Page 1

Data sheet

Thermostatic expansion valves

Type T2 / TE2

Thermostatic expansion valves regulate the

injection of refrigerant liquid into evaporators.

Injection is controlled by the refrigerant

superheat.

Therefore the valves are especially suitable

for liquid injection in ”dry“ evaporators where

the superheat at the evaporator outlet is

proportional to the evaporator load.

Features

y Large temperature range

– Equally applicable to freezing, refrigeration

and air conditioning applications.

y Interchangeable orice assembly

– easy storage

– easy capacity matching

– better service.

– easy cleaning and replacement of lter

y Rated capacities from 1 to 20.5 kW /

0.3 to 5.8 TR for R407C

y Can be supplied with MOP (Max. Operating

Pressure).

– Protects the compressor motor against

excessive evaporating pressure during

normal operation

y Stainless steel bulb and Danfoss patented

bulb strap

– Fast and easy to install

– Good temperature transfer from pipe to

bulb

y Valves for special temperature ranges can be

supplied

y Design protected

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 1

Page 2

Data sheet | Thermostatic expansion valves, type T2 / TE2

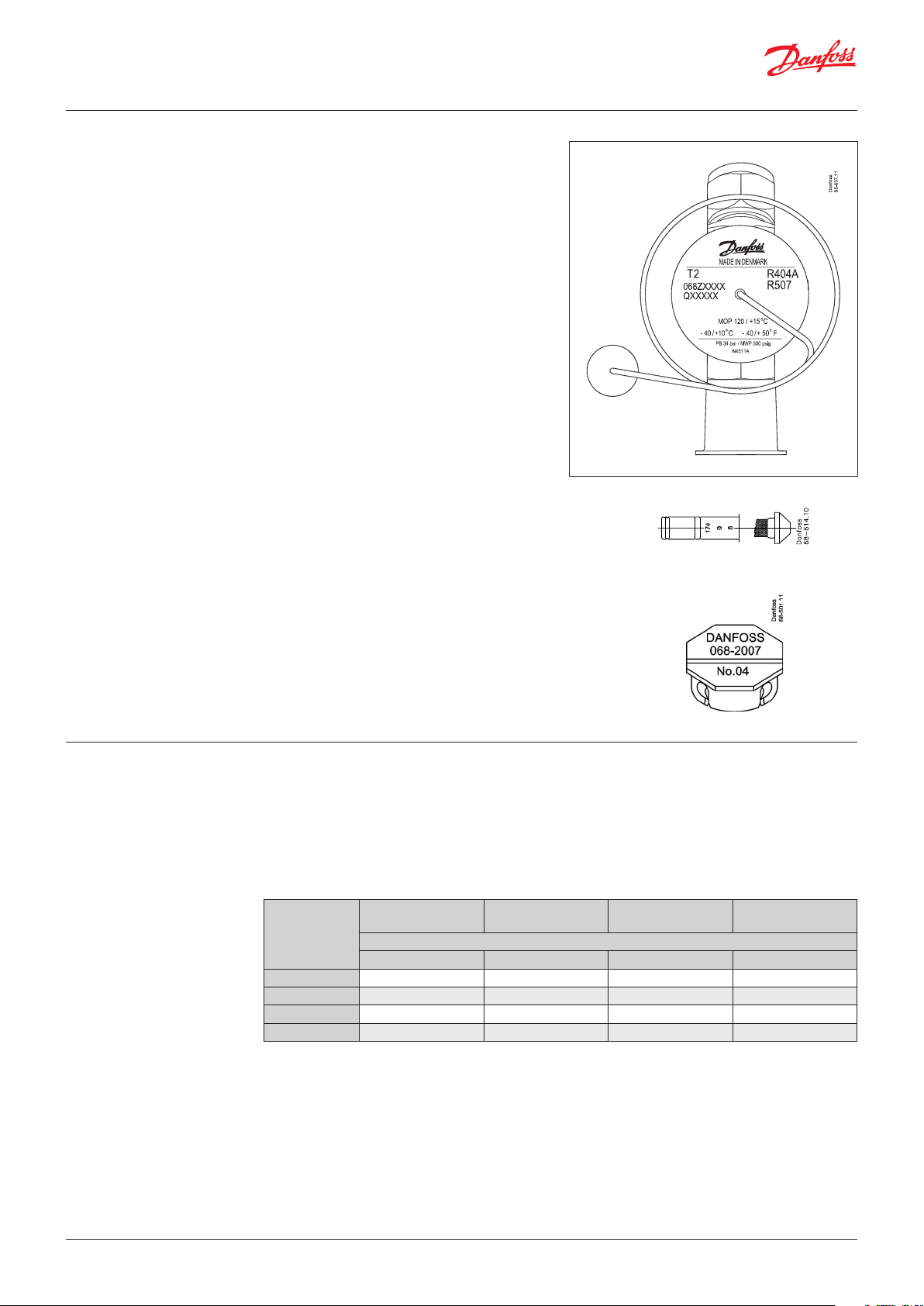

Identication The thermostatic element has laser engraved

data on top of the diaphragm. This engraving

gives valve type (with code number), evaporating

temperature range, MOP point, refrigerant, and

max. working pressure. PS/MWP.

T2 = internal equalization

TE2 = external equalization

Production place and date

N4511A =

N = Nordborg, Denmark

(BE = Wuqing, China)

45 = week

11 = 2011

A = Monday

Orice assembly for T2 and TE2

The orice assembly is marked with the orice

size (e.g. 06) and week stamp + last number in

the year (e.g. 174).

The orice assembly number is also given on the

lid of its plastic container.

Capillary tube label for T2 and TE2

The label gives the orice size (04) and consists

of the lid of the orice assembly plastic container.

It can easily be fastened around the expansion

valve capillary tube to clearly identify the valve

size.

Technical data Max. temperature

Bulb, when valve is installed: 100 °C

Bulb, element not mounted: 60 °C

Min. temperature

T2 – TE2: -60 °C

MOP-points

Refrigerant

R22 100 psig / 6.9 bar (abs) 60 psig / 4.0 bar (abs) 35 psig / 2.4 bar (abs) 20 psig / 1.4 bar (abs)

R407C 95 psig / 6.6 bar (abs) – – –

R134a 55 psig / 3.8 bar (abs) 30 psig / 2.0 bar (abs) 15 psig / 1.0 bar (abs) –

R404A/R507 120 psig / 8.3 bar (abs) 75 psig / 5.2 bar (abs) 50 psig / 3.4 bar (abs) 30 psig / 2.1 bar (abs)

1

) Pe in bar gauge

Orice assembly and lter for are x are version

for T2 and TE2

Capillary tube label

T2 and TE2

Max. test pressure

PT = 38 bar

Max. working pressure

PS/MWP = 34 bar

Range N

-40 °C – 10 °C

MOP-point in evaporating temperature te and evaporating pressure p

15 °C / 60 °F 0 °C / 32 °F -10 °C / 15 °F -20 °C / -4 °F

Range NM

-40 °C – -5 °C

Range NL

-40 °C – -15 °C

Range B

-60 °C – -25 °C

1

)

e

Superheat Standard superheat setting SS is 4K for all

SS = static superheat

OS = opening superheat

SH = SS + OS = total superheat

Q

= rated capacity

nom

Q

= maximum capacity

max

Static superheat SS can be adjusted with setting

spindle.

standard valves.

The opening superheat OS is 6 K from when

opening begins to where the valve gives its rated

capacity Q

nom.

Example

Static superheat SS = 5 K

Opening superheat OS = 6 K

Total superheat SH = 5 + 6 = 11 K

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 2

Page 3

Data sheet | Thermostatic expansion valves, type T2 / TE2

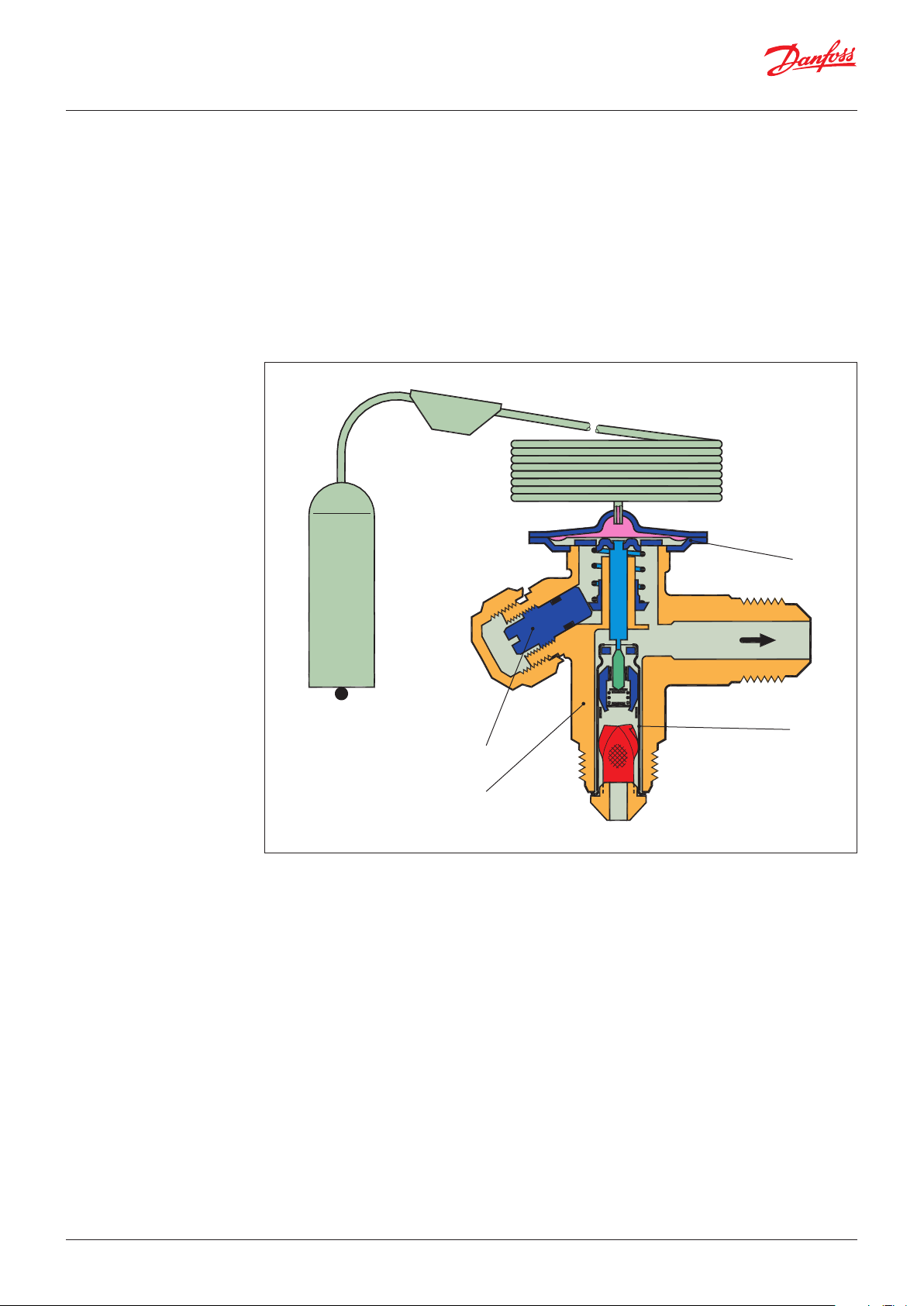

Design Function General

T2 and TE2 valves have an interchangeable orice

assembly.

