Page 1

Contents MCD 100 Design Guide

Contents

1.1.1 Introduction 2

1.2 Technical Data

1.3.1 Functional Diagram 4

1.3.4 Wiring 5

1.3.5 Adjustments 5

1.3.7 Dimensions 6

1.3.8 Operating at High Temperatures 7

1.3.10 Mounting Instructions 7

1.4 Application Examples

3

8

MG12A202 - VLT® is a registered trademark 1

Page 2

All about MCD 100 MCD 100 Design Guide

11

1.1.1 Introduction

The MCD 100 soft starters are designed for soft starting

and stopping of 3 phase a.c. motors, thus reducing the

inrush current and eliminating the damaging effects of

high starting torque surges.

The digitally controlled soft starter features accurate

settings and easy installation. The controller has

individually adjustable acceleration and deceleration times.

Thanks to the adjustable initial torque and the unique

breakaway (kick start) function the soft starter can be

optimized for almost any application.

The MCD 100 soft starters are typically used on motor

applications where a smooth stat and/or stop is

advantageous, such as conveyors, fans, pumps,

compressors and high inertia loads. MCD 100 soft starters

are also obvious as replacement for star/delta starters.

Features

1.1.2

Motor load max. 25 A

•

Acceleration times adjustable: 0-10 seconds

•

Deceleration times adjustable: 0-10 seconds

•

Initial torque adjustable up to 85%

•

Breakaway function (kick start)

