Page 1

MAKING MODERN LIVING POSSIBLE

Instruction Manual

VLT® AutomationDrive FC 300, 0.25–75 kW

Page 2

Page 3

Safety

Safety

VLT® AutomationDrive Instruction

Manual

WARNING

HIGH VOLTAGE!

Adjustable frequency drives contain high voltage when

connected to AC line power. Installation, startup, and

maintenance should be performed by qualified personnel

only. Failure to perform installation, startup, and

maintenance by qualified personnel could result in death

or serious injury.

High Voltage

Adjustable frequency drives are connected to hazardous

AC line voltage. Extreme care should be taken to protect

against shock. Only trained personnel familiar with

electronic equipment should install, start, or maintain this

equipment.

WARNING

UNINTENDED START!

When the adjustable frequency drive is connected to AC

line power, the motor may start at any time. The

adjustable frequency drive, motor, and any driven

equipment must be in operational readiness. Failure to be

in operational readiness when the adjustable frequency

drive is connected to AC line power could result in death,

serious injury, equipment, or property damage.

Unintended Start

When the adjustable frequency drive is connected to AC

line power, the motor may be started with an external

switch, a serial bus command, an input reference signal, or

a cleared fault condition. Use appropriate caution to guard

against an unintended start.

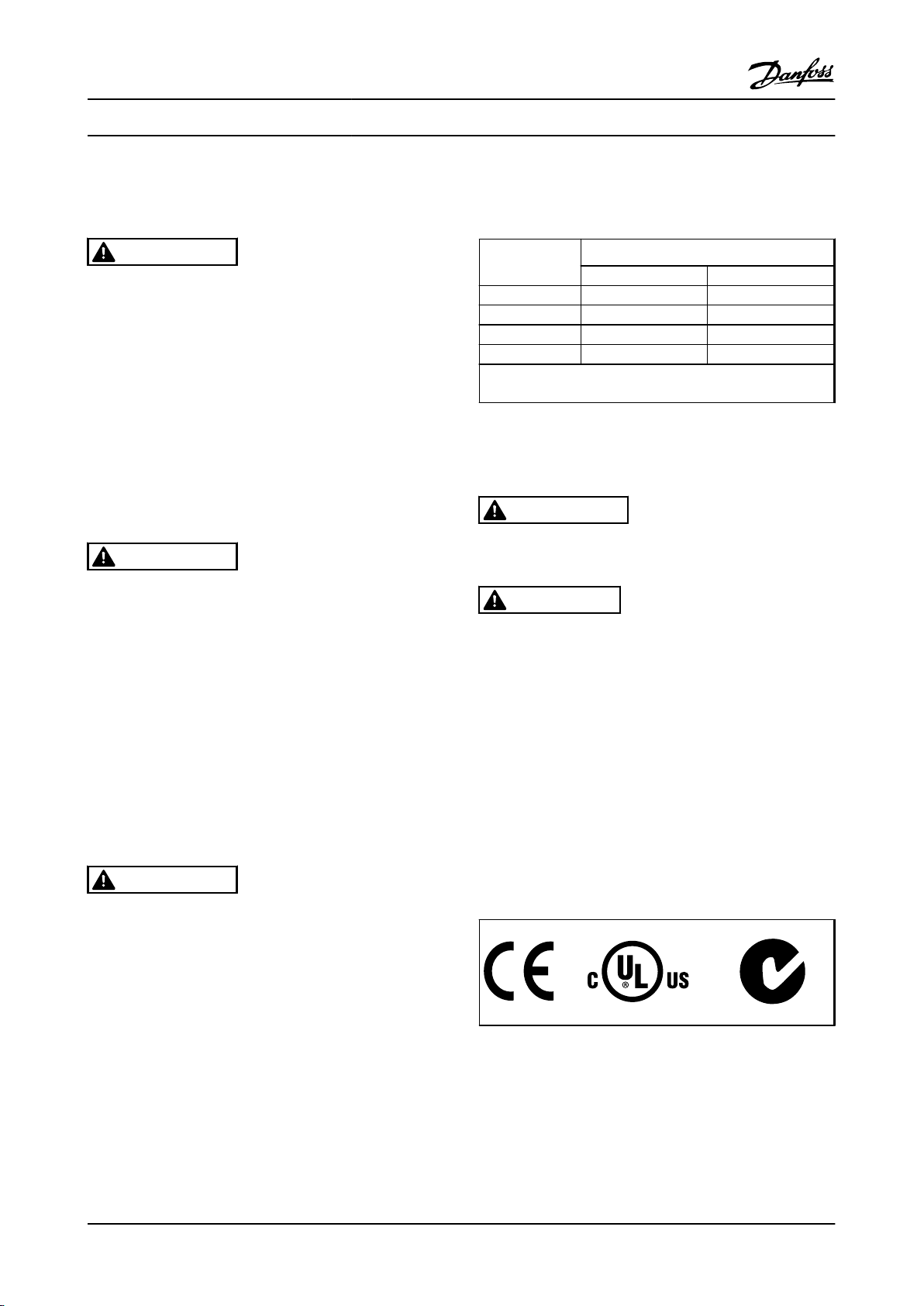

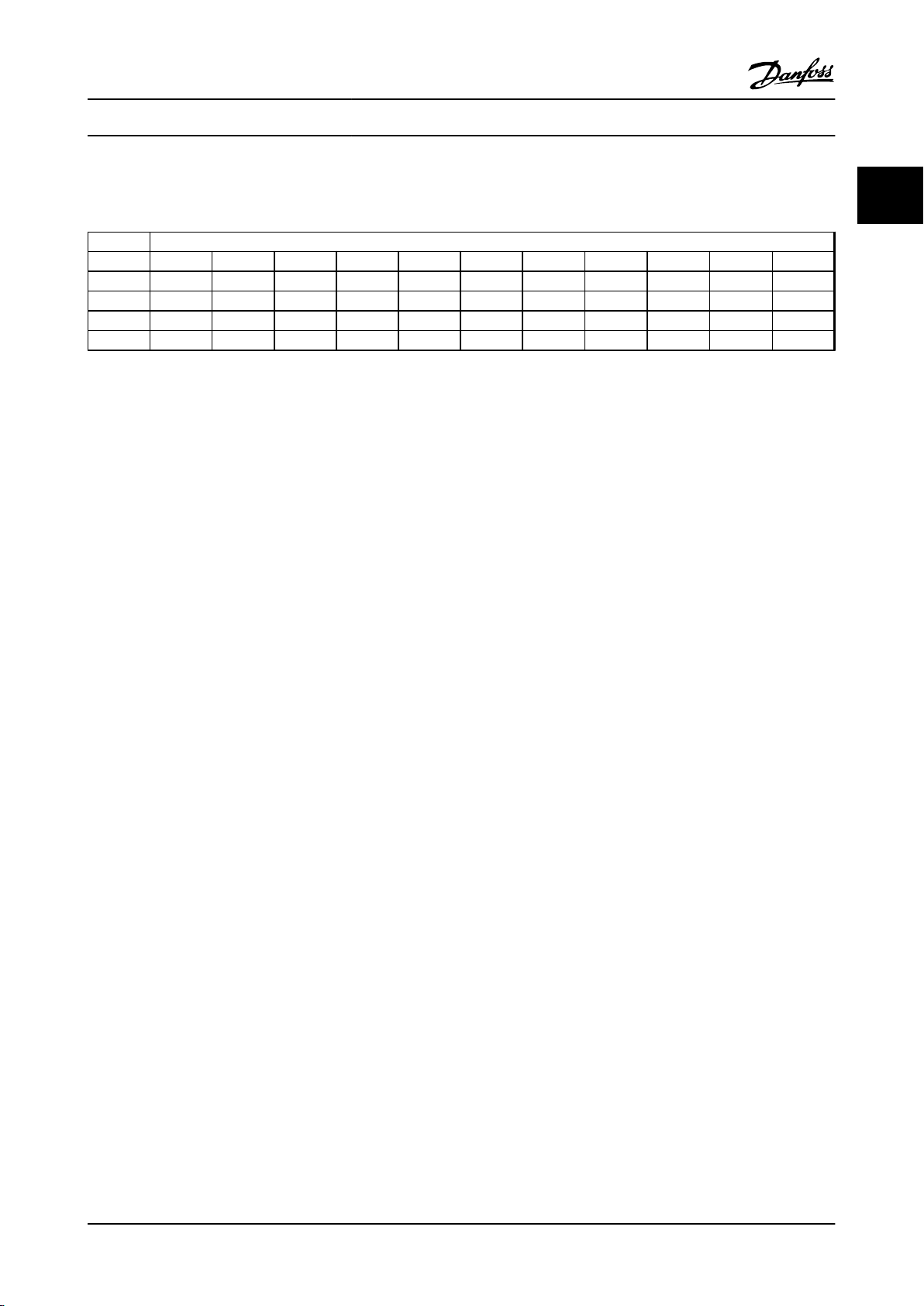

Voltage [V] Minimum waiting time [minutes]

4 15

200–240 0-34-0.5 hp 7.5-50 hp

380–480 0.34-10 hp 15-100 hp

525–600 1.0-10 hp 15-100 hp

525–690 15-100 hp

High voltage may be present even when the warning LED

indicator lights are off.

Discharge Time

Symbols

The following symbols are used in this manual.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

CAUTION

Indicates a situation that may result in equipment or

property damage-only accidents.

NOTE!

Indicates highlighted information that should be observed

in order to avoid mistakes or operate equipment at less

than optimal performance.

WARNING

DISCHARGE TIME!

Adjustable frequency drives contain DC link capacitors that

can remain charged even when the adjustable frequency

drive is not powered. To avoid electrical hazards,

disconnect AC line power, any permanent magnet type

motors, and any remote DC link power supplies, including

battery backups, UPS and DC link connections to other

adjustable frequency drives. Wait for the capacitors to fully

discharge before performing any service or repair work.

The wait time required is listed in the Discharge Time table.

Failure to wait for the specified period of time after power

has been removed to do service or repair could result in

death or serious injury.

MG33AM22 - VLT® is a registered Danfoss trademark

Approvals

Table 1.2

Page 4

Safety

VLT® AutomationDrive Instruction

Manual

NOTE!

Imposed limitations on the output frequency

(due to export control regulations):

From software version 6.72, the output frequency of the

adjustable frequency drive is limited to 590 Hz. Software

versions 6x.xx also limit the maximum output frequency to

590 Hz, but these versions cannot be flashed, i.e., neither

downgraded nor upgraded.

