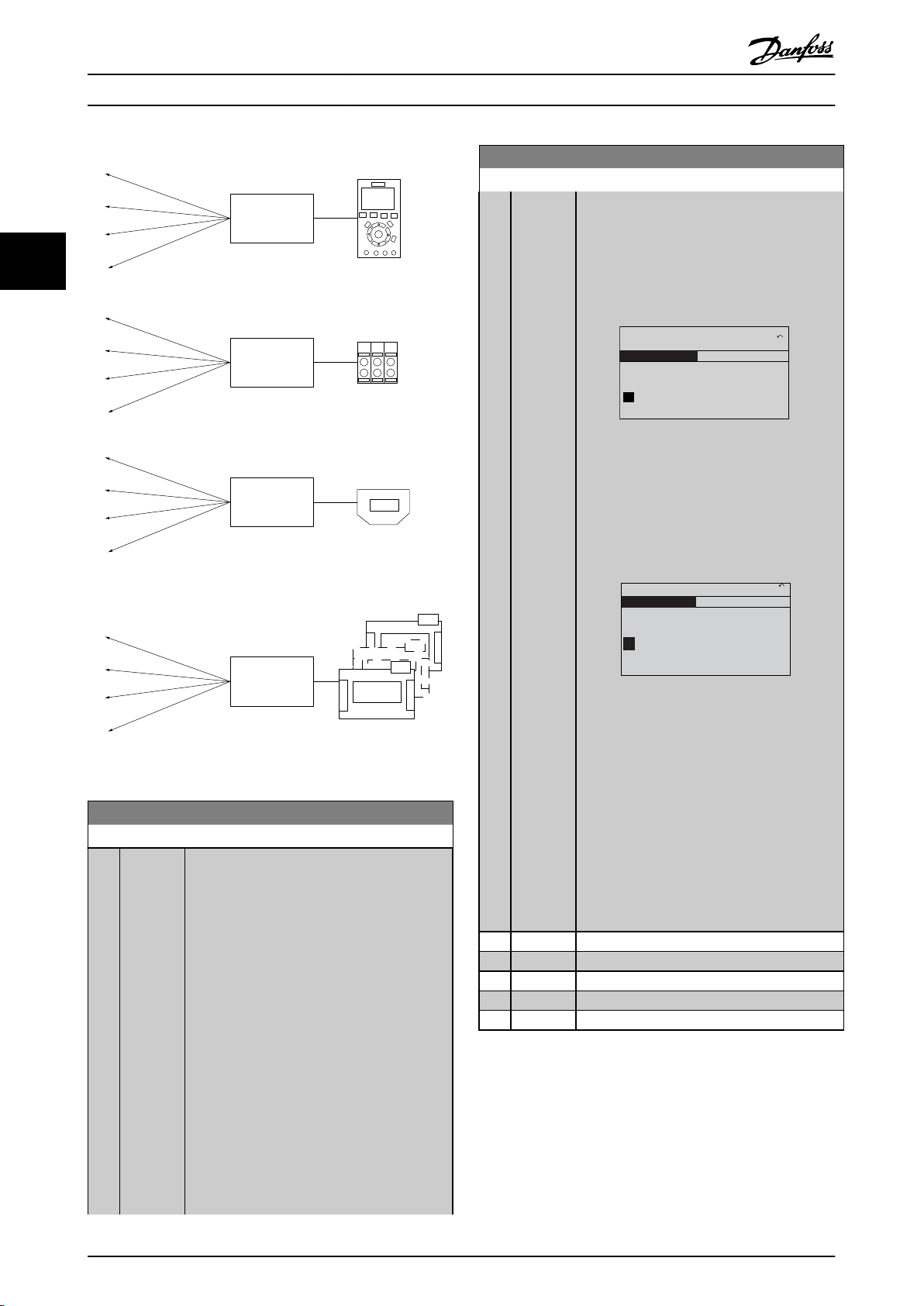

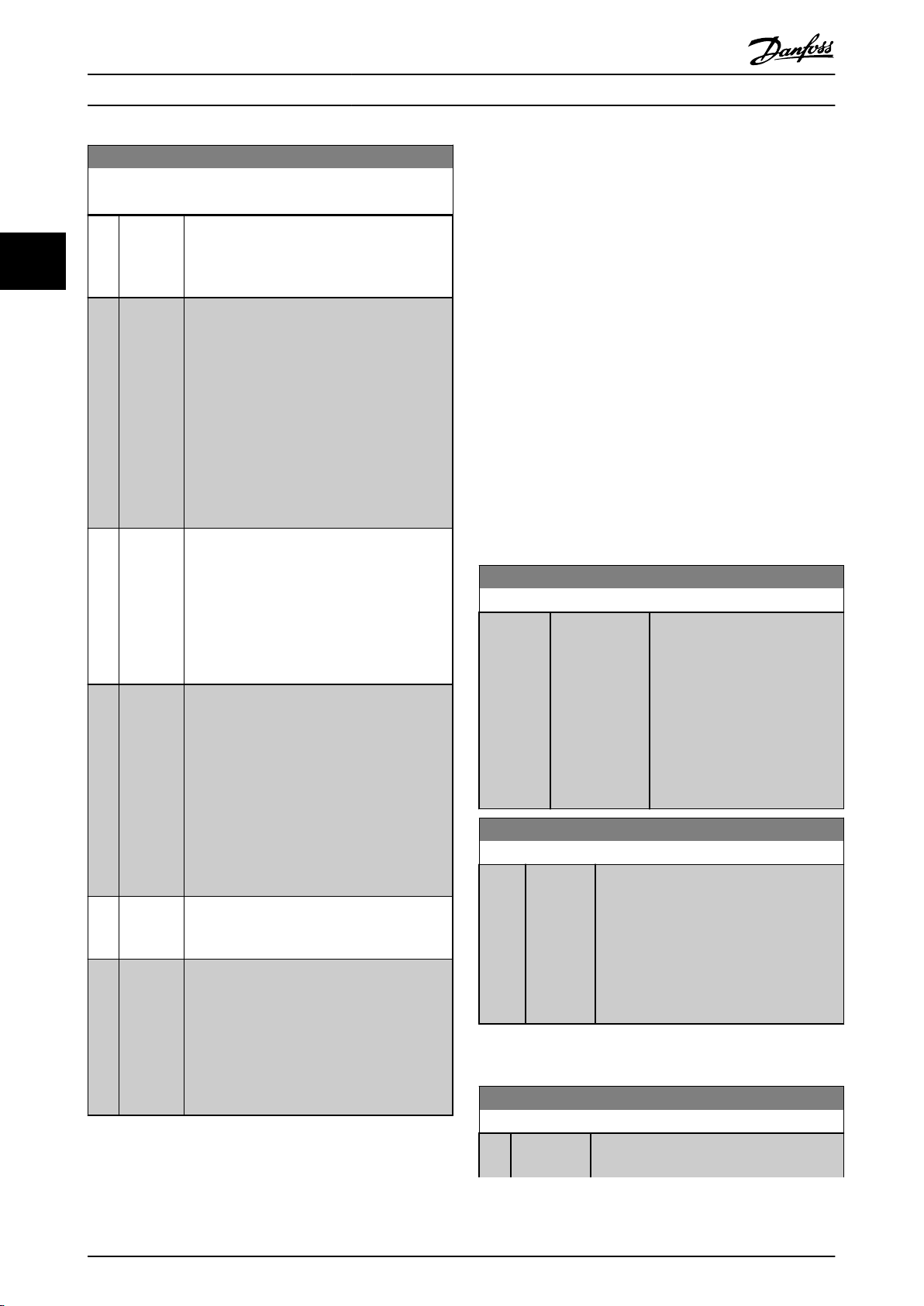

Auto

on

Reset

Hand

on

O

Status

Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

Status

1(0)

1234rpm 10,4A 43,5Hz

Run OK

43,5Hz

On

Alarm

Warn.

