MAKING MODERN LIVING POSSIBLE

Data sheet

Thermostatic Expansion Valves

Type TR 6

Introduction

The TR 6 series is a hermetic tight design,

designed and developed with features

especially for use in applications such as:

y Residential air conditioning systems

y Split systems

y Roof top units

y Heat pumps

y Light commercial air conditioning systems

y Chillers

Features y Compact size - hermetic design

y Refrigerants & rated capacities ranging up to

- R22: 6.7 TR / 23.6 kW

- R410A: 7 TR / 24.5 kW

- Others on request

y Laser-welded power element

- Longer diaphragm life.

- High pressure tolerance and working

pressure.

y Stainless steel capillary tube

- Tolerates more bending for easier installation

and longer life.

- High strength and vibration resistance.

y Stainless steel bulb

- Self-aligning for fast and easy installation;

secures with a single bulb strap/OEM strap

- More contact surface for better heat transfer

The TR design incorporates a hot-pressed

brass body with the entire power element,

including the capillary tube and bulb,

fabricated from stainless steel. All valves are

designed with balanced port which reduces

the inuence from varying condensing

pressures. The valves can be delivered with

special connections and ttings both at the

inlet and outlet and at the equalizer connection.

y Balance port design

y A complete program with internal check valve

with low pressure drop at full ow or without

internal check valve.

y Adjustable or non-adjustable superheat, for

customer specic factory setting.

y Bleed function available.

y Customer specic engravement.

y Solder and mechanical connections

y Straightway versions with xed orice and

with external equalization.

y UL listed, le SA7200

DKRCC.PD.AN0.A6.22 / 520H7258

Data sheet Thermostatic expansion valves , type TR 6

Valve program

Standard versions

Options on request

Technical data

Refrigerants:

R22 and R410A

Operating range:

+14 °F to +59 °F / –10 °C to +15 °C

Setting:

Fixed setting:

Static superheat in accordance with

customers' specications.

Adjustable setting:

Factory static superheat of 7.2 °F / 4 °K.

Refrigerants:

Other refrigerants.

Range:

Other temperature ranges.

MOP:

Special MOP charges.

Capillary tube lengths:

20 In. / 0.5 m

38.4 In / 0.975 m

Max. operating temperature

Thermostatic element:

R22: max. 212 °F / 100 °C

R410A: max. 212 °F / 100 °C

Valve body:

230 °F / 110 °C

Packing:

Single or industrial pack

Versions:

All valves are in straightway versions.

With or without internal check valve.

Standard connections:

3

/8 in. ODF inlet x 1/2 in. ODF outlet x

1

/4 In are nut 24.3 inch length

Capillary tube length: 31.5 In /0.8 m

Options for Connections:

Inlet/Outlet:

– Inlet: 3/8 in. ODM, 3/8 in. ODF, 1/2 in. ODF, chatle,

aeroquip

– Outlet: 3/8 in. ODF, 1/2 in ODF, 5/8 in ODF, chatle,

aeroquip, are

Equalizer:

Cu capillary tube size: Ø 1/8 in.

¼ in. Flare Nut with l = 9.5, 16.9 or 24.3 in.

Solder 1/8 in. ODM with l = 16.9 or 24.3 in.

Solder 1/4 in ODF with l = 31.7 or 39.1 in.

Max. working pressure

MWP 630 psig / PS = 45.5 bar

Max. test pressure

680 psig / Pf = 47 bar

Identication

Essential valve data is given on the power element.

Main valve data example:

TR6 = Valve type

R410A = Refrigerant

6.70 TR = Rated capacity Qnom

in Tons of Refrigeration

MWP 630psig/

PS 45.5 bar = Max. working pressure in

psig and bar

067Uxxxx = Code number

BC1109D = Date making (BC=Mexico,

week 11, year 2009,

weekday D=Thursday)

