Data sheet

Pressure switch

KP

The KP pressure switches can be used as safety

switches against too low a suction pressure and / or

too high a discharge pressure in refrigeration and

air conditioning systems. They can also be used

to start / stop compressors and fans for air-cooled

condensers.

They are available in both single and dual versions

and include a single pole double throw (SPDT)

switch.

Features • Ultra-short bounce time thanks to snap-action

function (reduces wear to a minimum and

increases reliability)

• Available with gold-plated contacts

• SPDT switch design

Offers open or close switching action on pressure

rise or fall

• Fail safe double bellows

Prevent refrigerant loss and system

contamination - standard on KP 7 and KP 17

pressure switches

• Convenient manual trip feature

To test electrical contact function

- no tools needed

UL listed for USA and Canada, file E31024Approvals

© Danfoss | DCS (rm) | 2019.09

• Pressure wire connectors

For easy electrical wiring

• No spade or lug terminals required

• Integral 1⁄2 NPSM swivel cable connector

Allows direct attachment of 1⁄2 in

male pipe thread connector

• Lockplate

Prevents tampering with range

and differential settings

• Universal mounting hole patterns

DKRCC.PD.CD0.1E.22 | 1

Data sheet | Pressure switch, type KP

Technical data

Ambient temperature -40 – 149 °F (175 °F for maximum 2 hours)

Maximum working pressure

Maximum test pressure

Switch Single pole changeover switch (SPDT)

Contact load

Terminal D, dual switches 240 V, 50 VA

Cable entry

Integral 1⁄2 in female NPSM swivel cable connector

allows direct attachment of 1⁄2 in

male pipe thread connector.

LP: MWP = 245 psig

HP: MWP = 465 psig

LP: pe = 285 psig

HP: pe = 510 psig

120 V AC: 16 FLA, 96 LRA

240 V AC: 8 FLA, 48 LRA

240 V DC: 12 W pilot duty

Enclosure

~NEMA 1

This grade of enclosure is obtained when the units

without top cover are mounted on a flat surface or

bracket. The bracket must be fixed

to the unit so that all unused holes are covered.

~ NEMA 2

This grade of enclosure is obtained when the units

with top cover are mounted on a flat surface or

bracket. The bracket must be fixed to the unit so

that all unused holes are covered.