130BA018.13

1

2

3

4

b

a

c

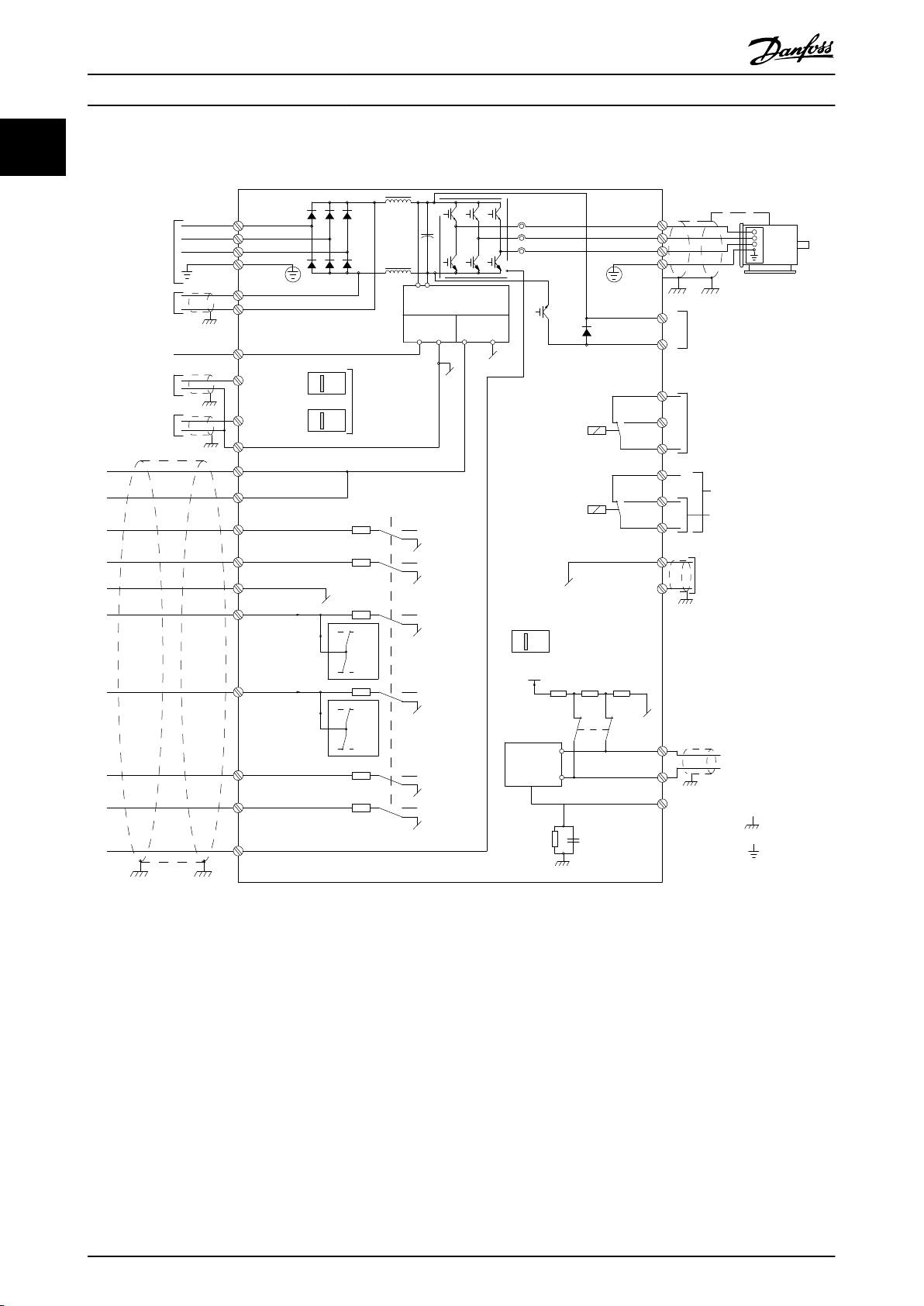

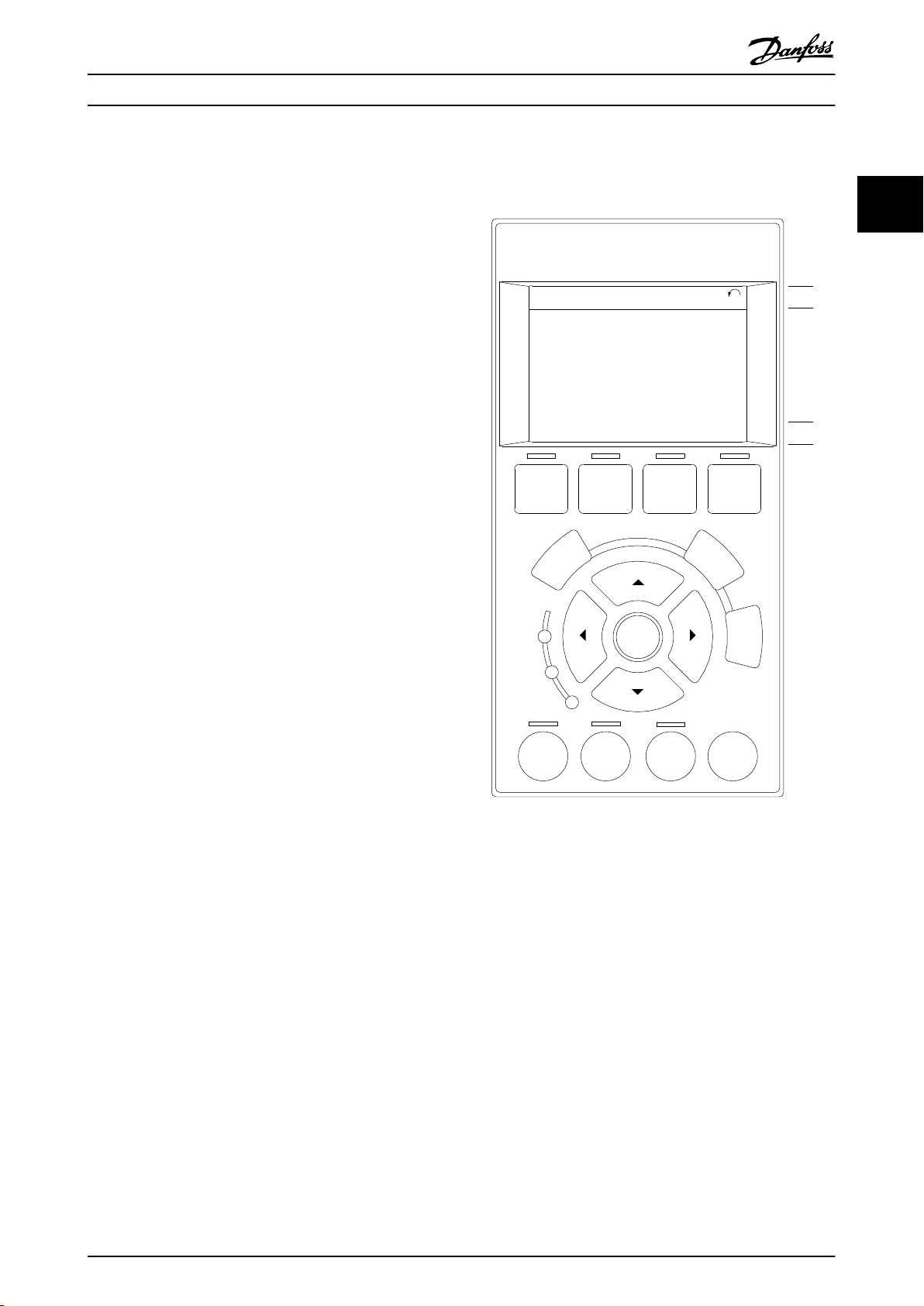

How to Programme

VLT® AutomationDrive Programming Guide

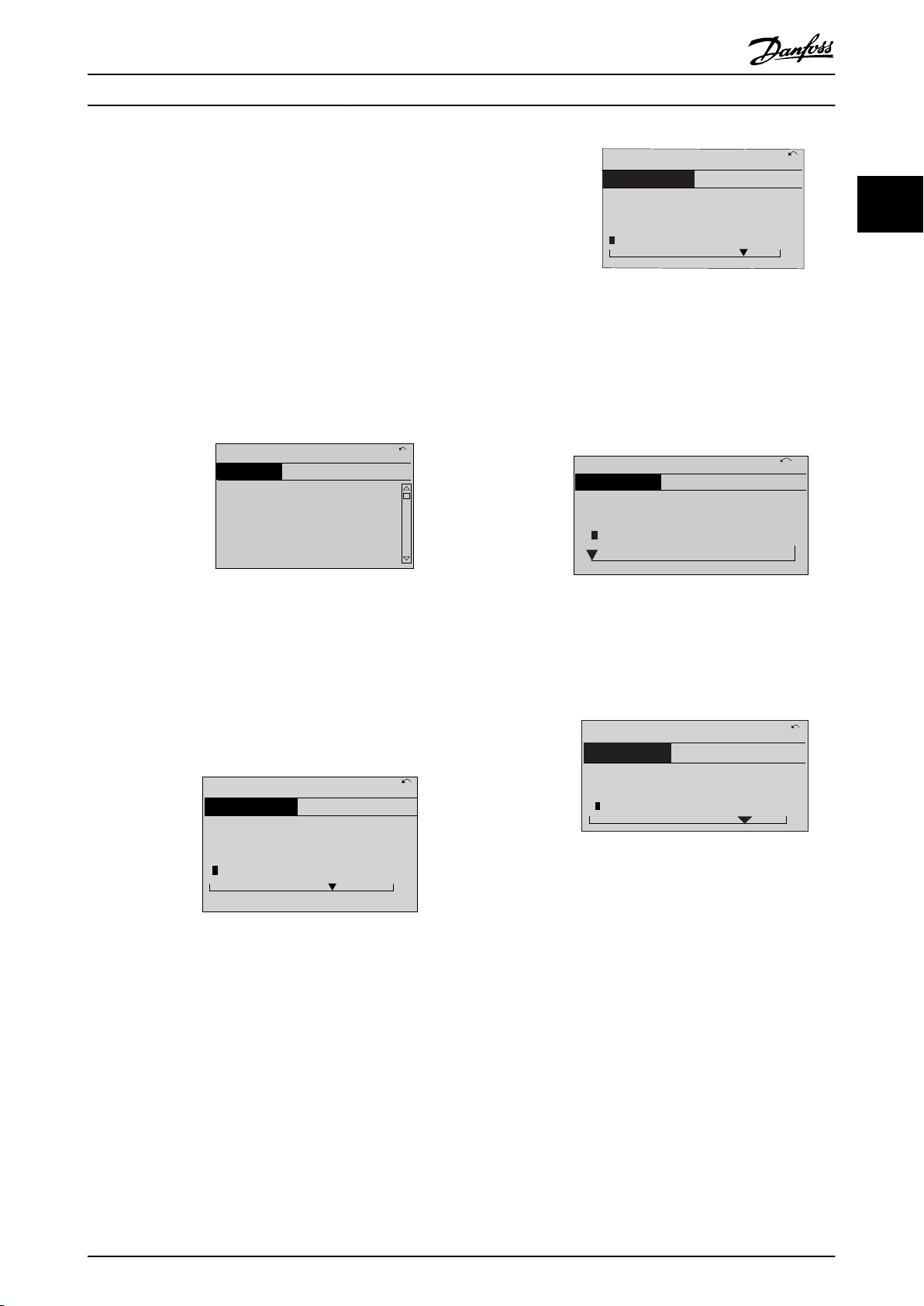

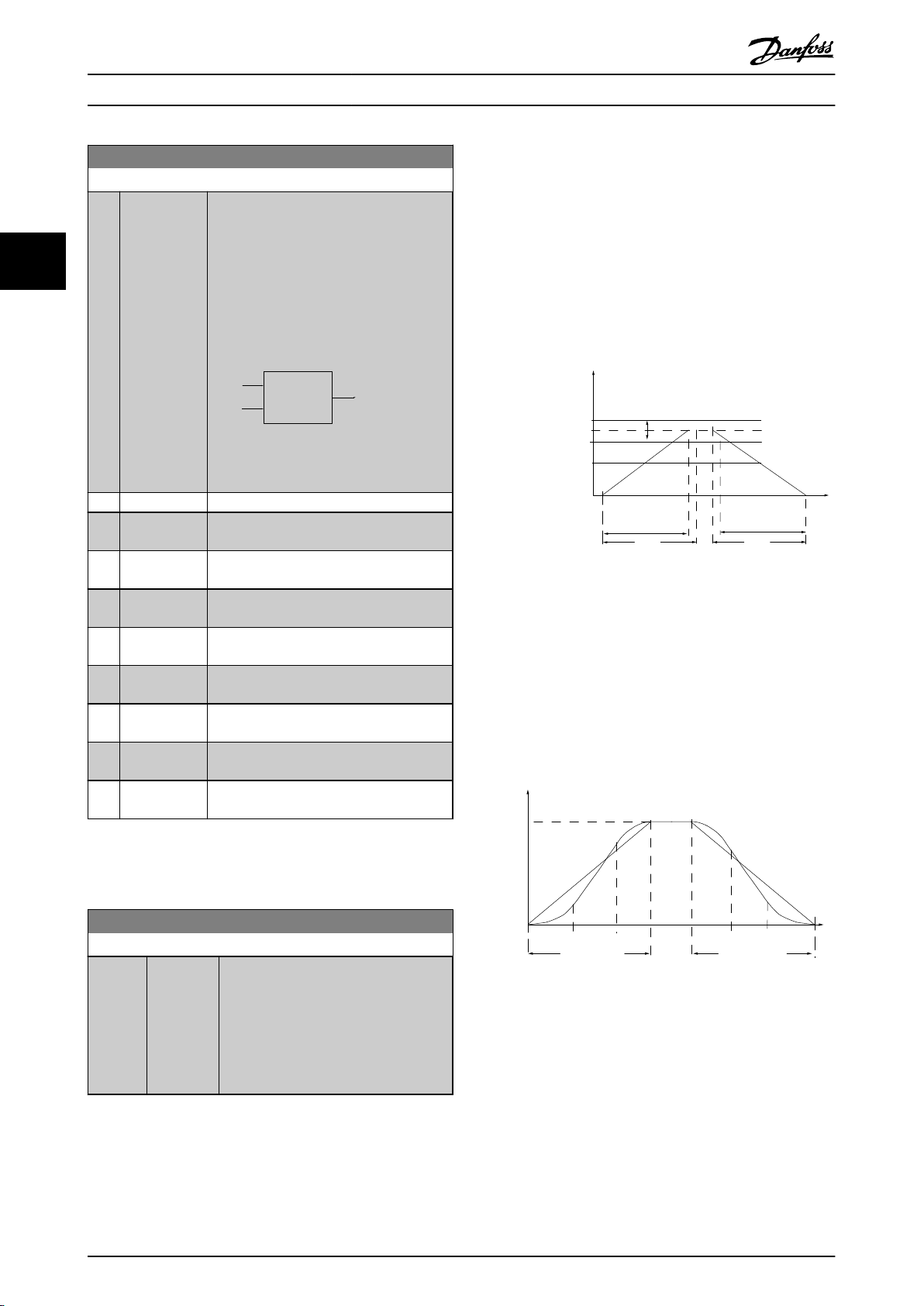

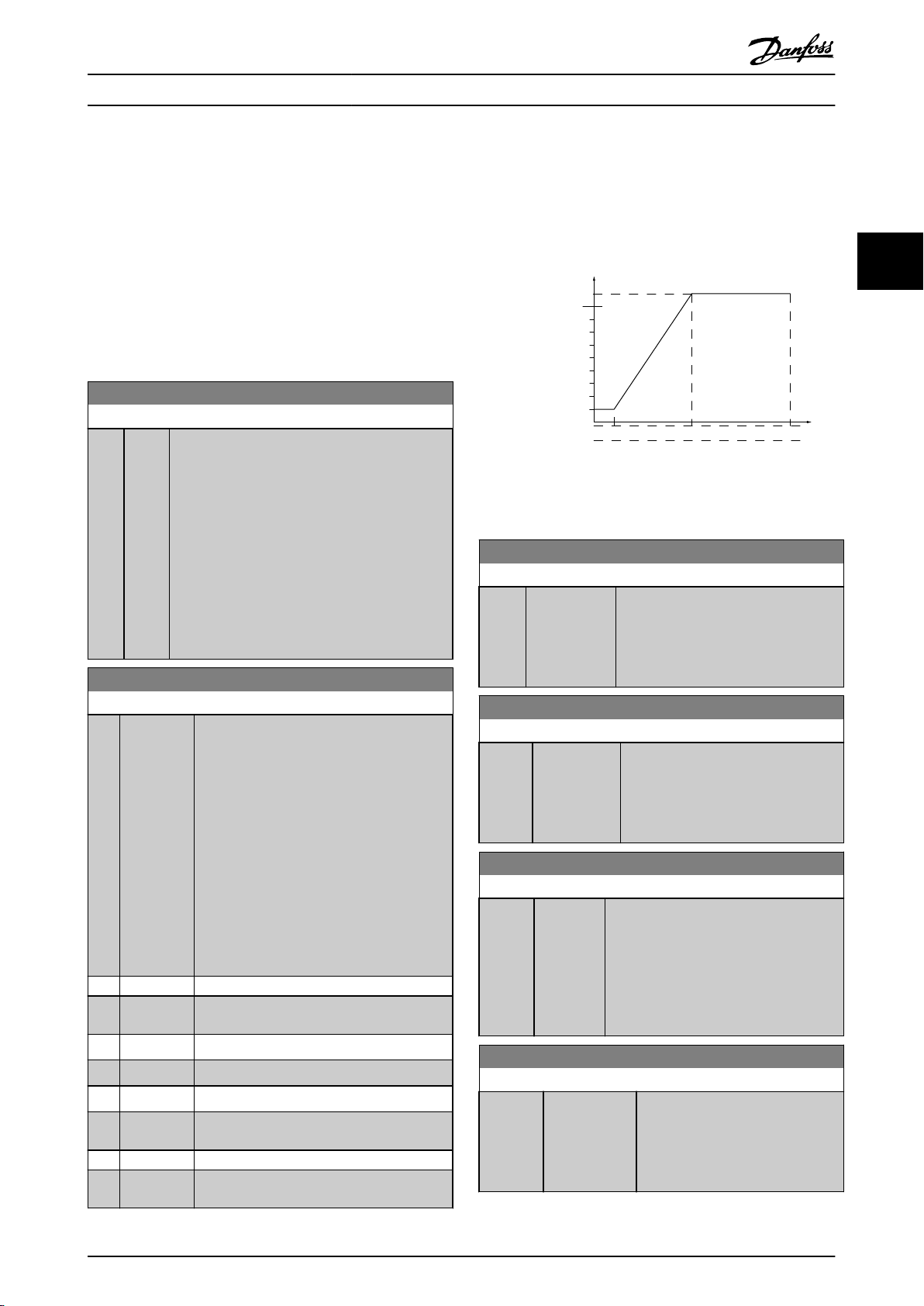

2 How to Programme

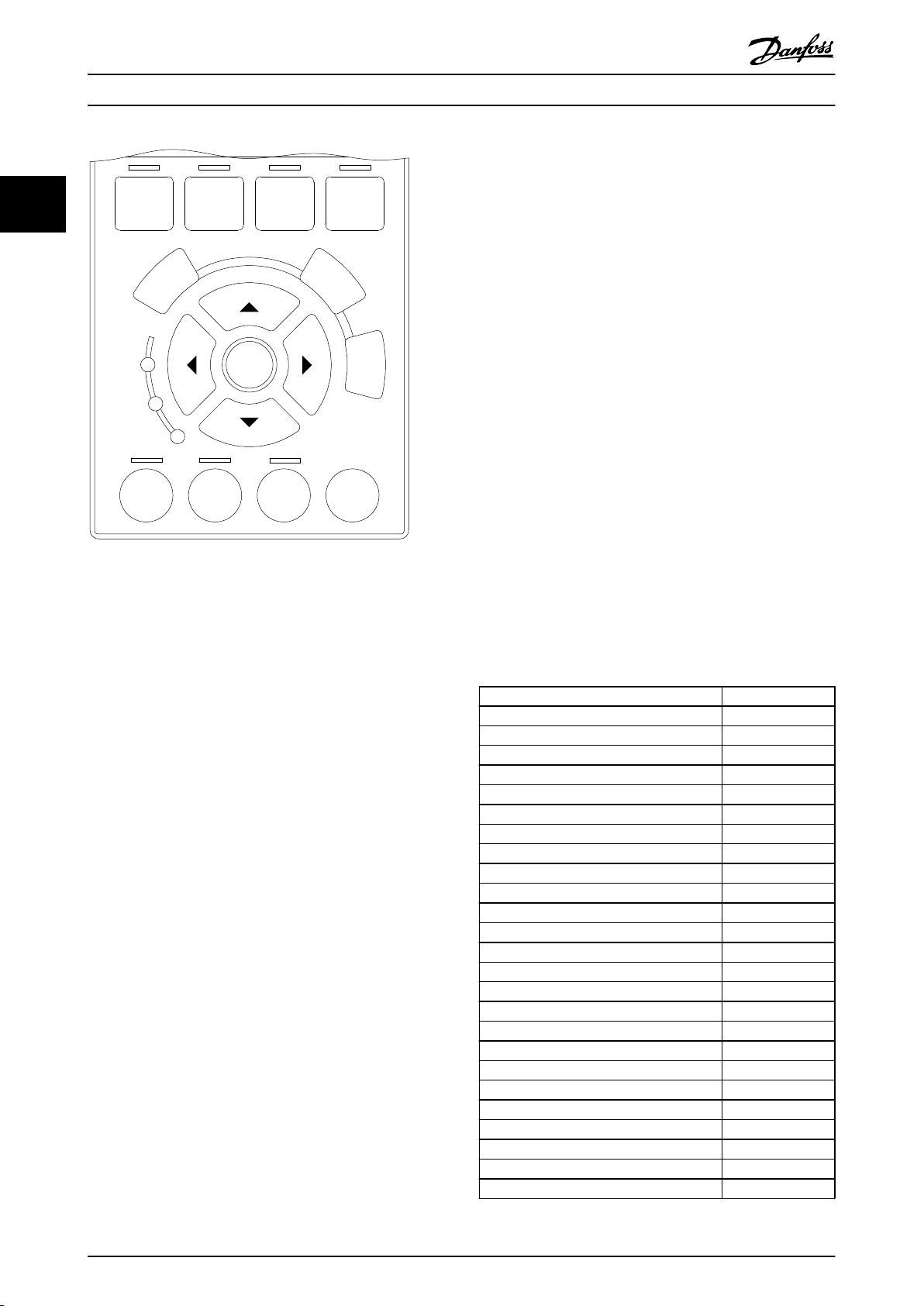

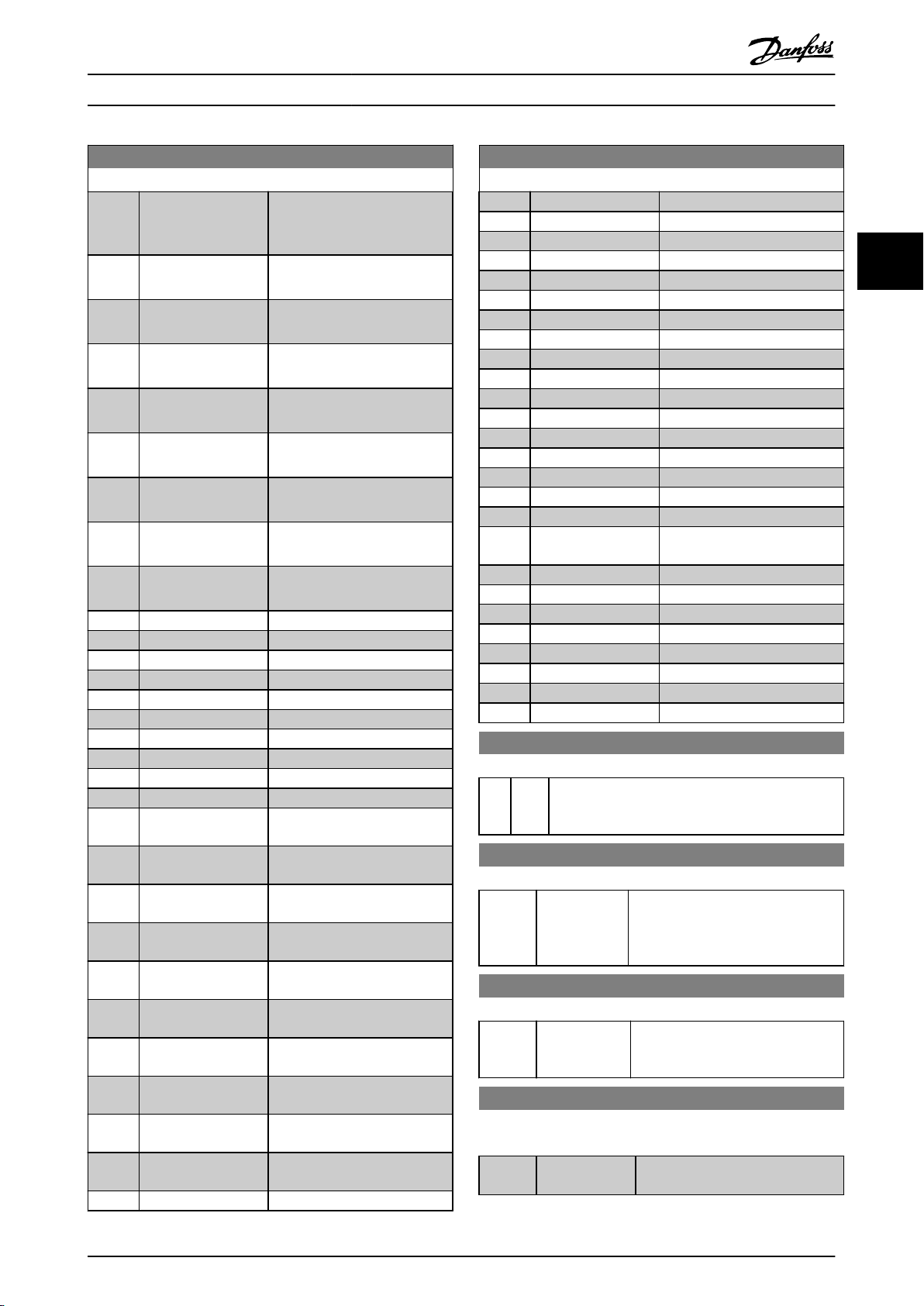

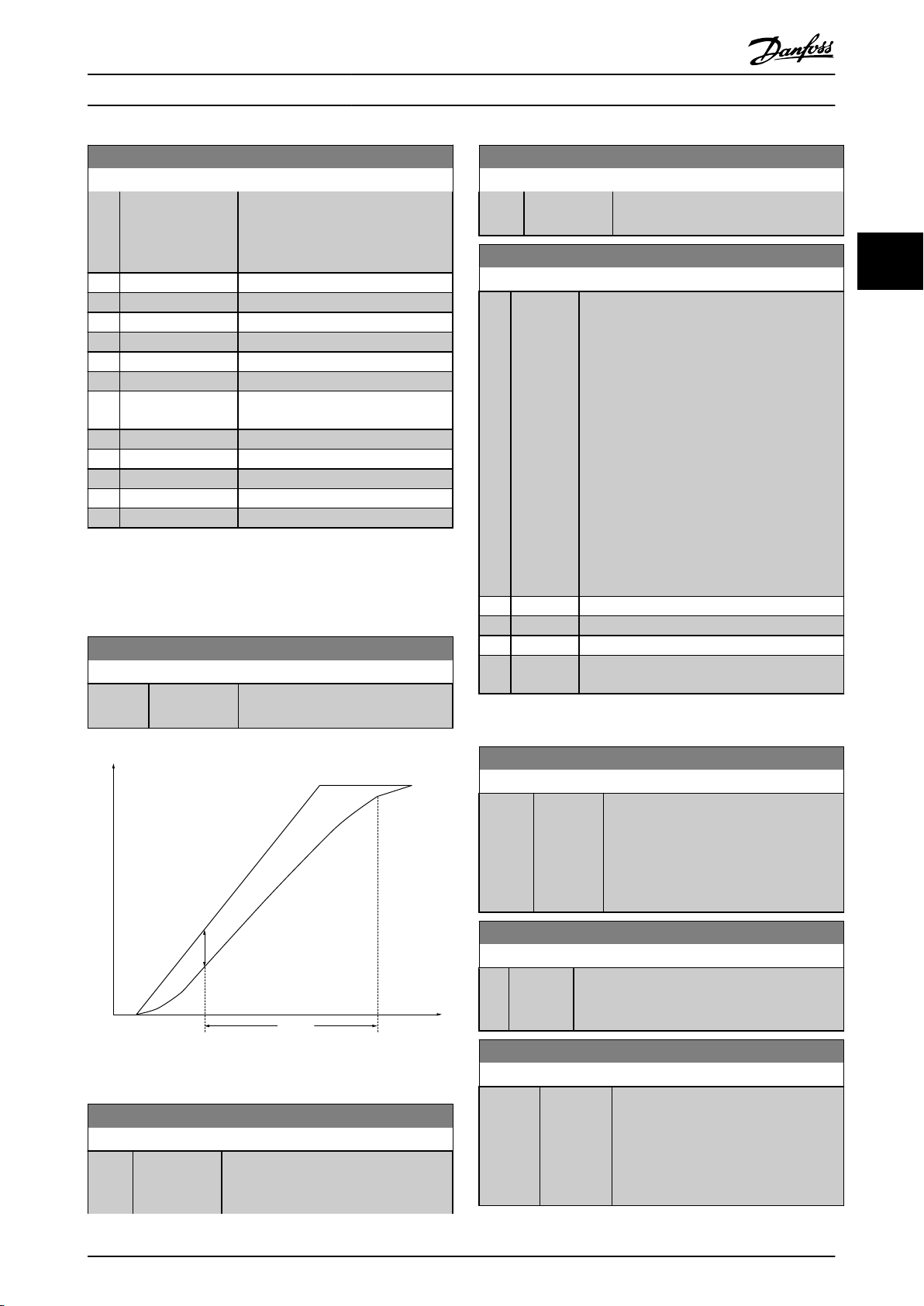

2.1 The Graphical and Numerical Local

Control Panels

The easiest programming of the frequency converter is

performed

to consult the frequency converter Design Guide, when

using the Numeric Local Control Panel (LCP 101).

