Page 1

Operating Instructions

VLT® Micro Drive FC 51

Page 2

Page 3

VLTp Micro Drive FC 51 Operating Instructions

Contents

Contents

1. Safety

Safety Instructions 5

Approvals 5

General Warning 5

Avoid unintended Start 6

Before Commencing Repair Work 6

2. Mechanical Installation

Before Starting 7

Mechanical Dimensions 8

3. Electrical Installation

How to Connect 9

Electrical Installation in General 9

EMC-Correct Installation 10

Mains Connection 11

Motor Connection 11

Control Terminals 12

Connecting to Control Terminals 13

Switches 13

Power Circuit - Overview 14

Load sharing/Brake 14

5

7

9

4. Programming

How to Programme 15

Programming with MCT-10 15

Programming with LCP 11 or LCP 12 15

Status Menu 17

Quick Menu 17

Quick Menu Parameters 17

Main Menu 22

5. Modbus RTU

Modbus RTU Overview 23

Modbus RTU Message Framing Structure 24

Remote Terminal Unit 24

Modbus RTU Message Structure 24

Start/Stop Field 24

Address Field 24

Function Field 25

Data Field

15

23

25

MG.02.A3.02 - VLTp is a registered Danfoss trademark

1

Page 4

Contents

VLTp Micro Drive FC 51 Operating Instruc-

CRC Check Field 25

Coil/Register Addressing 25

How to Control FC 51 27

Function Codes Supported by Modbus RTU 27

Exception and Error Codes 27

How to Access Parameters 28

Parameter Handling 28

Storage of Data 28

IND 28

Text Blocks 28

Conversion Factor 28

Parameter Values 28

Examples 29

Read Coil Status (01

Force/Write Single Coil (05

Force/Write Multiple Coils (0F

Read Holding Registers (03

Preset Single Register (06

Preset Multiple Registers (10

Danfoss FC Control Profile 33

Control Word According to FC Profile 33

Explanation of the Control Bits 33

Status Word According to FC Profile (STW) 35

Explanation of the Status Bits 35

Bus Speed Reference Value 37

HEX

)

)

HEX

)

HEX

)

HEX

)

HEX

)

HEX

29

29

30

31

31

32

tions

6. Parameter Overview

39

Conversion Index 43

Change during operation 43

2-Set-up 43

Type 43

0-** Operation/Display 44

1-** Load/Motor 45

2-** Brakes 46

3-** Reference/Ramps 47

4-** Limits/Warnings 48

5-** Digital In/Out 49

6-** Analog In/Out 50

7-** Controllers 51

8-** Comm. and Options 52

13-** Smart Logic 53

2

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 5

VLTp Micro Drive FC 51 Operating Instructions

14-** Speical Functions 54

15-** Drive Information 55

16-** Data Readouts 56

Contents

7. Troubleshooting

Alarm Word and Extended Status Word 58

8. Specifications

Mains Supply 59

Other Specifications 61

Special Conditions 63

The Purpose of Derating 63

Derating for Ambient Temperature 63

Derating for Low Air Pressure 63

Derating for Running at Low Speeds 63

Options for VLT Micro Drive FC 51 64

Index

57

59

65

MG.02.A3.02 - VLTp is a registered Danfoss trademark

3

Page 6

1

1. Safety

VLTp Micro Drive FC 51 Operating Instruc-

tions

4

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 7

VLTp Micro Drive FC 51 Operating Instructions

1. Safety

1.1.1. High Voltage Warning

The voltage of the frequency converter is dangerous whenever it is connected to mains. Incorrect installation of the motor or frequency

converter may cause damage to the equipment, serious injury or death. Consequently, it is essential to comply with the instructions

in this manual as well as local and national rules and safety regulations.

1.1.2. Safety Instructions

• Make sure the frequency converter is properly connected to earth.

• Do not remove mains connections, motor connections or other power connections while the frequency converter is connected to power.

• Protect users against supply voltage.

• Protect the motor against overloading according to national and local regulations.

• The earth leakage current exceeds 3.5 mA.

• The [OFF] key is not a safety switch. It does not disconnect the frequency converter from mains.

1.1.3. Approvals

1. Safety

1

1.1.4. General Warning

Warning:

Touching the electrical parts may be fatal - even after the equipment has been disconnected from mains.

Also make sure that other voltage inputs have been disconnected, (linkage of DC intermediate circuit).

Be aware that there may be high voltage on the DC link even when the LEDs are turned off.

Before touching any potentially live parts of the VLT Micro Drive, wait at least 4 minutes for all sizes.

Shorter time is allowed only if indicated on the nameplate for the specific unit.

Leakage Current

The earth leakage current from the VLT Micro Drive FC 51 exceeds 3.5 mA. According to IEC 61800-5-1 a reinforced Protective Earth

connection must be ensured by means of a min. 10mm² Cu or an addtional PE wire - with the same cable cross section as the Mains

wiring - must be terminated separately.

Residual Current Device

This product can cause a D.C. current in the protective conductor. Where a residual current device (RCD) is used for extra protection,

only an RCD of Type B (time delayed) shall be used on the supply side of this product. See also Danfoss Application Note on RCD, MN.

90.GX.YY.

Protective earthing of the VLT Micro Drive and the use of RCDs must always follow national and local regulations.

Motor overload protection is possible by setting Parameter 1-90 Motor thermal protection to the value ETR trip. For the North American

market: ETR functions provide class 20 motor overload protection, in accordance with NEC.

MG.02.A3.02 - VLTp is a registered Danfoss trademark

5

Page 8

1

VLTp Micro Drive FC 51 Operating Instruc-

1. Safety

Installation in high altitudes:

By altitudes above 2km, please contact Danfoss Drives regarding PELV.

1.1.5. IT Mains

IT Mains

Installation on isolated mains source, i.e. IT mains.

Max. supply voltage allowed when connected to mains: 440 V.

As an option, Danfoss offers line filters for improved harmonics performance.

1.1.6. Avoid unintended Start

While the frequency converter is connected to mains, the motor can be started/stopped using digital commands, bus commands, references or via the

Local Control Panel.

• Disconnect the frequency converter from mains whenever personal safety considerations make it necessary to avoid unintended start of any

motors.

• To avoid unintended start, always activate the [OFF] key before changing parameters.

1.1.7. Disposal Instruction

tions

Equipment containing electrical components must not be disposed of together with domestic waste.

It must be separately collected with electrical and electronic waste according to local and currently valid leg-

islation.

1.1.8. Before Commencing Repair Work

1. Disconnect FC 51 from mains (and external DC supply, if present.)

2. Wait for 4 minutes for discharge of the DC-link.

3. Disconnect DC bus terminals and brake terminals (if present)

4. Remove motor cable

6

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 9

VLTp Micro Drive FC 51 Operating Instructions

2. Mechanical Installation

2.1. Before Starting

2. Mechanical Installation

2.1.1. Checklist

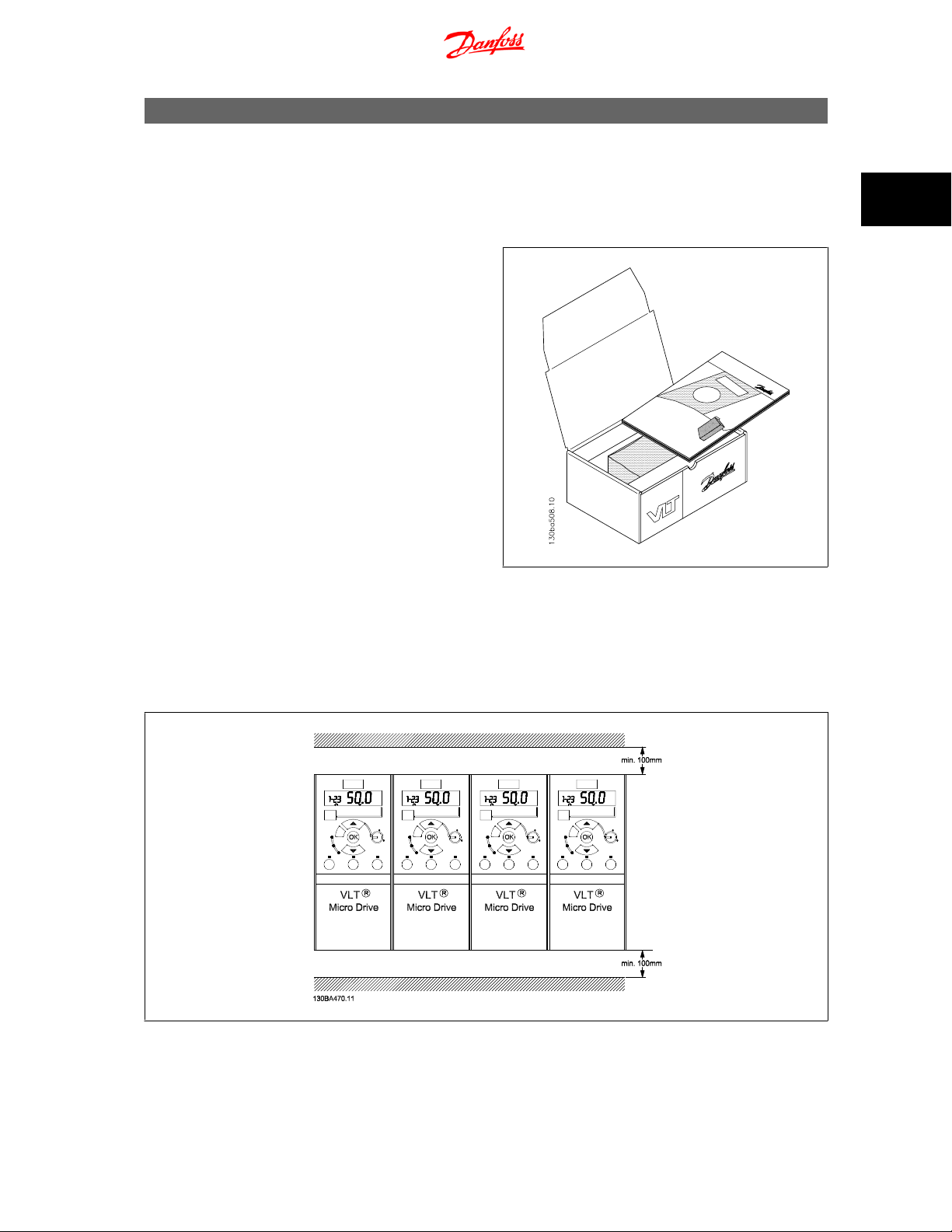

When unpacking the frequency converter, make sure that the unit is un-

damaged and complete. Check that the packaging contains the following:

• VLT Micro Drive FC 51

• Quick Guide

Optional: LCP and/or de-coupling plate.

2.2. Side-by-Side Installation

2

Illustration 2.1: Content of box.

The Danfoss VLT Micro Drive can be mounted side-by-side for IP 20 rating units and requires 100 mm clearance above and below for cooling. Regarding

surroundings in general, please see chapter

Illustration 2.2: Side-by-side installation.

7. Specifications

.

MG.02.A3.02 - VLTp is a registered Danfoss trademark

7

Page 10

2

2. Mechanical Installation

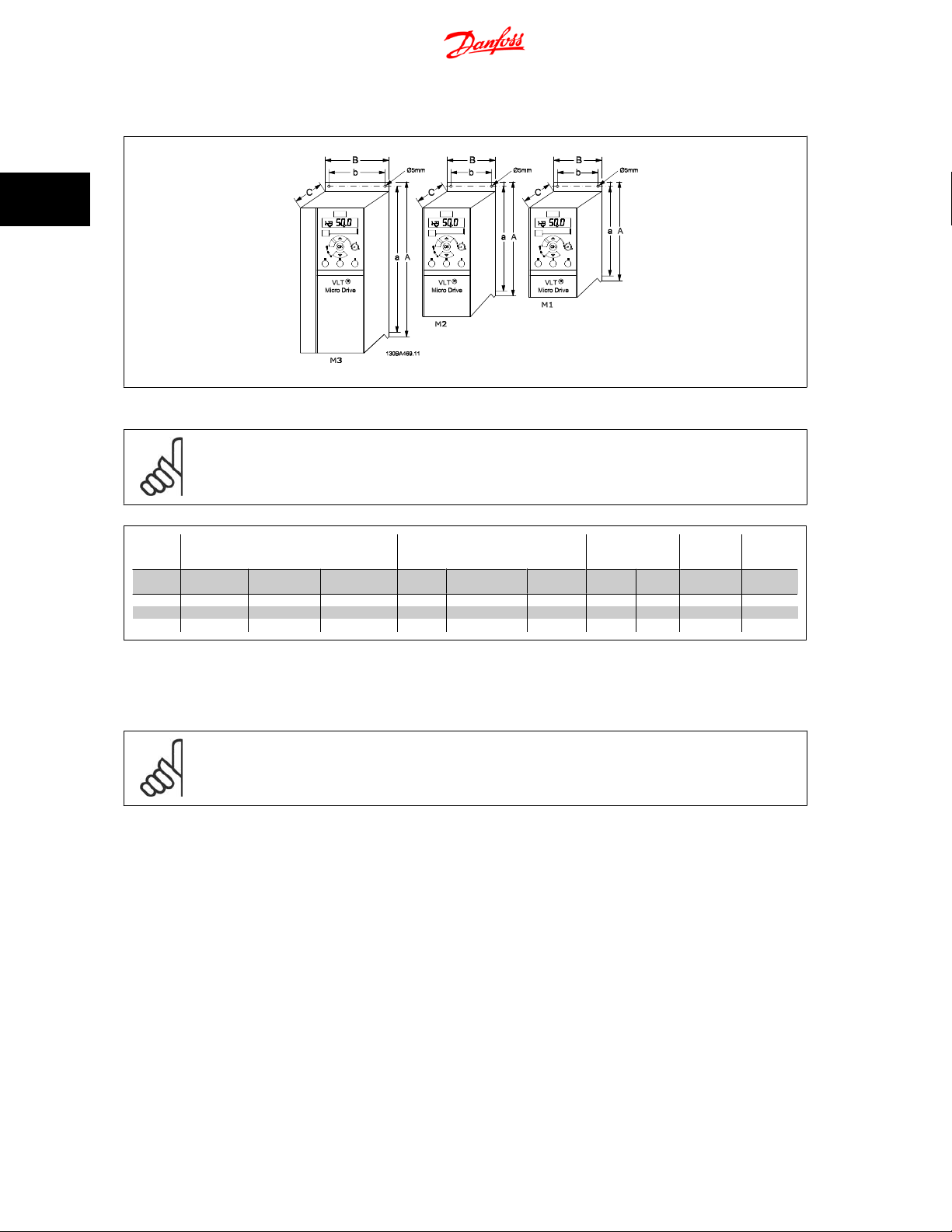

2.3.1. Mechanical Dimensions

Illustration 2.3: Mechanical dimensions.

