Page 1

MAKING MODERN LIVING POSSIBLE

Quick Guide

VLT® Micro Drive FC 51

Page 2

Page 3

Contents

Contents

VLT® Micro Drive FC 51 Quick Guide

1 Quick Guide

1.1 Safety

1.1.1 Safety Instructions 3

1.2 Introduction

1.2.1 Available Literature 3

1.2.2 IT Mains 3

1.2.3 Avoid Unintended Start 3

1.3 Installation

1.3.2 Side-by-Side Installation 4

1.3.3 Mechanical Dimensions 5

1.3.4 Connecting to Mains and Motor 7

1.3.5 Control Terminals 7

1.3.6 Power Circuit - Overview 8

1.3.7 Load Sharing/Brake 9

1.4 Programming

1.4.1 Programming on Automatic Motor Adaptation ( AMA) 9

1.4.2 Programming on Automatic Motor Tuning (AMT) 10

2

2

3

4

9

1.5 Parameter Overview

1.6 Troubleshooting

1.6.1 Warnings and Alarms 15

1.7 Specifications

1.8 General Technical Data

1.9 Special Conditions

1.9.1 Derating for Ambient Temperature 21

1.9.2 Derating for Low Air Pressure 21

1.9.3 Derating for Running at Low Speeds 21

1.10 Options

Index

11

15

16

18

21

22

23

MG02B902 - Rev. 2013-11-19 1

Page 4

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

11

1 Quick Guide

1.1 Safety

WARNING

HIGH VOLTAGE

Frequency

connected to AC mains input power. Failure to perform

installation, start-up, and maintenance by qualified

personnel could result in death or serious injury.

converters contain high voltage when

Installation, start-up, and maintenance must be

•

performed by qualified personnel only.

WARNING

UNINTENDED START

the frequency converter is connected to AC mains,

When

the motor may start at any time, causing risk of death,

serious injury, equipment, or property damage. The

motor can start by means of an external switch, a serial

bus command, an input reference signal from the LCP or

LOP, or after a cleared fault condition.

1. Disconnect the frequency converter from mains

whenever personal safety considerations make

it necessary to avoid unintended motor start.

2. Press [Off/Reset] on the LCP, before

programming parameters.

3. The frequency converter, motor, and any driven

equipment must be in operational readiness

when the frequency converter is connected to

AC mains.

WARNING

DISCHARGE TIME

frequency converter contains DC-link capacitors,

The

which can remain charged even when the frequency

converter is not powered. Failure to wait the specified

time after power has been removed before performing

service or repair work, could result in death or serious

injury.

1. Stop motor.

2. Disconnect AC mains, permanent magnet type

motors, and remote DC-link power supplies,

including battery back-ups, UPS, and DC-link

connections to other frequency converters.

3. Wait for the capacitors to discharge fully, before

performing any service or repair work. The

duration of waiting time is specified in

Table 1.1.

Leakage

Follow national and local codes regarding protective

earthing of equipment with a leakage current > 3,5 mA.

frequency converter technology implies high frequency

switching at high power. This generates a leakage current

in the ground connection. A fault current in the frequency

converter at the output power terminals might contain a

DC component which can charge the filter capacitors and

cause a transient ground current. The earth leakage

current depends on various system configurations

including RFI filtering, screened motor cables, and

frequency converter power.

EN/IEC61800-5-1 (Power Drive System Product Standard)

requires special care if the leakage current exceeds 3,5 mA.

Earth grounding must be reinforced in one of the

following ways:

See EN 60364-5-54 § 543.7 for further information.

Using RCDs

Where residual current devices (RCDs), also known as earth

leakage circuit breakers (ELCBs), are used, comply with the

following:

Motor Thermal Protection

Motor overload protection is possible by setting parameter

1-90 Motor Thermal Protection to [4] ETR trip. For the North

American market: Implemented ETR function provide class

20 motor overload protection, in accordance with NEC.

Installation at High Altitudes

For altitudes above 2.000 m, contact Danfoss regarding

PELV.

Size Minimum waiting time [min]

M1, M2 and M3 4

M4 and M5 15

Table 1.1 Discharge Time

Current (>3.5 mA)

Earth ground wire of at least 10 mm2.

•

Two separate ground wires both complying with

•

the dimensioning rules.

1. Use RCDs of type B only which are capable of

detecting AC and DC currents.

2. Use RCDs with an inrush delay to prevent faults

due to transient earth currents.

3. Dimension RCDs according to the system configuration and environmental considerations.

2 MG02B902 - Rev. 2013-11-19

Page 5

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

1.1.1 Safety Instructions

sure the frequency converter is properly

Make

•

connected to earth.

Do not remove mains connections, motor

•

connections or other power connections while

the frequency converter is connected to power.

Protect users against supply voltage.

•

Protect the motor against overloading according

•

to national and local regulations.

The earth leakage current exceeds 3.5 mA.

•

The [Off/Reset] key is not a safety switch. It does

•

not disconnect the frequency converter from

mains.

1.2 Introduction

1.2.1 Available Literature

NOTICE

This quick guide contains the basic information

necessary

converter.

for installing and running the frequency

Table 1.3 Approvals

The

frequency converter complies with UL508C thermal

memory retention requirements. For more information,

refer to the section Motor Thermal Protection in the Design

Guide.

1.2.2 IT Mains

NOTICE

IT Mains

Installation

Max. supply voltage allowed when connected to mains:

440 V.

As an option, Danfoss offers recommended line filters for

improved

1.2.3 Avoid Unintended Start

on isolated mains source, i.e. IT mains.

harmonics performance.

1 1

If more information is needed, the literature below can be

downloaded

www.danfoss.com/BusinessAreas/DrivesSolutions/Documentations

VLT Micro Drive FC 51 Design Guide MG02K

VLT Micro Drive FC 51 Quick Guide MG02B

VLT Micro Drive FC 51 Programming Guide MG02C

VLT Micro Drive FC 51 LCP Mounting Instruction MI02A

VLT Micro Drive FC 51 De-coupling Plate Mounting

Instruction

VLT Micro Drive FC 51 Remote Mounting Kit

Mounting

VLT Micro Drive FC 51 DIN Rail Kit Mounting

Instruction

VLT Micro Drive FC 51 IP21 Kit Mounting

Instruction

VLT Micro Drive FC 51 Nema1 Kit Mounting

Instruction

Line Filter MCC 107 Installation Instruction MI02U

Table 1.2 Available Literature

from:

Title Literature

no.

MI02B

MI02C

Instruction

MI02D

MI02E

MI02F

While the frequency converter is connected to mains, the

motor

can be started/stopped using digital commands, bus

commands, references or via the LCP or LOP.

Disconnect the frequency converter from mains

•

whenever personal safety considerations make it

necessary to avoid unintended start of any

motors.

To avoid unintended start, always press [Off/

•

Reset] before changing parameters.

Equipment containing electrical components

not be disposed of together with domestic

must

waste.

It must be separately collected with electrical

and electronic waste according to local and

currently valid legislation.

MG02B902 - Rev. 2013-11-19 3

Page 6

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

11

1.3 Installation

1.3.1 Before Commencing Repair Work

1. Disconnect the FC 51 from mains (and external

supply, if present.)

DC

2. Wait for 4 min (M1, M2 and M3) and 15 min (M4

and M5) for discharge of the DC-link. See

Table 1.1.

3. Disconnect DC bus terminals and brake terminals

(if present).

4. Remove motor cable.

1.3.2 Side-by-Side Installation

The frequency converter can be mounted side-by-side for

IP20 rating units and requires 100 mm clearance above

and below for cooling. Refer to chapter 1.7 Specifications

for details on environmental ratings of the frequency

converter.

