Page 1

Data sheet

Check valve

Types NRV and NRVH Version 2

NRV and NRVH can be used in liquid suction and

hot gas lines in refrigeration and air conditioning

plants.

The valves ensure the correct flow direction and

prevent back-condensation from a warm part of

the system to the cold evaporator.

The hermetic tight design of solder versions meet

the environmental demands for today and future.

A built-in damping piston makes the valves

suitable for installation in lines where pulsation

can occur, e. g. in the discharge line from the

compressor.

Features y Ensure correct flow direction

y Available in both straightway and angleway

versions

y Prevents back-condensation from warm to

cold system part

y Hermetic tight design for solder versions

y Built-in damping piston that makes the

valves suitable for installation in lines where

pulsation can occur, e.g. in the discharge line

from the compressor

y NRVH type check valve is with stronger spring

and it‘s recommended to use for compressors

in parallel (i.e. power packs) where higher level

of pulsation and vibration are expected

y Oversize connections provide flexibility in use

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 1

Page 2

Data sheet | Check valve, types NRV and NRVH

Approvals

Technical data

Dimensioning

and selection

Refrigerants

R134a, R22/R407C, R290, R32, R404A/R507, R407A, R407F, R407H, R410A, R448A, R449A, R449B, R450A, R452A,

R452B, R454A, R454B, R454C, R455A, R513A, R515B, R516A, R600, R600a, R1233zd(E), R1234ze(E), R1234yf, R1270

Note:

• For complete list of approved refrigerants, go to http://store.danfoss.com/ and search for individual code numbers, where

refrigerants are listed as part of product details.

• Only solder versions are allowed for flammable refrigerant.

This product is approved for R290, R32, R452B, R454A, R454B, R454C, R455A, R516A, R600, R600a, R1234yf and R1270 by

ignition source assessment in accordance to standard EN13463-1.

• R1234ze can be used for NRV size up to 35s according to the PED category I, Fluid II

• NRV/NRVH is not suitable for oil application. For detailed information please contact Danfoss.

When selecting the right Danfoss check valve

the capacity tables should be utilised together

with plant requirements concerning piping and

connection sizes.

The optimum solution should include the

highest capacity at lowest pressure drop across

the valve before it closes. Further, when

dimensioning and selecting Danfoss check

valves for mounting into the compressor

discharge line, it is important to be aware of the

following:

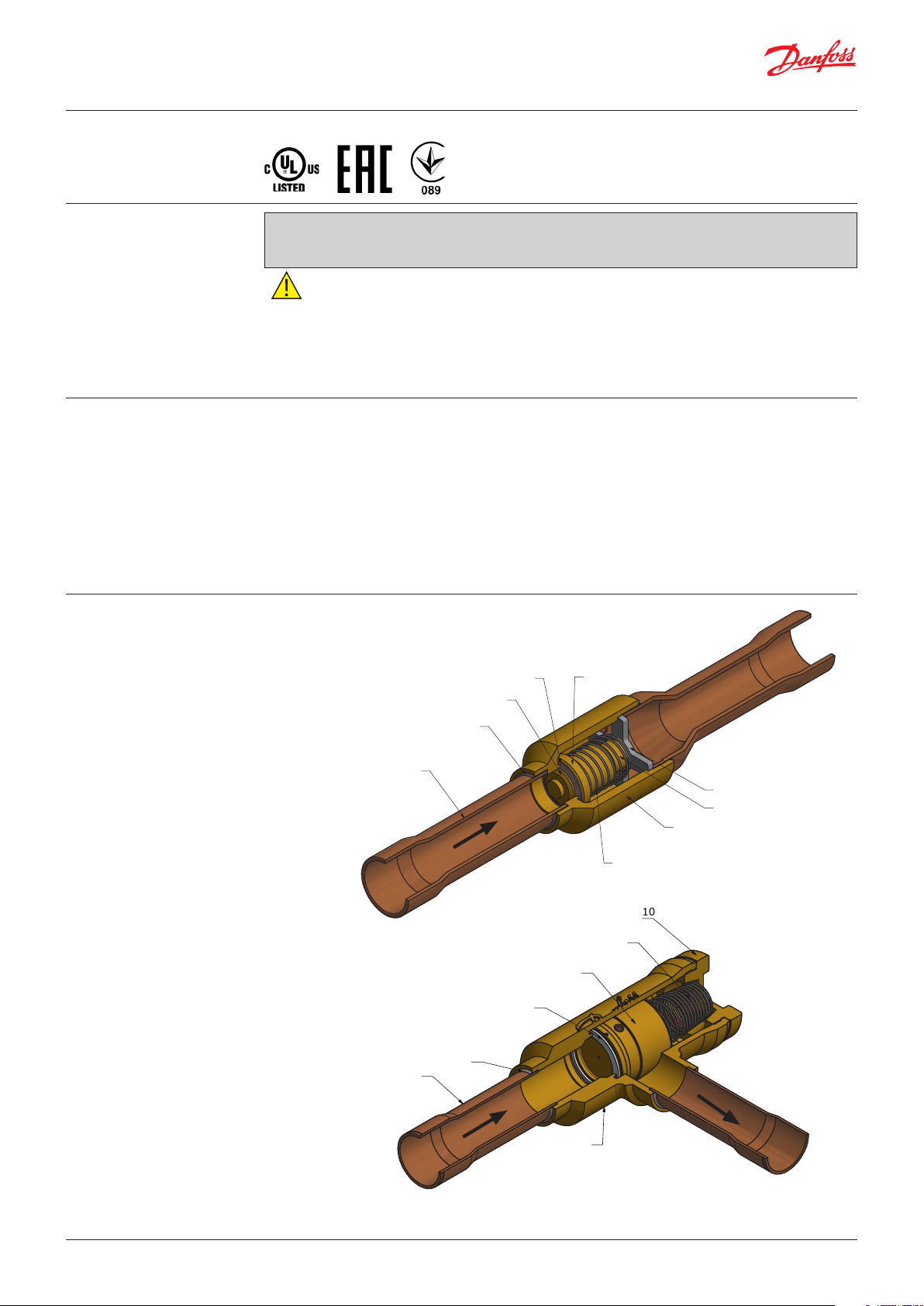

Design / Function Straightway solder version

1. Copper tube

2. Solder ring

3. Washer

4. Teflon disk

5. Piston

6. Spring

7. Valve body

8. Guide

1

9. Stop face

10. Cover

The differential pressure across the valve must

always be higher than the given minimum

pressure drop at which the valve is completely

open. This also applies to lowest capacities for

compressor with capacity regulation.

NRVH type check valve is with stronger spring

and it’s recommended to use for compressors in

parallel (i.e. power packs) where higher level of

pulsation and vibration are expected.

5

4

3

2

9

8

7

6

© Danfoss | DCS (nb) |2019.06

Angleway solder version

1

10

6

5

4

2

7

AI150286435592en-000702 | 2

Page 3

Data sheet | Check valve, types NRV and NRVH

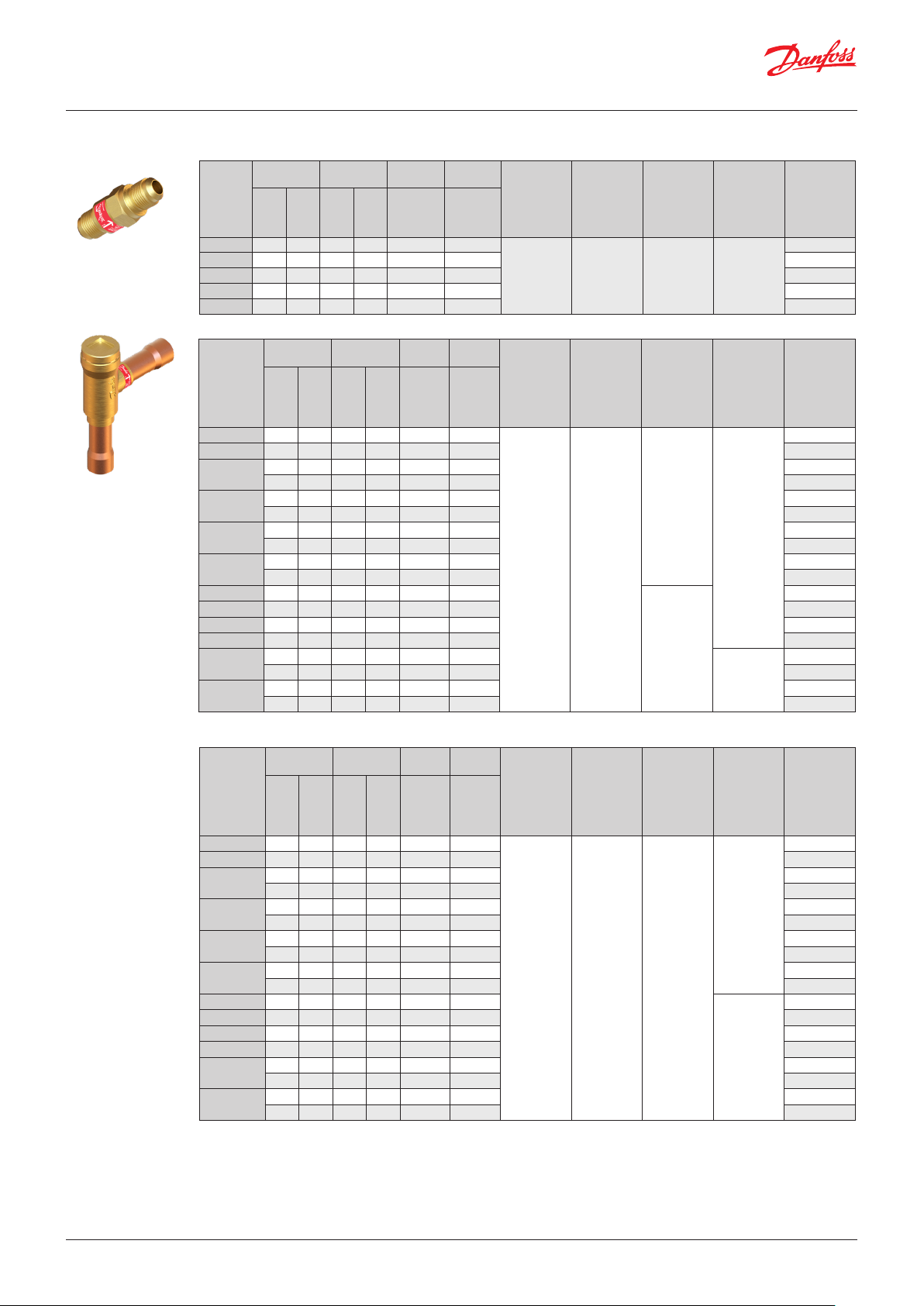

Ordering

Straightway Flare Version without flare nut

Min. OPD

Δp 2)

Valve

type

NRV 6

Connection

[in] [mm] [bar] [psi] [m3/h] [gal/min]

1

⁄4 6 0.07 1.01 0.56 0.65

NRV 103⁄8 10 0.07 1.01 1.2 1.39 020-1041

NRV 121⁄2 12 0.05 0.72 2.05 2.37 020-1042

NRV 165⁄8 16 0.05 0.72 3.6 4.16 020-1043

NRV 193⁄4 19 0.05 0.72 5.5 6.36 020-1044

Kv

value 3)

Cv

value 3)

Max.

working

pressure:

PS/MWP

46 bar /

667 psig

Media

temperature

range

-50 °C - 140 °C

/

-58 °F - 285 °F

For

flammable

refrigerant 4)

No

PED

category

Article 4,

Paragraph 3

Code no.

Multi pack 5)

020-1040

Angleway Solder ODF Version, PS = 46 bar

Connection

Min. OPD

Δp 2)

Valve

type

NRV 22s

[in] [mm] [bar] [psi] [m3/h]

7

⁄8 22 0.04 0.58 8.5 9.83

NRVH 22s 7⁄8 22 0.30 4.35 8.5 9.83 020-1032

NRV 22s 1)

NRVH 22s 1)

NRV 28s

NRVH 28s

1 1⁄8 – 0.04 0.58 8.5 9.83 020-1060

– 28 0.04 0.58 8.5 9.83 020-1055

1 1⁄8 – 0.30 4.35 8.5 9.83 020-1072

– 28 0.30 4.35 8.5 9.83 020-1067

1 1⁄8 – 0.04 0.58 16.5 19.07 020-1021

– 28 0.04 0.58 16.5 19.07 020-1025

1 1⁄8 – 0.30 4.35 16.5 19.07 020-1029

– 28 0.30 4.35 16.5 19.07 020-1033

NRV 28s 1) 1 3⁄8 35 0.04 0.58 16.5 19.07

NRVH 28s 1) 1 3⁄8 35 0.30 4.35 16.5 19.07 020-1068

NRV 35s

1 3⁄8 35 0.04 0.58 29 33.52 020-1026

NRVH 35s 1 3⁄8 35 0.30 4.35 29 33.52 020-1034

NRV 35s 1)

NRVH 35s 1)

1 5⁄8 – 0.04 0.58 29 33.52

– 42 0.04 0.58 29 33.52 020-1027

1 5⁄8 – 0.30 4.35 29 33.52 020-1073

– 42 0.30 4.35 29 33.52 020-1035

Kv

value 3)

Cv

value 3)

[gal/

min]

Max.

working

pressure:

PS/MWP

46 bar /

667 psig

Media

temperature

range

-50 °C - 140 °C

/

-58 °F - 285 °F

For

flammable

refrigerant 4)

Yes

No

PED

category

Article 4,

Paragraph 3

Ⅰ

Code no.

Multi pack 5)

020-1020

020-1056

020-1061

Angleway Solder ODF Version, PS = 49 bar

Min. OPD

Δp 2)

Valve

type

NRV 22s

Connection

[in] [mm] [bar] [psi] [m3/h]

7

⁄8 22 0.04 0.58 8.5 9.83

6

) (The availability of below codes will be updated in October 2019)

Kv

value 3)

Cv

value 3)

[gal/

min]

Max.

working

pressure:

PS/MWP

Media

temperature

range

For

flammable

refrigerant 4)

PED

category

Code no.

Multi pack

020-3020

NRVH 22s 7⁄8 22 0.30 4.35 8.5 9.83 020-3032

NRV 22s 1)

NRVH 22s 1)

NRV 28s

NRVH 28s

NRV 28s 1) 1 3⁄8 35 0.04 0.58 16.5 19.07

1 1⁄8 – 0.04 0.58 8.5 9.83 020-3060

– 28 0.04 0.58 8.5 9.83 020-3055

1 1⁄8 – 0.30 4.35 8.5 9.83 020-3072

– 28 0.30 4.35 8.5 9.83 020-3067

Article 4,

Paragraph 3

1 1⁄8 – 0.04 0.58 16.5 19.07 020-3021

– 28 0.04 0.58 16.5 19.07 020-3025

1 1⁄8 – 0.30 4.35 16.5 19.07 020-3029

– 28 0.30 4.35 16.5 19.07 020-3039

49 bar /

710 psig

-50 °C - 155 °C

/

-58 °F - 311 °F

Yes

020-3056

NRVH 28s 1) 1 3⁄8 35 0.30 4.35 16.5 19.07 020-3068

NRV 35s 1 3⁄8 35 0.04 0.58 29 33.52 020-3026

NRVH 35s 1 3⁄8 35 0.30 4.35 29 33.52 020-3036

NRV 35s 1)

NRVH 35s 1)

1)

Oversize connections

2)

∆ p =Minimum Opening Pressure Differential

3)

The Kv / Cv value is the flow of water in [m3/h – gal/min] at a pressure drop across valve of 1 bar/14.5 psig

ρ = 1000 kg/m3 - 2205 lbs/G

4

) Please refer to the Danfoss refrigerant list for flammable refrigerants, for other flammable refrigerants please contact Danfoss.

5

) For the code selection of Industrial pack version please contact Danfoss.

6

) The 49bar NRV angleway version can be only used with flammable refrigerants.