•

1.1.3

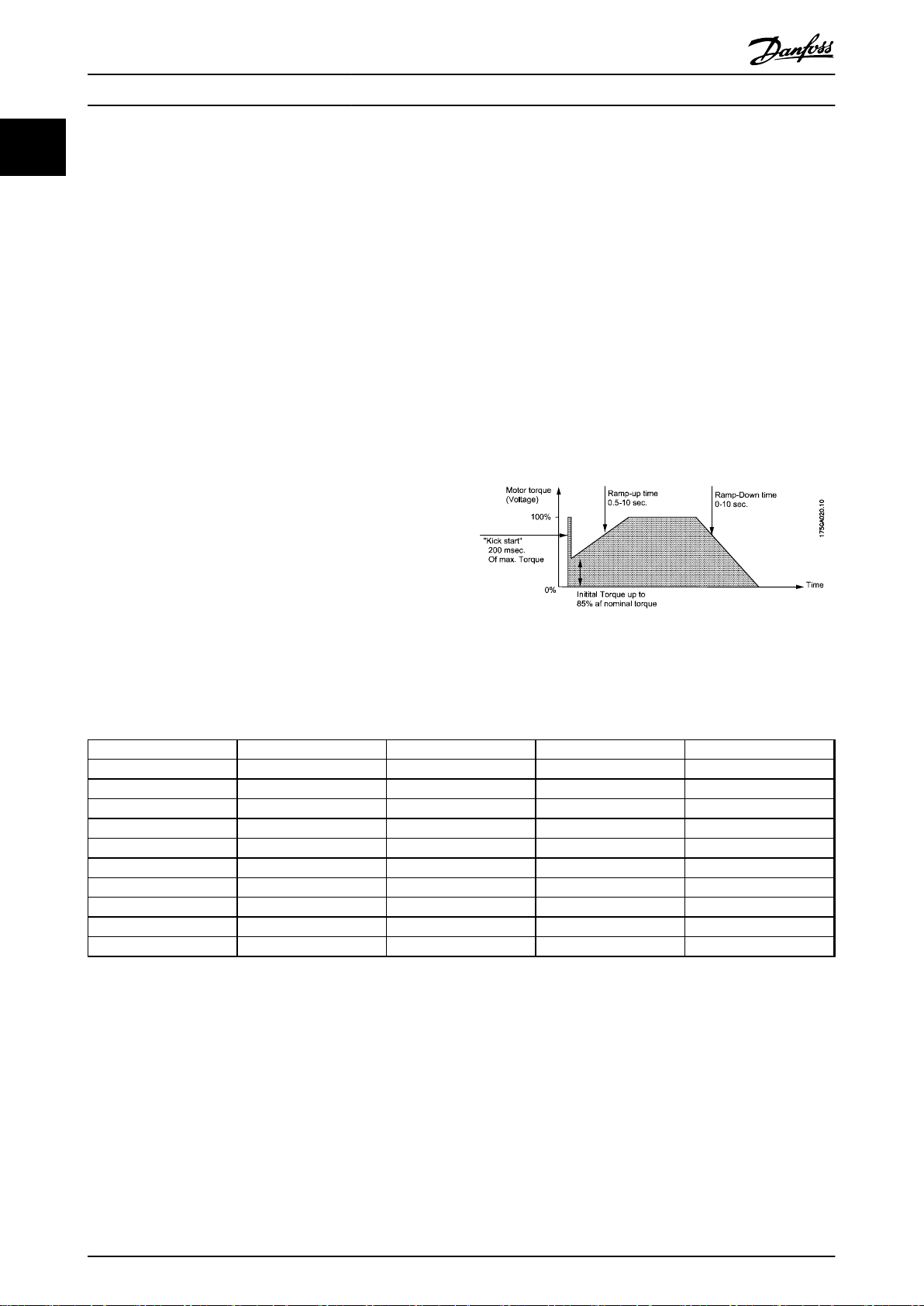

Illustration 1.1

Universal control voltage: 24 - 480 V AC / DC

•

Automatic detection of missing phases

•

Automatic adaptation to 50/60 Hz

•

LED Status indication

•

Unlimited start/stop operations per hour (15A &

•

25A)

Built in varistor protection

•

Compact modular design

•

DIN rail mountable

•

CE (EN 60947-4-2)

•

(UL 508)