MG33AM22 - VLT® is a registered Danfoss trademark

Page 5

Contents

Contents

VLT® AutomationDrive Instruction

Manual

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Product Overview

1.4 Internal Controller Functions

1.5 Frame Sizes and Power Ratings

2 Installation

2.1 Installation Site Checklist

2.2 Adjustable Frequency Drive and Motor Pre-installation Checklist

2.3 Mechanical Installation

2.3.1 Cooling 3-1

2.3.2 Lifting 3-2

2.3.3 Mounting 3-2

2.3.4 Tightening Torques 3-2

2.4 Electrical Installation

2.4.1 Requirements 3-5

2.4.2 Grounding Requirements 3-5

2-1

2-2

2-3

2-3

2-3

2-5

3-1

3-1

3-1

3-1

3-3

2.4.2.1 Leakage Current (>3.5 mA) 3-6

2.4.2.2 Grounding Using Shielded Cable 3-6

2.4.3 Motor Connection 3-6

2.4.4 AC Line Input Connection 3-7

2.4.5 Control Wiring 3-7

2.4.5.1 Access 3-7

2.4.5.2 Control Terminal Types 3-8

2.4.5.3 Wiring to Control Terminals 3-9

2.4.5.4 Using Shielded Control Cables 3-10

2.4.5.5 Control Terminal Functions 3-10

2.4.5.6 Jumper Terminals 12 and 27 3-10

2.4.5.7 Terminal 53 and 54 Switches 3-11

2.4.5.8 Mechanical Brake Control 3-11

2.4.6 Serial Communication 3-12

2.5 Safe Stop

2.5.1 Terminal 37 Safe Stop Function 3-13

2.5.2 Safe Stop Commissioning Test 3-16

3-12

3 Start-up and Functional Testing

3.1 Pre-start

MG33AM22 - VLT® is a registered Danfoss trademark

4-1

4-1

Page 6

Contents

VLT® AutomationDrive Instruction

Manual

3.1.1 Safety Inspection 4-1

3.2 Applying Power

3.3 Basic Operational Programming

3.4 Asynchronous Motor Set-up

3.5 PM Motor Set-up in VVC

plus

3.6 Automatic Motor Adaptation

3.7 Check Motor Rotation

3.8 Check Encoder Rotation

3.9 Local Control Test

3.10 System Start-up

4 User Interface

4.1 Local Control Panel

4.1.1 LCP Layout 5-1

4.1.2 Setting LCP Display Values 5-2

4.1.3 Display Menu Keys 5-2

4.1.4 Navigation Keys 5-3

4.1.5 Operation Keys 5-3

4.2 Backup and Copying Parameter Settings

4-3

4-3

4-4

4-5

4-5

4-6

4-6

4-7

4-7

5-1

5-1

5-3

4.2.1 Uploading Data to the LCP 5-4

4.2.2 Downloading Data from the LCP 5-4

4.3 Restoring Default Settings

4.3.1 Recommended Initialization 5-4

4.3.2 Manual Initialization 5-4

5 About Adjustable Frequency Drive Programming

5.1 Introduction

5.2 Programming Example

5.3 Control Terminal Programming Examples

5.4 International/North American Default Parameter Settings

5.5 Parameter Menu Structure

5.5.1 Main menu structure 6-5

5.6 Remote Programming with MCT 10 Set-up Software

6 Application Examples

6.1 Introduction

6.2 Application Examples

5-4

6-1

6-1

6-1

6-2

6-3

6-4

6-9

7-1

7-1

7-1

7 Status Messages

7.1 Status Display

8-1

8-1

MG33AM22 - VLT® is a registered Danfoss trademark

Page 7

Contents

VLT® AutomationDrive Instruction

Manual

7.2 Status Message Definitions Table

8 Warnings and Alarms

8.1 System Monitoring

8.2 Warning and Alarm Types

8.3 Warning and Alarm Displays

8.4 Warning and Alarm Definitions

9 Basic Troubleshooting

9.1 Start Up and Operation

10 Specifications

10.1 Power-dependent Specifications

10.2 General Technical Data

10.3 Fuse Specifications

10.3.2 Recommendations 11-19

10.3.3 CE Compliance 11-19

10.4 Connection Tightening Torques

8-1

9-1

9-1

9-1

9-1

9-2

10-1

10-1

11-1

11-1

11-14

11-19

11-28

12 Index

12-1

MG33AM22 - VLT® is a registered Danfoss trademark

Page 8

Contents

VLT® AutomationDrive Instruction

Manual

MG33AM22 - VLT® is a registered Danfoss trademark

Page 9

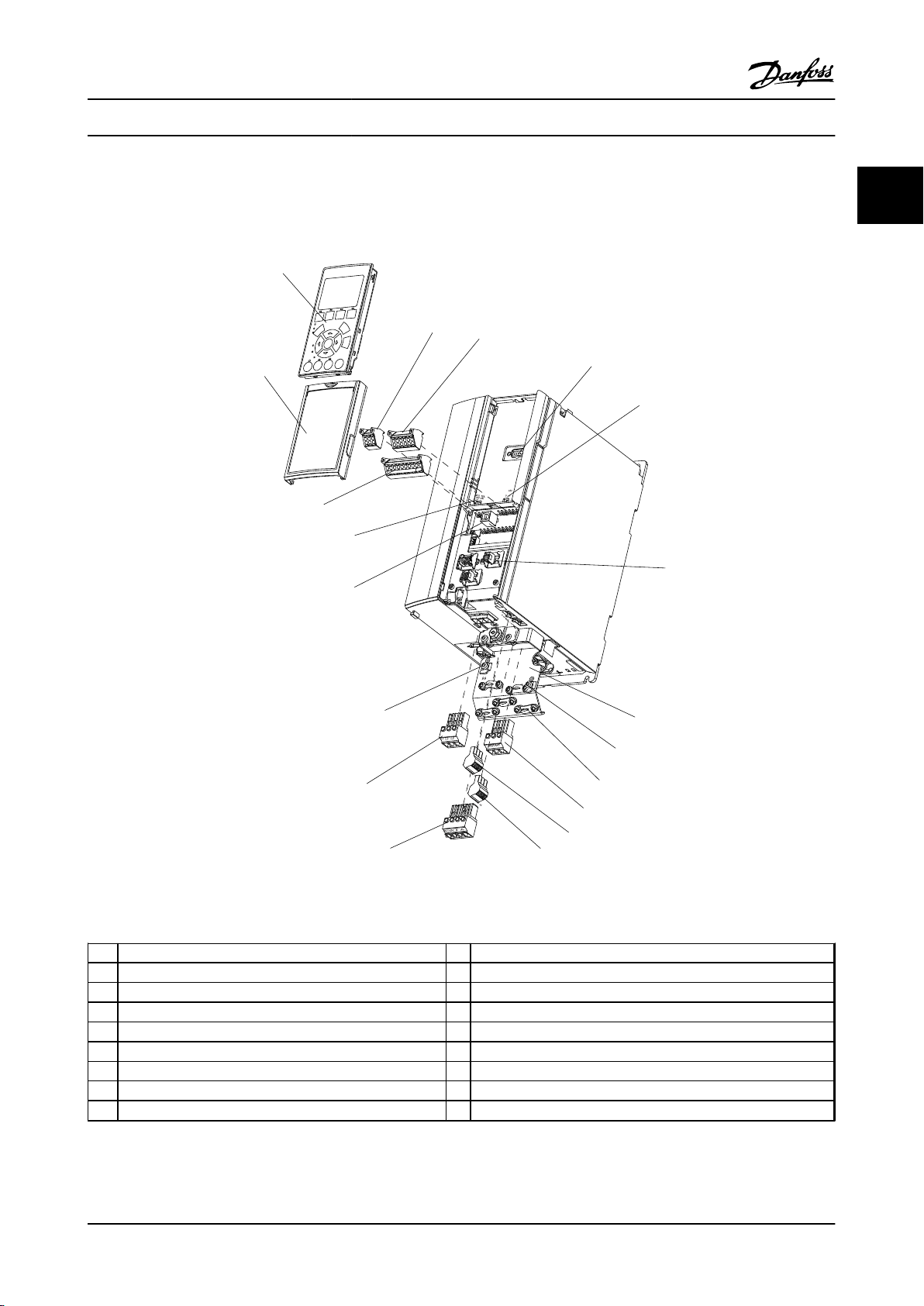

1

2

3

4

5

6

7

8

9

10

11

12

13

14

8

15

16

17

18

130BB492.10

Introduction

VLT® AutomationDrive Instruction

Manual

1 Introduction

1 1

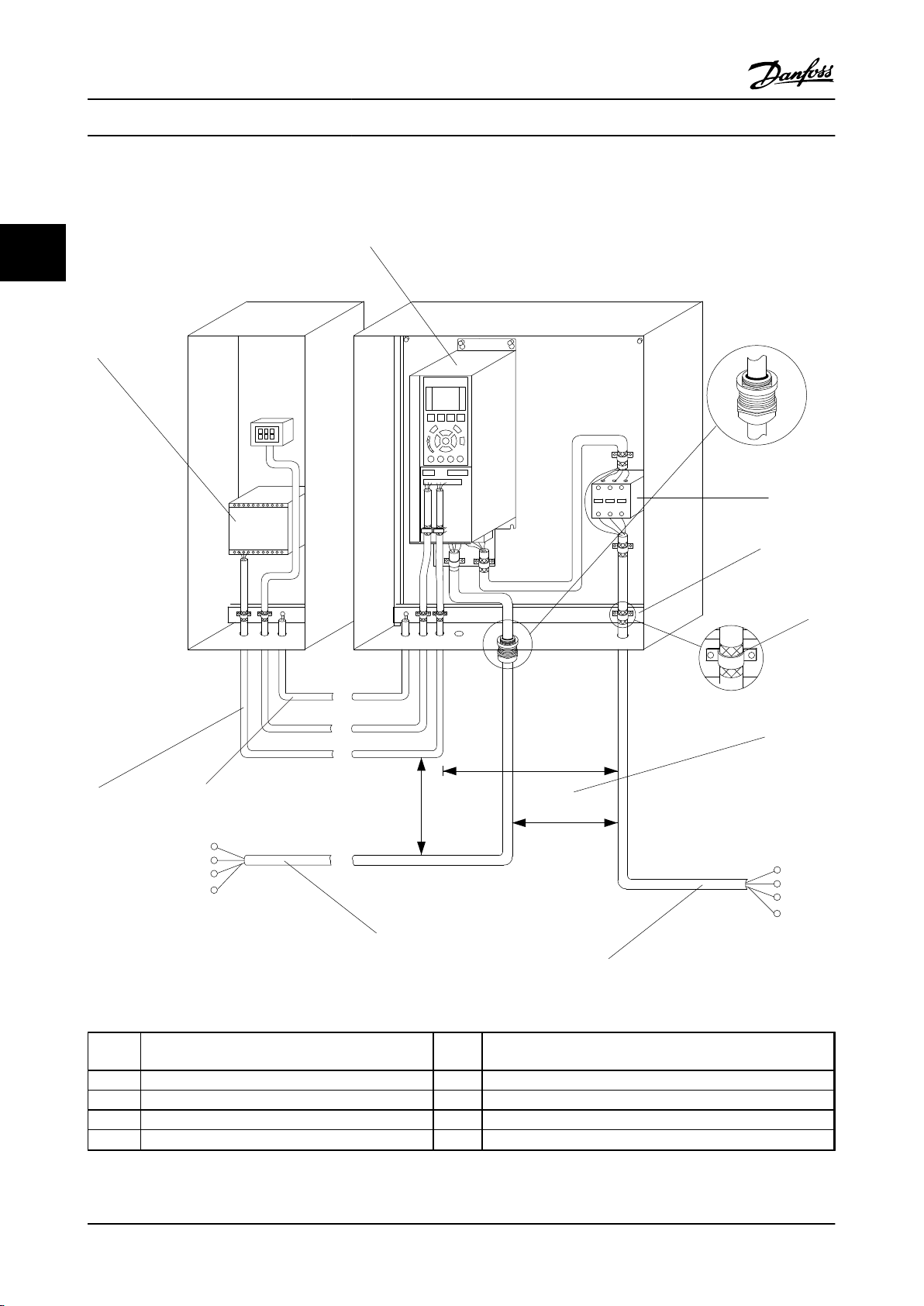

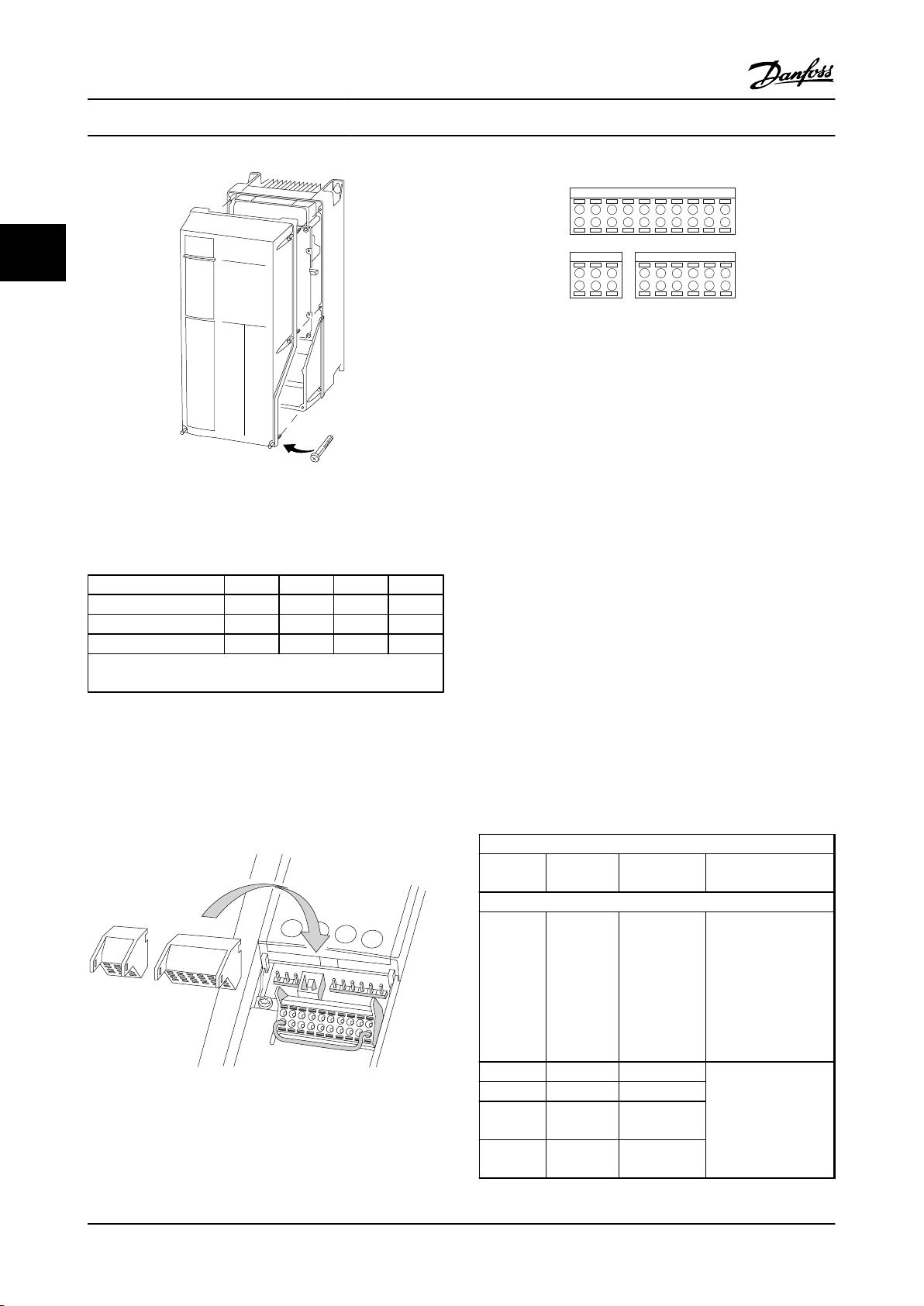

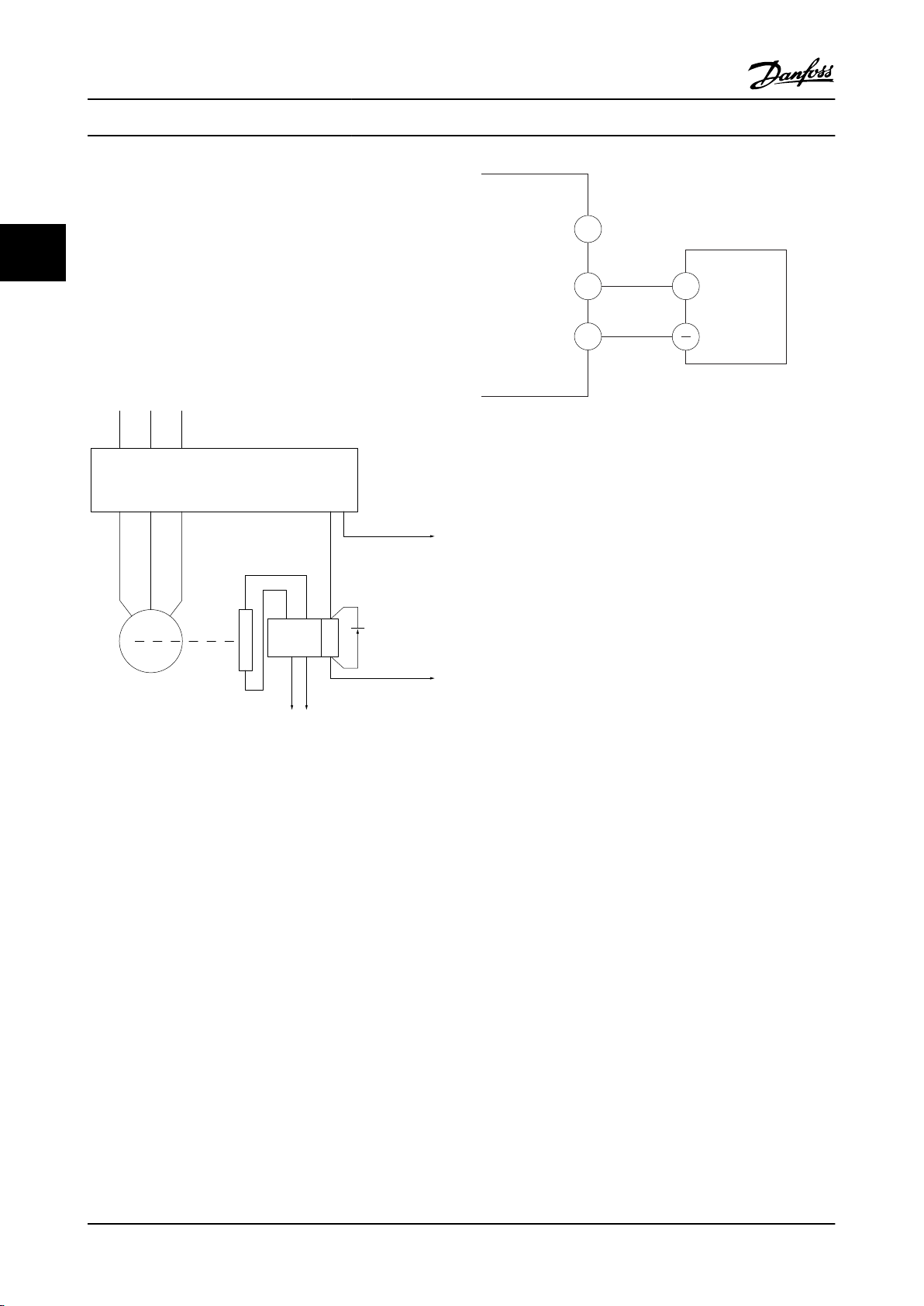

Figure 1.1 Exploded View A1-A3, IP20

LCP 10 Motor output terminals 96 (U), 97 (V), 98 (W)

1

2 RS-485 serial bus connector (+68, -69) 11 Relay 1 (01, 02, 03)

3 Analog I/O connector 12 Relay 2 (04, 05, 06)

4 LCP input plug 13 Brake (-81, +82) and load sharing (-88, +89) terminals

5 Analog switches (A53), (A54) 14 Line power input terminals 91 (L1), 92 (L2), 93 (L3)

6 Cable strain relief/PE ground 15 USB connector

7 Decoupling plate 16 Serial bus terminal switch

8 Grounding clamp (PE) 17 Digital I/O and 24 V power supply

9 Shielded cable grounding clamp and strain relief 18 Control cable cover plate

Table 1.1 Legend to Figure 1.1

MG33AM22 - VLT® is a registered Danfoss trademark 1-1

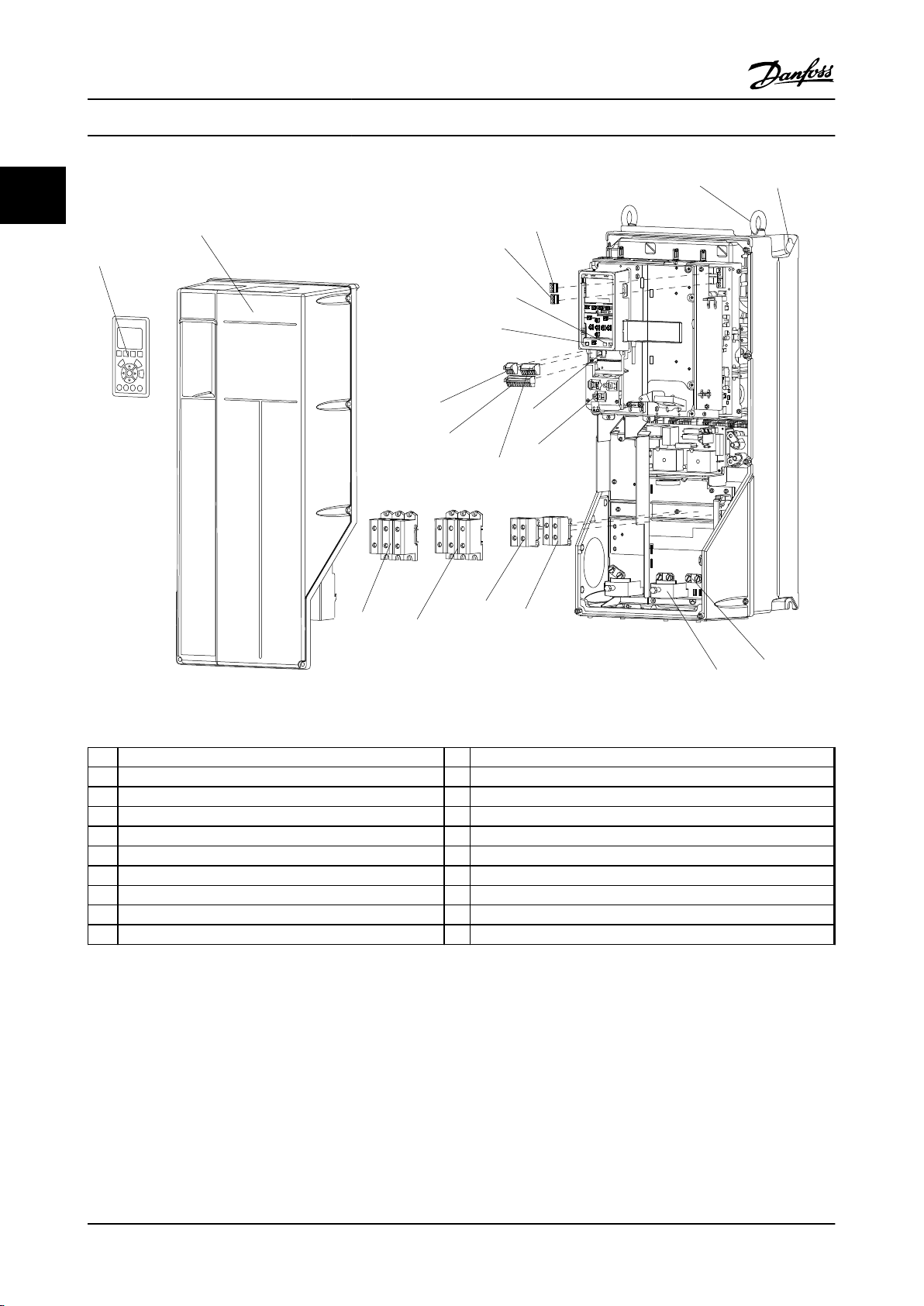

Page 10

1

2

3

4

5

6

7

8

9

10

11

12

13

16

17

18

19

14

15

FAN MOUNTING

QDF-30

DC-

DC+

Remove jumper to activate Safe Stop

Max. 24 Volt !