The orice assembly is suitable for all versions of

valve body and refrigerants and in all evaporating

temperature ranges.

The charge in the thermostatic element depends

on the refrigerant and evaporating temperature

range.

The valves are available with internal (T2) or

external (TE2) pressure equalization.

External pressure equalization should always be

used on systems with liquid distributors.

The bulb gives fast and precise reaction to

temperature changes in the

evaporator. The bulb is xed with a Danfoss

patented bulb strap for quick, easy and reliable

connection. The valves are able to withstand

the eects that normally occur with hot gas

defrosting.

To ensure long operating life, the valve cone and

seat are made of a special alloy with particularly

good wear qualities.

Danfoss

68Z05.14.20

1

1. Thermostatic element (diaphragm)

2. Interchangeable orifice assembly

3. Valve body

4. Superheat setting spindle (see

instructions)

2

4

3

T2

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 3

Page 4

Data sheet | Thermostatic expansion valves, type T2 / TE2

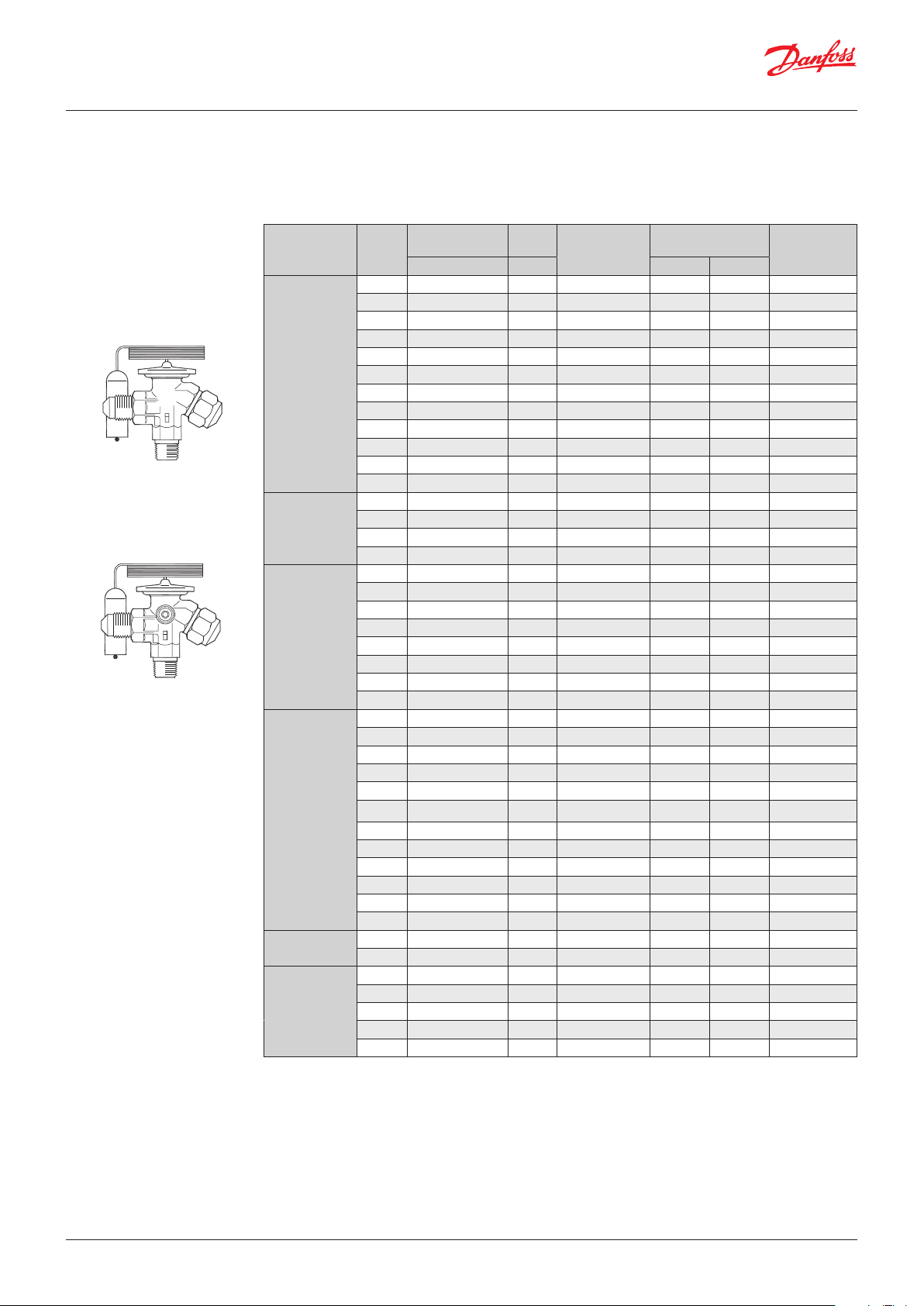

Technical data and ordering

T2/TE2 Thermostatic element with bulb strap

Flare x are

Refrigerant Typ e

T2 -40 – 10 – –

T2 -40 – 10 15 –

T2 -40 – -5 0 –

T2 -40 – -15 -10 –

T2 -60 – -25 – –

R22/R407C 1)

T2 -60 – -25 -20 –

TE2 -40 – 10 – ¼ in / 6mm

TE2 -40 – 10 15 ¼ in / 6mm

TE2 -40 – -5 0 ¼ in / 6mm

TE2 -40 – -15 -10 ¼ in / 6mm

TE2 -60 – -25 – ¼ in / 6mm

TE2 -60 – -25 -20 ¼ in / 6mm

T2 -40 – 10 – –

R407C

T2 -40 – 10 15 –

TE2 -40 – 10 – ¼ in / 6mm

TE2 -40 – 10 15 ¼ in / 6mm

T2 -40 – 10 – –

T2 -40 – 10 15 –

T2 -40 – -5 0 –

R134a /R513 A

T2 -40 – -15 -10 –

TE2 -40 – 10 – ¼ in / 6mm

TE2 -40 – 10 15 ¼ in / 6mm

TE2 -40 – -5 0 ¼ in / 6mm

TE2 -40 – -15 -10 ¼ in / 6mm

T2 -40 – 10 – –

T2 -40 – 10 15 –

T2 -40 – -5 0 –

T2 -40 – -15 -10 –

T2 -60 – -25 – –

R404A/R507

T2

TE2 -40 – 10 – ¼ in / 6mm

TE2 -40 – 10 15 ¼ in / 6mm

TE2 -40 – -5 0 ¼ in / 6mm

TE2 -40 – -15 -10 ¼ in / 6mm

TE2 -60 – -25 – ¼ in / 6mm

TE2 -60 – -25 -20 ¼ in / 6mm

R407F/R40 7A

T2 -40 – 10 – –

TE2 -40 – 10 – ¼ in / 6mm

T2 -40 – 10 – –

TE2 -40 – 10 – ¼ in / 6mm

R448A/R449A

T2 -40 – -15 -10 –

T2 -60 – -25 -20 –

TE2 -60 – -25 -20 ¼ in / 6mm

1

) For R407C plants. Please select valves from the dedicated R407C program

Range MOP

equlization

[°C] [°C] [in.] [mm]

-60 – -25 -20 –

Pressure

Flare

Capillary tube: 1.5 m

Range N = -40 – 10 °C

Range B = -60 – -25 °C

Range NM = -40 – -5 °C MOP 0 °C

Range NL = -40 – -15 °C MOP -10 °C

Connection are

inlet × outlet

3

/8 × 1/210×12 068Z3206

3

/8 × 1/210×12 068Z3208

3

/8 × 1/210×12 068Z3224

3

/8 × 1/210×12 068Z3226

3

/8 × 1/210×12 068Z3207

3

/8 × 1/210×12 068Z3228

3

/8 × 1/210×12 068Z3209

3

/8 × 1/210×12 068Z3211

3

/8 × 1/210×12 068Z3225

3

/8 × 1/210×12 068Z3227

3

/8 × 1/210×12 068Z3210

3

/8 × 1/210×12 068Z3229

3

/8 × 1/210×12 068Z3496

3

/8 × 1/210×12 068Z3516

3

/8 × 1/210×12 068Z3501

3

/8 × 1/210×12 068Z3517

3

/8 × 1/210×12 068Z3346

3

/8 × 1/210×12 068Z3347

3

/8 × 1/210×12 068Z3393

3

/8 × 1/210×12 068Z3369

3

/8 × 1/210×12 068Z3348

3

/8 × 1/210×12 068Z3349

3

/8 × 1/210×12 068Z3392

3

/8 × 1/210×12 068Z3370

3

/8 × 1/210×12 068Z3400

3

/8 × 1/210×12 068Z3402

3

/8 × 1/210×12 068Z3406

3

/8 × 1/210×12 068Z3408

3

/8 × 1/210×12 068Z3401

3

/8 × 1/210×12 068Z3410

3

/8 × 1/210×12 068Z3403

3

/8 × 1/210×12 068Z3405

3

/8 × 1/210×12 068Z3407

3

/8 × 1/210×12 068Z3409

3

/8 × 1/210×12 068Z3404

3

/8 × 1/210×12 068Z3411

3

/8 × 1/210×12 068Z3715

3

/8 × 1/210×12 068Z3714

3

2

/8 × 1/

3

/8 × 1/210×12 068Z3728

3

/8 × 1/210×12 068Z3675

3

/8 × 1/210×12 068Z3735

3

/8 × 1/210×12 068Z3736

– 068Z3727

Code no.