1 5⁄8 – 0.04 0.58 29 33.52 020-3061

– 42 0.04 0.58 29 33.52 020-3027

1 5⁄8 – 0.30 4.35 29 33.52 020-3073

– 42 0.30 4.35 29 33.52 020-3035

Ⅱ

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 3

Page 4

Data sheet | Check valve, types NRV and NRVH

Ordering

(continued)

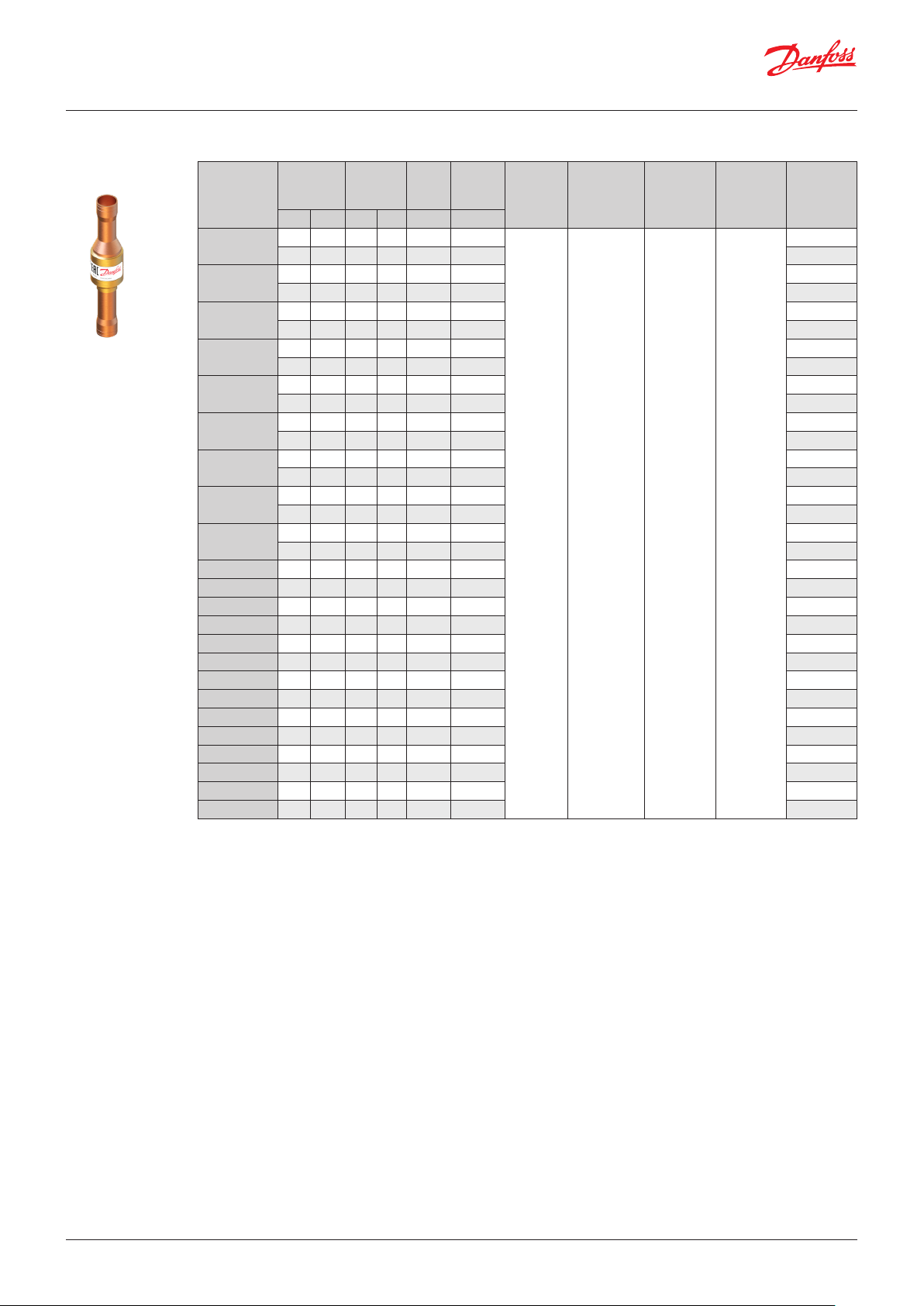

Straightway Solder ODF Version

Valve

type

NRV 6s v2

NRV 6s v2 1)

NRVH 6s v2 1)

NRV 10s v2

NRVH 10s v2

NRV 10s v2 1)

NRVH 10s v2 1)

NRV 12s v2

NRVH 12s v2

NRV 12s v2 1)

Connection

Min. OPD

Δp 2)

Kv

value 3)

Cv

value 3)

[in] [mm] [bar] [psi] [m3/h] [gal/min]

1

⁄4 – 0.04 0.58 0.67 0.77

– 6 0.04 0.58 0.67 0.77 020B1014

3

⁄8 – 0.04 0.58 0.67 0.77 020B1057

– 10 0.04 0.58 0.67 0.77 020B1050

3

⁄8 – 0.20 2.90 0.67 0.77 020B1069

– 10 0.20 2.90 0.67 0.77 020B1062

3

⁄8 – 0.04 0.58 1.64 1.90 020B1011

– 10 0.04 0.58 1.64 1.90 020B1015

3

⁄8 – 0.20 2.90 1.64 1.90 020B1046

– 10 0.20 2.90 1.64 1.90 020B1036

1

⁄2 – 0.04 0.58 1.64 1.90 020B1058

– 12 0.04 0.58 1.64 1.90 020B1051

1

⁄2 – 0.20 2.90 1.64 1.90 020B1070

– 12 0.20 2.90 1.64 1.90 020B1063

1

⁄2 – 0.02 0.29 2.50 2.89 020B1012

– 12 0.02 0.29 2.50 2.89 020B1016

1

⁄2 – 0.20 2.90 2.50 2.89 020B1039

– 12 0.20 2.90 2.50 2.89 020B1037

5

⁄8 16 0.02 0.29 2.50 2.89 020B1052

Max.

working

pressure:

PS/MWP

49 bar /

710 psig

Media

temperature

range

-50 °C - 155°C

/

-58 °F - 311 °F

NRVH 12s v2 1) 5⁄8 16 0.20 2.90 2.50 2.89 020B1064

NRV 16s v2

5

⁄8 16 0.02 0.29 4.00 4.62 020B1018

NRVH 16s v25⁄8 16 0.20 2.90 4.00 4.62 020B1038

NRV 16s v2 1) – 18 0.02 0.29 4.00 4.62 020B1053

NRVH 16s v2 1) – 18 0.20 2.90 4.00 4.62 020B1065

NRV 16s v2 1) 3⁄4 19 0.02 0.29 4.00 4.62 020B1059

NRVH 16s v2 1)3⁄4 19 0.20 2.90 4.00 4.62 020B1071

NRV 19s v2 – 18 0.02 0.29 6.50 7.51 020B1017

NRVH 19s v2 – 18 0.14 2.03 6.50 7.51 020B1008

NRV 19s v2

3

⁄4 19 0.02 0.29 6.50 7.51 020B1019

NRVH 19s v23⁄4 19 0.14 2.03 6.50 7.51 020B1023

NRV 19s v2 1)7⁄8 22 0.02 0.29 6.50 7.51 020B1054

NRVH 19s v2 1)7⁄8 22 0.14 2.03 6.50 7.51 020B1066

1)

Oversize connections

2)

∆p = Minimum Opening Pressure Differential

3)

The Kv / Cv value is the flow of water in [m3/h – gal/min] at a pressure drop across valve of 1 bar/14.5 psig

ρ = 1000 kg/m3 - 2205 lbs/G

4

) Please refer to the Danfoss refrigerant list for flammable refrigerants, for other flammable refrigerants please contact Danfoss

5

) For the code selection of Industrial pack version please contact Danfoss.

For

flammable

refrigerant 4)

Yes

PED

category

Article 4,

Paragraph 3

Code no.

Multi pack 5)

020B1010

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 4

Page 5

Data sheet | Check valve, types NRV and NRVH

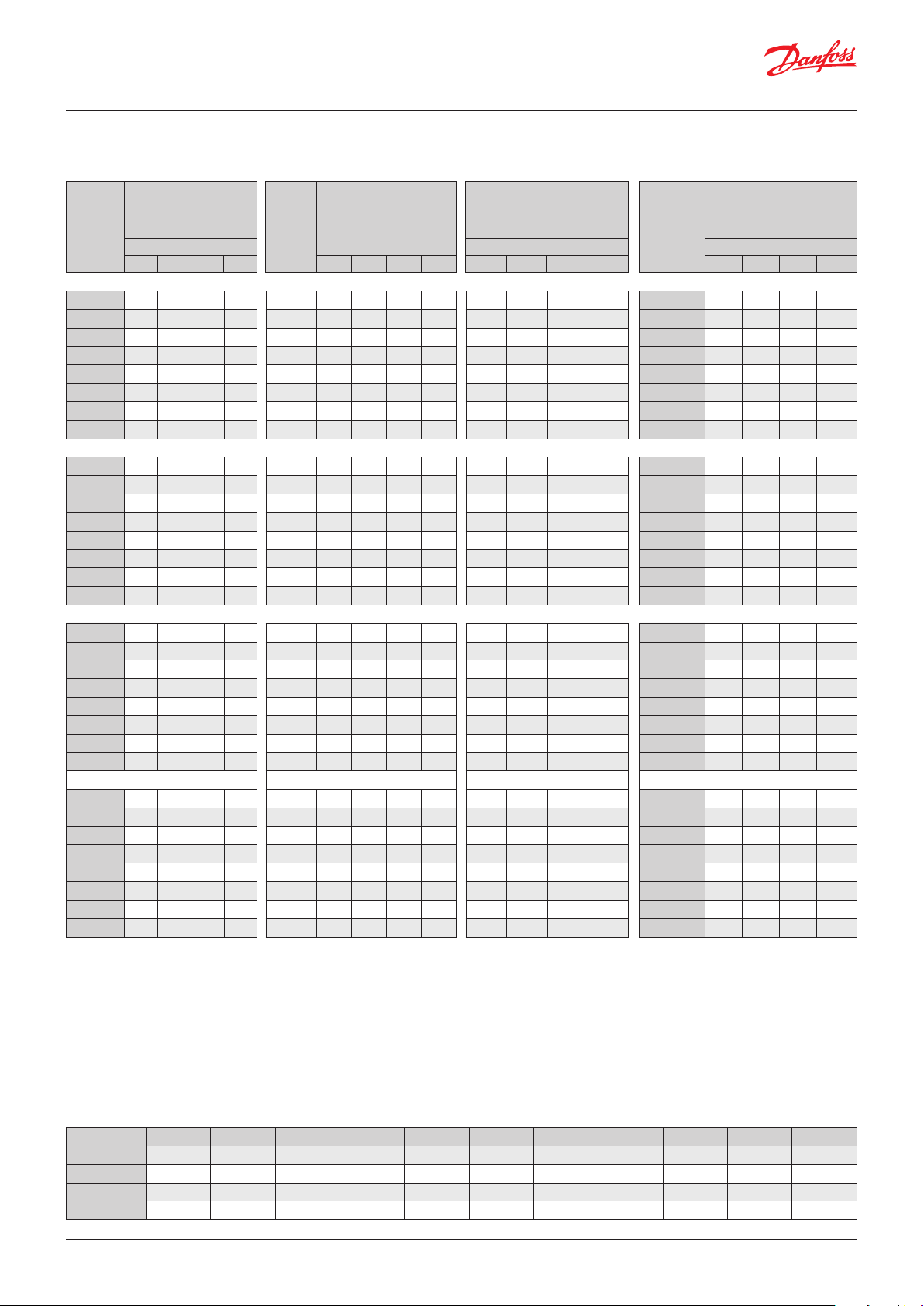

Capacity SI units

Liquid capacity (kW) Suction vapour capacity in [kW] Hot gas capacity in [kW] Hot gas capacity in [kW]

Liquid capacity 1)

at pressure drop

Typ e

R134 a R134 a R134 a R134 a

NRV 6 v2 1.4 4.6 11. 0 14.4 0.07 0.22 0.39 0.50 0.56 0.2 0.7 1. 7 2.2 NRVH 6 v2 0 .1 0.3 1. 4 2.0

NRV 10 v2 8.3 18 .2 29.5 35.2 0.07 0.91 1.59 2.01 2 .24 1.3 2.8 4.5 5.4 NRVH 10 v2 0.0 2.9 5.0 6.5

NRV 12 v2 26.9 31.8 4 4.9 53.7 0.07 1.6 8 2. 83 3.55 3.95 4.2 4.9 6.9 8.2 NRVH 12 v2 5.6 9.2 10.0 10. 8

NRV 16 v2 38.8 50.8 71.9 85.9 0.07 2.68 4.53 5.68 6.32 6.0 7. 9 11.1 13. 2 NRVH 16 v2 1.9 10.5 13 .8 15. 9

NRV 19 v2 69. 8 82.6 11 6. 9 139.7 0.07 4.36 7.37 9.24 10.27 10.8 12 .8 18 .0 21.4 NRVH 19 v2 16. 0 23.8 26.0 28.0

NRV 22 91.6 10 8.4 153. 3 183 .3 0.07 5.73 9.67 1 2.11 13.47 14.2 16 .8 23.6 28.1 NRVH 22 - - 34.1 36.7

NRV 28 177.9 210 .5 297.7 355. 8 0.07 11. 13 18.77 23.51 26.14 2 7.6 32.6 45.9 54.6 NRVH 28 - - 66.3 71.3

NRV 35 312. 7 369.9 523.2 625.3 0.07 19. 56 32.99 41.3 3 45.94 48.6 5 7.4 80.7 95.9 NRVH 35 - - 116.5 125.3

R22 R22 R22 R22

NRV 6 v2 1.5 4.9 11. 8 15 .5 0.07 0.34 0.54 0.66 0.72 0.3 0.9 2.1 2.8 NRVH 6 v2 0.1 0.4 1.8 2.6

NRV 10 v2 9. 0 19.7 31. 8 38.0 0.07 1.39 2.18 2.64 2.89 1. 6 3.5 5.7 6.8 NRVH 10 v2 0.0 3.6 6.3 8.2

NRV 12 v2 28.9 34.2 48.4 5 7.9 0 .07 2.50 3.84 4.6 4 5.07 5.2 6.2 8.7 10.4 NRVH 12 v2 7. 0 11. 6 12.7 13.6

NRV 16 v2 41.8 54.8 7 7.5 92.6 0.07 3.99 6.14 7. 42 8.11 7. 5 9.9 14.0 16.6 NRVH 16 v2 2.5 13.4 17.6 20.2

NRV 19 v2 75. 2 89.0 12 5.9 150 .5 0.07 6.49 9.98 12.05 13.17 13.6 16.1 22.7 27. 0 NRVH 19 v2 20.2 30.1 32.9 35.5

NRV 22 98.4 116 .4 164.6 196.8 0. 07 8.48 13 .05 15 .76 17. 23 17. 8 21. 0 29.6 35.3 NRVH 22 - - 43.0 46.4

NRV 28 191.0 226.0 319. 6 382.0 0.07 16. 47 25.33 30.59 33.44 34.5 40.8 57. 5 68.6 NRVH 28 - - 83.5 90.0

NRV 35 335.7 3 97.2 561. 7 671.4 0. 07 28.94 44.52 53.77 58.78 60.7 71. 8 101.1 120 .5 NRVH 35 - - 146 .8 158.2

R404A R404A R404A R404A

NRV 6 v2 1.0 3.4 8.0 10. 5 0. 07 0.29 0.47 0.59 0.65 0.2 0.8 1. 8 2.4 NRVH 6 v2 0.1 0.4 1.6 2.3

NRV 10 v2 6.1 13. 4 21. 6 25.8 0.07 1.17 1. 90 2.35 2.59 1.4 3.1 4.9 5.9 NRVH 10 v2 0.0 3.1 5.4 7.1

NRV 12 v2 19.7 23.3 32.9 39.3 0.07 2.09 3.34 4.12 4.54 4.5 5.3 7.5 9.0 NRVH 12 v2 6.1 10. 0 10.9 11. 8

NRV 16 v2 28.4 3 7.2 52.6 62.9 0.07 3.34 5.35 6.59 7. 27 6.5 8.5 12. 0 14. 3 NRVH 16 v2 2.1 11.6 15. 2 17.5

NRV 19 v2 51.1 60.5 85.5 102 .2 0.07 5.43 8.70 10.71 11. 81 11.7 13 .9 19.6 23.3 NRVH 19 v2 17. 5 26.0 28.4 30.6

NRV 22 67. 0 79.3 112 .2 134.1 0.07 7. 09 11. 37 14.01 15 .4 6 15.4 18 .2 25.6 30.6 NRVH 22 - - 3 7.2 4 0.1

NRV 28 13 0.1 154 .0 217. 8 260.3 0.07 13. 77 2 2.07 27.19 30. 02 29.9 35.3 49. 8 59.3 NRVH 28 - - 72.3 77. 9

NRV 35 228.7 270.6 382.7 4 57.5 0.07 24.20 38.79 47.7 9 52.76 52. 5 62.0 87. 4 104.2 NRVH 35 - - 12 7.1 137. 0

R410A R410A R410A R410A

NRV 6 v2 1.5 4.9 11. 6 15 .3 0.07 0.44 0.68 0.83 0.90 0.3 1.1 2.6 3.4 NRVH 6 v2 0.2 0.5 2.3 3.2

NRV 10 v2 8.8 19. 3 31. 2 37. 3 0.07 1.78 2.74 3.30 3.61 2.0 4.4 7.0 8.4 NRVH 10 v2 0.0 4.5 7. 8 10.1

NRV 12 v2 28.5 33.7 47. 6 56.9 0.07 3 .16 4.80 5.78 6.32 6.4 7.6 10.7 12. 8 NRVH 12 v2 8.7 14 .3 15. 6 16. 8

NRV 16 v2 41.1 53.9 76 .2 91.1 0 .07 5.05 7.6 9 9.26 10 .11 9.3 12 .2 17. 2 20.5 NRVH 16 v2 3.1 16.6 21. 8 2 5.1

NRV 19 v2 74.0 8 7.6 123 .8 148. 0 0.07 8. 21 12. 49 15 .04 16 .42 16. 7 19. 8 27. 9 33.3 NRVH 19 v2 25.0 37.1 40.6 43.8

NRV 22 96.7 114 .4 161.8 193.4 0.07 10.72 16.35 19. 70 21.52 21.9 25.9 36.5 43.6 NRVH 22 - - 53.2 57. 3

NRV 28 187.7 222.1 314.1 375.4 0.07 20 .81 31.73 38 .24 41. 77 42. 5 50.2 70.9 84.6 NRVH 28 - - 103 .2 111. 3

NRV 35 329.9 39 0.3 552. 0 659.7 0.07 36.57 55.77 67.2 1 73.42 74.7 88.3 124 .6 148 .6 NRVH 35 - - 181.4 195.7

1) Rated capacities are based on:

-Evaporating temperature, te = -10 °C.

-Condensing temperature, tc = 30 °C.

-Subcooling t

-Delta superheat tsh = 0 K.

-Discharge temperature, td = 80 °C ahead of

the valve.

The table values refer to the evaporator

capacity.

across valve ∆p

[bar]

NRV NRV NRVH

0.05 0.07 0.14 0.2 -30 -10 0 5 0.05 0.07 0.14 0.2 0.2 0. 25 0.3 0.35

= 5 K.

sub

Pressure

across

valve ∆p

Suction vapour capacity 1)

drop

[bar]

at evaporating

temperature te

[°C]

Correction factors

When selecting the evaporator capacity is to be multiplied by a correction factor depending on the liquid temperature tl ahead of the valve/the evaporator. The corrected

capacity can then be found from the table.