12

13

18

19 27 29 32

33

20

61

68

39

42

50

53 54

0605 04

0302 01

130BB493.10

Introduction

VLT® AutomationDrive Instruction

Manual

11

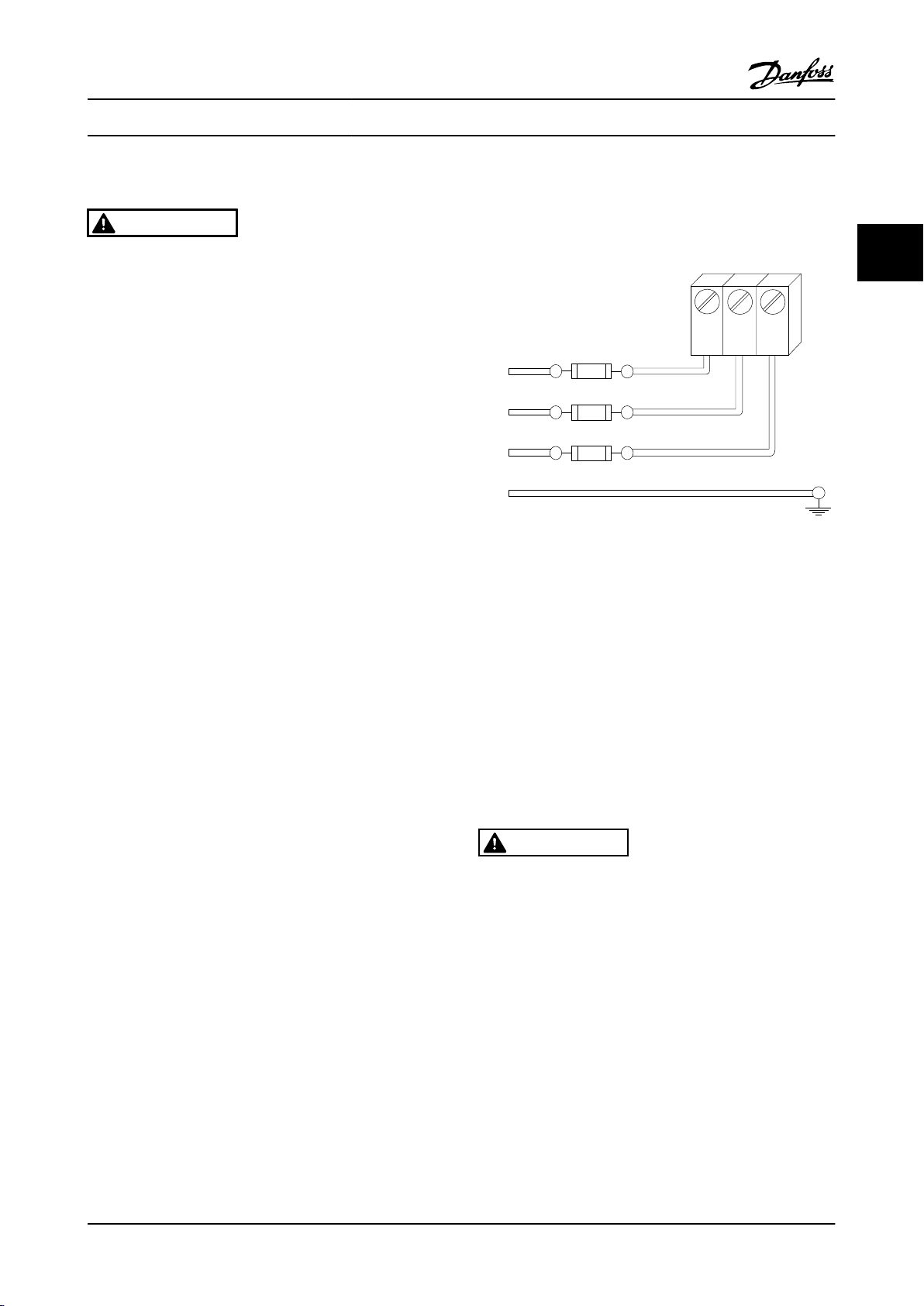

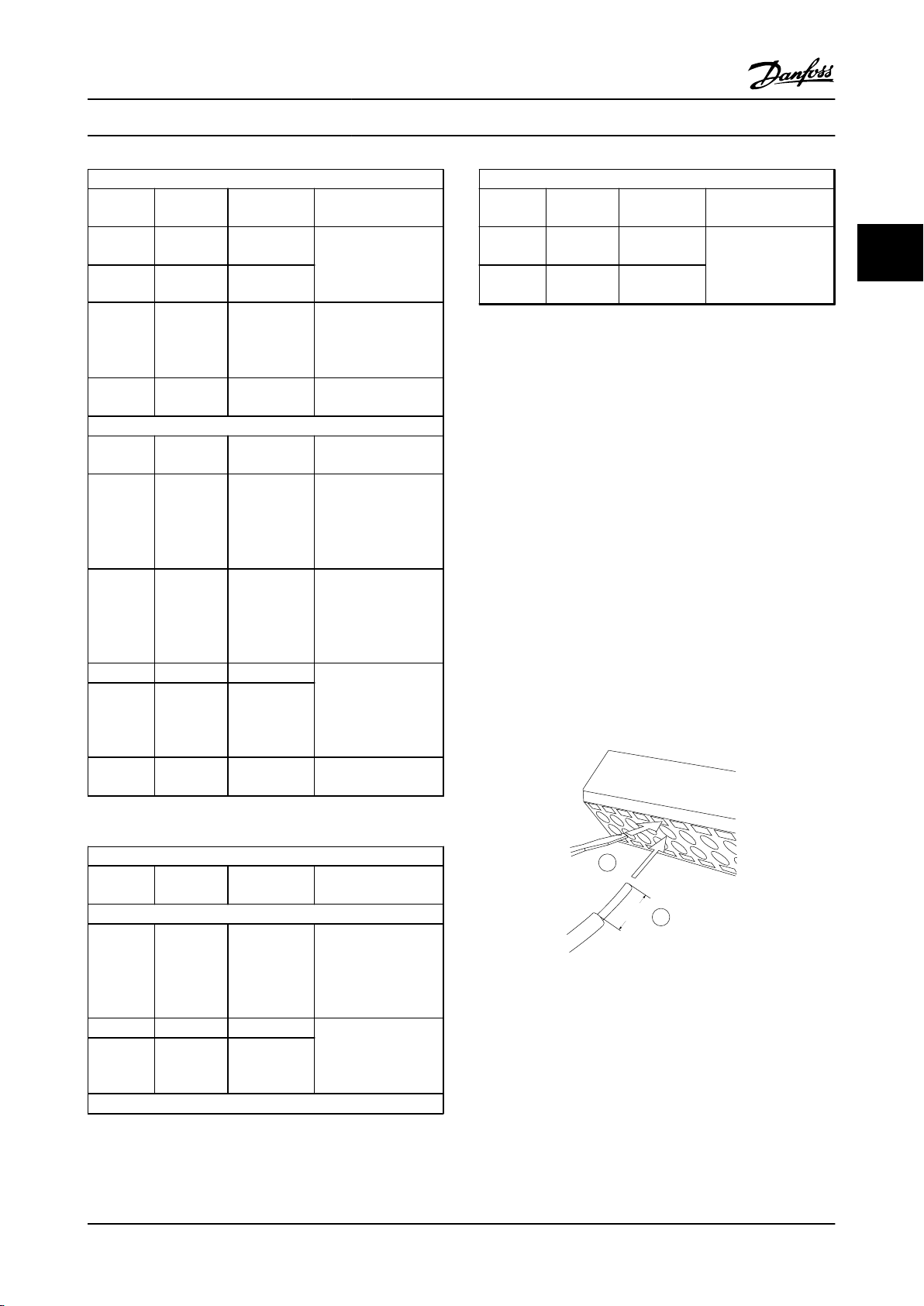

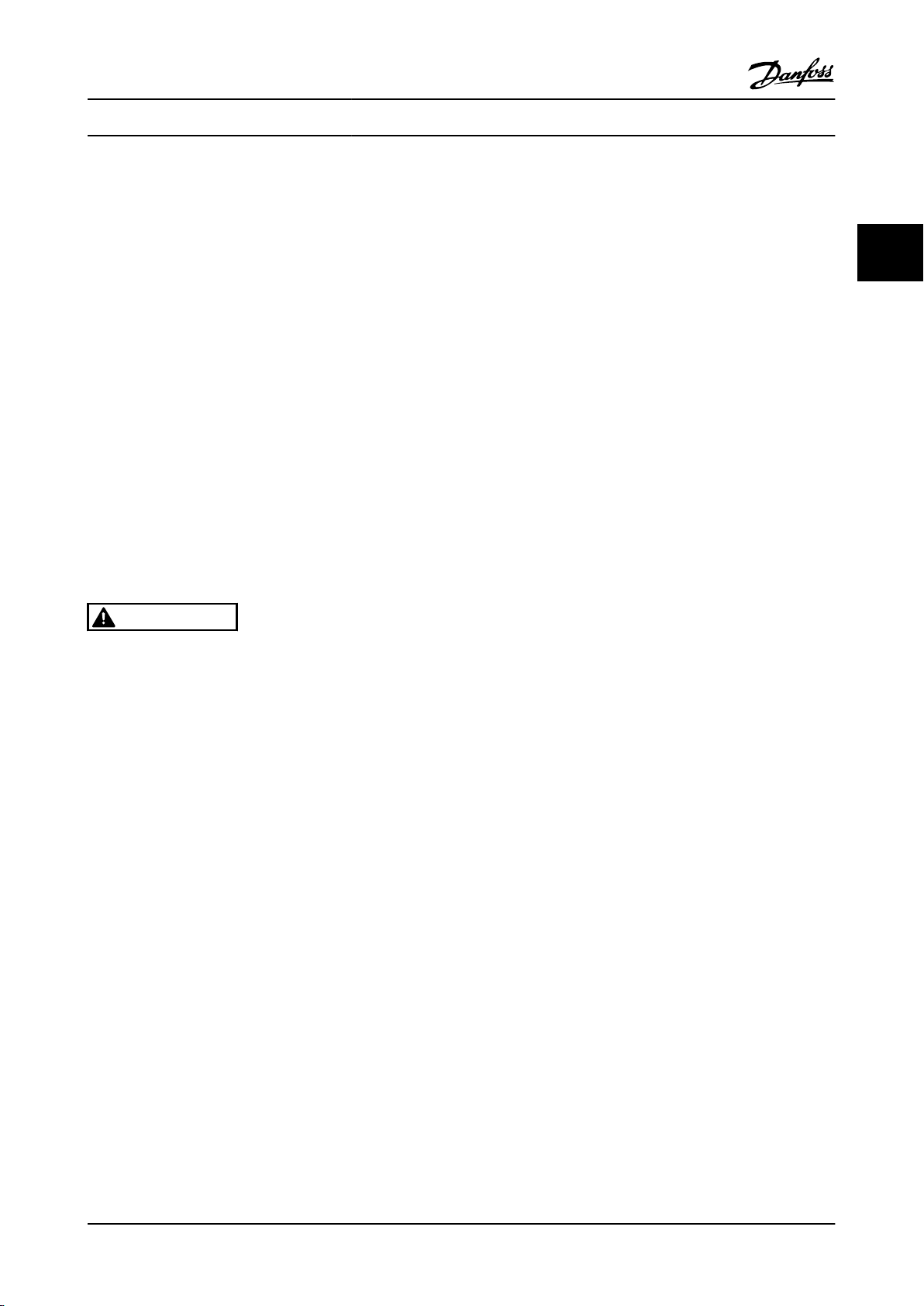

Figure 1.2 Exploded View B and C Sizes, IP55/66

LCP 11 Relay 2 (04, 05, 06)

1

2 Cover 12 Lifting ring

3 RS-485 serial bus connector 13 Mounting slot

4 Digital I/O and 24 V power supply 14 Grounding clamp (PE)

5 Analog I/O connector 15 Cable strain relief/PE ground

6 Cable strain relief/PE ground 16 Brake terminal (-81, +82)

7 USB connector 17 Load sharing terminal (DC bus) (-88, +89)

8 Serial bus terminal switch 18 Motor output terminals 96 (U), 97 (V), 98 (W)

9 Analog switches (A53), (A54) 19 Line power input terminals 91 (L1), 92 (L2), 93 (L3)

10 Relay 1 (01, 02, 03)

Table 1.2 Legend to Figure 1.2

programming, and functional testing. The remaining

1.1

Purpose of the Manual

This manual is intended to provide detailed information for

the installation and startup of the adjustable frequency

chapters provide supplementary details. These details

include user interface, detailed programming, application

examples, startup troubleshooting, and specifications.

drive. provides requirements for mechanical and electrical

installation, including input, motor, control and serial

communications wiring and control terminal functions.

provides detailed procedures for startup, basic operational

1-2 MG33AM22 - VLT® is a registered Danfoss trademark

Page 11

Introduction

VLT® AutomationDrive Instruction

Manual

1.2 Additional Resources

Other resources are available to understand advanced

adjustable frequency drive functions and programming.

®

The VLT

•

detail on working with parameters and many

application examples.

The VLT® Design Guide is intended to provide

•

detailed capabilities and functionality to design

motor control systems.

Supplementary publications and manuals are

•

available from Danfoss.

See http://www.danfoss.com/BusinessAreas/Drives-

Solutions/Documentations/Technical

+Documentation.htm for listings.

Optional equipment is available that may change

•

some of the procedures described. Reference the

instructions supplied with those options for

specific requirements. Contact the local Danfoss

supplier or visit the Danfoss website: http://

www.danfoss.com/BusinessAreas/DrivesSolutions/

Documentations/Technical+Documentation.htm, for

downloads or additional information.