The control panel is divided into four functional groups

All data is displayed in a graphical LCP display, which can

show up to five items of operating data while displaying

[Status].

by the Graphical LCP (LCP 102). It is necessary

1. Graphical display with Status lines.

2. Menu keys and indicator lights - changing

parameters and switching between display

functions.

3. Navigation keys and indicator lights (LEDs).

4. Operation keys and indicator lights (LEDs).

2 2

Display lines

a. Status line: Status messages displaying icons and

graphic.

b. Line 1-2: Operator data lines displaying data

defined or chosen by the user. By pressing

[Status], up to one extra line can be added.

c. Status line: Status messages displaying text.

Illustration 2.1

MG33MF02 - VLT® is a registered Danfoss trademark

11

Page 13

Top section

Middle section

Bottom section

Status

43 RPM

1.4 Hz

Auto Remote Running

! Pwr.card temp (W29)

2.9%

5.44 A 25.3kW

1(1)

130BP074.10

!

On

Warn.

Alarm

130BP044.10

130BP045.10

Status

Quick

Menu

Main

Menu

Alarm

Log

How to Programme

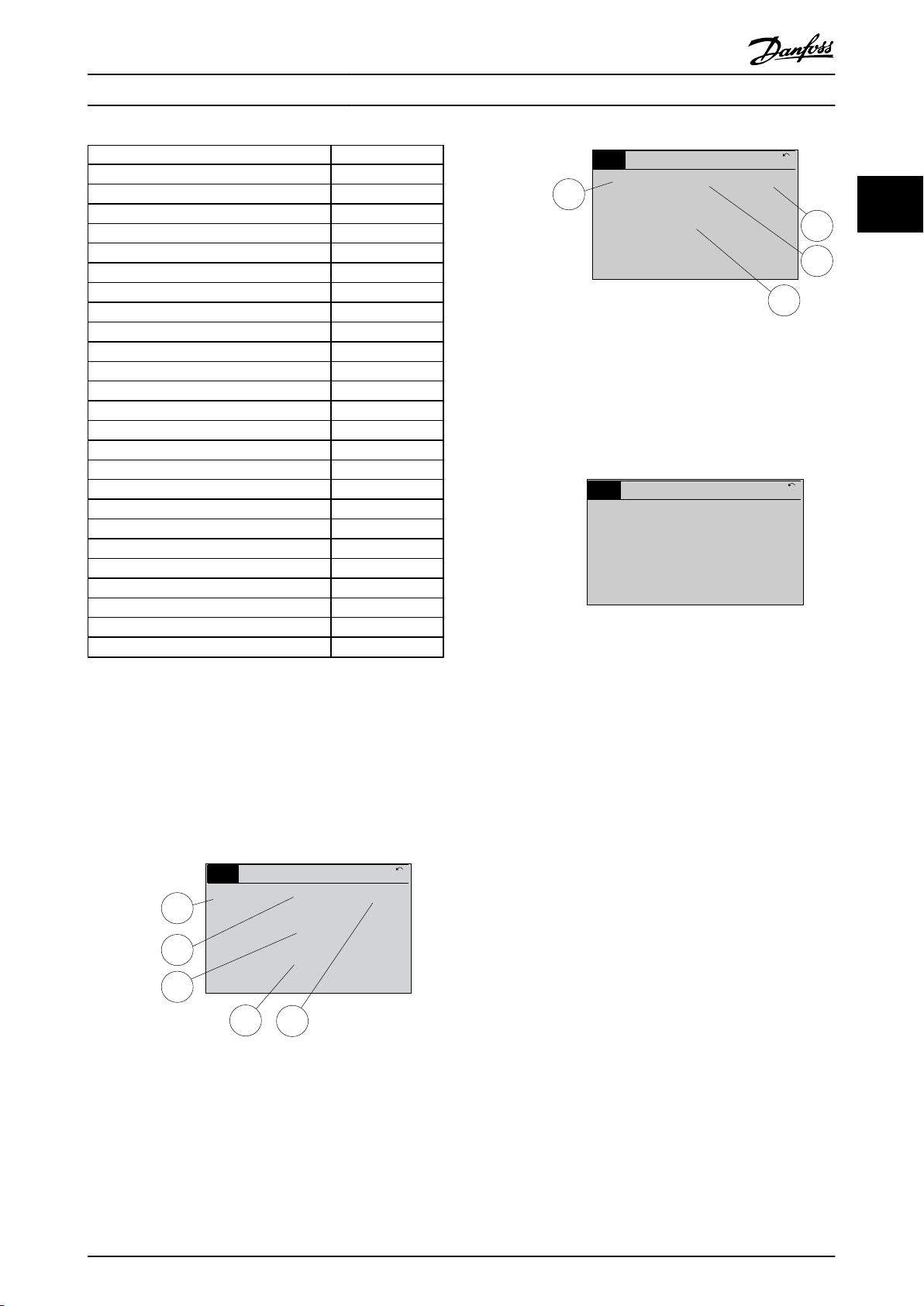

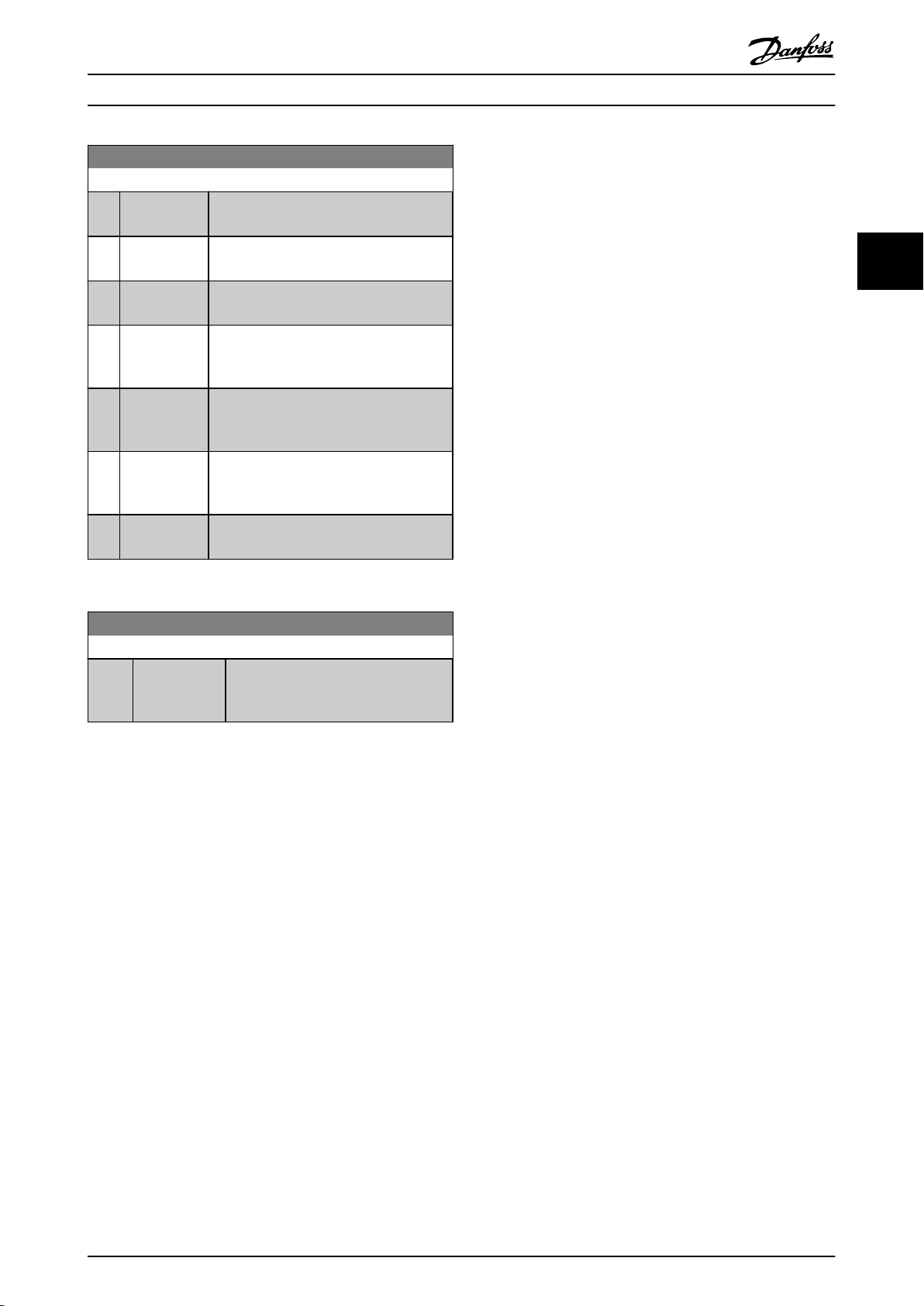

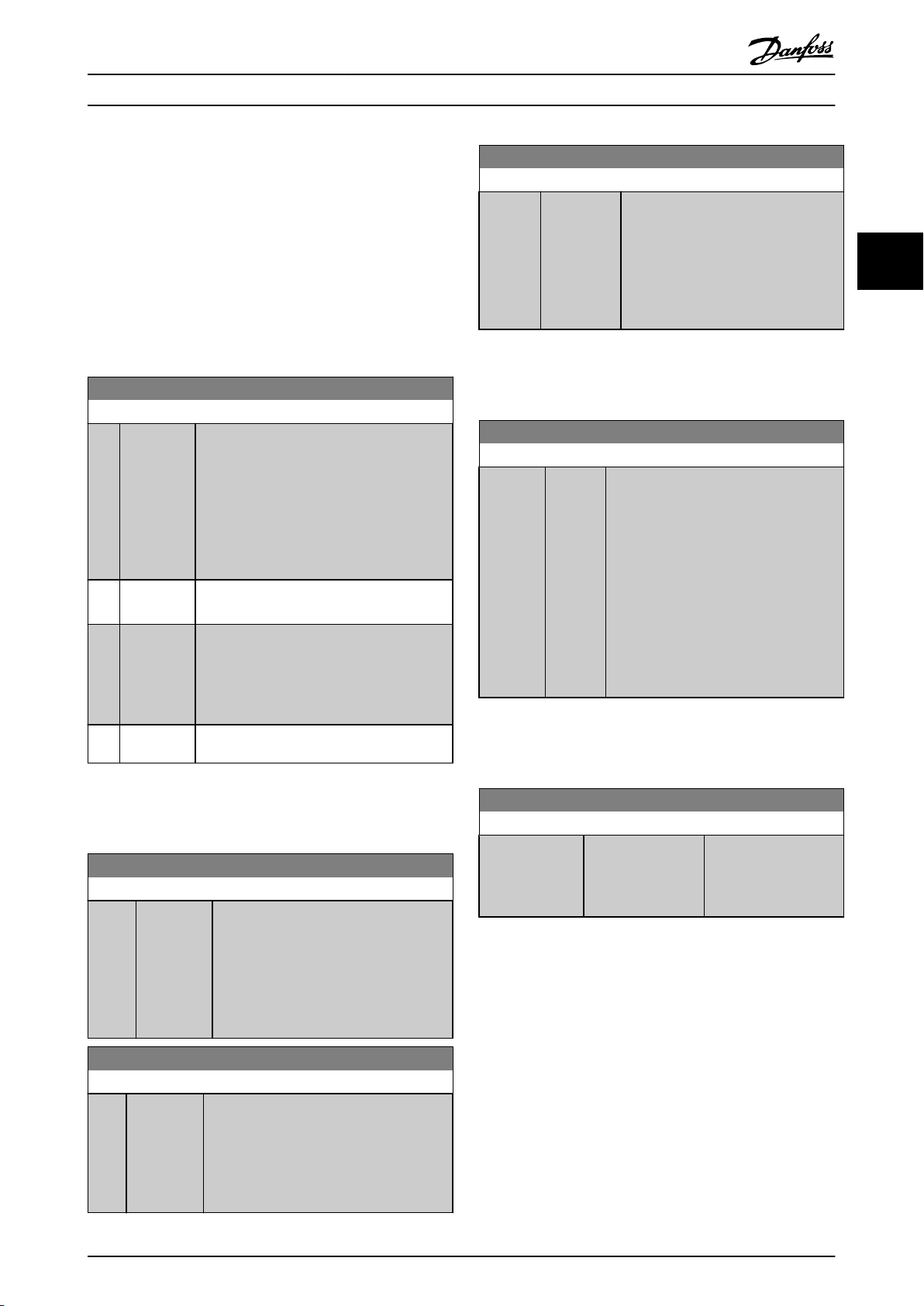

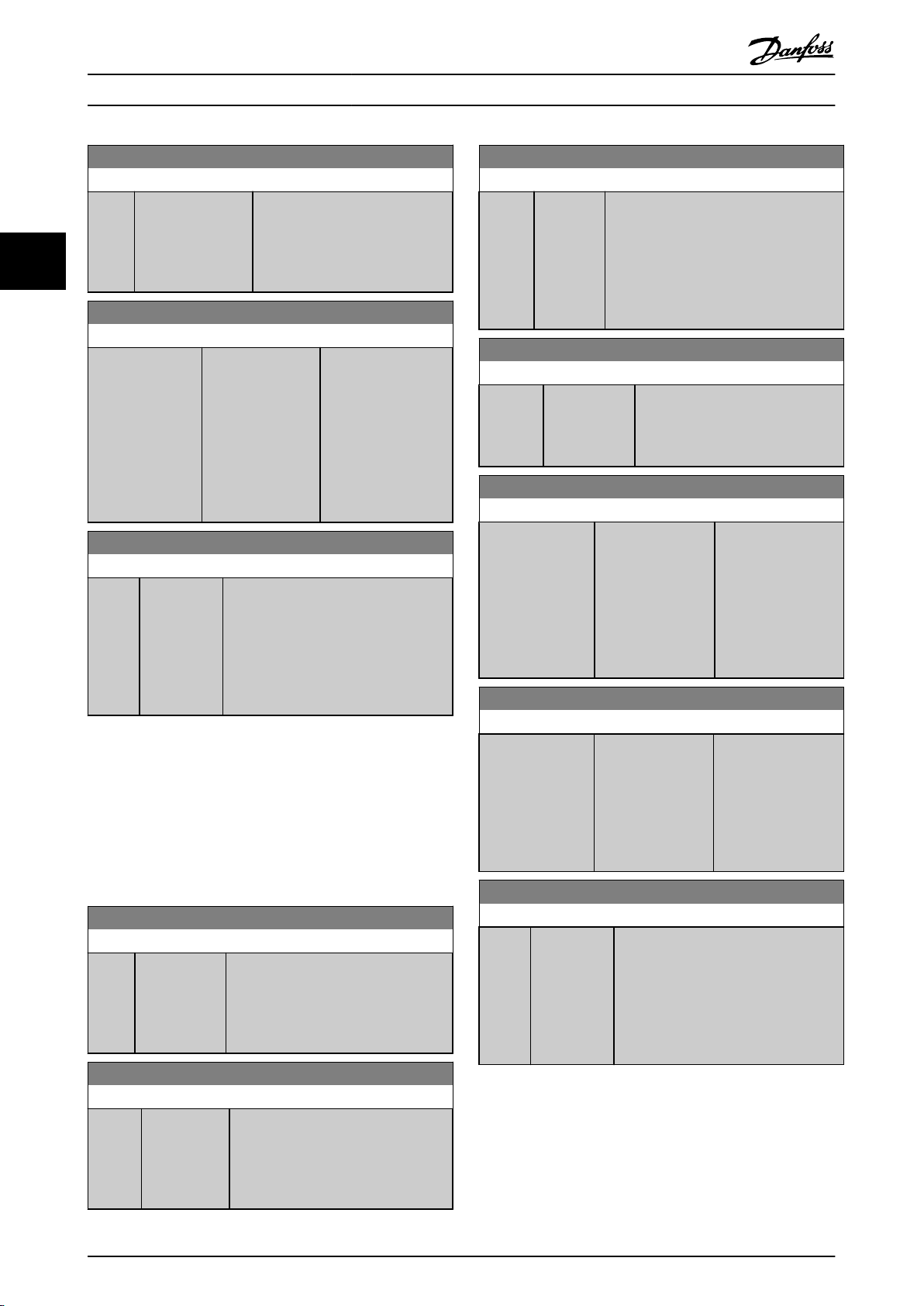

2.1.1 The LCD-Display

VLT® AutomationDrive Programming Guide

22

The LCD-display has back light and a total of 6 alphanumeric

rotation (arrow), the chosen Set-up as well as the

programming Set-up. The display is divided into 3 sections.