4 MG02B902 - Rev. 2013-11-19

Page 7

B

a A

a A

a A

a A

a A

C

C

C C C

b

B

b

B

b

B

b

B

b

Ø 7mm

M5

M4

M3

M2

M1

Ø 7mm Ø 5.5mm Ø 4.5mm

130BB321.11

Ø 4.5mm

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

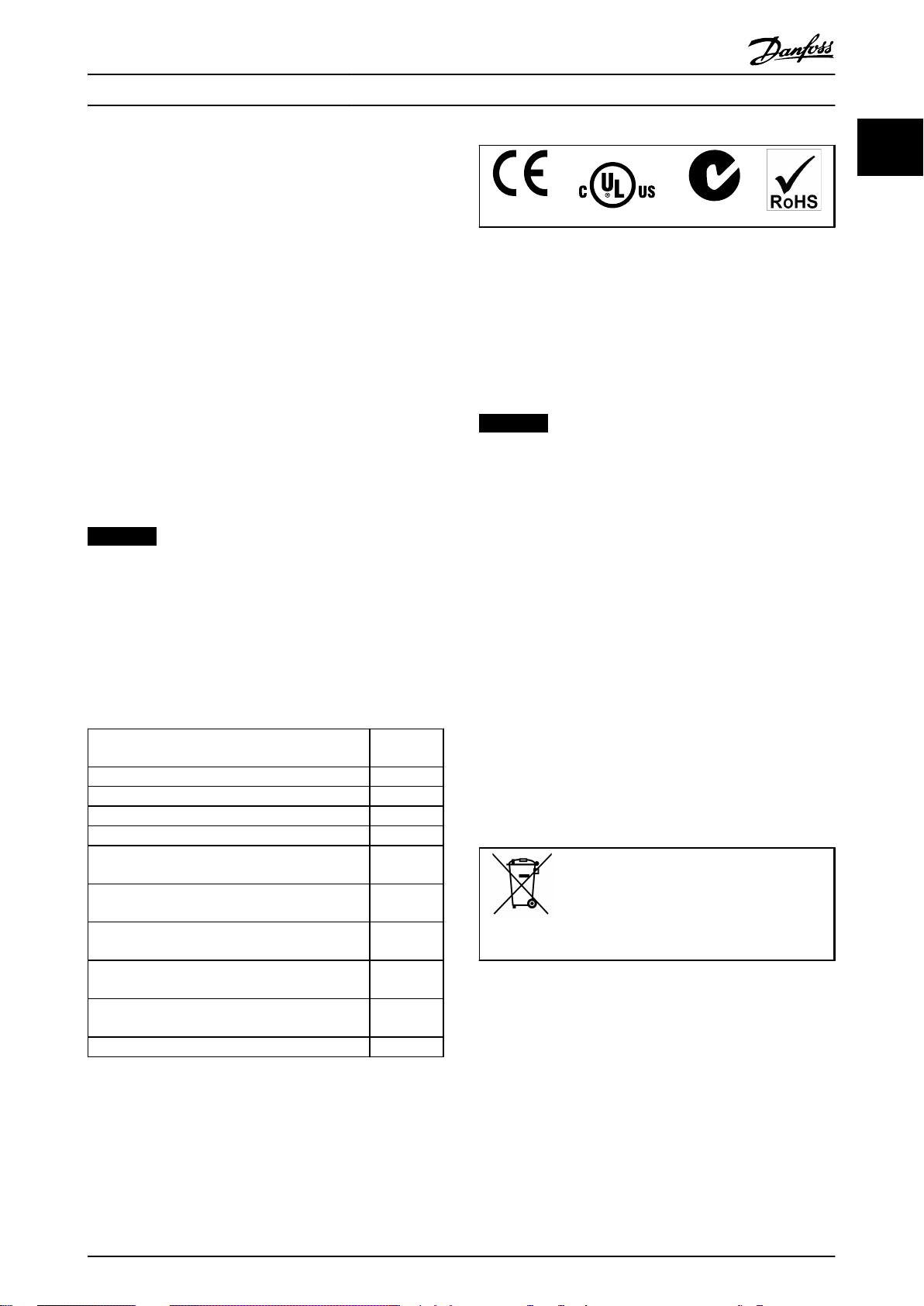

1.3.3 Mechanical Dimensions

A template for drilling can be found on the flap of the packaging.

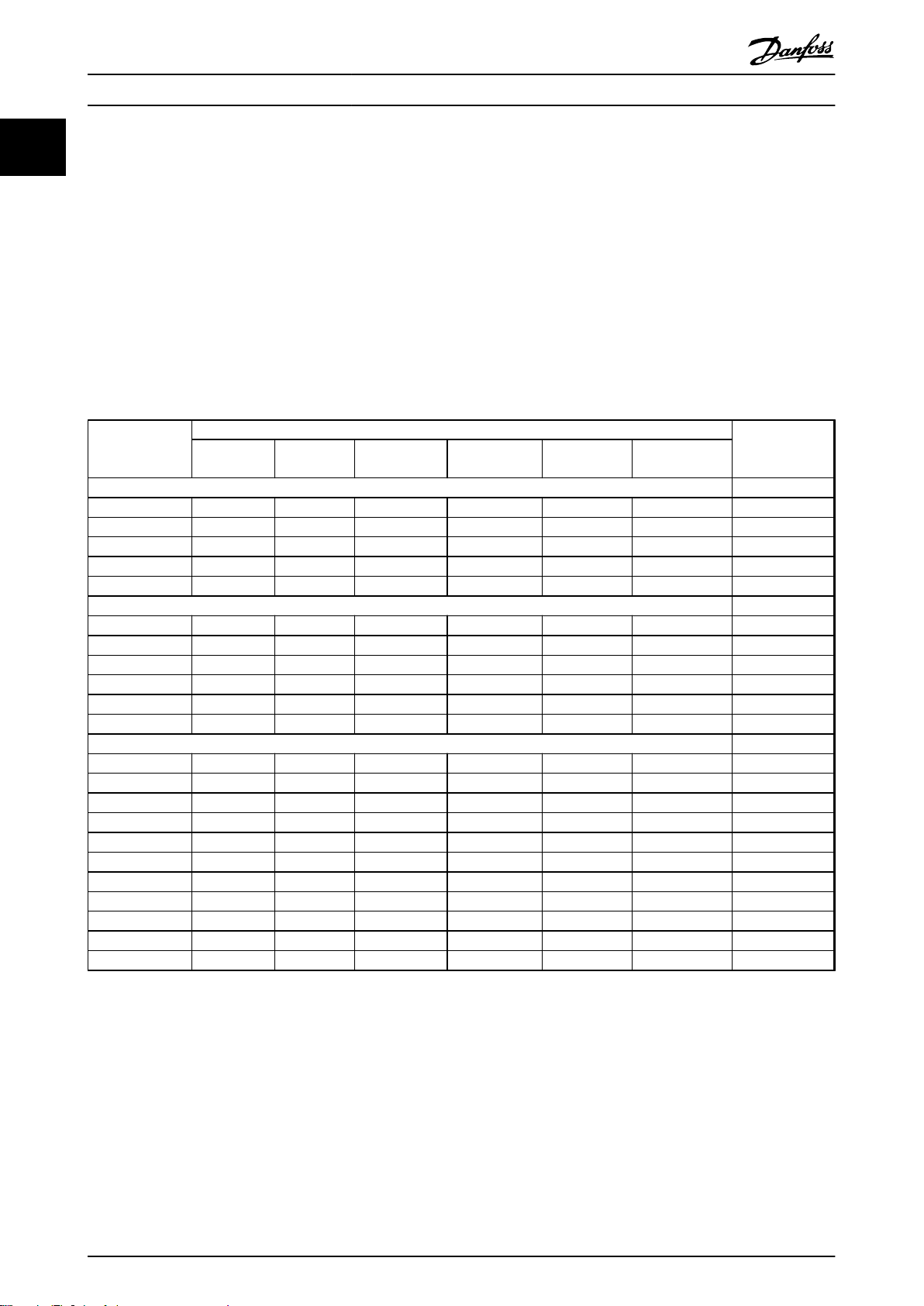

Power [kW] Height [mm] Width [mm]

Enclosure 1x200-240 V 3x200-240 V 3x380-480 V A

A (incl. decoupling

plate)

a B b C [kg]

M1 0.18-0.75 0.25-0.75 0.37-0.75 150 205 140.4 70 55 148 1.1

M2 1.5 1.5 1.5-2.2 176 230 166.4 75 59 168 1.6

M3 2.2 2.2-3.7 3.0-7.5 239 294 226 90 69 194 3.0

M4 11.0-15.0 292 347.5 272.4 125 97 241 6.0

M5 18.5-22.0 335 387.5 315 165 140 248 9.5

1)

For LCP with potentiometer, add 7.6 mm.

Depth

[mm]

1)

1 1

Max.

Weight

Illustration 1.1 Mechanical Dimensions

NOTICE

All cabling must comply with national and local regulations on cable cross-sections and ambient temperature. Copper

conductors

Enclosure 1x200-240 V 3x200-240 V 3x380-480 V Line Motor DC connection/Brake Control Terminals Earth Relay

1)

Spade connectors (6.3 mm Faston plugs)

Table 1.4 Tightening of Terminals

required, (60-75 °C) recommended.

Power [kW] Torque [Nm]

M1 0.18-0.75 0.25-0.75 0.37-0.75 1.4 0.7

M2 1.5 1.5 1.5-2.2 1.4 0.7

M3 2.2 2.2-3.7 3.0-7.5 1.4 0.7

M4 11.0-15.0 1.3 1.3 1.3 0.15 3 0.5

M5 18.5-22.0 1.3 1.3 1.3 0.15 3 0.5

Spade

Spade

Spade

1)

1)

1)

0.15 3 0.5

0.15 3 0.5

0.15 3 0.5

MG02B902 - Rev. 2013-11-19 5

Page 8

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

11

Branch circuit protection

protect the installation against electrical and fire hazard,

To

all branch circuits in an installation, switch gear, machines

etc., must be short-circuited and overcurrent protected

according to national/international regulations.

Short circuit protection

Danfoss recommends using the fuses mentioned in the

following tables to protect service personnel or other

equipment in case of an internal failure in the unit or

short-circuit on DC-link. The frequency converter provides

full short circuit protection in case of a short-circuit on the

motor or brake output.

Overcurrent protection

Provide overload protection to avoid overheating of the

cables in the installation. Overcurrent protection must

always be carried out according to national regulations.

Fuses must be designed for protection in a circuit capable

of supplying a maximum of 100,000 A

(symmetrical),

rms

480 V maximum.

Non UL compliance

If UL/cUL is not to be complied with, Danfoss recommends

using the fuses mentioned in Table 1.5, which ensures

compliance with EN50178/IEC61800-5-1:

In case of malfunction, not following the fuse recommendation may result in damage to the frequency converter

and the installation.

Max. Fuses UL

FC 51

1X200-240 V

kW Type RK1 Type J Type T Type RK1 Type CC Type RK1 Type gG

0K18-0K37 KTN-R15 JKS-15 JJN-15 KLN-R15 ATM-R15 A2K-15R 16A

0K75 KTN-R25 JKS-25 JJN-25 KLN-R25 ATM-R25 A2K-25R 25A

1K5 KTN-R35 JKS-35 JJN-35 KLN-R35 - A2K-35R 35A

2K2 KTN-R50 JKS-50 JJN-50 KLN-R50 - A2K-50R 50A

3x200-240 V

0K25 KTN-R10 JKS-10 JJN-10 KLN-R10 ATM-R10 A2K-10R 10A

0K37 KTN-R15 JKS-15 JJN-15 KLN-R15 ATM-R15 A2K-15R 16A

0K75 KTN-R20 JKS-20 JJN-20 KLN-R20 ATM-R20 A2K-20R 20A

1K5 KTN-R25 JKS-25 JJN-25 KLN-R25 ATM-R25 A2K-25R 25A

2K2 KTN-R40 JKS-40 JJN-40 KLN-R40 ATM-R40 A2K-40R 40A

3K7 KTN-R40 JKS-40 JJN-40 KLN-R40 - A2K-40R 40A

3x380-480 V

0K37-0K75 KTS-R10 JKS-10 JJS-10 KLS-R10 ATM-R10 A6K-10R 10A

1K5 KTS-R15 JKS-15 JJS-15 KLS-R15 ATM-R15 A2K-15R 16A

2K2 KTS-R20 JKS-20 JJS-20 KLS-R20 ATM-R20 A6K-20R 20A

3K0 KTS-R40 JKS-40 JJS-40 KLS-R40 ATM-R40 A6K-40R 40A

4K0 KTS-R40 JKS-40 JJS-40 KLS-R40 ATM-R40 A6K-40R 40A

5K5 KTS-R40 JKS-40 JJS-40 KLS-R40 - A6K-40R 40A

7K5 KTS-R40 JKS-40 JJS-40 KLS-R40 - A6K-40R 40A

11K0 KTS-R60 JKS-60 JJS-60 KLS-R60 - A6K-60R 63A

15K0 KTS-R60 JKS-60 JJS-60 KLS-R60 - A6K-60R 63A

18K5 KTS-R60 JKS-60 JJS-60 KLS-R60 - A6K-60R 80A

22K0 KTS-R60 JKS-60 JJS-60 KLS-R60 - A6K-60R 80A

Bussmann Bussmann Bussmann Littel fuse

Ferraz-

Shawmut

Ferraz-

Shawmut

Max. fuses non

UL

Table 1.5 Fuses

6 MG02B902 - Rev. 2013-11-19

Page 9

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

1.3.4 Connecting to Mains and Motor

The frequency converter is designed to operate all

standard

The frequency converter is designed to accept mains/

motor cables with a maximum cross-section of 4 mm2/10

AWG (M1, M2 and M3) and maximum cross-section 16

mm2/6 AWG (M4 and M5).