Materials in contact with the medium

Control type Material

KP 1, KP 2, KP 5, KP 7,

KP 15, KP 17, KP 25

KP with cap. tube Copper SF-Cu, no. 2.0090 to DIN 1787

Tin bronze, no. CW452K, EN 1652

Nickel plated free cutting steel, no. 1.0737 / 1.0718 to EN 10277

© Danfoss | DCS (rm) | 2019.09

DKRCC.PD.CD0.1E.22 | 2

Data sheet | Pressure switch, type KP

A60-1032.10

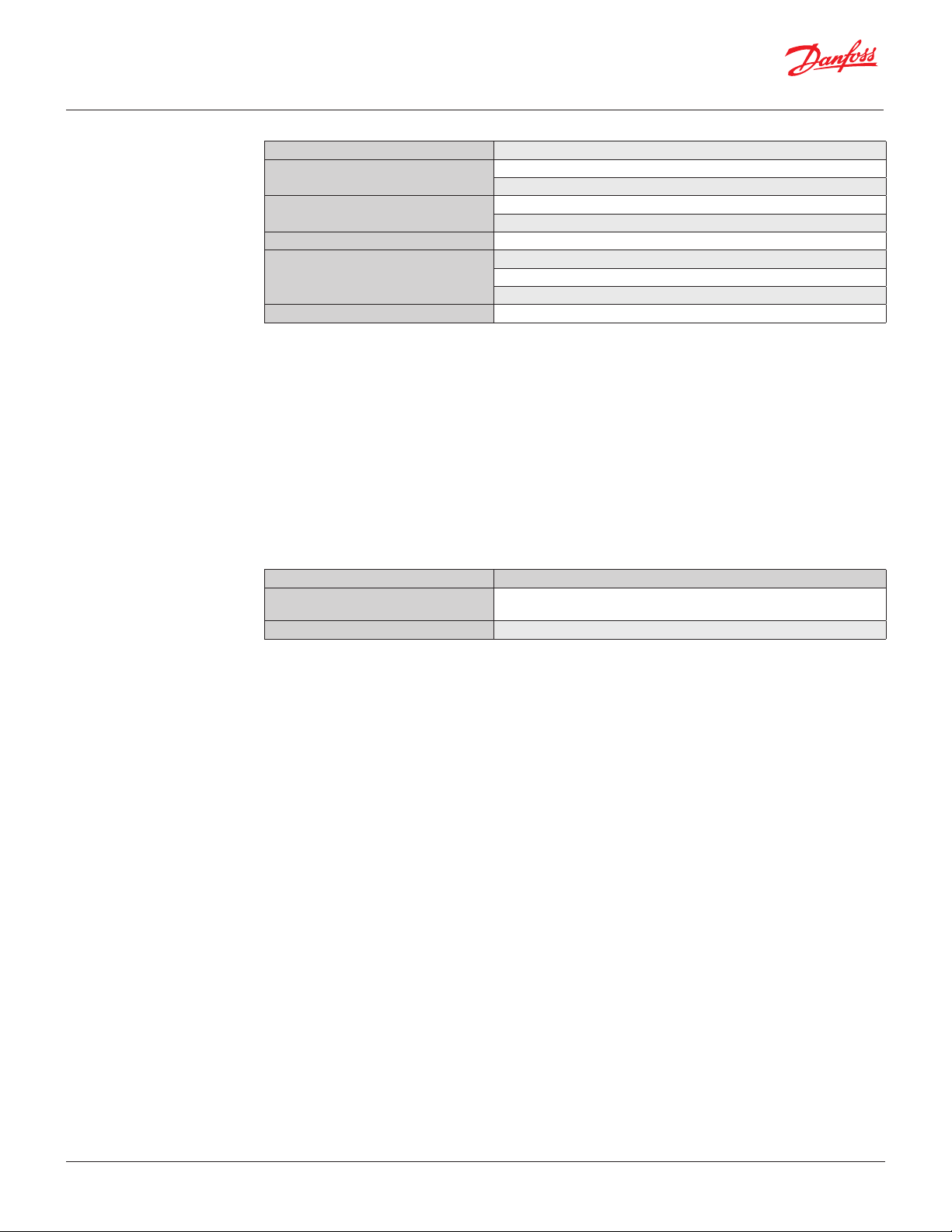

Technical data Electrical wiring

Low or high pressure

SPDT - signal pole double throw

Pressure / Temperature

Rise

Load

Cut-in

(te rm.1- 4)

Load

or or

Cut-out

(te rm.1-2)

421 421

Load

Cut-out

(te rm.1- 4)

Danfoss

Drop

Load

Cut-in

(te rm.1-2)

Load

Signal option

Line

Dual (low and high) pressure,

LP signal

LP - signal option

Load

Line

Dual (low and high) pressure,

LP and HP signal

LP - signal option

Load

A2115

A2113

Line

Wring instruction

Line

Low pressure, LP: KP 1 and KP 2 High pressure, HP: KP 5, KP 7W and KP 7B

Dual (low and high) pressure:

KP 15, KP 17W, KP 17B and KP 25

Dual (low and high) pressure:

KP 15, KP 17W, KP 17B and KP 25

HP - signal option

Bellows movement

on pressure rise

Bellows movement

on pressure drop

© Danfoss | DCS (rm) | 2019.09

Metric conversions

1 psi = 0.07 bar

5

⁄9 (t1 °F - 32) = t2 °C

DKRCC.PD.CD0.1E.22 | 3

Data sheet | Pressure switch, type KP

Ordering

For R22, R134a, R404A, R407A, R407C, R407F, R422B, R422D, R448A, R449A, R450A, R452A, R507A, R513A

For complete list of approved refrigerants, visit www.products.danfoss.com and search for individual code numbers, where refrigerants are

listed as part of technical data.