NB!

A template for drilling can be found on the flap of the packaging.

VLTp Micro Drive FC 51 Operating Instruc-

tions

Power (kW) Height (mm) Width (mm)

1 X 200-240

Frame

M1 0.18 - 0.75 0.25 - 0.75 0.37 - 0.75 150 205 140.4 70 55 148 1.1

M2 1.5 1.5 1.5 - 2.2 176 230 166.4 75 59 168 1.6

M3 2.2 2.2 -3.7 3.0 - 7.5

V

3 X

200 -240 V

3 X

380-480 V

A (incl. decou-

A

pling plate)

2) 2) 2) 2) 2) 2) 2)

a B b C Kg

Depth

(mm)

Table 2.1: Mechanical Dimensions

1)

For LCP with potentiometer, please add 7.6 mm.

2

These dimensions will be announced at a later point.

NB!

DIN rail mounting kit is available for M1. Please use ordering number 132B0111

1)

Max.

Weight

8

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 11

VLTp Micro Drive FC 51 Operating Instructions

3. Electrical Installation

3.1. How to Connect

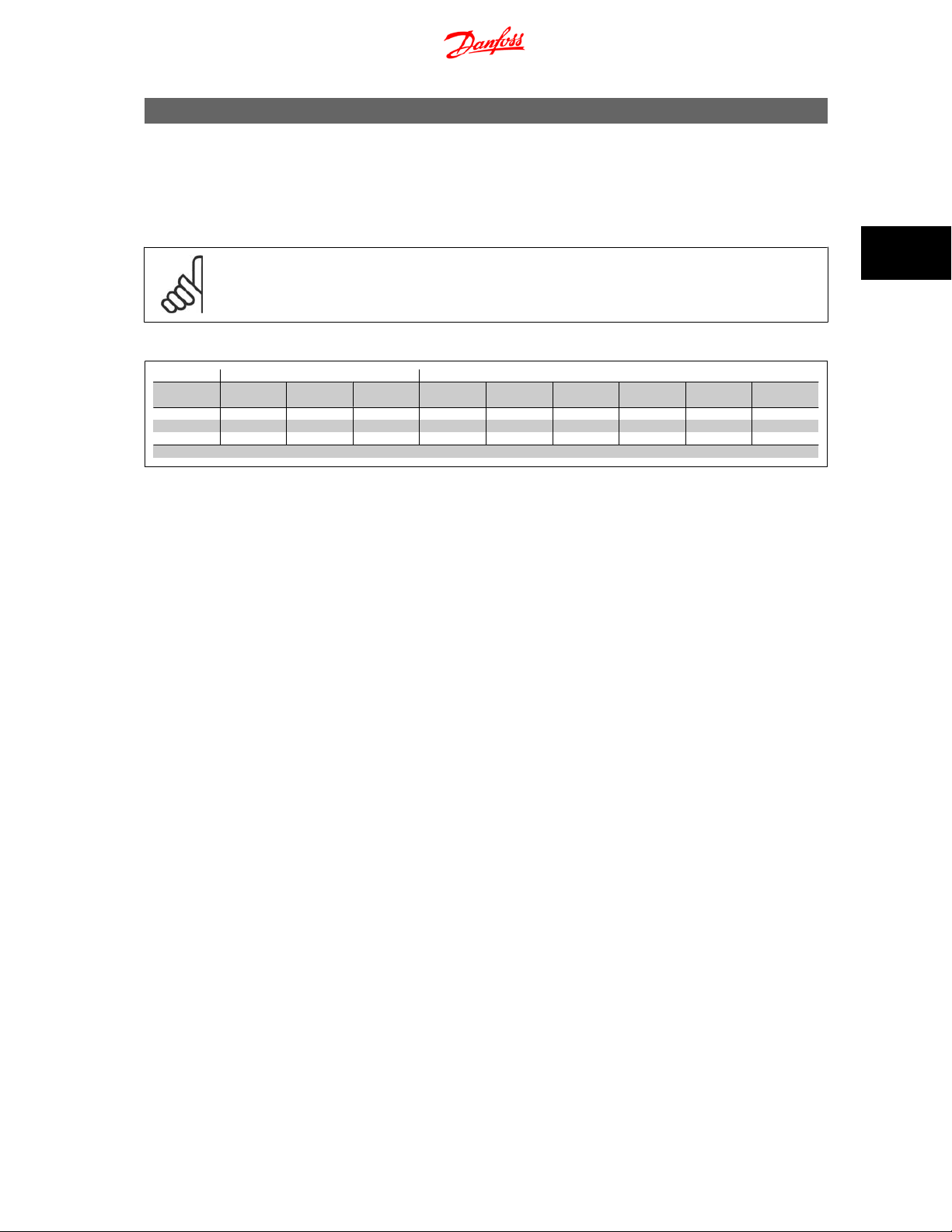

3.1.1. Electrical Installation in General

3. Electrical Installation

NB!

All cabling must comply with national and local regulations on cable cross-sections and ambient temperature. Copper conductors

required, (60-75° C) recommended.

Details of terminal tightening torques.

Frame

1)

Spade connectors

1 x 200-240V3 x 200-240V3 x 380-480

M1 0.18 - 0.75 0.25 - 0.75 0.37 - 0.75 1.4 0.7 - 0.15 3 0.5

M2 1.5 1.5 1.5 - 2.2 1.4 0.7 - 0.15 3 0.5

M3 2.2 2.2 - 3.7 3.0 - 7.5 1.4 0.7 - 0.15 3 0.5

Power (kW) Torque (Nm)

V

Line Motor

DC connection/Brake

Control Ter-

1)

minals

Earth Relay

Table 3.1: Tightening of terminals.

3.1.2. Fuses

Branch circuit protection:

In order to protect the installation against electrical and fire hazard, all branch circuits in an installation, switch gear, machines etc., must be short-circuited

and overcurrent protected according to national/international regulations.

Short circuit protection:

Danfoss recommends using the fuses mentioned in the following tables to protect service personnel or other equipment in case of an internal failure in

the unit or short-circuit on DC-link. The frequency converter provides full short circuit protection in case of a short-circuit on the motor or brake output.

Overcurrent protection:

Provide overload protection to avoid overheating of the cables in the installation. Overcurrent protection must always be carried out according to national

regulations. Fuses must be designed for protection in a circuit capable of supplying a maximum of 100,000 A

(symmetrical), 480 V maximum.

rms

3

NonUL compliance:

If UL/cUL is not to be complied with, Danfoss recommends using the fuses mentioned in table 1.3, which will ensure compliance with EN50178:

In case of malfunction, not following the fuse recommendation may result in damage to the frequency converter.

MG.02.A3.02 - VLTp is a registered Danfoss trademark

9

Page 12

3. Electrical Installation

VLTp Micro Drive FC 51 Operating Instruc-

tions

3

FC 51 Bussmann Bussmann Bussmann Littel fuse

1 X 200-240 V

kW Type RK1 Type J Type T Type RK1 Type CC Type RK1 Type gG

0K18 - 0K37 KTN-R15 JKS-15 JJN-15 KLN-R15 ATM-R15 A2K-15R 15A

0K75 KTN-R25 JKS-25 JJN-25 KLN-R25 ATM-R25 A2K-25R 25A

1K5 KTN-R35 JKS-35 JJN-35 KLN-R35 - A2K-35R 35A

2K2

3 x 200-240 V

0K25 KTN-R10 JKS-10 JJN-10 KLN-R10 ATM-R10 A2K-10R 10A

0K37 KTN-R15 JKS-15 JJN-15 KLN-R15 ATM-R15 A2K-15R 15A

0K75 KTN-R20 JKS-20 JJN-20 KLN-R20 ATM-R20 A2K-20R 20A

1K5 KTN-R25 JKS-25 JJN-25 KLN-R25 ATM-R25 A2K-25R 25A

2K2 KTN-R30 JKS-30 JJN-30 KLN-R30 ATM-R30 A2K-30R 30A

3K7 KTN-R45 JKS-45 JJN-45 KLN-R45 - A2K-45R 45A

3 x 380-480 V

0K37 - 0K75 KTS-R10 JKS-10 JJS-10 KLS-R10 ATM-R10 A6K-10R 10A

1K5 KTS-R15 JKS-15 JJS-15 KLS-R15 ATM-R15 A2K-15R 15A

2K2 KTS-R20 JKS-20 JJS-20 KLS-R20 ATM-R20 A6K-20R 20A

3K0 KTS-R25 JKS-25 JJS-25 KLS-R25 ATM-R25 A6K-25R 25A

4K0 KTS-R30 JKS-30 JJS-30 KLS-R30 ATM-R30 A6K-30R 30A

5K5 KTS-R35 JKS-35 JJS-35 KLS-R35 - A6K-35R 35A

7K5 KTS-R45 JKS-45 JJS-45 KLS-R45 - A6K-45R 45A

KTN-R45 JKS-45 JJN-45 KLN-R45 - A2K-45R 45A

Ferraz-

Shawmut

Ferraz-

Shawmut

Max. fuses non UL

Table 3.2: Fuses

3.1.3. EMC-Correct Installation

Following these guidelines is advised, where compliance with EN 61000-6-3/4, EN 55011 or EN 61800-3

is in EN 61800-3

Good engineering practice to ensure EMC-correct electrical installation:

Second environment

, then it is acceptable to deviate from these guidelines. It is however not recommended.

First environment

is required. If the installation

• Use only braided screened/armoured motor cables and control cables.

The screen should provide a minimum coverage of 80%.The screen material must be metal, not limited to but typically copper, aluminium, steel

or lead. There are no special requirements for the mains cable.

• Installations using rigid metal conduits are not required to use screened cable, but the motor cable must be installed in conduit separate from

the control and mains cables. Full connection of the conduit from the drive to the motor is required. The EMC performance of flexible conduits

varies a lot and information from the manufacturer must be obtained.

• Connect the screen/armour/conduit to earth at both ends for motor cables and control cables.

• Avoid terminating the screen/armour with twisted ends (pigtails). Such a termination increases the high frequency impedance of the screen,

which reduces its effectiveness at high frequencies. Use low impedance cable clamps or glands instead.

• Ensure good electrical contact between the de-coupling plate and the metal chassis of the frequency converter, see Instruction MI.02.BX.YY

• Avoid using unscreened/unarmoured motor or control cables inside cabinets housing the drive(s), where possible.