Top section shows up to 2 measurements in normal

operating status.

The top line in the Middle section shows up to 5

measurements with related unit, regardless of status

(except in the case of alarm/warning).

Bottom section always shows the state of the frequency

converter in Status mode.

lines. The display lines show the direction of

Illustration 2.3

Keys

LCP

The control keys are divided into functions. The keys

below the display and indicator lamps are used for

parameter Set-up, including choice of display indication

during normal operation.

Illustration 2.4

Illustration 2.2

[Status]

and/or the motor. Choose between 3 different readouts by

The Active Set-up (selected as the Active Set-up in

Active Set-up) is shown. When programming another

0-10

Set-up than the Active Set-up, the number of the

programmed Set-up appears to the right.

Display contrast adjustment

Press [Status] and [▲] for darker display

Press [Status] and [▼] for brighter display

Most parameter set-ups can be changed immediately via

the LCP, unless a password has been created via 0-60 Main

Menu Password or via 0-65 Quick Menu Password.

Indicator lights (LEDs)

If certain threshold values are exceeded, the alarm and/or

warning LED lights up. A status and alarm text appear on

the LCP.

The ON LED is activated when the frequency converter

receives mains voltage or via a DC bus terminal or 24 V

external supply. At the same time, the back light is on.

Green LED/On: Control section is working.

•

•

•

12 MG33MF02 - VLT® is a registered Danfoss trademark

Yellow LED/Warn.: Indicates a warning.

Flashing Red LED/Alarm: Indicates an alarm.

pressing the [Status] key: 5 line readouts, 4 line readouts

or Smart Logic Control.

Use [Status] for selecting the mode of display or for

changing back to Display mode from either the Quick

Menu mode, the Main Menu mode or Alarm mode. Also

use the [Status] key to toggle single or double read-out

mode.

[Quick Menu] allows quick access to different Quick Menus

such as

Use [Quick Menu] for programming the parameters

belonging to the Quick Menu. It is possible to switch

directly between Quick Menu mode and Main Menu mode.

[Main Menu] is used for programming all parameters.

It is possible to switch directly between Main Menu mode

and Quick Menu mode.

Parameter shortcut can be carried out by pressing down

the [Main Menu] key for 3 seconds. The parameter shortcut

allows direct access to any parameter.

indicates the status of the frequency converter

My Personal Menu

•

Quick Set-up

•

Changes Made

•

Loggings

•

Page 14

B

a

c

k

C

a

n

c

e

l

I

n

f

o

130BP046.10

Hand

on

O

Auto

on

Reset

How to Programme

VLT® AutomationDrive Programming Guide

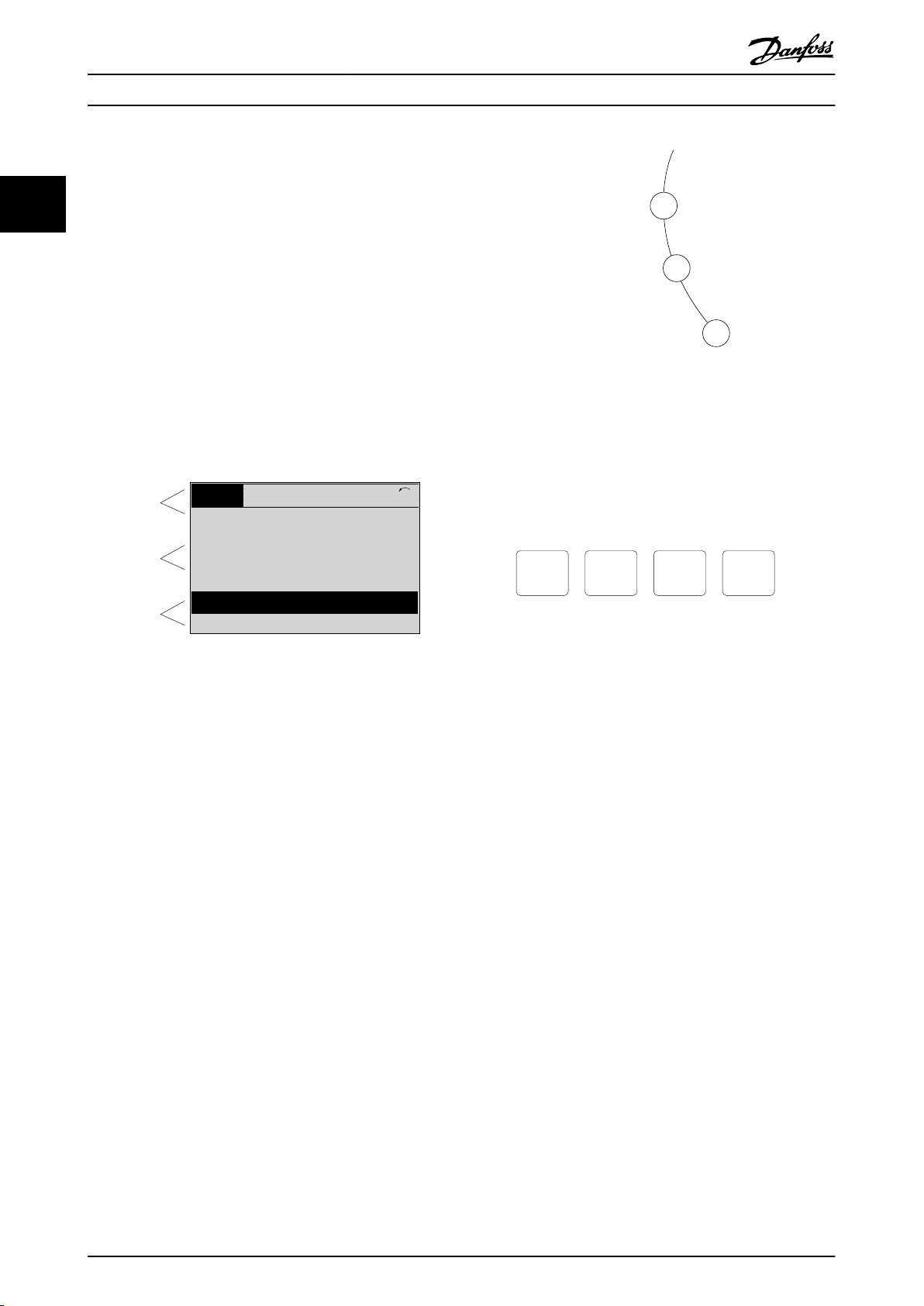

[Alarm Log]

displays an Alarm list of the five latest alarms

(numbered A1-A5). To obtain additional details about an

alarm, use the arrow keys to manoeuvre to the alarm

number and press [OK]. Information is displayed about the

condition of the frequency converter before it enters the

alarm mode.

[Back] reverts to the previous step or layer in the

navigation structure.

[Cancel] last change or command will be cancelled as long

as the display has not been changed.

[Info] supplies information about a command, parameter,

or function in any display window. [Info] provides detailed

information whenever help is needed.

Exit info mode by pressing either [Info], [Back], or [Cancel].

Illustration 2.5

[Hand On]

enables control of the frequency converter via

the LCP. [Hand On] also starts the motor, and it is now

possible to enter the motor speed data by means of the

arrow keys. The key can be selected as [1] Enable or [0]

Disable via 0-40 [Hand on] Key on LCP

External stop signals activated by means of control signals

or a serial bus will override a “start” command via the LCP.

The following control signals will still be active when

[Hand On] is activated

[Hand on] - [Off] - [Auto On]

•

Reset

•

Coasting stop inverse

•

Reversing

•

Set-up select bit 0- Set-up select bit 1

•

Stop command from serial communication

•

Quick stop

•

DC brake

•

[Off] stops the connected motor. The key can be selected

as [1] Enable or [0] Disable via 0-41 [Off] Key on LCP. If no

external stop function is selected and the [Off] key is

inactive the motor can be stopped by disconnecting the

voltage.

2 2

Illustration 2.6

Illustration 2.7

Navigation Keys

The

four navigation keys are used to navigate between the

different choices available in [Quick Menu], [Main Menu]

and [Alarm Log]. Use the keys to move the cursor.

[OK] is used for choosing a parameter marked by the

cursor and for enabling the change of a parameter.

Local Control Key for local control are found at the bottom

of the LCP.

[Auto On] enables the frequency converter to be

controlled via the control terminals and/or serial communication. When a start signal is applied on the control

terminals and/or the bus, the frequency converter will

start. The key can be selected as [1] Enable or [0] Disable

via 0-42 [Auto on] Key on LCP.

NOTE

active HAND-OFF-AUTO signal via the digital inputs has

An

higher priority than the control keys [Hand On] – [Auto

On].

is used for resetting the frequency converter after

[Reset]

an alarm (trip). It can be selected as [1] Enable or [0]

Disable via 0-43 [Reset] Key on LCP.

The parameter shortcut can be carried out by holding

down the [Main Menu] key for 3 seconds. The parameter

shortcut allows direct access to any parameter.

2.1.2 Quick Transfer of Parameter Settings

between

Converters

Multiple Frequency

Once the set-up of a frequency converter is complete, we

Illustration 2.8

recommend

that you store the data in the LCP or on a PC

via MCT 10 Set-up Software Tool.

MG33MF02 - VLT® is a registered Danfoss trademark

13

Page 15

Auto

on

Reset

Hand

on

O

Status

Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

On

Alarm

Warn.

130BA027.10

How to Programme

VLT® AutomationDrive Programming Guide

2.1.3 Display Mode

22

Illustration 2.9

storage in LCP

Data

1.

Go to 0-50 LCP Copy

2. Press the [OK] key

3. Select “All to LCP”

4. Press the [OK] key

All parameter settings are now stored in the LCP indicated

by the progress bar. When 100% is reached, press [OK].

NOTE

the motor before performing this operation.

Stop

Connect the LCP to another frequency converter and copy

parameter settings to this frequency converter as well.

the

Data transfer from LCP to frequency converter

1.

Go to 0-50 LCP Copy

3. Select “All from LCP”

2. Press the [OK] key

4. Press the [OK] key

The parameter settings stored in the LCP are now

transferred to the frequency converter indicated by the

progress bar. When 100% is reached, press [OK].

NOTE

Stop

the motor before performing this operation.

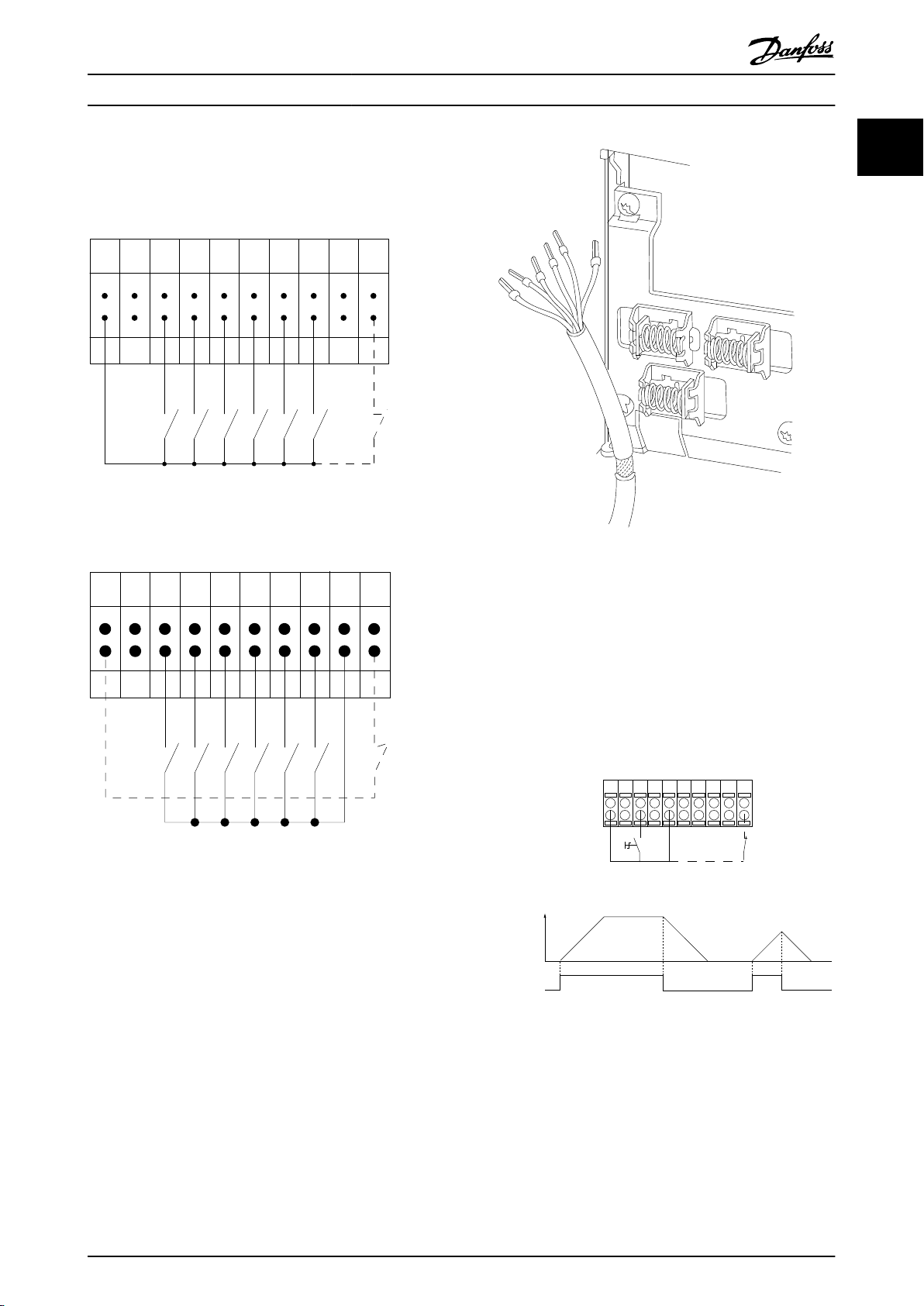

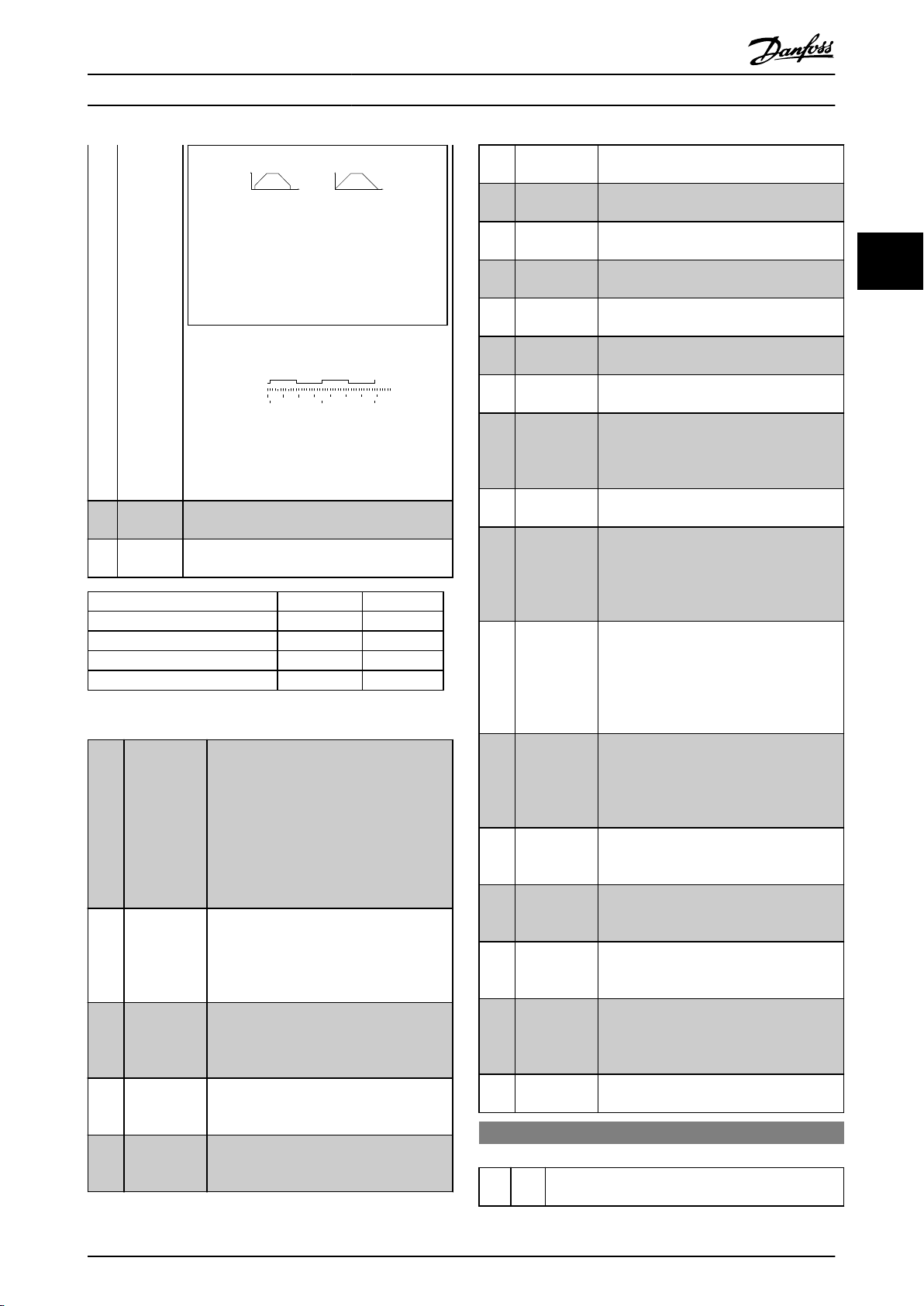

In normal operation, up to 5 different operating variables

be indicated continuously in the middle section: 1.1,

can

1.2, and 1.3 as well as 2 and 3.