Low pressure (LP) High pressure (HP) Reset

Typ e Pressure

Regulating

range

[inHg]

[psig]

Differential

∆p

Regulating

range

Differential

∆p

Low

pressure

[psi] [psig] [psi] [LP] [HP]

High

pressure

Contact functio

KP 1 Low 6 in – 108 10 – 58 – – Auto – SPDT 06 0-200191 –

KP 1 Low 6 in – 108 10 – 58 – – Auto –

SPDT

KP 1 Low 27 in – 100 10 – – Man. (Min.) – SPDT – 060-205291 1)

KP 2 Low 6 in – 50 6 – 32 – – Auto –

KP 2 Low 6 in – 50 6 – 32 – – Auto –

SPDT

SPDT

06 0-20136 6 –

KP 5 High – – 115 – 465 25 – 85 – Auto SPDT 060 -201491 –

KP 5 High – – 115 – 465 25 – 85 – Auto

KP 7W 2) High – – 115 – 465 58 – 140 – Auto

KP 7W 2) High – – 115 – 465 58 – 140 – Auto

KP7B 2) High – – 115 – 465 58 – Man. (Max.)

KP7B 2) High – – 115 – 465 58 – Man. (Max.)

SPDT

SPDT

SPDT

SPDT

SPDT

060-20 0391 –

060-20 0491 –

KP 15 Dual 6 in – 108 10 – 58 115 – 465 58 Auto Auto SPDT/w. L P signal 060-200891 –

KP 15 Dual 6 in – 108 10 – 58 115 – 465 58 Auto Auto SPDT/w. L P signal – 060-205891

KP 15 Dual 6 in – 108 10 – 58 115 – 465 58 Auto Man. (Max.) SPDT/w. L P signal – 060-205991

KP 15 Dual 6 in – 108 10 – 58 115 – 465 58 Man. (Min.) Man. (Max.) SPDT/w. L P signal – 060-206091

KP 15 Dual 6 in – 108 10 – 58 115 – 465 58 Auto Auto

KP 15 Dual 6 in – 108 10 – 58 115 – 465 58 Auto Man. (Max.)

KP 17 W 2) Dual 6 in – 108 10 – 58 115 – 465 58 Auto Auto

1

) With dial knob

2

) With fail safe double bellows

SPDT/w. LP + HP

signal

SPDT/w. LP + HP

signal

SPDT/w. LP + HP

signal

060-202691 –

Code no.