3-phased asynchronous motors.

Use a shielded/armoured motor cable to comply

•

with EMC emission specifications, and connect

this cable to both the decoupling plate and the

motor metal.

Keep motor cable as short as possible to reduce

•

the noise level and leakage currents.

For further details on mounting of the

•

decoupling plate, see VLT Micro FC 51 Decoupling

Mounting Plate Instructions.

Also see EMC-Correct Installation in the Design

•

Guide.

1. Mount the ground wires to PE terminal.

2. Connect motor to terminals U, V and W.

3. Mount mains supply to terminals L1/L, L2 and

L3/N (3-phase) or L1/L and L3/N (single-phase)

and tighten.

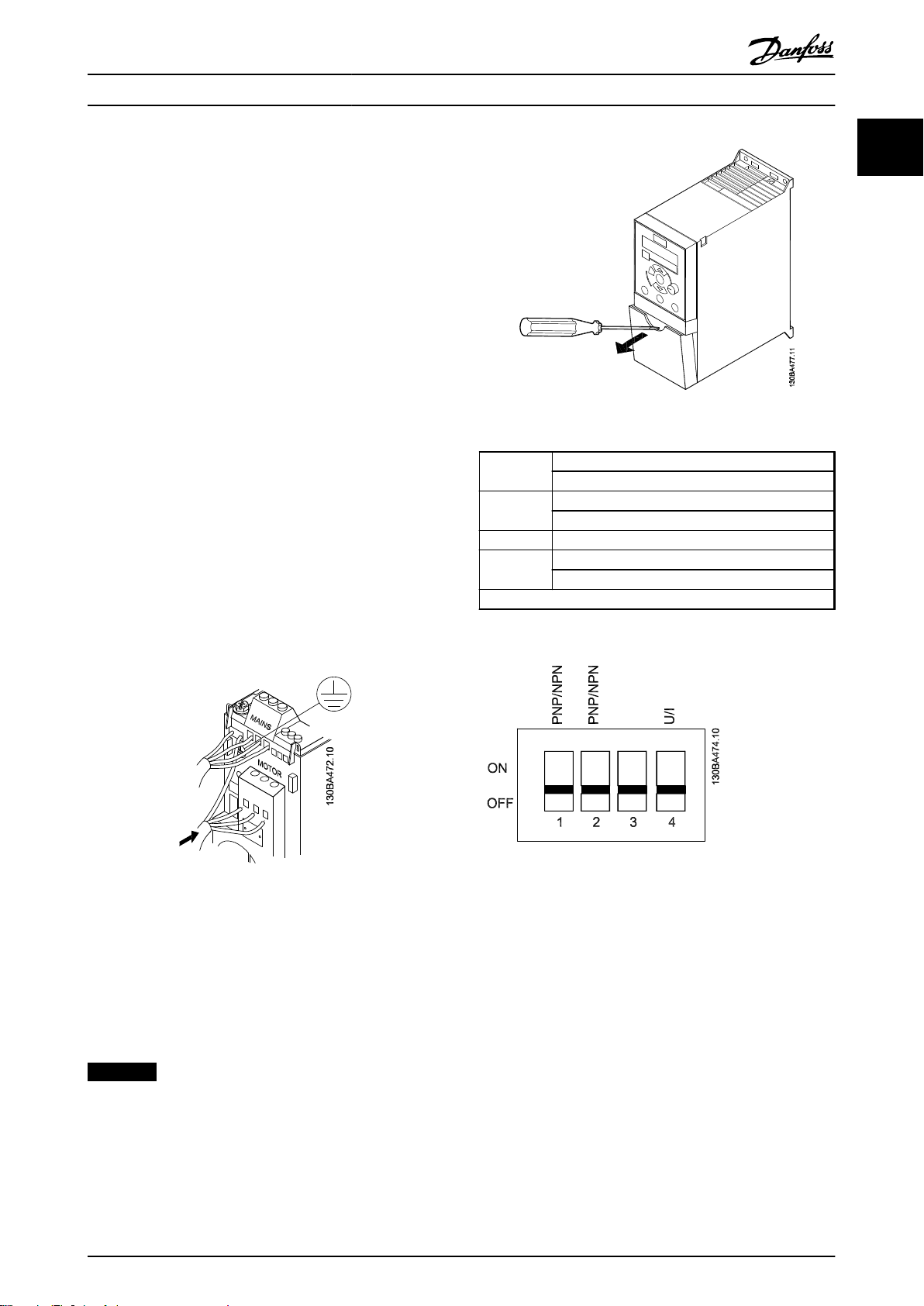

Illustration 1.3 Removing Terminal Cover

Switch 1

Switch 2

Switch 3 No function

Switch 4

*=default setting

Table 1.6 Settings for S200 Switches 1-4

*Off=PNP terminals 29

On=NPN terminals 29

*Off=PNP terminal 18, 19, 27 and 33

On=NPN terminal 18, 19, 27 and 33

*Off=Terminal 53 0-10 V

On=Terminal 53 0/4-20 mA

1 1

Illustration 1.2 Mounting of Ground Cable, Mains and Motor

Wires

1.3.5 Control Terminals

All control cable terminals are located underneath the

terminal cover in front of the frequency converter. Remove

the terminal cover using a screwdriver.

NOTICE

See back of terminal cover for outlines of control

terminals

Do not operate switches with power on the frequency

converter.

6-19 Terminal 53 Mode must be set according to Switch 4

position.

and switches.

MG02B902 - Rev. 2013-11-19 7

Illustration 1.4 S200 Switches 1-4

Illustration 1.5

converter. Applying Start (terminal 18) and an analog

reference (terminal 53 or 60) make the frequency converter

run.

shows all control terminals of the frequency

Page 10

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

11

Illustration 1.5 Overview of Control Terminals in PNP-configuration and Factory Setting

1.3.6 Power Circuit - Overview

Illustration 1.6 Diagram Showing all Electrical Terminals

Brake (BR+ and BR-) are not applicable for enclosure type M1.

*

8 MG02B902 - Rev. 2013-11-19

Page 11

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

Brake resistors are available from Danfoss.

Improved

achieved by installing optional Danfoss line filters.

Danfoss power filters can also be used for load sharing.

power factor and EMC performance can be

1.3.7 Load Sharing/Brake

Use 6.3 mm insulated Faston Plugs designed for high

voltage

for DC (Load Sharing and brake).

Contact Danfoss or see instruction MI50N for load sharing

and instruction MI90F for brake.

Load sharing

Connect terminals -UDC and +UDC/+BR.

Brake

Connect terminals -BR and +UDC/+BR (Not applicable for

enclosure type M1).

NOTICE

Voltage levels of up to 850 V DC may occur between

terminals

protected.

1.4 Programming

+UDC/+BR and -UDC. Not short circuit

Illustration 1.7 Description of LCP Keys and Display

[Menu] to select one of the following menus:

Press

Status

For readouts only.

Quick Menu

For access to Quick Menus 1 and 2, respectively.

1 1

1.4.1 Programming on Automatic Motor

Adaptation

For detailed information on programming, see VLT

Drive FC 51 Programming Guide.

( AMA)

Micro

NOTICE

The frequency converter can also be programmed from a

PC

via RS-485 com-port by installing the MCT 10 Set-up

Software.

This software can either be ordered using code number

130B1000 or downloaded from the Danfoss Web site:

www.danfoss.com/BusinessAreas/DrivesSolutions/

softwaredownload

Main Menu

For access to all parameters.

Navigation Keys

[Back]: For moving to the previous step or layer in the

navigation structure.

[▲] [▼]: For manoeuvring between parameter groups,

parameters and within parameters.

[OK]: For selecting a parameter and for accepting changes

to parameter settings.

Pressing [OK] for more than 1 s enters Adjust mode. In

Adjust mode, it is possible to make fast adjustment by

pressing [▲] [▼] combined with [OK].

Press [▲] [▼] to change value. Press [OK] to shift between

digits quickly.

To exit Adjust mode, press [OK] more than 1 s again with

changes saving or press [Back] without changes saving.

MG02B902 - Rev. 2013-11-19 9

Page 12

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

11

Operation Keys

yellow light above the operation keys indicates the

A

active key.

[Hand On]: Starts the motor and enables control of the

frequency converter via the LCP.

[Off/Reset]: The motor stops except in alarm mode. In that

case the motor is reset.

[Auto On]: The frequency converter is controlled either via

control terminals or serial communication.

[Potentiometer] (LCP12): The potentiometer works in 2

ways depending on the mode in which the frequency

converter is running.

In Auto Mode the potentiometer acts as an extra

programmable analog input.

In Hand on Mode the potentiometer controls local

reference.

1.4.2 Programming on Automatic Motor

Tuning

It is highly recommended to run AMT because it measures

the

electrical characteristics of the motor to optimise

compatibility between the frequency converter and the

motor under VVC

•

•

(AMT)

plus

mode.

The frequency converter builds a mathematical

model of the motor for regulating output motor

current thus enhancing motor performance.

Run this procedure on a cold motor for best

results To run AMT, use the numeric LCP (NLCP).

There are two AMT modes for frequency

converters.

Mode 1

1.

Enter the main menu.

2.

Go to parameter group 1-** Load and Motor.

3. Press [OK]

4. Set motor parameters using name plate data for

parameter group 1-2* Motor Data.

5.

Go to 1-29 Automatic Motor Tuning (AMT).

6. Press [OK].

7.