Programming Guide provides greater

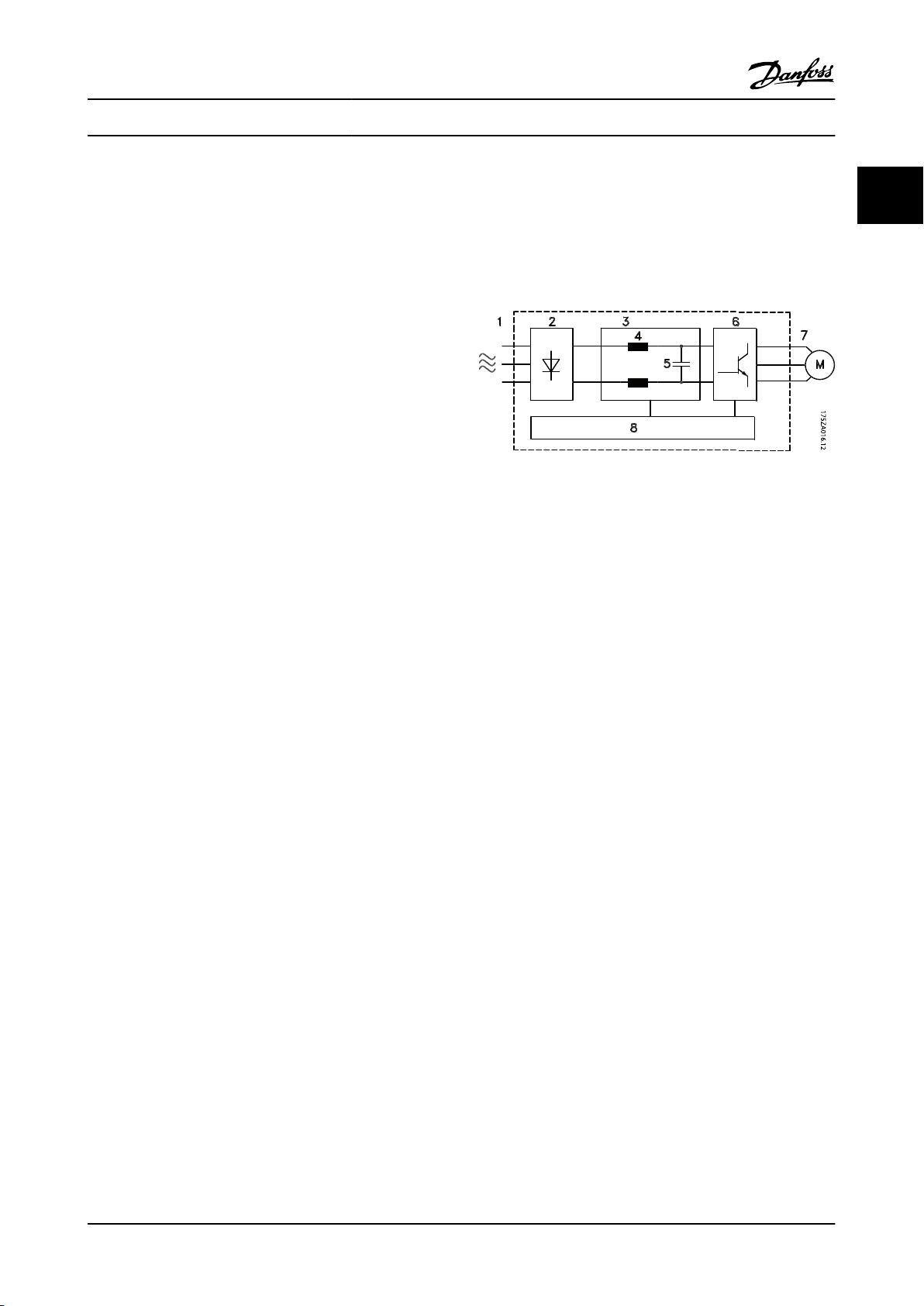

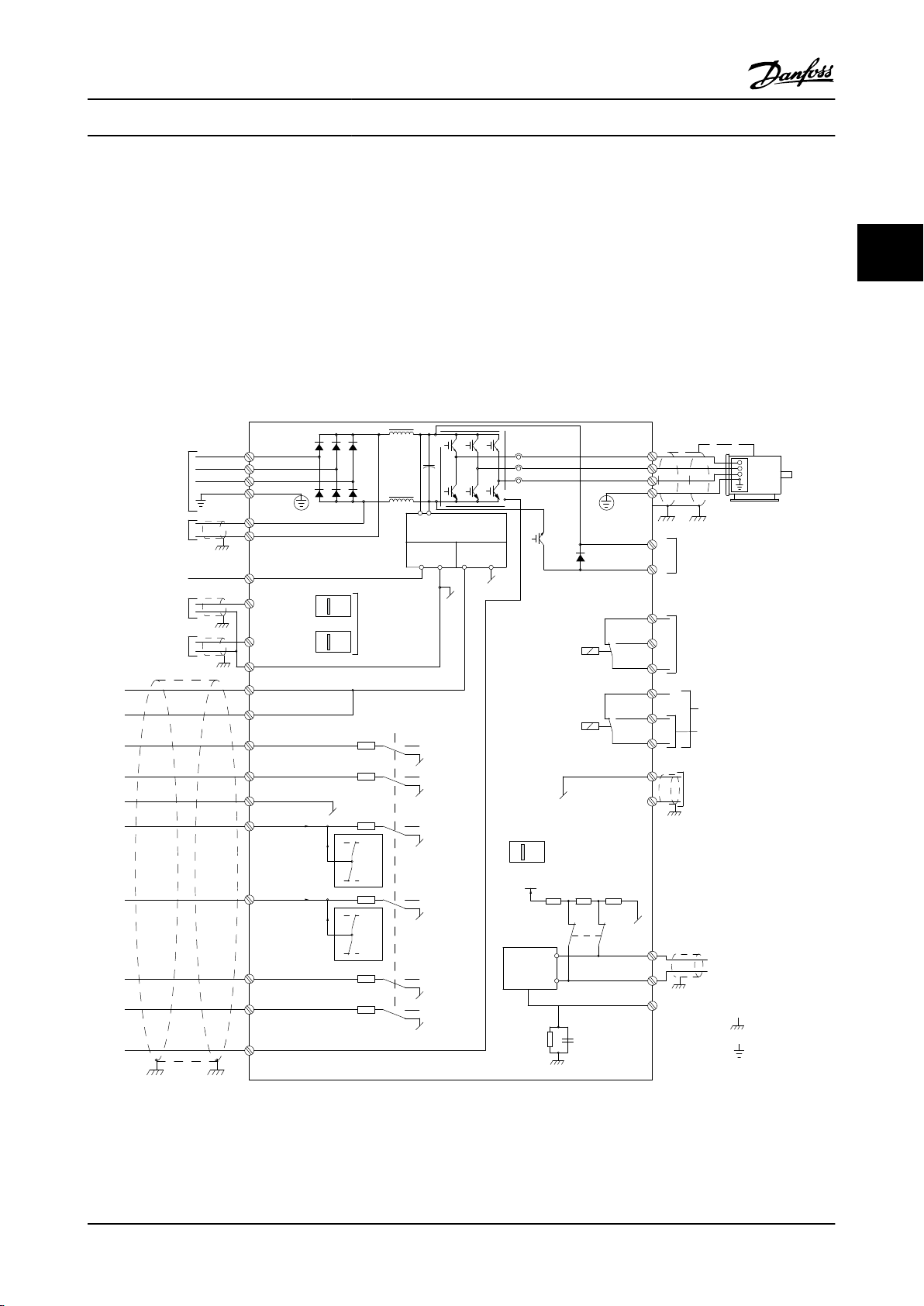

1.4

Internal Controller Functions

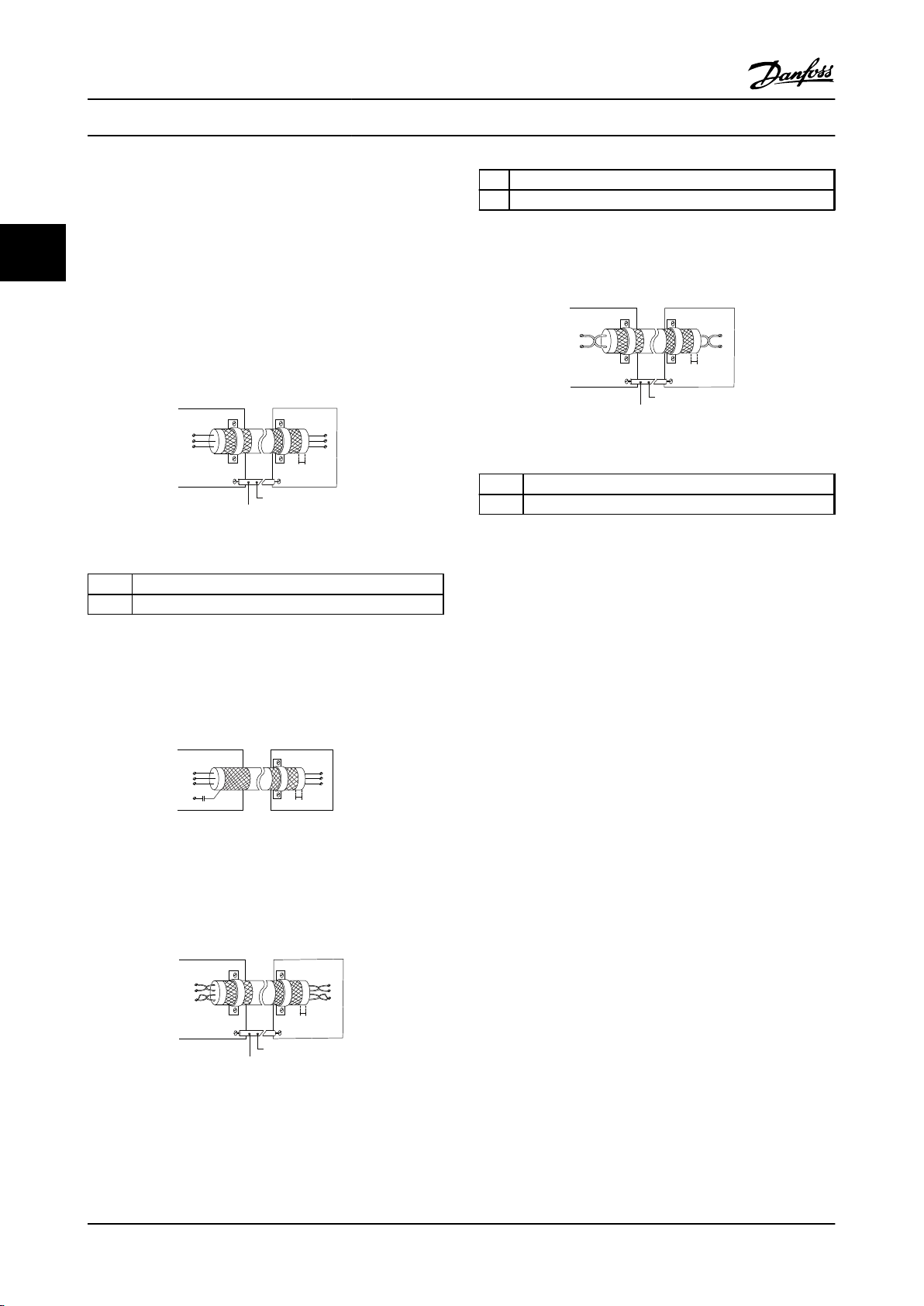

Figure 1.3 is a block diagram of the adjustable frequency

drive's internal components. See Table 1.3 for their

functions.

Figure 1.3 Adjustable Frequency Drive Block Diagram

1 1

1.3

Product Overview

An adjustable frequency drive is an electronic motor

controller that converts AC line power input into a variable

AC waveform output. The frequency and voltage of the

output are regulated to control the motor speed or torque.

The adjustable frequency drive can vary the speed of the

motor in response to system feedback, such as position

sensors on a conveyor belt. The adjustable frequency drive

can also regulate the motor by responding to remote

commands from external controllers.

In addition, the adjustable frequency drive monitors the

system and motor status, issues warnings or alarms for

fault conditions, starts and stops the motor, optimizes

energy efficiency, and offers many more control,

monitoring, and efficiency functions. Operation and

monitoring functions are available as status indications to

an outside control system or serial communication

network.

MG33AM22 - VLT® is a registered Danfoss trademark 1-3

Page 12

Introduction

Area Title Functions

11

1 Mains input

2 Rectifier

3 DC bus

4 DC reactors

5 Capacitor bank

6 Inverter

7 Output to motor

8 Control circuitry

Three-phase AC line power

•

supply to the adjustable

frequency drive

The rectifier bridge converts

•

the AC input to DC current to

supply inverter power

Intermediate DC bus circuit

•

handles the DC current

Filter the intermediate DC

•

circuit voltage

Prove line transient protection

•

Reduce RMS current

•

Raise the power factor

•

reflected back to the line

Reduce harmonics on the AC

•

input

Stores the DC power

•

Provides ride-through

•

protection for short power

losses

Converts the DC into a

•

controlled PWM AC waveform

for a controlled variable

output to the motor

Regulated three-phase output

•

power to the motor

Input power, internal

•

processing, output, and motor

current are monitored to

provide efficient operation

and control

User interface and external

•

commands are monitored and

performed

Status output and control can

•

be provided

VLT® AutomationDrive Instruction

Manual

Table 1.3 Legend to Figure 1.3

1-4 MG33AM22 - VLT® is a registered Danfoss trademark

Page 13

Introduction

VLT® AutomationDrive Instruction

Manual

1.5 Frame Sizes and Power Ratings

Frame size [hp]

[Volts] A1 A2 A3 A4 A5 B1 B2 C1 C2 C3 C4

200–240 0.34–2.0 0.34–3.0 4.00–5.00 0.34–3.0 0.34–5.0 7.5–10 15 20–30 40–50 25–30 40–50

380–480 0.5–2.0 0.5–5.0 7.5–10 0.5–5.0 0.5–10 15–20 25–30 40–60 75–100 50–60 75–100

525–600 N/A N/A 1.0–10 N/A 1.0–10 15–20 25–30 40–60 75–125 50–60 75–125

525–690 N/A N/A 1.5–10 N/A N/A N/A 15–30 N/A 40–100 50–60 N/A

Table 1.4 Frame Sizes and Power Ratings

1 1

MG33AM22 - VLT® is a registered Danfoss trademark 1-5

Page 14

Introduction

VLT® AutomationDrive Instruction

Manual

11

1-6 MG33AM22 - VLT® is a registered Danfoss trademark

Page 15

Installation

2 Installation

2.1 Installation Site Checklist

The adjustable frequency drive relies on the

•

ambient air for cooling. Observe the limitations

on ambient air temperature for optimal operation

Ensure that the installation location has sufficient

•

support strength to mount the adjustable

frequency drive

Keep the manual, drawings, and diagrams

•

accessible for detailed installation and operation

instructions. It is important that the manual is

available for equipment operators.

Locate equipment as near to the motor as

•

possible. Keep motor cables as short as possible.

Check the motor characteristics for actual

tolerances. Do not exceed

1,000 ft [300 m] for unshielded motor

•

leads

500 ft [150 m] for shielded cable.

•

Ensure that the ingress protection rating of the

•

adjustable frequency drive is suitable for the

installation environment. IP55 (NEMA 12) or IP66

(NEMA 4) enclosures may be necessary.

VLT® AutomationDrive Instruction

Manual

2.2

Adjustable Frequency Drive and Motor

Pre-installation Checklist

Compare the model number of unit on the

•

nameplate to what was ordered to verify the

proper equipment

Ensure each of the following are rated for the

•

same voltage:

Ensure that the adjustable frequency drive output

•

current rating is equal to or greater than motor

full load current for peak motor performance.

2.3

Mechanical Installation

Line power

Adjustable frequency drive

Motor

Motor size and adjustable frequency

drive power must match for proper

overload protection

If adjustable frequency drive rating is

less than motor, full motor output

cannot be achieved

2

2

CAUTION

Ingress protection

IP54, IP55 and IP66 ratings can only be guaranteed if the

unit is properly closed.

Ensure that all cable connectors and unused

•

holes for connectors are properly sealed.

Ensure that the unit cover is properly closed

•

CAUTION

Device damage through contamination

Do not leave the adjustable frequency drive uncovered.

For “spark-free” installations according to European

Agreement concerning International Carriage of Dangerous

Goods by Inland Waterways (ADN_2011 ###), refer to VLT

AutomationDrive FC 300 Design Guide.

2.3.1 Cooling

To provide cooling airflow, mount the unit to a

•

solid flat surface or to the optional backplate (see

2.3.3 Mounting)

Top and bottom clearance for air cooling must be

•

provided. Generally, 100–225 mm (4–10 in) is

required. See Figure 2.1 for clearance

requirements

Improper mounting can result in overheating and

•

reduced performance

Derating for temperatures starting between 104

•

°F [40 °C] and 122 °F [50 °C] and elevation 3,300

®

ft [1,000 m] above sea level must be considered.

See the equipment Design Guide for detailed

information.

MG33AM22 - VLT® is a registered Danfoss trademark 2-1

Page 16

a

b

130BA419.10

130BA219.10

A

130BA228.10

A

2

Installation

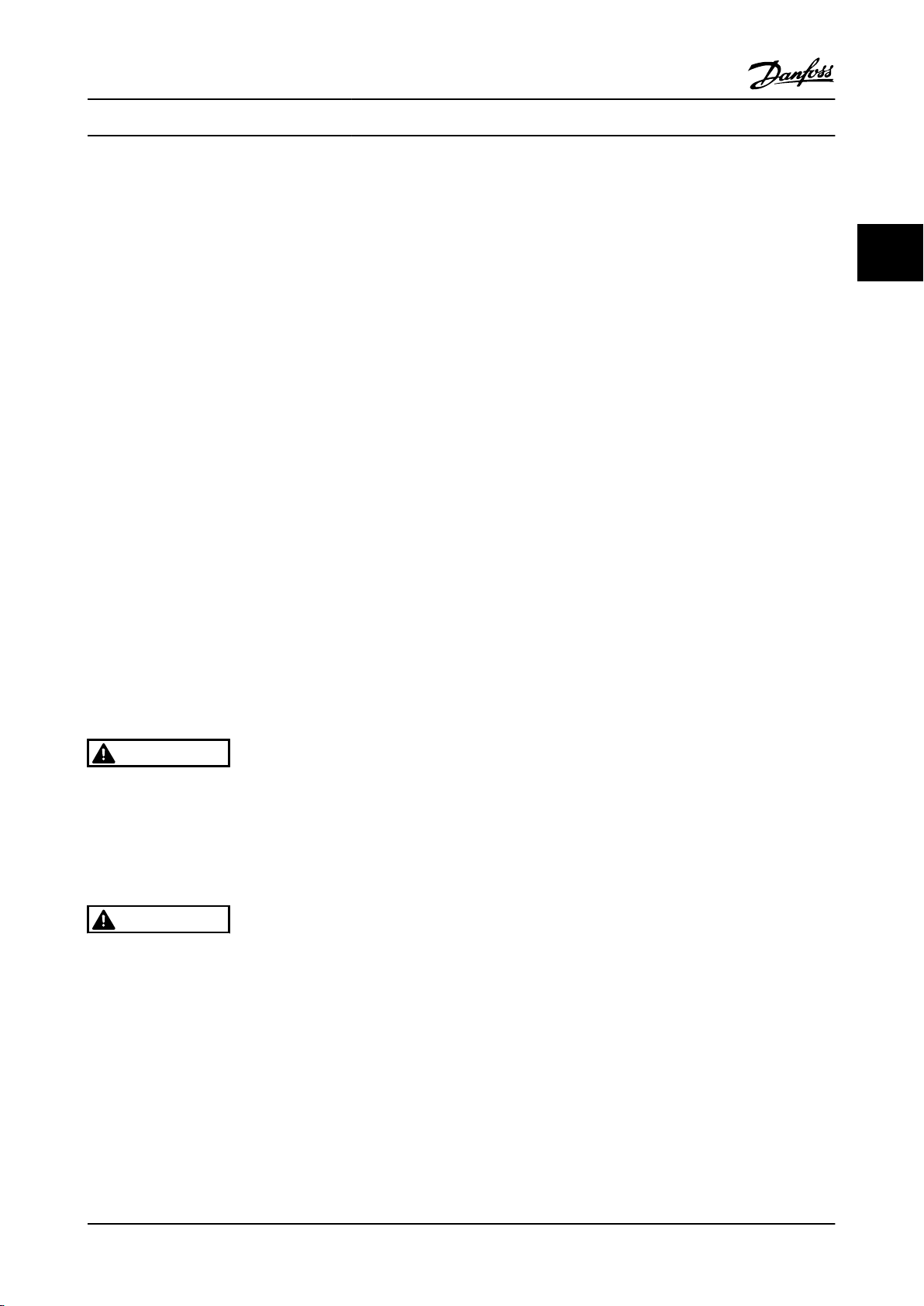

Figure 2.1 Top and Bottom Cooling Clearance

VLT® AutomationDrive Instruction

Manual

Improper mounting can result in overheating and

•

reduced performance

Use the slotted mounting holes on the unit for

•

wall mounting, when provided.