connection

1

⁄4 in flare

Cap. tube

flare nut 36 in

– 060-205191

– 060-206391

– 060-206491

– 060-205391

– 060-205491

– 06 0-203191

– 060 -202991

w. 1⁄4 in

Metric conversions

1 psi = 0.07 bar

5

⁄9 (t1 °F - 32) = t2 °C

© Danfoss | DCS (rm) | 2019.09

DKRCC.PD.CD0.1E.22 | 4

Data sheet | Pressure switch, type KP

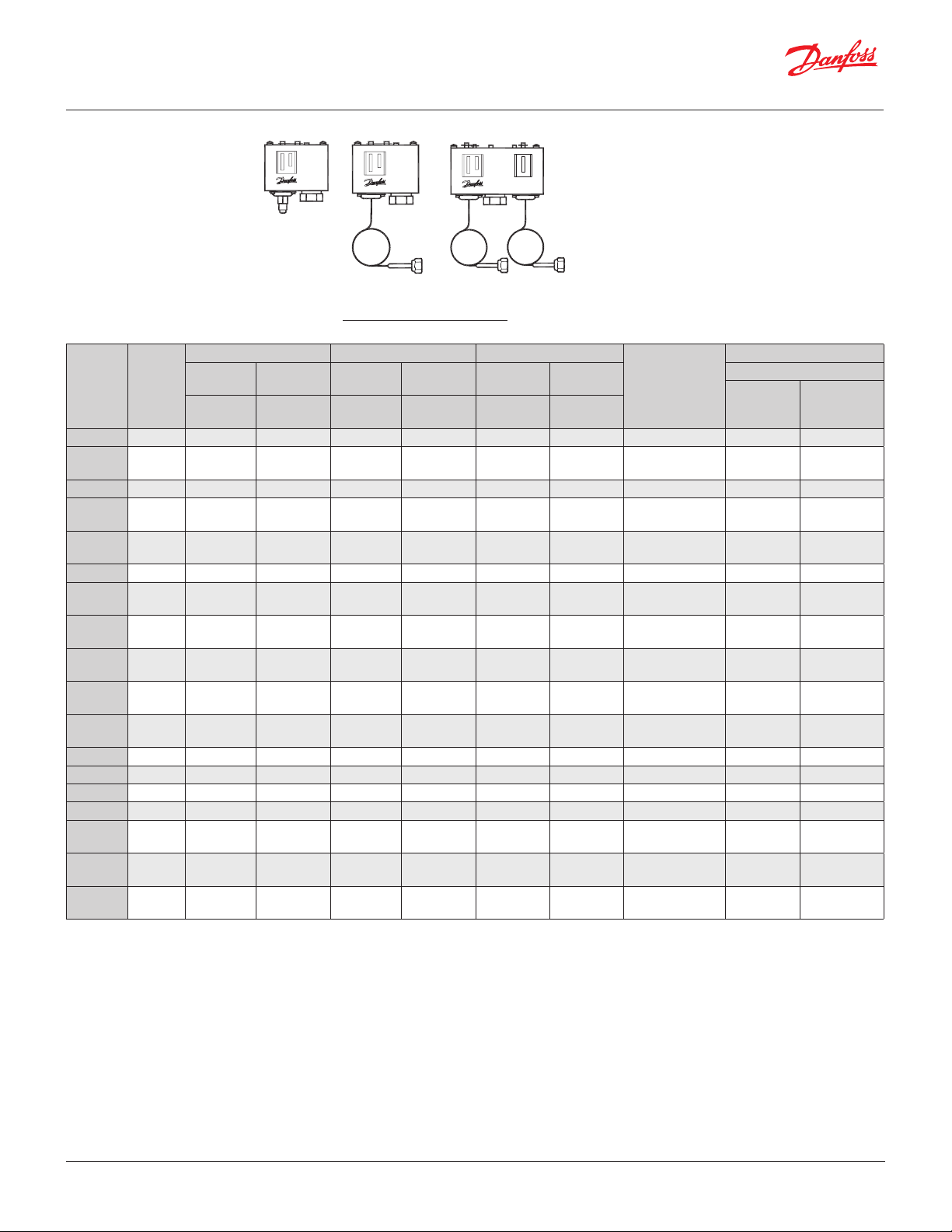

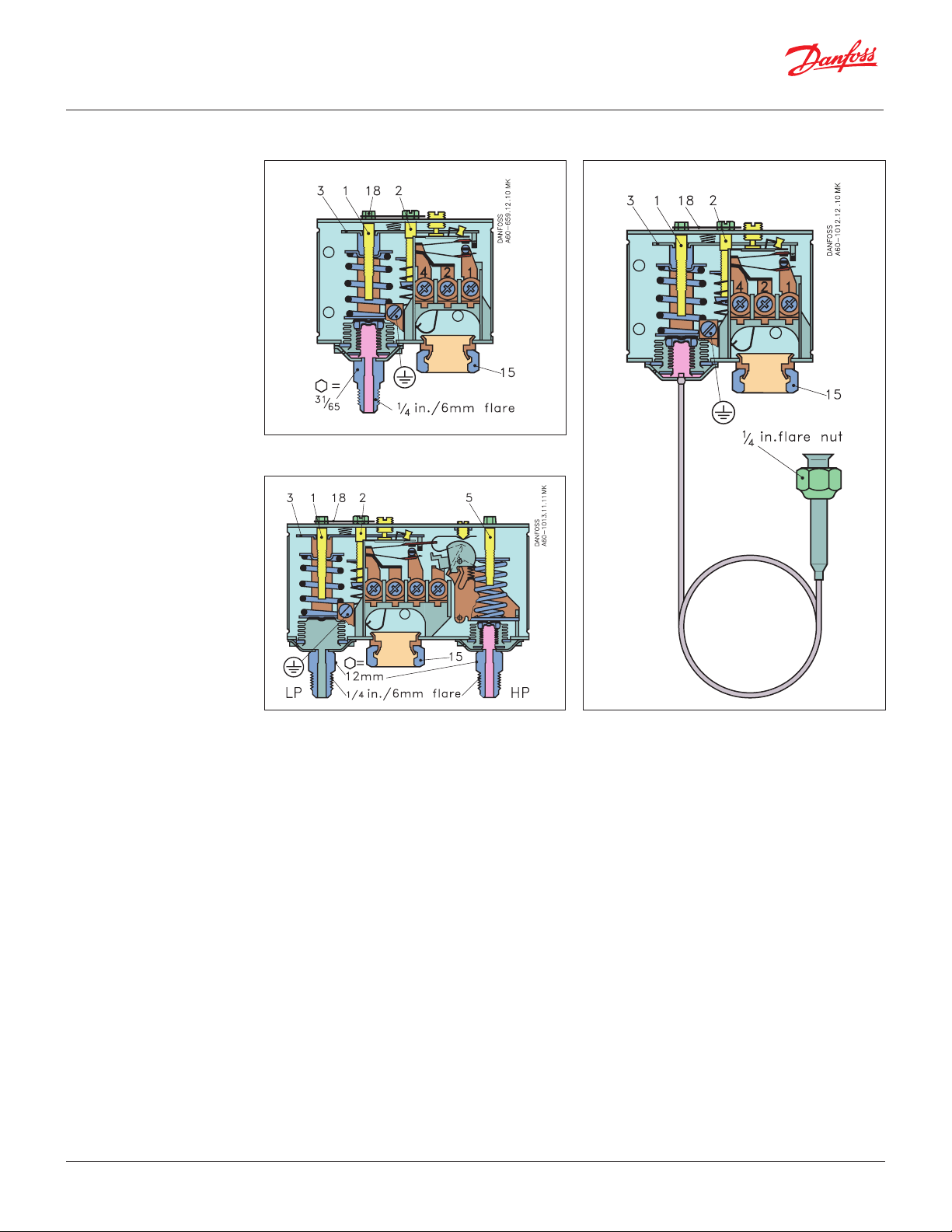

Design

1. Low pressure setting

spindle, (LP)

2. Differential setting

spindle

3. Main arm

5. High pressure setting

spindle, (HP)

7. Main spring

8. Differential spring

9. Bellows

10. LP connection

11. HP connection

12. Switch

13. Terminals

14. Earth terminal

15. Cable entry

16. Tumbler

18. Locking plate

19. Arm

30. Reset button

Pressure switch, type KP

FW

KP 1, KP 2, KP 5

KP 15, KP 25 flare KP 1, KP 2, KP 5, KP 15, KP 25, KP 7W,

KP 7B, KP 17W, capillary tube

FW

FW

© Danfoss | DCS (rm) | 2019.09

The switch in the KP has a snap-action

function where the bellows move only when

the cut-in or cut-out value is reached.

The bellows are connected to the low

or high pressure side of the system through

connection (10) or (11).

The design of the KP gives the following

advantages:

− high contact load

− ultra-short bounce time

− high resistance to pulsation

