Page 1

Data sheet

Heavy duty pressure switch

MBC 5000 and MBC 5100

MBC pressure switches are used in industrial and

marine applications where space and reliability

are the most important features.

MBCs are compact pressure switches, designed

according to our block design to survive in the

harsh conditions known from machine rooms

onboard ships.

MBCs have high vibration resistance and

MBC 5100 features all common marine approvals.

The fixed, but low differential guarantees

accurate monitoring of critical pressures.

MBV test valves can be delivered as standard

option for MBC.

Features

Approvals

Ship approvals,

Type MBC 5100

• Designed for use in severe industrial,

environments,

• High vibration stability

• Part of the Danfoss block system, consisting

of MBC pressure controls, MBS pressure

transmitters and MBV test valves

EN 60947-1

EN 60947-4-1

EN 60947-5-1

Lloyd’s Register, LR

Det Norske Veritas and Germanischer Lloyd, DNV GL

Registro Italiano Navale, RINA

Nippon Kaiji Kyokai, NKK

• MBC 5100 with all major ship approvals,

• High repeatability,

• Optimal compact design for machine

building purposes

• Intended for alarm indication, shut down,

control and diagnostics in many

applications - motors, gears, thrusters,

pumps, filters, compressors etc.

China Compulsory Certificate, CCC

Bureau Veritas, BV

American Bureau of Shipping, ABS

Korean Register of Shipping, KR

Russian Maritime Register of Shipping, RMRS

China Classification Society, CCS

© Danfoss | DCS (rm) | 2019.09

Note: For stainless steel types only DNV GL and BV approvals are available.

IC.PD.P10.4A.02 | 1

Page 2

Data sheet | Heavy duty pressure switch, type MBC 5000 and MBC 5100

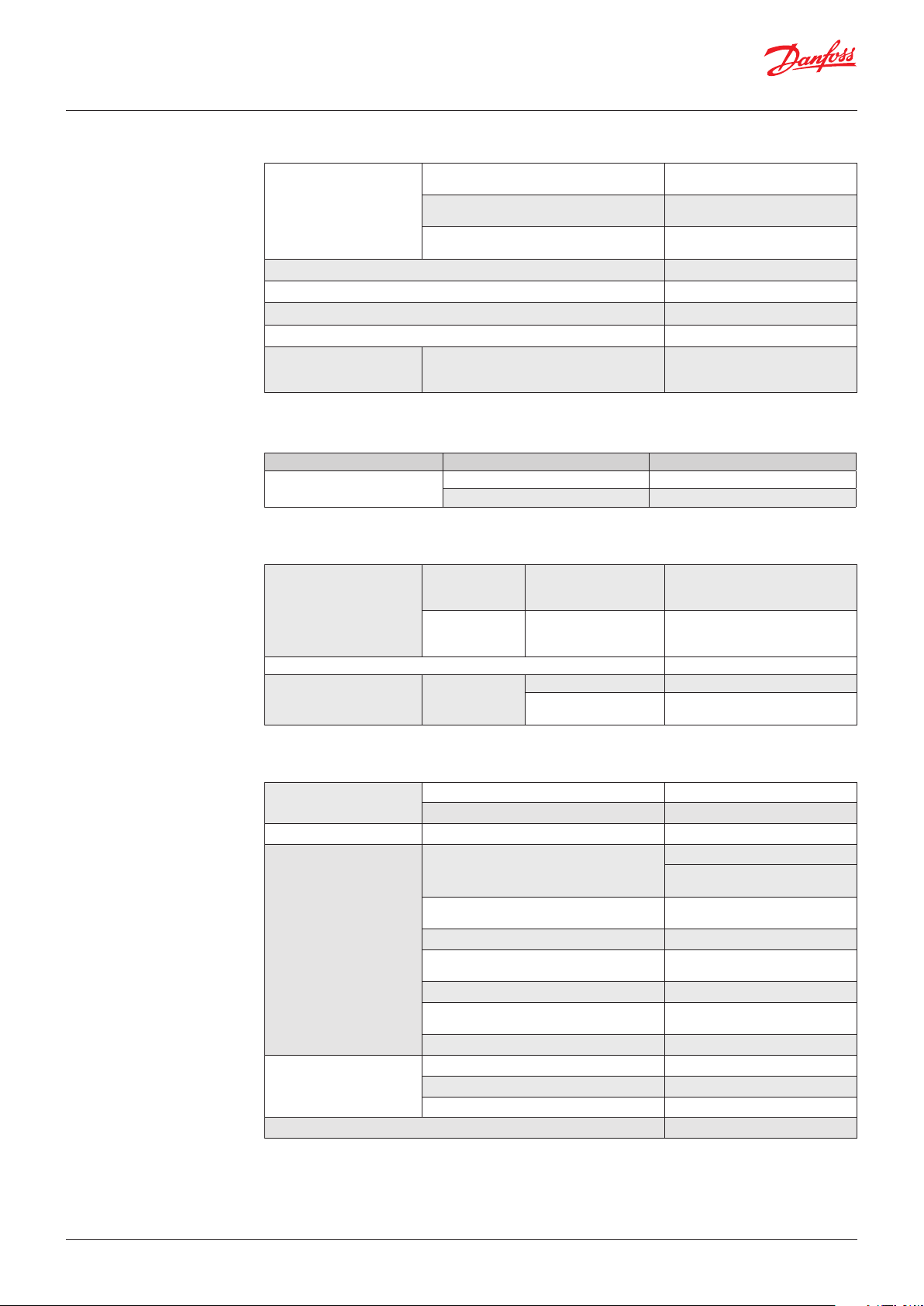

Technical data

Performance

Bellows versions

Repeatability

Max. switch frequency 10/min (0.16 Hz)