10

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 13

VLTp Micro Drive FC 51 Operating Instructions

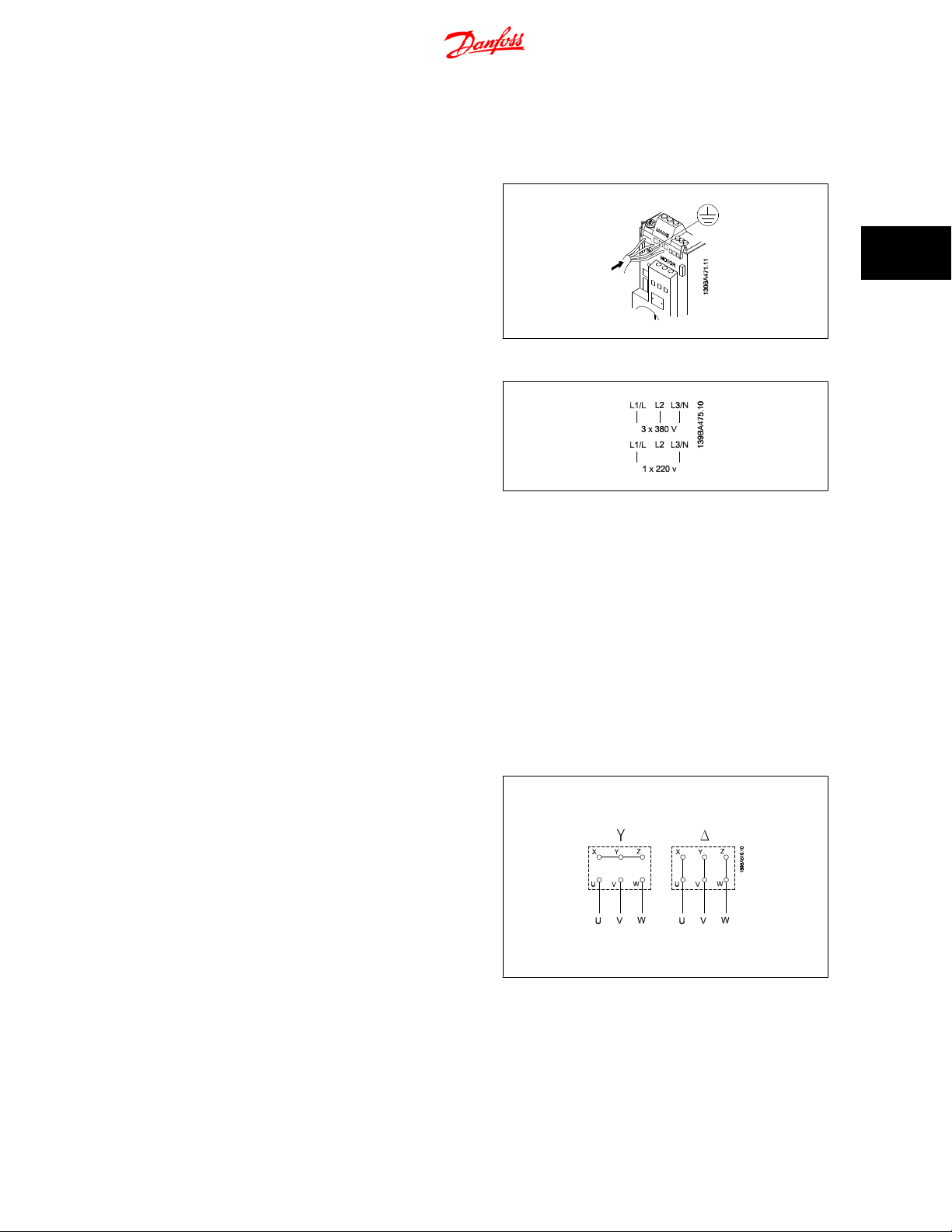

3.2. Mains Connection

3.2.1. Connecting to Mains

Step 1: First mount earth cable.

Step 2: Mount wires in terminals L1/L, L2 and L3/N and tighten.

For 3-phase connection, connect wires to all three terminals.

For single-phase connection, connect wires to terminals L1/L and L3/N.

3. Electrical Installation

3

Illustration 3.1: Mounting of earth cable and mains wires.

Illustration 3.2: Three-phase and single-phase wire connections.

3.3. Motor Connection

3.3.1. How to Connect the Motor

See the chapter

• Use a shielded/armored motor cable to comply with EMC emission specifications, and connect this cable to both the decoupling plate and the

• Keep motor cable as short as possible to reduce the noise level and leakage currents.

For further details on mounting of the decoupling plate, please see instruction MI.02.BX.YY.

All types of three-phased asynchronous standard motors can be connec-

ted to the frequency converter. Normally, small motors are star-connec-

ted (230/400 V, ˂/Y). Large motors are delta-connected (400/690 V, ˂/

Y). Refer to motor nameplate for correct connection and voltage.

Specifications

motor metal.

for correct dimensioning of motor cable cross-section and length.

Illustration 3.3: Star and delta connections.

MG.02.A3.02 - VLTp is a registered Danfoss trademark

11

Page 14

3. Electrical Installation

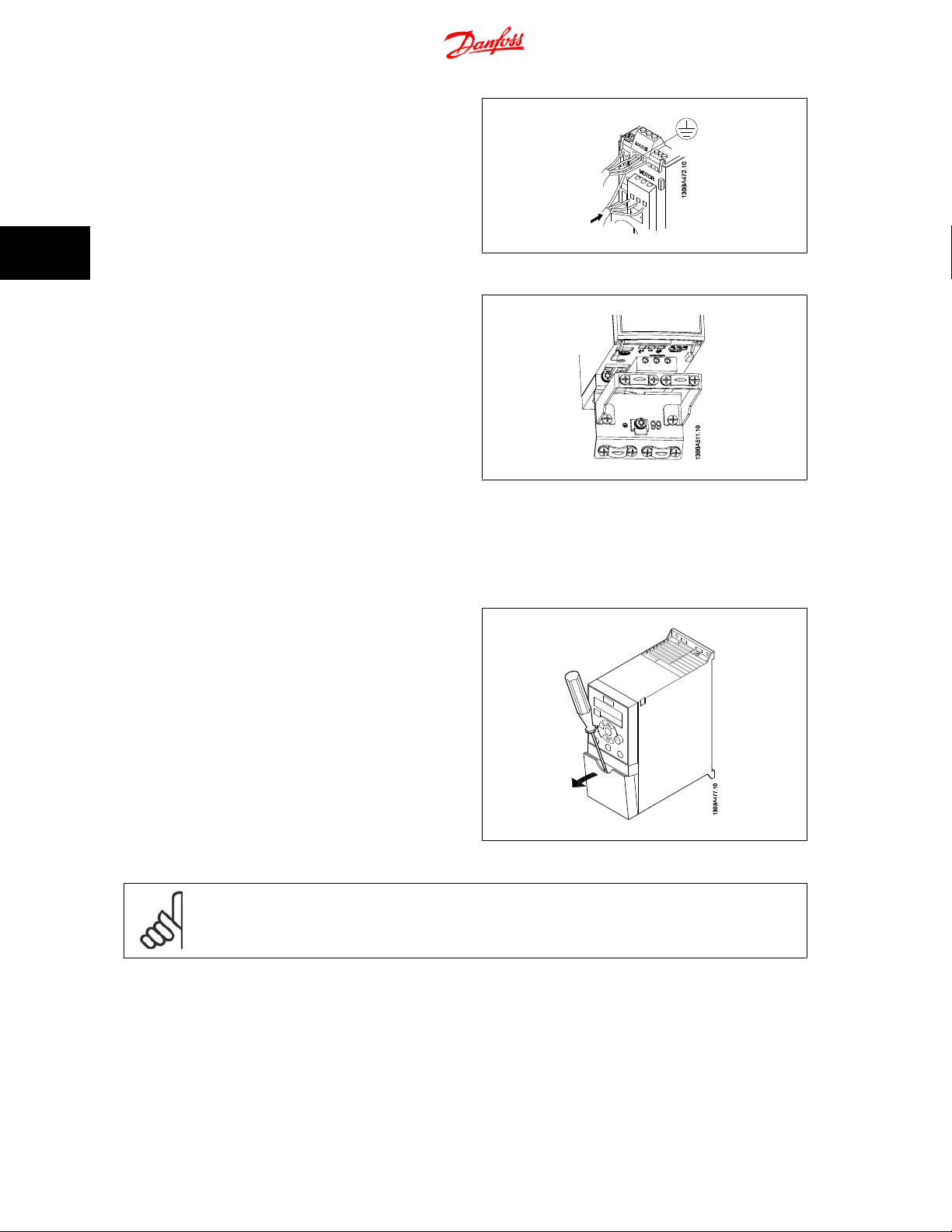

Step 1: First, mount the earth cable.

Step 2: Connect wires to terminals either in star or delta-connection. See

motor nameplate for further information.

VLTp Micro Drive FC 51 Operating Instruc-

tions

3

For EMC correct installation, use optional de-coupling plate, see chapter

Options for VLT Micro Drive FC 51

.

3.4. Control Terminals

3.4.1. Access to Control Terminals

All control cable terminals are located underneath the terminal cover in

front of the frequency converter. Remove the terminal cover using a

screwdriver.

Illustration 3.4: Mounting of earth cable and motor wires.

Illustration 3.5: VLT Micro Drive with de-coupling plate

Illustration 3.6: Removing terminal cover.

NB!

See back of terminal cover for outlines of control terminals and switches.