− vibration resistance up to 4 g in

the range 0 – 1000 Hz

− long mechanical and electrical life

DKRCC.PD.CD0.1E.22 | 5

Data sheet | Pressure switch, type KP

Design

(continued)

1. Pressure setting

spindle, (LP)

2.Differential setting spindle

3. Main arm

5. Pressure setting

spindle, (HP)

15.Cable entry

18.Locking plate

KP 7W (KP 7B), flare

KP 17W (KP 17B), flare

KP 7W (KP 7B), capillary tube

© Danfoss | DCS (rm) | 2019.09

The KP with designations W or B have been tested

and approved by TÜV (Germany) in accordance

with EN 12263.

Versions with designation W will cut in

automatically when the pressure has fallen

to the setpoint minus the differential.

Versions with designation B can be cut in

manually using the external reset button when:

KP 1 – the pressure has increased

to 10 psi above the setpoint.

KP 7 – the pressure has fallen 58 psi

below the setpoint.

KP 7 and KP 17 are equipped with fail-safe double

bellows; a regulation bellows and an outer bellows.

The double bellows system protects against loss of

system charge in the event of a bellows rupture.

A rupture in the outer bellows will cause the

control to trip approximately 43 psi lower than the

actual control setting. This features provides a

warning without a loss of charge.