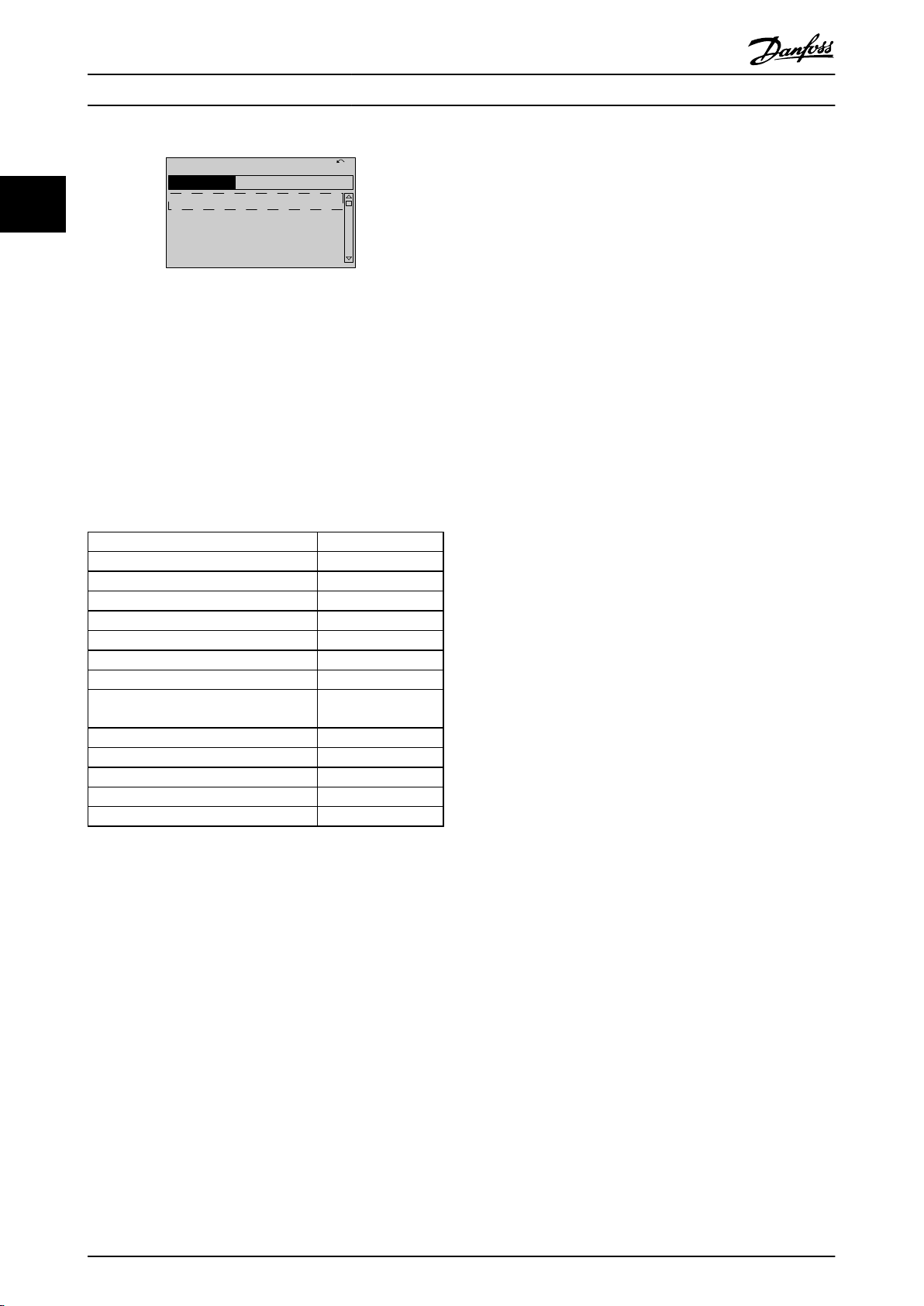

2.1.4 Display Mode - Selection of ReadOuts

It is possible to toggle between three status read-out

screens

by pressing the [Status] key.

Operating variables with different formatting are shown in

each status screen - see below.

Table 2.1 shows the measurements you can link to each of

the operating variables. When Options are mounted,

additional measurements are available. Define the links via

0-20 Display Line 1.1 Small, 0-21 Display Line 1.2 Small,

0-22 Display Line 1.3 Small, 0-23 Display Line 2 Large, and

0-24 Display Line 3 Large.

Each readout parameter selected in 0-20 Display Line 1.1

Small to 0-24 Display Line 3 Large has its own scale and

digits after a possible decimal point. By larger numeric

value of a parameter fewer digits are displayed after the

decimal point.

Ex.: Current readout 5.25A; 15.2A 105A.

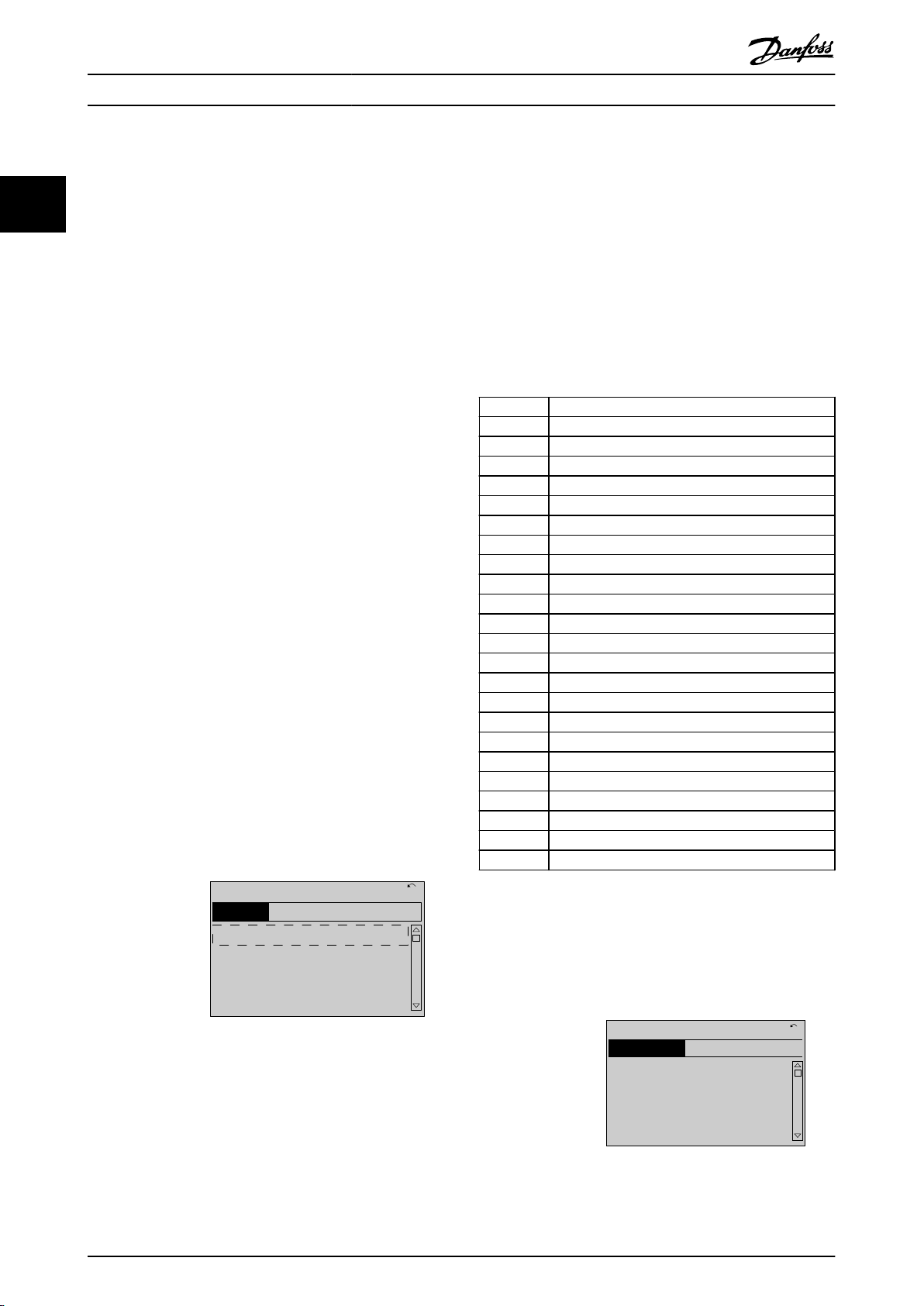

Operating variable Unit

16-00 Control Word hex

16-01 Reference [Unit] [unit]

16-02 Reference [%] %

16-03 Status Word hex

16-05 Main Actual Value [%] %

16-10 Power [kW] [kW]

16-11 Power [hp] [HP]

16-12 Motor Voltage [V]

16-13 Frequency [Hz]

16-14 Motor Current [A]

16-16 Torque [Nm] Nm

16-17 Speed [RPM] [RPM]

16-18 Motor Thermal %

16-20 Motor Angle

16-30 DC Link Voltage V

16-32 Brake Energy /s kW

16-33 Brake Energy /2 min kW

16-34 Heatsink Temp. C

16-35 Inverter Thermal %

16-36 Inv. Nom. Current A

16-37 Inv. Max. Current A

16-38 SL Controller State

16-39 Control Card Temp. C

16-40 Logging Buffer Full

16-50 External Reference

14 MG33MF02 - VLT® is a registered Danfoss trademark

Page 16

1.1

2

3

1.3

1.2

130BP041.10

799 RPM

Auto Remote Ramping

1 (1)

36.4 kw7.83 A

0.000

53.2 %

Status

1.1

1.2

2

1.3

130BP062.10

207RPM

Auto Remote Running

1 (1)

24.4 kW5.25A

6.9

Hz

Status

130BP063.10

778 RPM

Auto Remote Running

1 (1)

4.0 kW0.86 A

State: 0 o 0 (o)

When: Do: -

Status

How to Programme

Operating variable Unit

16-51 Pulse Reference

16-52 Feedback [Unit] [Unit]

16-53 Digi Pot Reference

16-60 Digital Input bin

16-61 Terminal 53 Switch Setting V

16-62 Analog Input 53

16-63 Terminal 54 Switch Setting V

16-64 Analog Input 54

16-65 Analog Output 42 [mA] [mA]

16-66 Digital Output [bin] [bin]

16-67 Pulse Input #29 [Hz] [Hz]

16-68 Freq. Input #33 [Hz] [Hz]

16-69 Pulse Output #27 [Hz] [Hz]

16-70 Pulse Output #29 [Hz] [Hz]

16-71 Relay Output [bin]

16-72 Counter A

16-73 Counter B

16-80 Fieldbus CTW 1 hex

16-82 Fieldbus REF 1 hex

16-84 Comm. Option STW hex

16-85 FC Port CTW 1 hex

16-86 FC Port REF 1 hex

16-90 Alarm Word

16-92 Warning Word

16-94 Ext. Status Word

VLT® AutomationDrive Programming Guide

Illustration 2.11

screen III

Status

This state displays the event and action of the Smart Logic

Control. For further information, see section Smart Logic

Control.

Illustration 2.12

2 2

Table 2.1

Status

screen I

This read-out state is standard after start-up or initialization.

Use [INFO] to obtain information about the measurement

links to the displayed operating variables (1.1, 1.2, 1.3, 2

and 3).

See the operating variables shown in the screen below.

Illustration 2.10

Status screen II

the operating variables (1.1, 1.2, 1.3 and 2) shown in

See

the screen below.

In the example, Speed, Motor current, Motor power and

Frequency are selected as variables in the first and second.

MG33MF02 - VLT® is a registered Danfoss trademark

2.1.5 Parameter Set-Up

The frequency converter can be used for practically all

assignments,

which is why the number of parameters is

quite large. The frequency converter offers a choice

between two programming modes - a Main Menu and a

Quick Menu mode.

The former provides access to all parameters. The latter

takes the user through a few parameters making it

possible to start operating the frequency converter.

Regardless of the mode of programming, you can change

a parameter both in the Main Menu mode and in the

Quick Menu mode.

2.1.6 Quick Menu Key Functions

Pressing [Quick Menus] The list indicates the different

areas

contained in the Quick menu.

Select My Personal Menu to display the chosen personal

parameters. These parameters are selected in 0-25 My

Personal Menu. Up to 50 different parameters can be

added in this menu.

15

Page 17

130BC916.10

Q1 My Personal Menu

Q2 Quick Setup

Q4 Smart Setup

Q5 Changes Made

0RPM 0.00A 1(1)

Quick Menus

How to Programme

VLT® AutomationDrive Programming Guide

22

Illustration 2.13

Quick setup to go through a limited amount of

Select

parameters to get the motor running almost optimally. The

default setting for the other parameters considers the

desired control functions and the configuration of signal

inputs/outputs (control terminals).

The selection of parameter is effected by means of the

arrow keys. The parameters in the following table are

accessible.

Parameter Setting

0-01 Language

1-20 Motor Power [kW] [kW]

1-22 Motor Voltage [V]

1-23 Motor Frequency [Hz]

1-24 Motor Current [A]

1-25 Motor Nominal Speed [rpm]

5-12 Terminal 27 Digital Input [0] No function*

1-29 Automatic Motor Adaptation (AMA) [1] Enable complete

3-02 Minimum Reference [rpm]

3-03 Maximum Reference [rpm]

3-41 Ramp 1 Ramp up Time [sec]

3-42 Ramp 1 Ramp Down Time [sec]

3-13 Reference Site

Table 2.2

*

If terminal 27 is set to “no function”, no connection to

+24 V on terminal 27 is necessary.

Select Changes made to get information about:

the last 10 changes. Use the [▲] [▼] navigation

•

keys to scroll between the last 10 changed

parameters.

the changes made since default setting.

•

Select Loggings to get information about the display line

read-outs. The information is shown as graphs.

Only display parameters selected in 0-20 Display Line 1.1

Small and 0-24 Display Line 3 Large can be viewed. It is

possible to store up to 120 samples in the memory for

later reference.

16 MG33MF02 - VLT® is a registered Danfoss trademark

AMA

Page 18

Quick

Menu

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

How to Programme

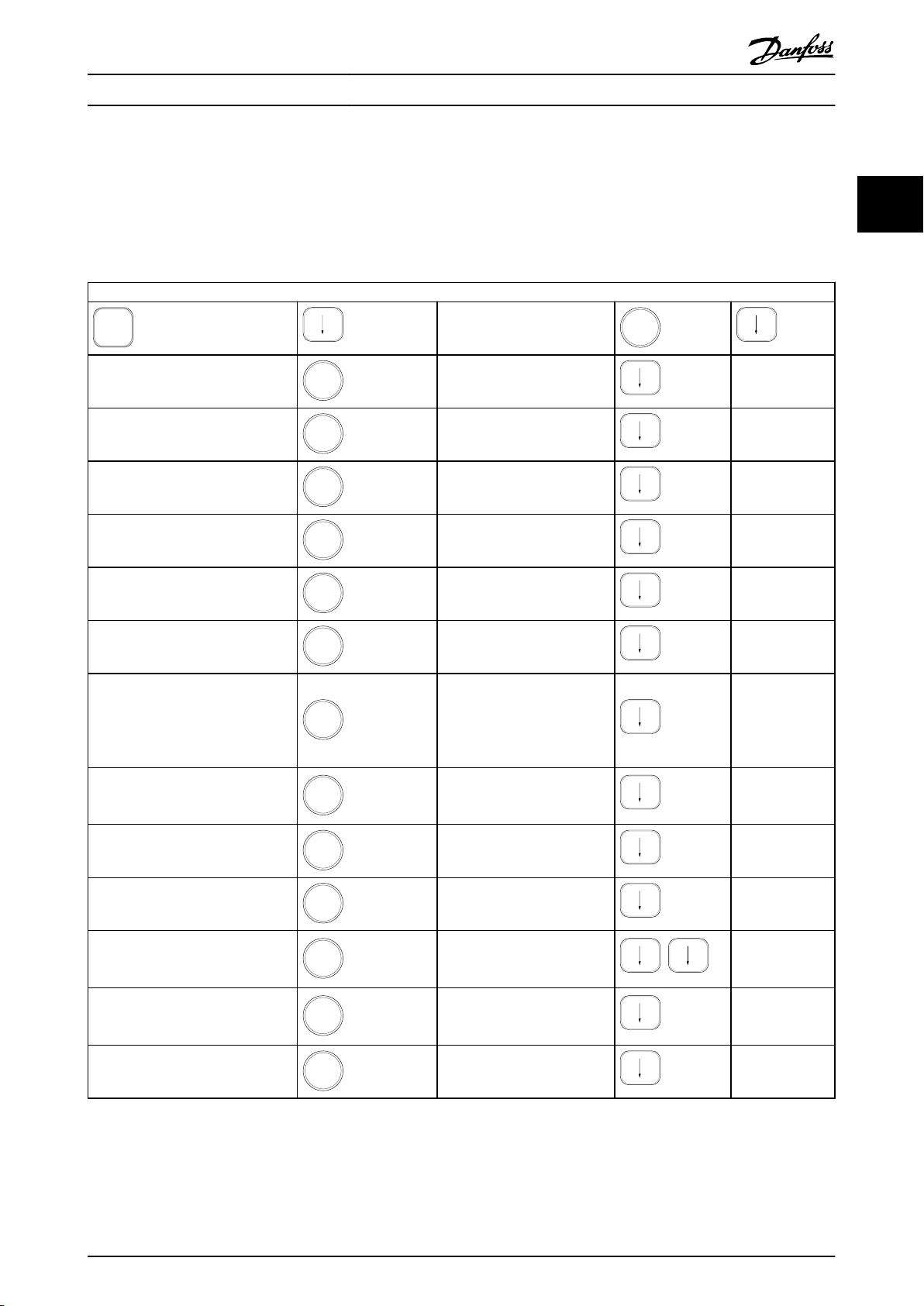

2.1.7 Initial Commissioning

VLT® AutomationDrive Programming Guide

The easiest way of carrying out the initial commissioning is

using the [Quick Menu] key and follow the quick set-up

by

procedure using LCP 102 (read Table 2.3Table 2.4 from left

to right). The example applies to open loop applications.