System capacity.Correction factor=Table capacity

Correction factors for liquid temperature t

tl [°C]

R134a

R22

R404A

R410A

-10 0 10 15 20 25 30 35 40 45 50

0.73 0.79 0.86 0.90 0.95 1.00 1.06 1.12 1.19 1.27 1.37

0.76 0.82 0.88 0.92 0.96 1.00 1.05 1.10 1.16 1.22 1.30

0.67 0.74 0.82 0.87 0.93 1.00 1.08 1.17 1.29 1.43 1.61

0.72 0.78 0.85 0.90 0.94 1.00 1.06 1.14 1.22 1.33 1.46

l

Hot gas capacity 1)

at pressure drop

across valve ∆p

[bar]

Typ e

Hot gas capacity1)

at pressure drop across valve

Δp

[bar]

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 5

Page 6

Data sheet | Check valve, types NRV and NRVH

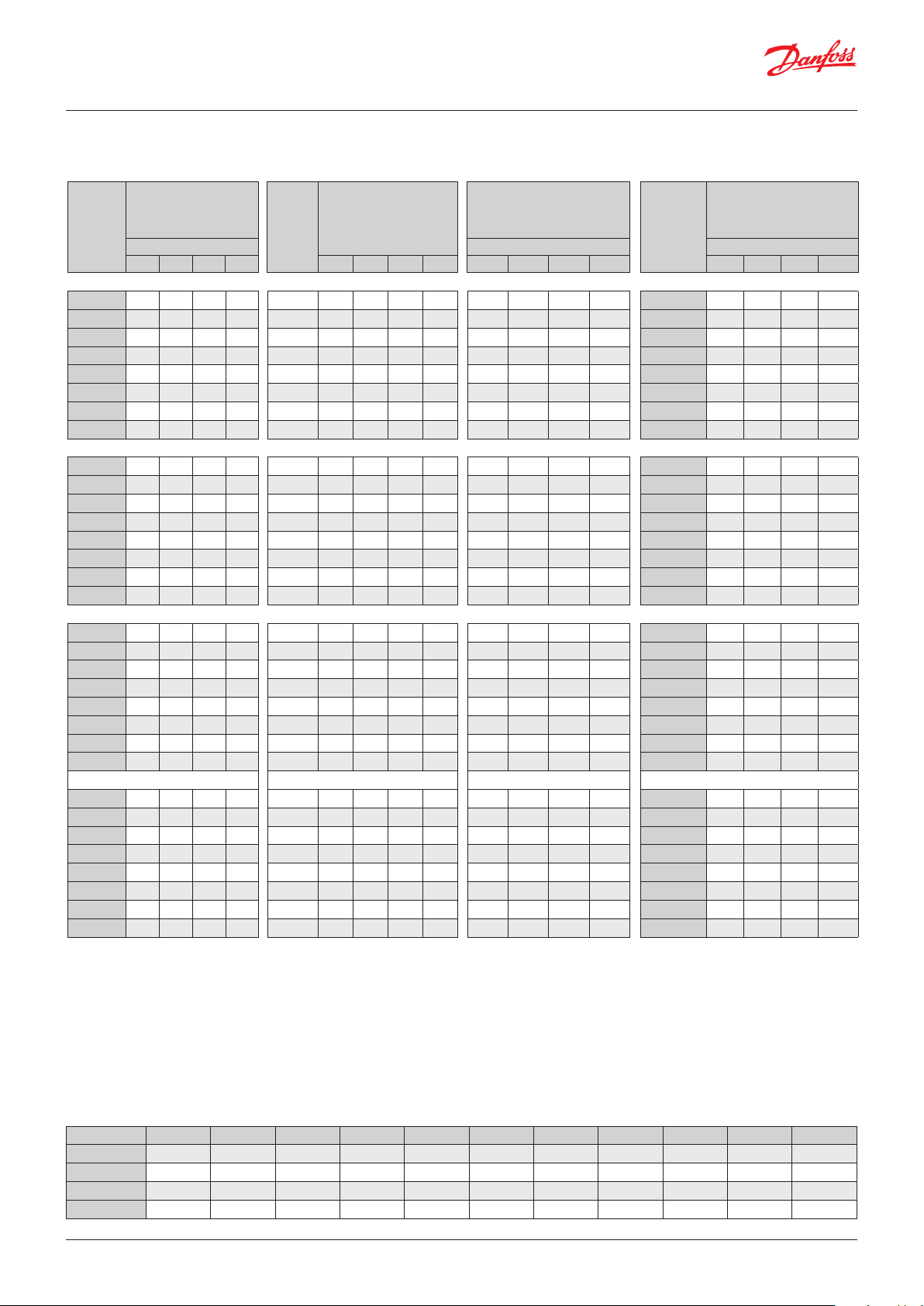

Capacity SI units

Liquid capacity (kW) Suction vapour capacity in [kW] Hot gas capacity in [kW] Hot gas capacity in [kW]

Liquid capacity 1)

at pressure drop

Typ e

R4 07A R 407A R40 7A R R407A

NRV 6 v2 1.4 4.4 10.5 13 .8 0.07 0.30 0.50 0.62 0.68 0.3 0.9 2.2 2.9 NRVH 6 v2 0.2 0.4 1. 9 2.7

NRV 10 v2 7.9 17.4 28.2 33.7 0.07 1. 21 2.00 2.47 2.74 1.7 3.6 5.9 7. 0 NRVH 10 v2 0.0 3.7 6.5 8.4

NRV 12 v2 25.7 30.4 42.9 51.3 0.07 2 .17 3.52 4.35 4.80 5.4 6.3 8.9 10.6 NRVH 12 v2 7. 2 11. 9 13 .0 14 .0

NRV 16 v2 37. 0 48.6 68.7 82.1 0.07 3.48 5.63 6.95 7. 68 7. 7 10.1 14.3 17. 0 NRVH 16 v2 2.5 13. 7 18.1 20.8

NRV 19 v2 66.7 78.9 111. 6 133 .4 0.07 5.65 9.15 11. 30 12 .48 13.9 16.5 23.2 27.7 NRVH 19 v2 20.8 30.9 33.8 36.4

NRV 22 87. 5 103.5 146.4 175. 0 0 .07 7.4 0 12 .00 14.82 16. 38 18.3 21.6 30.5 36.4 NRVH 22 - - 44.4 4 7.8

NRV 28 16 9.9 201.0 284.2 339.7 0.07 14. 37 23.29 28.77 31.79 35.5 42.0 59. 2 70.6 NRVH 28 - - 86.1 92. 8

NRV 35 298.5 353.2 499.5 597.1 0.07 25.25 40.94 50.57 55.87 62.5 73.9 10 4.1 124.1 NRV H 35 - - 151.3 163 .1

R407C R407C R4 07C R407C

NRV 6 v2 1.5 4.7 11 .3 14.8 0.07 0.30 0.50 0.62 0.69 0.3 0.9 2.2 2.9 NRVH 6 v2 0.2 0.5 1.9 2.8

NRV 10 v2 8.6 18. 8 30.4 36.3 0.07 1. 22 2.02 2.50 2.77 1.7 3.7 6.0 7.2 NRVH 10 v2 0.0 3.8 6.7 8.7

NRV 12 v2 27. 7 32. 8 46.3 55.4 0.07 2.20 3.56 4.40 4.86 5.5 6.5 9.2 11.0 NRVH 12 v2 7. 4 12. 2 13.4 14.4

NRV 16 v2 40.0 52.4 74.1 88.6 0.07 3.52 5.70 7. 04 7. 77 8.0 10.5 14.7 17. 6 NRVH 16 v2 2.6 14 .1 18.6 21.4

NRV 19 v2 72.0 85.2 120.5 144.0 0.07 5.72 9.27 11.4 4 12. 63 14.4 17.0 23.9 28.5 NRVH 19 v2 21. 4 31.8 34.8 3 7.5

NRV 22 94.4 111. 7 157. 9 188. 8 0.07 7. 48 12.14 14.99 16.56 18.9 22.3 31.4 3 7.4 NRVH 22 - - 45. 6 49. 2

NRV 28 183 .2 216 .8 306.6 366.5 0.07 14. 52 23.56 29.10 32.14 36.6 43. 3 61.0 72.7 NRVH 28 - - 88.6 95.5

NRV 35 322.0 381.0 538.9 6 44.1 0. 07 25. 52 41.41 51.14 56.49 64.3 76.0 1 07.2 127. 8 NRVH 35 - - 155. 7 1 67. 8

R407F R407F R407F R407F

NRV 6 v2 1.5 4.8 11 .5 15.1 0.07 0.33 0.54 0.67 0 .74 0.3 1.0 2.4 3.1 NRVH 6 v2 0.2 0.5 2.0 2.9

NRV 10 v2 8.7 19 .2 31. 0 37. 0 0.07 1.3 4 2.18 2.68 2.96 1.8 3.9 6.4 7.6 NRVH 10 v2 0.0 4.1 7. 0 9.2

NRV 12 v2 28.2 33.4 47. 2 56.4 0.07 2.39 3.83 4.71 5.19 5.8 6.9 9.7 11. 6 NRVH 12 v2 7.9 12. 9 14.1 15 .2

NRV 16 v2 40.7 53.4 75.5 90.2 0.07 3.83 6.14 7.5 4 8.31 8.4 11 .0 15 .6 18 .6 NRVH 16 v2 2.8 15. 0 19.7 22.7

NRV 19 v2 73.3 86.8 122.7 146.6 0. 07 6.22 9.97 12. 25 13. 50 15.2 17. 9 25.3 30.2 NRVH 19 v2 22.6 33.6 36.8 39.6

NRV 22 95.9 113 .4 16 0.4 191. 8 0.07 8 .14 13. 04 16.02 17.66 19. 8 23.5 33 .1 39.4 NRVH 22 - - 4 8.1 51. 9

NRV 28 18 6.1 220. 2 311.4 372. 2 0.07 15. 80 25. 31 31.10 34.27 38.5 45.5 64.2 76.6 NRVH 28 - - 93.4 10 0.7

NRV 35 327.1 3 87.1 547.4 654.3 0.07 2 7.77 44.48 54.66 60.24 67. 7 80.0 112 .9 134 .6 NRVH 35 - - 16 4.1 176 .9

R407H R407H R407H R407H

NRV 6 v2 1.6 5.1 12 .3 16 .2 0.07 0.33 0.54 0.67 0 .74 0.3 1.0 2.4 3.2 NRVH 6 v2 0.2 0.5 2 .1 3.0

NRV 10 v2 9. 3 20.5 33 .1 39. 6 0.07 1.33 2.18 2.69 2.97 1. 8 4.0 6.5 7.8 NRVH 10 v2 0.0 4.2 7.2 9.4

NRV 12 v2 30.2 35.7 50.5 60.3 0. 07 2. 39 3.85 4.73 5.21 6.0 7.0 9.9 11. 8 NRVH 12 v2 8.0 13. 2 14.4 15.6

NRV 16 v2 43.5 5 7.1 80.7 96.5 0.07 3.83 6.15 7. 56 8.34 8.6 11.3 15.9 18. 9 NRVH 16 v2 2.8 15. 3 2 0.1 23.1

NRV 19 v2 78.4 92.8 131.2 156. 8 0 .07 6.23 10. 00 12 .2 9 13.55 15 .5 18. 3 25.8 30.8 NRVH 19 v2 23 .1 34.3 37. 5 40.5

NRV 22 102. 5 121.3 17 1.6 20 5.1 0.07 8.14 13 .07 16.07 17. 71 20.3 24. 0 33.8 40.3 NRVH 22 - - 49.1 52.9

NRV 28 19 9.0 235.5 333.1 39 8.1 0.07 15. 80 25.38 31. 20 34.39 39.3 46.5 65.6 78.2 NRVH 28 - - 95.3 102.7

NRV 35 349.8 413.9 585.4 69 9.7 0.07 27. 78 44.60 54.83 60.44 69.1 81.7 115 .2 137.4 NRVH 35 - - 16 7.5 180.5

1) Rated capacities are based on:

-Evaporating temperature, te = -10 °C.

-Condensing temperature, tc = 30 °C.

-Subcooling t

-Delta superheat tsh = 0 K.

-Discharge temperature, td = 80 °C ahead of

the valve.

The table values refer to the evaporator

capacity.

across valve ∆p

[bar]

NRV NRV NRVH

0.05 0.07 0.14 0.2 -30 -10 0 5 0.05 0.07 0.14 0.2 0.2 0.25 0. 3 0.35

= 5 K.

sub

Pressure

across

valve ∆p

Suction vapour capacity 1)

drop

[bar]

at evaporating

temperature te

[°C]

Correction factors

When selecting the evaporator capacity is to be multiplied by a correction factor depending on the liquid temperature tl ahead of the valve/the evaporator. The corrected

capacity can then be found from the table.

System capacity.Correction factor=Table capacity

Correction factors for liquid temperature t

t

[°C]

l

R407A

R407C

R407F

-10 0 10 15 20 25 30 35 40 45 50

0.71 0.78 0.85 0.90 0.94 1.00 1.06 1.13 1.22 1.32 1.44

0.73 0.79 0.86 0.90 0.95 1.00 1.06 1.13 1.20 1.29 1.40

0.73 0.79 0.86 0.90 0.95 1.00 1.06 1.13 1.20 1.30 1.40

l

R407H 0.74 0.80 0.87 0.91 0.95 1.00 1.06 1.12 1.19 1.27 1.37

Hot gas capacity 1)

at pressure drop

across valve ∆p

[bar]

Typ e

Hot gas capacity 1)

at pressure drop across valve

Δp

[bar]

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 6

Page 7

Data sheet | Check valve, types NRV and NRVH

Capacity SI units

Liquid capacity (kW) Suction vapour capacity in [kW] Hot gas capacity in [kW] Hot gas capacity in [kW]

Liquid capacity 1)

at pressure drop

Typ e

R448A R448A R448A R448A

NRV 6 v2 1.4 4.4 10.6 13 .8 0.07 0.31 0.51 0.63 0.70 0.3 0.9 2.2 2.9 NRVH 6 v2 0.2 0.4 1.9 2.7

NRV 10 v2 8.0 17. 5 28.3 33.8 0.07 1.26 2.05 2.53 2.79 1.7 3.7 6.0 7.1 NRVH 10 v2 0.0 3.8 6.6 8.6

NRV 12 v2 25.8 30.5 43.2 51.6 0.07 2.25 3.61 4.44 4.90 5.5 6.5 9.1 10.9 NRVH 12 v2 7. 4 12.1 13.2 14. 3

NRV 16 v2 37. 2 48.8 6 9.1 82.5 0.07 3.60 5.78 7.11 7. 84 7. 9 10.3 14. 6 17. 4 NRVH 16 v2 2.6 14.0 18. 4 21.2

NRV 19 v2 67. 1 79.4 112 .2 134.1 0.07 5.86 9.39 11.5 5 12. 73 14. 2 16.8 23.7 28.2 NRVH 19 v2 21. 2 31.5 34.4 37.1

NRV 22 87. 7 103.8 146.7 175. 4 0 .07 7.6 6 12.30 15.14 16. 70 18.6 22.0 31.1 37. 0 NRVH 22 - - 45.1 48.7

NRV 28 17 0. 2 2 01.4 284.9 340.5 0.07 14.87 23.88 29.39 32.42 36.2 42.8 60.3 71.9 NRVH 28 - - 8 7.6 94.5

NRV 35 299.2 354.0 500.7 598.4 0 .07 26.13 41.9 7 51. 66 56.98 63.6 7 5.1 106 .0 126. 3 NRV H 35 - - 15 4.0 166 .0

R449A R449A R449A R449A

NRV 6 v2 1.3 4.3 10.4 13. 7 0.07 0.31 0.51 0.63 0.69 0.3 0.9 2.2 2.9 NRVH 6 v2 0.2 0.4 1.9 2.7

NRV 10 v2 7.9 17. 3 28.0 33.4 0.07 1.25 2.04 2.52 2.78 1. 7 3.7 5.9 7. 0 NRVH 10 v2 0.0 3.8 6.5 8.5

NRV 12 v2 25.5 30 .1 42.6 51.0 0.07 2.24 3.59 4.42 4.88 5.4 6.4 9.0 10.7 NRVH 12 v2 7.3 12. 0 13 .1 14 .1

NRV 16 v2 36.8 48.2 68.2 81.5 0.07 3.58 5.75 7. 08 7. 80 7. 8 10.2 14. 4 17. 2 NRVH 16 v2 2.6 13. 8 18 .2 20.9

NRV 19 v2 66.3 78 .4 110 .9 13 2.5 0.07 5.82 9. 34 11. 50 12 .68 14.0 16.6 23.4 2 7.9 NRVH 19 v2 20.9 31.1 34.0 36.7

NRV 22 86.6 102. 5 145.0 173.3 0.07 7. 61 12 .2 2 15. 04 16.59 18.4 21.7 30.6 36.5 NRVH 22 - - 44.5 4 7.9

NRV 28 168 .2 19 9.0 281.4 336 .4 0.07 14.77 23.71 29.19 32.20 35.6 42.1 59.4 70.8 NRVH 28 - - 86.4 93.1

NRV 35 295.6 349.7 494.6 591. 2 0. 07 25.95 41.68 51.30 56.59 62.7 74 .1 104 .4 124.5 NRVH 35 - - 151.8 16 3.6

R449B R449B R449B R449B

NRV 6 v2 1.4 4.4 10.6 13 .8 0.07 0.31 0.51 0.63 0.70 0.3 0.9 2.2 2.9 NRVH 6 v2 0.2 0.4 1.9 2.7

NRV 10 v2 8.0 17. 6 28.4 33.9 0.07 1.26 2.06 2.54 2.80 1.7 3.7 6.0 7.1 NRVH 10 v2 0.0 3.8 6.6 8.6

NRV 12 v2 25.8 30.6 43.2 51.7 0.07 2.26 3.63 4.46 4.92 5.5 6.5 9.1 10. 8 NRVH 12 v2 7. 3 12.1 13.2 14. 2

NRV 16 v2 37. 3 48.9 69.2 82.7 0.07 3.62 5.80 7.14 7. 87 7.9 10. 3 14. 6 17. 3 NRVH 16 v2 2.6 14. 0 18.4 21. 2

NRV 19 v2 67. 2 79.5 112 .4 13 4.3 0.07 5.88 9. 43 11.6 0 12. 80 14.2 16. 8 23.6 28.2 N RVH 19 v2 21.1 31.4 34.4 37.0

NRV 22 87. 8 103.9 14 7.0 17 5.7 0.07 7.68 12 .33 15.17 16. 73 18.6 21.9 30.9 36.9 NRVH 22 - - 45.0 48.4

NRV 28 17 0.5 201.7 285.3 341.0 0.07 14 .92 23.9 4 29.45 32.48 36.0 42. 6 60.0 71.6 NRVH 28 - - 87. 3 94.0

NRV 35 29 9.7 354.6 501. 5 599.4 0. 07 26.22 42.07 51.76 57. 09 63.3 74. 8 105.5 125 .8 NRVH 35 - - 153.4 16 5.3

R450A R450A R450A R450A

NRV 6 v2 1.3 4.3 10. 2 13. 4 0.07 0 .19 0.35 0.45 0.50 0.2 0.6 1.5 2.0 NRV H 6 v2 0.1 0.3 1. 3 1.8

NRV 10 v2 7. 7 16 .9 27. 3 32.7 0. 07 0.79 1.42 1. 80 2.02 1.2 2.6 4.1 4.9 NRVH 10 v2 0.0 2.6 4.5 5.9

NRV 12 v2 24.9 29.5 41.7 49.8 0.07 1.4 8 2.54 3.20 3.57 3.8 4.5 6.3 7.5 NRVH 12 v2 5.1 8.3 9.1 9.8

NRV 16 v2 35.9 47. 2 66.7 79.7 0.07 2.36 4.06 5.12 5.71 5.5 7. 2 10.1 12 .0 NRVH 16 v2 1.8 9.5 12. 5 14.4

NRV 19 v2 64.8 76.6 108 .4 12 9.5 0.07 3.84 6.60 8.32 9.28 9.9 11 .7 16 .4 19. 5 NRVH 19 v2 14.6 21.7 23.6 25.4

NRV 22 84.8 10 0.3 141.9 169.6 0.07 5.01 8.62 10.89 12 .14 12 .9 15.3 21.5 25.5 NRVH 22 - - 30.9 33. 2

NRV 28 164.6 194.8 275.5 329.2 0.07 9.72 16 .74 21.13 23.57 25.1 29.6 41.6 49.5 NRVH 28 - - 60.0 6 4.5

NRV 35 289.3 342. 3 484.2 578.7 0.07 17.09 29.42 3 7.14 41.43 4 4.1 52 .1 73.2 8 7.0 NRVH 35 - - 105.5 113. 4

1) Rated capacities are based on:

-Evaporating temperature, te = -10 °C.