Select [2] Enable AMT

8. Press [OK].

9. The test runs automatically and indicates when it

is complete.

Mode 2

1. Enter the main menu.

2.

Go to parameter group 1-** Load and Motor.

3. Press [OK].

4. Set motor parameters using name plate data for

parameter group 1-2* Motor Data.

5.

Go to 1-29 Automatic Motor Tuning (AMT).

6. Press [OK]

7.

Select [3] Complete AMT with Rotating motor

8. Press [OK]

9. The test will run automatically and indicate when

it is complete.

NOTICE

In mode 2, the rotorrotates during the AMT progress. No

should be added on motor in this AMT progress.

load

10 MG02B902 - Rev. 2013-11-19

Page 13

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

1.5 Parameter Overview

0-** Operation/Display

Basic Settings

0-0*

0-03 Regional Settings

*[0] International

[1] US

0-04 Oper. State at Power-up

(Hand)

[0] Resume

*[1] Forced stop, ref=old

[2] Forced stop, ref=0

0-1* Set-up Handling

0-10 Active Set-up

*[1] Setup 1

[2] Setup 2

[9] Multi Setup

0-11 Edit Set-up

*[1] Setup 1

[2] Setup 2

[9] Active Setup

0-12 Link Setups

[0] Not Linked

*[20] Linked

0-31 Custom Readout Min Scale

0.00 – 9999.00 * 0.00

0-32 Custom Readout Max Scale

0.00 – 9999.00 * 100.0

0-4* LCP Keypad

0-40 [Hand on] Key on LCP

[0] Disabled

*[1] Enabled

0-41 [Off / Reset] Key on LCP

[0] Disable All

*[1] Enable All

[2] Enable Reset Only

0-42 [Auto on] Key on LCP

[0] Disabled

*[1] Enabled

0-5* Copy/Save

0-50 LCP Copy

*[0] No copy

[1] All to LCP

[2] All from LCP

[3] Size indep. from LCP

0-51 Set-up Copy

*[0] No copy

[1] Copy from setup 1

[2] Copy from setup 2

[9] Copy from Factory setup

0-6* Password

0-60 (Main) Menu Password

0-999 *0

0-61 Access to Main/Quick Menu

w/o Password

*[0] Full access

[1] LCP:Read Only

[2] LCP:No Access

1-** Load/Motor

1-0* General Settings

1-00 Configuration Mode

*[0] Speed open loop

[3] Process

1-01 Motor Control Principle

[0] U/f

*[1] VVC+

1-03 Torque Characteristics

*[0] Constant torque

[2] Automatic Energy Optim.

1)

M4 and M5 only

1-05 Local Mode Configuration

[0]

Speed Open Loop

*[2] As config in par. 1-00

1-2* Motor Data

1-20 Motor Power [kW] [HP]

[1] 0.09 kW/0.12 HP

[2] 0.12 kW/0.16 HP

[3] 0.18 kW/0.25 HP

[4] 0.25 kW/0.33 HP

[5] 0.37 kW/0.50 HP

[6] 0.55 kW/0.75 HP

[7] 0.75 kW/1.00 HP

[8] 1.10 kW/1.50 HP

[9] 1.50 kW/2.00 HP

[10] 2.20 kW/3.00 HP

[11] 3.00 kW/4.00 HP

[12] 3.70 kW/5.00 HP

[13] 4.00 kW/5.40 HP

[14] 5.50 kW/7.50 HP

[15] 7.50 kW/10.00 HP

[16] 11.00 kW/15.00 HP

[17] 15.00 kW/20.00 HP

[18] 18.50 kW/25.00 HP

[19] 22.00 kW/29.50 HP

[20] 30.00 kW/40.00 HP

1-22 Motor Voltage

50-999 V *230 -400 V

1-23 Motor Frequency

20-400 Hz *50 Hz

1-24 Motor Current

0.01-100.00 A *Motortype dep.

1-25 Motor Nominal Speed

100-9999 rpm *Motortype dep.

1-29 Automatic Motor Tuning

(AMT)

*[0] Off

[2] Enable AMT

[3] Complete AMT with Rotating

motor

1-3* Adv. Motor Data

1-30 Stator Resistance (Rs)

[Ohm] * Dep. on motor data

1-33 Stator Leakage Reactance

(X1)

[Ohm] * Dep. on motor data

1-35 Main Reactance (Xh)

[Ohm] * Dep. on motor data

1-5* Load Indep. Setting

1-50 Motor Magnetisation at 0

Speed

0-300% *100%

1-52 Min Speed Norm. Magnet.

[Hz]

0.0-10.0 Hz *0.0Hz

1-55 U/f Characteristic - U

0-999.9 V

1-56 U/f Characteristic - F

0-400 Hz

1-6* Load Depen. Setting

1-60 Low Speed Load Compensation

0-199% *100%

1-61 High Speed Load Compensation

0-199% *100%

1-62 Slip Compensation

-400-399% *100%

Parameter Overwiev

1-63 Slip Compensation Time

Constant

0.05-5.00 s *0.10 s

1-7* Start Adjustments

1-71 Start Delay

0.0-10.0 s *0.0 s

1-72 Start Function

[0] DC hold/delay time

[1] DC brake/delay time

*[2] Coast/delay time

1-73 Flying Start

*[0] Disabled

[1] Enabled

1-8* Stop Adjustments

1-80 Function at Stop

*[0] Coast

[1] DC hold

1-82 Min Speed for Funct. at Stop

[Hz]

0.0-20.0 Hz *0.0 Hz

1-9*Motor Temperature

1-90 Motor Thermal Protection

*[0] No protection

[1] Termistor warning

[2] Thermistor trip

[3] Etr warning

[4] Etr trip

1-93 Thermistor Resource

*[0] None

[1] Analog input 53

[6] Digital input 29

2-** Brakes

2-0* DC-Brake

2-00 DC Hold Current

0-150% *50%

2-01 DC Brake Current

0-150% *50%

2-02 DC Braking Time

0.0-60.0 s *10.0s

2-04 DC Brake Cut In Speed

0.0-400.0 Hz *0.0Hz

2-1* Brake Energy Funct.

2-10 Brake Function

*[0] Off

[1] Resistor brake

[2] AC brake

2-11 Brake Resistor (ohm)

Min/Max/default: Powersize dep.

2-14 Brake Voltage reduce

0 - Powersize dep.* 0

2-16 AC Brake, Max current

0-150% *100%

2-17 Overvoltage Control

*[0] Disabled

[1] Enabled (not at stop)

[2] Enabled

2-2* Mechanical Brake

2-20 Release Brake Current

0.00-100.0 A *0.00 A

2-22 Activate Brake Speed [Hz]

0.0-400.0 Hz *0.0 Hz

3-** Reference / Ramps

3-0* Reference Limits

3-00 Reference Range

*[0] Min - Max

[1] -Max - +Max

1 1

3-02 Minimum Reference

-4999-4999 *0.000

3-03 Maximum Reference

-4999-4999 *50.00

3-1* References

3-10 Preset Reference

-100.0-100.0% *0.00%

3-11 Jog Speed [Hz]

0.0-400.0 Hz *5.0 Hz

3-12 Catch up/slow Down Value

0.00 - 100.0% * 0.00%

3-14 Preset Relative Reference

-100.0-100.0% *0.00%

3-15 Reference Resource 1

[0] No function

*[1] Analog Input 53

[2] Analog input 60

[8] Pulse input 33

[11] Local bus ref

[21] LCP Potentiometer

3-16 Reference Resource 2

[0] No function

[1] Analog in 53

*[2] Analog in 60

[8] Pulse input 33

*[11] Local bus reference

[21] LCP Potentiometer

3-17 Reference Resource 3

[0] No function

[1] Analog Input 53

[2] Analog input 60

[8] Pulse input 33

*[11] Local bus ref

[21] LCP Potentiometer

3-18 Relative Scaling Ref.

Resource

*[0] No function

[1] Analog Input 53

[2] Analog input 60

[8] Pulse input 33

[11] Local bus ref

[21] LCP Potentiometer

3-4* Ramp 1

3-40 Ramp 1 Type

*[0] Linear

[2] Sine2 ramp

3-41 Ramp 1 Ramp up Time

0.05-3600 s *3.00 s (10.00 s1))

3-42 Ramp 1 Ramp Down Time

0.05-3600 s *3.00s (10.00s 1))

3-5* Ramp 2

3-50 Ramp 2 Type

*[0] Linear

[2] Sine2 ramp

3-51 Ramp 2 Ramp up Time

0.05-3600 s *3.00 s (10.00 s 1))

3-52 Ramp 2 Ramp down Time

0.05-3600 s *3.00 s (10.00 s1))

3-8* Other Ramps

3-80 Jog Ramp Time

0.05-3600 s *3.00 s (10.00s1))

3-81 Quick Stop Ramp Time

0.05-3600 s *3.00 s (10.00s1))

MG02B902 - Rev. 2013-11-19 11

Page 14

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

11

4-** Limits/Warnings

4-1* Motor Limits

4-10 Motor Speed Direction

*[0] Clockwise If Par. 1-00 is set to

close loop control

[1] CounterClockwise

*[2] Both if Par. 1-00 is set to open

loop control

4-12 Motor Speed Low Limit [Hz]

0.0-400.0 Hz *0.0 Hz

4-14 Motor Speed High Limit [Hz]

0.1-400.0 Hz *65.0 Hz

4-16 Torque Limit Motor Mode

0-400% *150%

4-17 Torque Limit Generator

Mode

0-400% *100%

4-4* Adj. Warnings 2

4-40 Warning Frequency Low

0.00 - Value of 4-41 Hz *0.0 Hz

4-41 Warning Frequency High

Value of 4-40-400.0 Hz *400.00 Hz

4-5* Adj. Warnings

4-50 Warning Current Low

0.00-100.00 A *0.00 A

4-51 Warning Current High

0.0-100.00 A *100.00 A

4-54 Warning Reference Low

-4999.000 - Value of 4-55

* -4999.000

4-55 Warning Reference High

Value of 4-54 -4999.000

*4999.000

4-56 Warning Feedback Low

-4999.000 - Value of 4-57

* -4999.000

4-57 Warning Feedback High

Value of 4-56-4999.000 *4999.000

4-58 Missing Motor Phase

Function

[0] Off

*[1] On

4-6* Speed Bypass

4-61 Bypass Speed From [Hz]

0.0-400.0 Hz *0.0 Hz

4-63 Bypass Speed To [Hz]

0.0 -400.0 Hz *0.0 Hz

5-1* Digital Inputs

5-10 Terminal 18 Digital Input

[0] No function

[1] Reset

[2] Coast inverse

[3] Coast and reset inv.