+15/+60 °F = Evaporating temperature

range in °F

-10/+15 °C = Evaporating temperature

range in °C

Fig. 1

2 DKRCC.PD.AN0.A6.22 / 520H7258

Data sheet Thermostatic expansion valves , type TR 6

Design and function

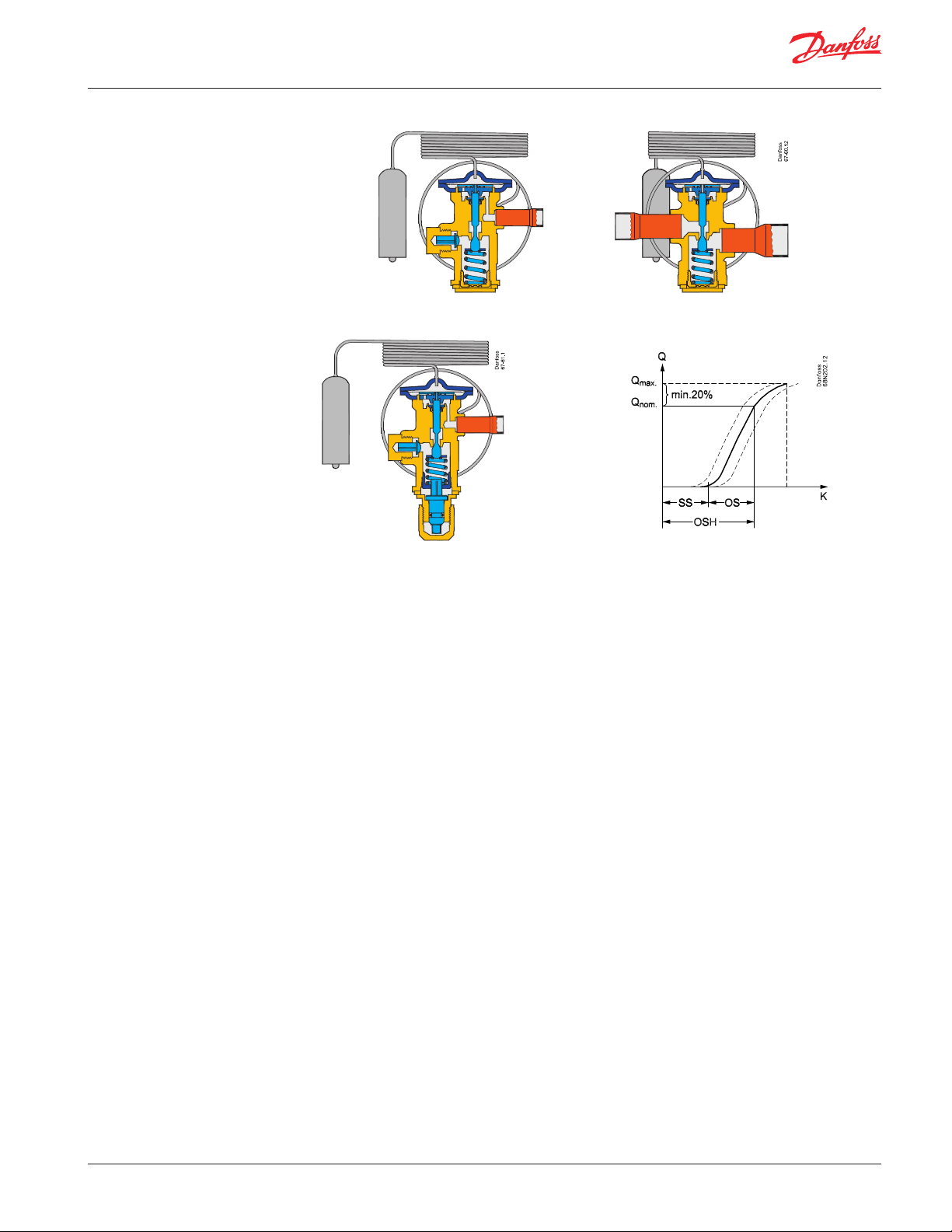

Fig. 2 TR 6 with xed setting

1. Bulb

2. Thermostatic element

3. Push pin seal

4. Balanced port

5. Check valve

6. Setting spindle for adjustment

of static superheat (SS)

7. Equalizer

8. Inlet connection

9. Outlet connection

Fig. 3 TR 6 with adjustable setting

The central push pin is sealed with a robust seal

(pos. 3) that ensures maximum tightness and

minimum friction through the lifetime of the

valve.

The balanced port (pos. 4) ensures minimal

superheat changes when condensing pressure

varies. This feature makes the valve ideal for biow operation.

Static superheat (SS) can be adjusted with the

setting spindle (see g. 3, pos. 6) . The standard

superheat setting is 3.6 ° F / 2 °K.

Fig. 4

Terminology (g.4)

SS = Static superheat

OS = Opening superheat

OSH = SS + OS = Operating superheat

Example

Static superheat

SS = 3.6°F (2K) (factory setting)

or according to customer specication.