-Condensing temperature, tc = 30 °C.

-Subcooling t

-Delta superheat tsh = 0 K.

-Discharge temperature, td = 80 °C ahead of

the valve.

The table values refer to the evaporator

capacity.

across valve ∆p

[bar]

NRV NRV NRVH

0.05 0.07 0.14 0.2 -30 -10 0 5 0.05 0.07 0.14 0.2 0.2 0.25 0. 3 0.35

= 5 K.

sub

Pressure

across

valve ∆p

Suction vapour capacity 1)

drop

[bar]

at evaporating

temperature te

[°C]

Correction factors

When selecting the evaporator capacity is to be multiplied by a correction factor depending on the liquid temperature tl ahead of the valve/the evaporator. The corrected

capacity can then be found from the table.

System capacity.Correction factor=Table capacity

Correction factors for liquid temperature t

tl [°C]

R448A

R449A

R449B

R450A

-10 0 10 15 20 25 30 35 40 45 50

0.71 0.78 0.85 0.90 0.94 1.00 1.06 1.13 1.22 1.32 1.44

0.71 0.77 0.85 0.89 0.94 1.00 1.06 1.14 1.22 1.32 1.44

0.71 0.78 0.85 0.90 0.94 1.00 1.06 1.13 1.22 1.32 1.44

0.72 0.79 0.86 0.90 0.95 1.00 1.06 1.12 1.20 1.28 1.38

l

Hot gas capacity 1)

at pressure drop

across valve ∆p

[bar]

Typ e

Hot gas capacity 1)

at pressure drop across valve

Δp

[bar]

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 7

Page 8

Data sheet | Check valve, types NRV and NRVH

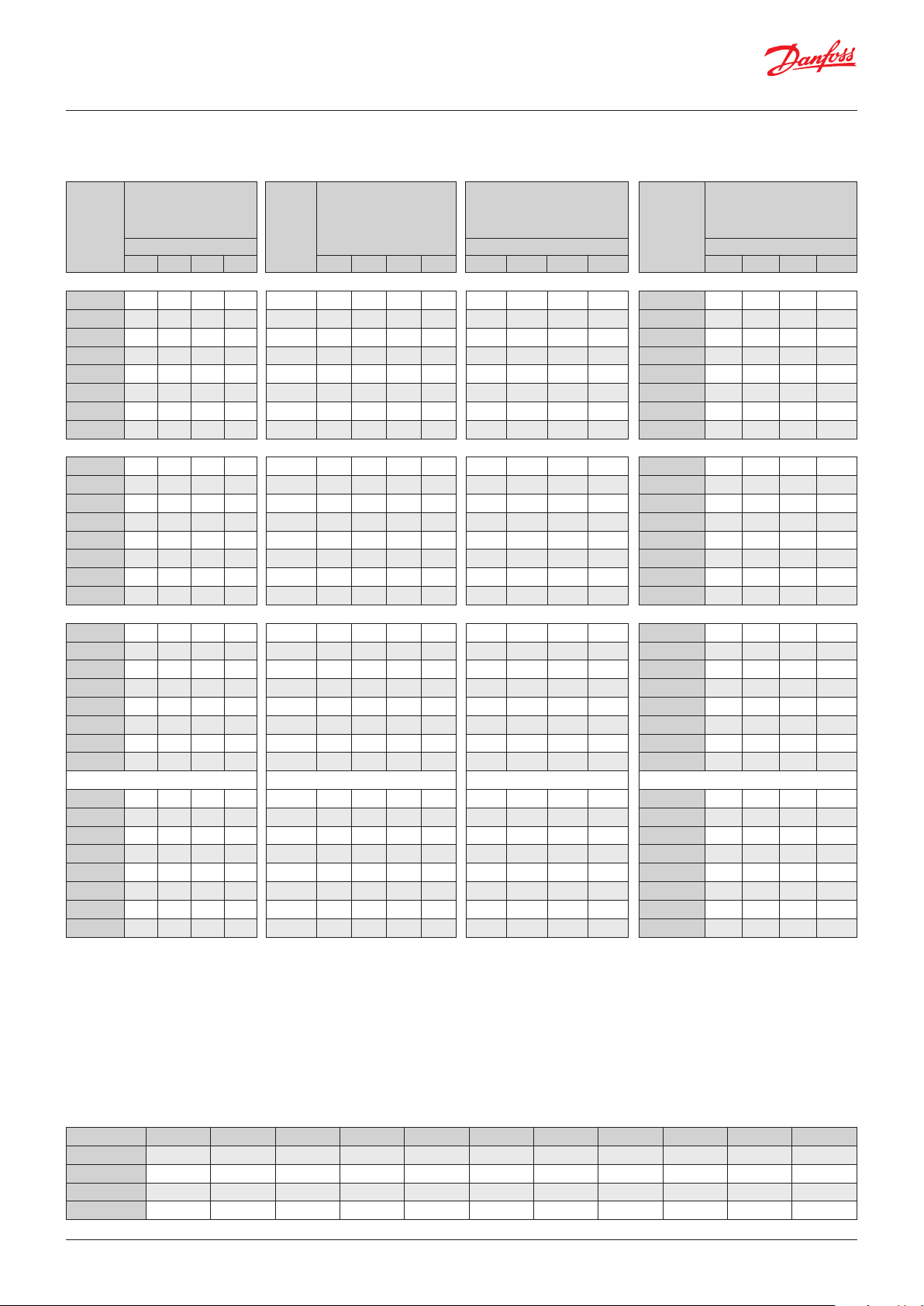

Capacity SI units

Liquid capacity (kW) Suction vapour capacity in [kW] Hot gas capacity in [kW] Hot gas capacity in [kW]

Liquid capacity 1)

at pressure drop

Typ e

R452A R452A R452A R452A

NRV 6 v2 1.1 3.4 8.2 10.7 0.07 0.27 0.45 0.56 0.62 0.2 0.8 1.9 2.5 NRVH 6 v2 0.1 0.4 1.6 2.3

NRV 10 v2 6.2 13. 6 21.9 26.2 0 .07 1.11 1. 82 2.26 2.50 1.4 3.1 5.1 6.0 NRVH 10 v2 0.0 3.2 5.6 7. 3

NRV 12 v2 20.0 23.6 33.4 40.0 0.07 1.98 3.20 3.9 6 4.38 4.6 5.5 7.7 9. 2 NRVH 12 v2 6.2 10.3 11 .2 12.1

NRV 16 v2 28.8 3 7.8 53.5 63.9 0.07 3 .17 5.13 6.34 7. 01 6.7 8.8 12.4 14.7 NRVH 16 v2 2.2 11. 9 15 .6 18 .0

NRV 19 v2 51.9 61. 5 86.9 103.9 0.07 5.14 8.33 10 .30 11. 40 12.1 14. 3 2 0.1 24.0 NRVH 19 v2 18. 0 26.7 29.2 31.5

NRV 22 67. 7 8 0.1 113. 3 135.4 0.07 6.70 10.87 13.4 5 14.8 8 15.7 18. 6 26.2 31. 3 NRVH 22 - - 38.1 41.1

NRV 28 131.4 155. 5 219.9 262.8 0.07 13.01 21.10 2 6.11 28.89 30.5 36.1 50.9 60.7 NRVH 28 - - 74. 0 79.8

NRV 35 230.9 273.3 386.4 461.9 0. 07 22. 87 37. 08 45.89 50.77 53.7 63.5 89.5 10 6.7 NRVH 35 - - 13 0.1 140 .2

R513 A R513 A R513A R513 A

NRV 6 v2 1.3 4 .1 9.8 12.8 0 .07 0 .21 0.38 0.48 0.54 0.2 0.6 1. 6 2.0 NRVH 6 v2 0.1 0.3 1.3 1.9

NRV 10 v2 7. 4 16.2 26.2 31.4 0.07 0.89 1. 54 1.9 4 2 .17 1. 2 2.6 4.2 5.0 NRVH 10 v2 0.0 2.6 4.6 6.0

NRV 12 v2 23.9 28.3 40.0 47.8 0.07 1.62 2.74 3.43 3.82 3.8 4.5 6.4 7.6 NRVH 12 v2 5.1 8.5 9. 2 9.9

NRV 16 v2 34.5 45.3 64.0 76.5 0.07 2.60 4.38 5.49 6.11 5.5 7.3 10.2 12. 2 NRVH 16 v2 1.8 9.7 12 .8 14 .7

NRV 19 v2 62. 2 73.6 10 4.0 124. 3 0.07 4.22 7.11 8.92 9.93 10.0 11 .8 16.6 19.8 NRVH 19 v2 14. 8 22.0 24.0 25.8

NRV 22 76.2 90.2 127. 5 152. 4 0.07 5. 45 9.15 11.4 6 12.74 13.1 15. 4 21.7 25. 8 NRVH 22 - - 31.4 33. 8

NRV 28 147.9 175.1 247.6 295.9 0.07 10.5 8 17.76 22.25 24 .74 25.4 30.0 42. 2 50.2 NRVH 28 - - 60.9 65.6

NRV 35 260.0 3 07.7 435.1 52 0.1 0.07 18.60 31.22 39.10 43.4 8 44.6 52.7 74.1 88.2 NRVH 35 - - 10 7.1 115.2

R515 B R515 B R515 B R515B

NRV 6 v2 1.2 4.0 9.6 12.5 0. 07 0 .16 0.30 0.40 0.45 0.2 0.6 1.4 1.8 NRVH 6 v2 0 .1 0.3 1.1 1.6

NRV 10 v2 7. 2 15.9 25.7 30.7 0. 07 0.67 1. 25 1.61 1.81 1.0 2.3 3.7 4.4 NRVH 10 v2 0.0 2.3 4.0 5.2

NRV 12 v2 23.4 27. 7 3 9.1 46.8 0.07 1.27 2.25 2.86 3 .21 3.4 4.0 5.6 6.6 NRVH 12 v2 4.5 7.4 8.0 8.6

NRV 16 v2 33.7 44.3 62.6 74. 8 0.07 2.04 3.60 4.58 5.13 4.9 6.4 9.0 10 .6 NRVH 16 v2 1.6 8.4 11 .0 12 .7

NRV 19 v2 60.8 71.9 101.7 121.6 0.07 3. 31 5.84 7.4 4 8.33 8.8 10. 4 14.6 17.3 NRVH 19 v2 12.9 19 .2 20.9 22.5

NRV 22 79.5 94.1 133.0 159.0 0.07 4.33 7.6 4 9.73 10.9 0 11. 5 13 .6 19. 0 22.6 NRVH 22 - - 27. 3 29.4

NRV 28 15 4.3 182. 6 258.2 308.6 0.07 8.40 14. 84 18 .89 21.16 22.3 26.3 36.9 43.8 NRVH 28 - - 53.1 57.0

NRV 35 271.2 320.9 453.8 542.4 0.07 14.77 26.08 33. 21 37.18 39.2 46.3 64.9 77. 1 NRVH 35 - - 93.3 100. 2

R123 3zd( E) R123 3zd( E) R12 33zd(E) R123 3zd( E)

NRV 6 v2 1.5 5.0 11.9 15. 6 0. 07 0.04 0. 11 0.18 0.22 0.1 0.3 0.8 1.1 NRVH 6 v2 0.0 0 .1 0.6 0.8

NRV 10 v2 9. 0 19.8 31.9 38.2 0.07 0.17 0.52 0.79 0.93 0.6 1. 4 2.3 2.6 NRVH 10 v2 0.0 1.3 2.2 2.9

NRV 12 v2 29.1 34.4 48.7 58.2 0. 07 0.42 1.11 1.54 1.77 2.1 2.5 3.4 4.0 NRVH 12 v2 2.7 4.4 4.7 4.9

NRV 16 v2 42.0 55.1 7 7.9 93 .1 0.07 0.67 1.78 2.46 2.83 3.1 4.0 5.5 6.4 NRVH 16 v2 0.8 4.5 5.9 6.8

NRV 19 v2 75.6 89.5 126.6 151.3 0.07 1.10 2.89 3.99 4.60 5.6 6.5 8.9 10.4 NRVH 19 v2 7. 7 11. 4 12.1 12 .8

NRV 22 98.9 117.0 165 .5 197. 8 0. 07 1.43 3.78 5.22 6 .02 7. 3 8.5 11.7 13 .6 NRVH 22 - - 15.9 16.7

NRV 28 192.0 2 27. 2 321.3 384.1 0.07 2.78 7.3 4 10.13 11. 68 14.1 16.5 22.7 26.4 NRVH 28 - - 30.8 32.5

NRV 35 33 7.5 399.3 564.8 675.0 0.07 4.89 12 .90 17.81 20.53 24.8 2 9.1 39.9 4 6.4 NRVH 35 - - 54.2 57.1

R123 4ze(E) R123 4ze(E) R12 34ze (E) R123 4ze (E)

NRV 6 v2 1.3 4 .1 9.8 12.9 0 .07 0.16 0. 31 0.41 0.46 0.2 0.6 1.4 1. 8 NRVH 6 v2 0.1 0.3 1. 2 1.7

NRV 10 v2 7. 4 16.3 26.4 31. 5 0. 07 0.69 1.28 1.64 1.85 1.1 2.3 3.8 4.5 NRVH 10 v2 0.0 2.3 4.1 5.3

NRV 12 v2 24 .0 28.4 40.2 48.0 0.07 1.31 2.30 2.93 3.27 3.5 4 .1 5.7 6.8 NRVH 12 v2 4.6 7.6 8.2 8.8

NRV 16 v2 34.6 45.4 64.3 76.8 0.07 2.09 3.68 4.68 5.24 5.0 6.5 9.2 10.9 NRVH 16 v2 1.6 8.6 11. 3 13 .0

NRV 19 v2 62.4 73.9 10 4.4 124.8 0.07 3.40 5.98 7. 61 8. 51 9.0 10.6 14.9 17. 7 NRVH 19 v2 13. 2 19.6 21.4 23.0

NRV 22 81.6 96.6 136.6 163.2 0.07 4.45 7. 82 9.95 11. 13 11 .7 13.9 19. 5 23.1 NRVH 22 - - 28.0 30.0

NRV 28 15 8.4 187. 5 265 .1 316 .9 0.07 8.64 15.19 19. 31 21.60 22.8 26.9 37.8 44.8 NRVH 28 - - 54.3 58.3

NRV 35 278.5 329. 5 466.0 557. 0 0.07 15 .18 26.69 33.94 37.97 40.1 47. 3 66.4 78.8 NRVH 35 - - 95.4 102 .5

across valve ∆p

[bar]

NRV NRV NRVH

0.05 0.07 0.14 0.2 -30 -10 0 5 0.05 0.07 0.14 0.2 0.2 0.25 0. 3 0.35

Pressure

across

valve ∆p

Correction factors for liquid temperature t

t

[°C]

l

R452A

R513A

R515B

R1233zd(E)

R1234ze(E)

-10 0 10 15 20 25 30 35 40 45 50

0.67 0.74 0.83 0.88 0.93 1.00 1.08 1.17 1.28 1.41 1.59

0.71 0.77 0.85 0.89 0.94 1.00 1.06 1.14 1.22 1.32 1.44

0.72 0.78 0.86 0.90 0.95 1.00 1.06 1.13 1.20 1.29 1.40

0.77 0.82 0.89 0.92 0.96 1.00 1.04 1.09 1.14 1.20 1.26

0.72 0.78 0.86 0.90 0.95 1.00 1.06 1.12 1.20 1.29 1.39

Suction vapour capacity 1)

drop

[bar]

l

at evaporating

temperature te

[°C]

Hot gas capacity 1)

at pressure drop

across valve ∆p

[bar]

Typ e

Hot gas capacity 1)

at pressure drop across valve

Δp

[bar]

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 8

Page 9

Data sheet | Check valve, types NRV and NRVH

Capacity SI units

Liquid capacity (kW) Suction vapour capacity in [kW] Hot gas capacity in [kW] Hot gas capacity in [kW]

Liquid capacity 1)

at pressure drop

Typ e

R290 R290 R290 R290

NRV 6 v2 1.7 5.5 13. 2 17. 3 0.07 0.42 0.66 0.81 0.89 0.3 1. 0 2.5 3.3 NRVH 6 v2 0.2 0.5 2.1 3.1

NRV 10 v2 10 .0 22.0 35.5 42.4 0.07 1. 71 2.67 3.25 3.57 1.9 4.2 6.8 8.0 NRVH 10 v2 0.0 4.3 7. 4 9.7

NRV 12 v2 32.3 38.2 54.1 64.6 0.07 3.06 4.72 5.72 6.26 6.2 7. 3 10. 3 12.3 NRVH 12 v2 8.3 13.7 14 .9 16 .1

NRV 16 v2 46.6 61. 2 86.5 103.4 0.07 4.89 7.5 4 9.14 10. 02 8.9 11. 7 16.5 19.6 NRVH 16 v2 2.9 15.7 20.7 23.8

NRV 19 v2 84.0 99.4 14 0.6 168.1 0.07 7.94 12. 26 14.8 6 16. 28 16.1 19. 0 26. 8 31.9 NRV H 19 v2 23.9 35.6 38.8 41. 8

NRV 22 110. 5 130.8 184.9 221.1 0.07 10. 41 16.07 19 .49 21.3 6 21.2 25.0 35.2 42. 0 NRVH 22 - - 51.1 55.0

NRV 28 214 .6 253.9 359.0 429 .1 0.07 20.20 31.20 3 7.83 41.4 6 41.1 48.6 68.4 81.5 NRVH 28 - - 99.2 106. 8

NRV 35 37 7.1 446.2 631. 0 754.2 0.07 35.50 54.84 66.50 72.86 72.2 85.4 120 .2 143. 2 NRVH 35 - - 174 .4 187. 8

R32 R32 R 32 R32

NRV 6 v2 2.1 6.9 16.6 21.8 0.07 0.58 0.87 1.05 1.14 0.4 1.4 3.4 4.4 NRVH 6 v2 0.2 0.7 2.9 4.2