[4] Quick stop inverse

[5] DC-brake inv.

[6] Stop inv

*[8] Start

[9] Latched start

[10] Reversing

[11] Start reversing

[12] Enable start forward

[13] Enable start reverse

[14] Jog

[16-18] Preset ref bit 0-2

[19] Freeze reference

5-10 Terminal 18 Digital Input

[20]

Freeze output

[21] Speed up

[22] Speed down

[23] Setup select bit 0

[28] Catch up

[29] Slow down

[34] Ramp bit 0

[60] Counter A (up)

[61] Counter A (down)

[62] Reset counter A

[63] Counter B (up)

[64] Counter B (down)

[65] ResetCounter B

5-11 Terminal 19 Digital Input

See par. 5-10. * [10] Reversing

5-12 Terminal 27 Digital Input

See par. 5-10. * [1] Reset

5-13 Terminal 29 Digital Input

See par. 5-10. * [14] Jog

5-15 Terminal 33 Digital Input

See par. 5-10. * [16] Preset ref bit 0

[26] Precise Stop Inverse

[27] Start, Precise Stop

[32] Pulse Input

5-3* Digital Outputs

5-34 On Delay, Terminal 42 Digital

Output

0.00 - 600.00 s * 0.01 s

5-35 Off Delay, Terminal 42 Digital

Output

0.00 - 600.00 s * 0.01 s

5-4* Relays

5-40 Function Relay

*[0] No operation

[1] Control ready

[2] Drive ready

[3] Drive ready, Remote

[4] Enable / No warning

[5] Drive running

[6] Running / No warning

[7] Run in range / No warning

[8] Run on ref / No warning

[9] Alarm

[10] Alarm or warning

[12] Out of current range

[13] Below current, low

[14] Above current, high

[16] Below frequency, low

[17] Above frequency, high

[19] Below feedback, low

[20] Above feedback, high

[21] Thermal warning

[22] Ready, No thermal warning

[23] Remote ready, No thermal

warning

[24] Ready, Voltage ok

[25] Reverse

[26] Bus ok

[28] Brake,NoWarn

[29] Brake ready/NoFault

[30] BrakeFault (IGBT)

[32] Mech.brake control

[36] Control word bit 11

[41] Below reference, low

[42] Above reference, high

[51] Local ref. active

5-40 Function Relay

[52] Remote ref. active

[53] No alarm

[54] Start cmd active

[55] Running reverse

[56] Drive in hand mode

[57] Drive in auto mode

[60-63] Comparator 0-3

[70-73] Logic rule 0-3

[81] SL digital output B

5-41 On Delay, Relay

0.00-600.00 s *0.01 s

5-42 Off Delay, Relay

0.00-600.00 s *0.01 s

5-5* Pulse Input

5-55 Terminal 33 Low Frequency

20-4999 Hz *20 Hz

5-56 Terminal 33 High Frequency

21-5000 Hz *5000 Hz

5-57 Term. 33 Low Ref./Feedb.

Value

-4999-4999 *0.000

5-58 Term. 33 High Ref./Feedb.

Value

-4999-4999 *50.000

6-** Analog In/Out

6-0* Analog I/O Mode

6-00 Live Zero Timeout Time

1-99 s *10 s

6-01 Live Zero TimeoutFunction

*[0] Off

[1] Freeze output

[2] Stop

[3] Jogging

[4] Max speed

[5] Stop and trip

6-1* Analog Input 1

6-10 Terminal 53 Low Voltage

0.00-9.99 V *0.07 V

6-11 Terminal 53 High Voltage

0.01-10.00 V *10.00 V

6-12 Terminal 53 Low Current

0.00-19.99 mA *0.14 mA

6-13 Terminal 53 High Current

0.01-20.00 mA *20.00 mA

6-14 Term. 53 Low Ref./Feedb.

Value

-4999-4999 *0.000

6-15 Term. 53 High Ref./Feedb.

Value

-4999-4999 *50.000

6-16 Terminal 53 Filter Time

Constant

0.01-10.00 s *0.01 s

6-19 Terminal 53 mode

*[0] Voltage mode

[1] Current mode

6-2* Analog Input 2

Terminal 60 Low Current

6-22

0.00-19.99 mA *0.14 mA

6-23 Terminal 60 High Current

0.01-20.00 mA *20.00 mA

6-24 Term. 60 Low Ref./Feedb.

Value

-4999-4999 *0.000

6-25 Term. 60 High Ref./Feedb.

Value

-4999-4999 *50.00

6-26 Terminal 60 Filter Time

Constant

0.01-10.00 s *0.01 s

6-8* LCP Potentiometer

6-80 LCP Potmeter Enable

[0] Disabled

*[1] Enable

6-81 LCP potm. Low Reference

-4999-4999 *0.000

6-82 LCP potm. High Reference

-4999-4999 *50.00

6-9* Analog Output xx

6-90 Terminal 42 Mode

*[0] 0-20 mA

[1] 4-20 mA

[2] Digital Output

6-91 Terminal 42 Analog Output

*[0] No operation

[10] Output Frequency

[11] Reference

[12] Feedback

[13] Motor Current

[16] Power

[19] DC Link Voltage

[20] Bus Reference

6-92 Terminal 42 Digital Output

See par. 5-40

*[0] No Operation

[80] SL Digital Output A

6-93 Terminal 42 Output Min

Scale

0.00-200.0% *0.00%

6-94 Terminal 42 Output Max

Scale

0.00-200.0% *100.0%

7-** Controllers

7-2* Process Ctrl. Feedb

7-20 Process CL Feedback 1

Resource

*[0] NoFunction

[1] Analog Input 53

[2] Analog input 60

[8] PulseInput33

[11] LocalBusRef

12 MG02B902 - Rev. 2013-11-19

Page 15

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

7-3* Process PI

Ctrl. 7-30 Process PI Normal/

Inverse Ctrl

*[0] Normal

[1] Inverse

7-31 Process PI Anti Windup

[0] Disable

*[1] Enable

7-32 Process PI Start Speed

0.0-200.0 Hz *0.0 Hz

7-33 Process PI Proportional Gain

0.00-10.00 *0.01

7-34 Process PI Integral Time

0.10-9999 s *9999 s

7-38 Process PI Feed Forward

Factor

0-400% *0%

7-39 On Reference Bandwidth

0-200% *5%

8-** Comm. and Options

8-0* General Settings

8-01 Control Site

*[0] Digital and ControlWord

[1] Digital only

[2] ControlWord only

8-02 Control Word Source

[0] None

*[1] FC RS485

8-03 Control Word Timeout Time

0.1-6500 s *1.0 s

8-04 Control Word Timeout

Function

*[0] Off

[1] Freeze Output

[2] Stop

[3] Jogging

[4] Max. Speed

[5] Stop and trip

8-06 Reset Control Word Timeout

*[0] No Function

[1] Do reset

8-3* FC Port Settings

8-30 Protocol

*[0] FC

[2] Modbus

8-31 Address

1-247 *1

8-32 FC Port Baud Rate

[0] 2400 Baud

[1] 4800 Baud

*[2] 9600 Baud For choose FC Bus

in 8-30

*[3] 19200 Baud For choose

Modbus in 8-30

[4] 38400 Baud

8-33 FC Port Parity

*[0] Even Parity, 1 Stop Bit

[1] Odd Parity, 1 Stop Bit

[2] No Parity, 1 Stop Bit

[3] No Parity, 2 Stop Bits

8-35 Minimum Response Delay

0.001-0.5 *0.010 s

8-36 Max Response Delay

0.100-10.00 s *5.000 s

8-4* FC MC protocol set

8-43

FC Port PCD Read Configu-

ration

*[0] None Expressionlimit

[1] [1500] Operation Hours

[2] [1501] Running Hours

[3] [1502] kWh Counter

[4] [1600] Control Word

[5] [1601] Reference [Unit]

[6] [1602] Reference %

[7] [1603] Status Word

[8] [1605] Main Actual Value [%]

[9] [1609] Custom Readout

[10] [1610] Power [kW]

[11] [1611] Power [hp]

[12] [1612] Motor Voltage

[13] [1613] Frequency

[14] [1614] Motor Current

[15] [1615] Frequency [%]

[16] [1618] Motor Thermal

[17] [1630] DC Link Voltage

[18] [1634] Heatsink Temp.

[19] [1635] Inverter Thermal

[20] [1638] SL Controller State

[21] [1650] External Reference

[22] [1651] Pulse Reference

[23] [1652] Feedback [Unit]

[24] [1660] Digital Input 18,19,27,33

[25] [1661] Digtial Input 29

[26] [1662] Analog Input 53 (V)

[27] [1663] Analog Input 53 (mA)

[28] [1664] Analog Input 60

[29] [1665] Analog Output 42 [mA]

[30] [1668] Freq. Input 33 [Hz]

[31] [1671] Relay Output [bin]