All KP pressure switches, including those which are

PED-approved, operate independently of changes

in the ambient temperature around the control

housing. Therefore the set cut-out pressure and

differential are kept constant provided the

permissible ambient temperatures are not

exceeded.

DKRCC.PD.CD0.1E.22 | 6

Data sheet | Pressure switch, type KP

Terminology

Setting Pressure switches with automatic reset – LP:

Metric conversions

1 psi = 0.07 bar

Reset

1. Manual reset:

Units with manual reset can only

be reset during operation by activation

of the reset button.

2. Automatic reset:

After operational stop, these units reset

automatically.

Maximum working pressure

The Maximum working pressure is determined by

the pressure that can be safely allowed

in the refrigerating system or any of the units

within it. The maximum working pressure is

designated MWP.

Test pressure

The test pressure is the pressure used

in strength tests and / or leakage tests on

refrigerating systems or individual parts in systems.

The test pressure is designated Pe.

Set the LP start pressure on the “CUT-IN” scale

(range scale). One rotation of the low pressure

spindle ~10 psi. Set the LP differential on the “DIFF”

scale. One rotation of the differential spindle ~ 3

psi. The LP cut-out pressure is the LP cut-in pressure

minus the differential.

Note:

The LP cut-out pressure must be above

absolute vacuum pe = 30 in Hg.

If compressor will not stop at low cut-out pressure,

check whether the differential value is set at too

high a value!

“Snap function”

A certain contact force is maintained until

irrevocable “snap” is initiated. The time during

which the contact force approaches zero is thus

limited to a very few milliseconds. Therefore

contact bounce cannot occur as a result of, for

example, slight vibrations, before the cut-out point.

Contact systems with “Snap function” will change

over even when micro-welds are created between

the contacts during cut-in. A very high force is

created during cut-out to separate the contacts.

This force immediately shears off all the welds.

Thus the cut-out point of the unit remains very

accurate and completely independent of the

magnitude of the current load.

Pressure switches with automatic reset – HP:

Set the HP cut-out pressure on the “CUT-OUT”

scale. One rotation of the HP spindle ~ 33 psi.

Set the HP differential on the “DIFF” scale.

One rotation of the differential spindle ~ 4 psi. The

HP cut-in pressure is the HP cut-out pressure minus

the differential. Pressure switches with manual

reset. Set the cut-out pressure on “CUT-OUT” scale

(range scale). Low pressure controls can be

manually reset when the pressure is equal to the

cut-out pressure plus the differential.

High pressure switches can be manually reset when

the pressure is equal to the cut-out pressure minus

the differential.

Cut-in and cut-out pressures for both the LP and HP

sides of the system should always be checked with

an accurate pressure gauge.

© Danfoss | DCS (rm) | 2019.09

DKRCC.PD.CD0.1E.22 | 7

60-950.13

60-991.14

Data sheet | Pressure switch, type KP

Dimensions [in]

and weight [lb]

Flare connection

Danfoss

60-760.13

KP 1, KP 2 and KP 5 KP 15 and KP 25

Danfoss

60-1014.12

Danfoss

60-908.11

Danfoss

60-1015.14

Net weight:

KP 1, KP 2, KP 5 and KP 7:

approx. 0.7 lbs.

KP 15, KP 17 and KP 25:

approx. 1.1lbs.

Metric conversions

1 in = 25.5 mm

1 lb = 0.454 kg

KP 7W and KP 7B KP 17W and KP 17B

Capillary tube connection

Danfoss

KP 1, KP 2, KP 5, KP 7W and KP 7B

KP 15, KP 17W, KP 17B and KP 25

Danfoss

© Danfoss | DCS (rm) | 2019.09

DKRCC.PD.CD0.1E.22 | 8

60-1011.13

Danfoss

60-1011.13

Dimensions [in]

KP single switches, rear side

KP dual switches, rear side

Danfoss

60-1023.14

Danfoss

60-1024.14

© Danfoss | DCS (rm) | 2019.09

Wall bracket Angle bracket

Danfoss

DKRCC.PD.CD0.1E.22 | 9

Loading...

Loading...