Opening superheat

OS = 7.2 °F (4K)

The opening superheat is 7.2 °F / 3.6 °C, i.e. from

the point the valve begins to open up to nominal

capacity. Opening superheat (OS) is a xed value

and cannot be changed.

Operating superheat

OSH = SS + OS

OSH = 3.6 °F + 7.2 °F = 10.8 °F (6 °K)

OSH is the total superheat that can be measured

on the system.

DKRCC.PD.AN0.A6.22 / 520H7258 3

Data sheet Thermostatic expansion valves , type TR 6

Application

TR 6

without

check valve

EVR/EVRH

Fig. 5. Traditional air conditioning system, cooling only

4-way

Indoor coil

valve

SGI/SGN/SGH

DCL/DML

Outdoor coil

TR 6

with check

valve

SGI/SGN/SGH

Fig. 6. Traditional air conditioning / heat pump system

Indoor coil Outdoor coil

TR 6

without

check valve

Fig. 7. Simplied air conditioning / heat pump system (bi-ow)

Fig. 5 illustrates the diagram of a traditional air

conditioning system where the TR 6 is controlling

liquid injection in one direction only.

Fig. 6 illustrates a split air conditioning/heat

pump system with cooling/heating mode and

two thermostatic expansion valves, one for

cooling mode and one for heating mode.

The thermostatic expansion valves each has a

built-in check valve, which has the function of

preventing ow in one direction and allowing the

ow in the opposite direction.

It means that one thermostatic expansion valve

is controlling liquid injection into the evaporator

DCB/DMB

4-way

valve

has an open check valve allowing the liquid

refrigerant ow in the liquid line.

Fig. 7 illustrates a similar system as the previous

one, but this time it is a packed unit with a

short distance between the evaporator and

the condenser, the bi-ow feature of the TR 6

thermostatic expansion valve can be used.

The two thermostatic expansion valves have,

therefore, been replaced by one TR 6 bi-ow valve

controlling liquid injection in both directions.

The normal ow direction marked with an arrow

should be used for the primary function, i.e.

cooling or heating.

and the other thermostatic expansion valve

TR 6

with check

valve

4 DKRCC.PD.AN0.A6.22 / 520H7258

Data sheet Thermostatic expansion valves , type TR 6

Ordering

Adjustable setting

Check valve capacity

Range N = 14 °F → 59 °F (–10 °C → +15 °C)

Rated capacity

1)

Q

Refrigerant

TR kW

3.3 11.4 3 067L5855

4.5 15.8 4 067L5856

R22

5.3 18.5 5 067L5857

5.6 19.6 6 067L5858

6.7 23.6 7 067L5859

3 10.5 3 067L5955

4 14.0 4 067L5956

R410A

5 17.5 5 067L5957

6 21.0 6 067L5958

7 24.5 7 067L5959

Pressure equalisation = ¼ in. ODF

1

) The rated capacity is based on: Evaporating temperature, t

Condensing temperature, t

2

) Partnumbers consist of a valve, bulbstrap and the following connectors:

1 Chatle

1 Aeroquip

3

8

/

" female connector

5

8

/

" female connector

= 90 °F / 32 °C, Opening superheat, OS = max. 7.2 °F / 4K

c

TC=90 °F/ 32 °C TI=75 °F/ 24 °C

nom

= 41 °F / 5 °C, Liquid temperature, tl = 82 °F / 28 °C,

e

Orice no.

R22 and R410A

Connection

3

/8 in. x 1/2 in. x 1/4 in. equalizer

with are nut ODF

Inlet × Outlet

2)

Mass ow lb/h

Dp (psi)

Fig. 8 Internal check valve for orice bypass in reverse ow (ow rate as a function of pressure dierential)

DKRCC.PD.AN0.A6.22 / 520H7258 5

Data sheet Thermostatic expansion valves , type TR 6

Capacity

US units

SI units

Capacity in TR for MAH +14/+59 °F at 7.2 °F static superheat SS

Type

TR 6

TR 6

Orice

no.