Multi pack

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 4

Page 5

Data sheet | Thermostatic expansion valves, type T2 / TE2

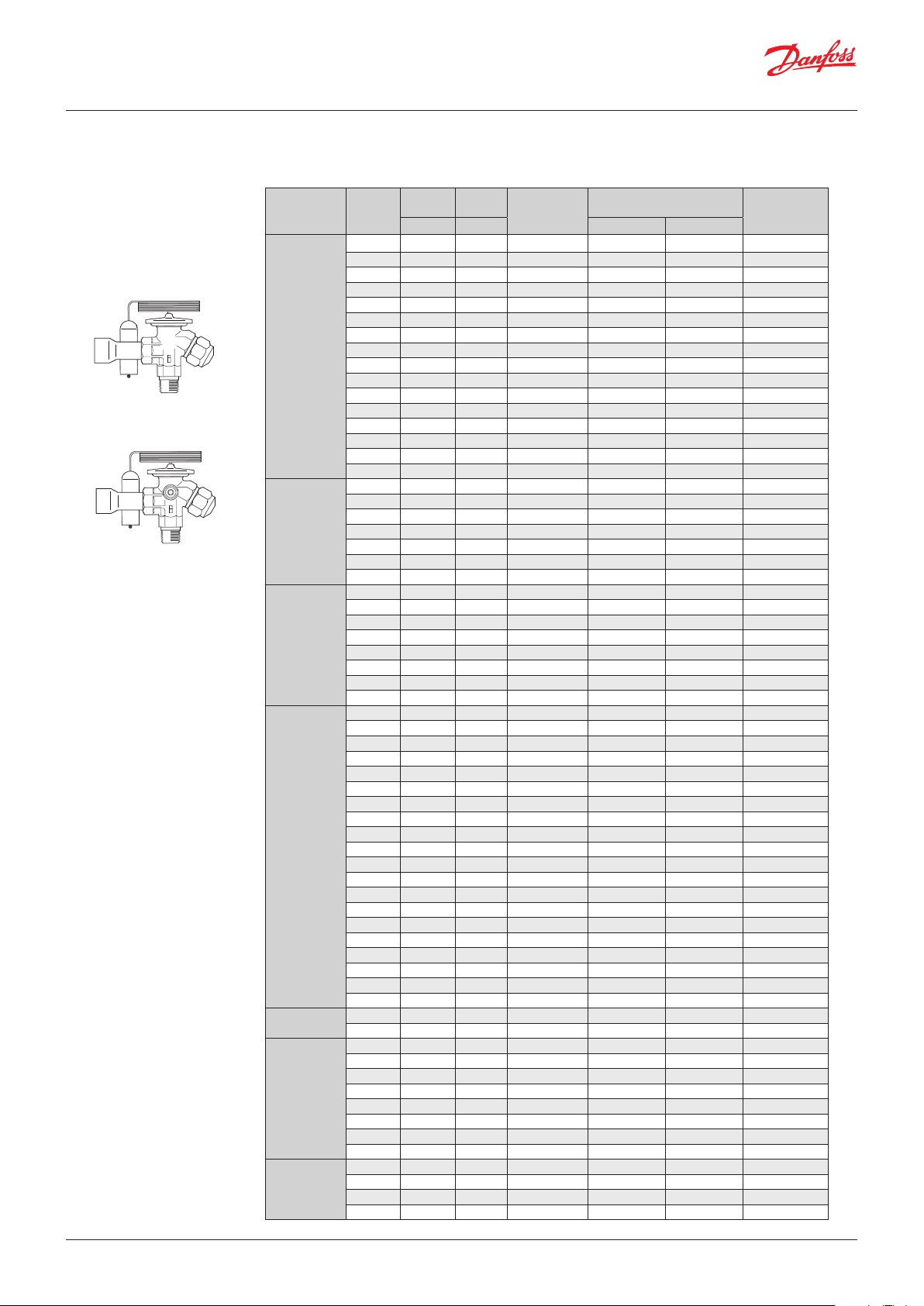

Technical data and ordering

T2/TE2 Thermostatic element with bulb strap

Flare x solder

Refrigerant Type

Range MOP

[°C] [°C]

-40 – 10 – –

T2

T2 -40 – 10 – – – 10×12 068Z3302

T2 -40 – 10 15 –

T2 -40 – 10 15 – – 10×12 068Z3308

T2 -40 – -15 -10 – – 10×12 068Z3366

T2 -60 – -25 – –

T2 -60 – -25 – – – 10×12 068Z3361

R22/R407C 1)

T2 -60 – -25 -20 –

TE2 -40 – 10 – ¼ in.

TE2 -40 – 10 – 6 mm – 10×12 068Z3305

TE2 -40 – 10 15 ¼ in.

TE2 -40 – 10 15 6 mm – 10×12 068Z3311

TE2 -40 – -15 -10 6 mm – 10×12 068Z3367

TE2 -60 – -25 – ¼ in.

TE2 -60 – -25 – 6 mm – 10×12 068Z3363

TE2 -60 – -25 -20 –

T2 -40 – 10 – – – 10×12 068Z3502

T2 -40 – 10 15 –

T2 -40 – 10 15 – – 10×12 068Z3514

R407C

TE2 -40 – 10 – ¼ in.

TE2 -40 – 10 – 6 mm – 10×12 068Z3503

TE2 -40 – 10 15 ¼ in.

TE2 -40 – 10 15 6 mm – 10×12 068Z3515

T2 -40 – 10 – –

T2 -40 – 10 – – – 10×12 068Z3384

T2 -40 – 10 15 –

R134a/R513A

T2 -40 – 10 15 – – 10×12 068Z3388

TE2 -40 – 10 – ¼ in.

TE2 -40 – 10 – 6 mm – 10×12 068Z3386

TE2 -40 – 10 15 ¼ in.

TE2 -40 – 10 15 6 mm – 10×12 068Z3390

T2 -40 – 10 – –

T2 -40 – 10 – – – 10×12 068Z3435

T2 -40 – 10 15 –

T2 -40 – 10 15 – – 10×12 068Z3423

T2 -40 – -15 -10 –

T2 -40 – -15 -10 – – 10×12 068Z3436

T2 -60 – -25 – –

T2 -60 – -25 – – – 10×12 068Z3425

T2 -60 – -25 -20 –

R404A/R507

T2 -60 – -25 -20 – – 10×12 068Z3427

TE2 -40 – 10 – ¼ in.

TE2 -40 – 10 – 6 mm – 10×12 068Z3422

TE2 -40 – 10 15 6 mm – 10×12 068Z3424

TE2 -40 – 10 15 ¼ in.

TE2 -40 – -15 -10 ¼ in.

TE2 -40 – -15 -10 6 mm – 10×12 068Z3437

TE2 -60 – -25 – ¼ in.

TE2 -60 – -25 – 6 mm – 10×12 068Z3426

TE2 -60 – -25 -20 ¼ in.

TE2 -60 – -25 -20 6 mm – 10×12 068Z3428

R407F/R407A

T2 -40 – 10 – –

TE2 -40 – 10 – ¼ in.

T2 -40 – 10 – –

TE2 -40 – 10 – ¼ in.

T2 -40 – -15 -10 –

R448A/R449A

T2 -60 – -25 -20 –

TE2 -40 – -15 -10 ¼ in.

TE2 -60 – -25 -20 ¼ in.

T2 -40 – -15 -10 – – 10×12 068Z3674

TE2 -60 – -25 -20 6 mm – 10×12 068Z3672

T2 -40 – 10 – –

R452A

1

) For R407C plants, please select valves from the dedicated R407C program

TE2 -40 – 10 – ¼ in

T2 -40 – 10 – – – 10×12 068Z3808

TE2 -40 – 10 – 6 mm – 10×12 068Z3809

Pressure

equalization

solder

Capillary tube: 1.5 m

Range N = -40 – 10 °C

Range NL = -40 – -15 °C

Range B = -60 – -25 °C

Connection

inlet (Flare) × outlet (Solder)

[in.] [mm]

3

2

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

3

/8 × 1/

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

– 068Z3281

– 068Z3287

– 068Z3357

– 068Z3319

– 068Z3284

– 068Z3290

– 068Z3359

– 068Z3320

– 068Z3329

1

/2 in. 068Z3446

– 068Z3447

– 068Z3383

– 068Z3387

– 068Z3385

– 068Z3389

– 068Z3414

– 068Z3416

– 068Z3429

– 068Z3418

– 068Z3420

– 068Z3415

– 068Z3417

– 068Z3430

– 068Z3419

– 068Z3421

– 068Z3716

– 068Z3713

– 068Z3729

– 068Z3730

– 068Z3664

– 068Z3737

– 068Z3665

– 068Z3738

– 068Z3806

– 068Z3807

Code no.

Multi pack

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 5

Page 6

Danfoss

68Z62.11

Data sheet | Thermostatic expansion valves, type T2 / TE2

Flare connections

The rated capacity is based on:

Evaporating temperature te = 40 °F

Condensing temperature tc = 100 °F

Refrigerant temperature ahead

of valve tl = 98 °F

Connection for copper tubing

with outside diameter

Reducer for copper tubing

with outside diameter

[in.] [mm] [in.] [mm]

1

4

/

3

8

/

1

2

/

– –

6 – – 011L1101

10 – – 011L1135

12 – – 011L1103

1

4

/

6 011L1107

Example :

A TE2 thermostatic expansion valve consists of

two elements + are nuts if required:

– 1 thermostatic element

– 1 orice assembly and are nuts

When ordering one thermostatic expansion valve,

TE2 with orice 01, ve code numbers are required:

– 1-o thermostatic element 068Z3209

– 1-o orice assembly 01 068-2010

– 1-o 3⁄8 in. are nut 011L1135

– 1-o 1⁄2 in. are nut 011L1103

– 1-o 1⁄4 in. are nut 011L1101

Range N: -40 to 50 °F

Rated capacity in tons (TR)

Orice no.

R22 R407C R134a R513A

0X 0.25 0.26 0.19 0.16 0.18 0.25 0.28 0.26 0.25

00 0.51 0.51 0.34 0.29 0.37 0.49 0.56 0.51 0.49

01 1.0 1.0 0.59 0.51 0.75 1.0 1.1 1.0 0.97

02 1.3 1.4 0.73 0.62 1.0 1.3 1.5 1.4 1.3

03 2.3 2.3 1.2 1.0 1.8 2.3 2.6 2.3 2.3

04 3.4 3.5 1.8 1.5 2.8 3.5 4.1 3.6 3.5

05 4.8 4.7 2.4 2.0 3.7 4.6 5.4 4.6 4.5

06 5.6 5.6 2.9 2.5 4.4 5.6 6.5 5.7 5.5

R404A

R507

R407A R407F R448A R449A

Code no.

The rated capacity is based on:

Evaporating temperature te = 4.4 °C

Condensing temperature tc = 38 °C

Refrigerant temperature ahead

of valve tl = 37 °C

1 2

1. Orice assembly with lter

2. Orice assembly with lter for

solder adaptor

Range N: -40 to 10 °C

Rated capacity in kW

Orice no.