12

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 15

VLTp Micro Drive FC 51 Operating Instructions

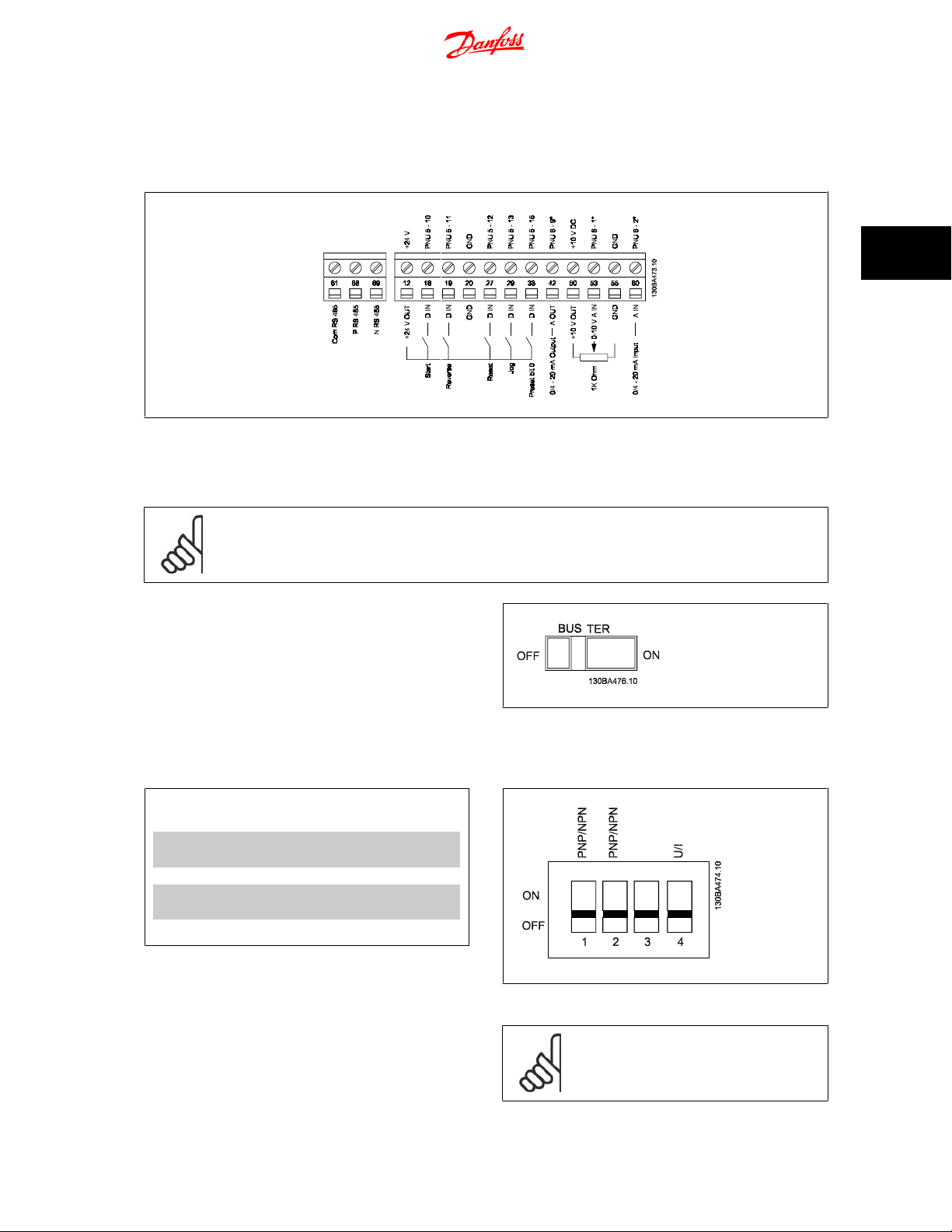

3.4.2. Connecting to Control Terminals

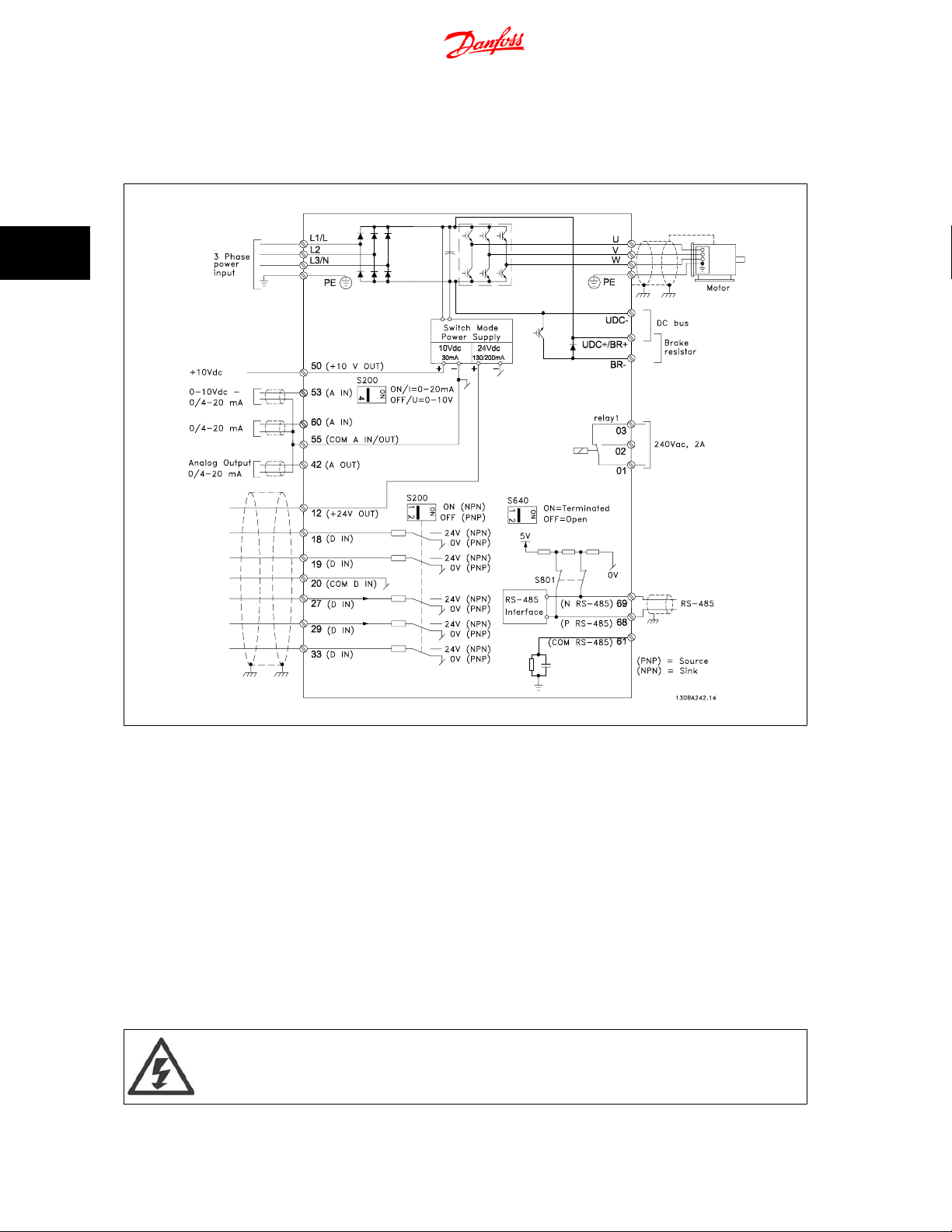

This illustration shows all control terminals of the VLT Micro Drive. Applying Start (term. 18) and an analog reference (term. 53 or 60) make the frequency

converter run.

Illustration 3.7: Overview of control terminals in PNP-configuration and factory setting.

3. Electrical Installation

3.5. Switches

3

NB!

Do not operate switches with power on the frequency converter.

Bus termination:

BUS TER

Switch

See power circuit drawing.

Default setting = Off.

S200 Switches 1-4:

Switch 1: *OFF = PNP terminals 29

Switch 2: *OFF = PNP terminal 18, 19, 27 and 33

Switch 3: No function

Switch 4: *OFF = Terminal 53 0 - 10 V

* = default setting

Table 3.3: Settings for S200 Switches 1-4

pos. ON terminates the RS485 port, terminals 68, 69.

ON = NPN terminals 29

ON = NPN terminal 18, 19, 27 and 33

ON = Terminal 53 0/4 - 20 mA

Illustration 3.8: S640 Bus termination.

Illustration 3.9: S200 Switches 1-4.

NB!

Parameter 6-19 must be set according to Switch 4 po-

sition.

MG.02.A3.02 - VLTp is a registered Danfoss trademark

13

Page 16

3

3. Electrical Installation

3.6. Power Circuit - Overview

3.6.1. Power Circuit - Overview

VLTp Micro Drive FC 51 Operating Instruc-

tions

Illustration 3.10: Diagram showing all electrical terminals.

Brake not applicable for frame M1.

Brake resistors are available from Danfoss.

Improved power factor and EMC performance can be achieved by installing optional Danfoss line filters.

Danfoss power filters can also be used for load sharing.

3.6.2. Load sharing/Brake

Use 6.3 mm insulated Faston Plugs designed for high voltage for DC (Load Sharing and brake).

Contact Danfoss or see instruction no. MI.50.Nx.02 for load sharing and instruction no. MI.90.Fx.02 for brake.

Load sharing: Connect terminals UDC- and UDC/BR+.

Brake: Connect terminals BR- and UDC/BR+.

Note that voltage levels of up to 850 V DC may occur between terminals

UDC+/BR+ and UDC-. Not short circuit protected.

14

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 17

VLTp Micro Drive FC 51 Operating Instructions

4. Programming

4. Programming

4.1. How to Programme

4.1.1. Programming with MCT-10

The frequency converter can be programmed from a PC via RS485 com-port by installing the MCT-10 Set-up Software.

This software can either be ordered using code number 130B1000 or downloaded from the Danfoss Web site: www.danfoss.com, Business Area: Motion

Controls.

Please refer to manual MG.10.RX.YY.

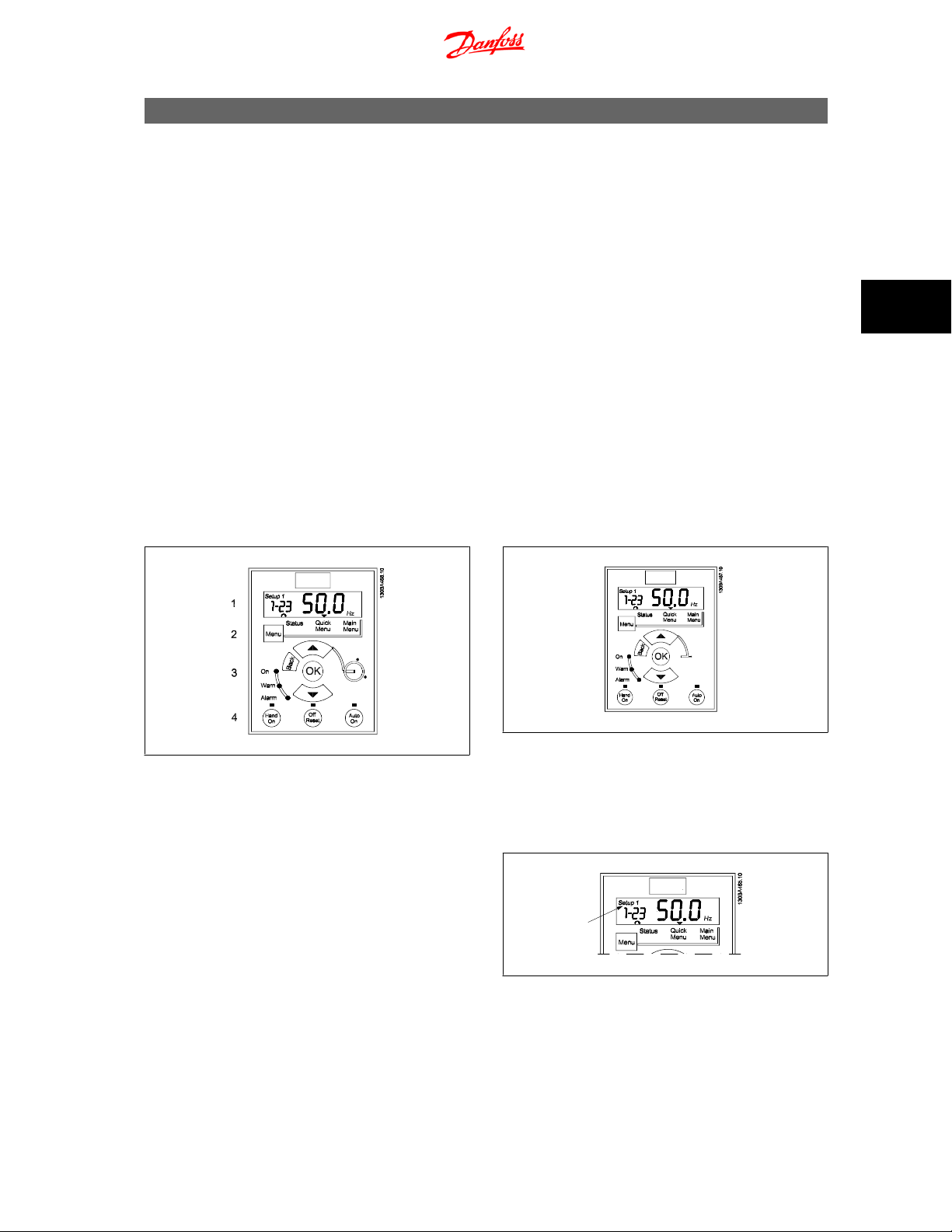

4.1.2. Programming with LCP 11 or LCP 12

The LCP is divided into four functional groups:

1. Numeric display.

2. Menu key.

3. Navigation keys.

4. Operation keys and indicator lights (LEDs).

4

Illustration 4.1: LCP 12 with potentiometer

The display:

A number of information can be read from the display.

Set-up number shows the active set-up and the edit set-up. If the same

set-up acts as both active and edit set-up, only that set-up number is

shown (factory setting).

When active and edit set-up differ, both numbers are shown in the display

(Setup 12). The number flashing, indicates the edit set-up.

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Illustration 4.2: LCP 11 without potentiometer

Illustration 4.3: Indicating Set-up

15

Page 18

4

4. Programming

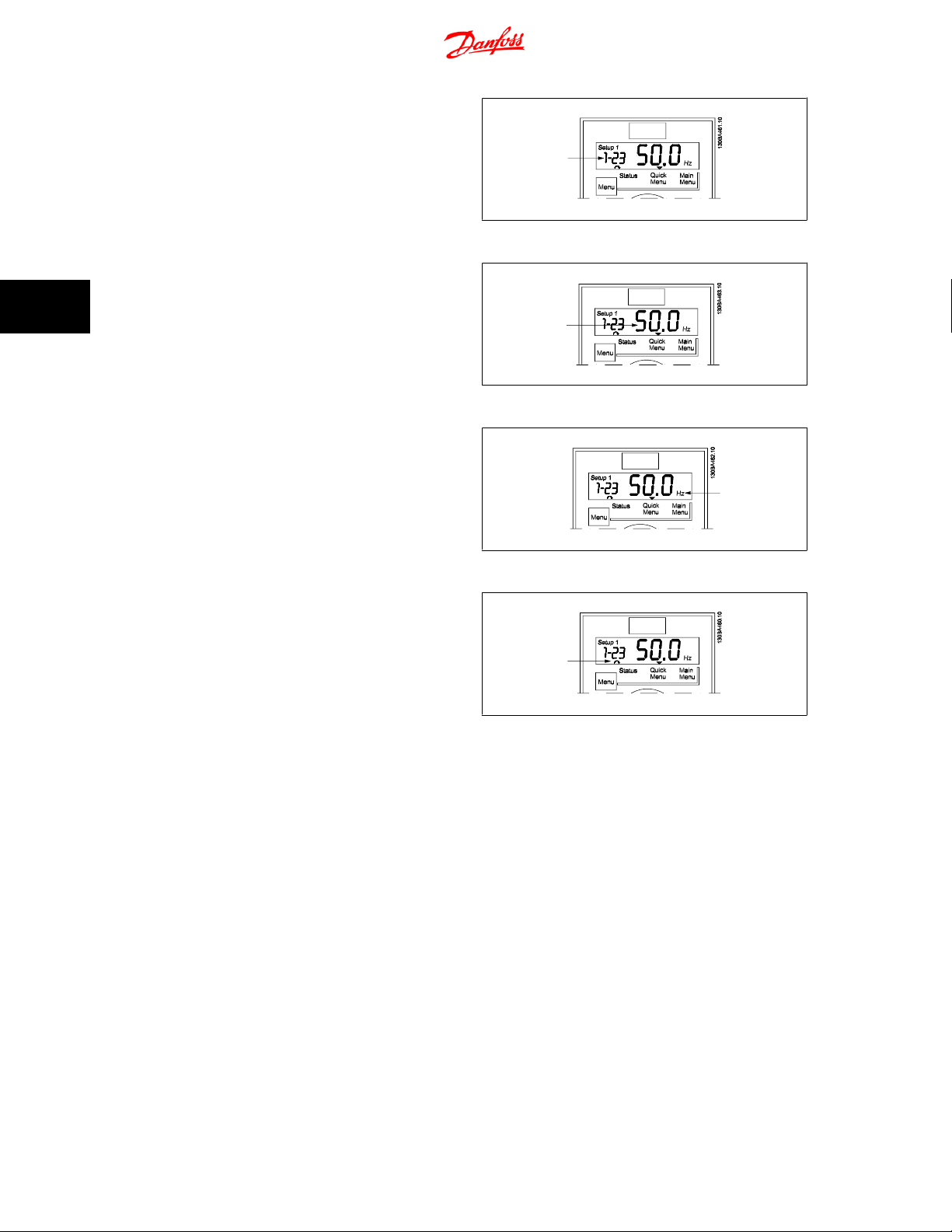

The small digits to the left are the selected parameter number .

The large digits in the middle of the display show the value of the

selected parameter.

The right side of the display shows the unit of the selected parameter.

This can be either Hz, A, V, kW, HP, %, s or RPM.

VLTp Micro Drive FC 51 Operating Instruc-

tions

Illustration 4.4: Indicating selected par. no.

Illustration 4.5: Indicating value of selected par.

Illustration 4.6: Indicating unit of selected par.

Motor direction is shown to the bottom left of the display - indicated

by a small arrow pointing either clockwise or counterclockwise.

Illustration 4.7: Indicating motor direction

Use the [MENU] key to select one of the following menus:

Status Menu:

The Status Menu is either in

display.

In

Hand on Mode

Quick Menu:

Displays Quick Menu parameters and their settings. Parameters in the Quick Menu can be accessed and edited from here. Most applications can be run

by setting the parameters in the Quick Menus.

