Page 1

Data sheet

Differential pressure switch / Lube oil protection control

MP 54 and MP 55

MP 54 and MP 55 oil dierential pressure switches

are used as safety switches to protect refrigeration

compressors against low lubricating oil pressure.

If the oil pressure fails, the switch will stop the

compressor after a predetermined time period has

elapsed.

MP 54 and MP 55 are used in refrigerating systems

using HCFC and non-ammable HFC refrigerants.

MP 54 has a xed dierential pressure setting. It

also incorporates a thermal time relay with a xed

release time setting.

MP 55 have adjustable dierential pressure and are

available with thermal time relay.

Features

Approvals

© Danfoss | DCS (jmn) | 2016.11 DKRCC.PD.CG0.C4.22 | 520H11527 | 1

• Fixed and adjustable dierentials available

• Extremely narrow switch dierential accuracy

• Reliable, long life stainless steel bellows

• Sturdy metal cover and universal mounting hole

patterns

• Integral ½ NPSM swivel cable connector allows

direct attachment of ½ in. male pipe thread

connector

UL listed for USA and Canada, le E31024

• Simple manual trip, electrical test function

eliminates need of tools and test “jumper” wires

• Standard four-wire hook-up

• Can be used for HCFC and non-ammable

HFC refrigerants

Page 2

Data sheet | Dierential pressure switch / Lube oil protection control, MP 54 and MP 55

Materials in contact

with the medium

Technical data

Unit type Material

MP 54

MP 55

MP with capillary tube

Ambient temperature

Stainless steel 19/11, no. 1.4306 to EN 10088

Deep-drawn steel plate, no. 1.0338 to EN 10130

Free cutting steel, no. 1.0718 to EN 10277

Copper Cu-DHP,

no. CW024A acc. to EN 12450

The time relay is temperature-compensated

in the range - 40 – 140 °F

Switch dierential Maximum 2.8 psi

Maximum working pressure MWP = 245 psig

Maximum test pressure Pe = 320 psig

Control voltage 240 or 120 V AC or DC

Permissible voltage variation -15 – 10%

Contact load of time

relay output contacts M-S

240 V AC: 2 FLA

240 V DC: 0.2 FLA

Electrical connection NPSM

Max. bellows temperature

Cable entry

212 °F

Integral ½ in. female NPSM swiwel cable connector allows

direct attachment of ½ in. male pipe thread connector.

Ordering

Enclosure ~NEMA 1

For R22, R134a, R404A, R407A, R407C, R407F, R422B, R422D, R448A, R449A, R450A, R452A, R507A, R513A

For complete list of approved refrigerants, visit www.products.danfoss.com and search for individual code

numbers, where refrigerants are listed as part of technical data.

Connection

Code no.

¼ in are nut

with 36 in

capillary tube

¼in are nut

with 88 in

capillary tube

–

Typ e

Control

dierential

∆p

Regulation

range

LP side

[psi] [inHg] – [psi] [s]

6.0 29 inHg – 175 psi 45 060B200866 – –

6.0 29 inHg – 175 psi 45 – 060B205066 –

MP 54

9.0 29 inHg – 175 psi 90 060B200266 – –

9.0 29 inHg – 175 psi 120 060B200366 2) – –

9.0 29 inHg – 175 psi 120 – 060B205366 2)

4.3 – 65 29 inHg – 175 psi 45 – 060B205466 –

4.3 – 65 29 inHg – 175 psi 60 060B201266 1) – –

MP 55

4.3 – 65 29 inHg – 175 psi 90 060B200666 – –

4.3 – 65 29 inHg – 175 psi 120 060B200766 – –

4.3 – 65 29 inHg – 175 psi 120 – 060B205766 –

1

) With glow lamp that remains on during normal

operation of compressor.

2

) Three-wire hook-up

Time relay

delay time

¼ in

are

Note:

When time delay is energized which also means that

min. permisible oil pressure (dierential ∆p) is reached,

light goes out.