Evaporating temperature 0°F Evaporating temperature 20°F

3 1.48 1.63 1.72 1.77 1.80 1.81 1.81 1.79 1.99 2.21 2.32 2.39 2.42 2.43 2.41 2.39

4 2.17 2.38 2.50 2.56 2.59 2.59 2.57 2.53 2.88 3.17 3.31 3.39 3.41 3.41 3.38 3.33

5 2.67 2.91 3.05 3.11 3.14 3.13 3.10 3.05 3.49 3.83 3.99 4.07 4.10 4.08 4.03 3.97

6 2.85 3.11 3.24 3.30 3.32 3.30 3.26 3.21 3.72 4.07 4.24 4.32 4.33 4.31 4.25 4.18

7 3.49 3.79 3.93 3.98 3.98 3.94 3.87 3.79 4.55 4.95 5.14 5.21 5.21 5.16 5.08 4.97

Evaporating temperature 40°F Evaporating temperature 50°F

3 2.61 3.01 3.27 3.36 3.35 3.32 3.28 3.22 2.56 2.96 3.24 3.41 3.54 3.63 3.69 3.72

4 3.78 4.36 4.51 4.55 4.54 4.49 4.43 4.34 3.70 4.28 4.68 4.94 5.12 5.24 5.12 4.99

5 4.55 5.13 5.28 5.33 5.33 5.27 5.19 5.09 4.45 5.16 5.64 5.95 6.14 6.02 5.89 5.75

6 4.91 5.42 5.59 5.64 5.63 5.56 5.47 5.36 4.81 5.57 6.09 6.42 6.45 6.33 6.20 6.05

7 6.00 6.53 6.73 6.79 6.76 6.67 6.55 6.40 6.07 7.03 7.68 7.81 7.72 7.58 7.42 7.23

Pressure drop across valve D psi Pressure drop across valve D psi

50 75 100 125 150 175 200 225 50 75 100 125 150 175 200 225

Capacity in kW for MAH –10 °C/+15 °C at 4 °K static superheat SS

Type

TR 6

TR 6

Orice

no.

Evaporating temperature –17.8°C Evaporating temperature –6.7°C

3 5.18 5.71 6.03 6.21 6.31 6.34 6.32 6.27 6.98 7.72 8.13 8.36 8.47 8.49 8.45 8.36

4 7.61 8.34 8.74 8.96 9.05 9.05 8.98 8.87 10.08 11.08 11.60 11.86 11.95 11.92 11.82 11.65

5 9.34 10.20 10.67 10.90 10.98 10.95 10.85 10.69 12.22 13.39 13.98 14.26 14.34 14.28 14.12 13.89

6 9.98 10.87 11.34 11.56 11.62 11.56 11.42 11.23 13.03 14.25 14.85 15.11 15.17 15.08 14.89 14.62

7 12.23 13.25 13.75 13.94 13.93 13.79 13.55 13.25 15.92 17.34 18.00 18.25 18.25 18.06 17.77 17.39

Evaporating temperature 4.4°C Evaporating temperature 10°C

3 9.14 10.55 11.44 11.75 11.73 11.63 11.47 11.27 8.95 10.36 11.33 11.95 12.39 12.71 12.91 13.03

4 13.22 15.27 15.78 15.92 15.89 15.73 15.50 15.20 12.95 14.99 16.39 17.28 17.92 18.35 17.91 17.45

5 15.93 17.94 18.49 18.67 18.64 18.46 18.18 17.82 15.59 18.05 19.74 20.81 21.49 21.07 20.63 20.14

6 17.19 18.97 19.55 19.73 19.69 19.47 19.15 18.76 16.84 19.49 21.31 22.46 22.58 22.16 21.70 21.17

7 21.00 22.85 23.57 23.77 23.67 23.36 22.93 22.41 21.25 24.60 26.89 27.33 27.02 26.54 25.96 25.31

Pressure drop across valve D bar Pressure drop across valve D bar

3.5 5.2 6.9 8.6 10.3 12.1 13.8 15.5 3.5 5.2 6.9 8.6 10.3 12.1 13.8 15.5

R22

R22

Correction for subcooling Dt

The evaporator capacity used must be

sub

corrected if subcooling deviates from 7.2°F/ 4°K.

The corrected capacity can be obtained by

multiplying the evaporator capacity by the

correction factor given below.

Correction factor for subcooling Dt

Correction factor

R22 1.00 1.06 1.11 1.15 1.20 1.24 1.29 1.33

4 °K 10 °K 15 °K 20 °K 25 °K 30 °K 35 °K 40 °K

7.2 °F 18 °F 27 °F 36 °F 45 °F 55 °F 63 °F 72 °F

sub

6 DKRCC.PD.AN0.A6.22 / 520H7258

Note:

Insucient subcooling can produce ash gas.