Main Menu:

Displays Main Menu parameters and their settings. All parameters can be accessed and edited here. A parameter overview is found later in this manual.

the local LCP reference is displayed.

Readout Mode

or

Hand on Mode

. In

Readout Mode

the value of the currently selected readout parameter is shown in the

Indicator lights:

• Green LED: Power is on the frequency converter.

• Yellow LED: Indicates a warning.

• Flashing red LED: Indicates an alarm.

16

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 19

Ⴃ

VLTp Micro Drive FC 51 Operating Instructions

Navigation Keys:

[Back]: For moving to the previous step or layer in the navigation structure.

Arrows [

[OK]: For selecting a parameter and for accepting changes to parameter settings.

Operation Keys:

A yellow light above the operation keys indicates the active key.

[Hand on]: Starts the motor and enables control of the frequency converter via the LCP.

[Off/Reset]: The motor stops except in alarm mode. In that case the motor will be reset.

[Auto on]: The frequency converter is controlled either via control terminals or serial communication.

[Potentiometer] (LCP12): The potentiometer works in two ways depending on the mode in which the frequency converter is running.

In

In

] [Ⴍ]: For manoeuvring between parameter groups, parameters and within parameters.

Auto Mode

Hand on Mode

the potentiometer acts as an extra programmable analog input.

the potentiometer controls local reference.

4.2. Status Menu

After power up the Status Menu is active. Use the [MENU] key to toggle

between Status, Quick Menu and Main Menu.

Arrows [Ⴃ] and [Ⴍ] toggles between the choices in each menu.

4. Programming

4

The display indicates the status mode with a small arrow above “Status”.

Illustration 4.8: Indicating Status mode

4.3. Quick Menu

The Quick Menu gives easy access to the most frequently used parameters.

1. To enter the Quick Menu, press [MENU] key until indicator in

display is placed above

2. Use [Ⴃ] [Ⴍ] to browse through the parameters in the Quick

Menu.

3. Press [OK] to select a parameter.

4.

Use [Ⴃ] [Ⴍ] to change the value of a parameter setting.

5. Press [OK] to accept the change.

6. To exit, press either [Back] twice to enter

[Menu] once to enter

Quick Menu

Main Menu

, then press [OK].

.

Status

Illustration 4.9: Indicating Quick Menu mode

, or press

4.4. Quick Menu Parameters

4.4.1. Quick Menu Parameters - Basic Settings QM1

Below are descriptions of all parameters found in the Quick Menu.

᧦ = Factory setting.

1-20 Motor Power [kW]/[HP] (P

Option: Function:

Enter motor power from nameplate data.

Two sizes down, one size up from nominal VLT rating.

[1] 0.09 kW/0.12 HP

MG.02.A3.02 - VLTp is a registered Danfoss trademark

m.n

)

17

Page 20

4

4. Programming

[2] 0.12 kW/0.16 HP

[3] 0.18kW/0.25 HP

[4] 0.25 kW/0.33 HP

[5] 0.37kW/0.50 HP

[6] 0.55 kW/0.75 HP

[7] 0.75 kW/1.00 HP

[8] 1.10 kW/1.50 HP

[9] 1.50 kW/2.00 HP

[10] 2.20 kW/3.00 HP

[11] 3.00 kW/4.00 HP

[12] 3.70 kW/5.00 HP

[13] 4.00 kW/5.40 HP

[14] 5.50 kW/7.50 HP

[15] 7.50 kW/10.0 HP

[16] 11.00 kW/15.00 HP

NB!

Changing this parameter affects par. 1-22 to 1-25, 1-30, 1-33 and 1-35.

VLTp Micro Drive FC 51 Operating Instruc-

tions

1-22 Motor Voltage (U

m.n

)

Range: Function:

230/400 V [50 - 999 V] Enter motor voltage from nameplate data.

1-23 Motor Frequency (f

m.n

)

Range: Function:

50 Hz* [20-400 Hz]

1-24 Motor Current (I

Enter motor frequency from nameplate data.

)

m.n

Range: Function:

M-type dependent* [0.01 - 26.00

A]

1-25 Motor Nominal Speed (n

Enter motor current from nameplate data.

)

m.n

Range: Function:

M-type Dependent* [100 - 9999

RPM]

Enter motor nominal speed from nameplate data.

1-29 Automatic Motor Tuning (AMT)

Option: Function:

Use AMT to optimize motor performance.

NB!

This parameter cannot be changed while motor runs.

1. Stop VLT – make sure motor is at standstill

2. Choose [2] Enable AMT

3. Apply start signal

– Via LCP: Press Hand On

- Or in Remote On mode: Apply start signal on terminal 18

18

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 21

VLTp Micro Drive FC 51 Operating Instructions

4. Programming

[0]

*

[2] Enable AMT AMT function starts running.

Off AMT function is disabled.

NB!

To gain optimum tuning of frequency converter, run AMT on a cold motor.

3-02 Minimum Reference

Range: Function:

0.00* [-4999 - 4999]

Enter value for minimum reference.

The sum of all internal and external references are clamped (limited) to the minimum reference value, par. 3-02.

3-03 Maximum Reference

Range: Function:

Maximum Reference is adjustable in the range Minimum Reference - 4999.

50.00

*

[-4999 - 4999]

Enter value for Maximum Reference.

The sum of all internal and external references are clamped (limited) to the maximum reference value, par.

3-03.

3-41 Ramp1 Ramp-up Time

Range: Function:

3.00 s* [0.05 - 3600 s ]

Enter ramp-up time from 0 Hz to rated motor frequency (f

Choose a ramp-up time ensuring that torque limit is not exceeded, see par. 4-16.

3-42 Ramp1 Ramp-down Time

Range: Function:

3.00* [0.05 - 3600 s]

Enter ramp down time from rated motor frequency (f

Choose a ramp down time that does not cause over-voltage in inverter due to regenerative operation of motor.

Furthermore, regenerative torque must not exceed limit set in par. 4-17.

) set in par. 1-23.

M,N

) in par. 1-23 to 0 Hz.

M,N

4

4.4.2. Quick Menu Parameters - PI Basic Settings QM2

The following is a brief description of the parameters for the PI Basic Settings. For a more detailed description, please see

, MG.02.CX.YY.

Guide

1-00 Configuration Mode

Range: Function:

[] Choose [3] Process Closed Loop

3-02 Min. Reference

Range: Function:

[-4999 - 4999] Sets limits for set-point and feedback.

3-03 Max. Reference

Range: Function:

[-4999 - 4999] Sets limits for set-point and feedback.

3-10 Preset Reference

Range: Function:

[-100.00 - 100.00] Preset [0] works as set-point.

4-12 Motor Speed Low Limit

Range: Function:

[0.0 - 400 Hz] Lowest possible output frequency.

VLT Micro Drive Programming

MG.02.A3.02 - VLTp is a registered Danfoss trademark

19

Page 22

4

4. Programming

4-14 Motor Speed High Limit

Range: Function:

[0.0 - 400.00 Hz] Highest possible output frequency.

NB!

Default 65 Hz should normally be reduced to 50 - 55 Hz.

6-22 Terminal 60 Low Current

Range: Function:

[0.00 - 19.99 mA] Normally set to 0 or 4 mA.

6-23 Terminal 60 High Current

Range: Function:

[0.01 - 20.00 mA] Normally (default) set to 20 mA.

6-24 Terminal 60 Low Feedback Value

Range: Function:

[-4999 - 4999] Value corresponding to P. 6-22 setting.

VLTp Micro Drive FC 51 Operating Instruc-

tions

6-25 Terminal 60 High Feedback Value

Range: Function:

[-4999 - 4999] Value corresponding to P. 6-23 setting.

6-26 Terminal 60 Filter Time Constant

Range: Function:

[0.01 - 10.00 s] Filter for suppressing electrical noise.

7-20 Process CL Feedback Resource

Range: Function:

[] Choose [2] analog input 60.

7-30 Process PI Normal/Inverse

Range: Function:

[] Most PI controllers are “Normal”.

7-31 Process PI Anti Windup

Range: Function:

[] Leave

Enabled

normally.

7-32 Process PI Start Speed

Range: Function:

[0.0 - 200.0 Hz] Choose expected normal running speed.

7-33 Process PI Proportional Gain

Range: Function:

[0.00 - 10.00] Enter the P-factor.

7-34 Process PI Integral Time

Range: Function:

[0.10 - 9999.00 s] Enter the I-factor.

20

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 23

VLTp Micro Drive FC 51 Operating Instructions

7-38 Process Feed Forward Factor

Range: Function:

[0 - 400%] Only applicable with changing set-points.

4. Programming

4

MG.02.A3.02 - VLTp is a registered Danfoss trademark

21

Page 24

4

4. Programming

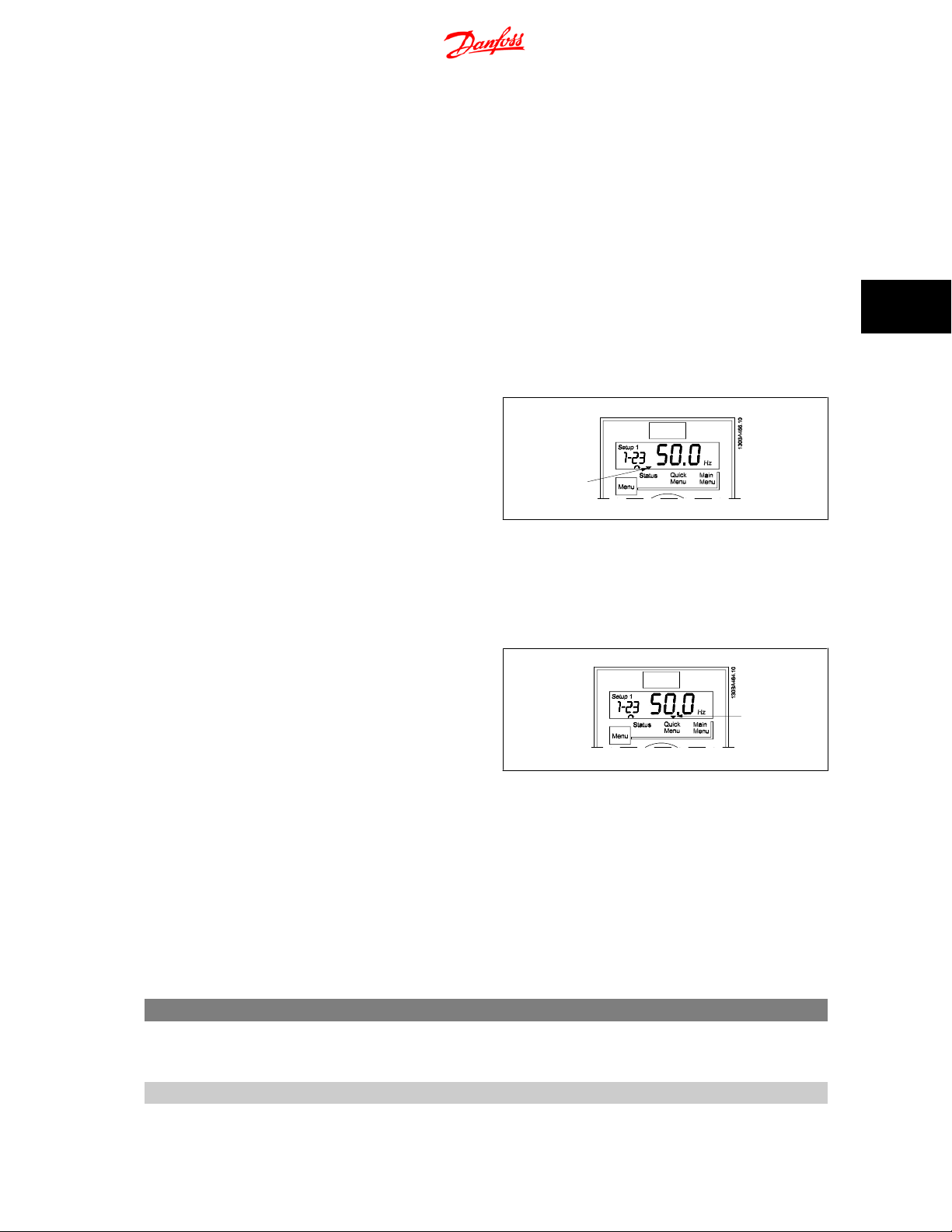

4.5. Main Menu

The Main Menu gives access to all parameters.

1. To enter the Main Menu, press [MENU] key until indicator in

display is placed above

2. Use [Ⴃ] [Ⴍ] to browse through the parameter groups.

3. Press [OK] to select a parameter group.

4. Use [Ⴃ] [Ⴍ] to browse through the parameters in the specific

group.

5. Press [OK] to select the parameter.

6.

Use [Ⴃ] [Ⴍ] to set/change the parameter value.

7. Press [OK] to accept the value.

8. To exit, press either [Back] twice to enter

[Menu] once to enter

Main Menu

Status

.

Quick Menu

.

VLTp Micro Drive FC 51 Operating Instruc-

tions

Illustration 4.10: Indicating Main Menu mode

, or press

22

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 25

VLTp Micro Drive FC 51 Operating Instructions

5. Modbus RTU

5. Modbus RTU

5.1. Modbus RTU Overview

5.1.1. Assumptions

These operating instructions assume that the installed controller supports the interfaces in this document and that all the requirements stipulated in the

controller, as well as the frequency converter, are strictly observed, along with all limitations therein.