Figure 2.2 Proper Mounting with Backplate

Item A is a backplate properly installed for required airflow

to cool the unit.

Enclosure

a/b (inch

[mm])

Table 2.1 Minimum Airflow Clearance Requirements

Lifting

2.3.2

Check the weight of the unit to determine a safe

•

lifting method

Ensure that the lifting device is suitable for the

•

task

If necessary, plan for a hoist, crane, or forklift with

•

the appropriate rating to move the unit

For lifting, use hoist rings on the unit, where

•

provided

Mounting

2.3.3

Mount the unit vertically

•

The adjustable frequency drive allows side by

•

side installation

Ensure that the strength of the mounting location

•

will support the unit weight

Mount the unit onto a solid flat surface or onto

•

the optional backplate to provide cooling airflow

(see Figure 2.2 and Figure 2.3)

A1-A5 B1-B4 C1, C3 C2, C4

3.94 [100] 7.87 [200] 7.87 [200] 8.86 [225]

Figure 2.3 Proper Mounting with Railings

NOTE!

Backplate is needed when mounted on railings.

2.3.4 Tightening Torques

See 10.4 Connection Tightening Torques for proper

tightening specifications.

2-2 MG33AM22 - VLT® is a registered Danfoss trademark

Page 17

3 Phase

power

input

DC bus

Switch Mode

Power Supply

Motor

Analog Output

Interface

relay1

* relay2

ON=Terminated

OFF=Open

Brake

resistor

130BC931.10

91 (L1)

92 (L2)

93 (L3)

PE

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

0/4-20 mA

12 (+24V OUT)

13 (+24V OUT)

37 (D IN)

18 (D IN)

20 (COM D IN)

10Vdc

15mA 130/200mA

+ - + -

(U) 96

(V) 97

(W) 98

(PE) 99

(COM A OUT) 39

(A OUT) 42

(P RS-485) 68

(N RS-485) 69

(COM RS-485) 61

0V

5V

S801

0/4-20 mA

RS-485

RS-485

03

+10Vdc

0/-10Vdc -

+10Vdc

+10Vdc

0/4-20 mA

0/-10Vdc -

240Vac, 2A

24Vdc

02

01

05

04

06

240Vac, 2A

24V (NPN)

0V (PNP)

0V (PNP)

24V (NPN)

19 (D IN)

24V (NPN)

0V (PNP)

27

24V

0V

(D IN/OUT)

0V (PNP)

24V (NPN)

(D IN/OUT)

0V

24V

29

24V (NPN)

0V (PNP)

0V (PNP)

24V (NPN)

33 (D IN)

32 (D IN)

1 2

ON

S201

ON

21

S202

ON=0/4-20mA

OFF=0/-10Vdc +10Vdc

95

400Vac, 2A

P 5-00

21

ON

S801

(R+) 82

(R-) 81

*

*

: Chassis

: Earth

**

Installation

VLT® AutomationDrive Instruction

Manual

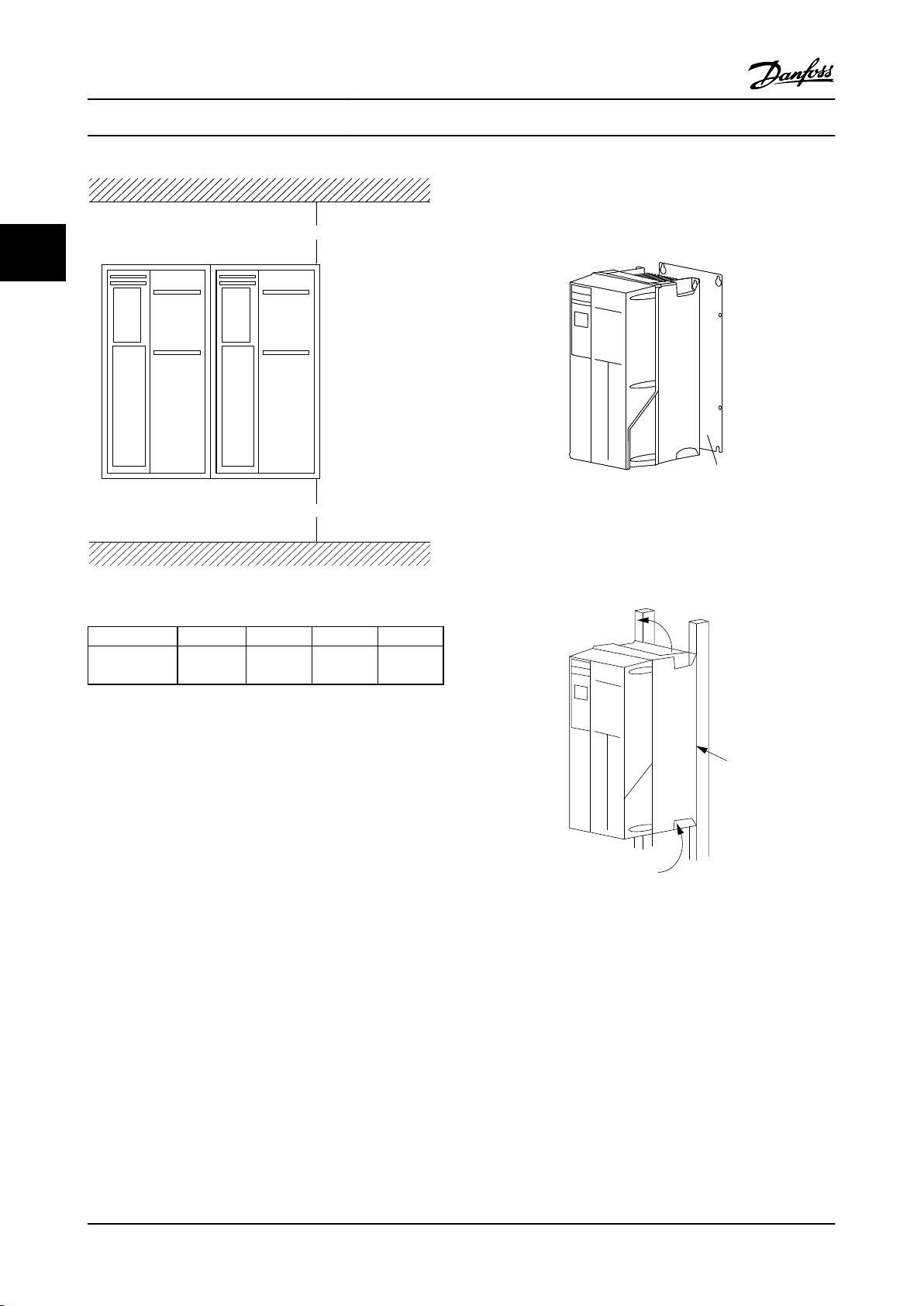

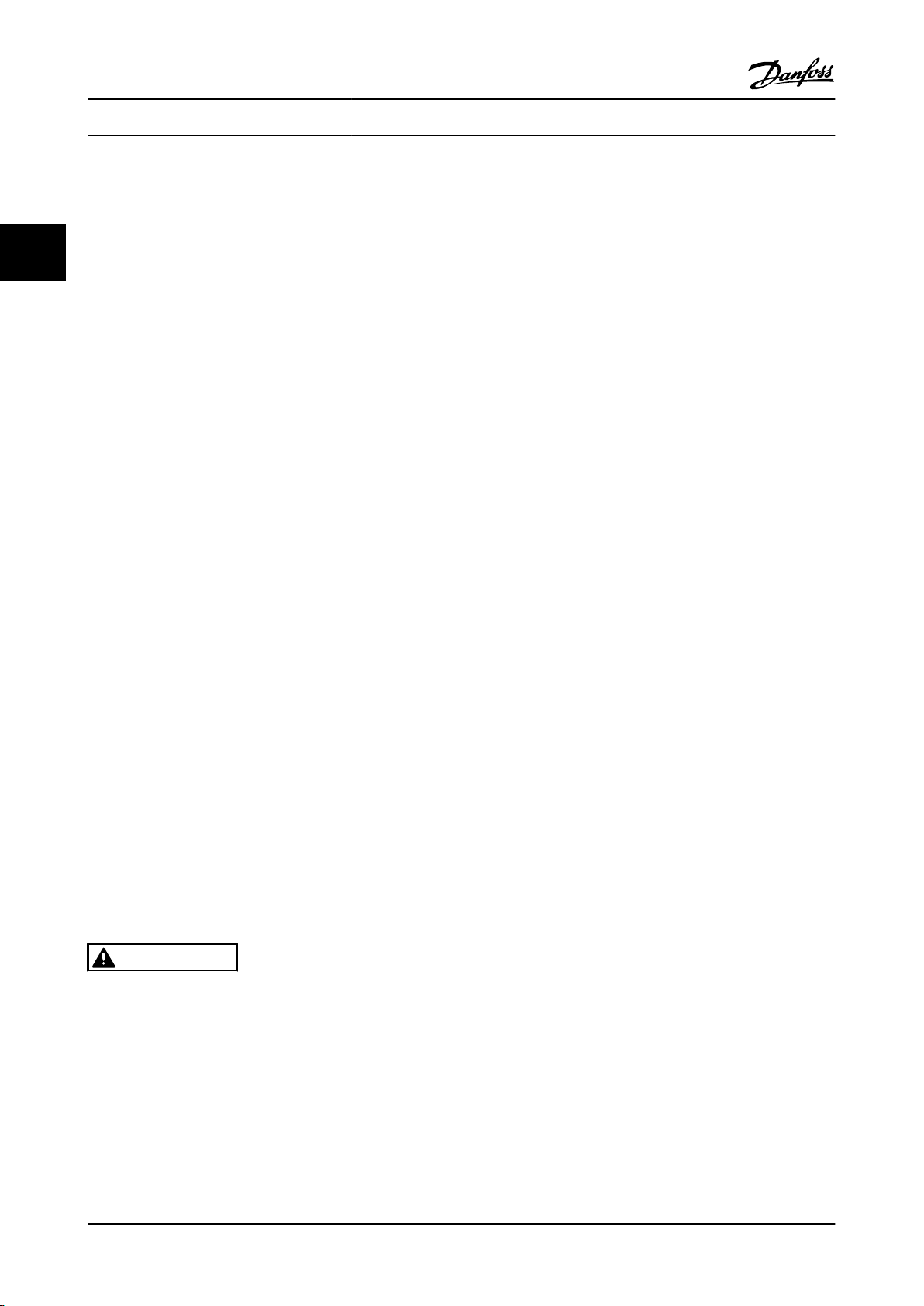

2.4 Electrical Installation

This section contains detailed instructions for wiring the

adjustable frequency drive. The following tasks are

described.

Wiring the motor to the adjustable frequency drive output terminals

•

Wiring the AC line power to the adjustable frequency drive input terminals

•

Connecting control and serial communication wiring

•

After power has been applied, checking input and motor power; programming control terminals for their intended

•

functions

2

2

Figure 2.4 Basic Wiring Schematic Drawing

A=Analog, D=Digital Terminal 37 is used for Safe Stop. For Safe Stop installation

MG33AM22 - VLT® is a registered Danfoss trademark 2-3

instructions, refer to the Design Guide.

Page 18

1

2

3

4

5

6

7

8

PE

U

V

W

9

L1

L2

L3

PE

130BB607.10

10

Installation

VLT® AutomationDrive Instruction

Manual

2

* Terminal 37 is not included in FC 301 (except frame size

A1). Relay 2 and terminal 29 have no function in FC 301.

** Do not connect cable screen.

Figure 2.5 Typical Electrical Connection

1

2 Adjustable frequency drive 7 Motor, 3-phase and PE

PLC 6 Min. 200 mm (7.9 in) between control cables, motor and line

power

3 Output contactor (Generally not recommended) 8 Line power, 3-phase and reinforced PE

4 Grounding rail (PE) 9 Control wiring

5 Cable insulation (stripped) 10

Equalizing min. 16 mm2 (0.025 in2)

Table 2.2 Legend to Figure 2.5

2-4 MG33AM22 - VLT® is a registered Danfoss trademark

Page 19

L1

L1L2L2L3L3

GND

91 92 93

Fuses

130BB460.10

Installation

VLT® AutomationDrive Instruction

Manual

2.4.1 Requirements

WARNING

EQUIPMENT HAZARD!

Rotating shafts and electrical equipment can be hazardous.

All electrical work must conform to national and local

electrical codes. It is strongly recommended that installation, start-up, and maintenance be performed only by

trained and qualified personnel. Failure to follow these

guidelines could result in death or serious injury.

Input fusing is required to provide this

protection, see Figure 2.6. If not factory supplied,

fuses must be provided by the installer as part of

installation. See maximum fuse ratings in

10.3 Fuse Specifications.

2

2

CAUTION

WIRING ISOLATION!

Run input power, motor wiring and control wiring in three

separate metallic conduits or use separated shielded cable

for high frequency noise isolation. Failure to isolate power,

motor and control wiring could result in less than

optimum adjustable frequency drive and associated

equipment performance.

For your safety, comply with the following requirements.

Electronic controls equipment is connected to

•

hazardous AC line voltage. Extreme care should

be taken to protect against electrical hazards

when applying power to the unit.

Run motor cables from multiple adjustable

•

frequency drives separately. Induced voltage from

output motor cables run together can charge

equipment capacitors even with the equipment

turned off and locked out.

Overload and Equipment Protection

An electronically activated function within the

•

adjustable frequency drive provides overload

protection for the motor. The overload calculates

the level of increase to activate timing for the trip

(controller output stop) function. The higher the

current draw, the quicker the trip response. The

overload provides Class 20 motor protection. See

8 Warnings and Alarms for details on the trip

function.

Because the motor wiring carries high frequency

•

current, it is important that wiring for line power,

motor power, and control is run separately. Use

metallic conduit or separated shielded wire.

Failure to isolate power, motor, and control

wiring could result in less than optimum

equipment performance.

All adjustable frequency drives must be provided

•

with short-circuit and overcurrent protection.

Figure 2.6 Adjustable Frequency Drive Fuses

Wire Type and Ratings

All wiring must comply with local and national

•

regulations regarding cross-section and ambient

temperature requirements.

Danfoss recommends that all power connections

•

be made with a minimum 167 °F [75 °C] rated

copper wire.

See 10.1 Power-dependent Specifications for

•

recommended wire sizes.

Grounding Requirements

2.4.2

WARNING

GROUNDING HAZARD!

For operator safety, it is important to ground the

adjustable frequency drive properly in accordance with

national and local electrical codes, as well as instructions

contained within these instructions. Ground currents are

higher than 3.5 mA. Failure to ground the adjustable

frequency drive properly could result in death or serious

injury.

NOTE!

It is the responsibility of the user or certified electrical

installer to ensure correct grounding of the equipment in

accordance with national and local electrical codes and

standards.

MG33AM22 - VLT® is a registered Danfoss trademark 2-5

Page 20

130BA266.10

+DC

BR-

B

MAINS

L1 L2 L3

91 92 93

RELAY 1 RELAY 2

99

- LC -

UVW

MOTOR

Installation

VLT® AutomationDrive Instruction

Manual

2

Follow all local and national electrical codes to

•

ground electrical equipment properly.

Proper protective grounding for equipment with

•

ground currents higher than 3.5 mA must be

established, see Leakage Current (>3,5 mA)

A dedicated ground wire is required for input

•

power, motor power and control wiring

Use the clamps provided with the equipment for

•

proper ground connections

Do not ground one adjustable frequency drive to

•

another in a “daisy chain” fashion

Keep the ground wire connections as short as

•

possible

Use of high strand wire to reduce electrical noise

•

is recommended

Follow the motor manufacturer wiring

•

requirements

2.4.2.1

Follow national and local codes regarding protective

grounding of equipment with a leakage current > 3.5 mA.

Adjustable frequency drive technology implies high

frequency switching at high power. This will generate a

leakage current in the ground connection. A fault current

in the adjustable frequency drive at the output power

terminals might contain a DC component which can

charge the filter capacitors and cause a transient ground

current. The ground leakage current depends on various

system configurations including RFI filtering, shielded

motor cables, and adjustable frequency drive power.

EN/IEC61800-5-1 (Power Drive System Product Standard)

requires special care if the leakage current exceeds 3.5 mA.

Grounding must be reinforced in one of the following

ways:

See EN 60364-5-54 § 543.7 for further information.