CULUS

•

Adjustments

1.1.4 Selection Guide

Type Max. power Max. FLC Voltage DD order code

MCD 100-001 0,75 kW 3 A 208 - 240 V 175G4000

MCD 100-001 1,5 kW 3 A 400 - 415 V 175G4001

MCD 100-001 1,5 kW 3 A 440 - 480 V 175G4002

MCD 100-001 2,2 kW 3 A 550 - 600 V 175G4003

MCD 100-007 4 kW 15 A 208 - 240 V 175G4004

MCD 100-007 7,5 kW 15 A 400 - 480 V 175G4005

MCD 100-007 7,5 kW 15 A 500 - 600 V 175G4006

MCD 100-011 7,5 kW 25 A 208 - 240 V 175G4007

MCD 100-011 11 kW 25 A 400 - 480 V 175G4008

MCD 100-011 15 kW 25 A 500 - 600 V 175G4009

Table 1.1

2 MG12A202 - VLT® is a registered trademark

Page 3

All about MCD 100 MCD 100 Design Guide

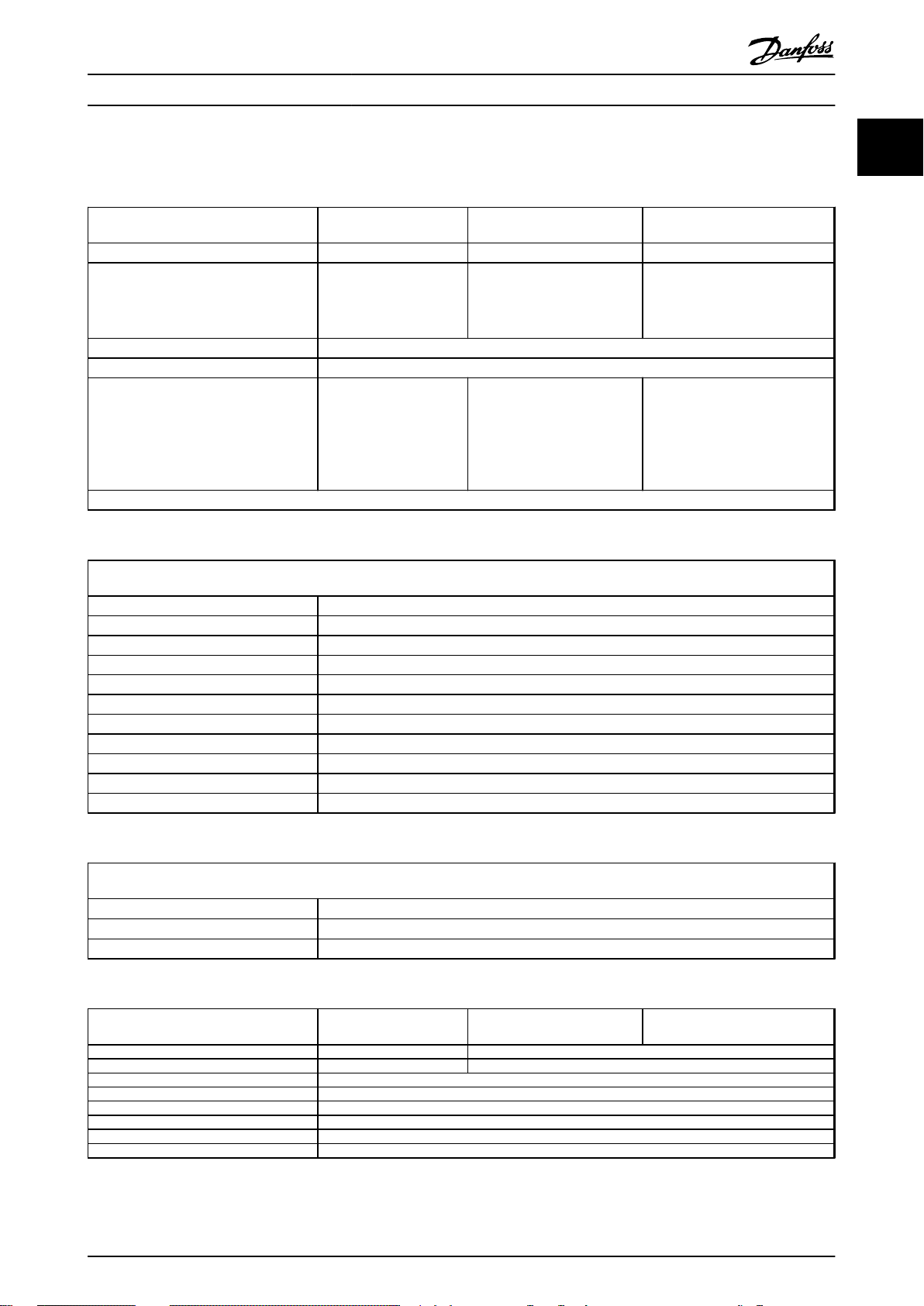

1.2 Technical Data

Output specifications MCD 100 - 001 MCD 100 - 007 MCD 100 - 011

Operational current max. 3A 15A 25A

Motor size at:

208 - 240 V AC 0.1-0.75 kW (0.18-1 HP) 0.1-4.0 kW (0.18-5.5 HP) 0.1-7.5 kW (0.18-10 HP)

400 - 480 V AC 0.1-1.5 kW (0.18-2 HP) 0.1-7.5 kW (0.18-10 HP) 0.1-11 kW (0.18-15 HP)

550 - 600 V AC 0.1-2.2 kW (0.18-3 HP) 0.1-7.5 kW (0.18-10 HP) 0.1-15 kW (0.18-20 HP)

Leakage current max. 5 mA

Min. operational current 50 mA

Ratings:

AC-53a Asynchronous motors - 15A : AC-53a : 8-3 :100 - 3000 25A : AC-53a : 8-3 : 100-3000

AC-53b Asynchronous motors with

bypass

AC-58a Hermetic refrigeration

compressors

Table 1.2

3A : AC-53b : 4-10 : 110 - -

- 15A : AC-58a : 6-6 : 100 - 3000 25A : AC-58a : 6-6 : 100-3000

1 1

Control Circuit Specifications

Control voltage range, 230 V 24-230 V

Control voltage range, 400-600 V 24 - 480 V AC / DC

Pick-Up voltage max. 20.4 V AC / DC

Drop-out voltage min. 5 V AC / DC

Max. control current for no operation 1 mA

Control current / Power max. 15 mA / 2 VA

Response time max. 70 ms

Ramp-up time Adjust. from 0-10 sec.