R22 R407C R134a R513A

R404A

R507

R407A R407F R448A R449A

0X 0.90 0.92 0.68 0.58 0.64 0.88 1.0 0.90 0.88

00 1.8 1.8 1.2 1.0 1.3 1.7 2.0 1.8 1.7

01 3.5 3.5 2.1 1.8 2.6 3.4 3.9 3.5 3.4

02 4.7 4.8 2.6 2.2 3.7 4.7 5.4 4.8 4.6

03 8.0 8.1 4.3 3.7 6.3 8.0 9.2 8.1 7.9

04 12.1 12.4 6.4 5.4 9.9 12.4 14.3 12.6 12.1

05 16.7 16.5 8.4 6.9 13.0 16.3 19.0 16.3 15.7

06 19.7 19.7 10.1 8.6 15.5 19.6 22.9 19.8 19.1

Orice assembly with lter

Orice no. Code no.

0X 068-2002

00 068-2003

01 068-2010

02 068-2015

03 068-2006

04 068-2007

05 068-2008

06 068-2009

Orice assembly with lter for solder adaptor

Orice no. Code no.

0X 068-2089

00 068-2090

01 068-2091

02 068-2092

03 068-2093

04 068-2094

05 068-2095

06 068-2096

Filter

Filter type Code no. Multi pack

For flare connection 068-0003

For solder adaptor 068-0015

© Danfoss | DCS (rm) | 2019.07

The adaptor is for use with thermostatic expansion

valves T2 and TE2. When the adaptor is fitted

correctly it meets the sealing requirements of

DIN 8964. The flare orifice in T2 and TE2 can be

used with a solder adaptor when the orifice filter

is replaced with a specific filter intended for solder

adaptors.

Only in this way the sealing requirements of

DIN 8964 can be fulfilled. Solder adaptors for filter

driers (FSA) must not be used on the T2 inlet.

DKRCC.PD.AA0.3A.02 | 6

Page 7

Data sheet | Thermostatic expansion valves, type T2 / TE2

Solder adaptor

Bulb strap (Danfoss patented)

The adaptor is for use with thermostatic

expansion valves T2 and TE2 with

are × solder connections. When the adaptor is

tted correctly it meets the sealing requirements

of DIN 8964.

The adaptor oers the following advantages:

The orice assembly can be replaced.

The lter can be cleaned or replaced.

Solder adaptor without orice assembly and lter

Connection ODF solder Code no.

1

⁄4 in. 068-2062

6 mm 068-2063

3

⁄8 in. 068-2060

10 mm 068-2061

When using the solder adapter, a special orice

assembly is required. Please use the following

tables to select both the appropriate adapter and

orice asembly.

Only in this way can the sealing requirements of

DIN 8964 be fullled.

Solder adaptor for lter drier (FSA) may not be

used in the T2 inlet.

Filter for solder adaptor

Description Code no.

Filter excl. orifice assembly 068-0015

Each valve is delivered with a Danfoss patented

bulb strap. Spares can be ordered.

Description Pack mode Quantity / pack Code no.

Bulb strap 0.4 mm Max. 28 mm tube I 45 068U3505

Bulb strap 0.4 mm Max. 50 mm tube I 45 068U3506

Bulb strap 0.4 mm Max. 28 mm tube M 25 068U3507

Bulb strap 0.4 mm Max. 50 mm tube M 25 068U3508

How to select a valve

Example:

Refrigerant = R407C

Q (capacity) = 1.1kW

cond

T

(condensing temperature) = 25 °C

T

(evaporator temperature) = -30 °C

evap

sub

T

(subcooling temperature) = 2 K

Dpd (distributer pressure drop) = 1 bar

Q (capacity) = 1.1kW

sub

f

(subcooling correction factor) = 0.98

fp (distribution correction factor) = 0.96

Q

sub

f

x f

= Selected capacity

p

1.1

0.98 x 0.96

= 1.17 kW

The selection will be:

TE2 orice 00 (1.21 kW > 1.17 kW)

Capacity in kW, range N -40 °C to 10 °C. Opening superheat sh= 6 K

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.99 1. 21 1.42 1.60

T2 / TE2 01 1.41 1.8 0 2.27 2.77

Cond. temp.

[°C]

25

-40 -30 -20 -10

0.76 0.83 0.88 0.90

Evaporating [°C]

Subcooling correction factor 'fsub'

Subcooling [K] 2 4 10 15

Correction factor 0.98 1.00 1.07 1.12

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

0 1 1 1 1

1 0.96 0.96 0.96 0.96

1.5 0.94 0.94 0.94 0.94

2 0.92 0.92 0.92 0.92

-40 -35 -30 -25

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 7

Page 8

Data sheet | Thermostatic expansion valves, type T2 / TE2

Capacity

Capacity in kW, range N -40 °C to 10 °C. Opening superheat sh= 6 K R22

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.95 1.18 1. 39 1.53 1.55 1.37

T2 / TE2 01 1.32 1.72 2 .18 2.63 2.91 2.78

T2 / TE2 02 1.49 1.98 2.57 3. 24 3.82 3.88

T2 / TE2 03 2.49 3.32 4.32 5.43 6.40 6.57

T2 / TE2 04 3.59 4.79 6. 35 8.16 9.72 9.88

T2 / TE2 05 4.69 6.25 8.30 10.8 0 13.10 13 .50

T2 / TE2 06 5.53 7. 3 6 9.73 12.70 15. 40 16 .00

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.99 1.23 1.47 1.67 1.77 1. 72

T2 / TE2 01 1.37 1.80 2.31 2.86 3.33 3.50

T2 / TE2 02 1.56 2.08 2. 74 3.54 4.38 4.92

T2 / TE2 03 2.62 3.51 4.62 5.96 7. 39 8.35

T2 / TE2 04 3.85 5 .12 6.83 8.98 11. 20 12 .70

T2 / TE2 05 5.03 6.68 8.93 11.9 0 15.30 17. 50

T2 / TE2 06 5.89 7. 82 10.40 13.9 0 17.90 20.70

Cond. temp.

[°C]

25

Cond. temp.

[°C]

35

-40 -30 -20 -10 0 10

0.75 0.82 0.86 0.86 0 .81 0.68

-40 -30 -20 -10 0 10

0.78 0.86 0.91 0.93 0.92 0.85

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 1.01 1.26 1. 52 1.75 1.9 0 1.94

T2 / TE2 01 1.41 1.85 2.39 3.00 3.59 3.96

T2 / TE2 02 1.61 2.14 2.84 3.72 4 .74 5.60

T2 / TE2 03 2.71 3.64 4.82 6.32 8.08 9.63

T2 / TE2 04 4.06 5.37 7.14 9.47 12 . 20 14.50

T2 / TE2 05 5.30 7. 01 9. 37 12.60 16.70 20.30

T2 / TE2 06 6 .19 8.18 10 .9 0 14.70 19. 50 24.0 0

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 1.01 1.26 1. 53 1.77 1.95 2.04

T2 / TE2 01 1.42 1. 87 2.42 3.06 3.71 4.19

T2 / TE2 02 1.63 2.18 2.89 3. 81 4.92 5.95

T2 / TE2 03 2.76 3.70 4.93 6.51 8.46 10.30

T2 / TE2 04 4.23 5.53 7. 32 9.68 12. 50 15 . 30

T2 / TE2 05 5.52 7. 24 9.64 13. 00 17. 30 21.70

T2 / TE2 06 6.42 8.43 11. 20 15 .10 20.30 25.80

Cond. temp.

[°C]

45

Cond. temp.

[°C]

55

-40 -30 -20 -10 0 10

Capacity [kW]

0.80 0.88 0.94 0.97 0.98 0.95

Evaporating [°C]

-40 -30 -20 -10 0 10

Capacity [kW]

0.79 0.88 0.94 0.98 1.00 0.99

Subcooling correction factor 'fsub'

Subcooling [K] 2 4 10 15 20 25 30 35 40 45 50

Correction factor 0.98 1.00 1.05 1.10 1.14 1.19 1.23 1.28 1.32 1.36 1.41

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

-40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15

0 1 1 1 1 1 1 1 1 1 1 1 1

1 0.96 0.95 0.95 0.95 0.95 0.95 0.94 0.94 0.93 0.92 0.91 0.89

1.5 0.93 0.93 0.93 0.93 0.92 0.92 0.91 0.91 0.90 0.88 0.86 0.82

2 0.91 0.91 0.90 0.90 0.90 0.89 0.88 0.87 0.86 0.84 0.81 0.76

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 8

Page 9

Data sheet | Thermostatic expansion valves, type T2 / TE2

Capacity

Capacity in kW, range B -60 °C to -25 °C. Opening superheat sh= 6 K R22

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.55 0.77 1.03 1.28

T2 / TE2 01 0.72 1.06 1.47 1.95

T2 / TE2 02 0.80 1.17 1.6 6 2.26

T2 / TE2 03 1.32 1.94 2.76 3.77

T2 / TE2 04 1.87 2.76 3.95 5.45

T2 / TE2 05 2.45 3.60 5.15 7.14

T2 / TE2 06 2.91 4.26 6.10 8.50

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.56 0.79 1.06 1.3 4

T2 / TE2 01 0.74 1.0 8 1.52 2.04

T2 / TE2 02 0.82 1. 20 1.72 2.36

T2 / TE2 03 1.35 1.99 2.85 3.93

T2 / TE2 04 1.90 2.81 4.04 5.63

T2 / TE2 05 2.50 3.66 5.26 7.36

T2 / TE2 06 2.96 4.33 6.21 8.71

Cond. temp.

[°C]

25

Cond. temp.

[°C]

35

-60 -50 -40 -30

0.54 0.67 0.78 0.84

-60 -50 -40 -30

0.56 0.69 0.80 0.88

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.57 0.80 1.0 8 1.37

T2 / TE2 01 0.75 1.10 1. 55 2.09

T2 / TE2 02 0.82 1. 22 1. 74 2.41

T2 / TE2 03 1.36 2.01 2.88 4.00

T2 / TE2 04 1.91 2.82 4.06 5.70

T2 / TE2 05 2.52 3.68 5.29 7. 42

T2 / TE2 06 2.98 4.35 6.23 8.75

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.57 0.80 1.0 8 1.38

T2 / TE2 01 0.75 1.10 1. 55 2.10

T2 / TE2 02 0.82 1. 21 1.74 2 .41

T2 / TE2 03 1.36 2.00 2.87 4.01

T2 / TE2 04 1.89 2.79 4.03 5.66

T2 / TE2 05 2.52 3.67 5.25 7.3 7

T2 / TE2 06 2.98 4.32 6.17 8.66

Cond. temp.

[°C]

45

Cond. temp.