© Danfoss | DCS (jmn) | 2016.112 | 520H11527 | DKRCC.PD.CG0.C4.22

Page 3

Data sheet | Dierential pressure switch / Lube oil protection control, MP 54 and MP 55

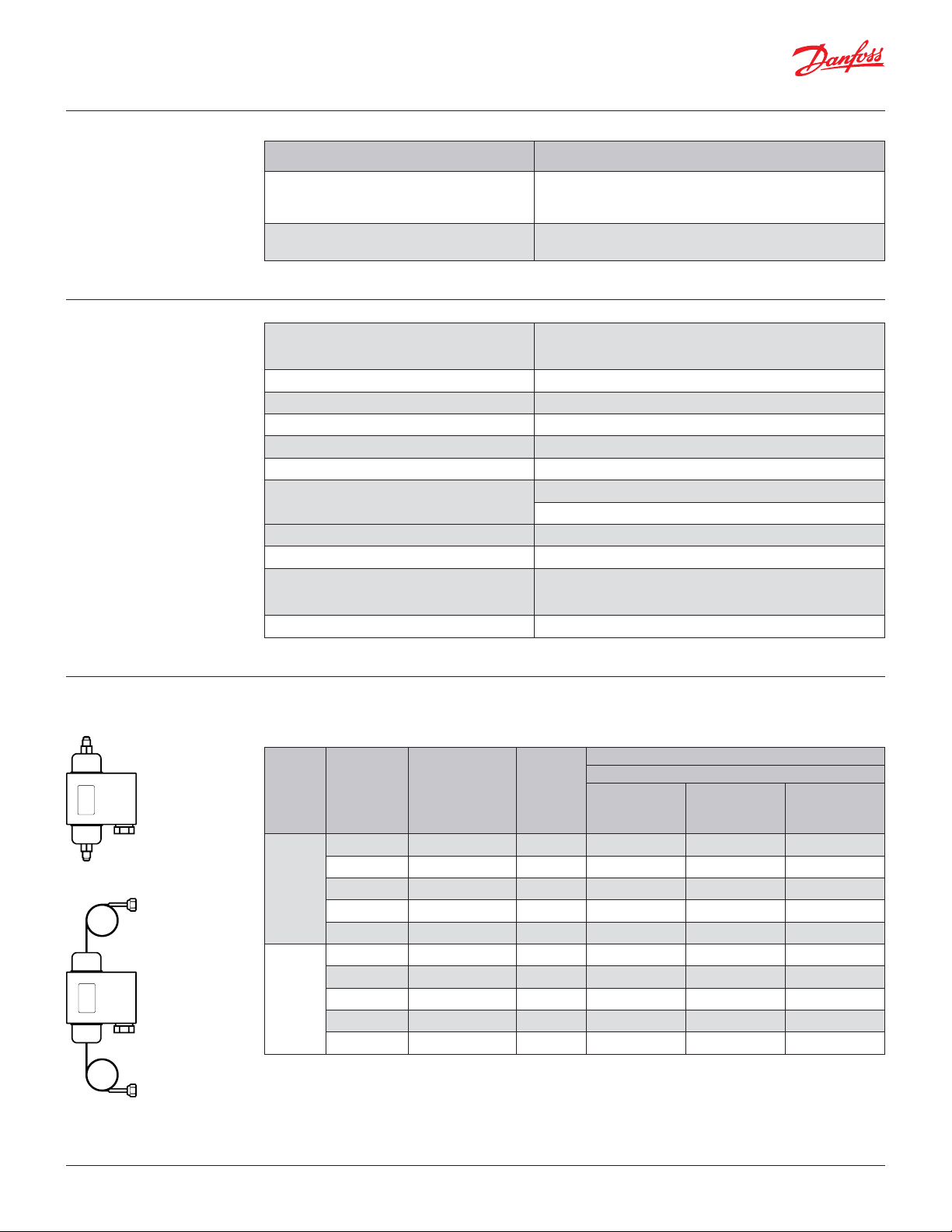

Design

1. Connection to pressure

side of lubrication

system, OIL

2. Connection to suction side

of refrigeration plant, LP

3. Setting disc (MP 55)

4. Reset button

5. Test device

The operation of the pressure switch is based only

on the dierential pressure, i.e. the dierence in

pressure between the two counteracting bellows,

whereas it is independent of the absolute pressure

acting on both bellows.