Ramp-down time Adjust. from 0-10 sec.

Initial torque Adjust from 0-85% of nominal torque with optional, Kick start.

EMC immunity and emission Meets requirements of EN 60947-4-2

Table 1.3

Insulation

Rated insulation Voltage, U

Rated impulse withstand Voltage, U

Installation Category III

Table 1.4

Thermal Specifications

i

imp

660 V AC

4 kV

MCD 100 - 001 MCD 100 - 007 MCD 100 - 011

Power dissipation continuous duty max.: 4W 2W/A

Power dissipation intermittent duty max.: 4W 2W/A x Duty cycle

Ambient temperature range -5° C to 40°C

Cooling method Natural convection

Mounting Vertical +/- 30°

Max. ambient temperature with limited rating

Storage temp. range -20°C to 80°C

Protection degree/pollution degree IP 20 / 3

Table 1.5

60°C, see derating for high temperatures in paragraph Operating at High Temperatures.

MG12A202 - VLT® is a registered trademark 3

Page 4

All about MCD 100 MCD 100 Design Guide

11

Materials

Housing Self extinguishing PPO UL94V1

Heatsink Aluminium black anodized

Base Electroplated steel

Table 1.6

1.3.1 Functional Diagram

Example 1: Example 2:

Soft start and soft stop Soft start with kick start and soft stop

Table 1.7

Functional Description

1.3.2

Ramp up

During ramp-up the controller will gradually increase the

voltage to the motor until it reaches full line voltage. The

motor speed will depend on the actual load on the motor

shaft. A motor with little or no load will reach full speed

before the voltage has reached its maximum value. The

actual ramp time is digitally calculated and will not be

influenced by other settings, net frequency or load

variations.

Initial torque

The initial torque is used to set the initial starting voltage.

This way it is possible to adapt the controller to an

application requiring a higher starting torque. In some

cases the application will need a high break-away torque.

Here, the initial starting torque level can be combined with

a kick start function. The kick start is a period of 200 ms

where the motor receives full voltage.

Soft stop

During ramp-down the controller will gradually reduce the

voltage to the motor thus reducing the torque and

current. As a consequence the motor speed will fade off.

The soft stop feature is advantageous to avoid liquid

hammering and cavitation on pumps, and to avoid goods

tilting on conveyors.

LED Status Indication

1.3.3

LED 1

LED 2

Stand

by

Table 1.8

RampupFull on Ramp down Line on

load error

4 MG12A202 - VLT® is a registered trademark

Page 5

All about MCD 100 MCD 100 Design Guide

1.3.4 Wiring

Illustration 1.2 MCD 100 - 007 / MCD 100 - 011

Adjustments

1.3.5

Fuses and short circuit protection

1.3.6

1 1

MCD 100 provides Timed Voltage Ramp up. This means

that the motor voltage is gradually ramped up to full line

voltage according to the time set by the rotary switch.

To avoid soft starter damage, proper settings of initial

torque level and ramp up time must be considered. It is

important to ensure that the motor is accelerated to full

speed before the soft starter is in full on mode.

Setting the initial torque level:

1. Set ramp up time to max.

2. Set initial torque switch to min.

3. Apply control signal for a few seconds. If the

motor does not rotate immediately increase the

initial torque level with on step and try again.

Repeat until the motor starts to rotate

immediately after control signal is applied.

Setting the ramp up time:

1. Set ramp up time to max.

2. Decrease the ramp up time until mechanical

surge is observed.

3. Increase ramp up time with one step.

In case of short circuits normal fuses can be used to

protect the installation – but not the soft starter. The

following table lists data for the selection of normal fuses.

MCD 100-001 Protection max 25 A gL/gG

MCD 100-007 Protection max 50 A gL/gG

MCD 100-011 Protection max 80 A gL/gG

Table 1.9

Semiconductor fuses may be used with MCD 100 soft start

controllers. Use of semiconductor fuses will protect the

SCR’s in case of short circuits and reduce the potential of

SCR damage due to transient overload currents. When

selecting semiconductor fuses ensure that the fuse has a

lower total clearing I2t rating than the SCR (see data in the

following table), and that the fuse can carry the start

current for the actual start duration.