5.1.2. What the User Should Already Know

The Modbus RTU (Remote Terminal Unit) is designed to communicate with any controller that supports the interfaces defined in this document. It is

assumed that the user has full knowledge of the capabilities and limitations of the controller.

5.1.3. Modbus RTU Overview

Regardless of the type of physical communication networks, the Modbus RTU Overview describes the process a controller uses to request access to

another device. This includes i.a. how it will respond to requests from another device, and how errors will be detected and reported. It also establishes

a common format for the layout and contents of message fields.

During communications over a Modbus RTU network, the protocol determines how each controller will learn its device address, recognise a message

addressed to it, determine the kind of action to be taken, and extract any data or other information contained in the message. If a reply is required, the

controller will construct the reply message and send it.

Controllers communicate using a master-slave technique in which only one device (the master) can initiate transactions (called queries). The other devices

(slaves) respond by supplying the requested data to the master, or by taking the action requested in the query.

The master can address individual slaves, or can initiate a broadcast message to all slaves. Slaves return a message (called a response) to queries that

are addressed to them individually. No responses are returned to broadcast queries from the master. The Modbus RTU protocol establishes the format

for the master’s query by placing into it the device (or broadcast) address, a function code defining the requested action, any data to be sent, and an

error-checking field. The slave’s response message is also constructed using Modbus protocol. It contains fields confirming the action taken, any data to

be returned, and an error-checking field. If an error occurs in receipt of the message, or if the slave is unable to perform the requested action, the slave

will construct an error message and send it in response, or a time-out will occur.

5

5.1.4. Frequency Converter with Modbus RTU

The frequency converter communicates in Modbus RTU format over the built-in RS-485 interface. Modbus RTU provides access to the Control Word and

Bus Reference of the frequency converter.

The Control Word allows the Modbus master to control several important functions of the frequency converter:

• Start

• Stop of the frequency converter in various ways:

Coast stop

Quick stop

DC Brake stop

Normal (ramp) stop

• Reset after a fault trip

• Run at a variety of preset speeds

• Run in reverse

• Change the active set-up

• Control the frequency converter’s built-in relay

The Bus Reference is commonly used for speed control. It is also possible to access the parameters, read their values, and where possible, write values

to them. This permits a range of control options, including controlling the setpoint of the frequency converter when its internal PI controller is used.

MG.02.A3.02 - VLTp is a registered Danfoss trademark

23

Page 26

VLTp Micro Drive FC 51 Operating Instruc-

5. Modbus RTU

5.2. Modbus RTU Message Framing Structure

5.2.1. Remote Terminal Unit

The controllers are set up to communicate on the Modbus network using RTU (Remote Terminal Unit) mode, with each 8-bit byte in a message containing

two 4-bit hexadecimal characters.

The format for each byte is shown below.

tions

5

Start bit

Coding system: 8-bit binary, hexadecimal 0-9, A-F. Two hexadecimal characters contained in each 8-bit field of

Bits per byte: 1 start bit

Error Check Field: Cyclical Redundancy Check (CRC).

Data bit Stop/pari-tyStop

the message.

8 data bits, least significant bit sent first

Parity: 1 bit for even/odd parity is used; 1 or 2 stop bits if no parity is selected (see par. 8-33).

5.2.2. Modbus RTU Message Structure

The transmitting device places a Modbus RTU message into a frame with a known beginning and ending point. This allows receiving devices to begin at

the start of the message, read the address portion, determine which device is addressed (or all devices, if the message is broadcast), and to recognise

when the message is completed. Partial messages are detected and errors set as a result - or timeouts occur. Characters for transmission must be in

hexadecimal 00 to FF format in each field.

The frequency converter continuously monitors the network bus, also during “silent” intervals. When the first field (the address field) is received, each

frequency converter or device decodes it to determine which device is being addressed. Modbus RTU messages addressed to zero are broadcast messages.

No response is permitted for boradcast messages. A typical message frame is shown below.

Start

T1-T2-T3-T4 1 byte 1 byte N x 1 byte 2 bytes T1-T2-T3-T4

Address Function Data CRC check End

Table 5.1: Typical Modbus RTU Message Structure

5.2.3. Start/Stop Field

Messages start with a silent period of at least 3.5 character intervals. This is implemented as a multiple of character intervals at the selected network

baud rate (shown as Start T1-T2-T3-T4). The first field to be transmitted is the device address. Following the last transmitted character, a similar period

of at least 3.5 character intervals marks the end of the message. A new message can begin after this period.

The entire message frame must be transmitted as a continuous stream. If a silent period of more than 1.5 character intervals occurs before completion

of the frame, the receiving device flushes the incomplete message and assumes that the next byte will be the address field of a new message. Similarly,

if a new message begins prior to 3.5 character intervals after a previous message, the receiving device will ignore both messages. This will cause a time-

out (no response from the slave).

5.2.4. Address Field

The address field of a message frame contains 1 byte. Valid slave device addresses are in the range of 0 - 247 decimal. The individual slave devices are

assigned addresses in the range of 1 - 247 (0 is reserved for broadcast mode, which all slaves recognise). A master addresses a slave by placing the

slave address in the address field of the message.

24

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 27

VLTp Micro Drive FC 51 Operating Instructions

When the slave sends its response, it places its own address in this address field to let the master know which slave is responding.

5.2.5. Function Field

The function field of a message frame contains 1 byte. Function fields are used to send messages between master and slave. When a message is sent

from a master to a slave device, the function code field tells the slave what kind of action to perform. When the slave responds to the master, it uses the

function code field to indicate either a normal (error-free) response, or that some kind of error occurred (called an exception response).

For a normal response, the slave simply echoes the original function code. For an exception response, the slave returns a code that is equivalent to the

original code with its most significant bit set to logic 1. In addition, the slave places a unique code into the data field of the response message. This tells

the master what kind of error occurred, or the reason for the exception. Please also refer to the sections

Exception Codes

.

5.2.6. Data Field

The data field is constructed using sets of two hexidecimal digits in the range of 00 to FF hexidecimal. These are made up of one RTU character. The

data field of messages sent from a master to a slave device contains additional information which the slave must use to take the action defined by the

function code. This can include items such as addresses of coils or registers, the quantity of items to be handled. and the count of actual data bytes in

the field.

5.2.7. CRC Check Field

Function Codes Supported by Modbus RTU

5. Modbus RTU

and

5

Messages include an error-checking field, operating on the basis of a Cyclical Redundancy Check (CRC) method. The CRC field checks the content of the

entire message. It is applied regardless of any parity check method used for the individual characters of the message.

The CRC value is calculated by the transmitting device, which appends the CRC as the last field in the message. The receiving device recalculates a CRC

during receipt of the message and compares the calculated value to the actual value received in the CRC field. If the two values are unequal, a bus time-

out occurs. The error-checking field contains a 16-bit binary value implemented as two 8-bit bytes. When this is done, the low-order byte of the field is

appended first, followed by the high-order byte. The CRC high-order byte is the last byte sent in the message.

5.2.8. Coil/Register Addressing

In Modbus, all data are organised in coils and holding registers. Coils hold a single bit, whereas holding registers hold a 2-byte word (i.e. 16 bits). All

data addresses in Modbus messages are referenced to zero. The first occurrence of a data item is addressed as item number zero.

Example:

The coil known as “coil 1” in programmable controller is addressed as coil 0000 in the data address field of a Modbus message. Coil 127 decimal is

addressed as coil 007E

Holding register 40001 is addressed as register 0000 in the data address field of the message. The function code field already specifies a “holding register”

operation. Therefore, the “4XXXX” reference is implicit. Holding register 40108 is addressed as register 006B

(126 decimal).

HEX

(107 decimal).

HEX

MG.02.A3.02 - VLTp is a registered Danfoss trademark

25

Page 28

5

VLTp Micro Drive FC 51 Operating Instruc-

5. Modbus RTU

Coil number Description Signal direction

1 - 16 Frequency converter control word (see table below) Master to slave

17 - 32 Frequency converter speed or set-point reference

Range 0x0 - 0xFFFF (-200% ... ~ 200%)

33 - 48 Frequency converter status word (see table below) Slave to master

49 - 64 Open loop mode: Frequency converter output fre-

quency

Closed loop mode: Frequency converter feedback

signal

65 Parameter write control (master to slave)

0 = Parameter changes are written to the RAM of

the frequency converter

1 = Parameter changes are written to the RAM and

EEPROM of the frequency converter

66 - 65536 Reserved

Master to slave

Slave to master

Master to slave

tions

Coil 0 1

01 Preset reference LSB

02 Preset reference MSB

03 DC brake No DC brake

04 Coast stop No coast stop

05 Quick stop No quick stop

06 Freeze outp No freeze outp

07 Ramp stop Start

08 No function Reset

09 No jog Jog

10 Ramp 1 Ramp 2

11 Data not valid Data valid

12 Relay 1 off Relay 1 on

13 Not used Not used

14 Setup 1 Setup 2

15 Not used Not used

16 No reversing Reversing

Frequency converter control word (FC profile)

Register number Description

00001 – 00006 Reserved

00007 Last error code from an FC data object interface

00008 Reserved

00009 Parameter index*

00100 – 00999 000 parameter group (parameters 001 through 099)

01000 – 01999 100 parameter group (parameters 100 through 199)

02000 – 02999 200 parameter group (parameters 200 through 299)

03000 – 03999 300 parameter group (parameters 300 through 399)

04000 – 04999 400 parameter group (parameters 400 through 499)

……

49000 – 49999 4900 parameter group (parameters 4900 through 4999)

50000 Input data: Frequency converter control word register (CTW).

50010 Input data: Bus reference register (REF).

……

50200 Output data: Frequency converter status word register (STW).

50210 Output data: Frequency converter main actual value register (MAV).

Coil 0 1

33 Control not ready Control ready

34 Unit not ready Unit ready

35 Coasted Not coasted

36 Error, tripped

37 Error, no trip

38 Not used Not used

39 Error, trip locked

40 No warning Warning

41 Not on reference On reference

42 Hand mode Auto mode

43 Out of freq. range In frequency range

44 Not running Running

45 No res. brake fault Resistor brake fault

46 No voltage warning Voltage warning

47 Not in current limit Current limit

48 No thermal warning Thermal warning

Frequency converter status word (FC profile)

Table 5.2: Holding Registers

* Used to specify the index number to be used when accessing an indexed parameter

26

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 29

VLTp Micro Drive FC 51 Operating Instructions

5. Modbus RTU

5.3. How to Control FC 51

This section describes codes which can be used in the function and data fields of a Modbus RTU message. For a complete description of all the message

fields please refer to the section

5.3.1. Function Codes Supported by Modbus RTU

Modbus RTU supports use of the following function codes in the function field of a message:

Function Function Code

Read coils 1 hex

Read holding registers 3 hex

Write single coil 5 hex

Write single register 6 hex

Write multiple coils F hex

Write multiple registers 10 hex

Get comm. event counter B hex

Report slave ID 11 hex

Function Function code Sub-function code Sub-function

Diagnostics 8 1 Restart communication

2 Return diagnostic register

11 Return bus message count

13 Return bus exception error count

Modbus RTU Message Framing Structure

.

10 Clear counters and diagnostic register

12 Return bus communication error count

14 Return slave message count

5

5.3.2. Exception and Error Codes

In the event of an error, the following exception codes may appear in the data field of a response message. For a full explanation of the structure of an

exception (i.e. error) response, please refer to

Code Name Meaning

1 Illegal function The function code received in the query is not an allowable action for the server (or slave). This may be because the

function code is only applicable to newer devices, and was not implemented in the unit selected. It could also indicate

that the server (or slave) is in the wrong state to process a request of this type, for example it is not configured and is

being asked to return register values.

2 Illegal data address The data address received in the query is not an allowable address for the server (or slave). More specifically, the

combination of reference number and transfer length is invalid. For a controller with 100 registers, a register with offset

96 and length 4 would succeed, a request with offset 96 and length 5 will generate exception 02.

3 Illegal data value A value contained in the query data field is not an allowable value for server (or slave). This indicates a fault in the

structure of the remainder of a complex request, such as an incorrect implied length. It specifically does NOT mean that

a data item submitted for storage in a register has a value outside the expectation of the application program, since the

MODBUS protocol is unaware of the significance of any particular value of any particular register.

4 Slave device failure An unrecoverable error occurred while the server (or slave) was attempting to perform the requested action

In case of an exception code 4 while accessing parameter values in the drive, detailed information about the latest exception can be read from the drives

Holding Register 0007. This register may contain one of the following, detailed error codes regarding the latest occurring MODBUS Exception.

Function Field

in section

MODBUS Exception Codes

Modbus RTU Message Framing Structure

.

MG.02.A3.02 - VLTp is a registered Danfoss trademark

27

Page 30

5

VLTp Micro Drive FC 51 Operating Instruc-

5. Modbus RTU

Error code in holding register 0007 Description

00 The parameter number does not exist

01 There is no write access to the parameter

02 The data value exceeds the parameter limits

03 The sub-index in use does not exist

05 The data type does not match the parameter called

17 Data change in the parameter called is not possible in the present mode

18 Other error

130 There is no bus access to the parameter called

5.4. How to Access Parameters

5.4.1. Parameter Handling

The PNU (Parameter Number) is translated from the register address contained in the Modbus read or write message. The parameter number is translated

to Modbus register address as (10 x parameter number -1)

5.4.2. Storage of Data

The Coil 65 decimal determines whether data written to the frequency converter are stored in EEPROM and RAM (coil 65 = 1) or only in RAM (coil 65 =

0).