Press

0-01 Language

1-20 Motor Power [kW]

1-22 Motor Voltage

1-23 Motor Frequency

1-24 Motor Current

2 2

Q2 Quick Menu

Set language

Set Motor nameplate power

Set Nameplate voltage

Set Nameplate frequency

Set Nameplate current

1-25 Motor Nominal Speed

5-12 Terminal 27 Digital Input

1-29 Automatic Motor Adaptation

(AMA)

3-02 Minimum Reference

3-03 Maximum Reference

3-41 Ramp 1 Ramp up Time

3-42 Ramp 1 Ramp Down Time

3-13 Reference Site

Set Nameplate speed in RPM

If terminal default is Coast

inverse it is possible to change

this setting to No function. No

connection to terminal 27 is

then needed for running AMA

Set desired AMA function.

complete AMA is

Enable

recommended

Set the minimum speed of the

shaft

motor

Set the maximum speed of the

shaft

motor

Set the ramping up time with

reference

motor speed, n

to synchronous

s

Set the ramping down time

reference to synchronous

with

motor speed, n

s

Set the site from where the

reference

must work

Table 2.3

MG33MF02 - VLT® is a registered Danfoss trademark

17

Page 19

130BP066.10

1107 RPM

0 -

**

Operation/Display

1 -

**

Load/Motor

2 -

**

Brakes

3 -

**

Reference / Ramps

3.84 A 1 (1)

Main menu

130BP067.10

740RPM

0 -01 Language

[0] English

10.64A 1 [1]

0-0

*

Basic Settings

How to Programme

VLT® AutomationDrive Programming Guide

Another easy way of commissioning the drive is by using

Smart Application Setup (SAS), which can also be

the

found under the Quick Menu. Follow the indications on

22

the successive screens for setting-up the applications

listed.

All parameters can be changed in the Main Menu.

However,

depending on the choice of configuration

(1-00 Configuration Mode), some parameters can be

"missing". E.g. open loop hides all the PID parameters, and

other enabled options make more parameter groups

visible.

[Info] can be used throughout the SAS to see help

information for various selections, settings, and messages.

2.1.9 Parameter Selection

The following three applications are included:

In the Main menu mode, the parameters are divided into

Mechanical Brake

•

Conveyor

•

Pump/Fan

•

The following four field-busses can be selected:

Profibus

•

Profinet

•

DeviceNet

•

EthernetIP

•

NOTE

start conditions will be ignored while in the wizard.

The

NOTE

Smart Setup runs automatically on the first power-up

The

of the frequency converter or after a reset to factory

settings. If no action is taken, the SAS screen will automatically disappear after 10 min.

2.1.8 Main Menu Mode

Start the Main Menu mode by pressing [Main Menu]. The

read-out

The middle and bottom sections on the display show a list

of parameter groups which can be chosen by toggling [▲]

and [▼] keys.

shown below appears on the display.

groups. Select a parameter group with the navigation keys.

The following parameter groups are accessible:

Group no. Parameter group

0-** Operation/Display

1-** Load/Motor

2-** Brakes

3-** References/Ramps

4-** Limits/Warnings

5-** Digital In/Out

6-** Analog In/Out

7-** Controls

8-** Comm. and Options

9-** Profibus

10-** CAN Fieldbus

11-** Reserved Com. 1

12-** Reserved Com. 2

13-** Smart Logic

14-** Special Functions

15-** Drive Information

16-** Data Readouts

17-** Motor Feedb. Option

18-** Data Readouts 2

30-** Special Features

32-** MCO Basic Settings

33-** MCO Adv. Settings

34-** MCO Data Readouts

Table 2.4

After

selecting a parameter group, choose a parameter by

means of the navigation keys.

The middle section on the display shows the parameter

number and name as well as the selected parameter value.

Illustration 2.14

Each parameter has a name and number which remain the

regardless of the programming mode. In the Main

same

Menu mode, the parameters are divided into groups. The

first digit of the parameter number (from the left) indicates

the parameter group number.

18 MG33MF02 - VLT® is a registered Danfoss trademark

Illustration 2.15

Page 20

130BP068.10

740RPM

0 -01 Language

[0] English

10.64 A 1 [1]

0-0

*

Basic Settings

130BP069.10

1- 6*

113 RPM 1.78 A 1(1)

Load depen. setting

1 - 60 Low speed load

compensation

100%

130BP070.10

1 - 60 Low speed load

compensation

1 0%

Load depen. setting 1- 6*

729RPM 6.21A 1(1)

6

130BP073.10

635 RPM

1 - 71 Start Delay

00.0s

0.44 A 1 (1)

1- 7*

Start Adjustments

130BP072.10

957RPM

1-71 High starting torque time

0. s

11.58A 1 (1)

1-7*Start Adjustments

4

How to Programme

2.1.10 Changing Data

VLT® AutomationDrive Programming Guide

The procedure for changing data is the same in the Quick

and the Main menu mode. Press [OK] to change the

menu

selected parameter.

The procedure for changing data depends on whether the

selected parameter represents a numerical data value or a

text value.

2.1.11 Changing a Text Value

If the selected parameter is a text value, change the text

value

with the [▲] [▼] keys.

Place the cursor on the value to save and press [OK].

Illustration 2.16

2.1.12 Changing

If the chosen parameter represents a numeric data value,

the chosen data value by means of the [◀] [▶]

change

navigation keys as well as the [▲] [▼] navigation keys. Press

[◀] [▶] keys to move the cursor horizontally.

Illustration 2.18

2.1.13 Infinitely Variable Change of

Numeric

If the chosen parameter represents a numeric data value,

select

a digit with [◀] [▶].

Illustration 2.19

Change the selected digit infinitely variably with [▲] [▼].

The chosen digit is indicated by the cursor. Place the

cursor on the digit to save and press [OK].

Data Value

2 2

Illustration 2.17

Press [▲]

[▼] keys to change the data value. [▲] increases

the data value, and [▼] decreases the data value. Place the

cursor on the value to save and press [OK].

MG33MF02 - VLT® is a registered Danfoss trademark

Illustration 2.20

2.1.14 Value, Step-by-Step

Certain parameters can be changed step by step or

infinitely

1-22 Motor Voltage and 1-23 Motor Frequency.

The parameters are changed both as a group of numeric

data values and as numeric data values infinitely varying.

varying. This applies to 1-20 Motor Power [kW],

19

Page 21

130BA191.10

1

Auto

on

Reset

Hand

on

O

Menu

Status

Quick

Setup

Main

Menu

Back

2

3

4

OK

On

Alarm

Warn.

Setup

130BP077.10

22.8

rpm

Setup 1

How to Programme

VLT® AutomationDrive Programming Guide

2.1.15 Read-out and Programming of

Indexed

Parameters

22

Parameters are indexed when placed in a rolling stack.

15-30

Fault Log: Error Code to 15-32 Alarm Log: Time contain

a fault log which can be read out. Choose a parameter,

press [OK], and use [▲] [▼] to scroll through the value log.

Use 3-10 Preset Reference as another example:

Choose the parameter, press [OK], and use [▲] [▼] to scroll

through the indexed values. To change the parameter

value, select the indexed value and press [OK]. Change the

value by pressing [▲] [▼]. Press [OK] to accept the new

setting. Press [Cancel] to abort. Press [Back] to leave the

parameter.

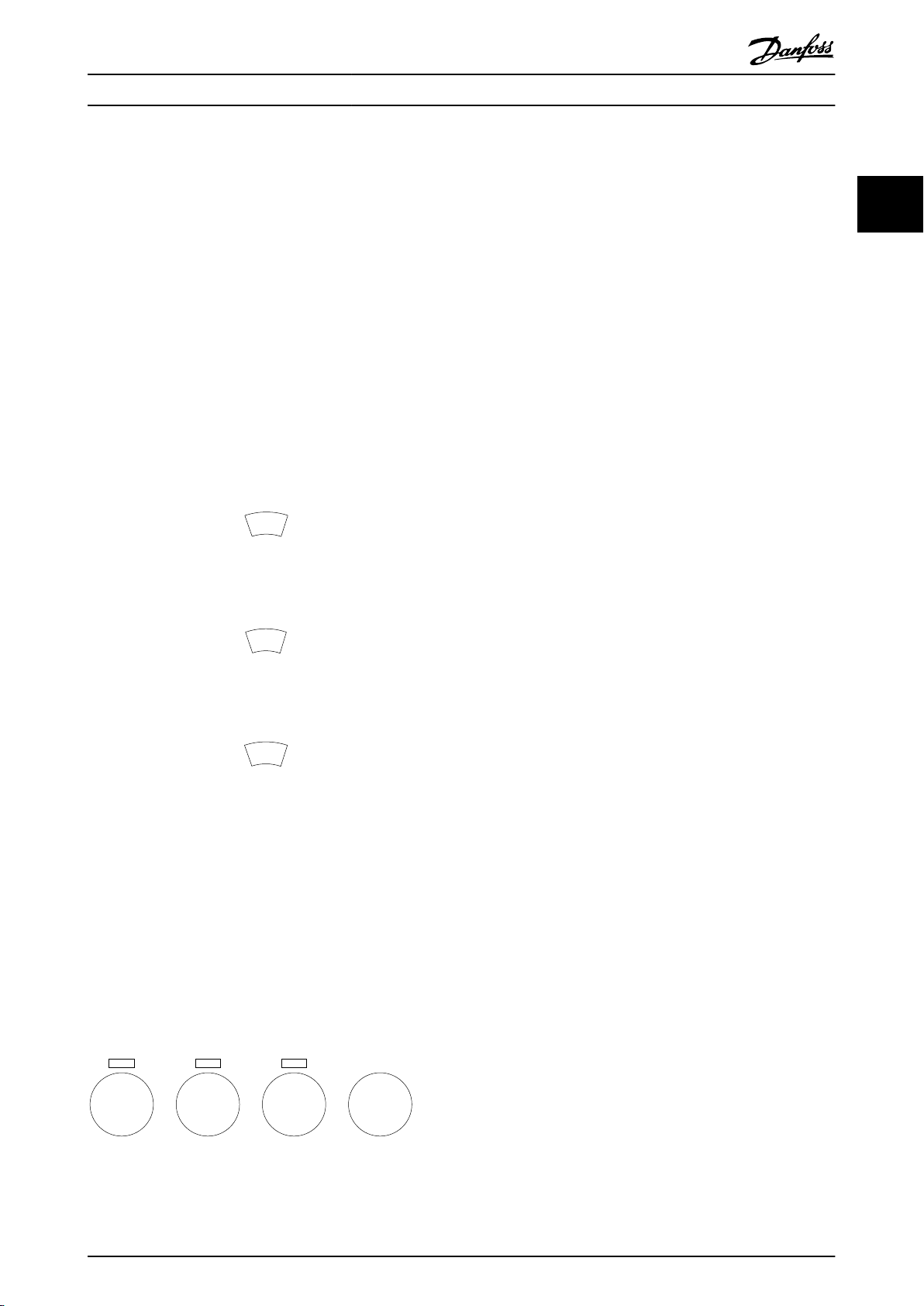

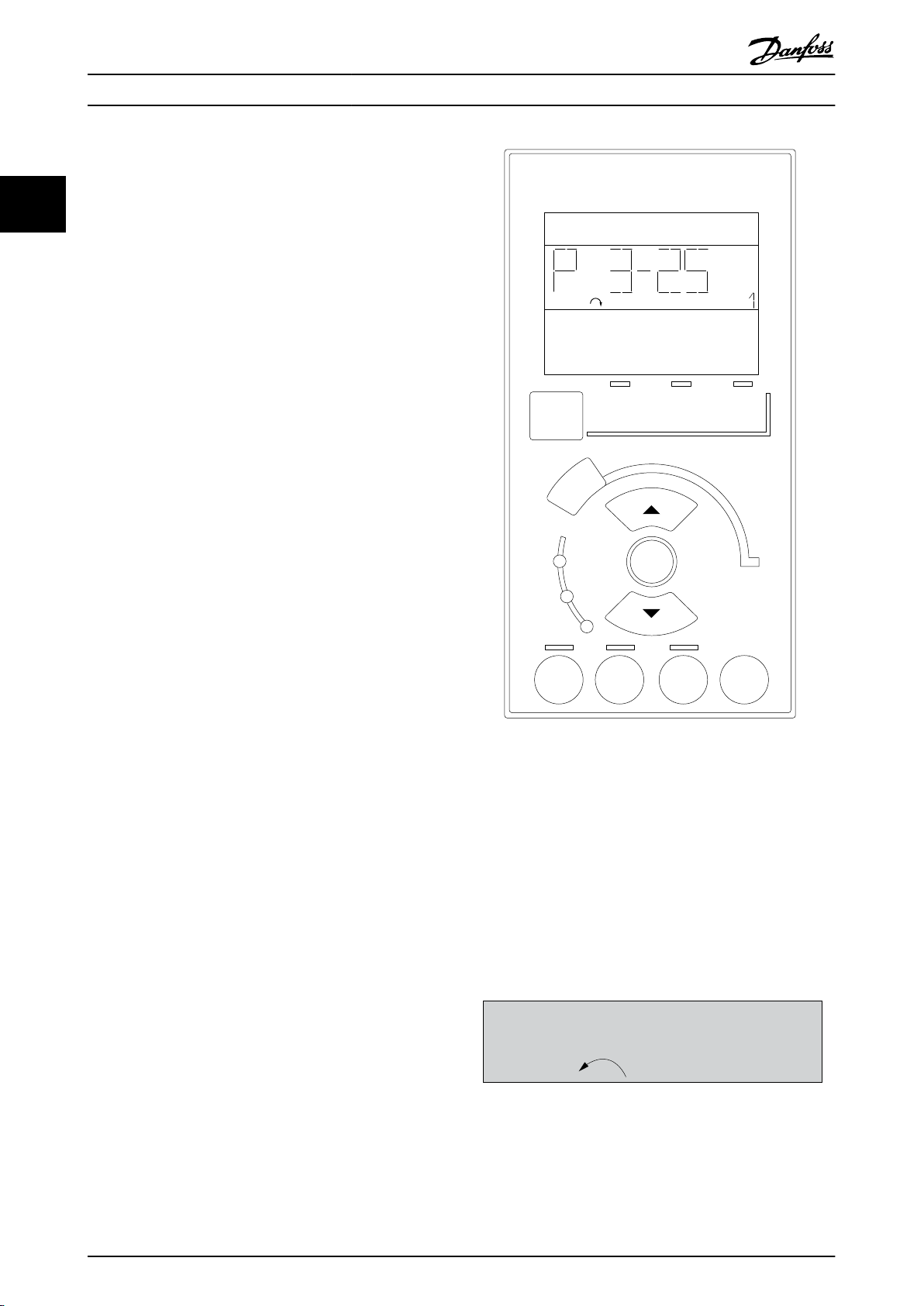

The following instructions are valid for the Numerical LCP

(LCP 101).

The control panel is divided into four functional groups:

1. Numerical display.

2. Menu keys and indicator lights - changing

parameters and switching between display

functions.

3. Navigation keys and indicator lights (LEDs).

4. Operation keys and indicator lights (LEDs).

Display line: Status messages displaying icons and numeric

value.

Indicator lights (LEDs)

Green LED/On: Indicates if control section is on.

•

Yellow LED/Wrn.: Indicates a warning.

•

Flashing red LED/Alarm: Indicates an alarm.

•

LCP keys

[Menu] Select one of the following modes:

Status

•

Quick Setup

•

Main Menu

•

Illustration 2.21

Mode

Status

Displays the status of the frequency converter or the

motor.

If an alarm occurs the NLCP automatically switches to

status mode.

A number of alarms can be displayed.

NOTE

Parameter copy is not possible with LCP 101 Numerical

Local Control Panel.

Illustration 2.22

20 MG33MF02 - VLT® is a registered Danfoss trademark

Page 22

Setup 1

130BP078.10

A 17

130BP079.10

Menu

Status Quick

Setup

Main

Menu

P 2-03

Setup 1

130BP046.10

Hand

on

O

Auto

on

Reset

How to Programme

Illustration 2.23

Main

Menu/Quick Setup is used for programming all

parameters or only the parameters in the Quick Menu (see

also description of the LCP 102 earlier in ).

The parameter values can be changed by pressing [▲] or

[▼] when the value is flashing.

Select Main Menu by pressing [Menu] a number of times.

Select the parameter group [xx-__] and press [OK]

Select the parameter [__-xx] and press [OK]

If the parameter is an array parameter select the array

number and press [OK]

Select the wanted data value and press [OK]

Parameters with functional choices display values such as

[1], [2], etc. For a description of the different choices, see

the individual description of the parameters in 3 Parameter

Descriptions

[Back] for stepping backwards

[▲] [▼] are used for manoeuvring between commands and

within parameters.

VLT® AutomationDrive Programming Guide

possible to enter the motor speed data by means of the

arrow

keys. The key can be selected as [1] Enable or [0]

Disable via 0-40 [Hand on] Key on LCP.

External stop signals activated by means of control signals

or a serial bus will override a 'start' command via the LCP.

The following control signals are still active when [Hand

On] is activated:

[Hand On] - [Off] - [Auto On]

•

Reset

•

Coasting stop inverse

•

Reversing

•

Set-up select lsb - Set-up select msb

•

Stop command from serial communication

•

Quick stop

•

DC brake

•

[Off] stops the connected motor. The key can be selected

as [1] Enable or [0] Disable via 0-41 [Off] Key on LCP.

If no external stop function is selected and the [Off] key is

inactive the motor can be stopped by disconnecting the

voltage.

[Auto On] enables the frequency converter to be

controlled via the control terminals and/or serial communication. When a start signal is applied on the control

terminals and/or the bus, the frequency converter will

start. The key can be selected as [1] Enable or [0] Disable

via 0-42 [Auto on] Key on LCP.