MCD 100

MCD 100-001 72

MCD 100-007 1800

MCD 100-011 6300

Table 1.10

SCR I2t

(A2s)

MG12A202 - VLT® is a registered trademark 5

Page 6

All about MCD 100 MCD 100 Design Guide

11

1.3.7 Dimensions

Illustration 1.3 MCD 100 - 001

Illustration 1.4 MCD 100 - 007

Illustration 1.5 MCD 100 - 011

6 MG12A202 - VLT® is a registered trademark

Page 7

All about MCD 100 MCD 100 Design Guide

1.3.8 Operating at High Temperatures

Ambient temperature

40°C 3 A 15 A 25 A

50°C 2.5 A* 12.5 A 20 A

60°C 2.0 A* 10 A 17 A

Table 1.11

* Minimum 10 mm side clearance between products

Ambient temperature

40°C 15 A (100 % duty-cycle) 25 A (100 % duty-cycle)

50°C 15 A (80 % duty-cycle) 25 A (80 % duty-cycle)

60°C 15 A (65 % duty-cycle) 25 A (65 % duty-cycle)

Table 1.12

MCD 100 - 001 MCD 100 - 007 MCD 100 - 011

MCD 100 - 007 MCD 100 - 011

Continous current

Duty-cycle rating (15 min. max. on-time)

1.3.9 Over Heat Protection

If required the controller can be protected against

overheating by inserting a thermostat in the slot on the

right-hand side of the controller.

1 1

Order: UP 62 thermostat 037N0050

Depending on the application the thermostat can be

connected in series with the control circuit of the main

contactor. When the temperature of the heat sink exceeds

90° C the main contactor will be switched OFF. A manual

reset is necessary to restart this circuit.

For wiring connections see 1.4 Application Examples.

Illustration 1.6

1.3.10

The controller is designed for vertical mounting. If the

controller is mounted horizontally the load current must

be reduced by 50%.

Mounting Instructions

The controller needs no side clearance.

Clearance between two vertical mounted controllers must

be minimum 80 mm (3.15”).

MG12A202 - VLT® is a registered trademark 7

Page 8

All about MCD 100 MCD 100 Design Guide

11

Clearance between controller and top and bottom walls

must be minimum 30 mm (1.2”).

Illustration 1.7

When the contactor C1 is switched to the OFF-State, the

motor will be switched off instantaneously.

In this application the contactor will have no load during

making operation. The contactor will carry and break the

nominal motor current.

1.4 Application Examples

1.4.1 Overheat protection

Example 1

The thermostat can be connected in series with the control

input of the soft starter. When the temperature of the heat

sink exceedes 90°C the soft starter will be switched OFF.

NOTE

When the temperature has dropped approximately 30°C

the controller will automatically be switched On again. This

is not acceptable in some applications.

Example 2

The thermostat is connected in series with the control

circuit of the main contactor. When the temperature of the

heat sink exceeds 90°C the main contactor will be

switched OFF. This circuit requires manual reset to restart

the motor.

Illustration 1.8

1.4.2 Line Controlled Soft Start

When the contractor C1 is switched to the ON-State, the

soft starter will start the motor, according to the settings

of the Ramp-up time and Initial torque adjustments.

8 MG12A202 - VLT® is a registered trademark

Page 9

All about MCD 100 MCD 100 Design Guide

1 1

Illustration 1.9

Input Controlled Soft Start

1.4.3

When the control voltage is applied to A1 - A2, the MCD

soft starter will start the motor, according to the settings

of the Ramp-up time and Initial torque adjustments.

When the control voltage is switched OFF, the motor will

be soft stopped according to the settings of the Rampdown time adjustments.

To switch off instantaneously set the Ramp-down time to

0.

Illustration 1.10

MG12A202 - VLT® is a registered trademark 9

Loading...

Loading...