[32] [1672] Counter A

[33] [1673] Counter B

[34] [1690] Alarm Word

[35] [1692] Warning Word

[36] [1694] Ext. Status Word

8-5* Digital/Bus

8-50 Coasting Select

[0] DigitalInput

[1] Bus

[2] LogicAnd

*[3] LogicOr

8-51 Quick Stop Select

See par. 8-50 * [3] LogicOr

8-52 DC Brake Select

See par. 8-50 *[3] LogicOr

8-53 Start Select

See par. 8-50 *[3] LogicOr

8-54 Reversing Select

See par. 8-50 *[3] LogicOr

8-55 Set-up Select

See par. 8-50 *[3] LogicOr

8-56 Preset Reference Select

See par. 8-50 * [3] LogicOr

8-8* Bus communication

Diagnostics

8-80 Bus Message Count

0-0 N/A *0 N/A

8-81 Bus Error Count

0-0 N/A *0 N/A

8-82 Slave Messages Rcvd

0-0 N/A *0 N/A

8-83 Slave Error Count

0-0 N/A *0 N/A

8-9* Bus Jog / Feedback

8-94 Bus feedback 1

0x8000-0x7FFF *0

13-** Smart Logic

13-0* SLC Settings

13-00 SL Controller Mode

*[0] Off

[1] On

13-01 Start Event

[0] False

[1] True

[2] Running

[3] InRange

[4] OnReference

[7] OutOfCurrentRange

[8] BelowILow

[9] AboveIHigh

[16] ThermalWarning

[17] MainOutOfRange

[18] Reversing

[19] Warning

[20] Alarm_Trip

[21] Alarm_TripLock

[22-25] Comparator 0-3

[26-29] LogicRule0-3

[33] DigitalInput_18

[34] DigitalInput_19

[35] DigitalInput_27

[36] DigitalInput_29

[38] DigitalInput_33

*[39] StartCommand

[40] DriveStopped

13-02 Stop Event

See par. 13-01 * [40] DriveStopped

13-03 Reset SLC

*[0] Do not reset

[1] Reset SLC

13-1* Comparators

13-10 Comparator Operand

*[0] Disabled

[1] Reference

[2] Feedback

[3] MotorSpeed

[4] MotorCurrent

[6] MotorPower

[7] MotorVoltage

[8] DCLinkVoltage

[12] AnalogInput53

[13] AnalogInput60

[18] PulseInput33

[20] AlarmNumber

[30] CounterA

[31] CounterB

13-11 Comparator Operator

[0] Less Than

*[1] Approximately equals

[2] Greater Than

13-12 Comparator Value

-9999-9999 *0.0

13-2* Timers

13-20 SL Controller Timer

0.0-3600 s *0.0 s

13-4* Logic Rules

13-40 Logic Rule Boolean 1

See par. 13-01 *[0] False

[30] - [32] SL Time-out 0-2

13-41 Logic Rule Operator 1

*[0] Disabled

[1] And

[2] Or

[3] And not

[4] Or not

[5] Not and

[6] Not or

[7] Not and not

[8] Not or not

13-42 Logic Rule Boolean 2

See par. 13-40 * [0] False

13-43 Logic Rule Operator 2

See par. 13-41 *[0] Disabled

13-44 Logic Rule Boolean 3

See par. 13-40 * [0] False

13-5* States

13-51 SL Controller Event

See par. 13-40 *[0] False

13-52 SL Controller Action

*[0] Disabled

[1] NoAction

[2] SelectSetup1

[3] SelectSetup2

[10-17] SelectPresetRef0-7

[18] SelectRamp1

[19] SelectRamp2

[22] Run

[23] RunReverse

[24] Stop

[25] Qstop

[26] DCstop

[27] Coast

[28] FreezeOutput

[29] StartTimer0

[30] StartTimer1

[31] StartTimer2

[32] Set Digital Output A Low

[33] Set Digital Output B Low

[38] Set Digital Output A High

[39] Set Digital Output B High

[60] ResetCounterA

[61] ResetCounterB

14-** Special Functions

14-0* Inverter Switching

14-01 Switching Frequency

[0] 2 kHz

*[1] 4 kHz

[2] 8 kHz

[4] 16 kHz not available for M5

14-03 Overmodulation

[0] Off

*[1] On

14-1* Mains monitoring

14-12 Function at mains

imbalance

*[0] Trip

[1] Warning

[2] Disabled

1 1

MG02B902 - Rev. 2013-11-19 13

Page 16

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

11

14-2* Trip Reset

14-20 Reset Mode

*[0] Manual reset

[1-9] AutoReset 1-9

[10] AutoReset 10

[11] AutoReset 15

[12] AutoReset 20

[13] Infinite auto reset

[14] Reset at power up

14-21 Automatic Restart Time

0 - 600s * 10s

14-22 Operation Mode

*[0] Normal Operation

[2] Initialisation

14-26 Action At Inverter Fault

*[0] Trip

[1] Warning

14-4* Energy Optimising

14-41 AEO Minimum Magnetisation

40 - 75 % * 66 %

14-9* Fault Settings

14-90 Fault level[3] Trip Lock

[4] Trip with delayed reset

15-** Drive Information

15-0* Operating Data

15-00 Operating Days

15-01 Running Hours

15-02 kWh Counter

15-03 Power Ups

15-04 Over Temps

15-05 Over Volts

15-06 Reset kWh Counter

*[0] Do not reset

[1] Reset counter

15-07 Reset Running Hours

Counter

*[0] Do not reset

[1] Reset counter

15-3* Fault Log

15-30 Fault Log: Error Code

15-4* Drive Identification

15-40 FC Type

15-41 Power Section

15-42 Voltage

15-43 Software Version

15-46 Frequency Converter Order.

No

15-48 LCP Id No

15-51 Frequency Converter Serial

No

16-** Data Readouts 16-0* General

Status

16-00 Control Word

0-0XFFFF

16-01 Reference [Unit]

-4999-4999 *0.000

16-02 Reference %

-200.0-200.0% *0.0%

16-03 Status Word

0-0XFFFF

16-05 Main Actual Value [%]

-200.0-200.0% *0.0%

16-09 Custom Readout

Dep. on par. 0-31, 0-32

16-1* Motor Status

16-10 Power [kW]

16-11 Power [hp]

16-12 Motor Voltage [V]

16-13 Frequency [Hz]

16-14 Motor Current [A]

16-15 Frequency [%]

16-18 Motor Thermal [%]

16-3* Drive Status

16-30 DC Link Voltage

16-34 Heatsink Temp.

16-35 Inverter Thermal

16-36 Inv.Nom. Current

16-37 Inv. Max. Current

16-38 SL Controller State

16-5* Ref./Feedb.

16-50 External Reference

16-51 Pulse Reference

16-52 Feedback [Unit]

16-6* Inputs/Outputs

16-60 Digital Input 18,19,27,33

0-1111

16-61 Digital Input 29

0-1

16-62 Analog Input 53 (volt)

16-63 Analog Input 53 (current)

16-64 Analog Input 60

16-65 Analog Output 42 [mA]

16-68 Pulse Input [Hz]

16-71 Relay Output [bin]

16-72 Counter A

16-73 Counter B

16-8* Fieldbus/FC Port

16-86 FC Port REF 1

0x8000-0x7FFFF

16-9* Diagnosis Readouts

16-90 Alarm Word

0-0XFFFFFFFF

16-92 Warning Word

0-0XFFFFFFFF

16-94 Ext. Status Word

0-0XFFFFFFFF

18-** Extended Motor Data

18-8* Motor Resistors

18-80 Stator Resistance (High

resolution)

0.000-99.990 ohm *0.000 ohm

18-81 Stator Leakage

Reactance(High resolution)

0.000-99.990 ohm *0.000 ohm

14 MG02B902 - Rev. 2013-11-19

Page 17

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

1.6 Troubleshooting

1.6.1 Warnings and Alarms

No. Description Warning Alarm Trip

2 Live zero error X X Signal on terminal 53 or 60 is less than 50% of value set in

nom

limits

nom

1)

1)

and I

X X X Missing phase on supply side, or too high voltage imbalance. Check

1)

nom

X X Intermediate circuit voltage exceeds limit.

X X Intermediate circuit voltage drops below “voltage warning low” limit.

X X Thermistor or thermistor connection is disconnected.

X Wrong setting for motor voltage and/or motor current.

X Motor current is too low. Check settings.

X No communication between LCP and frequency converter

X Occurs when trying to write an illegal value to a parameter.

X Occurs when trying to set a value outside the range.

X Parameter can only be changed when the motor is stopped.

4

Mains phase loss

7

DC over voltage

8

DC under voltage

9 Inverter overloaded X X More than 100% load for too long.

10 Motor ETR over temperature X X Motor is too hot due to more than 100% load for too long.

11 Motor thermistor over

temperature

12 Torque limit X

13 Over Current X X X Inverter peak current limit is exceeded.

14 Earth fault X X X Discharge from output phases to ground.

16 Short Circuit X X Short-circuit in motor or on motor terminals.

17 Control word timeout X X No communication to frequency converter.

25 Brake resistor short-circuited X X Brake resistor is short-circuited, thus brake function is disconnected.

27 Brake chopper short-circuited X X Brake transistor is short-circuited, thus brake function is discon-

28 Brake check X Brake resistor is not connected/working

29 Power board over temp X X X Heatsink cut-out temperature has been reached.

30 Motor phase U missing X X Motor phase U is missing. Check the phase.

31 Motor phase V missing X X Motor phase V is missing. Check the phase.

32 Motor phase W missing X X Motor phase W is missing. Check the phase.

38 Internal fault X X Contact local Danfoss supplier.

44 Earth fault X X Discharge from output phases to ground.

47 Control Voltage Fault X X 24 V DC may be overloaded.

51 AMA check U

52 AMA low I

59 Current limit X Frequency converter overload.

63 Mechanical Brake Low X Actual motor current has not exceeded “release brake” current

80 Drive Initialised to Default Value X All parameter settings are initialized to default settings.

84 The connection between drive

85 Button disabled X

86 Copy fail X An error occurred while copying from frequency converter to LCP or

87 LCP data invalid X Occurs when copying from LCP if the LCP contains erroneous data -

88 LCP data not compatible X Occurs when copying from LCP if data are moved between

89 Parameter read only X Occurs when trying to write to a read-only parameter.

90 Parameter database busy X LCP and RS485 connection are trying to update parameters simulta-

91 Parameter value is not valid in this

92 Parameter value exceeds the

nw

run

Err. A wrong password was entered X Occurs when using a wrong password for changing a password-

1)

LCP is lost

and

mode

min/max

While RUNning

Not

These faults may be caused by mains distortions. Installing Danfoss Line Filter may rectify this problem.

Error Cause of Problem

Lock

Terminal 53 Low Voltage, 6-12 Terminal 53 Low Currentand

6-10

6-22 Terminal 54 Low Current.

voltage.

supply

Torque exceeds value set in either parameter 4-16

Motor Mode or 4-17Torque Limit Generator Mode.

nected.

within

“start delay” time window.

See parameter group 0-4* 0-4*

versa.

vice

if no data was uploaded to the LCP.

or

frequency

neously.

protected

converters with major differences in software versions.

parameter.