NRV 10 v2 12.6 2 7.6 44.7 53.4 0.07 2.33 3.50 4.18 4.55 2.5 5.6 9.0 10 .8 NRVH 10 v2 0.0 5.8 10.0 13 .0

NRV 12 v2 40.7 4 8.1 68 .1 81.4 0.07 4 .12 6.14 7. 32 7. 96 8.2 9.7 13 .8 16 .4 NRVH 12 v2 11 .1 18. 3 20.0 21. 6

NRV 16 v2 58.7 7 7.0 108 .9 130 .2 0. 07 6.59 9.83 11.7 2 12. 73 11.9 15. 6 22.0 26.3 NRVH 16 v2 3.9 21.2 28.0 32.2

NRV 19 v2 105. 8 125.1 17 7.0 211.5 0.07 10.72 15.9 7 19. 04 20.69 21.4 25.3 35.8 42.7 NRVH 19 v2 32.0 47.6 52.1 56.2

NRV 22 138 .3 163.7 231.4 276.6 0.07 14. 01 20.89 24.90 27. 06 28.0 3 3.1 46.8 55. 8 NRVH 22 - - 68.1 73.5

NRV 28 268.5 317.7 4 49.3 5 37.0 0.07 27.2 0 40.54 48.34 52.52 54.4 64.3 90.8 108.3 NRVH 28 - - 132 .2 142. 6

NRV 35 471.9 558. 3 789.6 943.8 0.07 47.8 1 71.26 84.95 92. 31 95.6 113 .0 159.5 19 0.3 N RVH 35 - - 232.4 250.7

R452B R452B R452B R452B

NRV 6 v2 1.7 5.6 13. 4 17. 5 0.07 0.47 0.72 0.87 0.96 0.4 1. 2 2.8 3.7 NRVH 6 v2 0.2 0.6 2.5 3.5

NRV 10 v2 10.1 22.2 35. 8 42.8 0.07 1.9 0 2.90 3.50 3.82 2.2 4.7 7.6 9.1 NRVH 10 v2 0.0 4.9 8.4 11. 0

NRV 12 v2 32.6 38.6 54.6 65.3 0.07 3.37 5.10 6.13 6.68 7.0 8.2 11 .6 13.9 NRVH 12 v2 9.4 15 .5 16.9 18 .3

NRV 16 v2 47. 1 61.8 8 7.4 104.4 0.07 5.39 8.16 9.80 10 .69 10 .1 13 .2 18.6 22.2 NRVH 16 v2 3.3 17. 9 23.6 2 7.2

NRV 19 v2 84.9 10 0.4 142.0 169.7 0.07 8.75 13. 26 15.93 17. 38 18.1 21.4 30.2 36 .1 NRVH 19 v2 27.1 40.3 44.0 4 7.5

NRV 22 111. 0 131. 3 185.7 222.0 0.07 11 .45 17. 34 20.83 22.72 23.7 28.0 39.5 4 7.2 NRVH 22 - - 5 7.6 6 2.1

NRV 28 16.5 215.4 254.9 360.5 0.07 22.22 33.66 40.44 4 4.11 46.0 54.4 76 .8 91.6 NRVH 28 - - 111.8 120 .5

NRV 35 29.0 378 .6 448.0 633.6 0.07 39.05 59.16 71.07 7 7.5 2 80.9 95.6 134 .9 161. 0 NRVH 35 - - 196.5 211 .9

R455A R455A R455A R 455A

NRV 6 v2 1.2 4.0 9.7 12 .7 0. 07 0.28 0.47 0.58 0.64 0.3 0.9 2.2 2.9 NRVH 6 v2 0.2 0.4 1.9 2.7

NRV 10 v2 7. 3 16.0 25.9 31.0 0.07 1.15 1.88 2.34 2.58 1.7 3.7 5.9 7.1 NRVH 10 v2 0.0 3.8 6.6 8.5

NRV 12 v2 23.6 27. 9 39.5 47. 2 0.07 2.06 3. 32 4 .10 4.54 5.4 6.4 9.0 10. 8 NRVH 12 v2 7. 3 12. 0 13 .2 14.2

NRV 16 v2 3 4.1 44.7 63.2 75.6 0.07 3.29 5.32 6.57 7. 26 7. 8 10.3 14. 5 17. 3 NRVH 16 v2 2.6 13.9 18 .3 21.1

NRV 19 v2 61.4 72.7 102. 8 122.8 0.07 5.35 8.64 10. 67 11.79 14.1 16.7 23.5 28.0 NRVH 19 v2 21.0 31. 3 34.2 36.9

NRV 22 80.3 95.0 134.4 160 .6 0.07 7. 00 11.3 0 13.96 15.42 18.4 21. 8 30.8 36.7 NRVH 22 - - 44.7 48.2

NRV 28 15 5.9 184.4 260.8 3 11. 8 0. 07 13.59 21. 94 27.0 9 29.93 35.8 42.3 59.7 71.2 NRVH 28 - - 86.8 93. 6

NRV 35 274. 0 324. 2 458.4 548.0 0.07 23.88 38.57 47. 62 52. 61 62.9 74.4 10 4.9 125 .1 N RVH 35 - - 152 .6 16 4.5

1) Rated capacities are based on:

-Evaporating temperature, te = -10 °C.

-Condensing temperature, tc = 30 °C.

-Subcooling t

-Delta superheat tsh = 0 K.

-Discharge temperature, td = 80 °C ahead of

the valve.

The table values refer to the evaporator

capacity.

across valve ∆p

[bar]

NRV NRV NRVH

0.05 0.07 0.14 0.2 -30 -10 0 5 0.05 0.07 0.14 0.2 0.2 0.25 0. 3 0.35

= 5 K.

sub

Pressure

across

valve ∆p

Suction vapour capacity 1)

drop

[bar]

at evaporating

temperature te

[°C]

Correction factors

When selecting the evaporator capacity is to be multiplied by a correction factor depending on the liquid temperature tl ahead of the valve/the evaporator. The corrected

capacity can then be found from the table.

System capacity.Correction factor=Table capacity

Correction factors for liquid temperature t

t

[°C]

l

R290

R32

R452B

R455A

-10 0 10 15 20 25 30 35 40 45 50

0.73 0.79 0.86 0.90 0.95 1.00 1.06 1.12 1.19 1.28 1.38

0.76 0.82 0.88 0.92 0.96 1.00 1.05 1.11 1.17 1.24 1.33

0.74 0.80 0.86 0.91 0.95 1.00 1.06 1.12 1.20 1.28 1.39

0.70 0.77 0.84 0.89 0.94 1.00 1.07 1.14 1.23 1.34 1.47

l

Hot gas capacity 1)

at pressure drop

across valve ∆p

[bar]

Typ e

Hot gas capacity 1)

at pressure drop across valve

Δp

[bar]

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 9

Page 10

Data sheet | Check valve, types NRV and NRVH

Capacity SI units

Liquid capacity (kW) Suction vapour capacity in [kW] Hot gas capacity in [kW] Hot gas capacity in [kW]

Liquid capacity 1)

at pressure drop

Typ e

R454A R454A R454A R454A

NRV 6 v2 1.4 4.4 10.5 13 .8 0.07 0.33 0.53 0.65 0.72 0.3 1.0 2.3 3.0 NRVH 6 v2 0.2 0.5 2.0 2.8

NRV 10 v2 8.0 17. 5 28.3 33.8 0.07 1.33 2.13 2.62 2.89 1.7 3.8 6.1 7. 3 NRVH 10 v2 0.0 3.9 6.8 8.8

NRV 12 v2 25.8 30.5 43.1 51. 5 0.07 2. 37 3.76 4.60 5.07 5.6 6.6 9.4 11. 2 NRVH 12 v2 7. 6 12. 5 13 .6 14.7

NRV 16 v2 37. 2 48.8 69.0 82.5 0.07 3.80 6.02 7. 37 8 .11 8 .1 10 .6 15. 0 17. 9 NRVH 16 v2 2.7 14.4 19. 0 21.8

NRV 19 v2 67. 0 79.3 112 .1 13 4.0 0.07 6.17 9.77 11 .97 13 .18 14 .6 17. 3 24.4 29.1 NRVH 19 v2 21.8 32.4 35.4 38.2

NRV 22 87. 6 103.7 146.6 175.2 0.07 8.07 12. 78 15.65 17. 23 19.1 22.6 31.9 38.0 NRVH 22 - - 46.3 49.9

NRV 28 170.1 201.2 284.6 340.1 0.07 15. 66 24.81 30.39 33.45 37.1 43.9 61.9 73.7 NRVH 28 - - 89.9 97.0

NRV 35 298 .9 353.7 500.1 5 97. 8 0.07 27.5 3 43. 61 53.41 58.78 65.2 77. 1 10 8.7 129.6 NRVH 35 - - 158 .1 170.4

R454B R454B R454B R454B

NRV 6 v2 1.7 5.6 13. 5 17. 7 0.07 0.47 0.73 0.88 0.96 0.4 1.2 2.9 3.7 NRVH 6 v2 0.2 0.6 2.5 3.5

NRV 10 v2 10 .2 22.5 36.3 43.4 0.07 1.91 2.91 3 .51 3.83 2.2 4.8 7.7 9.2 NRVH 10 v2 0.0 4.9 8.5 11.1

NRV 12 v2 33.1 39.2 55.4 66.2 0.07 3.38 5.12 6 .15 6.70 7. 0 8.3 11 .7 14. 0 NRVH 12 v2 9.5 15. 6 17. 0 18 .4

NRV 16 v2 47. 8 62.7 88.6 105.9 0.07 5.40 8.18 9.83 10.72 10.1 13 .3 18.7 22.3 NRVH 16 v2 3.4 18 .1 23.8 27.3

NRV 19 v2 8 6.1 101. 8 144.0 172 .2 0.07 8.78 13. 30 15.9 8 17.43 18.2 21.6 30.4 36.3 NRVH 19 v2 27. 2 40.5 44.3 4 7.8

NRV 22 112. 6 133. 2 18 8.3 225.1 0.07 11. 48 17. 39 20.89 22.79 23.9 28.2 39.8 47. 5 NRVH 22 - - 58.0 62.5

NRV 28 218 .5 258.5 365.6 4 37. 0 0.07 22.29 33 .76 40.56 44.23 46.3 54.8 7 7.3 92.2 NRVH 28 - - 112 .5 121. 3

NRV 35 384.0 454.4 642.6 76 8.1 0.07 39.18 59.34 71.28 77. 75 81.4 96.2 135 .8 162. 0 NRVH 35 - - 197. 7 213 .2

R454C R454C R454C R454C

NRV 6 v2 1.2 4.0 9.5 12.5 0. 07 0.27 0.45 0.56 0. 62 0.3 0.8 2.0 2.7 NRVH 6 v2 0.1 0.4 1.7 2.5

NRV 10 v2 7. 2 15. 8 25.5 30.5 0.07 1.10 1.82 2.26 2.50 1.5 3.4 5.5 6.5 NRVH 10 v2 0.0 3.5 6.0 7. 8

NRV 12 v2 23.2 2 7.5 38.9 46.5 0.07 1.9 8 3. 21 3.97 4.39 5.0 5.9 8.3 9.9 NRVH 12 v2 6.7 11 .1 12.1 13. 0

NRV 16 v2 33.5 44.0 62.2 74 .4 0 .07 3.17 5.14 6.35 7.0 3 7.2 9.5 13. 3 15.9 NRVH 16 v2 2.4 12 .8 16.9 19 .4

NRV 19 v2 60.4 71. 5 101.1 12 0.9 0.07 5.15 8.35 10.33 11. 42 13.0 15.4 21.7 25.8 NRVH 19 v2 19. 4 28.8 31.5 33.9

NRV 22 79.0 93.5 132. 2 158.1 0.07 6.73 10 .92 13. 50 14.93 17. 0 20 .1 28.3 33.8 NRVH 22 - - 41.2 44.4

NRV 28 15 3.4 181.5 256.7 306.8 0. 07 13.07 21.19 2 6.21 28 .99 33.0 39.0 55.0 65.6 NRVH 28 - - 79.9 8 6.1

NRV 35 269.6 319.0 451.2 539.3 0.07 22.96 37. 25 46 .07 50.94 58.0 68.6 96.7 115 .2 NRVH 35 - - 14 0.5 151. 4

R516A R 516A R516A R516A

NRV 6 v2 1.2 3.9 9.3 12.2 0.07 0. 21 0.38 0.48 0.53 0.2 0.7 1.6 2.0 NRVH 6 v2 0 .1 0.3 1. 3 1.9

NRV 10 v2 7.1 15 .5 25.0 29.9 0.07 0.89 1. 53 1.93 2.14 1.2 2.6 4.2 5.0 NRVH 10 v2 0.0 2.7 4.6 6.0

NRV 12 v2 22.8 2 7.0 38.2 45.6 0.07 1.6 3 2.72 3.4 0 3.78 3.9 4.6 6.4 7. 6 NRVH 12 v2 5.2 8.5 9.3 10.0

NRV 16 v2 32 .9 43.2 61.0 73.0 0.07 2. 61 4.36 5.45 6.05 5.6 7.3 10. 3 12. 2 NRVH 16 v2 1.8 9.7 12 .8 14. 7

NRV 19 v2 59.3 70 .1 99. 2 11 8. 6 0.07 4.25 7.0 8 8.85 9. 83 10.1 11 .9 16. 7 19.9 NRVH 19 v2 14.9 22 .1 24.1 26.0

NRV 22 77. 5 91.7 129.7 155.0 0.07 5.56 9.26 11 .57 12. 86 13.1 15 .5 21. 8 26.0 NRVH 22 - - 31. 5 33.9

NRV 28 15 0.5 17 8.0 2 51.8 301.0 0.07 10.79 17. 98 22.47 24.96 25.5 30 .1 42.4 50.4 NRVH 28 - - 61. 2 65.9

NRV 35 264.5 312 .9 4 42.6 529.0 0.07 18.96 31. 61 39.49 43.8 6 4 4.9 53.0 74. 5 88.6 N RVH 35 - - 1 07.6 115 .8

1) Rated capacities are based on:

-Evaporating temperature, te = -10 °C.

-Condensing temperature, tc = 30 °C.

-Subcooling t

-Delta superheat tsh = 0 K.

-Discharge temperature, td = 80 °C ahead of

the valve.

The table values refer to the evaporator

capacity.

across valve ∆p

[bar]

NRV NRV NRVH

0.05 0.07 0.14 0.2 -30 -10 0 5 0.05 0.07 0.14 0.2 0.2 0.25 0. 3 0.35

= 5 K.

sub

Pressure

across

valve ∆p

Suction vapour capacity 1)

drop

[bar]

at evaporating

temperature te

[°C]

Correction factors

When selecting the evaporator capacity is to be multiplied by a correction factor depending on the liquid temperature tl ahead of the valve/the evaporator. The corrected

capacity can then be found from the table.

System capacity.Correction factor=Table capacity

Correction factors for liquid temperature t

t

[°C]

l

R454A

R454B

R454C

R516A

-10 0 10 15 20 25 30 35 40 45 50

0.71 0.77 0.85 0.89 0.94 1.00 1.06 1.14 1.22 1.32 1.44

0.74 0.80 0.87 0.91 0.95 1.00 1.06 1.12 1.19 1.28 1.38

0.70 0.77 0.84 0.89 0.94 1.00 1.07 1.14 1.23 1.34 1.47

0.71 0.77 0.85 0.89 0.94 1.00 1.06 1.14 1.22 1.32 1.43

l

Hot gas capacity 1)

at pressure drop

across valve ∆p

[bar]

Typ e

Hot gas capacity 1)

at pressure drop across valve

Δp

[bar]

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 10

Page 11

Data sheet | Check valve, types NRV and NRVH

Capacity SI units

Liquid capacity (kW) Suction vapour capacity in [kW] Hot gas capacity in [kW] Hot gas capacity in [kW]

Liquid capacity 1)

at pressure drop

Typ e

R600 R600 R600 R600

NRV 6 v2 1.9 6.2 15.0 19. 6 0.07 0.12 0.29 0.40 0.45 0.2 0.6 1.4 1.9 NRVH 6 v2 0.1 0.3 1.1 1.6

NRV 10 v2 11. 3 24.9 40.2 48.0 0.07 0.58 1. 25 1.64 1.86 1.1 2.4 3.9 4.6 NRVH 10 v2 0.0 2.4 4.1 5.4

NRV 12 v2 36.6 43 .3 61. 2 73.2 0.07 1.25 2.34 3.00 3.37 3.7 4.3 6.0 7.1 NRVH 12 v2 4.8 7. 8 8.5 9.0

NRV 16 v2 52. 8 69.3 98.0 117.1 0.07 2 .01 3.74 4.80 5.40 5.3 6.9 9.6 11. 3 NRVH 16 v2 1.6 8.6 11.3 13. 0

NRV 19 v2 95.2 112.6 159. 2 19 0.3 0.07 3.26 6 .07 7.81 8.77 9.5 11. 2 15. 6 18 .4 N RVH 19 v2 13 .7 20.4 22.0 23.5

NRV 22 124 .4 147.2 208.2 248.9 0. 07 4. 27 7.9 4 10. 21 11. 47 12.5 14.7 20.4 24 .1 NRVH 22 - - 28.8 30.7

NRV 28 241.6 285.8 40 4.2 483.1 0.07 8.28 15 .42 19. 82 22.26 24.2 28.5 39.7 46.8 NRVH 28 - - 55.9 59.7

NRV 35 424.5 502.3 710.4 849.1 0.07 14. 55 27.10 34.83 39 .12 42.6 50.2 69.8 82.2 NRVH 35 - - 98.3 104. 8

R600a R600a R600a R600a

NRV 6 v2 1.7 5.5 13. 3 17. 4 0.07 0 .18 0.36 0 .47 0.53 0.2 0.7 1.6 2.1 NRVH 6 v2 0.1 0.3 1.3 1.9

NRV 10 v2 10 .0 22 .1 35.6 42. 6 0.07 0.80 1.49 1.91 2.14 1.2 2.7 4.3 5.1 NRVH 10 v2 0.0 2.7 4.6 6.0

NRV 12 v2 32.5 38.4 54.3 6 4.9 0.07 1.57 2.72 3.44 3.83 4.0 4.7 6.6 7. 8 NRVH 12 v2 5.3 8.7 9.4 10.1