2 2

Illustration 2.24

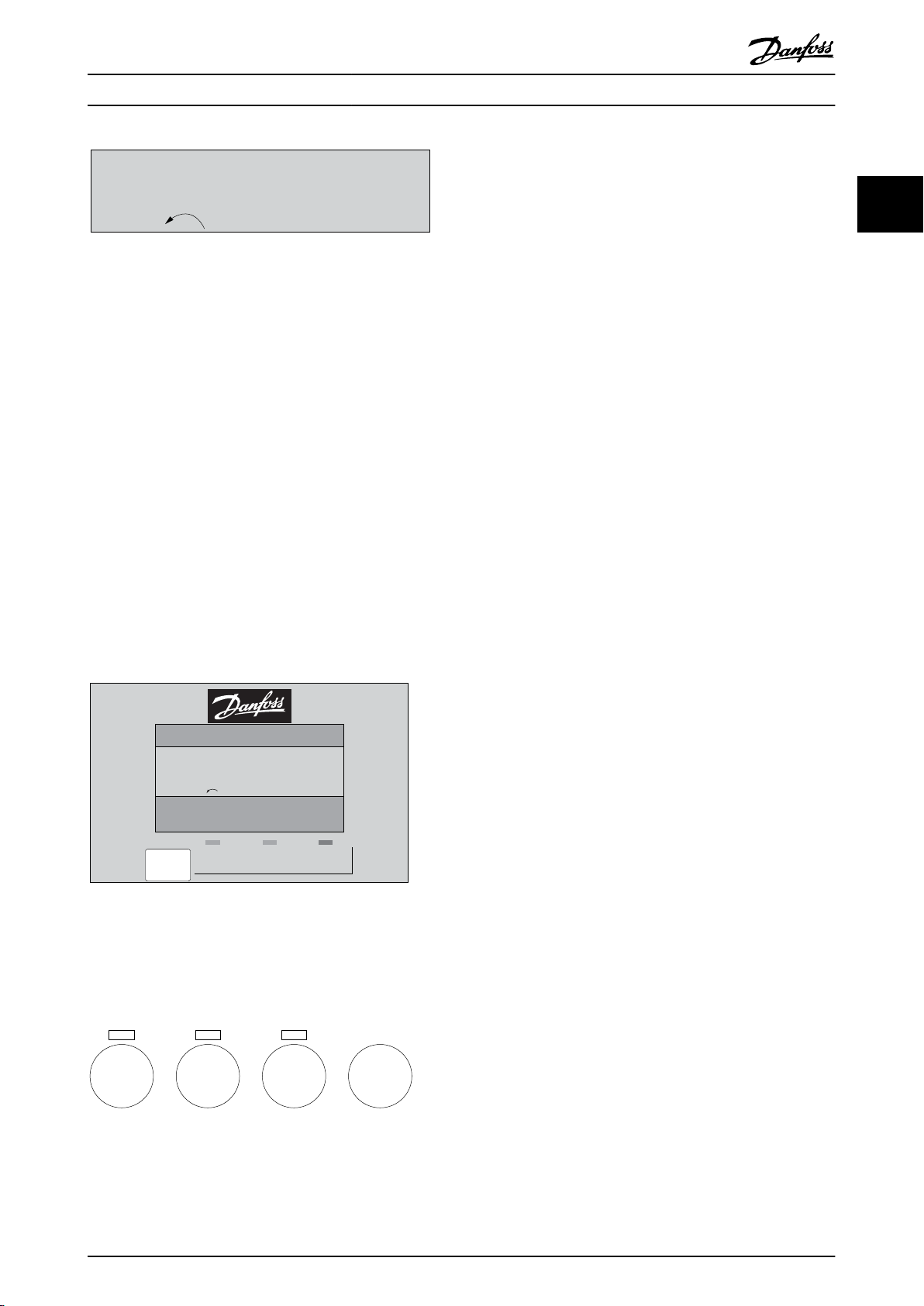

2.1.16 Local Control Keys

Keys for local control are found at the bottom of the LCP.

Illustration 2.25

[Hand On] enables

the LCP. [Hand On] also starts the motor and it is now

control of the frequency converter via

NOTE

active HAND-OFF-AUTO signal via the digital inputs has

An

higher priority than the control keys [Hand On] [Auto On].

is used for resetting the frequency converter after

[Reset]

an alarm (trip). It can be selected as [1] Enable or [0]

Disable via 0-43 [Reset] Key on LCP.

2.1.17 Initialisation to Default Settings

Initialise the frequency converter to default settings in two

ways.

Recommended

1.

2. Press [OK]

3. Select “Initialisation”

4. Press [OK]

5. Cut off the mains supply and wait until the

initialisation (via 14-22 Operation Mode)

Select 14-22 Operation Mode

display turns off.

MG33MF02 - VLT® is a registered Danfoss trademark

21

Page 23

How to Programme

6. Reconnect the mains supply - the frequency

converter

22

14-22 Operation Mode initialises all except:

14-50 RFI Filter

8-30 Protocol

8-31 Address

8-32 FC Port Baud Rate

8-35 Minimum Response Delay

8-36 Max Response Delay

8-37 Max Inter-Char Delay

15-00 Operating Hours to 15-05 Over Volt's

15-20 Historic Log: Event to 15-22 Historic Log:

Time

15-30 Fault Log: Error Code to 15-32 Alarm Log:

Time

Manual initialisation

is now reset.

VLT® AutomationDrive Programming Guide

1. Disconnect from mains and wait until the display

turns off.

2. 2a Press [Status] - [Main Menu] - [OK] at

the same time while power up for LCP

102, Graphical Display

2b Press [Menu] while power up for LCP

101, Numerical Display

3. Release the keys after 5 s.

4. The frequency converter is now programmed

according to default settings.

This procedure initialises all except:

15-00 Operating Hours

15-03 Power Up's

15-04 Over Temp's

15-05 Over Volt's

NOTE

A

manual initialisation also resets serial communication, RFI

filter settings (14-50 RFI Filter) and fault log settings.

22 MG33MF02 - VLT® is a registered Danfoss trademark

Page 24

Parameter Descriptions

3 Parameter Descriptions

VLT® AutomationDrive Programming Guide

16-** Readout parameters

3.1 Parameter Selection

Parameters for FC 300 are grouped into various parameter

for easy selection of the correct parameters for

groups

optimized operation of the frequency converter.

0-** Operation and Display parameters

Basic Settings, set-up handling

•

Display and Local Control Panel parameters for

•

choosing readouts, setting up selections and

copying functions

1-** Load and Motor parameters includes all load and

motor related parameters

2-** Brake parameters

DC brake

•

Dynamic brake (Resistor brake)

•

Mechanical brake

•

Over Voltage Control

•

3-** References and ramping parameters includes DigiPot

function

17-**

Encoder Option parameters

18-** Readout 2 parameters

30-** Special Features

32-** MCO Basic Settings parameters

33-** MCO Adv. Settings parameters

34-** MCO Data Readouts

35-** Sensor Input Option parameters

Too see if a parameter can be used in a specific control

mode,

use the table in 4.1.2 Active/Inactive Parameters in

Different Drive Control Modes.

3 3

4-** Limits Warnings; setting of limits and warning

parameters

5-** Digital inputs and outputs includes relay controls

6-** Analog inputs and outputs

7-** Controls; Setting parameters for speed and process

controls

8-** Communication and option parameters for setting of

FC RS485 and FC USB port parameters.

9-** Profibus parameters

10-** DeviceNet and CAN Fieldbus parameters

12-** Ethernet parameters

13-** Smart Logic Control parameters

14-** Special function parameters

15-** Drive information parameters

MG33MF02 - VLT® is a registered Danfoss trademark

23

Page 25

Parameter Descriptions

VLT® AutomationDrive Programming Guide

3.2 Parameters: 0-** Operation and Display

Parameters related to the fundamental functions of the

frequency

ration of the LCP display.

33

3.2.1 0-0* Basic Settings

converter, function of the LCP keys and configu-

0-01 Language

Option: Function:

[51] Bahasa Indonesia Part of Language package 2

[52] Hrvatski Part of Language package 3

0-02 Motor Speed Unit

Option: Function:

0-01 Language

Option: Function:

Defines the language to be used in the

The frequency converter can be

display.

delivered with 4 different language

packages. English and German are

included in all packages. English cannot

be erased or manipulated.

[0] * English Part of Language packages 1 - 4

The display showing depends on settings in

Motor Speed Unit and 0-03 Regional Settings. The

0-02

default setting of 0-02 Motor Speed Unit and

0-03 Regional Settings depends on which region of

the world the frequency converter is supplied to, but

can be re-programmed as required.

NOTE

Changing the Motor Speed Unit will reset certain

parameters to their initial value. It is

recommended to select the motor speed unit

[1] Deutsch Part of Language packages 1 - 4

[2] Francais Part of Language package 1

[3] Dansk Part of Language package 1

[4] Spanish Part of Language package 1

[5] Italiano Part of Language package 1

[6] Svenska Part of Language package 1

[0] RPM Selects display of motor speed variables and

[1] * Hz Selects display of motor speed variables and

first, before modifying other parameters.

parameters

terms of motor speed (RPM).

parameters

terms of output frequency to the motor (Hz).

(i.e. references, feedbacks and limits) in

(i.e. references, feedbacks and limits) in

[7] Nederlands Part of Language package 1

[10] Chinese Part of Language package 2

[20] Suomi Part of Language package 1

[22] English US Part of Language package 4

[27] Greek Part of Language package 4

[28] Bras.port Part of Language package 4

[36] Slovenian Part of Language package 3

[39] Korean Part of Language package 2

[40] Japanese Part of Language package 2

[41] Turkish Part of Language package 4

[42] Trad.Chinese Part of Language package 2

[43] Bulgarian Part of Language package 3

[44] Srpski Part of Language package 3

[45] Romanian Part of Language package 3

[46] Magyar Part of Language package 3

[47] Czech Part of Language package 3

[48] Polski Part of Language package 4

[49] Russian Part of Language package 3

NOTE

This

parameter cannot be adjusted while the motor is

running.

0-03 Regional Settings

Option: Function:

[0] * Interna-

tional

[1] US

Activates 1-20

the motor power in kW and sets the default

value of 1-23 Motor Frequency to 50Hz.

Activates 1-20

the motor power in HP and sets the default

value of 1-23 Motor Frequency to 60Hz.

Motor Power [kW] for setting

Motor Power [kW] for setting

NOTE

This

parameter cannot be adjusted while the motor is

running.

0-04 Operating State at Power-up (Hand)

Option: Function:

Selects the operating mode upon

reconnection of the frequency converter to

mains voltage after power down in Hand

(local) operation mode.

[0] Resume Restarts the frequency converter, maintaining

same and the same start/stop settings

the

[50] Thai Part of Language package 2

24 MG33MF02 - VLT® is a registered Danfoss trademark

Page 26

Parameter Descriptions

VLT® AutomationDrive Programming Guide

0-04 Operating State at Power-up (Hand)

Option: Function:

(applied by [Hand On/Off]) as before the

converter was powered down.

local reference, after mains voltage

the frequency converter.

[1] * Forced stop,

ref=old

[2] Forced stop,

ref=0

frequency

Restarts the frequency converter with a

saved

reappears and after pressing [Hand On].

Resets the local reference to 0 upon

restarting

3.2.2 0-1* Set-up Operations

Define and control the individual parameter setups.

The

frequency converter has four parameter setups that

can be programmed independently of each other. This

makes the frequency converter very flexible and able to

solve advanced control functionality problems, often

saving the cost of external control equipment. For example

these can be used to program the frequency converter to

operate according to one control scheme in one setup

(e.g. motor 1 for horizontal movement) and another

control scheme in another setup (e.g. motor 2 for vertical

movement). Alternatively they can be used by an OEM

machine builder to identically program all their factory

fitted frequency converters for different machine types

within a range to have the same parameters and then

during production/commissioning simply select a specific

setup depending on which machine the frequency

converter is installed on.

The active setup (i.e. the setup in which the frequency

converter is currently operating) can be selected in

0-10 Active Set-up and is displayed in the LCP. Using Multi

set-up it is possible to switch between setups with the

frequency converter running or stopped, via digital input

or serial communication commands. If it is necessary to

change setups whilst running, ensure 0-12 This Set-up

Linked to is programmed as required. Using 0-11 Edit Set-up

it is possible to edit parameters within any of the setups

whilst continuing the frequency converter operation in its

Active Setup which can be a different setup to that being

edited. Using 0-51 Set-up Copy it is possible to copy

parameter settings between the setups to enable quicker

commissioning if similar parameter settings are required in

different setups.

0-10 Active Set-up

Option: Function:

[1] * Set-up 1

[2] Set-up 2

[3] Set-up 3

[4] Set-up 4

[9] Multi Set-up Remote selection of set-ups using digital

Use 0-51

Set-up Copy to copy a set-up to one or all other

[1] Set-up 1

separate parameter set-ups within which all

parameters can be programmed.

inputs

This set-up uses the settings from 0-12 This

Set-up Linked to. Stop the frequency

converter before making changes to openand closed loop functions

to [4] Set-up 4 are the four

and the serial communication port.

set-ups. Stop the frequency converter before switching

between set-ups where parameters marked ‘not

changeable during operation’ have different values. To

avoid conflicting settings of the same parameter within

two different set-ups, link the set-ups together using

0-12 This Set-up Linked to. Parameters which are ‘not

changeable during operation’ are marked FALSE in the

parameter lists in 4 Parameter Lists.

0-11 Edit Set-up

Option: Function:

Select the set-up to be edited (i.e.

programmed)

active set-up or one of the inactive set-ups.

[0] Factory setup Cannot be edited but it is useful as a data

source

known state.

[1] * Set-up 1

[2] Set-up 2

[3] Set-up 3

[4] Set-up 4

[9] Active Set-up Can also be edited during operation. Edit

[1] Set-up 1

freely during operation, independently of

the active set-up.

chosen set-up from a range of sources:

the

LCP, FC RS-485, FC USB or up to five fieldbus

sites.

during operation; either the

to return the other set-ups to a

to [4] Set-up 4 can be edited

3 3

0-10 Active Set-up

Option: Function:

Select the set-up to control the frequency

converter

[0] Factory setup Cannot be changed. It contains the Danfoss

data

when returning the other set-ups to a

known state.

functions.