DECIMAL

.

tions

5.4.3. IND

The array index is set in Holding Register 9 and used when accessing array parameters.

5.4.4. Text Blocks

Parameters stored as text strings are accessed in the same way as the other parameters. The maximum text block size is 20 characters. If a read request

for a parameters is for more characters than the parameter stores, the response is truncated. If the read request for a parameter is for fewer characters

than the parameter stores, the response is space filled.

5.4.5. Conversion Factor

The different attributes for each parameter can be seen in the section on factory settings. Since a parameter value can only be transferred as a whole

number, a conversion factor must be used to transfer decimals. Please refer to the section

Conversion Index

.

5.4.6. Parameter Values

Standard Data Type

Standard data types are int16, int32, uint8, uint16 and uint32. They are stored as 4x registers (40001 - 4FFFF). The parameters are read using function

03

“Read Holding Registers”. Parameters are writtein using the function 6

HEX

“Preset Multiple Registers” for 2 registers (32 bits). Readable sizes range from 1 register (16 bits) up to 10 registers (20 characters).

Non Standard Data Types

Non standard data types are text strings and are stored as 4x registers (40001 - 4FFFF). The parameters are read using function 03

“Read Holding Registers” and written using function 10

HEX

registers (20 characters).

“Preset Multiple Registers”. Readable sizes range from 1 register (2 characters) up to 10

HEX

“Preset Single Register” for 1 register (16 bits), and the function 10

HEX

HEX

28

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 31

VLTp Micro Drive FC 51 Operating Instructions

5.5. Examples

5. Modbus RTU

The following examples illustrate various Modbus RTU commands. If an error occurs, please refer to the

5.5.1. Read Coil Status (01

Description

This function reads the ON/OFF status of discrete outputs (coils) in the frequency converter. Broadcast is never supported for reads.

Query

The query messages specifies the staring coil and quantity of coils to be read. Coil addresses start at zero, i.e. coil 33 is addressed as 32.

Example of a request to read coils 33-48 (Status Word) from slave device

01:

Field Name Example (HEX)

Slave address 01 (frequency converter address)

Function 01 (read address)

Starting Address HI 00

Starting Address LO 20 (32 decimal)

No. of Points HI 00

No. of Points LO 10 (16 decimal)

Error Check (CRC) -

Response

The coil status in the response message is packed as one coil per bit of the data field. Status is indicated as: 1 = ON; 0 = OFF.

The LSB of the first data byte contains the coil addressed in the query. The other coils follow toward the high order end of this byte, and from “low order

to high order” in subsequent bytes.

If the returned coil quantity is not a multiple of eight, the remaining bits in the final data byte will padded with zeros (toward the high order and of the

byte). The Byte Count field specifies the number of complete bytes of data.

HEX

)

Exception Codes

section.

5

Field Name Example (HEX)

Slave address 01 (frequency converter address)

Function 01 (read coils)

Byte count 02 (2 bytes of data)

Data (Coils 40-33) 07

Data (Coils 48-41) 06 (STW = 0607hex)

Error Check (CRC) -

5.5.2. Force/Write Single Coil (05

Description

This function forces a coil to either ON or OFF. When broadcast the function forces the same coil references in all attached sl aves.

Query

The query message specifies the coil 65 (parameter write control) to be forced. Coil addresses start at zero, i.e. coil 65 is addressed as 64. Force Data

= 00 00HEX (OFF) or FF 00HEX (ON).

Field Name Example (HEX)

Slave address 01 (frequency converter address)

Function 05 (write single coil)

Coil Address HI 00

Coil Address LO 40 (coil no. 65)

Force Data HI FF

Force Data LO 00 (FF 00 = ON)

Error Check (CRC) -

HEX

)

MG.02.A3.02 - VLTp is a registered Danfoss trademark

29

Page 32

5. Modbus RTU

Response

The normal response is an echo of the query, returned after the coil state has been forced.

Field Name Example (HEX)

Slave address 01

Function 05

Force Data HI FF

Force Data LO 00

Quantity of coils HI 00

Quantity of coils LO 01

Error Check (CRC) -

VLTp Micro Drive FC 51 Operating Instruc-

tions

5

5.5.3. Force/Write Multiple Coils (0F

Description

This function forces each coil in a sequence of coils to either ON or OFF. When broadcast the function forces the same coil references in all attached

slaves.

Query

The query message specifies the coils 17 to 32 (speed set-point) to be forced. Coil addresses start at zero, i.e. coil 17 is addressed as 16.

Field Name Example (HEX)

Slave address 01 (frequency converter address)

Function 0F (write multiple coil)

Coil Address HI 00

Coil Address LO 10 (coil address 17)

Quantity of coils HI 00

Quantity of coils LO 10 (16 coils)

Byte count 02

Force Data HI (coils 8-1) 20

Force Data LO (coils 10-9) 00 (ref. = 2000hex)

Error Check (CRC) -

Response

The normal response returns the slave address, function code, starting address, and quantity of coils forced.

Field Name Example (HEX)

Slave address 01 (frequency converter address)

Function 0F (write multiple coils)

Coil Address HI 00

Coil Address LO 10 (coil address 17)

Quantity of coils HI 00

Quantity of coils LO 10 (16 coils)

Error Check (CRC) -

HEX

)

30

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 33

VLTp Micro Drive FC 51 Operating Instructions

5. Modbus RTU

5.5.4. Read Holding Registers (03

Description

This function reads the content of holding registers in the slave.

Query

The query message specifies the starting register and quantity to be read. Register addresses start at zero, i.e. registers 1-4 are addressed as 0-3.

Example

Read PNU 342 which is mapped to register 0x0D5B(RegAdr = 342 x 10 - 1)

Field Name Example (HEX)

Slave address 01

Function 03

Starting Address HI 0D

Starting Address LO 5B

No. of Points HI 00

No. of Points LO 02

Error Check (CRC) -

HEX

)

Table 5.3: Request frame

Response

The register data in the response message are packed as two bytes per register, with the binary contents right justified within each byte. For each register,

the first byte contains the high order bits and the second contains the low order bits.

Field Name Example (HEX)

Slave address 01

Function 03

Data HI (Register 3419) 00

Data LO (Register 3419) 00

Data HI (Register 3420) 00

Data LO (Register 3420) 03

Error Check (CRC) -

5

Table 5.4: Normal response frame

5.5.5. Preset Single Register (06

Description

This function presets a value into a single holding register.

Query

The query message specifies the register reference to be preset. Register addresses start at zero, i.e. register 1 is addressed as 0.

Example

Write 1 to PNU3 which is mapped to register 0x001D (3 x 10-1 = 29 = 001DHex)

Field Name Example (HEX)

Slave address 01

Function 06

Starting Address HI 00

Starting Address LO 1D

No. of Points HI 00

No. of Points LO 01

Error Check (CRC) -

HEX

)

Table 5.5: Request frame

MG.02.A3.02 - VLTp is a registered Danfoss trademark

31

Page 34

VLTp Micro Drive FC 51 Operating Instruc-

5. Modbus RTU

Response

The normal response is an echo of the query, returned after the register contents have been passed.

Field Name Example (HEX)

Slave address 01

Function 06

Starting Address HI 00

Starting Address LO 1D

No. of Points HI 00

No. of Points LO 01

Error Check (CRC) -

Table 5.6: Normal response frame

tions

5

5.5.6. Preset Multiple Registers (10

Description

This function presets a value into a sequence of holding registers.

Query

The query message specifies the register references to be preset. Register addresses start at zero, i.e. register 1 is addressed as 0.

Example Write 65535 (655.35s) to PNU734 (4-bytes) mapped to 0 x 1CAB

Field Name Example (HEX)

Slave address 01

Function 10

Starting Address HI 1C

Starting Address LO AB

No. of Registers HI 00

No. of Registers LO 02

Byte count 04

Write Data HI (Register 7339) 00

Write Data LO (Register 7339) 00

Write Data HI (Register 7340) FF

Write Data LO (Register 7340) FF

Error Check (CRC) -

HEX

)

Table 5.7: Request frame

Response

The normal response returns the slave address, function code, starting address, and quantity of registers preset.

Field Name Example (HEX)

Slave address 01

Function 10

Starting Address HI 1C

Starting Address LO AB

No. of Registers HI 00

No. of Registers LO 02

Error Check (CRC) -

Table 5.8: Normal response frame

32

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 35

VLTp Micro Drive FC 51 Operating Instructions

5.6. Danfoss FC Control Profile

5.6.1. Control Word According to FC Profile

5. Modbus RTU

Bit Bit value = 0 Bit value = 1

00 Preset reference select - lsb

01 Preset reference select - msb

02 DC brake Ramp

03 Coasting No coasting

04 Quick stop Ramp

05 Freeze output No freeze output

06 Ramp stop Start

07 No function Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data invalid Data valid

11 No function Relay 01 active

12 No function No function

13 Setup 1 Setup 2

14 No function No function

15 No function Reverse

5.6.2. Explanation of the Control Bits

Bits 00/01

Bits 00 and 01 are used to choose between the four reference values, which are pre-programmed in par. 3-10

table:

Programmed ref. value Parameter Bit 01 Bit 02

1 3-10 [0] 0 0

23-10 [1]0 1

3 3-10 [2] 1 0

43-10 [3]1 1

Preset Reference

5

according to the following

NB!

In par. 8-56

Bit 02, DC brake:

Bit 02 = “0” leads to DC braking and stop. Braking current and duration are set in par. 2-01

Bit 02 = “1” leads to ramping.

Bit 03, Coasting:

Bit 03 = “0” shuts off the output transistors causing the motor to coast to a standstill.

Preset reference

a selection is made to define how Bit 00/01 gates with the corresponding function on the digital inputs.

MG.02.A3.02 - VLTp is a registered Danfoss trademark

DC Brake current

and 2-02

Braking time

.

33

Page 36

VLTp Micro Drive FC 51 Operating Instruc-

5. Modbus RTU

Bit 03 = “1” enables the frequency converter to start the motor if the other starting conditions have been fulfilled.

NB!

In par. 8-50

Bit 04, Quick stop:

Bit 04 = “0” causes a stop, in which the motor speed is ramped down to stop via 9ar. 3-81

Bit 05, Hold output frequency:

Bit 05 = “0” causes the present output frequency (in Hz) to freeze. The frozen output frequency can then be changed only by means of the digital inputs

(par. 5-10 to 5-15) programmed to

Coasting select

Speed up

a selection is made to define how Bit 03 gates with the corresponding function on a digital input.

and

Speed down

Quick stop ramp time

.

.

tions

5

NB!

If

Freeze output

• Bit 03 Coasting stop

• Bit 02 DC braking

• Digital input (par. 5-10 to 5-15) programmed to

Bit 06, Ramp stop/start:

Bit 06 = “0” causes a stop, in which the motor speed is ramped down to stop via the selected ramp down parameter.

Bit 06 = “1” permits the frequency converter to start the motor, if the other starting conditions have been fulfilled.

NB!

In par. 8-53

input.

Bit 07, Reset:

Bit 07 = “0” does not cause a reset.

Bit 07 = “1” causes the reset of a trip. Reset is activated on the signal's leading edge, i.e. when changing from logic “0” to logic “1”.

Bit 08, Jog:

Bit 08 = “1” causes the output frequency to be determined by par. 3-19

Bit 09, Selection of ramp 1/2:

Bit 09 = “0” means the ramp 1 is active (par. 3-40 to 3-47).

Bit 09 = ”1” means that ramp 2 (par. 3-50 to 3-57) is active.

is active, the frequency converter can only be stopped by the following:

DC braking,Coasting stop

Start select

a selection is made to define how Bit 06

Jog speed

Ramp stop/start

.

or

Reset and coasting stop.

gates with the corresponding function on a digital

Bit 10, Data not valid/Data valid:

Is used to tell the frequency converter whether the control word is to be used or ignored.

Bit 10 = “0” causes the control word to be ignored.

Bit 10 =”1” causes the control word to be used.

Bit 11, Relay 01:

Bit 11 = “0” Relay 01 not activated

Bit 11 = “1” Relay 01 is activated, provided

Bit 12:

Not used.

34

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Control word Bit 11

has been chosen in par. 5-40

Function relay

.

Page 37

VLTp Micro Drive FC 51 Operating Instructions

Bit 13, Selection of set-up:

Bit 13 = is used to choose the active set-up. The function is only possible when

NB!

In par. 8-55

Bit 14:

Not used.

Bit 15, Reverse:

Bit 15 = “0” causes no reversing.

Bit 15 = “1” causes reversing.

NB!

Depends on par. 8-54

5.6.3. Status Word According to FC Profile (STW)

Set-up select

Reversing select

a selection is made to define how Bit 13 gates with the corresponding function on the digital inputs.

.

Multi set-ups

is selected in par. 0-10

Active Set-up

5. Modbus RTU

.

5

Bit Bit value = 0 Bit value = 1

00 Control not ready Control ready

01 Unit not ready Unit ready

02 Coasting Enable

03 No error Error, trip

04 No error Error (no trip)

05 Reserved -

06 Not trip locked Trip locked

07 No warning Warning

08 Speed ำ reference Speed = reference

09 Local operation Bus control

10 Out of frequency limit Frequency limit OK

11 Not running Running

12 No resistor brake fault Resistor brake fault

13 Voltage OK Voltage exceeded

14 Torque OK Torque exceeded

15 No thermal warning Thermal warning

5.6.4. Explanation of the Status Bits

Bit 00, Control not ready/ready:

Bit 00 = “0” means that the frequency converter has tripped.