The MP 55 can be set for dierent dierential

pressures by the setting disc (3). The set dierential

pressure can be read from the internal scale.

The MP 54 has a xed dierential and has no

pressure setting disc. The factory-set dierential

pressure is stamped on the front plate of the

switch.

Terminology

Dierential range

The pressure dierence between LP and OIL

connections within which the control can be set to

operate.

Scale reading

The dierential between the oil pump pressure and

the pressure in the crankcase that exists at the

moment the contact system cuts in current to the

time relay on falling oil pressure.

Operating range

The pressure range on the LP connection within

which the switch can operate.

Contact dierential

The pressure rise above the set dierential

pressure (scale reading) necessary to cut o

current to the time relay.

Release time

The period for which the dierential pressure

control allows the compressor to run with too low

an oil pressure during start-up and operation.

© Danfoss | DCS (jmn) | 2016.11 DKRCC.PD.CG0.C4.22 | 520H11527 | 3

Page 4

Data sheet | Dierential pressure switch / Lube oil protection control, MP 54 and MP 55

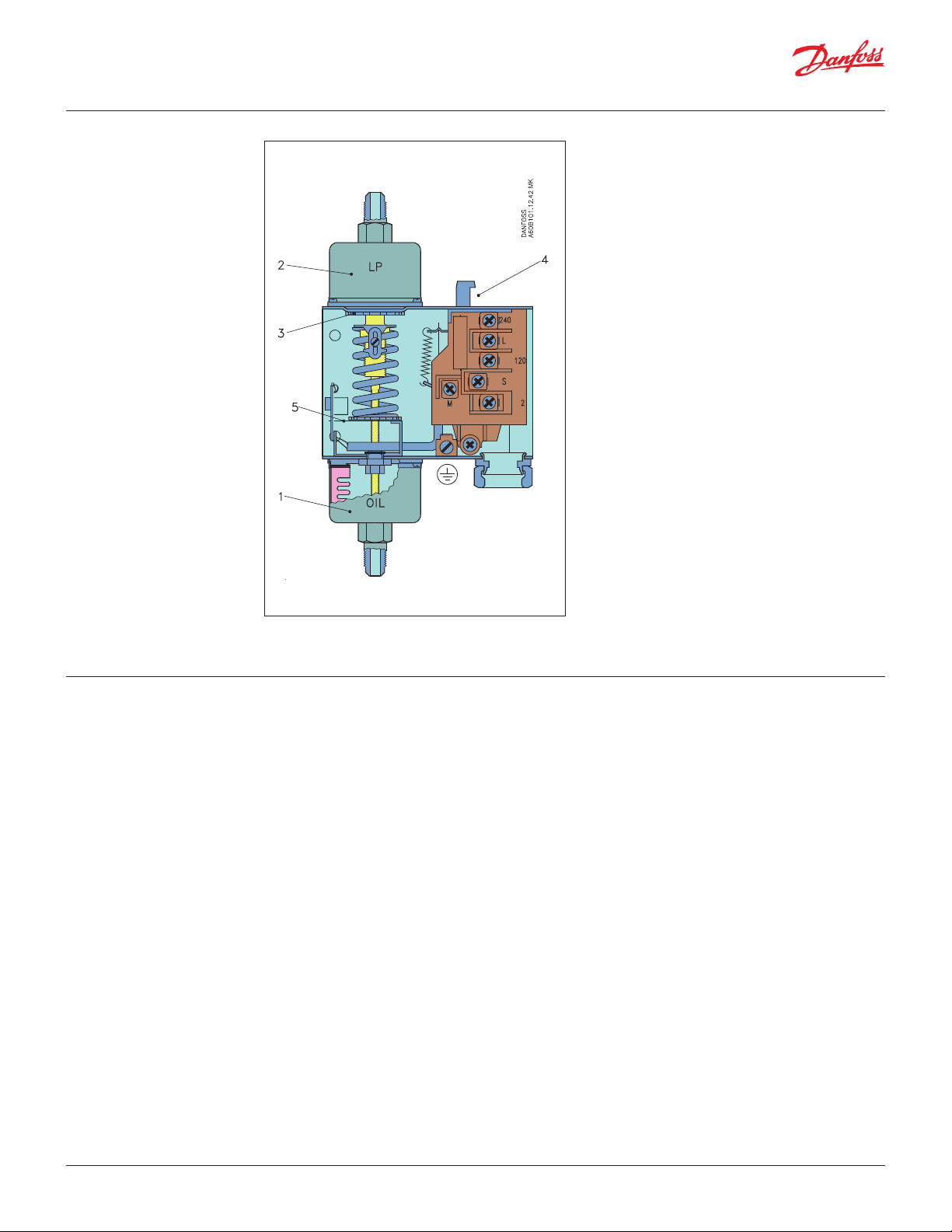

Electrical diagram

Function

If there is no oil pressure on starting, or if the oil

pressure falls below the set pressure during

operation, the compressor will stop after the

release time has elapsed. The electrical circuit is

divided into two completely separate circuits,

a safety circuit and an operational circuit.

The timer in the safety circuit is activated when the

eective lubricating oil pressure, the oil dierential

pressure (the dierence between the oil pump

pressure and suction pressure), is lower than the set

value.

[bar]

The timer is deactivated when the oil dierential

pressure is more than the set value plus the contact

dierential.