Using RCDs

Where residual current devices (RCDs), also known as

ground leakage circuit breakers (GLCBs), are used, comply

with the following:

Leakage Current (>3.5 mA)

Ground wire of at least 0.0155 in2 [10 mm2]

•

Two separate ground wires both complying with

•

the dimensioning rules

Use RCDs of type B only which are capable of

detecting AC and DC currents

Use RCDs with an inrush delay to prevent faults

due to transient ground currents

Dimension RCDs according to the system configuration and environmental considerations

2.4.2.2

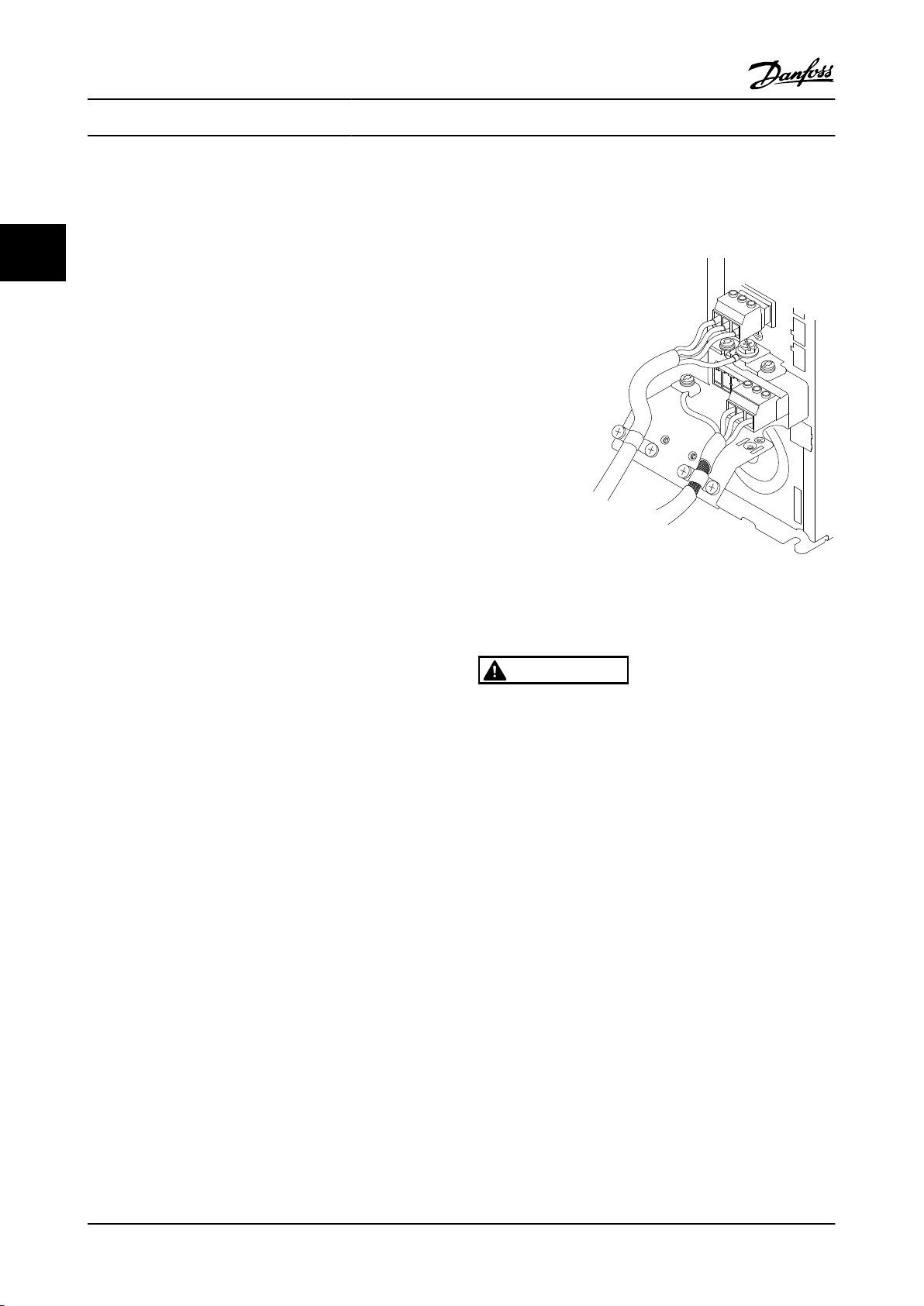

Grounding clamps are provided for motor wiring (see

Figure 2.7).

Figure 2.7 Grounding with Shielded Cable

2.4.3

Grounding Using Shielded Cable

Motor Connection

WARNING

INDUCED VOLTAGE!

Run output motor cables from multiple adjustable

frequency drives separately. Induced voltage from output

motor cables run together can charge equipment

capacitors even with the equipment turned off and locked

out. Failure to run output motor cables separately could

result in death or serious injury.

For maximum wire sizes, see 10.1 Power-

•

dependent Specifications

Comply with local and national electrical codes

•

for cable sizes.

Motor wiring knockouts or access panels are

•

provided at the base of IP21 and higher

(NEMA1/12) units

Do not install power factor correction capacitors

•

between the adjustable frequency drive and the

motor

Do not wire a starting or pole-changing device

•

between the adjustable frequency drive and the

motor.

Connect the 3-phase motor wiring to terminals

•

96 (U), 97 (V), and 98 (W).

2-6 MG33AM22 - VLT® is a registered Danfoss trademark

Page 21

95

130BB920.10

+DC

BR-

B

M A I N S

L1 L2 L3

91 92 93

RELAY 1 RELAY 2

99

- LC -

U V W

MOTOR

99

130BT248.10

Installation

VLT® AutomationDrive Instruction

Manual

Ground the cable in accordance with grounding

•

instructions provided.

Torque terminals in accordance with the

•

information provided in

Follow the motor manufacturer wiring

•

requirements

Figure 2.8 represents line power input, motor, and

grounding for basic adjustable frequency drives. Actual

configurations vary with unit types and optional

equipment.

reference power lines. When supplied from an

isolated line power source (IT line power or

floating delta) or TT/TN-S line power with a

grounded leg (grounded delta), set 14-50 RFI 1 to

[0] Off. When off, the internal RFI filter capacitors

between the chassis and the intermediate circuit

are isolated to avoid damage to the intermediate

circuit and to reduce ground capacity currents in

accordance with IEC 61800-3.

2.4.5 Control Wiring

Isolate control wiring from high power

•

components in the adjustable frequency drive.

If the adjustable frequency drive is connected to

•

a thermistor, for PELV isolation, optional

thermistor control wiring must be reinforced/

double insulated. A 24 V DC supply voltage is

recommended.

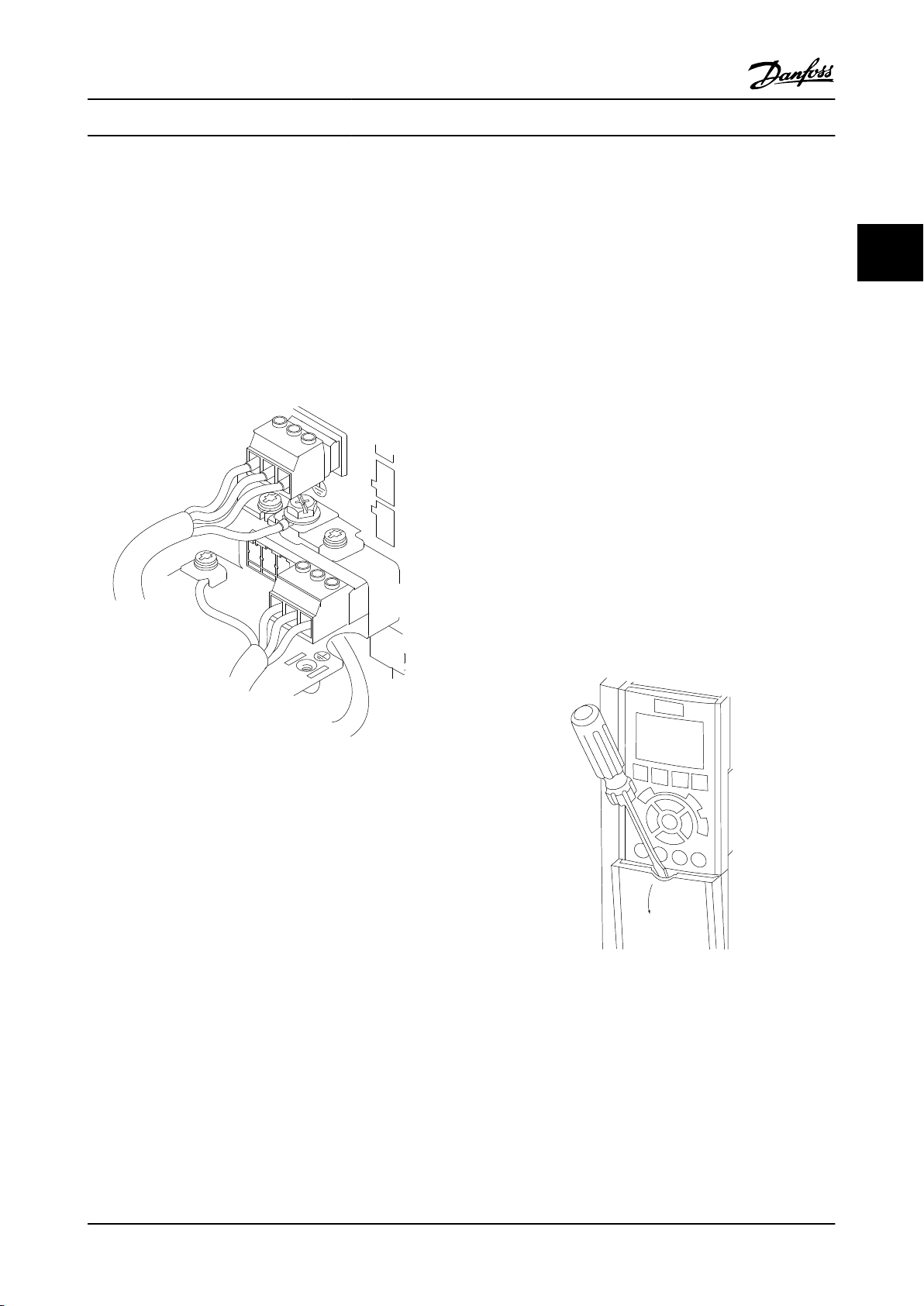

2.4.5.1

Access

Remove access cover plate with a screw driver.

•

See Figure 2.9.

Or remove front cover by loosening attaching

•

screws. See Figure 2.10.

2

2

Figure 2.8 Example of Motor, Line Power and Ground Wiring

AC Line Input Connection

2.4.4

Size wiring based upon the input current of the

•

adjustable frequency drive. For maximum wire

sizes, see 10.1 Power-dependent Specifications.

Comply with local and national electrical codes

•

for cable sizes.

Connect 3-phase AC input power wiring to

•

terminals L1, L2, and L3 (see Figure 2.8).

Depending on the configuration of the

•

equipment, input power will be connected to the

line input power or the input disconnect.

Ground the cable in accordance with grounding

•

instructions provided in 2.4.2 Grounding

Requirements

All adjustable frequency drives may be used with

•

an isolated input source as well as with ground

Figure 2.9 Control Wiring Access for A2, A3, B3, B4, C3 and C4

Enclosures

MG33AM22 - VLT® is a registered Danfoss trademark 2-7

Page 22

130BT334.10

2

3

4

1

130BB921.11

12 13 18 19 27 29 32 33 20 37

39 42 50 53 54 55

61 68 69

130BB931.10

1

2 3

Installation

2

Figure 2.10 Control Wiring Access for A4, A5, B1, B2, C1 and C2

Enclosures

See Table 2.3 before tightening the covers.

Frame IP20 IP21 IP55 IP66

A3/A4/A5 - - 2 2

B1/B2 - * 2.2 2.2

C1/C2/C3/C4 - * 2.2 2.2

* No screws to tighten

- Does not exist

Table 2.3 Tightening Torques for Covers (Nm)

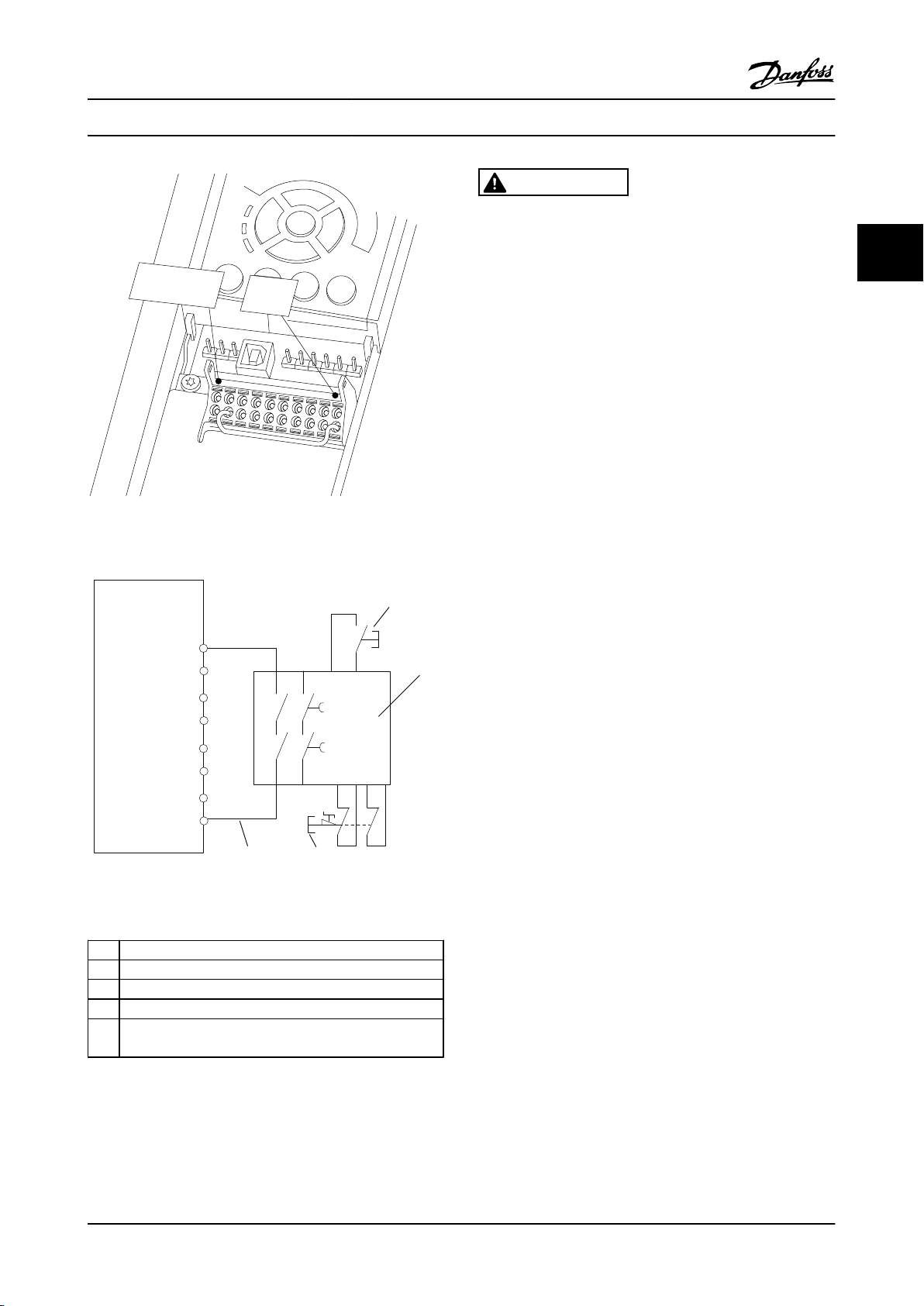

2.4.5.2

Figure 2.11 and shows the removable adjustable frequency

drive connectors. Terminal functions and default settings

are summarized in Table 2.5.

Figure 2.11 Control Terminal Locations

2-8 MG33AM22 - VLT® is a registered Danfoss trademark

Control Terminal Types

VLT® AutomationDrive Instruction

Manual

Figure 2.12 Terminal Numbers

Connector 1 provides four programmable digital

•

inputs terminals, two additional digital terminals

programmable as either input or output, a 24 V

DC terminal supply voltage, and a common for

optional customer supplied 24 V DC voltage. FC

302 and FC 301 (optional in A1 enclosure) also

provide a digital input for STO (Safe Torque Off)

function.

Connector 2 terminals (+)68 and (-)69 are for an

•

RS-485 serial communications connection

Connector 3 provides two analog inputs, one

•

analog output, 10 V DC supply voltage, and

commons for the inputs and output

Connector 4 is a USB port available for use with

•

the MCT 10 Set-up Software

Also provided are two Form C relay outputs that

•

are in various locations depending upon the

adjustable frequency drive configuration and size

Some options available for ordering with the unit

•

may provide additional terminals. See the manual

provided with the equipment option.

See 10.2 General Technical Data for terminal ratings details.

Terminal Parameter

12, 13 - +24 V DC 24 V DC supply

18 5-10 [8] Start

19 5-11 [10] Reversing

32 5-14 [0] No

33 5-15 [0] No

Terminal description

Default

setting Description

Digital inputs/outputs

operation

operation

voltage. Maximum

output current is 200

mA total (130 mA for

FC 301) for all 24 V

loads. Usable for

digital inputs and

external transducers.

Digital inputs.

Page 23

2

1

10 mm

130BA310.10

12 13

18

19

27

29

32

33

Installation

VLT® AutomationDrive Instruction

Manual

Terminal description

Default

Terminal Parameter

27 5-12 [2] Coast

29 5-13 [14] JOG

20 - Common for digital

37 - Safe Torque

39 -

42 6-50 [0] No

50 - +10 V DC 10 V DC analog

53 6-1* Reference Analog input.

54 6-2* Feedback

55 -

setting Description

inverse

Off (STO)

Analog inputs/outputs

operation

Selectable for either

digital input or

output. Default setting

is input.

inputs and 0 V

potential for 24 V

supply.

Safe input. Used for

STO.

Common for analog

output

Programmable analog

output. The analog

signal is 0–20 mA or

4–20 mA at a

maximum of 500 Ω

supply voltage. 15 mA

maximum commonly

used for potentiometer or thermistor.

Selectable for voltage

or current. Switches

A53 and A54 select

mA or V.

Common for analog

input

Terminal description

Default

Terminal Parameter

01, 02, 03 5-40 [0]

04, 05, 06 5-40 [1] [0] No

Table 2.5 Terminal Description Serial Communication

setting Description

[0] No

operation

operation

Form C relay output.

Usable for AC or DC

voltage and resistive

or inductive loads.