Bit 00 = “1” means that the frequency converter controls are ready, but that the power component is not necessarily receiving any power supply (in case

of external 24 V supply to controls).

MG.02.A3.02 - VLTp is a registered Danfoss trademark

35

Page 38

5

VLTp Micro Drive FC 51 Operating Instruc-

5. Modbus RTU

Bit 01, Frequency converter ready:

Bit 01 = “1”. The frequency converter is ready for operation, but there is an active coasting command via the digital inputs or via serial communication.

Bit 02, Coasting stop:

Bit 02 = “0”. The frequency converter released the motor.

Bit 02 = “1”. The frequency converter can start the motor when a start command is given.

Bit 03, No error/trip:

Bit 03 = “0” means that the frequency converter is not in fault mode.

Bit 03 = “1” means that the frequency converter is tripped, and that a reset signal is required to re-establish operation.

Bit 04, No error/error (trip):

Bit 04 = “0” means that the frequency converter is not in fault mode.

Bit 04 = “1” means that there is a frequency converter error but no trip.

Bit 05:

Not used.

Bit 06, No error/trip lock:

Bit 06 = “0” means that the frequency converter is not in fault mode.

Bit 06 = “1” means that the frequency converter is tripped and locked.

tions

Bit 07, No warning/warning:

Bit 07 = “0” means that there are no warnings.

Bit 07 = “1” means that a warning has occurred.

Bit 08, Speed ำ reference/speed = reference:

Bit 08 = “0” means that the motor is running, but that the present speed is different from the preset speed reference. For example, this might occur

while the speed is being ramped up/down during start/stop.

Bit 08 = “1” means that the present motor speed matches the preset speed reference.

Bit 09, Local operation/bus control:

Bit 09 = “0” means that [Stop/Reset] is activated on the control unit. It is not possible to control the frequency converter via serial communication.

Bit 09 = “1” means that it is possible to control the frequency converter via serial communication.

Bit 10, Out of frequency limit:

Bit 10 = “0”, if the output frequency has reached the value in par. 4-12

Bit 10 = “1” means that the output frequency is within the defined limits.

Bit 11, Running:

Bit 11 = “0” means that the motor is not running.

Bit 11 = “1” means that the frequency converter has a start signal or that the output frequency is higher than 0 Hz.

Bit 12, Resistor brake fault:

Bit 12 = “0” means that there is no resistor brake fault.

Bit 12 = “1” means that there is a resistor brake fault.

Motor speed low limit

or par . 4-13

Motor speed high limit

.

Bit 13, Voltage OK/limit exceeded:

Bit 13 = “0” means that there are no voltage warnings.

Bit 13 = “1” means that the DC voltage in the frequency converter's intermediate circuit is too low or too high.

Bit 14, Torque OK/limit exceeded:

Bit 14 = “0” means that there are no current/torque warnings or errors.

Bit 14 = “1” means that there is a current/torque warning or error.

36

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 39

VLTp Micro Drive FC 51 Operating Instructions

Bit 15, Thermal warning:

Bit 15 = “0” means that there is no thermal warning or error.

Bit 15 = “1” means that one of the thermal limits has been exceeded.

5.6.5. Bus Speed Reference Value

The speed reference value is transmitted to the frequency converter in a

relative value in %.

The value is transmitted in the form of a 16-bit word; in integers

(0-32767) the value 16384 (4000 Hex) corresponds to 100%. Negative

figures are formatted by means of 2's complement.

The Actual Output Frequency (MAV) is scaled in the same way as the bus

reference.

The reference and MAV are scaled as follows:

5. Modbus RTU

5

MG.02.A3.02 - VLTp is a registered Danfoss trademark

37

Page 40

6

6. Parameter Overview

VLTp Micro Drive FC 51 Operating Instruc-

tions

38

MG.02.A3.02 - VLTp is a registered Danfoss trademark

Page 41

VLTp Micro Drive FC 51 Operating Instructions

6. Parameter Overview

[1] Analog input 53

[6] Digital input 29

2-** Brakes

2-00 DC Hold Current

0 - 150 % * 50 %

2-01 DC Brake Current

0 - 150 % * 50 %

2-02 DC Braking Time

0.0 - 60.0 s * 10.0 s

2-04 DC Brake Cut In Speed

0.0 - 400.0 Hz * 0.0 Hz

2-1* Brake Energy Funct.

2-10 Brake Function

*[0] Off

[1] Resistor brake

[2] AC brake

2-11 Brake Resistor (ohm)

5 - 5000 * 5

2-0* DC-Brake

2-16 AC Brake, Max current

6. Parameter Overview

6

0 - 150 % * 100 %

2-17 Over-voltage Control

*[0] Disabled

[1] Enabled (not at stop)

[2] Enabled

2-2* Mechanical Brake

2-20 Release Brake Current

0.00 - 100.0 A * 0.00 A

2-22 Activate Brake Speed [Hz]

0.0 - 400.0 Hz * 0.0 Hz

3-** Reference / Ramps

3-00 Reference Range

*[0] Min - Max

[1] -Max - +Max

3-02 Minimum Reference

-4999 - 4999 * 0.000

3-03 Maximum Reference

-4999 - 4999 * 50.00

3-1* References

3-10 Preset Reference

-100.0 - 100.0 % * 0.00 %

3-11 Jog Speed [Hz]

0.0 - 400.0 Hz * 5.0 Hz

3-12 Catch up/slow Down Value

3-0* Reference Limits

0.00 - 100.0 % * 0.00 %

Parameter Overwiev

1-33 Stator Leakage Reactance (X1)

[Ohm] * Dep. on motor data

1-0* General Settings

1-00 Configuration Mode

0-** Operation/Display

0-0* Basic Settings

1-5* Load Indep. Setting

1-50 Motor Magnetisation at 0 Speed

0 - 300 % * 100 %

1-01 Motor Control Principle

[0] U/f

[1] US

0-04 Oper. State at Power-up (Hand)

1-52 Min Speed Norm. Magnet. [Hz]

*[1] VVC+

1-03 Torque Characteristics

[0] Resume

*[1] Forced stop, ref = old

1-35 Main Reactance (Xh)

[Ohm] * Dep. on motor data

*[0] Speed open loop

[3] Process

0-03 Regional Settings

*[0] International

0.0 - 10.0 Hz * 0.0 Hz

1-55 U/f Characteristic - U

0 - 999.9 V

*[0] Constant torque

[2] Automatic Energy Optim.

1-05 Local Mode Configuration

[2] Forced stop, ref = 0

0-1* Set-up Handling

0-10 Active Set-up

1-56 U/f Characteristic - F

[0] Speed Open Loop

*[1] Setup 1

0 - 400 Hz

1-6* Load Depen. Setting

*[2] As config in param. 1-00

1-2* Motor Data

[2] Setup 2

[9] Multi Setup

1-60 Low Speed Load Compensation

0 - 199 % * 100 %

1-61 High Speed Load Compensation

1-20 Motor Power [kW] [HP]

[1] 0.09 kW/0.12 HP

[2] 0.12 kW/0.16 HP

0-11 Edit Set-up

*[1] Setup 1

[2] Setup 2

0 - 199 % * 100 %

[3] 0.18 kW/0.25 HP

[9] Active Setup

1-62 Slip Compensation

[4] 0.25 kW/0.33 HP

0-12 Link Setups

-400 - 399 % * 100 %

1-63 Slip Compensation Time Constant

[5] 0.37 kW/0.50 HP

[6] 0.55 kW/0.75 HP

[0] Not Linked

*[20] Linked

0.05 - 5.00 s * 0.10 s

1-7* Start Adjustments

[7] 0.75 kW/1.00 HP

[8] 1.10 kW/1.50 HP

0-4* LCP Keypad

0-40 [Hand on] Key on LCP

1-71 Start Delay

[9] 1.50 kW/2.00 HP

[0] Disabled

0.0 - 10.0 s * 0.0 s

[10] 2.20 kW/3.00 HP

*[1] Enabled

1-72 Start Function

[11] 3.00 kW/4.00 HP

0-41 [Off / Reset] Key on LCP

[0] DC hold / delay time

[12] 3.70 kW/5.00 HP

[0] Disable All

[1] DC brake / delay time

[13] 4.00 kW/5.40 HP

*[1] Enable All

*[2] Coast / delay time

1-73 Flying Start

[14] 5.50 kW/7.50 HP

[15] 7.50 kW/10.00 HP

[2] Enable Reset Only

0-42 [Auto on] Key on LCP

*[0] Disabled

[1] Enabled

1-8* Stop Adjustments

[16] 11.00 kW/15.00 HP

1-22 Motor Voltage

50 - 999 V * 230 - 400 V

[0] Disabled

*[1] Enabled

0-5* Copy/Save

1-80 Function at Stop

*[0] Coast

[1] DC hold

1-82 Min Speed for Funct. at Stop [Hz]

1-23 Motor Frequency

20 - 400 Hz * 50 Hz

1-24 Motor Current

0.01 - 26.00 A * Motortype dep.

0-50 LCP Copy

*[0] No copy

[1] All to LCP

[2] All from LCP

0.0 - 20.0 Hz * 0.0 Hz

1-25 Motor Nominal Speed

[3] Size indep. from LCP

1-9* Motor Temperature

1-90 Motor Thermal Protection

100 - 9999 rpm * Motortype dep.

1-29 Automatic Motor Tuning (AMT)

0-51 Set-up Copy

*[0] No copy

*[0] No protection

[1] Termistor warning

*[0] Off

[2] Enable AMT

[1] Copy from setup 1

[2] Copy from setup 2

[2] Thermistor trip

[3] Etr warning

[4] Etr trip

1-93 Thermistor Resource

1-3* Adv. Motor Data

1-30 Stator Resistance (Rs)

[Ohm] * Dep. on motor data

[9] Copy from Factory setup

0-6* Password

0-60 (Main) Menu Password

0 - 999 * 0

*[0] None

1-** Load/Motor

MG.02.A3.02 - VLTp is a registered Danfoss trademark

39

Page 42

6

6. Parameter Overview

[25] Reverse

[26] Bus ok

[28] Brake,NoWarn

[29] Brake ready/NoFault

[30] BrakeFault (IGBT)

[32] Mech.brake control

[36] Control word bit 11

[51] Local ref. active

[52] Remote ref. active

[53] No alarm

[54] Start cmd active

[55] Running reverse

[56] Drive in hand mode

[57] Drive in auto mode

[60-63] Comparator 0-3

[70-73] Logic rule 0-3

[81] SL digital output B

5-5* Pulse Input

5-55 Terminal 33 Low Frequency

20 - 4999 Hz * 20 Hz

5-56 Terminal 33 High Frequency

21 - 5000 Hz * 5000 Hz

5-57 Term. 33 Low Ref./Feedb. Value

-4999 - 4999 * 0.000

5-58 Term. 33 High Ref./Feedb. Value

-4999 - 4999 * 50.000

6-** Analog In/Out

6-00 Live Zero Timeout Time

1 - 99 s * 10 s

6-0* Analog I/O Mode

VLTp Micro Drive FC 51 Operating Instruc-

6-01 Live Zero TimeoutFunction

*[0] Off

[1] Freeze output

[2] Stop

[3] Jogging

[4] Max speed

[5] Stop and trip

6-1* Analog Input 1

6-10 Terminal 53 Low Voltage

0.00 - 9.99 V * 0.07 V

6-11 Terminal 53 High Voltage

0.01 - 10.00 V * 10.00 V

6-12 Terminal 53 Low Current

0.00 - 19.99 mA * 0.14 mA

tions

[16-18] Preset ref bit 0-2

3-80 Jog Ramp Time

[19] Freeze reference

[20] Freeze output

0.05 - 3600 s * 3.00 s

3-81 Quick Stop Ramp Time

[21] Speed up

0.05 - 3600 s * 3.00 s

5-4* Relays

5-40 Function Relay

*[0] No opreation

[1] Control ready

[2] Drive ready

[3] Drive ready, Remote

[4] Enable / No warning

[5] Drive running

[6] Running / No warning

[7] Run in range / No warning

[8] Run on ref / No warning

[9] Alarm

[10] Alarm or warning

[12] Out of current range

[13] Below current, low

[14] Above current, high

[21] Thermal warning

[22] Ready, No thermal warning

[23] Remote ready, No thermal warning

[22] Speed down

[23] Setup select bit 0

[28] Catch up

[29] Slow down

[34] Ramp bit 0

[60] Counter A (up)

[61] Counter A (down)

[62] Reset counter A

[63] Counter B (up)

[64] Counter B (down)

[65] ResetCounter B

5-11 Terminal 19 Digital Input

See par. 5-10. * [10] Reversing

5-12 Terminal 27 Digital Input

See par. 5-10. * [1] Reset

5-13 Terminal 29 Digital Input

See par. 5-10. * [14] Jog

5-15 Terminal 33 Digital Input

See par. 5-10. * [16] Preset ref bit 0

[26] Precise Stop Inverse

[27] Start, Precise Stop

[32] Pulse Input

4-** Limits / Warnings

4-10 Motor Speed Direction

[0] Clockwise

[1] CounterClockwise

*[2] Both

4-12 Motor Speed Low Limit [Hz]