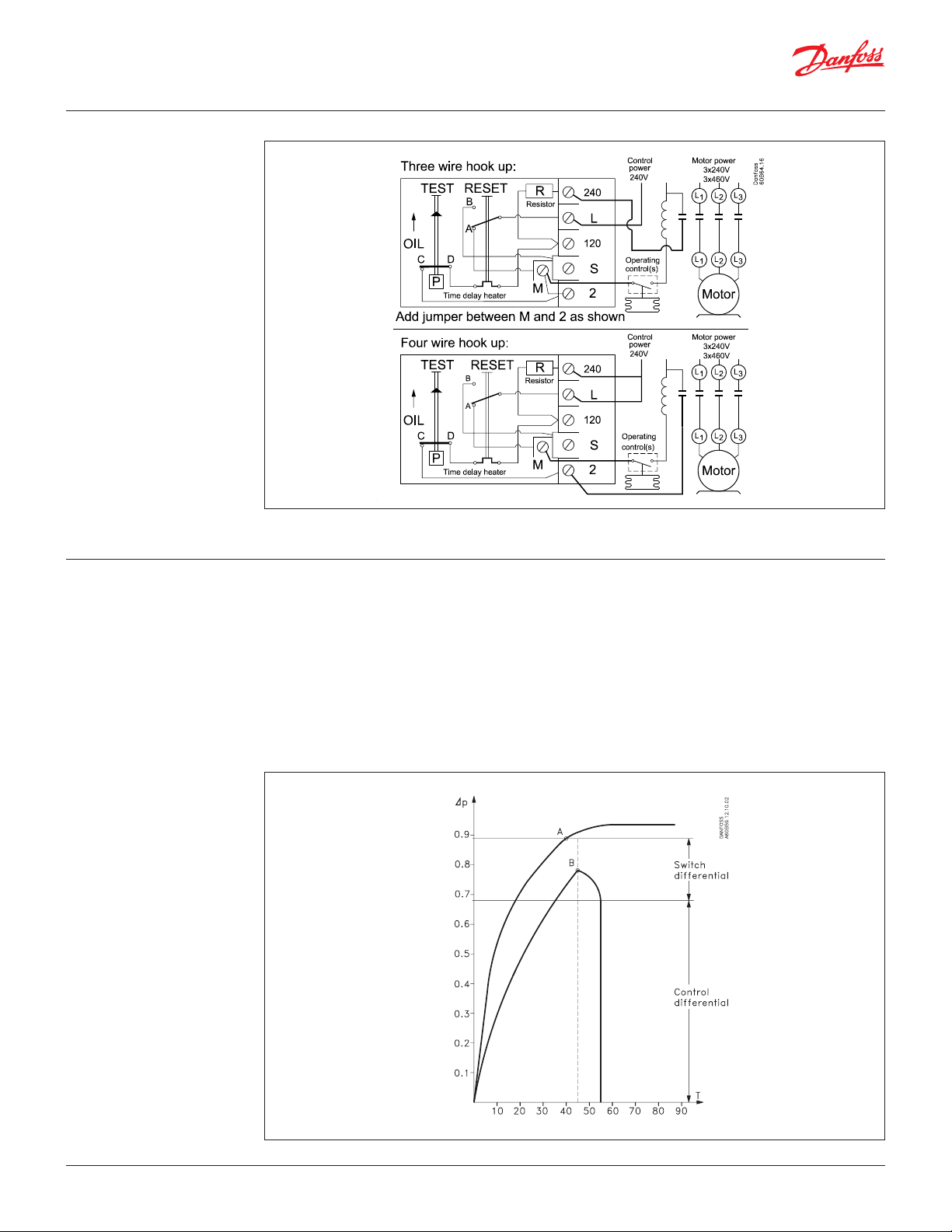

The two diagrams below explain the terms

oil dierential pressure” and “contact dierential”,

both have to be considered when using oil

dierential pressure switches.

The rst diagram shows the function of the

dierential switch during start; the second shows

the function of the switch during operation.

On start-up

[s]

© Danfoss | DCS (jmn) | 2016.114 | 520H11527 | DKRCC.PD.CG0.C4.22

Page 5

Data sheet | Dierential pressure switch / Lube oil protection control, MP 54 and MP 55