[°C]

55

-60 -50 -40 -30

Capacity [kW]

0.56 0.70 0.82 0.91

Evaporating [°C]

-60 -50 -40 -30

Capacity [kW]

0.56 0.70 0.82 0.91

Subcooling correction factor 'fsub'

Subcooling [K] 2 4 10 15 20 25 30 35 40 45 50

Correction factor 0.98 1.00 1.07 1.12 1.18 1.23 1.28 1.34 1.39 1.45 1.50

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

-40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15

0 1 1 1 1 1 1 1 1 1 1 1 1

1 0.96 0.96 0.96 0.96 0.96 0.96 0.95 0.95 0.95 0.94 0.93 0.92

1.5 0.94 0.94 0.94 0.94 0.94 0.93 0.93 0.93 0.92 0.91 0.90 0.88

2 0.92 0.92 0.92 0.92 0.91 0.91 0.91 0.90 0.89 0.88 0.86 0.84

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 9

Page 10

Data sheet | Thermostatic expansion valves, type T2 / TE2

Capacity

Capacity in kW, range N -40 °C to 10 °C. Opening superheat sh= 6 K R407C

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.99 1. 21 1.42 1. 60 1.69 1.63

T2 / TE2 01 1.41 1. 80 2.27 2.77 3.19 3. 31

T2 / TE2 02 1.59 2.06 2.67 3.40 4.18 4.64

T2 / TE2 03 2.65 3.44 4.46 5.73 7. 07 7. 85

T2 / TE2 04 3.86 4.98 6.4 4 8.35 10.6 0 12 .50

T2 / TE2 05 5.04 6.52 8.46 11 . 00 14.0 0 16 .30

T2 / TE2 06 5.94 7.71 10.10 13.20 16. 80 19. 40

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.99 1.22 1.45 1. 67 1.81 1. 85

T2 / TE2 01 1.40 1.81 2. 32 2.88 3.43 3.76

T2 / TE2 02 1.59 2.08 2.72 3.54 4.48 5.28

T2 / TE2 03 2.66 3.48 4.57 5.98 7. 62 8.98

T2 / TE2 04 3.93 5.10 6.65 8 .74 11.4 0 14.20

T2 / TE2 05 5.13 6.66 8.73 11. 50 15.10 18.60

T2 / TE2 06 6. 01 7.85 10.4 0 13 . 8 0 18.10 22.20

Cond. temp.

[°C]

25

Cond. temp.

[°C]

35

-40 -30 -20 -10 0 10

0.76 0.83 0.88 0.90 0.88 0. 81

-40 -30 -20 -10 0 10

0.76 0.84 0.90 0.94 0.95 0.92

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.95 1.19 1.43 1.67 1.85 1.94

T2 / TE2 01 1.36 1.77 2.28 2.88 3.50 3.97

T2 / TE2 02 1.55 2.04 2.69 3.54 4.58 5.58

T2 / TE2 03 2.60 3.42 4.53 6. 01 7.82 9.52

T2 / TE2 04 3.89 5.07 6.66 8.83 11. 70 15.00

T2 / TE2 05 5.06 6.62 8.73 11. 70 15 .60 19 . 80

T2 / TE2 06 5.90 7.76 10.30 13 .90 18 .70 23.60

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.89 1.12 1. 37 1. 61 1.81 1.93

T2 / TE2 01 1. 27 1.67 2.18 2.78 3.43 3.96

T2 / TE2 02 1.4 6 1.93 2.57 3.42 4.49 5.58

T2 / TE2 03 2.46 3.27 4.36 5.84 7. 71 9.60

T2 / TE2 04 3.74 4.90 6.48 8.65 11. 60 15 .10

T2 / TE2 05 4.85 6.39 8.49 11. 4 0 15 .40 20.00

T2 / TE2 06 5.61 7.45 9.99 13.60 18. 50 24.0 0

Cond. temp.

[°C]

45

Cond. temp.

[°C]

55

-40 -30 -20 -10 0 10

Capacity [kW]

0.73 0.82 0.89 0.94 0.97 0.97

Evaporating [°C]

-40 -30 -20 -10 0 10

Capacity [kW]

0.68 0.77 0.85 0.91 0.95 0.96

Subcooling correction factor 'fsub'

Subcooling [K] 2 4 10 15 20 25 30 35 40 45 50

Correction factor 0.98 1.00 1.07 1.12 1.18 1.23 1.28 1.34 1.39 1.45 1.50

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

-40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15

0 1 1 1 1 1 1 1 1 1 1 1 1

1 0.96 0.96 0.96 0.96 0.96 0.96 0.95 0.95 0.95 0.94 0.93 0.92

1.5 0.94 0.94 0.94 0.94 0.94 0.93 0.93 0.93 0.92 0.91 0.90 0.88

2 0.92 0.92 0.92 0.92 0.91 0.91 0.91 0.90 0.89 0.88 0.86 0.84

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 10

Page 11

Data sheet | Thermostatic expansion valves, type T2 / TE2

Capacity

Capacity in kW, range N -40 °C to 10 °C. Opening superheat sh= 6 K R134a

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.52 0.67 0.82 0.95 1.03 0.98

T2 / TE2 01 0.70 0.92 1.19 1.48 1.72 1.77

T2 / TE2 02 0.78 1.03 1.35 1.73 2.08 2.24

T2 / TE2 03 1.31 1.72 2.27 2.89 3.49 3.76

T2 / TE2 04 1.89 2.49 3.28 4.21 5.15 5.69

T2 / TE2 05 2.50 3.28 4.33 5.57 6.80 7.4 8

T2 / TE2 06 2.98 3.93 5.20 6.69 8 .16 8.96

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.54 0.69 0.86 1.03 1.17 1. 22

T2 / TE2 01 0.72 0.96 1.25 1.6 0 1.95 2.20

T2 / TE2 02 0.81 1.07 1.43 1. 87 2.36 2.79

T2 / TE2 03 1.36 1. 80 2.40 3.14 3.96 4.69

T2 / TE2 04 2.02 2.64 3.51 4.60 5.85 7. 07

T2 / TE2 05 2.66 3.48 4.62 6.06 7.72 9.31

T2 / TE2 06 3 .15 4 .14 5.51 7. 24 9.24 11.10

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.54 0.70 0.88 1.07 1.25 1.36

T2 / TE2 01 0.73 0.97 1.28 1.66 2.08 2.46

T2 / TE2 02 0.82 1.09 1.46 1.93 2. 51 3 .11

T2 / TE2 03 1.38 1. 83 2.45 3.25 4.22 5.24

T2 / TE2 04 2.10 2.73 3.63 4.80 6.24 7. 8 9

T2 / TE2 05 2.76 3.59 4.76 6. 31 8.23 10.40

T2 / TE2 06 3.25 4.24 5.64 7.51 9. 82 12. 4 0

Cond. temp.

[°C]

25

Cond. temp.

[°C]

35

Cond. temp.

[°C]

45

-40 -30 -20 -10 0 10

0.48 0.54 0.59 0.62 0. 61 0.54

-40 -30 -20 -10 0 10

0.49 0.57 0.63 0.67 0.69 0.66

-40 -30 -20 -10 0 10

0.49 0.57 0.64 0.69 0.73 0.74

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.53 0.69 0. 87 1.07 1.27 1. 43

T2 / TE2 01 0.72 0.95 1. 26 1.65 2 .11 2.57

T2 / TE2 02 0.81 1.08 1.45 1.94 2.55 3.24

T2 / TE2 03 1.38 1. 82 2.44 3. 27 4.30 5.50

T2 / TE2 04 2.14 2.77 3.66 4.85 6.38 8.25

T2 / TE2 05 2.81 3.63 4.80 6 .37 8.40 10.90

T2 / TE2 06 3.30 4.26 5.65 7. 54 10 .00 13 .00

Cond. temp.

[°C]

55

-40 -30 -20 -10 0 10

0.47 0.56 0.63 0.69 0. 74 0.76

Evaporating [°C]

Capacity [kW]

Subcooling correction factor 'fsub'

Subcooling [K] 2 4 10 15 20 25 30 35 40 45 50

Correction factor 0.98 1.00 1.07 1.12 1.18 1.23 1.29 1.34 1.40 1.45 1.50

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

-40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15

0 1 1 1 1 1 1 1 1 1 1 1 1

1 0.93 0.93 0.93 0.93 0.92 0.92 0.92 0.91 0.90 0.89 0.87 0.83

1.5 0.90 0.89 0.89 0.89 0.88 0.88 0.87 0.86 0.84 0.82 0.79 0.74

2 0.86 0.86 0.85 0.85 0.84 0.83 0.82 0.81 0.79 0.76 0.71 0.62

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 11

Page 12

Data sheet | Thermostatic expansion valves, type T2 / TE2

Capacity

Capacity in kW, range N -40 °C to 10 °C. Opening superheat sh= 6 K R404A

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.72 0.92 1.09 1.21 1. 22 1.08

T2 / TE2 01 1.00 1.38 1. 81 2.20 2.40 2.25

T2 / TE2 02 1.12 1. 58 2 .17 2.79 3.25 3.22

T2 / TE2 03 1.86 2.65 3.65 4.72 5.49 5.42

T2 / TE2 04 2.68 3.83 5.36 7.12 8.53 8.69

T2 / TE2 05 3.51 5.04 7. 06 9.38 11. 20 11. 3 0

T2 / TE2 06 4 .15 5.99 8.43 11. 2 0 13.40 13 . 30

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.67 0.88 1.08 1.2 5 1. 34 1.29

T2 / TE2 01 0.95 1. 33 1.79 2.28 2.64 2.70

T2 / TE2 02 1.07 1.53 2 .15 2.90 3.59 3.89

T2 / TE2 03 1.78 2.57 3.64 4.93 6.11 6.57

T2 / TE2 04 2.60 3.75 5. 37 7.45 9.53 10. 60

T2 / TE2 05 3.40 4.93 7. 07 9.82 12 .50 13.70

T2 / TE2 06 4.00 5.83 8.40 11 . 7 0 14 .9 0 16.3 0

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.61 0.81 1.01 1.20 1.34 1. 38

T2 / TE2 01 0.86 1.22 1.68 2 .19 2.66 2.87

T2 / TE2 02 0.97 1.41 2.02 2.81 3.64 4.16

T2 / TE2 03 1.63 2.38 3.43 4.80 6.23 7. 06

T2 / TE2 04 2.43 3.50 5.08 7. 2 6 9 .74 11 . 4 0

T2 / TE2 05 3.17 4.60 6.69 9.58 12.9 0 14.9 0

T2 / TE2 06 3.71 5.41 7.92 11. 4 0 15 .40 17. 70

Cond. temp.

[°C]

25

Cond. temp.

[°C]

35

Cond. temp.