NRV 16 v2 46.9 61.5 8 6.9 103.9 0.07 2.51 4.36 5.50 6.13 5.8 7.6 10. 6 12. 5 NRV H 16 v2 1.8 9.7 12 .8 14.7

NRV 19 v2 84.4 99.9 141.3 16 8.8 0. 07 4.08 7. 08 8.93 9.96 10.4 12. 3 17. 2 20.4 NRVH 19 v2 15.2 22.6 24.5 26.3

NRV 22 11 0. 4 130.6 184.7 220.8 0.07 5.33 9.26 11 .6 8 13. 03 13 .6 16 .1 22.5 26.6 NRVH 22 - - 32.1 34.4

NRV 28 214 .3 253.5 358.6 428.6 0.07 10. 35 17.9 7 22.68 25.29 26.5 31.2 43.7 51.7 NRVH 28 - - 62.3 66.7

NRV 35 376.6 445.6 630.2 753. 2 0.07 18 .19 31.58 39.86 44.44 46.6 54.9 76. 8 90.9 NRVH 35 - - 109.5 117.2

R123 4yf R123 4yf R1234y f R123 4yf

NRV 6 v2 1.1 3.4 8.1 10.7 0. 07 0.19 0.34 0.44 0.49 0.2 0.6 1. 4 1.9 NRVH 6 v2 0.1 0.3 1. 2 1.7

NRV 10 v2 6.2 13. 5 21.8 26 .1 0.07 0.80 1.39 1.76 1.97 1.1 2.4 3.8 4.5 NRVH 10 v2 0.0 2.4 4.2 5.4

NRV 12 v2 19.9 23.5 33.3 39.8 0.07 1.47 2.48 3 .11 3.47 3.5 4.1 5.8 6.9 NRVH 12 v2 4.7 7. 7 8.4 9. 0

NRV 16 v2 28.7 3 7.7 53.3 63.7 0.07 2.34 3.96 4.98 5.55 5.0 6.6 9.3 11. 1 NRVH 16 v2 1. 6 8.8 11 .6 13 .3

NRV 19 v2 51.7 61. 2 86.6 103. 5 0.07 3.81 6.44 8.09 9.01 9.1 10. 8 15 .1 18. 0 N RVH 19 v2 13 .5 20.0 21.8 23.5

NRV 22 67.9 80.4 113. 7 135.9 0.07 5.00 8.44 10. 61 11. 81 11. 9 14 .1 19.8 23.5 NRVH 22 - - 28.6 30.7

NRV 28 131.9 156. 0 220.7 263.8 0.07 9.71 16. 39 20.59 22.93 23.1 2 7.3 38.4 45.7 NRVH 28 - - 55.4 59.6

NRV 35 231.8 2 74.2 387. 8 463.6 0.07 17.07 28.81 36 .19 4 0.31 40.6 48.0 67.5 80.3 N RVH 35 - - 97. 5 104 .8

R1270 R 1270 R12 70 R1270

NRV 6 v2 1.8 5.7 13 .7 18. 0 0. 07 0.48 0.75 0.90 0.99 0.4 1.2 2.8 3.7 NRVH 6 v2 0.2 0.6 2.4 3.4

NRV 10 v2 10 .4 22.8 36.9 44.1 0.07 1.97 3.00 3.62 3.95 2 .1 4.6 7.5 8.9 NRVH 10 v2 0.0 4.8 8.3 10. 8

NRV 12 v2 33.6 39. 8 56.2 67. 2 0.07 3.50 5.29 6.35 6.93 6.9 8 .1 11. 4 13. 6 NRVH 12 v2 9.2 15. 2 16.6 17.9

NRV 16 v2 48.5 63. 6 90.0 107. 5 0.07 5.60 8.46 10.16 11. 09 9.9 13. 0 18 .3 21.8 NRVH 16 v2 3.3 17. 5 23.1 26.6

NRV 19 v2 87. 4 103 .4 146.2 174 .7 0.07 9. 09 13 .74 16.51 18 .01 17.8 21.1 29.7 35.4 NRVH 19 v2 26.6 39.5 43.2 46.5

NRV 22 114. 2 135. 2 191.2 228.5 0.07 11.8 9 17. 97 21.59 23.56 23.3 27. 6 38.9 46.3 NRVH 22 - - 56.5 60.8

NRV 28 221.8 262.4 371.1 443.5 0. 07 23.08 34.89 41.91 45.73 45.3 53.5 75.4 89.9 NRVH 28 - - 109.6 118.1

NRV 35 389.8 4 61.2 652.2 779. 5 0.07 4 0.57 61.32 73.67 80.37 79.6 94.1 132 .6 158 .0 NRVH 35 - - 19 2.6 2 07.5

1) Rated capacities are based on:

-Evaporating temperature, te = -10 °C.

-Condensing temperature, tc = 30 °C.

-Subcooling t

-Delta superheat tsh = 0 K.

-Discharge temperature, td = 80 °C ahead of

the valve.

The table values refer to the evaporator

capacity.

across valve ∆p

[bar]

NRV NRV NRVH

0.05 0.07 0.14 0.2 -30 -10 0 5 0.05 0.07 0.14 0.2 0.2 0.25 0. 3 0.35

= 5 K.

sub

Pressure

across

valve ∆p

Suction vapour capacity 1)

drop

[bar]

at evaporating

temperature te

[°C]

Hot gas capacity 1)

at pressure drop

across valve ∆p

[bar]

Correction factors

When selecting the evaporator capacity is to be multiplied by a

correction factor depending on the liquid temperature tl ahead of

the valve/the evaporator. The corrected capacity can then be found

from the table.

System capacity.Correction factor=Table capacity

Typ e

Hot gas capacity 1)

at pressure drop across valve

Δp

[bar]

Correction factors for liquid temperature t

t

[°C]

l

R600

R600a

R1234yf

R1270

-10 0 10 15 20 25 30 35 40 45 50

0.77 0.82 0.88 0.92 0.96 1.00 1.05 1.10 1.15 1.22 1.29

0.75 0.81 0.87 0.91 0.95 1.00 1.05 1.11 1.17 1.25 1.33

0.69 0.76 0.84 0.89 0.94 1.00 1.07 1.15 1.24 1.36 1.49

0.74 0.80 0.87 0.91 0.95 1.00 1.06 1.12 1.19 1.27 1.37

Note:

- For capacity calculation of other refrigerants, please contact Danfoss.

© Danfoss | DCS (nb) |2019.06

l

AI150286435592en-000702 | 11

Page 12

Data sheet | Check valve, types NRV and NRVH

Capacity US units

Liquid capacity [TR] Suction vapour capacity [TR] Hot gas capacity [TR] Hot gas capacity [TR]

Liquid capacity 1)

at pressure drop

Typ e

R134 a R134 a R134 a R134 a

NRV 6 v2 0.3 1. 3 3 .1 4.2 1 0.06 0 .11 0.14 0.15 0.0 0.2 0.4 0.6 NRVH 6 v2 0.0 0.1 0.5 0.6

NRV 10 v2 2.1 5.1 8.3 10 .2 1 0.26 0.45 0.56 0.62 0.3 0.7 1.1 1.6 NRVH 10 v2 0.1 1.0 1.6 1.9

NRV 12 v2 7. 5 9.0 12. 7 15. 6 1 0.49 0. 81 1.01 1.11 1.0 1. 2 1.7 2.4 NRVH 12 v2 1.6 2.4 2.6 2.9

NRV 16 v2 10.7 14 .3 20.4 24.9 1 0.78 1.29 1.60 1. 76 1.4 1.9 2.7 3.8 NRVH 16 v2 0.7 3.1 3.9 4.4

NRV 19 v2 19.6 23.4 33 .1 40.5 1 1.28 2 .11 2.61 2.87 2.6 3.1 4.4 6.1 NRVH 19 v2 4.3 6 .1 6.8 7.4

NRV 22 25.6 30.6 43.3 53. 0 1 1.67 2.77 3.42 3.76 3.4 4.1 5.7 8.0 NRVH 22 7.0 8.0 8.9 9.7

NRV 28 49.7 59.4 84.0 102 .9 1 3.25 5.37 6.64 7. 29 6.7 7.9 11 .2 15.6 NRVH 28 13. 6 15 .6 17. 3 18 .9

NRV 35 8 7.3 104.4 147. 6 180. 8 1 5.71 9.4 4 11.6 7 12. 82 11 .7 14. 0 19.6 27. 4 NRVH 35 23.9 27.4 30.5 33.2

R22 R22 R22 R22

NRV 6 v2 0.4 1.4 3.3 4.5 1 0.10 0.15 0.18 0.20 0.1 0.2 0.5 0.8 NRVH 6 v2 0.0 0.2 0.6 0.8

NRV 10 v2 2.2 5.5 8.9 11 .0 1 0.40 0. 62 0.74 0.80 0.3 0.8 1.4 1.9 NRVH 10 v2 0.1 1.2 2.0 2.4

NRV 12 v2 8.1 9.7 13. 7 16.7 1 0.72 1.10 1. 31 1. 42 1.3 1.5 2.1 3.0 NRVH 12 v2 2.1 3.0 3.3 3.6

NRV 16 v2 11. 5 15. 4 21.9 26.8 1 1.15 1. 74 2.08 2.25 1. 8 2.4 3.4 4.7 NRVH 16 v2 0.8 3.9 4.9 5.6

NRV 19 v2 21.0 25.1 35.5 43.5 1 1. 88 2.85 3.40 3.68 3.3 3.9 5.5 7.7 NRVH 19 v2 5.4 7. 7 8.6 9.4

NRV 22 27. 5 32.9 46.5 56.9 1 2.46 3.72 4.45 4.82 4.3 5.1 7.2 10.1 NRVH 22 8.8 10 .1 11. 2 12. 3

NRV 28 53.4 63.8 90.2 110 .5 1 4.77 7.2 3 8.63 9.35 8.3 9.9 13.9 19. 6 NRVH 28 17. 0 19. 6 21.8 23.8

NRV 35 93.8 112 .1 158. 5 194.1 1 8.39 12. 70 15.18 16. 43 14. 6 17. 4 24.5 34.4 NRVH 35 29.9 34.4 38.3 41.8

R404A R404A R404A R404A

NRV 6 v2 0.2 0.9 2.3 3.1 1 0.08 0.13 0.16 0.18 0.0 0.2 0.4 0.7 NRVH 6 v2 0.0 0.1 0.5 0.7

NRV 10 v2 1.5 3.7 6 .1 7. 5 1 0.34 0.54 0.66 0.72 0.3 0.7 1.2 1.7 NRVH 10 v2 0.1 1.1 1.7 2.0

NRV 12 v2 5.5 6.6 9.3 11. 4 1 0. 61 0.96 1.16 1.27 1.1 1. 3 1.8 2.5 NRVH 12 v2 1. 8 2.5 2.8 3.1

NRV 16 v2 7.9 10.5 14.9 18. 2 1 0.96 1.52 1. 85 2.02 1.5 2.0 2.9 4.0 NRVH 16 v2 0.7 3.3 4.2 4.8

NRV 19 v2 14 .3 17.1 24.2 29.6 1 1. 58 2.48 3.02 3.30 2.8 3.3 4.7 6.6 NRVH 19 v2 4.6 6.6 7. 3 8.0

NRV 22 18.7 22.4 31.7 38.8 1 2.06 3.25 3.95 4.32 3.6 4.3 6.1 8.6 NRVH 22 7. 5 8.6 9.6 10.5

NRV 28 36.4 43.5 61. 5 75.3 1 4.00 6.30 7. 67 8.38 7. 1 8.4 11.9 16 .7 NRVH 28 14.5 16.7 18. 6 20.3

NRV 35 63.9 76.4 108.0 132. 3 1 7. 03 11. 08 13. 49 14.73 12. 4 14 .8 20.9 29.3 NRVH 35 25.5 29.3 32.7 35.7

R410A R410A R410A R410A

NRV 6 v2 0.3 1. 3 3.3 4.4 1 0.12 0 .19 0.23 0.25 0 .1 0.3 0.6 1.0 NRVH 6 v2 0.1 0.2 0.8 0.9

NRV 10 v2 2.2 5.4 8.8 10.8 1 0. 51 0.77 0.93 1.00 0.4 1. 0 1.7 2.4 NRVH 10 v2 0.2 1. 5 2.4 2.9

NRV 12 v2 7.9 9.5 13.4 16.4 1 0.91 1.37 1.6 4 1.77 1.5 1.8 2.6 3.6 NRVH 12 v2 2.5 3.6 4.0 4.4

NRV 16 v2 11. 3 15.1 21. 5 26.3 1 1.45 2.18 2.60 2.81 2.2 2.9 4.1 5.8 NRVH 16 v2 1.0 4.7 6.0 6.8

NRV 19 v2 20.7 24.7 34.9 42.8 1 2.37 3.57 4.25 4.60 3.9 4.7 6.7 9.4 NRVH 19 v2 6.6 9.4 10 .5 11 .4

NRV 22 27. 0 32.3 45.7 55.9 1 3.10 4.66 5.56 6 .01 5.2 6.2 8.7 12 .3 NRVH 22 10.6 12 .3 13 .7 14.9

NRV 28 52.4 62.7 88.6 108. 5 1 6.03 9.05 10.79 11. 68 10.0 12 .0 16 .9 23.8 NRVH 28 20.6 23.8 26.5 29.0

NRV 35 92.2 110 .1 155.8 19 0.8 1 10.59 15.91 18.97 20.52 17. 6 21.0 29.7 41. 8 NRVH 35 36.3 41.8 46.6 51.0

1) Rated capacities are based on:

-Evaporating temperature, te = 14 °F

-Condensing temperature, tc = 86 °F

-Subcooling t

-Superheat tsh = 0 °F

-Discharge temperature, t

the valve.

The table values refer to the evaporator

capacity.

across valve ∆p

[psi]

NRV NRV NRVH

0.7 1 2 3 -20 15 32 40 0.7 1 2 4 3 4 5 6

= 9 °F

sub

=176 °F ahead of

d

Pressure

across

valve ∆p

Suction vapour capacity 1)

drop

[psi]

at evaporating

temperature te

[°F]

Correction factors

When selecting the evaporator capacity is to be multiplied by a correction factor depending on the liquid temperature tl ahead of the valve/the evaporator. The corrected

capacity can then be found from the table.

System capacity.Correction factor=Table capacity

Correction factors for liquid temperature t

t

[°F]

l

R134a

R22

R404A

R410A

15 32 50 60 70 80 86 95 105 115 125

0.74 0.79 0.86 0.91 0.96 1.02 1.08 1.16 1.24 1.34 1.46

0.77 0.82 0.88 0.92 0.97 1.02 1.07 1.13 1.20 1.28 1.38

0.67 0.74 0.82 0.88 0.95 1.02 1.12 1.23 1.38 1.57 1.83

0.72 0.78 0.85 0.90 0.96 1.02 1.09 1.18 1.29 1.43 1.60

l

Hot gas capacity 1)

at pressure drop

across valve ∆p

[psi]

Typ e

Hot gas capacity 1)

at pressure drop across valve

Δp

[psi]

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 12

Page 13

Data sheet | Check valve, types NRV and NRVH

Capacity US units

Liquid capacity [TR] Suction vapour capacity [TR] Hot gas capacity [TR] Hot gas capacity [TR]

Liquid capacity 1)

at pressure drop

Typ e

R4 07A R 407A R407A R407A

NRV 6 v2 0.3 1. 2 3.0 4.0 1 0.08 0.14 0.17 0.19 0.1 0.2 0.5 0.8 NRVH 6 v2 0.0 0.2 0.6 0.8

NRV 10 v2 2.0 4.9 8.0 9. 8 1 0.35 0.57 0.69 0.76 0.3 0.9 1.4 2.0 NRVH 10 v2 0.1 1.3 2.0 2.4

NRV 12 v2 7. 2 8.6 12. 2 14.9 1 0.63 1.01 1. 23 1. 34 1. 3 1.5 2 .1 3.0 NRVH 12 v2 2 .1 3.0 3.4 3.7

NRV 16 v2 10 .3 13. 7 19. 4 23.8 1 1.01 1.60 1.9 6 2 .14 1. 8 2.4 3.4 4.8 NRVH 16 v2 0.9 4.0 5.0 5.7

NRV 19 v2 18 .7 22.3 31.6 38.7 1 1.65 2.62 3.20 3.50 3.3 4.0 5.6 7.9 NRVH 19 v2 5.5 7. 9 8.8 9.6

NRV 22 24.4 29. 2 41. 3 50.6 1 2 .15 3.43 4 .18 4.57 4.3 5.2 7.3 10.3 NRVH 22 8.9 10.3 11 .5 12 .5

NRV 28 4 7.5 56.7 80.2 98.2 1 4.18 6.66 8.12 8.87 8.4 10.1 14.2 19 .9 NRVH 28 17. 3 19.9 22.2 24.3

NRV 35 83.4 99.7 141.0 172.7 1 7.3 4 11. 70 14.2 7 15 .60 14.8 17. 7 24.9 35.1 NRVH 35 30.4 35.1 39.1 42.7

R407C R4 07C R407C R 407C

NRV 6 v2 0.3 1. 3 3.2 4.3 1 0.08 0.14 0.17 0.19 0.1 0.2 0.5 0.8 NRVH 6 v2 0.0 0.2 0.7 0.8

NRV 10 v2 2.1 5.3 8.6 10.5 1 0. 35 0.57 0.70 0.77 0.4 0.9 1.5 2.0 NRVH 10 v2 0.2 1.3 2.1 2.5

NRV 12 v2 7. 8 9.3 13.1 16.1 1 0.64 1. 02 1. 24 1.36 1.3 1. 6 2.2 3.1 NRVH 12 v2 2.2 3.1 3.5 3.8

NRV 16 v2 11. 1 14.7 21. 0 25.7 1 1.02 1.62 1.98 2.16 1.9 2.5 3.5 5.0 NRVH 16 v2 0.9 4.1 5 .1 5.9

NRV 19 v2 20.2 24 .1 34.1 41.7 1 1.66 2.65 3. 24 3.53 3.4 4 .1 5.8 8.1 NRVH 19 v2 5.7 8.1 9.0 9.9