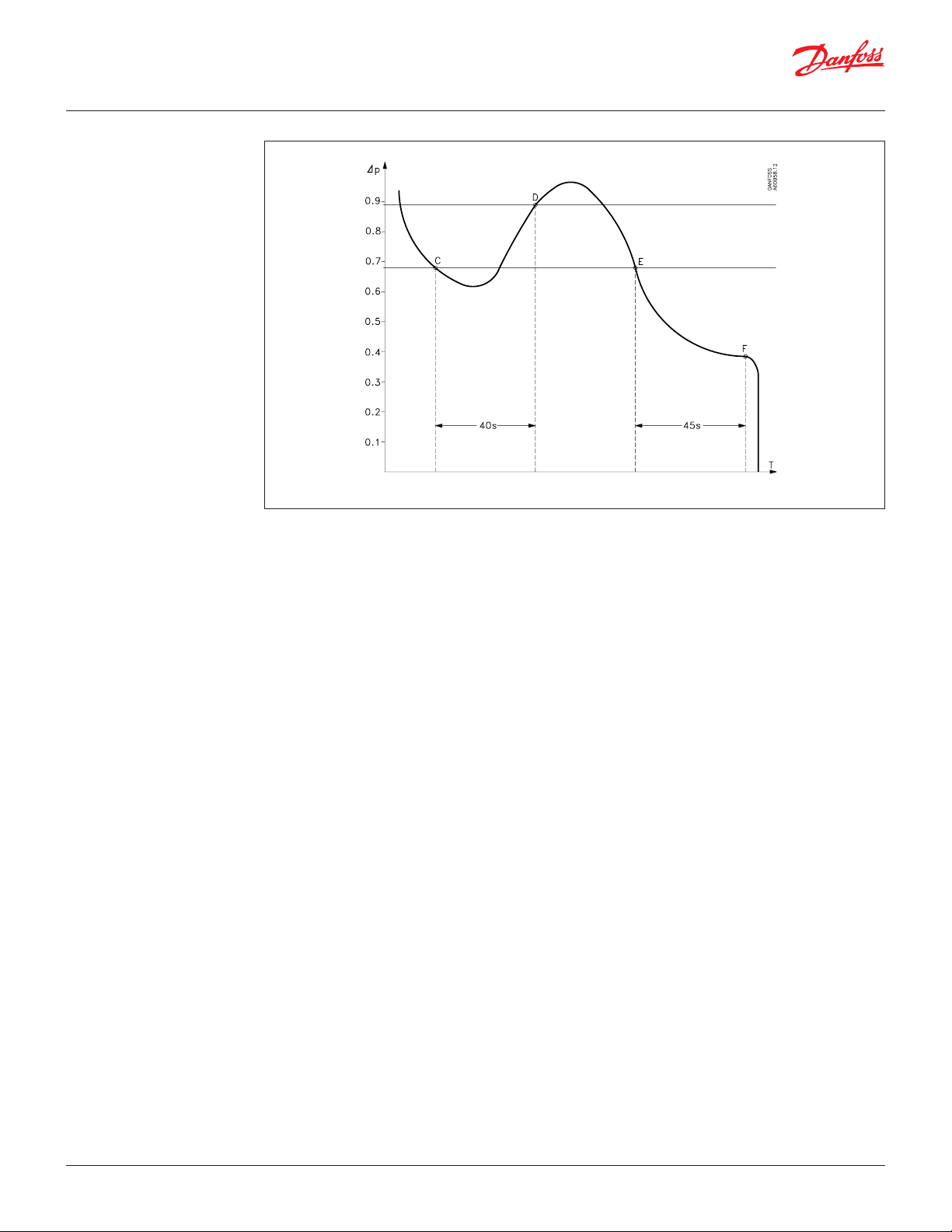

[bar]

During operation 1 bar = 14.5 psi

Pos. A:

Normal start-up

The lubricating oil pressure is built up during start

to the set/xed dierential plus the contact

dierential, before the timer cuts out (in this

example, after 45 seconds). At point A contacts

T1-T2 open and timer (e) is stopped, i.e. normal

lubricating oil conditions for the compressor have

been established.

Pos. B:

The lubricating oil pressure does not reach the set/

xed dierential plus the contact dierential

before the timer period elapses.

At point B the timer cuts out operational circuit

L-M and the compressor stops.

If a signal source is connected to terminal S, it will

be activated. Restart can only be performed after

about 2 minutes by activation of the reset button,

provided the cause of the fault has been

determined.

Pos. C:

The lubricating oil pressure falls during operation

to a value lower than the set/xed dierential. At

point C, safety circuit T1-T2 cuts in and the timer is

activated.

Pos. D:

The lubricating oil pressure reaches the set/xed

dierential plus the contact dierential before the

timer period elapses. At point D, safety circuit T1-T2

cuts out and the timer is stopped, i.e. normal

lubricating oil conditions for the compressor have

been established.

[s]

Pos. E:

The lubricating oil pressure falls to a value lower

than the set/xed dierential during operation. At

point E, safety circuit T1-T2 cuts in and the timer is

activated.

Pos. F:

The lubricating oil pressure remains lower than the

set/xed dierential. At point F the timer cuts out

operational circuit L-M and the compressor stops. If

a signal source is connected to terminal S, it will be

activated. Restart can only be performed after

about 2 minutes by activation of the reset button,

provided the cause of the fault has been

determined.

After start-up

It is important that a function check should be

made to ensure that the dierential pressure switch

is operating as it should. This check can be made

by pressing the test device (inside the unit on the

left hand side).

When the test device is pressed down and held in

this position the compressor motor should stop

after the release time determined by the time relay

has elapsed.