set, and can be used as a data source

MG33MF02 - VLT® is a registered Danfoss trademark

25

Page 27

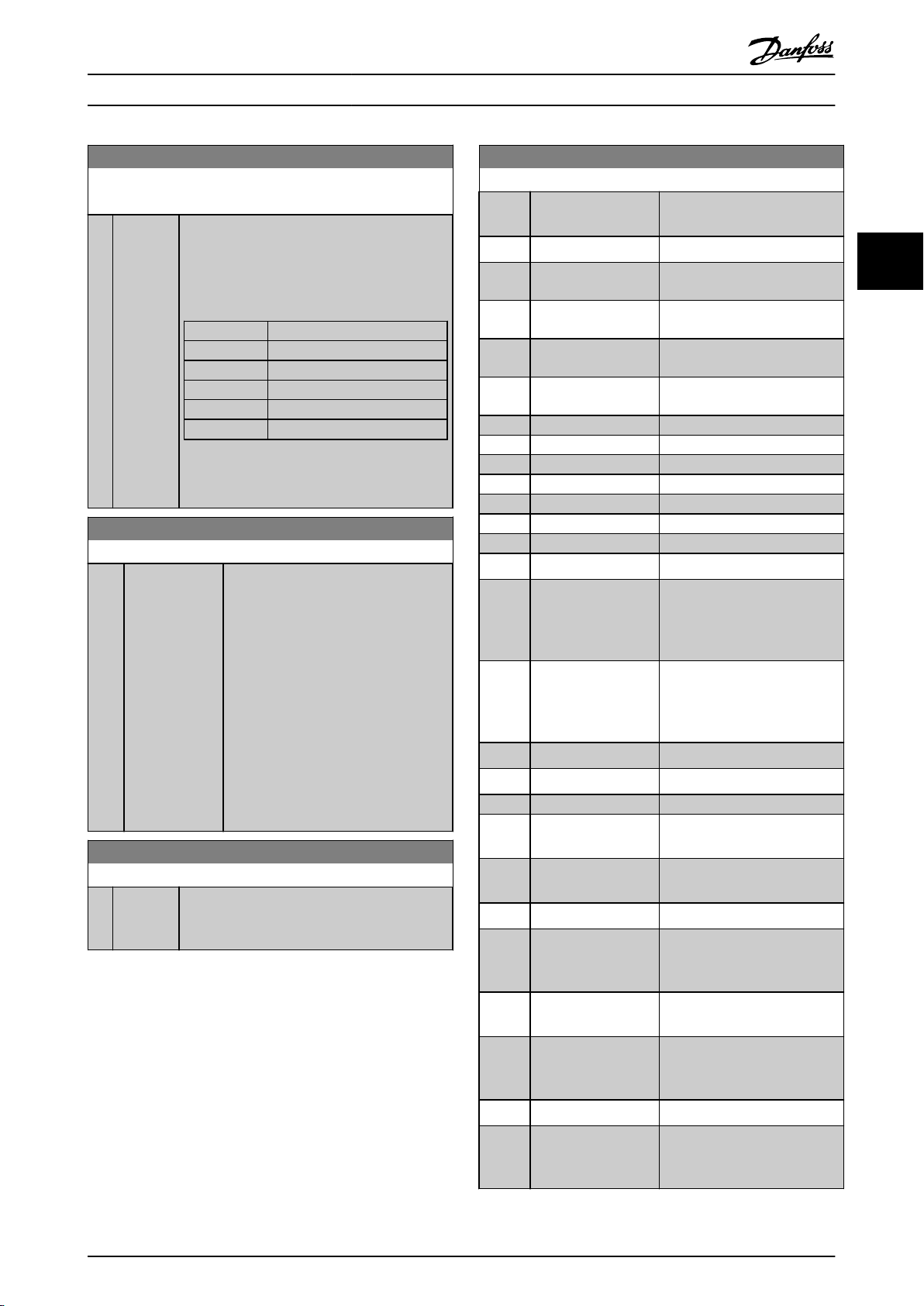

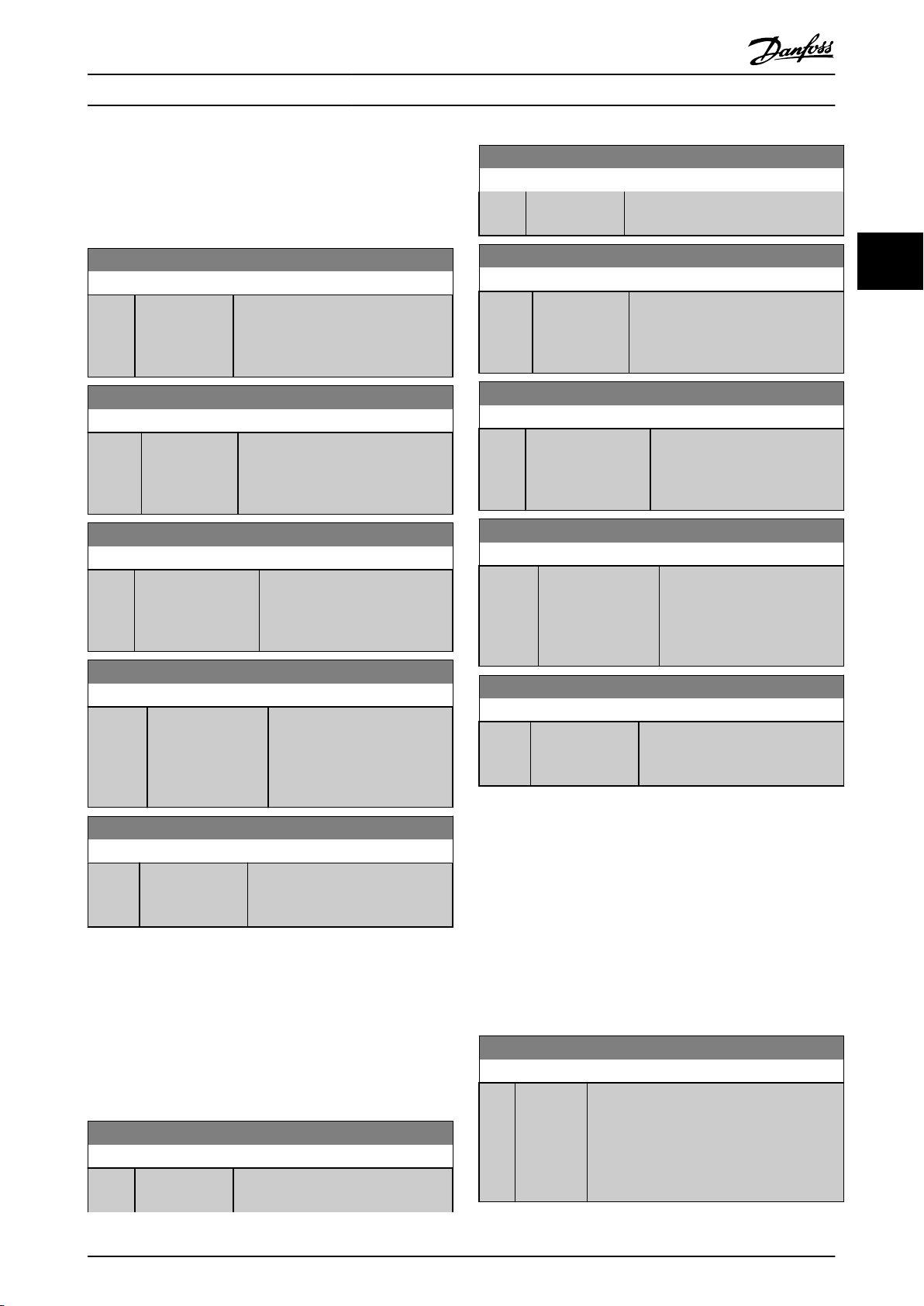

130BA199.10

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

P 0-11

P 0-11

P 0-11

P 0-11

Set-up

Set-up

Set-up

Set-up

PLC Fieldbus

130BP075.10

0-12 This Set-up Linked to

0 RPM

0.00A

1(1)

Set-up Handling 0-1*

[1]

Setup 1

130BP076.10

0-12 This Set-up Linked to

0 RPM

0.00A

1(1)

Set-up Handling

0-1*

[2]

Setup 2

Parameter Descriptions

VLT® AutomationDrive Programming Guide

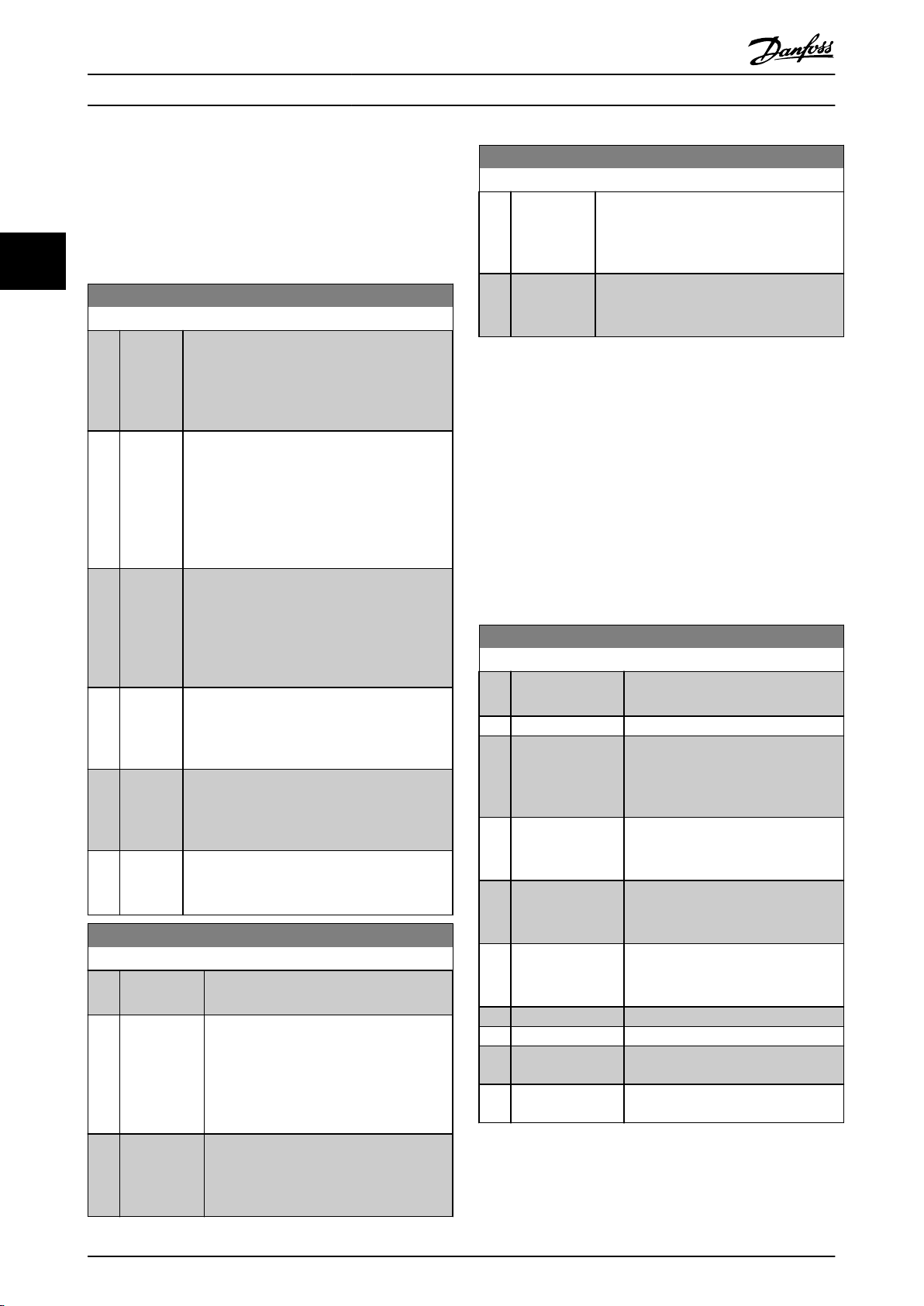

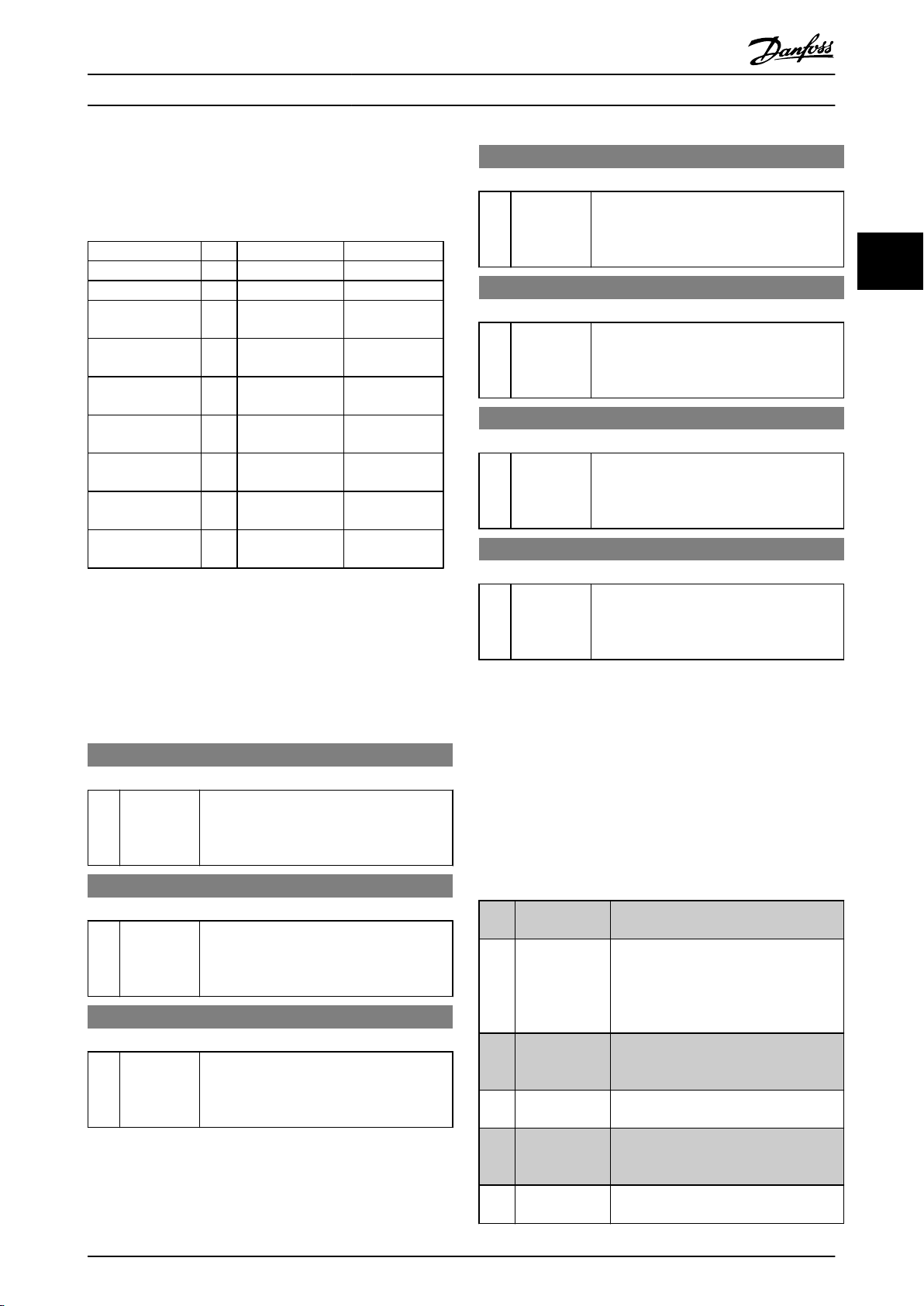

0-12 This Set-up Linked to

Option: Function:

Set-up 2 are synchronised (or ‘linked’). Synchro-

can be performed in two ways:

nisation

1. Change the edit set-up to Set-up 2 [2] in

33

0-11 Edit Set-up and set 0-12 This Set-up Linked

to to Set-up 1 [1]. This will start the linking

(synchronising) process.

Illustration 3.2

OR

While still in Set-up 1, copy Set-up 1 to Set-

2.

up 2. Then set 0-12 This Set-up Linked to to Set-

up 2 [2]. This will start the linking process.

Illustration 3.1

0-12 This Set-up Linked to

Option: Function:

26 MG33MF02 - VLT® is a registered Danfoss trademark

To enable conflict-free changes from one set-up

another during operation, link set-ups

to

containing parameters which are not

changeable during operation. The link will

ensure synchronising of the ‘not changeable

during operation’ parameter values when

moving from one set-up to another during

operation. ‘Not changeable during operation’

parameters can be identified by the label FALSE

in the parameter lists in the section Parameter

Lists.

0-12 This Set-up Linked to is used by Multi set-

up in 0-10 Active Set-up. Multi set-up is used to

move from one set-up to another during

operation (i.e. while the motor is running).

Example:

Use Multi set-up to shift from Set-up 1 to Setup 2 whilst the motor is running. Programme in

Set-up 1 first, then ensure that Set-up 1 and

[0] * Not linked

[1] Set-up 1

[2] Set-up 2

[3] Set-up 3

[4] Set-up 4

Illustration 3.3

After the link is complete, 0-13

Readout: Linked

Set-ups will read {1,2} to indicate that all ‘not

changeable during operation’ parameters are

now the same in Set-up 1 and Set-up 2. If there

are changes to a ‘not changeable during

operation’ parameter, e.g. 1-30 Stator Resistance

(Rs), in Set-up 2, they will also be changed

automatically in Set-up 1. A switch between

Set-up 1 and Set-up 2 during operation is now

possible.

Page 28

Parameter Descriptions

VLT® AutomationDrive Programming Guide

0-13 Readout: Linked Set-ups

Array [5]

Range: Function:

0 * [0 - 255 ] View a list of all the set-ups linked by means of

This Set-up Linked to. The parameter has one

0-12

index for each parameter set-up. The parameter

value displayed for each index represents which

set-ups are linked to that parameter set-up.

Index LCP value

0 {0}

1 {1,2}

2 {1,2}

3 {3}

4 {4}

Table 3.2 Example: Set-up 1 and Set-up 2 are

linked

0-14 Readout: Edit Set-ups / Channel

Range: Function:

0

N/A*

[-2147483648 2147483647

N/A]

View the setting of 0-11

each of the four different communication channels. When the number is

displayed in hex, as it is in the LCP, each

number represents one channel.

Numbers 1-4 represent a set-up number;

‘F’ means factory setting; and ‘A’ means

active set-up. The channels are, from

right to left: LCP, FC-bus, USB, HPFB1-5.

Example: The number AAAAAA21h

means that the FC bus selected Set-up 2

in 0-11 Edit Set-up, the LCP selected Setup 1 and all others used the active setup.

Edit Set-up for

0-15 Readout: actual setup

Range: Function:

0 * [0 - 255 ] Makes it possible to read out the active set-up,

when multi set-up is selected in 0-10 Active

also

Set-up.

3.2.3 0-2* LCP Display

Define the variables displayed in the Graphical Local

Control

Panel.

NOTE

Please

refer to 0-37 Display Text 1, 0-38 Display Text 2 and

0-39 Display Text 3 for information on how to write display

texts.

0-20 Display Line 1.1 Small

Option: Function:

Select a variable for display in

1, left position.

line

[0] * None No display value selected.

[953] Profibus Warning

Word

[1005] Readout Transmit

Counter

Error

[1006] Readout Receive Error

Counter

[1007] Readout Bus Off

Counter

[1013] Warning Parameter

[1230] Warning Parameter

[1472] VLT Alarm Word

[1473] VLT Warning Word

[1474] VLT Ext. Status Word

[1501] Running Hours

[1502] kWh Counter

[1600] Control Word Present control word

[1601] Reference [Unit] Total reference (sum of digital/

analog/preset/bus/freeze

catch up and slow-down) in

selected unit.

[1602] Reference % Total reference (sum of digital/

analog/preset/bus/freeze

catch up and slow-down) in

percent.

[1603] Status Word Present status word.

[1605] Main Actual Value [%] Actual value as a percentage.

[1609] Custom Readout

[1610] Power [kW] Actual power consumed by the

in kW.

motor

[1611] Power [hp] Actual power consumed by the

in HP.

motor

[1612] Motor Voltage Voltage supplied to the motor.

[1613] Frequency Motor frequency, i.e. the output

frequency

converter in Hz

[1614] Motor Current Phase current of the motor

measured

[1615] Frequency [%] Motor frequency, i.e. the output

frequency

converter in percent.

[1616] Torque [Nm] Actual motor torque in Nm

[1617] * Speed [RPM] Speed in RPM (revolutions per

minute)

speed in closed loop.

from the frequency

as effective value.

from the frequency

i.e. the motor shaft

ref./

ref./

3 3

MG33MF02 - VLT® is a registered Danfoss trademark

27

Page 29

Parameter Descriptions

VLT® AutomationDrive Programming Guide

0-20 Display Line 1.1 Small

Option: Function:

[1618] Motor Thermal Thermal load on the motor,

calculated

[1619] KTY sensor

33

[1620] Motor Angle

[1622] Torque [%] Present motor load as a

[1625] Torque [Nm] High

[1630] DC Link Voltage Intermediate circuit voltage in

[1632] Brake Energy /s Present brake power transferred

[1633] Brake Energy /2 min Brake power transferred to an

[1634] Heatsink Temp. Present heat sink temperature

[1635] Inverter Thermal Percentage load of the inverters.

[1636] Inv. Nom. Current Nominal current of the

[1637] Inv. Max. Current Maximum current of the

[1638] SL Controller State State of the event executed by

[1639] Control Card Temp. Temperature of the control card.

[1650] External Reference Sum of the external reference as

[1651] Pulse Reference Frequency in Hz connected to

[1652] Feedback [Unit] Reference value from

[1653] Digi Pot Reference

[1660] Digital Input Signal states form the 6 digital

temperature

percentage

torque.

the

to

Stated as an instantaneous

value.

external

mean power is calculated

continuously for the most

recent 120 s.

of

cut-out limit is 95 ±5 °C; cutting

back in occurs at 70 ±5 °C.

frequency

frequency

the

a

analog/pulse/bus.

the

33).

programmed

terminals

33). There are 16 bits in total,

but only six of them are used.

Input 18 corresponds to the

leftmost of the used bits. Signal

low = 0; Signal high = 1.

by the ETR function.

of the rated motor

frequency converter.

an external brake resistor.

brake resistor. The