Differential See page 4

Permissible operating pressure See page 4

Burst pressure See page 4

Life time

Diaphragm versions

Piston versions

Mechanical for diaphragm and bellows

Mechanical for piston type

Electrical at max. contact load

± 0.2 % FS (typ.)

± 0.5 % FS (max.)

± 0.5 % FS (typ.)

± 1.0 % FS (max.)

± 1.0 % FS (typ.)

± 1.0 % FS (max.)

> 400,000 cycles

>1 million cycles

> 100,000 cycles

Electrical specifications

Switch SPDT

Contact load

AC 15 0.5 A, 250 V

DC 13 12 W, 125 V

Environmental conditions

Operation

Temperature

Transport

Enclosure IP65, EN 60529

Vibration stability Sinusoidal

Bellows versions

Diaphragm versions

Piston versions

Bellows versions

Diaphragm versions

Piston versions

20 g, 25 – 2 kHz EN 60068-2-6

Piston type 4.4 g,

25 – 200 Hz

-40 – 85 °C

-10 – 85 °C

-40 – 85 °C

-50 – 85 °C

-50 – 85 °C

-40 – 85 °C

IEC 60068-2-27

Mechanical characteristics

Pressure connection

Electrical connection Plug DIN 43650, Pg 9 / Pg 11 / Pg 13.5

Wetted parts material

Enclosure material

Net weight 0.25 kg

Standard G ¼ female (ISO 228-1) or flange

Option See specification form, page 4

Anodized AIMgSi1, AW-6082T6

Housing

Bellows

Diaphragm FKM

Piston

O-ring NBR

Hole plug

(flange version)

Seal (piston version) Turcon T05

Housing Anodized AIMgSi1, AW-6082T6

Plug fixture Glass filled polyamid, PA 6.6

Contact system Silver (AG) microprofile

Stainless steel 1.4306 (18/8),

acc. to EN10088-3

Stainless steel 1.4306 (18/8),

acc. to EN10088-2

Stainless steel 1.4028 (3H13),

acc. to EN10088-2

Nickel plated brass or zinc plated

steel

© Danfoss | DCS (rm) | 2019.09

IC.PD.P10.4A.02 | 2

Page 3

Data sheet | Heavy duty pressure switch, type MBC 5000 and MBC 5100

Electrical connection

Out NO

Out NC

Adjustment

Out NO

Out NC

InIn

Danfoss

93Z19.11

Input

Input

Normally closed (NC)

Normally closed (NC)

Normally open (NO)

Normally open (NO)

Connected to enclosure of pressure control

Connected to enclosure

of pressure control

Mechanical connection

Mechanical difference

One full turn (360°) of MBC setting screw is approx. equal to 7% of the setting range

Thread

Flange connection on MBV 5000 Test Valve

Not applicable for piston type

How to choose To achieve the best operating conditions for MBC

pressure controls, it is recommended to apply the

following rules of thumb.

Choose:

• The MBC type/types which meet the demands

for the operating pressure

• The MBC version with the lowest possible

setting range

© Danfoss | DCS (rm) | 2019.09

• A diaphragm type, if pressure peaks and

pulsations occur in the system (if possible)

• Bellows type, if low differential is needed

• Piston type for high pressure

IC.PD.P10.4A.02 | 3

Page 4

Data sheet | Heavy duty pressure switch, type MBC 5000 and MBC 5100

Ordering

standard types

Type:

LP

Low pressure /

HP

High pressure

Setting

range

Pe

[bar]

Diff. at

min.

range 1)

Pe

[bar]

Diff. at

max.

range 1)

Pe

[bar]

Permissible

operating

pressure

Pe

[bar]

Min. burst

pressure

Pe

[bar]

Type

designation

MBC 5000- /

MBC 5100-

MBC 5100

Ship

approved

Code no.