LCP

Torque Limit

1 1

Table 1.7 Warnings and Alarms Code List

MG02B902 - Rev. 2013-11-19 15

Page 18

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

11

1.7 Specifications

1.7.1 Mains Supply 1x200-240 V AC

Normal overload 150% for 1 minute

Frequency converter

Shaft Output [kW]

Typical

Typical Shaft Output [HP] 0.25 0.5 1 2 3

IP20 M1 M1 M1 M2 M3

Output current

Continuous (1x200-240 V AC) [A] 1.2 2.2 4.2 6.8 9.6

Intermittent (1x200-240 V AC) [A] 1.8 3.3 6.3 10.2 14.4

Max. cable size:

(mains, motor) [mm2/AWG]

Max. input current

Continuous (1x200-240 V) [A] 3.3 6.1 11.6 18.7 26.4

Intermittent (1x200-240 V) [A] 4.5 8.3 15.6 26.4 37.0

Max. mains fuses [A]

Environment

Estimated power loss [W],

case/Typical

Best

Weight enclosure IP20 [kg] 1.1 1.1 1.1 1.6 3.0

Efficiency [%],

Best

case/Typical

1)

1)

Table 1.8 Mains Supply 1x200-240 V AC

1.

At rated load conditions.

PK18

0.18

12.5/

15.5

95.6/

94.5

PK37

0.37

See chapter

20.0/

25.0

96.5/

95.6

PK75

0.75

4/10

1.3.4 Fuses

36.5/

44.0

96.6/

96.0

P1K5

1.5

61.0/

67.0

97.0/

96.7

P2K2

2.2

81.0/

85.1

96.9/

97.1

1.7.2 Mains Supply 3x200-240 V AC

Normal overload 150% for 1 min

Frequency converter

Shaft Output [kW]

Typical

Typical Shaft Output [HP] 0.33 0.5 1 2 3 5

IP20 M1 M1 M1 M2 M3 M3

Output current

Continuous (3x200-240 V) [A] 1.5 2.2 4.2 6.8 9.6 15.2

Intermittent (3x200-240 V) [A] 2.3 3.3 6.3 10.2 14.4 22.8

Max. cable size:

(mains, motor) [mm2/AWG]

Max. input current

Continuous (3x200-240 V) [A] 2.4 3.5 6.7 10.9 15.4 24.3

Intermittent (3x200-240 V) [A] 3.2 4.6 8.3 14.4 23.4 35.3

Max. mains fuses [A]

Environment

Estimated power loss [W]

case/Typical

Best

Weight enclosure IP20 [kg] 1.1 1.1 1.1 1.6 3.0 3.0

Efficiency [%]

Best

case/Typical

1)

1)

Table 1.9 Mains Supply 3x200-240 V AC

1)

At rated load conditions.

PK25

0.25

14.0/

20.0

96.4/

94.9

PK37

0.37

19.0/

24.0

96.7/

95.8

PK75

0.75

See chapter

31.5/

39.5

97.1/

96.3

4/10

1.3.4 Fuses

P1K5

1.5

51.0/

57.0

97.4/

97.2

P2K2

2.2

72.0/

77.1

97.2/

97.4

P3K7

115.0/

122.8

97.3/

97.4

3.7

16 MG02B902 - Rev. 2013-11-19

Page 19

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

1.7.3 Mains Supply 3x380-480 V AC

Normal overload 150% for 1 minute

Frequency converter

Shaft Output [kW]

Typical

Typical Shaft Output [HP] 0.5 1 2 3 4 5

IP20 M1 M1 M2 M2 M3 M3

Output current

Continuous (3x380-440 V) [A] 1.2 2.2 3.7 5.3 7.2 9.0

Intermittent (3x380-440 V) [A] 1.8 3.3 5.6 8.0 10.8 13.7

Continuous (3x440-480 V) [A] 1.1 2.1 3.4 4.8 6.3 8.2

Intermittent (3x440-480 V) [A] 1.7 3.2 5.1 7.2 9.5 12.3

Max. cable size:

(mains, motor) [mm2/AWG]

Max. input current

Continuous (3x380-440 V) [A] 1.9 3.5 5.9 8.5 11.5 14.4

Intermittent (3x380-440 V) [A] 2.6 4.7 8.7 12.6 16.8 20.2

Continuous (3x440-480 V) [A] 1.7 3.0 5.1 7.3 9.9 12.4

Intermittent (3x440-480 V) [A] 2.3 4.0 7.5 10.8 14.4 17.5

Max. mains fuses [A]

Environment

Estimated power loss [W]

case/Typical

Best

Weight enclosure IP20 [kg] 1.1 1.1 1.6 1.6 3.0 3.0

Efficiency [%]

case/Typical

Best

Table 1.10 Mains Supply 3x380-480 V AC

1.

1)

1)

At rated load conditions.

PK37

0.37

18.5/

25.5

96.8/

95.5

PK75

0.75

28.5/

43.5

97.4/

96.0

P1K5

1.5

4/10

See chapter

41.5/

56.5

98.0/

97.2

P2K2

2.2

1.3.4 Fuses

57.5/

81.5

97.9/

97.1

P3K0

3.0

75.0/

101.6

98.0/

97.2

P4K0

98.5/

133.5

98.0/

97.3

1 1

4.0

Normal overload 150% for 1 minute

Frequency converter

Shaft Output [kW]

Typical

Typical Shaft Output [HP] 7.5 10 15 20 25 30

IP20 M3 M3 M4 M4 M5 M5

Output current

Continuous (3x380-440 V) [A] 12.0 15.5 23.0 31.0 37.0 43.0

Intermittent (3x380-440 V) [A] 18.0 23.5 34.5 46.5 55.5 64.5

Continuous (3x440-480 V) [A] 11.0 14.0 21.0 27.0 34.0 40.0

Intermittent (3x440-480 V) [A] 16.5 21.3 31.5 40.5 51.0 60.0

Max. cable size:

(mains, motor) [mm2/AWG]

Max. input current

Continuous (3x380-440 V) [A] 19.2 24.8 33.0 42.0 34.7 41.2

Intermittent (3x380-440 V) [A] 27.4 36.3 47.5 60.0 49.0 57.6

Continuous (3x440-480 V) [A] 16.6 21.4 29.0 36.0 31.5 37.5

Intermittent (3x440-480 V) [A] 23.6 30.1 41.0 52.0 44.0 53.0

Max. mains fuses [A]

Environment

Estimated power loss [W]

case/Typical

Best

Weight enclosure IP20 [kg] 3.0 3.0

Efficiency [%]

case/Typical

Best

Table 1.11 Mains Supply 3x380-480 V AC

1.

1)

1)

At rated load conditions.

P5K5

5.5

131.0/

166.8

98.0/

97.5

P7K5

7.5

4/10 16/6

175.0/

217.5

98.0/

97.5

P11K

11

See chapter

290.0/

342.0

97.8/

97.4

P15K

15

1.3.4 Fuses

387.0/

454.0

97.7/

97.4

P18K

18.5

395.0/

428.0

98.1/

98.0

P22K

22

467.0/

520.0

98.1/

97.9

MG02B902 - Rev. 2013-11-19 17

Page 20

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

11

1.8 General Technical Data

Protection and features

Electronic thermal motor protection against overload.

•

Temperature monitoring of the heat sink ensures that the frequency converter trips in case of overtemperature

•

The frequency converter is protected against short-circuits between motor terminals U, V, W.

•

When a motor phase is missing, the frequency converter trips and issues an alarm.

•

When a mains phase is missing, the frequency converter trips or issues a warning (depending on the load).

•

Monitoring of the intermediate circuit voltage ensures that the frequency converter trips, when the intermediate

•

circuit voltage is too low or too high.

The frequency converter is protected against ground faults on motor terminals U, V, W.

•

Mains supply (L1/L, L2, L3/N)

Supply voltage 200-240 V ±10%

Supply voltage 380-480 V ±10%

Supply frequency 50/60 Hz

Max. imbalance temporary between mains phases 3.0% of rated supply voltage

True Power Factor ≥0.4 nominal at rated load

Displacement Power Factor (cosφ) near unity (>0.98)

Switching on input supply L1/L, L2, L3/N (power-ups) maximum 2 times/min.

Environment according to EN60664-1 overvoltage category III/pollution degree 2

The unit is suitable for use on a circuit capable of delivering not more than 100.000 RMS symmetrical Amperes, 240/480 V

maximum.

Motor output (U, V, W)

Output voltage 0-100% of supply voltage

Output frequency 0-200 Hz (VVC

Switching on output Unlimited

Ramp times 0.05-3600 s

plus

), 0-400 Hz (u/f)

Cable lengths and cross sections

Max. motor cable length, screened/armoured (EMC correct installation) 15 m

Max. motor cable length, unscreened/unarmoured 50 m

Max. cross section to motor, mains*

Connection to load sharing/brake (M1, M2, M3) 6.3 mm insulated Faston Plugs

Max. cross section to load sharing/brake (M4, M5) 16 mm2/6

Maximum cross section to control terminals, rigid wire 1.5 mm2/16

Maximum cross section to control terminals, flexible cable 1 mm2/18

Maximum cross section to control terminals, cable with enclosed core 0.5 mm2/20

Minimum cross section to control terminals 0.25 mm

* See chapter 1.7 Specifications for more information!