2.4.5.3 Wiring to Control Terminals

Control terminal connectors can be unplugged from the

adjustable frequency drive for ease of installation, as

shown in Figure 2.11.

1. Open the contact by inserting a small screwdriver

into the slot above or below the contact, as

shown in Figure 2.13.

2. Insert the bared control wire into the contact.

3. Remove the screwdriver to fasten the control wire

into the contact.

4. Ensure the contact is firmly established and not

loose. Loose control wiring can be the source of

equipment faults or less than optimal operation.

See 10.1 Power-dependent Specifications for control terminal

wiring sizes.

See 6 Application Examples for typical control wiring

connections.

2

2

Table 2.4 Terminal Description Digital Inputs/Outputs, Analog Inputs/Outputs

Terminal description

Default

Terminal Parameter

61 -

68 (+) 8-3* RS-485 Interface. A

69 (-) 8-3*

setting Description

Serial communication

Relays

Integrated RC filter for

cable screen. ONLY for

connecting the shield

when experiencing

EMC problems.

control card switch is

provided for

termination resistance.

Figure 2.13 Connecting Control Wiring

MG33AM22 - VLT® is a registered Danfoss trademark 2-9

Page 24

1

2

PE

FC

PE

PLC

130BB922.12

PE PE

<10 mm

100nF

FC

PE

PE

PLC

<10 mm

130BB609.12

PE

FC

PE

FC

130BB923.12

PE PE

69

68

61

69

68

61

1

2

<10 mm

PE

FC

PE

FC

130BB924.12

PE PE

69

69

68

68

1

2

<10 mm

2

Installation

VLT® AutomationDrive Instruction

Manual

2.4.5.4 Using Shielded Control Cables

Correct shielding

The preferred method in most cases is to secure control

and serial communication cables with shielding clamps

provided at both ends to ensure best possible high

frequency cable contact.

If the ground potential between the adjustable frequency

drive and the PLC is different, electrical noise may occur

that will disturb the entire system. Solve this problem by

fitting an equalizing cable next to the control cable.

Minimum cable cross-section: 0.025 in2 [16 mm2].

Figure 2.14 Correct Shielding

1

Min. 0.025 in2 [16 mm2]

2 Equalizing cable

Table 2.7 Legend to Figure 2.16

Alternatively, the connection to terminal 61 can be

omitted:

Figure 2.17 Twisted-pair Cables without Terminal 61

1

Min. 0.025 in2 [16 mm2]

2 Equalizing cable

Table 2.8 Legend to Figure 2.17

1

Min. 0.025 in2 [16 mm2]

2 Equalizing cable

Table 2.6 Legend to Figure 2.14

50/60 Hz ground loops

With very long control cables, ground loops may occur. To

eliminate ground loops, connect one end of the shield-toground with a 100 nF capacitor (keeping leads short).

Figure 2.15 50/60 Hz Ground Loops

Avoid EMC noise on serial communication

This terminal is grounded via an internal RC link. Use

twisted-pair cables to reduce interference between

conductors. The recommended method is shown below:

Figure 2.16 Twisted-pair Cables

2.4.5.5

Control Terminal Functions

Adjustable frequency drive functions are commanded by

receiving control input signals.

Each terminal must be programmed for the

•

function it will be supporting in the parameters

associated with that terminal. See Table 2.5 for

terminals and associated parameters.

It is important to confirm that the control

•

terminal is programmed for the correct function.

See 4 User Interface for details on accessing

parameters and 5 About Adjustable Frequency

Drive Programming for details on programming.

The default terminal programming is intended to

•

initiate adjustable frequency drive functioning in

a typical operational mode.

2.4.5.6

Jumper Terminals 12 and 27

A jumper wire may be required between terminal 12 (or

13) and terminal 27 for the adjustable frequency drive to

operate when using factory default programming values.

Digital input terminal 27 is designed to receive an

•

24 V DC external interlock command. In many

applications, the user wires an external interlock

device to terminal 27

When no interlock device is used, wire a jumper

•

between control terminal 12 (recommended) or

13 to terminal 27. This provides an internal 24 V

signal on terminal 27.

2-10 MG33AM22 - VLT® is a registered Danfoss trademark

Page 25

130BT310.10

1

2

N O

V LT

BUS TER.

OFF-ON

A53 A54

U- I U- I

Installation

•

•

•

No signal present prevents the unit from

operating.

When the status line at the bottom of the LCP

reads AUTO REMOTE COAST, this indicates that

the unit is ready to operate but is missing an

input signal on terminal 27.

When factory installed optional equipment is

wired to terminal 27, do not remove that wiring

VLT® AutomationDrive Instruction

Manual

2.4.5.7 Terminal 53 and 54 Switches

Analog input terminals 53 and 54 can select

•

either voltage (-10 to 10 V) or current (0/4–20

mA) input signals

Remove power to the adjustable frequency drive

•

before changing switch positions.

Set switches A53 and A54 to select the signal

•

type. U selects voltage, I selects current.

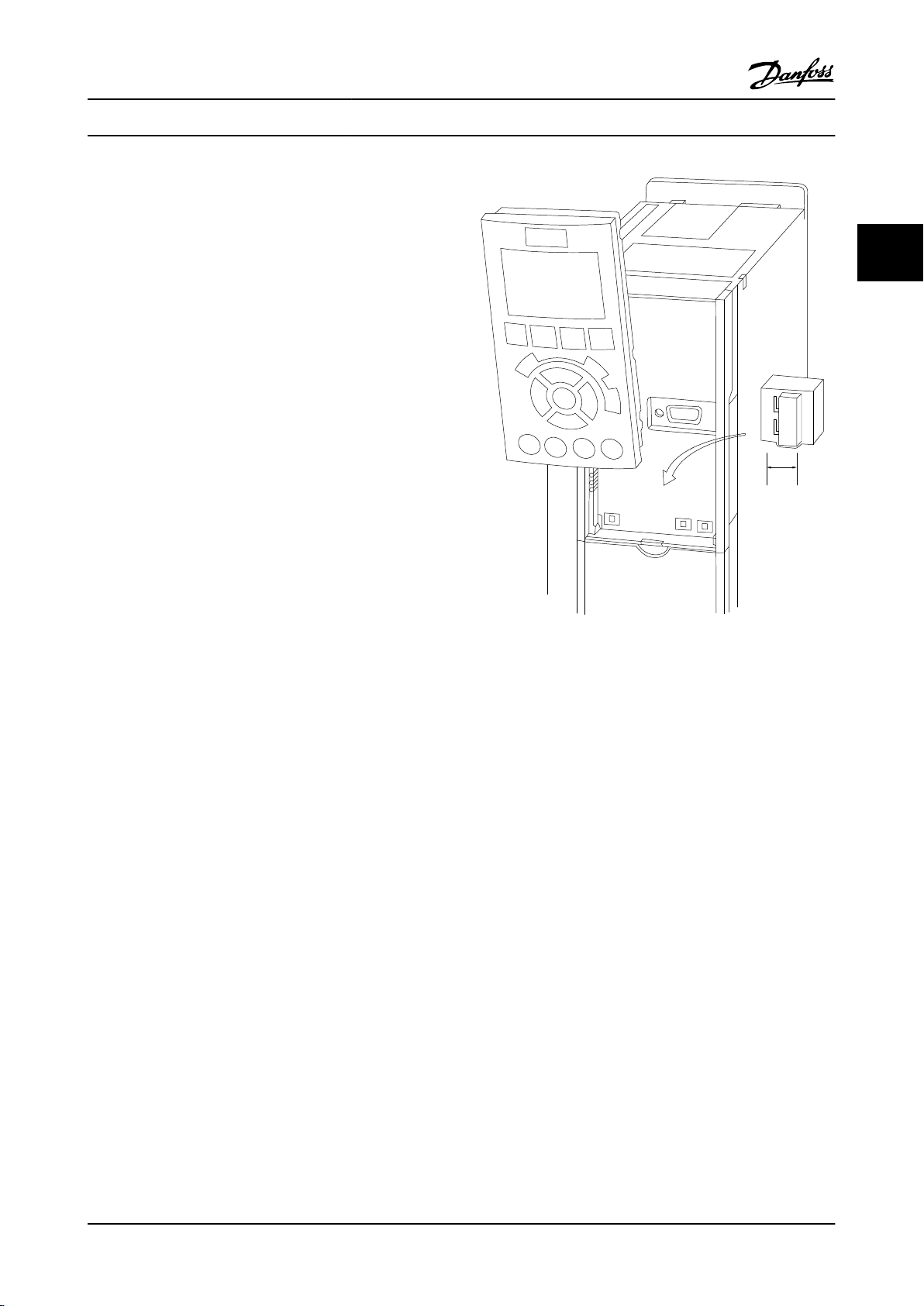

The switches are accessible when the LCP has

•

been removed (see Figure 2.18).

2

2

NOTE!

Some option cards available for the unit may cover these

switches and must be removed to change switch settings.

Always remove power to the unit before removing option

cards.

Terminal 53 default is for a speed reference signal

•

in open-loop set in 16-61 Terminal 53 Switch

Setting

Terminal 54 default is for a feedback signal in

•

closed-loop set in 16-63 Terminal 54 Switch Setting

Figure 2.18 Location of Terminals 53 and 54 Switches and Bus

Termination Switch

2.4.5.8

In hoisting/lowering applications, it is necessary to be able

to control an electro-mechanical brake:

Mechanical Brake Control

Control the brake using any relay output or

•

digital output (terminal 27 or 29).

Keep the output closed (voltage-free) as long as

•

the adjustable frequency drive is unable to

‘support’ the motor, such as when the load is too

heavy, for example.

Select [32] Mechanical brake control in parameter

•

group 5-4* for applications with an electromechanical brake.

The brake is released when the motor current

•

exceeds the preset value in 2-20 Release Brake

Current.

The brake is engaged when the output frequency

•

is less than the frequency set in 2-21 Activate

Brake Speed [RPM] or 2-22 Activate Brake Speed

[Hz], and only if the adjustable frequency drive

carries out a stop command.

MG33AM22 - VLT® is a registered Danfoss trademark 2-11

Page 26

L1 L2 L3

U V W

02 01

A1

A2

130BA902.10

Drive

Output

relay

Command Circuit

220Vac

Mechanical

Brake

Shaft

Motor

Frewheeling

diode

Brake

380Vac

Output

Contactor

Input

Power Circuit

61

68

69

+

130BB489.10

RS-485

2

Installation

VLT® AutomationDrive Instruction

Manual

If the adjustable frequency drive is in alarm mode or in an

overvoltage situation, the mechanical brake immediately

cuts in.

In the vertical movement, the key point is that the load

must be held, stopped, controlled (raised, lowered) in a

perfectly safe mode during the entire operation. Because

the adjustable frequency drive is not a safety device, the

crane/lift designer (OEM) must decide on the type and

number of safety devices (e.g. speed switch, emergency

brakes, etc.) to be used, in order to be able to stop the

load in case of emergency or malfunction of the system,

according to relevant national crane/lift regulations.

Figure 2.20 Serial Communication Wiring Diagram

For basic serial communication set-up, select the following

1.

Protocol type in 8-30 Protocol.

2. Adjustable frequency drive address in

8-31 Address.

3.

Baud rate in 8-32 Baud Rate.

Two communication protocols are internal to the

•

adjustable frequency drive. Follow the motor

manufacturer wiring requirements.

Danfoss FC

Modbus RTU

Functions can be programmed remotely using

•

the protocol software and RS-485 connection or

Figure 2.19 Connecting the Mechanical Brake to the Adjustable

Frequency Drive

in parameter group 8-** Communications and

Options.

Selecting a specific communication protocol

•

changes various default parameter settings to

Serial Communication

2.4.6

match that protocol’s specifications along with

making additional protocol-specific parameters

Connect RS-485 serial communication wiring to terminals

(+)68 and (-)69.

available

Option cards which can be installed in the

•

adjustable frequency drive are available to

A shielded serial communication cable is

•

recommended

See 2.4.2 Grounding Requirements for proper

•

provide additional communication protocols. See

the option-card documentation for installation

and instruction manual

grounding

2-12 MG33AM22 - VLT® is a registered Danfoss trademark

2.5

Safe Stop

The adjustable frequency drive can perform the safety

function Safe Torque Off (STO, as defined by EN IEC

61800-5-21) and Stop Category 0 (as defined in EN

60204-12).

Danfoss has named this functionality Safe Stop. Before

integration and use of Safe Stop in an installation, perform

a thorough risk analysis to determine whether the Safe

Page 27

Installation

VLT® AutomationDrive Instruction

Manual

Stop functionality and safety levels are appropriate and

sufficient. Safe Stop is designed and approved suitable for

the requirements of:

- Safety Category 3 according to EN ISO 13849-1

- Performance Level "d" according to EN ISO

13849-1:2008

- SIL 2 Capability according to IEC 61508 and EN

61800-5-2

- SILCL 2 according to EN 62061

1)

Refer to EN IEC 61800-5-2 for details of Safe torque off

(STO) function.

2)

Refer to EN IEC 60204-1 for details of stop category 0

and 1.

Activation and Termination of Safe Stop

The Safe Stop (STO) function is activated by removing the

voltage at Terminal 37 of the Safe Inverter. By connecting

the Safe Inverter to external safety devices providing a safe

delay, an installation for a safe Stop Category 1 can be

obtained. The Safe Stop function can be used for

asynchronous, synchronous, and permanent magnet

motors.

WARNING

After installation of Safe Stop (STO), a commissioning test

as specified in 2.5.2 Safe Stop Commissioning Test must be

performed. A passed commissioning test is mandatory

after first installation and after each change to the safety

installation.

Safe Stop Technical Data

The following values are associated to the different types

of safety levels:

Reaction time for T37

- Maximum reaction time: 10 ms

Reaction time = delay between de-energizing the STO

input and switching off the adjustable frequency drive

output bridge.

Data for EN ISO 13849-1

- Performance Level "d"

- MTTFd (Mean Time To Dangerous Failure): 14,000

years

- DC (Diagnostic Coverage): 90%

- Category 3

- Lifetime 20 years

Data for EN IEC 62061, EN IEC 61508, EN IEC 61800-5-2

- SIL 2 Capability, SILCL 2

- PFH (Probability of Dangerous failure per

Hour)=1e-10FIT=7e-19/h-9/h>90%

- SFF (Safe Failure Fraction) >99%

- HFT (Hardware Fault Tolerance)=0 (1001

architecture)

- Lifetime 20 years

Data for EN IEC 61508 low demand

- PFDavg for one year proof test: 1E-10

- PFDavg for three year proof test: 1E-10

- PFDavg for five year proof test: 1E-10

No maintenance of the STO functionality is needed.

Security measures have to be taken by the user, e.g.,

installation in a closed cabinet that is only accessible for

skilled personnel.

SISTEMA Data

Functional safety data is available via a data library for use

with the SISTEMA calculation tool from the IFA (Institute

for Occupational Safety and Health of the German Social

Accident Insurance) and data for manual calculation. The

library is complete and continually extended.

Terminal 37 Safe Stop Function

2.5.1

The adjustable frequency drive is available with safe stop

functionality via control terminal 37. Safe stop disables the

control voltage of the power semiconductors of the

adjustable frequency drive output stage. This in turn

prevents generating the voltage required to rotate the

motor. When the Safe Stop (T37) is activated, the

adjustable frequency drive issues an alarm, trips the unit,

and coasts the motor to a stop. Manual restart is required.

The safe stop function can be used as an emergency stop

for the adjustable frequency drive. In normal operating

mode when safe stop is not required, use the regular stop

function instead. When automatic restart is used, ensure

the requirements of ISO 12100-2 paragraph 5.3.2.5 are

fulfilled.

Liability Conditions

It is the responsibility of the user to ensure that qualified

personnel installs and operates the safe stop function:

Read and understand the safety regulations

•

concerning health and safety/accident prevention

Understand the generic and safety guidelines

•

given in this description and the extended

description in the relevant Design Guide

Have a good knowledge of the generic and safety

•

standards applicable to the specific application

2

2

MG33AM22 - VLT® is a registered Danfoss trademark 2-13

Page 28

Installation

VLT® AutomationDrive Instruction

Manual

2

User is defined as: integrator, operator, service technician,

maintenance technician.

Standards

Use of safe stop on terminal 37 requires that the user

satisfies all provisions for safety including relevant laws,

regulations and guidelines. The optional safe stop function

complies with the following standards.

IEC 60204-1: 2005 category 0 – uncontrolled stop

•

IEC 61508: 1998 SIL2

•

IEC 61800-5-2: 2007 – safe torque off (STO)

•

function

IEC 62061: 2005 SIL CL2

•

ISO 13849-1: 2006 Category 3 PL d

•

ISO 14118: 2000 (EN 1037) – prevention of

•

unexpected start-up

The information and instructions of the instruction manual

are not sufficient for a proper and safe use of the safe stop

functionality. The related information and instructions of

the relevant Design Guide must be followed.

Protective Measures

Qualified and skilled personnel are required for

•

installation and commissioning of safety

engineering systems

The unit must be installed in an IP54 cabinet or

•

in an equivalent environment. In special

applications, a higher IP degree is required

The cable between terminal 37 and the external

•

safety device must be short circuit protected

according to ISO 13849-2 table D.4

When external forces influence the motor axis (for

•

example, suspended loads), additional measures

are required (for example, a safety holding brake)

to eliminate potential hazards

Safe Stop Installation and Set-up

It is not recommended to stop the adjustable

•

frequency drive by using the Safe Torque Off

function. If a running adjustable frequency drive

is stopped by using the function, the unit trips

and stops by coasting. If unacceptable or

dangerous, use another stopping mode to stop

the adjustable frequency drive and machinery,

before using this function. Depending on the

application, a mechanical brake can be required.