© Danfoss | DCS (jmn) | 2016.11 DKRCC.PD.CG0.C4.22 | 520H11527 | 5

Page 6

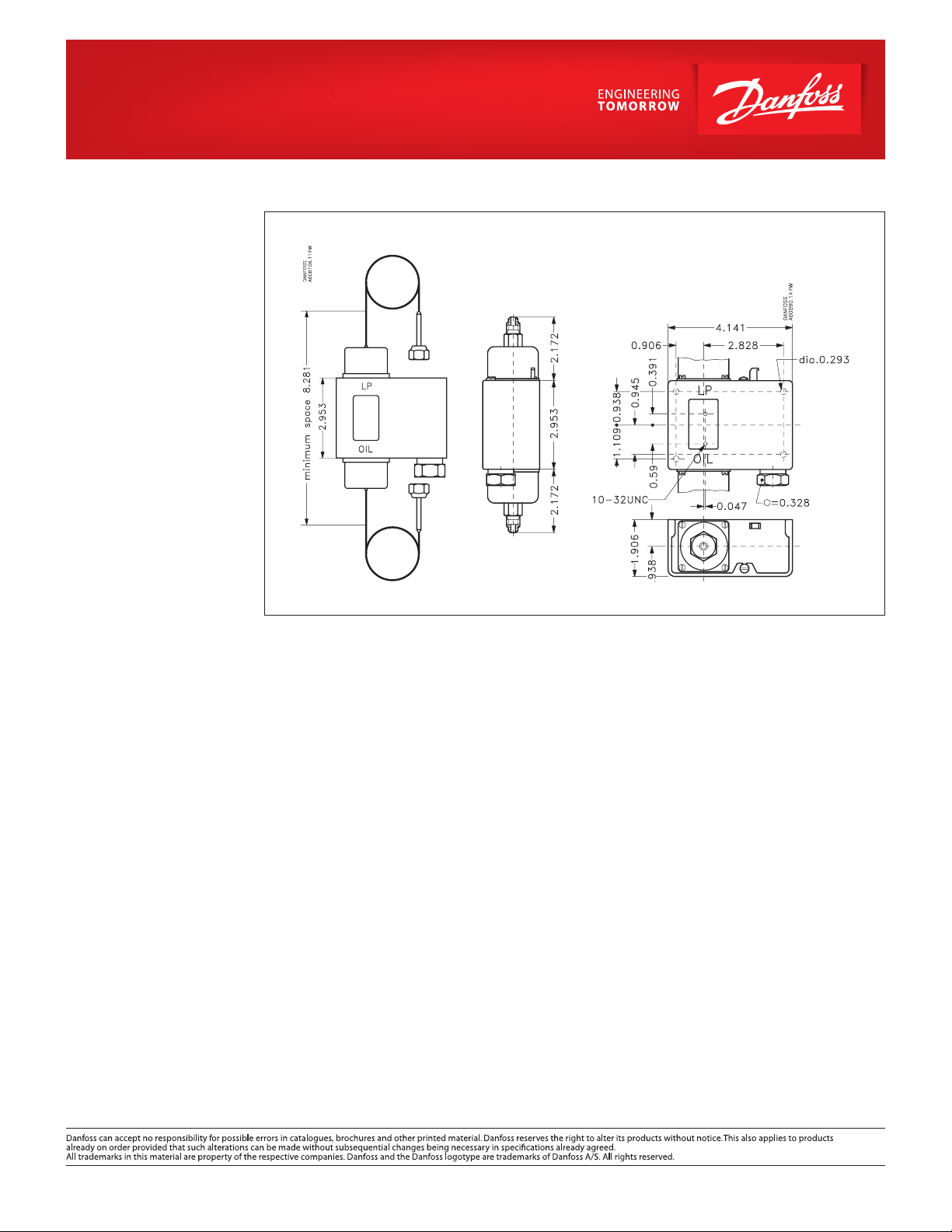

Dimensions [in]

and weights [lb]

MP 54, MP 55

Net weight:

approx. 1.8 lbs

© Danfoss | DCS (jmn) | 2016.11 DKRCC.PD.CG0.C4.22 | 520H11527 | 6

Loading...

Loading...