Dt

sub

Data sheet Thermostatic expansion valves , type TR 6

Capacity (cont.)

US units

SI units

Capacity in TR for MAH +14/+59°F at 7.2°F static superheat SS

Type

TR 6

TR 6

Orice

no.

Evaporating temperature 0°F Evaporating temperature 20°F

3 1.48 1.67 1.79 1.86 1.90 1.93 1.94 1.94 1.87 2.13 2.30 2.40 2.46 2.50 2.51 2.51

4 2.20 2.47 2.63 2.72 2.78 2.81 2.81 2.80 2.74 3.12 3.36 3.49 3.56 3.60 3.61 3.59

5 2.71 3.05 3.23 3.34 3.41 3.43 3.43 3.41 3.36 3.82 4.10 4.25 4.33 4.37 4.37 4.35

6 2.91 3.25 3.45 3.56 3.62 3.65 3.64 3.61 3.59 4.08 4.37 4.53 4.61 4.65 4.64 4.61

7 3.58 3.99 4.22 4.34 4.40 4.41 4.39 4.34 4.42 5.00 5.34 5.52 5.61 5.64 5.62 5.56

Evaporating temperature 40°F Evaporating temperature 50°F

3 2.30 2,63 2.86 3.01 3.09 3.14 3.15 3.15 2.53 2.90 3.15 3.32 3.43 3.48 3.49 3.48

4 3.33 3.80 4.11 4.31 4.41 4.46 4.47 4.44 3.63 4.15 4.49 4.71 4.85 4.90 4.90 4.87

5 4.03 4.59 4.96 5.20 5.31 5.36 5.36 5.32 4.36 4.97 5.37 5.63 5.79 5.84 5.84 5.80

6 4.31 4.90 5.29 5.54 5.65 5.70 5.69 5.65 4.66 5.31 5.73 6.00 6.16 6.21 6.21 6.16

7 5.29 6.01 6.47 6.77 6.89 6.93 6.91 6.85 5.73 6.51 7.02 7.34 7.53 7.57 7.55 7.48

Pressure drop across valve D psi Pressure drop across valve D psi

50 75 100 125 150 175 200 225 50 75 100 125 150 175 200 225

Capacity in kW for MAH –10 °C/+15 °C at 4 °K static superheat SS

Type

TR 6

TR 6

Orice

no.

Evaporating temperature –17.8°C Evaporating temperature –6.7°C

3 5.19 5.86 6.25 6.50 6.66 6.76 6.79 6.79 6.53 7.47 8.06 8.40 8.62 8.74 8.79 8.78

4 7.69 8.65 9.19 9.53 9.73 9.83 9.85 9.80 9.60 10.93 11.75 12.20 12.47 12.60 12.63 12.57

5 9.50 10.66 11.31 11.70 11.92 12.02 12.02 11.95 11.76 13.37 14.34 14.87 15.16 15.30 15.31 15.22

6 10.17 11.39 12.07 12.47 12.68 12.77 12.74 12.65 12.58 14.28 15.30 15.84 16.13 16.26 16.24 16.13

7 12.53 13.98 14.76 15.19 15.40 15.44 15.36 15.20 15.46 17.51 18.70 19.32 19.63 19.73 19.66 19.47

Evaporating temperature 4.4°C Evaporating temperature 10°C

3 8.04 9.22 10.01 10.55 10.82 10.98 11.03 11.01 8.86 10.16 11.03 11.62 12.01 12.17 12.22 12.19

4 11.64 13.30 14.38 15.10 15.44 15.61 15.63 15.55 12.71 14.52 15.70 16.48 16.97 17.14 17.16 17.05

5 14.10 16.07 17.35 18.19 18.57 18.75 18.75 18.63 15.26 17.40 18.79 19.70 20.25 20.44 20.43 20.29

6 15.07 17.16 18.51 19.38 19.77 19.94 19.92 19.77 16.31 18.58 20.05 20.99 21.57 21.74 21.72 21.55

7 18.52 21.05 22.66 23.68 24.11 24.27 24.20 23.98 20.05 22.80 24.56 25.68 26.34 26.51 26.44 26.19

Pressure drop across valve D bar Pressure drop across valve D bar

3.5 5.2 6.9 8.6 10.3 12.1 13.8 15.5 3.5 5.2 6.9 8.6 10.3 12.1 13.8 15.5

R410A

R410A

Correction for subcooling Dt

The evaporator capacity used must be

sub

Note:

Insucient subcooling can produce ash gas.

corrected if subcooling deviates from 7.2 °F/ 4 °K.