NRV 22 26.4 31.5 44.6 54.6 1 2 .18 3.47 4.23 4.62 4.5 5.3 7.5 10.6 NRVH 22 9.2 10 .6 11. 8 12.9

NRV 28 51. 2 61. 2 86.5 106.0 1 4.22 6.73 8 .21 8.97 8.7 10.4 14 .6 20.6 NRVH 28 17. 9 20.6 22.9 25.0

NRV 35 90.0 10 7.5 152.1 18 6.3 1 7.42 11 .8 3 14.43 15 .77 15.3 18 .2 25.7 36.1 N RVH 35 31.4 36 .1 40.3 44.0

R407F R4 07F R407F R407F

NRV 6 v2 0.3 1. 3 3.2 4.4 1 0.09 0.15 0 .18 0.20 0.1 0.2 0.6 0.9 NRVH 6 v2 0.0 0.2 0.7 0.8

NRV 10 v2 2.1 5.4 8.7 10. 7 1 0.38 0.62 0.75 0.82 0.4 0.9 1.5 2.1 NRVH 10 v2 0.2 1.4 2.2 2.6

NRV 12 v2 7.9 9.4 13.3 16.3 1 0.70 1.10 1.33 1.45 1.4 1.7 2.3 3.3 NRVH 12 v2 2.3 3.3 3.7 4.0

NRV 16 v2 11. 2 15. 0 21.3 26 .1 1 1.11 1. 74 2.12 2.31 2.0 2.6 3.7 5.2 NRVH 16 v2 0.9 4.3 5.4 6.2

NRV 19 v2 20.5 24.5 34.6 42.4 1 1.81 2.85 3.46 3.77 3.6 4.3 6.1 8.5 NRVH 19 v2 6.0 8.5 9.5 10.4

NRV 22 26.8 32.0 45.3 55. 5 1 2.36 3.72 4.52 4.93 4.7 5.6 7.9 11.1 NRVH 22 9.7 11 .1 12 .4 13. 6

NRV 28 52.0 62.1 87.9 107. 6 1 4. 59 7. 23 8.78 9.57 9.1 10.9 15. 4 21.6 NRVH 28 18.8 21.6 24.1 26.3

NRV 35 91. 4 109.2 154 .5 189.2 1 8.07 12 .71 15.43 16.82 16 .0 19. 2 27. 0 38.0 NRVH 35 33.0 38.0 42.4 46.3

R407H R407H R407H R407H

NRV 6 v2 0.4 1.4 3.5 4.7 1 0.09 0.15 0.18 0.20 0.1 0.2 0.6 0.9 NRVH 6 v2 0.0 0.2 0.7 0.9

NRV 10 v2 2.3 5.7 9.3 11 .4 1 0.38 0.62 0.75 0.82 0.4 1. 0 1.6 2.2 NRVH 10 v2 0.2 1. 4 2.2 2.7

NRV 12 v2 8.4 10 .1 14 .2 17.4 1 0.70 1.10 1.33 1.45 1.4 1.7 2.4 3.3 N RVH 12 v2 2.3 3.3 3.7 4.1

NRV 16 v2 12.0 16. 0 22.8 2 7.9 1 1.11 1.75 2.12 2. 31 2.0 2.7 3.8 5.4 NRVH 16 v2 1.0 4.4 5.5 6.3

NRV 19 v2 21.9 26. 2 37. 0 45. 3 1 1. 81 2.86 3.47 3.78 3.7 4.4 6.2 8.7 NRVH 19 v2 6.1 8.7 9.7 10.6

NRV 22 28.6 34.2 48.4 59.3 1 2. 37 3.73 4.54 4.95 4.8 5.7 8.1 11.4 NRVH 22 9.9 11. 4 12 .7 13.9

NRV 28 55.6 66.5 94.0 115 .1 1 4.59 7. 25 8.81 9.60 9.3 11 .2 15 .7 2 2.1 NRVH 28 19. 2 22.1 24.6 26.9

NRV 35 9 7.7 116. 8 165. 2 202.3 1 8.07 12 .74 15. 48 16 .88 16 .4 19.6 27.6 38.8 NRVH 35 33.7 38.8 43.3 47. 3

1) Rated capacities are based on:

-Evaporating temperature, te = 14 °F

-Condensing temperature, tc = 86 °F

-Subcooling t

-Superheat tsh = 0 °F

-Discharge temperature, t

the valve.

The table values refer to the evaporator

capacity.

c

Correction factors

When selecting the evaporator capacity is to be multiplied by a correction factor depending on the liquid temperature tl ahead of the valve/the evaporator. The corrected

capacity can then be found from the table.

System capacity.Correction factor=Table capacity

across valve ∆p

[psi]

NRV NRV NRVH

0.7 1 2 3 -20 15 32 40 0.7 1 2 4 3 4 5 6

= 9 °F

sub

=176 °F ahead of

d

Pressure

across

valve ∆p

Correction factors for liquid temperature t

t

[°F]

l

R407A

R407C

R407F

R407H

15 32 50 60 70 80 86 95 105 115 125

0.72 0.78 0.85 0.90 0.96 1.02 1.09 1.18 1.28 1.41 1.56

0.73 0.79 0.86 0.91 0.96 1.02 1.09 1.17 1.26 1.37 1.51

0.73 0.79 0.86 0.91 0.96 1.02 1.09 1.17 1.26 1.38 1.52

0.74 0.80 0.87 0.91 0.96 1.02 1.08 1.16 1.24 1.35 1.47

Suction vapour capacity 1)

drop

[psi]

l

at evaporating

temperature te

[°F]

Hot gas capacity 1)

at pressure drop

across valve ∆p

[psi]

Typ e

Hot gas capacity 1)

at pressure drop across valve

Δp

[psi]

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 13

Page 14

Data sheet | Check valve, types NRV and NRVH

Capacity US units

Liquid capacity [TR] Suction vapour capacity [TR] Hot gas capacity [TR] Hot gas capacity [TR]

Liquid capacity 1)

at pressure drop

Typ e

R448A R448A R448A R448A

NRV 6 v2 0.3 1. 2 3.0 4.0 1 0.09 0.14 0.17 0.19 0.1 0.2 0.5 0.8 NRVH 6 v2 0.0 0.2 0.6 0.8

NRV 10 v2 2.0 4.9 8.0 9. 8 1 0.36 0.58 0.71 0.77 0.4 0.9 1.4 2.0 NRVH 10 v2 0.1 1.3 2.0 2.5

NRV 12 v2 7. 2 8.6 12. 2 14.9 1 0.65 1.03 1. 26 1. 37 1.3 1.5 2.2 3.1 NRVH 12 v2 2 .1 3.1 3.4 3.7

NRV 16 v2 10 .3 13. 7 19. 5 23.9 1 1.04 1.64 2.00 2.18 1. 8 2.5 3.5 4.9 NRVH 16 v2 0.9 4.0 5.1 5.8

NRV 19 v2 18 .7 22.4 31.7 38.8 1 1.70 2.69 3.27 3.57 3.4 4.0 5.7 8.0 NRVH 19 v2 5.6 8.0 8 .9 9.7

NRV 22 24.5 29. 3 41. 4 50.7 1 2.23 3 .51 4.27 4.66 4.4 5.3 7. 4 10.4 NRVH 22 9.1 10 .4 11 .6 12 .7

NRV 28 4 7.6 56.8 80.4 98.5 1 4.32 6.82 8.30 9.05 8.6 10. 2 14.4 20.3 NRVH 28 17. 6 20.3 22.6 24.7

NRV 35 83.6 99.9 141.3 17 3.0 1 7. 59 11. 99 14.5 8 15.91 15.1 18. 0 25.3 35.6 NRVH 35 30.9 35.6 39.7 43.4

R449A R449A R449A R449A

NRV 6 v2 0.3 1. 2 2.9 3.9 1 0.09 0.14 0.17 0.19 0 .1 0.2 0.5 0.8 NRVH 6 v2 0.0 0.2 0.6 0.8

NRV 10 v2 1.9 4.8 7. 9 9.7 1 0.36 0.58 0.70 0.77 0.3 0.9 1.4 2.0 NRVH 10 v2 0.1 1.3 2.0 2.4

NRV 12 v2 7.1 8.5 12. 0 14 .7 1 0.65 1.03 1. 25 1. 36 1.3 1.5 2.2 3.0 NRVH 12 v2 2 .1 3.0 3.4 3.7

NRV 16 v2 10 .2 13. 5 19. 3 23.6 1 1.03 1.6 3 1.99 2.17 1.8 2.4 3.4 4.8 NRVH 16 v2 0.9 4.0 5.0 5.7

NRV 19 v2 18 .5 22 .1 31.3 38.3 1 1. 69 2.67 3.25 3.54 3.3 4.0 5.6 7.9 NRVH 19 v2 5.5 7.9 8.8 9.6

NRV 22 24.2 28.9 40.9 5 0.1 1 2.21 3.49 4.24 4.63 4.3 5.2 7.3 10.3 NRVH 22 8.9 10 .3 11. 5 12. 5

NRV 28 4 7.0 56.2 79.4 9 7.3 1 4.29 6.77 8 .24 8.99 8.4 10.1 14.2 20.0 NRVH 28 17.4 20.0 22.3 24.3

NRV 35 82.6 98.7 139.6 17 0.9 1 7.54 11. 90 14.4 8 15. 80 14. 8 17. 7 25.0 35.1 NRVH 35 30.5 35.1 39.1 42.7

R449B R449B R449B R449B

NRV 6 v2 0.3 1. 2 3.0 4.0 1 0.09 0.14 0.17 0.19 0.1 0.2 0.5 0.8 NRVH 6 v2 0.0 0.2 0.6 0.8

NRV 10 v2 2.0 4.9 8.0 9. 8 1 0.36 0.58 0.71 0.78 0.4 0.9 1.4 2.0 NRVH 10 v2 0.1 1.3 2.0 2.4

NRV 12 v2 7. 2 8.6 12. 2 14.9 1 0.66 1. 04 1.26 1.37 1.3 1.5 2.2 3 .1 NRVH 12 v2 2.1 3 .1 3.4 3.7

NRV 16 v2 10 .3 13. 7 19. 5 23.9 1 1.04 1.65 2.00 2.19 1. 8 2.5 3.5 4.9 NRVH 16 v2 0.9 4.0 5.0 5.8

NRV 19 v2 18 .8 22.4 31.7 38.8 1 1.71 2.69 3.27 3.57 3.4 4.0 5.7 8.0 NRVH 19 v2 5.6 8.0 8 .9 9.7

NRV 22 24.5 29. 3 41. 5 50.8 1 2.23 3.52 4.28 4.67 4.4 5.2 7.4 10. 4 NRVH 22 9.0 10.4 11 .6 12 .7

NRV 28 4 7.6 56 .9 80.5 98.6 1 4.33 6.84 8.31 9.07 8.5 10 .2 14.4 20.2 NRVH 28 17. 5 20.2 22.5 24.6

NRV 35 83.7 10 0.1 141.5 17 3.3 1 7. 62 12 .02 14 .61 15.94 15.0 17. 9 25.2 35.5 NRVH 35 30.8 35.5 39.6 43 .2

R450A R450A R450A R450A

NRV 6 v2 0.3 1. 2 2.9 3.9 1 0.05 0.10 0.12 0.14 0.0 0.2 0.4 0.6 NRVH 6 v2 0.0 0.1 0.4 0.5

NRV 10 v2 1.9 4.7 7.7 9.5 1 0.23 0.40 0.50 0.56 0.2 0.6 1.0 1.4 NRVH 10 v2 0.1 0.9 1. 4 1.7

NRV 12 v2 7. 0 8.3 11.8 14.4 1 0.43 0.73 0.90 1.00 0.9 1.1 1. 5 2.1 NRVH 12 v2 1.5 2 .1 2.4 2.6

NRV 16 v2 9.9 13. 3 18 .8 23 .1 1 0.68 1.15 1.4 4 1.5 8 1.3 1.7 2.5 3.4 NRVH 16 v2 0.6 2.8 3.5 4.0

NRV 19 v2 18.1 21.7 30.6 37. 5 1 1.12 1.89 2.35 2.59 2.4 2.8 4.0 5.6 NRVH 19 v2 3.9 5.6 6.2 6.7

NRV 22 23.7 28.3 40.0 49.0 1 1.46 2.47 3. 07 3.39 3.1 3.7 5.2 7.3 NRVH 22 6.4 7. 3 8.1 8.8

NRV 28 46.0 55.0 77. 7 95.2 1 2.84 4.79 5.97 6.57 6 .1 7. 2 10.1 14.2 NRVH 28 12 .3 14. 2 15.7 17.1

NRV 35 80.8 96.6 136.6 167.3 1 4.99 8.42 10.4 8 11.5 6 10 .6 12 .7 17.8 24 .9 NRVH 35 21. 7 24 .9 2 7.6 30.1

1) Rated capacities are based on:

-Evaporating temperature, te = 14 °F

-Condensing temperature, tc = 86 °F

-Subcooling t

-Superheat tsh = 0 °F

-Discharge temperature, t

the valve.

The table values refer to the evaporator

capacity.

across valve ∆p

[psi]

NRV NRV NRVH

0.7 1 2 3 -20 15 32 40 0.7 1 2 4 3 4 5 6

= 9 °F

sub

=176 °F ahead of

d

Pressure

across

valve ∆p

Suction vapour capacity 1)

drop

[psi]

at evaporating

temperature te

[°F]

Correction factors

When selecting the evaporator capacity is to be multiplied by a correction factor depending on the liquid temperature tl ahead of the valve/the evaporator. The corrected

capacity can then be found from the table.

System capacity.Correction factor=Table capacity

Correction factors for liquid temperature t

t

[°F]

l

R448A

R449A

R449B

R450A

15 32 50 60 70 80 86 95 105 115 125

0.72 0.78 0.85 0.90 0.96 1.02 1.09 1.18 1.28 1.41 1.56

0.72 0.77 0.85 0.90 0.96 1.02 1.09 1.18 1.29 1.41 1.57

0.72 0.78 0.85 0.90 0.96 1.02 1.09 1.18 1.28 1.41 1.56

0.73 0.79 0.86 0.91 0.96 1.02 1.09 1.16 1.25 1.36 1.49

l

Hot gas capacity 1)

at pressure drop

across valve ∆p

[psi]

Typ e

Hot gas capacity 1)

at pressure drop across valve

Δp

[psi]

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 14

Page 15

Data sheet | Check valve, types NRV and NRVH

Capacity US units

Liquid capacity (kW) Suction vapour capacity in [kW] Hot gas capacity in [kW] Hot gas capacity in [kW]

Liquid capacity 1)

at pressure drop

Typ e

R452A R452A R452A R452A

NRV 6 v2 0.2 0.9 2.3 3.1 1 0.08 0.13 0.15 0 .17 0.0 0.2 0.4 0.7 NRVH 6 v2 0.0 0.2 0.5 0.7

NRV 10 v2 1.5 3.8 6.2 7.6 1 0.32 0. 51 0.63 0.69 0.3 0.7 1. 2 1.7 NRVH 10 v2 0.1 1.1 1. 7 2.1

NRV 12 v2 5.6 6.6 9.4 11. 5 1 0.57 0.91 1.12 1.2 2 1.1 1.3 1.8 2.6 NRVH 12 v2 1.8 2.6 2.9 3.2

NRV 16 v2 7.9 10.6 15.0 18.4 1 0.91 1.45 1.78 1.94 1.6 2.1 2.9 4.1 NRVH 16 v2 0.7 3.4 4.3 4.9

NRV 19 v2 14 .5 17. 3 24.4 29.9 1 1.49 2.37 2.90 3 .18 2.8 3.4 4.8 6.7 NRVH 19 v2 4.7 6.7 7. 5 8.2

NRV 22 18.9 22.6 32.0 39.1 1 1.95 3 .11 3.80 4.15 3.7 4.4 6.3 8.8 NRVH 22 7. 6 8.8 9.8 10.7

NRV 28 36.7 43.9 62.0 76.0 1 3.78 6.03 7. 37 8.06 7.2 8.6 12 .1 17.1 NRVH 28 14. 8 17.1 19. 0 20.8

NRV 35 64.5 7 7.1 109.1 133. 6 1 6.65 10.59 12.95 14.17 12. 7 15.1 21. 4 30.0 NRVH 35 26.1 30.0 33.5 36.5

R513 A R 513A R513A R513A

NRV 6 v2 0.3 1.1 2.6 3.5 1 0.06 0.10 0.13 0.14 0.0 0.2 0.4 0.6 NRVH 6 v2 0.0 0.1 0.5 0.6

NRV 10 v2 1.7 4.3 6.9 8.5 1 0.25 0.43 0.53 0.59 0.2 0.6 1. 0 1.4 NRVH 10 v2 0.1 0.9 1.4 1.7

NRV 12 v2 6.3 7. 5 10.6 13. 0 1 0.47 0.77 0.95 1.0 5 0.9 1.1 1. 5 2.2 NRVH 12 v2 1.5 2.2 2.4 2.6

NRV 16 v2 8.9 11. 9 16 .9 20.7 1 0.74 1. 22 1.51 1.66 1.3 1.8 2.5 3.5 NRVH 16 v2 0.6 2.8 3.5 4.0

NRV 19 v2 16 .3 19. 5 27.5 33.7 1 1. 22 2.00 2 .47 2.72 2.4 2.9 4.0 5.6 NRVH 19 v2 4.0 5.6 6.3 6.8

NRV 22 21.3 25.4 36.0 44.1 1 1.59 2.62 3.24 3.56 3.1 3.7 5.3 7.4 NRVH 22 6.4 7. 4 8.2 8.9

NRV 28 41. 3 49.4 69.9 85.6 1 3.09 5.08 6.28 6.90 6 .1 7. 3 10.2 14. 3 NRVH 28 12.4 14. 3 15 .9 17. 3

NRV 35 72.6 86.8 122 .8 150.4 1 5.42 8.93 11. 04 12 .13 10.7 12.8 18 .0 25.1 NRVH 35 21.9 25 .1 27. 9 30.4

R515 B R515B R515B R515 B

NRV 6 v2 0.3 1.1 2.7 3.6 1 0.04 0.09 0. 11 0.12 0.0 0.1 0.3 0.5 NRVH 6 v2 0.0 0.1 0.4 0.5

NRV 10 v2 1.8 4.4 7. 2 8.9 1 0.20 0.35 0.45 0.50 0.2 0.5 0.9 1.2 NRVH 10 v2 0.1 0.8 1. 2 1. 5

NRV 12 v2 6.5 7. 8 11.0 13.5 1 0.37 0.64 0.81 0.89 0.8 1.0 1.4 1.9 NRVH 12 v2 1. 3 1.9 2.1 2.3

NRV 16 v2 9. 3 12.4 17.7 21.6 1 0.59 1.02 1. 29 1. 42 1.2 1.5 2.2 3.0 NRVH 16 v2 0.5 2.5 3 .1 3.5