AWG (2x0.75 mm2)

AWG

AWG

AWG

2

18 MG02B902 - Rev. 2013-11-19

Page 21

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

Digital inputs (pulse/encoder inputs)

Programmable digital inputs (pulse/encoder) 5 (1)

Terminal number 18, 19, 27, 29, 33,

Logic PNP or NPN

Voltage level 0-24 V DC

Voltage level, logic'0' PNP <5 V DC

Voltage level, logic'1' PNP >10 V DC

Voltage level, logic '0' NPN >19 V DC

Voltage level, logic '1' NPN <14 V DC

Maximum voltage on input 28 V DC

Input resistance, R

Max. pulse frequency at terminal 33 5000 Hz

Min. pulse frequency at terminal 33 20 Hz

Analog inputs

Number of analog inputs 2

Terminal number 53, 60

Voltage mode (Terminal 53) Switch S200=OFF(U)

Current mode (Terminal 53 and 60) Switch S200=ON(I)

Voltage level 0-10 V

Input resistance, R

Max. voltage 20 V

Current level 0/4 to 20 mA (scaleable)

Input resistance, R

Max. current 30 mA

i

i

i

approx. 4 kΩ

approx. 10 kΩ

approx. 200 Ω

1 1

Analog output

Number of programmable analog outputs 1

Terminal number 42

Current range at analog output 0/4-20 mA

Max. load to common at analog output 500 Ω

Max. voltage at analog output 17 V

Accuracy on analog output Max. error: 0.8% of full scale

Scan interval 4 ms

Resolution on analog output 8 bit

Scan interval 4 ms

Control card, RS-485 serial communication

Terminal number 68 (P,TX+, RX+), 69 (N,TX-, RX-)

Terminal number 61 Common for terminals 68 and 69

Control card, 24 V DC output

Terminal number 12

Max. load (M1 and M2) 100 mA

Max. load (M3) 50 mA

Max. load (M4 and M5) 80 mA

MG02B902 - Rev. 2013-11-19 19

Page 22

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

11

Relay output

Programmable relay output 1

Relay 01 Terminal number 01-03 (break), 01-02 (make)

Max. terminal load (AC-1)1)

Max. terminal load (AC-15)1)

Max. terminal load (DC-1)1)

Max. terminal load (DC-13)1)

Max. terminal load (AC-1)1) on 01-03 (NC) (Resistive load) 250 V AC, 2 A

Max. terminal load (AC-15)1)

Max. terminal load (DC-1)1)

Min. terminal load on 01-03 (NC), 01-02 (NO) 24 V DC 10 mA, 24 V AC 20 mA

Environment according to EN 60664-1 overvoltage category III/pollution degree 2

1)

IEC 60947 part 4 and 5

Control card, 10 V DC output

Terminal number 50

Output voltage 10.5 V ±0.5 V

Max. load 25 mA

on 01-02 (NO) (Resistive load) 250 V AC, 2 A

on 01-02 (NO) (Inductive load @ cosφ 0.4) 250 V AC, 0.2 A

on 01-02 (NO) (Resistive load) 30 V DC, 2 A

on 01-02 (NO) (Inductive load) 24 V DC, 0.1 A

on 01-03 (NC) (Inductive load @ cosφ 0.4) 250 V AC, 0.2 A

on 01-03 (NC) (Resistive load) 30 V DC, 2 A

NOTICE

All inputs, outputs, circuits, DC supplies and relay contacts are galvanically isolated from the supply voltage (PELV) and

high-voltage terminals.

other

Surroundings

Enclosure IP20

Enclosure kit available IP21, TYPE 1

Vibration test 1.0 g

Max. relative humidity 5%-95 % (IEC 60721-3-3; Class 3K3 (non-condensing) during operation

Aggressive environment (IEC 60721-3-3), coated class 3C3

Test method according to IEC 60068-2-43 H2S (10 days)

Ambient temperature Max. 40 °C

Derating for high ambient temperature, see chapter 1.9.1 Derating for Ambient Temperature

Minimum ambient temperature during full-scale operation 0 °C

Minimum ambient temperature at reduced performance - 10 °C

Temperature during storage/transport -25 to +65/70 °C

Maximum altitude above sea level without derating 1000 m

Maximum altitude above sea level with derating 3000 m

Derating for high altitude, see chapter 1.9 Special Conditions

Safety standards EN/IEC 61800-5-1, UL 508C

EMC standards, Emission EN 61800-3, EN 61000-6-3/4, EN 55011, IEC 61800-3

EN 61800-3, EN 61000-6-1/2, EN 61000-4-2, EN 61000-4-3,

EMC standards, Immunity

See chapter 1.9 Special Conditions

EN

61000-4-4, EN 61000-4-5, EN 61000-4-6

20 MG02B902 - Rev. 2013-11-19

Page 23

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

1.9 Special Conditions

1.9.1 Derating for Ambient Temperature

The ambient temperature measured over 24 hours should

at least 5 °C lower than the max. ambient temperature.

be

If the frequency converter is operated at high ambient

temperature, the continuous output current should be

decreased.

The frequency converter has been designed for operation

at max 50 °C ambient temperature with one motor size

smaller than nominal. Continuous operation at full load at

50 °C ambient temperature will reduce the lifetime of the

frequency converter.

1.9.2 Derating for Low Air Pressure

The cooling capability of air is decreased at low air

pressure.

For altitudes above 2.000 m, contact Danfoss regarding

PELV.

Below 1.000 m altitude no de-rating is necessary, but

above 1.000 m the ambient temperature or the maximum

output current should be decreased.

Decrease the output by 1% per 100 m altitude above 1000

m or reduce the max. ambient temperature by 1 ° C per

200 m.

1.9.3 Derating for Running at Low Speeds

When a motor is connected to at frequency converter,

check

that the cooling of the motor is adequate.

A problem may occur at low speeds in constant torque

applications. Running continuously at low speeds – below

half the nominal motor speed – may require additional air

cooling. Alternatively, select a larger motor (one size up).

1 1

MG02B902 - Rev. 2013-11-19 21

Page 24

Quick Guide

VLT® Micro Drive FC 51 Quick Guide

11

1.10 Options

Ordering No Description

132B0100 VLT Control Panel LCP 11 w/o potentiometer

132B0101 VLT Control Panel LCP 12 with potentiometer

132B0102 Remote Mounting Kit for LCP incl. 3 m cable IP55 with LCP 11, IP21 with LCP 12

132B0103 Nema Type 1 kit for enclosure type M1

132B0104 Type 1 kit for enclosure type M2

132B0105 Type 1 kit for enclosure type M3

132B0106 De-coupling plate kit for enclosure type M1 and M2

132B0107 De-coupling plate kit for enclosure type M3

132B0108 IP21 for enclosure type M1

132B0109 IP21 for enclosure type M2

132B0110 IP21 for frame M3

132B0111 DIN rail mounting kit for enclosure types M1 and M2

132B0120 Type 1 kit for enclosure type M4

132B0121 Type 1 kit for enclosure type M5

132B0122 De-coupling plate kit for enclosure types M4 and M5

132B0126 Enclosure type M1 spare parts kits

132B0127 Enclosure type M2 spare parts kits

132B0128 Enclosure type M3 spare parts kits

132B0129 Enclosure type M4 spare parts kits

132B0130 Enclosure type M5 spare parts kits

132B0131 Blank cover

130B2522 MCC 107 filter for 132F0001

130B2522 MCC 107 filter for 132F0002

130B2533 MCC 107 filter for 132F0003

130B2525 MCC 107 filter for 132F0005

130B2530 MCC 107 filter for 132F0007

130B2523 MCC 107 filter for 132F0008

130B2523 MCC 107 filter for 132F0009

130B2523 MCC 107 filter for 132F0010

130B2526 MCC 107 filter for 132F0012

130B2531 MCC 107 filter for 132F0014

130B2527 MCC 107 filter for 132F0016

130B2523 MCC 107 filter for 132F0017

130B2523 MCC 107 filter for 132F0018

130B2524 MCC 107 filter for 132F0020

130B2526 MCC 107 filter for 132F0022

130B2529 MCC 107 filter for 132F0024

130B2531 MCC 107 filter for 132F0026

130B2528 MCC 107 filter for 132F0028

130B2527 MCC 107 filter for 132F0030

Table 1.12

Danfoss Line Filters and brake resistors are available upon request.

22 MG02B902 - Rev. 2013-11-19

Page 25

Index

VLT® Micro Drive FC 51 Quick Guide

Index

A

Active Set-up.........................................................................................

Ambient temperature....................................................................... 20

Analog inputs....................................................................................... 19

B

Brake

Resistor (ohm)...................................................................................

resistor short-circuited................................................................... 15

C

Cable lengths and cross sections.................................................

Clearance...................................................................................................

Control card, 24 V DC output.........................................................

L

Load

11

Compensation...................................................................................

Sharing/Brake...................................................................................... 9

M

Main Menu................................................................................................

Mains

supply................................................................................................... 16

11

18

4

19

supply (L1/L, L2, L3/N).................................................................... 18

supply 1x200-240 V AC.................................................................. 16

supply 3x200-240 V AC.................................................................. 16

supply 3x380-480 V AC.................................................................. 17

Motor

output (U, V, W)................................................................................. 18

overload protection........................................................................... 2

Phase.................................................................................................... 12

protection........................................................................................... 18

Temperature...................................................................................... 11

11

9

D

DC-brake.................................................................................................

DC-Brake................................................................................................. 11

De-coupling plate kit......................................................................... 22

Derating

for ambient temperature.............................................................. 21

for low air pressure.......................................................................... 21

for running at low speeds............................................................. 21

Digital

inputs................................................................................................... 19

inputs (pulse/encoder inputs)..................................................... 19

DIN rail mounting kit......................................................................... 22

Discharge time........................................................................................ 2

12

E

Earth leakage current..........................................................................

Edit Set-up.............................................................................................. 11

Electronic waste..................................................................................... 3

G

Ground wire.............................................................................................

Grounding................................................................................................ 2

H

Hand mode............................................................................................

High voltage............................................................................................

12

I

IP21............................................................................................................

Isolated mains source.......................................................................... 3

IT mains......................................................................................................

22

N

Navigation Keys.....................................................................................

Nema type 1 kit.................................................................................... 22

O

Operation Keys.......................................................................................

Output performance (U, V, W)....................................................... 18

Overcurrent protection....................................................................... 6

Overvoltage Control.......................................................................... 11

P

Power Circuit - Overview....................................................................

Protection

3

Protection.............................................................................................. 6

and features....................................................................................... 18

Q

Quick Menu..............................................................................................

2

R

RCD..............................................................................................................

Relay output.......................................................................................... 20

Remote mounting kit........................................................................ 22

2

S

Slip Compensation.............................................................................

Status.......................................................................................................... 9

Surroundings........................................................................................ 20

3

9

9

8

9

2

11

MG02B902 - Rev. 2013-11-19 23

Page 26

Index

VLT® Micro Drive FC 51 Quick Guide

T

Thermal Protection...............................................................................

Thermistor.............................................................................................. 11

U

UL compliance........................................................................................

Unintended start.................................................................................... 2

V

VLT

Control Panel LCP 11......................................................................

Control Panel LCP 12...................................................................... 22

Voltage level.......................................................................................... 19

22

W

Warnings and alarms.........................................................................

15

3

6

24 MG02B902 - Rev. 2013-11-19

Page 27

Index

VLT® Micro Drive FC 51 Quick Guide

MG02B902 - Rev. 2013-11-19 25

Page 28

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property

of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

132R0029 MG02B902 Rev. 2013-11-19

*MG02B902*

Loading...

Loading...