The corrected capacity can be obtained by

multiplying the evaporator capacity by the

correction factor given below.

Correction factor for subcooling Dt

Correction factor

R410A 1.00 1.08 1.14 1.20 1.26 1.31 1.37 1.43

4 °K 10 °K 15 °K 20 °K 25 °K 30 °K 35 °K 40 °K

7.2 °F 18 °F 27 °F 36 °F 45 °F 55 °F 63 °F 72 °F

sub

Dt

sub

DKRCC.PD.AN0.A6.22 / 520H7258 7

Data sheet Thermostatic expansion valves , type TR 6

Sizing

t

l

pe~t

e

EVR/EVRH

Fig. 9

Q

e

SGI/SGN/SGH

DCL/DML

p

c

t

c

US units

Example:

Refrigerant R22

The corrected evaporator capacity then becomes

4.0 × 1.06 = 4.24 TR

Evaporating temperature te = 40°F

pe = 79 psi

Condensing temperature tc = 118°F

pc = 256 psi

Pressure drop in liquid line,

As the selected valve must be equal to or slightly

larger than the corrected evaporator capacity

of 4.24 TR, the TR 6 with orice 4 having a table

capacity of 5.4 TR would be a suitable choice.

drier and distributor system Dp2+ Dp1 = 27 psi

Pressure drop in valve

Dp = 256 – 79 – 27 = 150 psi

Subcooling Dt

= tc – tl = 18 °F

sub

Evaporator capacity = 4.0 TR

Correction factor from table = 1.06

Capacity in TR for MAH +14/+59°F at 7.2°F static superheat SS

Type

TR 6

TR 6

Orice

no.

Evaporating temperature 0°F Evaporating temperature 20°F

3 1.48 1.63 1.72 1.77 1.80 1.81 1.81 1.79 1.99 2.21 2.32 2.39 2.42 2.43 2.41 2.39

4 2.17 2.38 2.50 2.56 2.59 2.59 2.57 2.53 2.88 3.17 3.31 3.39 3.41 3.41 3.38 3.33

5 2.67 2.91 3.05 3.11 3.14 3.13 3.10 3.05 3.49 3.83 3.99 4.07 4.10 4.08 4.03 3.97

6 2.85 3.11 3.24 3.30 3.32 3.30 3.26 3.21 3.72 4.07 4.24 4.32 4.33 4.31 4.25 4.18

7 3.49 3.79 3.93 3.98 3.98 3.94 3.87 3.79 4.55 4.95 5.14 5.21 5.21 5.16 5.08 4.97

Evaporating temperature 40°F Evaporating temperature 50°F

3 2.61 3.01 3.27 3.36 3.35 3.32 3.28 3.22 2.56 2.96 3.24 3.41 3.54 3.63 3.69 3.72

4 3.78 4.36 4.51 4.55 4.54 4.49 4.43 4.34 3.70 4.28 4.68 4.94 5.12 5.24 5.12 4.99

5 4.55 5.13 5.28 5.33 5.33 5.27 5.19 5.09 4.45 5.16 5.64 5.95 6.14 6.02 5.89 5.75

6 4.91 5.42 5.59 5.64 5.63 5.56 5.47 5.36 4.81 5.57 6.09 6.42 6.45 6.33 6.20 6.05

7 6.00 6.53 6.73 6.79 6.76 6.67 6.55 6.40 6.07 7.03 7.68 7.81 7.72 7.58 7.42 7.23

Pressure drop across valve D psi Pressure drop across valve D psi

50 75 100 125 150 175 200 225 50 75 100 125 150 175 200 225

R22

8 DKRCC.PD.AN0.A6.22 / 520H7258

Data sheet Thermostatic expansion valves , type TR 6

Dimensions and weights

Fixed setting

Adjustable setting

All dimensions in inches

Fig. 10

All dimensions in inches

Fig. 11

Weight

0.57 lbs

Weight

0.67 lbs

9 DKRCC.PD.AN0.A6.22 / 520H7258 © Danfoss A/S (AC-MCI sw) 2012-12

Loading...

Loading...