NRV 19 v2 17. 0 20.3 28.7 35.2 1 0.97 1.67 2.10 2. 32 2.1 2.5 3.6 4.9 NRVH 19 v2 3.5 4.9 5.5 6.0

NRV 22 22.2 26.5 3 7.5 46.0 1 1.27 2.19 2.75 3.04 2.8 3.3 4.6 6.5 NRVH 22 5.6 6.5 7. 2 7. 8

NRV 28 43 .1 51.5 72.9 89.2 1 2.46 4.25 5.33 5.90 5.4 6.4 9.0 12 .6 NRVH 28 11. 0 12 .6 13 .9 15.1

NRV 35 75.8 90.6 128.1 156 .8 1 4.32 7.47 9.37 10. 37 9.5 11 .3 15 .9 2 2.1 NRVH 35 19 .3 22 .1 24.5 26.6

R123 3zd( E) R123 3zd( E) R12 33zd(E) R123 3zd( E)

NRV 6 v2 0.4 1.4 3.3 4.5 1 0.01 0.03 0.05 0.06 0.0 0.1 0.2 0.3 NRVH 6 v2 0.0 0.1 0.2 0.2

NRV 10 v2 2.2 5.5 9.0 11 .0 1 0.05 0.15 0.22 0. 26 0.1 0.3 0.6 0.7 NRVH 10 v2 0.1 0.4 0.7 0.8

NRV 12 v2 8.1 9.7 13. 7 16. 8 1 0.13 0. 32 0.43 0.49 0.5 0.6 0.9 1.1 NRVH 12 v2 0.8 1.1 1.2 1. 3

NRV 16 v2 11. 6 15. 5 22.0 26.9 1 0.20 0. 51 0.69 0.78 0.7 1. 0 1.4 1.8 NRVH 16 v2 0.3 1.3 1.7 1.9

NRV 19 v2 21.1 25.3 35.7 43.7 1 0.33 0.83 1.13 1.28 1.4 1. 6 2.2 2.9 NRVH 19 v2 2.1 2.9 3.2 3.4

NRV 22 27. 6 33. 0 46.7 5 7.2 1 0.44 1. 09 1.48 1.67 1.8 2.1 2.9 3.8 NRVH 22 3.4 3.8 4.2 4.4

NRV 28 53.6 6 4.1 90.7 111.1 1 0.85 2.12 2.86 3.25 3.5 4.1 5.6 7. 5 NRVH 28 6.7 7. 5 8.1 8.5

NRV 35 94.3 112. 7 159. 4 19 5.2 1 1.49 3.72 5.03 5.71 6.1 7. 2 9.9 13.1 NRVH 35 11. 7 13.1 14. 2 15. 0

R123 4ze(E) R123 4ze(E) R12 34ze (E) R123 4ze (E)

NRV 6 v2 0.3 1.1 2.8 3.7 1 0.05 0.09 0 .11 0.12 0.0 0.1 0.3 0.5 NRVH 6 v2 0.0 0.1 0.4 0.5

NRV 10 v2 1.8 4.6 7. 4 9 .1 1 0.20 0.36 0.46 0.51 0.2 0.6 0.9 1.3 NRVH 10 v2 0.1 0.8 1.3 1.5

NRV 12 v2 6.7 8.0 11. 3 13 .9 1 0.38 0.66 0. 83 0.91 0.8 1. 0 1.4 1.9 NRVH 12 v2 1.4 1.9 2.2 2.3

NRV 16 v2 9. 6 12.8 18.1 22.2 1 0.61 1.05 1.31 1.45 1.2 1.6 2.2 3 .1 NRVH 16 v2 0.5 2.5 3.2 3.6

NRV 19 v2 17. 4 20.8 29.5 3 6.1 1 1.00 1.71 2 .15 2 .37 2.2 2.6 3.6 5 .1 NRVH 19 v2 3.6 5.1 5.6 6.1

NRV 22 22.8 2 7.3 38.5 47. 2 1 1.30 2.24 2.81 3.10 2.8 3.4 4.8 6.6 NRVH 22 5.8 6.6 7. 3 8.0

NRV 28 44.3 52.9 74 .8 91. 6 1 2. 53 4.35 5.45 6 .02 5.5 6.6 9.2 12 .8 NRVH 28 11. 2 12 .8 14. 2 15. 5

NRV 35 7 7.8 93.0 131.5 161.1 1 4.44 7. 64 9.58 10.59 9.7 11. 6 16. 2 22.6 NRVH 35 19.7 22.6 25.0 27.2

across valve ∆p

[bar]

NRV NRV NRVH

0.05 0.07 0.14 0.2 -30 -10 0 5 0.05 0.07 0.14 0.2 0.2 0.25 0. 3 0.35

Pressure

across

valve ∆p

Correction factors for liquid temperature t

t

[°F]

l

R452A

R513A

R515B

R1233zd(E)

R1234ze(E)

15 32 50 60 70 80 86 95 105 115 125

0.68 0.74 0.83 0.88 0.95 1.02 1.12 1.23 1.37 1.54 1.79

0.71 0.77 0.85 0.90 0.96 1.02 1.10 1.18 1.29 1.41 1.57

0.72 0.78 0.86 0.90 0.96 1.02 1.09 1.17 1.26 1.37 1.51

0.77 0.82 0.89 0.93 0.97 1.01 1.06 1.12 1.18 1.25 1.33

0.72 0.78 0.86 0.91 0.96 1.02 1.09 1.17 1.26 1.36 1.49

Suction vapour capacity 1)

drop

[bar]

l

at evaporating

temperature te

[°C]

Hot gas capacity 1)

at pressure drop

across valve ∆p

[bar]

Typ e

Hot gas capacity 1)

at pressure drop across valve

Δp

[bar]

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 15

Page 16

Data sheet | Check valve, types NRV and NRVH

Capacity US units

Liquid capacity [TR] Suction vapour capacity [TR] Hot gas capacity [TR] Hot gas capacity [TR]

Liquid capacity 1)

at pressure drop

Typ e

R290 R290 R290 R290

NRV 6 v2 0.4 1.5 3.7 5.0 1 0.12 0.19 0.22 0.24 0 .1 0.2 0.6 0.9 NRVH 6 v2 0 .1 0.2 0.7 0.9

NRV 10 v2 2.5 6.2 10.1 12.3 1 0.49 0.76 0.91 0.99 0.4 1.0 1.6 2.3 NRVH 10 v2 0.2 1.5 2.3 2.8

NRV 12 v2 9.1 10.9 15. 4 18 .8 1 0.89 1. 35 1. 62 1.76 1.5 1. 8 2.5 3.5 NRVH 12 v2 2.4 3.5 3.9 4.3

NRV 16 v2 13.0 17.3 24.6 30 .1 1 1.41 2 .15 2.57 2.79 2 .1 2.8 4.0 5.6 NRVH 16 v2 1.0 4.6 5.8 6.6

NRV 19 v2 23.6 28.2 39.9 48.9 1 2 .31 3 .51 4 .21 4.56 3.9 4.6 6.5 9.1 NRVH 19 v2 6.4 9 .1 10.2 11. 1

NRV 22 30.9 36.9 52. 2 63.9 1 3.02 4.59 5.50 5.97 5.1 6.1 8.5 12 .0 NRVH 22 10.4 12. 0 13 .3 14 .5

NRV 28 59.9 71.6 101.3 124.1 1 5.85 8.90 10.6 8 11.5 8 9.8 11 .8 16.6 23.2 NRVH 28 20.2 23.2 25.9 28.2

NRV 35 10 5.3 125 .9 178 .1 218.1 1 10. 29 15.6 5 18.77 20.36 17. 3 20.7 29 .1 40.8 NRVH 35 35.5 40.8 45.4 49.6

R32 R32 R32 R32

NRV 6 v2 0.5 1.9 4.7 6.3 1 0.16 0.24 0.29 0. 31 0.1 0.3 0.8 1. 2 NRVH 6 v2 0.1 0.3 1. 0 1. 2

NRV 10 v2 3.1 7. 7 12. 6 15. 4 1 0.67 0.99 1.17 1.26 0.5 1. 3 2.2 3.0 NRVH 10 v2 0.2 1.9 3 .1 3.7

NRV 12 v2 11. 4 13. 6 19. 2 23.5 1 1.19 1.75 2.07 2.23 1.9 2.3 3.3 4.6 N RVH 12 v2 3.2 4.6 5.2 5.6

NRV 16 v2 16 .2 21.6 30.7 3 7.6 1 1.90 2.79 3.29 3.54 2.8 3.7 5.3 7.4 NRVH 16 v2 1. 3 6 .1 7. 6 8.7

NRV 19 v2 29.5 35. 3 49.9 61.2 1 3.10 4.55 5.37 5.79 5.1 6.1 8.5 12 .0 NRVH 19 v2 8.5 12. 0 13. 4 14.7

NRV 22 38.6 46.2 65.3 80.0 1 4.05 5.95 7. 03 7. 57 6.6 7. 9 11. 2 15.7 NRVH 22 13.7 15.7 17.6 19. 2

NRV 28 75.0 89. 6 126.8 155.3 1 7.8 7 11. 56 13 .64 14.69 12.9 15. 4 21.7 30.5 NRVH 28 26.5 30.5 34.1 3 7.3

NRV 35 131. 8 157. 6 222.8 272.9 1 13. 83 20.32 23.98 25.82 22.6 2 7.0 3 8.1 53.7 NRVH 35 46.6 53.7 59.9 65.5

R452B R452B R 452B R 452B

NRV 6 v2 0.4 1.5 3.7 5 .1 1 0.13 0.20 0. 24 0. 26 0.1 0.3 0.7 1.0 NRVH 6 v2 0 .1 0.2 0.8 1.0

NRV 10 v2 2.5 6.2 10.1 12.4 1 0.55 0.82 0.98 1.0 6 0.4 1.1 1.8 2.6 NRVH 10 v2 0.2 1. 6 2.6 3.1

NRV 12 v2 9.1 10.9 15. 4 18.9 1 0.97 1. 45 1.73 1.87 1. 6 2.0 2.8 3.9 NRVH 12 v2 2.7 3.9 4.4 4.8

NRV 16 v2 13.0 17.3 24.7 30.2 1 1.55 2.31 2.75 2.97 2.3 3.1 4.4 6.3 NRVH 16 v2 1.1 5.1 6.5 7. 4

NRV 19 v2 23.7 28.3 4 0.1 49.1 1 2.53 3.78 4.50 4.86 4.3 5.1 7.2 10. 2 NRVH 19 v2 7.2 10 .2 11. 3 12.4

NRV 22 31.0 37.1 52.4 64.2 1 3.31 4.95 5.88 6.35 5.6 6.7 9.4 13. 3 NRVH 22 11. 5 13 .3 14.8 16 .2

NRV 28 60.2 71.9 101.7 124 .6 1 6 .43 9. 60 11. 41 12 .33 10.9 13.0 18 .3 25.8 NRVH 28 22.4 25.8 28.8 31.4

NRV 35 10 5.8 126 .4 178. 8 219.0 1 11. 30 16.87 20.06 21. 67 19.1 22.8 32.2 45.3 NRVH 35 39.3 45.3 50.5 55.2

R455A R455A R455A R 455A

NRV 6 v2 0.3 1.1 2.7 3.7 1 0.08 0.13 0.16 0.18 0 .1 0.2 0.5 0.8 NRVH 6 v2 0.0 0.2 0.6 0.8

NRV 10 v2 1.8 4.5 7. 3 9.0 1 0. 33 0.53 0.65 0.71 0.3 0.9 1.4 2.0 NRVH 10 v2 0.1 1.3 2.0 2.4

NRV 12 v2 6.6 7. 9 11.2 13.7 1 0.60 0.95 1.16 1. 27 1.3 1. 5 2.2 3.0 NRVH 12 v2 2.1 3.0 3.4 3.7

NRV 16 v2 9.4 12. 5 17. 8 21.9 1 0.95 1. 51 1. 84 2 .01 1. 8 2.4 3.4 4.8 NRVH 16 v2 0.9 4.0 5.0 5.7

NRV 19 v2 17. 2 20.5 29.0 35.5 1 1.56 2.47 3.01 3.29 3.3 4.0 5.6 7.9 NRVH 19 v2 5.5 7. 9 8.8 9.6

NRV 22 22.4 26.8 37. 9 46.4 1 2.03 3.23 3.94 4.30 4.3 5.2 7.3 10. 3 NRVH 22 8.9 10. 3 11. 5 12. 5

NRV 28 43.5 52. 0 73.6 90.2 1 3.95 6.27 7.65 8.36 8.4 10.1 14. 2 20.0 NRVH 28 17.3 20.0 22.3 24.3

NRV 35 76.5 91. 5 129.4 158 .5 1 6.94 11.0 2 13.44 14. 69 14. 8 17. 7 24.9 35.1 NRVH 35 30.5 35.1 39 .1 42.7

1) Rated capacities are based on:

-Evaporating temperature, te = 14 °F

-Condensing temperature, tc = 86 °F

-Subcooling t

-Superheat tsh = 0 °F

-Discharge temperature, t

the valve.

The table values refer to the evaporator

capacity.

across valve ∆p

[psi]

NRV NRV NRVH

0.7 1 2 3 -20 15 32 40 0.7 1 2 4 3 4 5 6

= 9 °F

sub

=176 °F ahead of

d

Pressure

across

valve ∆p

Suction vapour capacity 1)

drop

[psi]

at evaporating

temperature te

[°F]

Correction factors

When selecting the evaporator capacity is to be multiplied by a correction factor depending on the liquid temperature tl ahead of the valve/the evaporator. The corrected

capacity can then be found from the table.

System capacity.Correction factor=Table capacity

Correction factors for liquid temperature t

t

[°F] 15 32 50 60 70 80 86 95 105 115 125

l

l

R290 0.74 0.79 0.86 0.91 0.96 1.02 1.08 1.16 1.25 1.35 1.48

R32 0.76 0.82 0.88 0.92 0.97 1.02 1.07 1.14 1.22 1.31 1.42

R452B 0.74 0.80 0.86 0.91 0.96 1.02 1.08 1.16 1.25 1.36 1.50

R455A 0.70 0.77 0.84 0.90 0.95 1.02 1.10 1.19 1.30 1.44 1.61

Hot gas capacity 1)

at pressure drop

across valve ∆p

[psi]

Typ e

Hot gas capacity 1)

at pressure drop across valve

Δp

[psi]

© Danfoss | DCS (nb) |2019.06

AI150286435592en-000702 | 16

Page 17

Data sheet | Check valve, types NRV and NRVH

Capacity US units

Liquid capacity [TR] Suction vapour capacity [TR] Hot gas capacity [TR] Hot gas capacity [TR]

Liquid capacity 1)

at pressure drop

Typ e

R454A R454A R454A R454A

NRV 6 v2 0.3 1. 2 3.0 4.0 1 0.09 0.15 0.18 0.20 0.1 0.2 0.5 0.8 NRVH 6 v2 0.0 0.2 0.7 0.8

NRV 10 v2 2.0 4.9 8.0 9. 8 1 0.38 0.60 0.73 0.80 0.4 0.9 1.5 2.1 NRVH 10 v2 0.2 1. 3 2.1 2.5

NRV 12 v2 7. 2 8.6 12. 2 14.9 1 0.69 1.07 1. 30 1. 42 1. 3 1.6 2.2 3.1 NRVH 12 v2 2.2 3.1 3.5 3.8

NRV 16 v2 10 .3 13. 7 19. 5 23.8 1 1.10 1. 71 2.07 2.25 1.9 2.5 3.6 5.0 NRVH 16 v2 0.9 4.1 5.2 5.9

NRV 19 v2 18 .7 22.4 31.6 38.7 1 1.79 2.79 3.38 3.68 3.5 4.1 5.8 8.2 NRVH 19 v2 5.8 8.2 9.1 10.0

NRV 22 24.5 29. 3 41. 4 50.7 1 2.34 3.65 4.42 4 .81 4.5 5.4 7. 6 10.7 NRVH 22 9. 3 10.7 11 .9 13 .0

NRV 28 4 7.5 56.8 80.3 98.4 1 4 .55 7.0 9 8.58 9.34 8.8 10. 5 14.8 20.7 NRVH 28 18. 0 20.7 2 3.1 25.3

NRV 35 83.5 99.8 141.1 172.9 1 7.9 9 12. 45 15. 07 16.42 15. 4 18 .4 25.9 36.5 NRVH 35 31. 7 36.5 40.6 44.4

R454B R454B R454B R454B

NRV 6 v2 0.4 1.6 3.8 5 .1 1 0.13 0.20 0.24 0.26 0.1 0.3 0.7 1.1 NRVH 6 v2 0.1 0.2 0.8 1.0

NRV 10 v2 2.5 6.3 10.2 12 .6 1 0.55 0.82 0.98 1.0 6 0.5 1.1 1.8 2.6 NRVH 10 v2 0.2 1.7 2.6 3.1

NRV 12 v2 9. 2 11.1 15.6 19.1 1 0.98 1.46 1.73 1.87 1.7 2.0 2.8 3.9 NRVH 12 v2 2.7 3.9 4.4 4.8

NRV 16 v2 13 .2 17. 6 25.0 30.6 1 1.56 2.32 2.76 2.98 2.4 3 .1 4.5 6.3 NRVH 16 v2 1.1 5.2 6.5 7.4

NRV 19 v2 24 .0 28.7 40.6 49. 8 1 2.54 3.79 4.51 4.87 4.3 5.1 7.3 10.2 NRVH 19 v2 7. 2 10.2 11 .4 12 .5

NRV 22 31.4 3 7.6 53.2 65.1 1 3.32 4.96 5.90 6 .37 5.6 6.7 9.5 13. 4 NRVH 22 11. 6 13. 4 14. 9 16 .3

NRV 28 61. 0 73.0 103 .2 12 6.4 1 6.45 9.63 11 .45 12.37 10.9 13.1 18.4 26.0 NRVH 28 22.5 26.0 28.9 31.6

NRV 35 10 7.3 128 .2 181.3 222.1 1 11. 34 16.93 20.12 21.73 19.2 23.0 32.4 45.6 NRVH 35 39.6 45.6 50.9 55. 6

R454C R454C R454C R454C

NRV 6 v2 0.3 1.1 2.7 3.6 1 0.08 0.13 0.15 0 .17 0.1 0.2 0.5 0.7 NRVH 6 v2 0.0 0.2 0.6 0.7

NRV 10 v2 1.8 4.4 7. 2 8.8 1 0.32 0 .51 0.63 0.69 0.3 0.8 1.3 1.8 NRVH 10 v2 0 .1 1.2 1.9 2.2