[°C]

45

-40 -30 -20 -10 0 10

0.55 0. 61 0.64 0.65 0.62 0.54

-40 -30 -20 -10 0 10

0.52 0. 59 0.64 0.67 0.68 0.64

-40 -30 -20 -10 0 10

0.46 0.54 0.60 0.65 0.68 0.67

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.52 0.70 0.89 1.07 1. 23 1.30

T2 / TE2 01 0 .74 1. 06 1. 47 1.96 2.44 2.73

T2 / TE2 02 0.85 1.23 1. 78 2.52 3.35 3.96

T2 / TE2 03 1.43 2.09 3.03 4.32 5.78 6.76

T2 / TE2 04 2 .17 3.10 4.50 6.51 8.98 10.90

T2 / TE2 05 2.83 4.07 5.92 8.61 11.9 0 14.4 0

T2 / TE2 06 3.29 4.77 6.99 10.3 0 14.30 17. 20

Cond. temp.

[°C]

55

-40 -30 -20 -10 0 10

0.39 0.47 0.54 0.59 0.62 0.64

Evaporating [°C]

Capacity [kW]

Subcooling correction factor 'fsub'

Subcooling [K] 2 4 10 15 20 25 30 35 40 45 50

Correction factor 0.97 1.00 1.09 1.16 1.23 1.30 1.38 1.45 1.52 1.59 1.65

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

-40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15

0 1 1 1 1 1 1 1 1 1 1 1 1

1 0.96 0.96 0.96 0.96 0.96 0.96 0.95 0.95 0.94 0.94 0.92 0.91

1.5 0.94 0.94 0.94 0.94 0.94 0.93 0.93 0.92 0.91 0.90 0.88 0.86

2 0.92 0.92 0.92 0.92 0.91 0.91 0.90 0.89 0.88 0.87 0.84 0.80

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 12

Page 13

Data sheet | Thermostatic expansion valves, type T2 / TE2

Capacity

Capacity in kW, range B, -60 °C to -25 °C, opening superheat sh= 6 K R404A

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.50 0.65 0.83 1.02

T2 / TE2 01 0.68 0.90 1.22 1. 62

T2 / TE2 02 0.75 1.0 0 1.39 1.91

T2 / TE2 03 1.2 2 1.64 2.30 3.22

T2 / TE2 04 1.69 2.31 3.23 4.46

T2 / TE2 05 2.20 3.02 4.22 5.82

T2 / TE2 06 2.60 3.55 4.98 6.92

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.47 0 . 61 0.80 1. 0 0

T2 / TE2 01 0.64 0.86 1.18 1.59

T2 / TE2 02 0.70 0.96 1.34 1.88

T2 / TE2 03 1.16 1.58 2.24 3.18

T2 / TE2 04 1.72 2.31 3.22 4.47

T2 / TE2 05 2.23 3.01 4 .19 5.83

T2 / TE2 06 2.63 3.51 4.90 6.87

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.41 0. 55 0.73 0.93

T2 / TE2 01 0.56 0.77 1.08 1.4 8

T2 / TE2 02 0.63 0.86 1.23 1.76

T2 / TE2 03 1.0 4 1.44 2.07 2.99

T2 / TE2 04 1.6 8 2.20 3.04 4.23

T2 / TE2 05 2.16 2.84 3.94 5.52

T2 / TE2 06 2.57 3.30 4.57 6.46

Cond. temp.

[°C]

25

Cond. temp.

[°C]

35

Cond. temp.

[°C]

45

-60 -50 -40 -30

0.44 0. 51 0.58 0.63

-60 -50 -40 -30

0. 41 0.49 0.56 0.62

-60 -50 -40 -30

0.36 0.44 0.52 0.58

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.33 0.46 0.62 0.81

T2 / TE2 01 0.46 0.64 0.92 1.29

T2 / TE2 02 0. 51 0.73 1.06 1. 54

T2 / TE2 03 0.86 1. 22 1.80 2.65

T2 / TE2 04 1.56 1.96 2.67 3.73

T2 / TE2 05 1.98 2.50 3.44 4.85

T2 / TE2 06 2.39 2.93 3.97 5.63

Cond. temp.

[°C]

55

-60 -50 -40 -30

0.29 0.36 0.44 0.50

Evaporating [°C]

Capacity [kW]

Subcooling correction factor 'fsub'

Subcooling [K] 2 4 10 15 20 25 30 35 40 45 50

Correction factor 0.97 1.00 1.10 1.19 1.27 1.35 1.43 1.52 1.60 1.68 1.76

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

0 1 1 1 1 1 1 1 1

1 0.97 0.96 0.96 0.96 0.96 0.96 0.96 0.96

1.5 0.95 0.95 0.95 0.94 0.94 0.94 0.94 0.94

2 0.93 0.93 0.93 0.93 0.92 0.92 0.92 0.92

-60 -55 -50 -45 -40 -35 -30 -25

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 13

Page 14

Data sheet | Thermostatic expansion valves, type T2 / TE2

Capacity

Capacity in kW, range N -40 °C to 10 °C. Opening superheat sh= 6 K R407F

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 1.1 1.4 1.6 1.8 1. 8 1.7

T2 / TE2 01 1.6 2.0 2.6 3.1 3.6 3.6

T2 / TE2 02 1.8 2.3 3.0 3.9 4.8 5.1

T2 / TE2 03 2.9 3.9 5.1 6.6 8.1 8.7

T2 / TE2 04 4.3 5.6 7.4 9.6 12 . 2 14. 0

T2 / TE2 05 5.6 7.4 9.7 12 .7 16.1 18.1

T2 / TE2 06 6.6 8.7 11.6 15.2 19.3 21.5

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 1.1 1.4 1.6 1.9 2.0 2.0

T2 / TE2 01 1.6 2 .1 2.7 3.3 3.9 4.1

T2 / TE2 02 1.8 2.4 3.1 4.1 5.2 5.9

T2 / TE2 03 3.0 4.0 5.3 7.0 8.8 10.0

T2 / TE2 04 4.4 5.8 7.7 10.2 13 .3 16 .0

T2 / TE2 05 5.8 7.6 10.1 13.5 17.5 20.9

T2 / TE2 06 6.7 9.0 12 . 0 16.1 21.0 24.8

Cond. temp.

[°C]

25

Cond. temp.

[°C]

35

-40 -30 -20 -10 0 10

0.84 0.92 0.96 0.98 0.95 0.86

-40 -30 -20 -10 0 10

0.85 0.93 0.99 1.0 1.0 0.98

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 1.1 1.4 1.6 1.9 2.0 2 .1

T2 / TE2 01 1.5 2.0 2.6 3.3 4.0 4.4

T2 / TE2 02 1.8 2.3 3.1 4.1 5.3 6.3

T2 / TE2 03 3.0 4.0 5.3 7.1 9.1 10.7

T2 / TE2 04 4.4 5.9 7.8 10.4 13. 8 17.1

T2 / TE2 05 5.8 7.6 10. 2 13 .8 18 .3 22.4

T2 / TE2 06 6.7 8.9 12 .1 16.4 21.9 26.6

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 1.0 1.3 1. 6 1.8 2.0 2.1

T2 / TE2 01 1.5 2.0 2.6 3.3 3.9 4.4

T2 / TE2 02 1.7 2.3 3.0 4.1 5.3 6.4

T2 / TE2 03 2.9 3.8 5.2 7. 0 9.1 10.9

T2 / TE2 04 4.3 5.7 7.7 10. 3 13. 8 17.4

T2 / TE2 05 5.6 7.5 10.1 13.7 18.4 22.9

T2 / TE2 06 6.5 8.7 11.9 16 .3 2 2.1 27. 4

Cond. temp.

[°C]

45

Cond. temp.

[°C]

55

-40 -30 -20 -10 0 10

0.83 0.92 0.99 1.0 1.1 1.0

-40 -30 -20 -10 0 10

0.79 0.89 0.96 1.0 1. 0 1.0

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Subcooling correction factor 'fsub'

Subcooling [K] 1 4 10 15 20 25 30 35 40 45 50

Correction factor 0.96 1.00 1.07 1.14 1.20 1.26 1.33 1.40 1.47 1.54 1.65

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

-40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15

0 1 1 1 1 1 1 1 1 1 1 1 1

1 1.00 0.93 0.91 0.88 0.87 0.82 0.79 0.76 0.73 0.69 0.65 0.91

1.5 1.04 0.91 0.88 0.84 0.82 0.77 0.74 0.69 0.64 0.60 0.57 0.86

2 1.07 0.93 0.85 0.81 0.77 0.72 0.67 0.63 0.58 0.54 0.50 0.80

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 14

Page 15

Data sheet | Thermostatic expansion valves, type T2 / TE2

Capacity

Capacity in kW, range N -40 °C to 10 °C. Opening superheat sh= 6 K R407A

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.97 1.2 1.4 1. 6 1.7 1.6

T2 / TE2 01 1.4 1. 8 2.3 2.8 3.2 3.2

T2 / TE2 02 1.6 2.1 2.7 3.5 4.3 4.6

T2 / TE2 03 2.6 3.4 4.6 5.9 7.3 7. 8

T2 / TE2 04 3.8 5.0 6.6 8.6 11. 0 12.6

T2 / TE2 05 5.0 6.5 8.6 11.4 14 .5 16 .4

T2 / TE2 06 5.8 7. 7 10.3 13.6 17.3 19.4

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.97 1.2 1.4 1.7 1.8 1. 8

T2 / TE2 01 1.4 1. 8 2.3 2.9 3.4 3.7

T2 / TE2 02 1.6 2.1 2.8 3.6 4.6 5.3

T2 / TE2 03 2.6 3.5 4.7 6.2 7. 8 9.0

T2 / TE2 04 3.9 5.1 6.8 9.0 11. 9 14.4

T2 / TE2 05 5.0 6.7 8.9 12.0 15. 7 18.7

T2 / TE2 06 5.9 7. 9 10 .6 14.3 18. 8 22.2

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.94 1. 2 1.4 1.7 1. 8 1.9

T2 / TE2 01 1.3 1. 8 2.3 2.9 3.5 3.9

T2 / TE2 02 1.5 2.0 2.7 3.7 4.7 5.6

T2 / TE2 03 2.6 3.4 4.6 6.2 8 .1 9.5

T2 / TE2 04 3.8 5.1 6.8 9.2 12 . 2 15. 2

T2 / TE2 05 5.0 6.6 8.9 12 .1 16.2 19.9

T2 / TE2 06 5.8 7. 8 10.6 14. 5 19.4 23.7

Cond. temp.

[°C]

25

Cond. temp.

[°C]

35

Cond. temp.

[°C]

45

-40 -30 -20 -10 0 10

0.74 0.81 0.86 0.87 0.85 0.77

-40 -30 -20 -10 0 10

0.74 0.82 0.88 0.91 0.91 0.88

-40 -30 -20 -10 0 10

0.72 0.80 0.87 0.91 0.93 0.92

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.88 1.1 1.4 1.6 1.8 1.9

T2 / TE2 01 1.3 1.7 2.2 2.8 3.5 3.9

T2 / TE2 02 1.4 1.9 2.6 3.5 4.6 5.6

T2 / TE2 03 2.4 3.3 4.5 6.1 8.0 9.6

T2 / TE2 04 3.7 4.9 6.6 9.0 12.1 15.4

T2 / TE2 05 4.8 6.4 8.7 11 . 9 16.1 20.3

T2 / TE2 06 5.5 7. 5 10.3 14. 2 19.4 24.2

Cond. temp.