LP bellows -0.20 – 1.00 0.30 0.45 15 30 1011-1DB04 061B000566

LP bellows -0.20 – 4.00 0.30 0.45 15 30 1211-1DB04 061B000466 2)

LP bellows -0.20 – 10.00 0.40 0.60 15 30 1411-1DB04 061B000266 2)

LP bellows -0.20 – 10.00 0.40 0.60 15 30 1411-1CB04 061B000066

LP bellows 0.50 – 3.00 0.25 0.30 15 30 2011-1DB04 061B002966

LP bellows 1.00 – 6.00 0.30 0.45 15 30 2211-1DB04 061B000766

HP bellows 5.00 – 30.00 0.90 2.00 45 90 3421-1DB04 061B000366 2)

LP diaphragm 0.50 – 3.00 0.50 0.80 150 300 2031-1DB04 061B101766

LP diaphragm 1.00 – 6.00 1.00 2.50 150 300 2231-1DB04 061B100966

LP diaphragm 1.00 – 10.00 1.00 2.50 150 300 2431-1DB04 061B100466 2)

LP diaphragm 5.00 – 20.00 1.00 2.50 150 300 3231-1DB04 061B100266 2)

LP diaphragm 5.00 – 25.00 1.00 2.50 150 300 3331-1DB04 061B102466

HP diaphragm 5.00 – 40.00 2.00 7.00 150 300 3641-1DB04 061B100566 2)

HP diaphragm 10.00 – 100.00 4.00 12.00 150 300 4241-1DB04 061B100366 2)

HP piston 16.00 – 160.00 15.00 30.00 600 1200 5251-1CB04 061B510066

HP piston 25.00 – 250.00 20.00 40.00 600 1200 5451-1CB04 061B510166

HP piston 40.00 – 400.00 20.00 50.00 600 1200 5651-1CB04 061B510266

1

)

Max value, all values lower or equal are correct

2

)

Preferred versions

Ordering stainless

steel types

Ordering

customized types

Type:

LP

Low pressure /

HP

High pressure

Setting

range

Pe

[bar]

Diff. at

min.

range 1)

Pe

[bar]

Diff. at

max.

range 1)

Pe

[bar]

Permissible

operating

pressure

Pe

[bar]

Min. burst

pressure

Pe

[bar]

Type

designation

MBC 5000- /

MBC 5100-

MBC 5100

Ship

approved

Code no.

LP bellows -0.20 – 10.00 0.40 0.60 15 30 1411-1DB04S 061B025066

LP bellows -0.20 – 4.00 0.30 0.45 15 30 1211-1DB04S 061B025166

LP bellows -0.20 – 10.00 0.40 0.60 15 30 1411-2DB04S 061B025266

LP bellows -0.20 – 4.00 0.30 0.45 15 30 1211-2DB04S 061B025366

1

)

Max value, all values lower or equal are correct

MBC 5000-

MBC 5100-

Setting range

-0.2 – 1 bar.......................................... 1 0

-0.2 – 4 bar.......................................... 1 2

-0.2 – 10 bar ....................................... 1 4

0.5 – 3 bar ........................................... 2 0

1 – 6 bar .............................................. 2 2

1 – 10 bar ............................................ 2 4

2 – 6 bar .............................................. 2 6

5 – 0 bar .............................................. 3 2

5 – 25 bar ............................................ 3 3

5 – 30 bar ............................................ 3 4

5 – 40 bar ............................................ 3 6

10 – 100 bar ....................................... 4 2

16 – 160 bar ....................................... 5 2

25 – 250 bar ....................................... 5 4

40 – 400 bar ....................................... 5 6

Others .................................................. x x

Type

Low pressure bellows (-0.2 – 10 bar) ....................... 1

High pressure bellows (2 – 30 bar) ........................... 2

Low pressure diaphragm (0.5 – 25 bar) .................. 3

High pressure diaphragm (5 – 100 bar) .................. 4

High pressure piston (40 – 400 bar) ......................... 5

Pressure connection

C A 0 5 .......... M10x1 female

C B 0 4 .......... G ¼ female

D A 0 5 .......... M10x1 female with flange connection

D B 0 4 .......... G ¼ female with flange connection

x x x x .......... Others

Electrical connection

0 .................................................................. No plug (DIN 43650 A)

1 .................................................................. Pg 11 plug (DIN 43650 A)

2 .................................................................. Pg 13.5 plug (DIN 43650 A)

3 .................................................................. Pg 9 plug (DIN 43650 A)

x .................................................................. Others

Microswitch

1 ..................................................................................... 0.5 A, 250 V (AC 15)

12 W, 125 V (DC 13)

x ..................................................................................... Others

......... 6082 (AIMgSi1) version

.......... Stainless steel (1.4306)

S

version

© Danfoss | DCS (rm) | 2019.09

IC.PD.P10.4A.02 | 4

Page 5

Data sheet | Heavy duty pressure switch, type MBC 5000 and MBC 5100

Dimensions [mm]

and weights [kg]

93

Danfoss

93Z05.15

Net weight: 0.25 kg

93

Danfoss

93Z14.18

Net weight: 0.25 kg

© Danfoss | DCS (rm) | 2019.09

IC.PD.P10.4A.02 | 5

Page 6

61B41.10

61B40.10

Accessories

Part Description Code number:

Pulse snubber

Danfoss

61B42.10

Male, G¼A, length 20 mm 061B400166

Pulse snubber

Danfoss

Male, G¼A, length 34 mm 061B400266

Pulse snubber

Danfoss

For flange connection 061B722166

© Danfoss | DCS (rm) | 2019.09

IC.PD.P10.4A.02 | 6

Loading...

Loading...