[°C]

55

-40 -30 -20 -10 0 10

0.67 0.76 0.83 0.88 0.91 0.92

Evaporating [°C]

Capacity [kW]

Subcooling correction factor 'fsub'

Subcooling [K] 1 4 10 15 20 25 30 35 40 45 50

Correction factor 0.96 1.00 1.08 1.14 1.21 1.28 1.35 1.42 1.50 1.57 1.65

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

-40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15

0 1 1 1 1 1 1 1 1 1 1 1 1

1 0.97 0.93 0.92 0.89 0.86 0.83 0.80 0.78 0.74 0.72 0.67 0.91

1.5 1.01 0.92 0.88 0.85 0.81 0.78 0.73 0.71 0.67 0.63 0.59 0.86

2 1.01 0.90 0.86 0.82 0.77 0.74 0.69 0.63 0.59 0.56 0.52 0.80

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 15

Page 16

Data sheet | Thermostatic expansion valves, type T2 / TE2

Capacity

Capacity in kW, range N -40 °C to 10 °C. Opening superheat sh= 6 K R448A

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 1.0 5 1. 25 1.4 4 1. 60 1.67 1.59

T2 / TE2 01 1. 51 1.90 2.35 2.82 3.19 3.25

T2 / TE2 02 1.72 2.19 2.78 3.50 4.22 4.58

T2 / TE2 03 2.86 3.65 4.67 5.90 7. 14 7. 7 3

T2 / TE2 04 4 .17 5.30 6.77 8.67 10.9 12. 4

T2 / TE2 05 5.45 6.93 8.87 11. 3 14.1 15. 8

T2 / TE2 06 6.45 8.26 10. 6 13. 7 17.1 19.1

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 1.0 5 1.26 1.4 8 1. 67 1.79 1.81

T2 / TE2 01 1. 51 1.91 2.40 2.94 3.43 3.70

T2 / TE2 02 1.72 2.21 2.84 3.64 4.54 5.23

T2 / TE2 03 2.88 3.70 4.78 6.16 7.70 8.87

T2 / TE2 04 4.24 5.42 6.99 9.08 11. 7 14.1

T2 / TE2 05 5.53 7. 08 9.15 11.9 15.2 18.1

T2 / TE2 06 6.52 8.40 10.9 14. 3 18 .5 22.0

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 1.01 1. 23 1.4 6 1.67 1.8 3 1.90

T2 / TE2 01 1.47 1.87 2.37 2.94 3. 51 3.90

T2 / TE2 02 1.67 2.16 2. 81 3.65 4.64 5.52

T2 / TE2 03 2.82 3.64 4.75 6.20 7.91 9.41

T2 / TE2 04 4.20 5.39 6.99 9.18 12 . 0 14.9

T2 / TE2 05 5.47 7.03 9.16 12. 0 15. 7 19. 2

T2 / TE2 06 6 .41 8 .31 10.9 14. 5 19. 0 23.4

Cond. temp.

[°C]

25

Cond. temp.

[°C]

35

Cond. temp.

[°C]

45

-40 -30 -20 -10 0 10

0.77 0.83 0.87 0.88 0.86 0.79

-40 -30 -20 -10 0 10

0.77 0.84 0.89 0.92 0.93 0.90

-40 -30 -20 -10 0 10

0.75 0.82 0.88 0.93 0.95 0.94

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.95 1.17 1.39 1. 61 1.79 1. 89

T2 / TE2 01 1.38 1.77 2.26 2.84 3.44 3.90

T2 / TE2 02 1.58 2.06 2.70 3.54 4.56 5.54

T2 / TE2 03 2.68 3.49 4.59 6.04 7.82 9. 51

T2 / TE2 04 4.06 5.23 6.82 9.01 11. 9 15.1

T2 / TE2 05 5.26 6.81 8.92 11. 8 15.6 19.4

T2 / TE2 06 6 .13 8.00 10.6 14. 2 19.0 23.8

Cond. temp.

[°C]

55

-40 -30 -20 -10 0 10

0.70 0.78 0.84 0.89 0.93 0.94

Evaporating [°C]

Capacity [kW]

Subcooling correction factor 'fsub'

Subcooling [K] 2 4 10 15 20 25 30 35 40 45 50

Correction factor 0.98 1.00 1.07 1.13 1.19 1.25 1.31 1.37 1.42 1.48 1.54

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

-40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15

0 1 1 1 1 1 1 1 1 1 1 1 1

1 0.96 0.96 0.96 0.96 0.96 0.96 0.96 0.95 0.95 0.94 0.94 0.93

1.5 0.95 0.94 0.94 0.94 0.94 0.94 0.93 0.93 0.92 0.92 0.90 0.89

2 0.93 0.93 0.92 0.92 0.92 0.92 0.91 0.90 0.90 0.89 0.87 0.85

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 16

Page 17

Data sheet | Thermostatic expansion valves, type T2 / TE2

Capacity

Capacity in kW. range N -40 °C to 10 °C. Opening superheat sh= 6 K R449A

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 1.0 5 1.24 1.42 1.57 1.63 1.56

T2 / TE2 01 1.53 1.90 2. 32 2.76 3.12 3 .17

T2 / TE2 02 1. 74 2 .19 2.76 3.43 4.11 4.45

T2 / TE2 03 2.91 3.66 4.63 5.79 6.95 7.52

T2 / TE2 04 4.24 5.33 6.75 8.54 10.6 12. 0

T2 / TE2 05 5.55 6.98 8.84 11. 2 13.7 15. 3

T2 / TE2 06 6.59 8.32 10.6 13. 5 16. 6 18 .5

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 1.0 5 1. 25 1.45 1. 63 1.75 1.77

T2 / TE2 01 1.53 1.91 2.36 2.87 3.34 3.61

T2 / TE2 02 1. 74 2.20 2.81 3.56 4.40 5.07

T2 / TE2 03 2.92 3.70 4.73 6.03 7. 48 8.60

T2 / TE2 04 4.30 5.43 6.93 8.92 11.4 13 .6

T2 / TE2 05 5.61 7. 10 9.09 11 . 67 14. 8 17. 4

T2 / TE2 06 6.63 8.43 10.9 14.1 17.9 21.2

Cond. temp.

[°C]

25

Cond. temp.

[°C]

35

-40 -30 -20 -10 0 10

0.76 0.82 0.85 0.87 0.85 0.78

-40 -30 -20 -10 0 10

0.76 0.82 0.87 0.90 0.91 0.88

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 1.01 1. 22 1.43 1. 63 1.79 1. 86

T2 / TE2 01 1.48 1.86 2.33 2.87 3.41 3.80

T2 / TE2 02 1.69 2.15 2.77 3.56 4.49 5.35

T2 / TE2 03 2.84 3.63 4.68 6.05 7. 66 9.10

T2 / TE2 04 4.23 5.37 6.91 8.99 11. 6 14.4

T2 / TE2 05 5.51 7.02 9.06 11. 8 15. 2 18. 5

T2 / TE2 06 6.49 8 .31 10. 8 14.2 18.4 22.6

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.95 1.15 1. 36 1.57 1.74 1.85

T2 / TE2 01 1.39 1.76 2.22 2.76 3.34 3.80

T2 / TE2 02 1.59 2.04 2.64 3.44 4 .41 5.36

T2 / TE2 03 2.69 3.46 4.49 5.87 7.54 9.15

T2 / TE2 04 4.06 5.18 6.71 8.78 11. 5 14.5

T2 / TE2 05 5.27 6.76 8.78 11 . 5 15. 0 18.7

T2 / TE2 06 6 .17 7.96 10.4 13. 9 18.3 22.9

Cond. temp.

[°C]

45

Cond. temp.

[°C]

55

-40 -30 -20 -10 0 10

Capacity [kW]

0.74 0.81 0.87 0.91 0.93 0.93

Evaporating [°C]

-40 -30 -20 -10 0 10

Capacity [kW]

0.69 0.76 0.82 0.87 0.91 0.92

Subcooling correction factor 'fsub'

Subcooling [K] 2 4 10 15 20 25 30 35 40 45 50

Correction factor 0.98 1.00 1.07 1.13 1.19 1.25 1.31 1.37 1.43 1.49 1.55

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

-40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15

0 1 1 1 1 1 1 1 1 1 1 1 1

1 0.96 0.96 0.96 0.96 0.96 0.96 0.96 0.95 0.95 0.94 0.94 0.93

1.5 0.95 0.94 0.94 0.94 0.94 0.94 0.93 0.93 0.92 0.91 0.90 0.89

2 0.93 0.93 0.92 0.92 0.92 0.91 0.91 0.90 0.90 0.88 0.87 0.84

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 17

Page 18

Data sheet | Thermostatic expansion valves, type T2 / TE2

Capacity

Capacity in kW. range N -40 °C to 10 °C. Opening superheat sh= 6 K R452A

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.75 0.96 1.15 1. 29 1.32 1. 22

T2 / TE2 01 1.05 1.45 1.91 2.35 2.60 2.53

T2 / TE2 02 1.17 1.6 6 2.29 2.98 3.53 3.64

T2 / TE2 03 1.94 2.78 3.85 5.04 5.97 6 .11

T2 / TE2 04 2.79 4.01 5.66 7. 6 0 9.27 9.80

T2 / TE2 05 3.66 5.28 7.45 10.0 12.2 12. 7

T2 / TE2 06 4.33 6.27 8.89 12.0 14.5 15. 0

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.70 0.93 1.14 1.33 1. 44 1.41

T2 / TE2 01 0.99 1.40 1.89 2.42 2.83 2.95

T2 / TE2 02 1.12 1.61 2.27 3.08 3.86 4.26

T2 / TE2 03 1.86 2.70 3.84 5.24 6.56 7.18

T2 / TE2 04 2.72 3.94 5.67 7. 92 10.2 11. 6

T2 / TE2 05 3.56 5.17 7. 46 10.4 13.4 15.0

T2 / TE2 06 4 .19 6 .12 8.87 12.5 16.1 17.8

Cond. temp.

[°C]

25

Cond. temp.

[°C]

35

-40 -30 -20 -10 0 10

0.57 0.63 0.68 0.70 0.68 0.60

-40 -30 -20 -10 0 10

0.54 0.62 0.68 0.71 0.73 0.69

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.64 0.85 1.07 1.28 1. 44 1. 49

T2 / TE2 01 0.91 1. 29 1.78 2.34 2.85 3.11

T2 / TE2 02 1.03 1.49 2.14 2.99 3.90 4.51

T2 / TE2 03 1.72 2.52 3.64 5 .11 6.68 7. 65

T2 / TE2 04 2.56 3.70 5.39 7.73 10.4 12. 4

T2 / TE2 05 3.35 4.86 7. 09 10. 2 13. 8 16 .2

T2 / TE2 06 3.91 5.72 8.40 12.2 16 .5 19. 2

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.56 0.75 0.95 1.15 1. 32 1.42

T2 / TE2 01 0.79 1.14 1.58 2 .11 2.63 2.97

T2 / TE2 02 0.91 1.32 1.91 2.71 3.62 4.31

T2 / TE2 03 1.53 2.24 3.25 4.65 6.24 7. 35

T2 / TE2 04 2.33 3. 33 4.82 7. 00 9.70 11.9

T2 / TE2 05 3.04 4.36 6.35 9.26 12 .9 15 .7

T2 / TE2 06 3.53 5 .11 7. 50 11. 0 15.5 18.7

Cond. temp.

[°C]

45

Cond. temp.

[°C]

55

-40 -30 -20 -10 0 10

0.49 0.57 0.64 0.69 0.73 0.73

-40 -30 -20 -10 0 10

0.42 0 .51 0.58 0.63 0.67 0.69

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Subcooling correction factor 'fsub'

Subcooling [K] 2 4 10 15 20 25 30 35 40 45 50

Correction factor 0.97 1.00 1.09 1.16 1.23 1.30 1.38 1.45 1.52 1.59 1.66

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

-40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15

0 1 1 1 1 1 1 1 1 1 1 1 1

1 0.96 0.96 0.96 0.96 0.96 0.96 0.96 0.95 0.95 0.94 0.94 0.92

1.5 0.95 0.95 0.94 0.94 0.94 0.94 0.93 0.93 0.92 0.91 0.90 0.88

2 0.93 0.93 0.93 0.92 0.92 0.92 0.91 0.90 0.90 0.88 0.87 0.84

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 18

Page 19

Data sheet | Thermostatic expansion valves, type T2 / TE2

Capacity

Capacity in kW, range N, -40°C to 10°C, opening superheat sh= 6 K R513A

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.42 0.55 0.70 0.83 0.91 0.86

T2 / TE2 01 0. 55 0.76 1.0 1.3 1.5 1.6

T2 / TE2 02 0.62 0.85 1.1 1.5 1.8 2.0

T2 / TE2 03 1.0 1.4 1.9 2.5 3.1 3.3

T2 / TE2 04 1.5 2.1 2.8 3.6 4.5 5.0

T2 / TE2 05 1.9 2.6 3.5 4.6 5.7 6.4

T2 / TE2 06 2.4 3.2 4.4 5.7 7.1 7. 9

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.41 0.56 0.72 0.88 1.0 1.1

T2 / TE2 01 0. 55 0.77 1.0 1.4 1.7 1.9

T2 / TE2 02 0.61 0.86 1. 2 1.6 2.0 2.4

T2 / TE2 03 1.0 1.4 2.0 2.6 3.4 4.1

T2 / TE2 04 1.5 2.1 2.9 3.9 5.0 6.2

T2 / TE2 05 2.0 2.7 3.7 4.9 6.4 7.8

T2 / TE2 06 2.4 3.3 4.5 6.1 7.9 9.8

Cond. temp.

[°C]

25

Cond. temp.

[°C]

35

-40 -30 -20 -10 0 10

0.39 0.46 0 .51 0.54 0.53 0.47

-40 -30 -20 -10 0 10

0.39 0.46 0.52 0.57 0.59 0.58

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.40 0.54 0.71 0.88 1.0 1.2

T2 / TE2 01 0.54 0.75 1.0 1.4 1. 7 2.1

T2 / TE2 02 0.60 0.84 1.2 1.6 2.1 2.6

T2 / TE2 03 1.0 1.4 2.0 2.7 3.5 4.5

T2 / TE2 04 1.5 2.1 2.9 3.9 5.2 6.7

T2 / TE2 05 2.0 2.7 3.7 5.0 6.7 8.5

T2 / TE2 06 2.4 3.3 4.6 6.2 8.3 10.7

Valve type Orice no.

T2 / TE2 0X

T2 / TE2 00 0.38 0.52 0.68 0.85 1.0 1.2

T2 / TE2 01 0.51 0.72 0.99 1.3 1.7 2 .1

T2 / TE2 02 0.57 0.81 1.1 1.6 2.1 2.7

T2 / TE2 03 0.98 1. 4 1.9 2.6 3.5 4.6

T2 / TE2 04 1.5 2.1 2.9 3.9 5.2 6.8

T2 / TE2 05 1.9 2.7 3.7 5.0 6.6 8.7

T2 / TE2 06 2.3 3.2 4.5 6.1 8.2 10.8

Cond. temp.

[°C]

45

Cond. temp.

[°C]

55

-40 -30 -20 -10 0 10

0.37 0.45 0.51 0.57 0. 61 0.62

-40 -30 -20 -10 0 10

0.35 0.42 0.49 0.55 0.59 0.63

Evaporating [°C]

Capacity [kW]

Evaporating [°C]

Capacity [kW]

Subcooling correction factor 'fsub'

Subcooling [K] 2 4 10 15 20 25 30 35 40 45 50

Correction factor 0.98 1.00 1.07 1.13 1.18 1.24 1.31 1.37 1.43 1.49 1.55

Distributer correction factor 'fp' *)

Pressure drop

[bar]

“Pressure

drop

[bar]”

*) calculated at 32 °C condensing temperature

-40 -35 -30 -25 -20 -15 -10 -5 0 5 10 15

0 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

1 0.94 0.93 0.93 0.93 0.93 0.92 0.92 0.91 0.90 0.89 0.87 0.84

1.5 0.90 0.90 0.90 0.89 0.89 0.88 0.88 0.86 0.85 0.83 0.80 0.75

2 0.87 0.86 0.86 0.85 0.85 0.84 0.83 0.81 0.79 0.77 0.72 0.64

Evaporating temp. [°C]

© Danfoss | DCS (rm) | 2019.07

DKRCC.PD.AA0.3A.02 | 19

Page 20

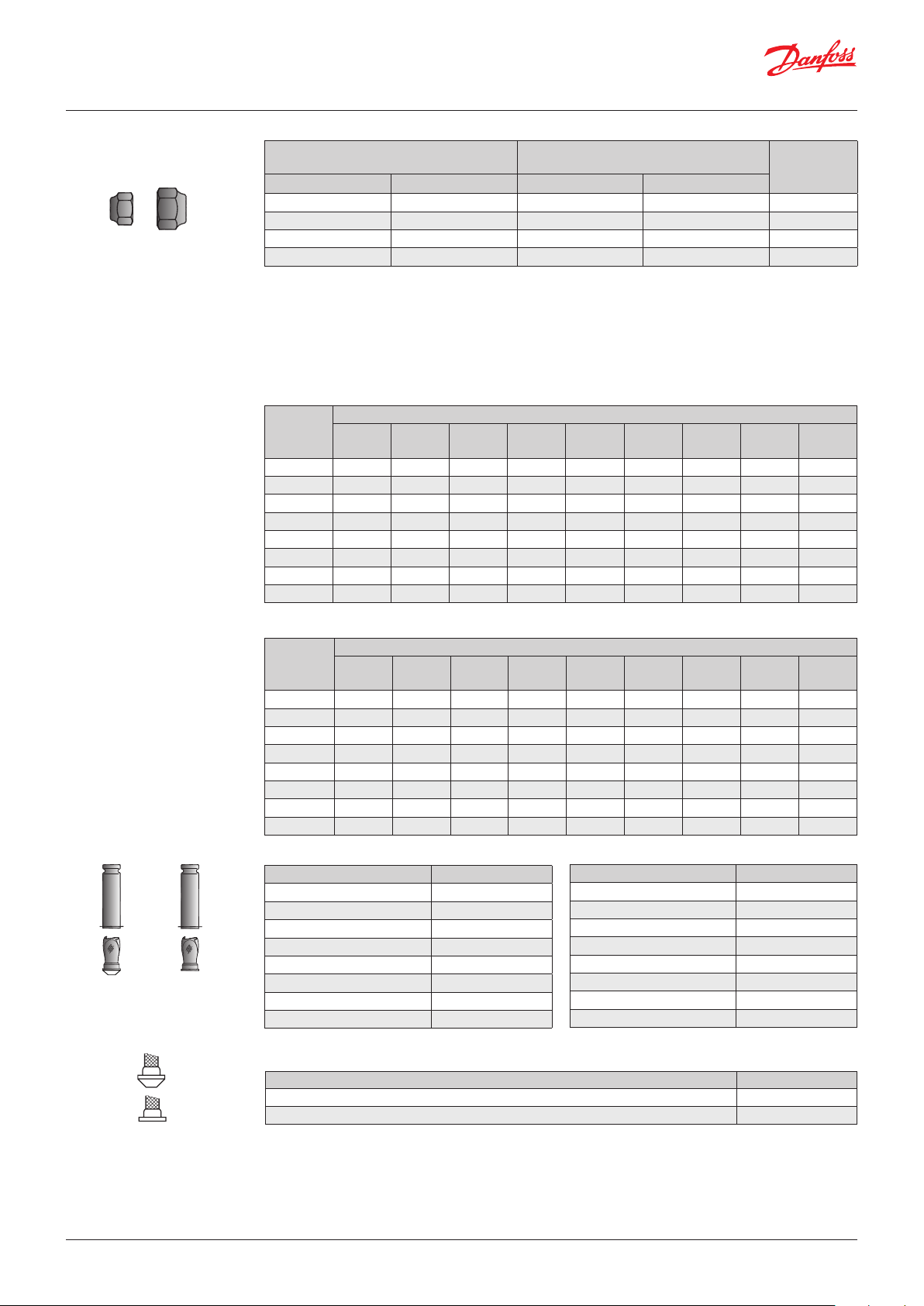

Dimensions and weights

T2 and TE2

Flare × are

All dimentions are in mm

Flare × solder

All dimentions are in mm

Solder adaptor

Flare × are

Flare × solder

Outlet Equalization Weight

A B [kg / lb]

1

/2 ” are

1

/2 ” solder

12 mm solder

1

/4 ” are 0.3 / 0.7

1

/4 ” solder

6 mm solder

0.3 / 0.7

Solder ODF Weight

[in.] [mm] [kg / lb]

1

4

/

3

8

/

6 0.05 / 0.11

10 0.05 / 0.11

© Danfoss | DCS (rm) | 2019.07 DKRCC.PD.AA0.3A.02 | 20

Loading...

Loading...