For synchronous and permanent magnet motor

•

adjustable frequency drives, in a multiple IGBT

power semiconductor failure: In spite of the

activation of the Safe Torque Off function, the

system can produce an alignment torque which

maximally rotates the motor shaft by 180/p

degrees. p denotes the pole pair number.

This function is suitable for performing

•

mechanical work on the system or affected area

of a machine only. It does not provide electrical

safety. Do not use this function as a control for

starting and/or stopping the adjustable frequency

drive.

Follow these steps to perform a safe installation of the

adjustable frequency drive:

1. Remove the jumper wire between control

terminals 37 and 12 or 13. Cutting or breaking

the jumper is not sufficient to avoid shortcircuiting. (See jumper on Figure 2.21.)

2. Connect an external Safety monitoring relay via a

NO safety function to terminal 37 (safe stop) and

either terminal 12 or 13 (24 V DC). Follow the

instructions for the safety device. The Safety

monitoring relay must comply with Category

3 /PL “d” (ISO 13849-1) or SIL 2 (EN 62061).

WARNING

SAFE STOP FUNCTION!

The safe stop function does NOT isolate AC line voltage to

the adjustable frequency drive or auxiliary circuits. Perform

work on electrical parts of the adjustable frequency drive

or the motor only after isolating the AC line voltage supply

and waiting the length of time specified in Table 1.1.

Failure to isolate the AC line voltage supply from the unit

and waiting the time specified could result in death or

serious injury.

2-14 MG33AM22 - VLT® is a registered Danfoss trademark

Page 29

12/13

37

130BA874.10

130BC971.10

12

2

4

1

5

3

37

Installation

Figure 2.21 Jumper between Terminal 12/13 (24 V) and 37

VLT® AutomationDrive Instruction

Manual

WARNING

Safe Stop activation (that is removal of 24 V DC voltage

supply to terminal 37) does not provide electrical safety.

The Safe Stop function itself is therefore not sufficient to

implement the Emergency-Off function as defined by EN

60204-1. Emergency-Off requires measures of electrical

isolation, for example, by switching off line power via an

additional contactor.

1. Activate the Safe Stop function by removing the

24 V DC voltage supply to the terminal 37.

2. After activation of Safe Stop (that is, after the

response time), the adjustable frequency drive

coasts (stops creating a rotational field in the

motor). The response time is typically less than 10

ms.

The adjustable frequency drive is guaranteed not to restart

creation of a rotational field by an internal fault (in

accordance with Cat. 3 PL d acc. EN ISO 13849-1 and SIL 2

acc. EN 62061). After activation of Safe Stop, the display

shows the text ”Safe Stop activated”. The associated help

text says, "Safe Stop has been activated”. This means that

the Safe Stop has been activated, or that normal operation

has not been resumed yet after Safe Stop activation.

2

2

Figure 2.22 Installation to Achieve a Stopping Category 0 (EN

60204-1) with Cat. 3 /PL “d” (ISO 13849-1) or SIL 2 (EN 62061).

1 Adjustable frequency drive

2 [Reset] key

3 Safety relay (cat. 3, PL d or SIL2

4 Emergency stop button

5 Short-circuit protected cable (if not inside installation IP54

cabinet)

Table 2.9 Legend to Figure 2.22

Safe Stop Commissioning Test

After installation and before first operation, perform a

commissioning test of the installation using safe stop. Also,

perform the test after each modification of the installation.

NOTE!

The requirements of Cat. 3 /PL “d” (ISO 13849-1) are only

fulfilled while 24 V DC supply to terminal 37 is kept

removed or low by a safety device which itself fulfills Cat.

3 PL “d” (ISO 13849-1). If external forces act on the motor,

it must not operate without additional measures for fall

protection. External forces can arise for example, in the

event of vertical axis (suspended loads) where an

unwanted movement, for example caused by gravity, could

cause a hazard. Fall protection measures can be additional

mechanical brakes.

By default the Safe Stop function is set to an Unintended

Restart Prevention behavior. Therefore, to resume

operation after activation of Safe Stop,

1. reapply 24 V DC voltage to terminal 37 (text Safe

Stop activated is still displayed)

2. create a reset signal (via bus, digital I/O, or

[Reset] key.

The Safe Stop function can be set to an Automatic Restart

behavior. Set the value of 5-19 Terminal 37 Safe Stop from

default value [1] to value [3].

Automatic Restart means that Safe Stop is terminated, and

normal operation is resumed, as soon as the 24 V DC are

applied to Terminal 37. No Reset signal is required.

MG33AM22 - VLT® is a registered Danfoss trademark 2-15

Page 30

Installation

VLT® AutomationDrive Instruction

Manual

2

WARNING

Automatic Restart Behavior is permitted in one of the two

situations:

1. Unintended restart prevention is implemented by

other parts of the safe stop installation.

2. A presence in the hazard zone can be physically

excluded when safe stop is not activated. In

particular, paragraph 5.3.2.5 of ISO 12100-2 2003

must be observed

2.5.2 Safe Stop Commissioning Test

After installation and before first operation, perform a

commissioning test of an installation or application, using

Safe Stop.

Perform the test again after each modification of the

installation or application involving the Safe Stop.

NOTE!

A passed commissioning test is mandatory after first installation and after each change to the safety installation.

The commissioning test (select one of cases 1 or 2 as

applicable):

Case 1: Restart prevention for Safe Stop is required (that is

Safe Stop only where 5-19 Terminal 37 Safe Stop is set to

default value [1], or combined Safe Stop and MCB 112

where 5-19 Terminal 37 Safe Stop is set to [6] PTC 1 & Relay

A or [9] PTC 1 & Relay W/A):

1.1 Remove the 24 V DC voltage supply to

terminal 37 using the interrupt device while the

adjustable frequency drive drives the motor (that

is line power supply is not interrupted). The test

step is passed when

the motor reacts with a coast, and

•

the mechanical brake is activated (if

•

connected)

the alarm “Safe Stop [A68]” is displayed

•

in the LCP, if mounted

1.2 Send Reset signal (via bus, digital I/O, or

[Reset] key). The test step is passed if the motor

remains in the safe stop state, and the

mechanical brake (if connected) remains

activated.

1.3 Reapply 24 V DC to terminal 37. The test step

is passed if the motor remains in the coasted

state, and the mechanical brake (if connected)

remains activated.

1.4 Send Reset signal (via bus, digital I/O, or

[Reset] key). The test step is passed when the

motor becomes operational again.

The commissioning test is passed if all four test steps 1.1,

1.2, 1.3 and 1.4 are passed.

Case 2: Automatic Restart of Safe Stop is wanted and

allowed (that is, Safe Stop only where 5-19 Terminal 37

Safe Stop is set to [3], or combined Safe Stop and MCB

112 where 5-19 Terminal 37 Safe Stop is set to [7] PTC 1 &

Relay W or [8] PTC 1 & Relay A/W):

2.1 Remove the 24 V DC voltage supply to

terminal 37 by the interrupt device while the

adjustable frequency drive drives the motor (that

is line power supply is not interrupted). The test

step is passed when

the motor reacts with a coast, and

•

the mechanical brake is activated (if

•

connected)

the alarm “Safe Stop [A68]” is displayed

•

in the LCP, if mounted

2.2 Reapply 24 V DC to terminal 37.

The test step is passed if the motor becomes operational

again. The commissioning test is passed if both test steps

2.1 and 2.2 are passed.

NOTE!

See warning on the restart behavior in 2.5.1 Terminal 37

Safe Stop Function

WARNING

The Safe Stop function can be used for asynchronous,

synchronous and permanent magnet motors. Two faults

can occur in the power semiconductor of the adjustable

frequency drive. When using synchronous or permanent

magnet motors a residual rotation can result from the

faults. The rotation can be calculated to Angle = 360/

(Number of Poles). The application using synchronous or

permanent magnet motors must take this residual rotation

into consideration and ensure that it does not pose a

safety risk. This situation is not relevant for asynchronous

motors.

2-16 MG33AM22 - VLT® is a registered Danfoss trademark

Page 31

Start-up and Functional Tes...

VLT® AutomationDrive Instruction

Manual

3 Start-up and Functional Testing

3.1 Pre-start

3.1.1 Safety Inspection

WARNING

HIGH VOLTAGE!

If input and output connections have been connected

improperly, there is potential for high voltage on these

terminals. If power leads for multiple motors are

improperly run in same conduit, there is potential for

leakage current to charge capacitors within the adjustable

frequency drive, even when disconnected from line power

input. For initial start-up, make no assumptions about

power components. Follow pre-start procedures. Failure to

follow pre-start procedures could result in personal injury

or damage to equipment.

1. Input power to the unit must be OFF and locked

out. Do not rely on the adjustable frequency

drive disconnect switches for input power

isolation.

2. Verify that there is no voltage on input terminals

L1 (91), L2 (92), and L3 (93), phase-to-phase and

phase-to-ground,

3. Verify that there is no voltage on output

terminals 96 (U), 97 (V), and 98 (W), phase-tophase and phase-to-ground.

4. Confirm continuity of the motor by measuring

ohm values on U-V (96-97), V-W (97-98), and W-U

(98-96).

5. Check for proper grounding of the adjustable

frequency drive as well as the motor.

6. Inspect the adjustable frequency drive for loose

connections on terminals.

7. Record the following motor nameplate data:

power, voltage, frequency, full load current, and

nominal speed. These values are needed to

program motor nameplate data later.

8. Confirm that the supply voltage matches voltage

of adjustable frequency drive and motor.

3 3

MG33AM22 - VLT® is a registered Danfoss trademark 3-1

Page 32

Start-up and Functional Tes...

VLT® AutomationDrive Instruction

Manual

CAUTION

Before applying power to the unit, inspect the entire

installation as detailed in Table 3.1. Check mark those items

when completed.

Inspect for Description

33

Auxiliary equipment

Cable routing

Control wiring

Cooling clearance

EMC considerations

Environmental considerations

Fusing and circuit

breakers

Grounding

Input and output power

wiring

Panel interior

Switches

Vibration

Look for auxiliary equipment, switches, disconnects, or input fuses/circuit breakers that may reside

•

on the input power side of the adjustable frequency drive or output side to the motor. Ensure that

they are ready for full speed operation.

Check function and installation of any sensors used for feedback to the adjustable frequency drive

•

Remove power factor correction caps on motor(s), if present

•

Ensure that input power, motor wiring and control wiring are separated or in three separate metallic

•

conduits for high frequency noise isolation

Check for broken or damaged wires and loose connections.

•

Check that control wiring is isolated from power and motor wiring for noise immunity.

•

Check the voltage source of the signals, if necessary.

•

The use of shielded cable or twisted pair is recommended. Ensure that the shield is terminated

•

correctly

Make sure that the top and bottom clearance is adequate to ensure proper airflow for cooling.

•

Check for proper installation regarding electromagnetic compatibility.

•

See equipment label for the maximum ambient operating temperature limits.

•

Humidity levels must be 5%–95% non-condensing.

•

Check for proper fusing or circuit breakers.

•

Check that all fuses are inserted firmly and in operational condition and that all circuit breakers are

•

in the open position.

The unit requires a ground wire from its chassis to the building ground

•

Check for good ground connections that are tight and free of oxidation

•

Grounding to conduit or mounting the back panel to a metal surface is not a suitable ground

•

Check for loose connections.

•

Check that motor and line power are in separate conduits or separated shielded cables

•

Make sure that the unit interior is free of dirt, metal chips, moisture, and corrosion.

•

Ensure that all switch and disconnect settings are in the proper positions

•

Check that the unit is mounted solidly or that shock mounts are used, as necessary.

•

Check for an unusual amount of vibration

•

☑

Table 3.1 Start-up Check List

3-2 MG33AM22 - VLT® is a registered Danfoss trademark

Page 33

130BP066.10

1107 RPM

0 - ** Operation/Display

1 - ** Load/Motor

2 - ** Brakes

3 - ** Reference / Ramps

3.84 A 1 (1)

Main Menu

Start-up and Functional Tes...

3.2 Applying Power

VLT® AutomationDrive Instruction

Manual

WARNING

HIGH VOLTAGE!

Adjustable frequency drives contain high voltage when

connected to AC line power. Installation, start-up and

maintenance should be performed by qualified personnel

only. Failure to perform installation, start-up and

maintenance by qualified personnel could result in death

or serious injury.

WARNING

UNINTENDED START!

When the adjustable frequency drive is connected to AC

line power, the motor may start at any time. The

adjustable frequency drive, motor, and any driven

equipment must be in operational readiness. Failure to be

in operational readiness when the adjustable frequency

drive is connected to AC line power could result in death,

serious injury, equipment, or property damage.

1. Confirm input voltage is balanced within 3%. If

not, correct input voltage imbalance before

proceeding. Repeat procedure after voltage

correction.

2. Ensure optional equipment wiring, if present,

matches installation application.

3. Ensure that all operator devices are in the OFF

position. Panel doors closed or cover mounted.

4. Apply power to the unit. DO NOT start the

adjustable frequency drive at this time. For units

with a disconnect switch, turn to the ON position

to apply power to the adjustable frequency drive.

NOTE!

If the status line at the bottom of the LCP reads AUTO

REMOTE COAST, this indicates that the unit is ready to

operate but is missing an input signal on terminal 27.

3.3 Basic Operational Programming

Programming

For best performance, adjustable frequency drives require

basic operational programming before running. Basic

operational programming requires entering motor

nameplate data for the motor being operated and the

minimum and maximum motor speeds. The recommended

parameter settings are intended for start-up and checkout

purposes. Application settings may vary. See 4.1 Local

Control Panel for detailed instructions on entering data

through the LCP.

Enter data with power ON, but before operating the

adjustable frequency drive. There are two ways of

programming the adjustable frequency drive: either by

using the Smart Application Set-up (SAS) or by using the

procedure described further down. The SAS is a quick

wizard for setting up the most commonly used

applications. At first power-up and after a reset, the SAS

appears on the LCP. Follow the instructions that appear on

the successive screens for setting up the applications

listed. SAS can also be found under the Quick Menu. [Info]

can be used throughout the Smart Set-up to see help

information for various selections, settings and messages.

NOTE!

The start conditions will be ignored while in the wizard.

NOTE!

If no action is taken after first power-up or reset, the SAS

screen will automatically disappear after 10 minutes.

When not using the SAS, enter data in accordance with

the following procedure.

1. Press [Main Menu] twice on the LCP.

2. Press the navigation keys to scroll to parameter

group Q2 Quick Set-up and press [OK].

3 3

Figure 3.1 0-** Operation/Display

MG33AM22 - VLT® is a registered Danfoss trademark 3-3

Page 34

0-

**

Operation / Display

0.0%

0-0

*

Basic Settings

0-1

*

Set-up Opperations

0-2

*

LCP Display

0-3

*

LCP Custom Readout

0.00A 1(1)

130BP087.10

0-0

*

Basic Settings

0.0%

0-03 Regional Settings

[0] International

0.00A 1(1)

130BP088.10

130BB847.10

Q1 My Personal Menu

Q2 Quick Setup

Q5 Changes Made

Q6 Loggings

13.7% 13.0A 1(1)

Quick Menus

130BT772.10

Q2

0.0 Hz 0.00kW 1(1)

Motor Setup

1 - 21 Motor Power [kW]

4.0 kW

130BT772.10

Q2

0.0 Hz 0.00kW 1(1)

Motor Setup

1 - 21 Motor Power [kW]

4.0 kW

Start-up and Functional Tes...

VLT® AutomationDrive Instruction

Manual

3. Press the navigation keys to scroll to parameter

8. Select language and press [OK].

group 0-0* Basic Settings and press [OK].

33

Figure 3.5 Select Language

Figure 3.2 0-0* Basic Settings

9. A jumper wire should be in place between

4. Press the navigation keys to scroll to

0-03 Regional Settings and press [OK].

Figure 3.3 0-03 Regional Settings

control terminals 12 and 27. If this is the case,

leave 5-12 Terminal 27 Digital Input at factory

default. Otherwise select No Operation. For

adjustable frequency drives with an optional

bypass, no jumper wire is required.

10.

3-02 Minimum Reference

11.

3-03 Maximum Reference

12.

3-41 Ramp 1 Ramp-up Time

13.

3-42 Ramp 1 Ramp-down Time

14.

3-13 Reference Site. Linked to Hand/Auto* Local

Remote.

5.

Press the navigation keys to select International

or North America as appropriate and press [OK].

(This changes the default settings for a number

of basic parameters. See for a complete list.)

6. Press [Quick Menu] on the LCP.

7. Press the navigation keys to scroll to parameter

group Q2 Quick Set-up and press [OK].

Figure 3.4 Q2 Quick Set-up

3.4

Asynchronous Motor Set-up

Enter the motor data in parameters 1-20/1-21 to 1-25. The

information can be found on the motor nameplate.

1.

1-20 Motor Power [kW] or 1-21 Motor

Power [HP]

1-22 Motor Voltage

1-23 Motor Frequency

1-24 Motor Current

1-25 Motor Nominal Speed

Figure 3.6 Motor Setup

3-4 MG33AM22 - VLT® is a registered Danfoss trademark

Page 35

Start-up and Functional Tes...

VLT® AutomationDrive Instruction

Manual

3.5

PM Motor Set-up in VVC

This section is only relevant when using a PM motor.

Set up the basic motor parameters:

1-10 Motor Construction

•

1-14 Damping Gain

•

1-15 Low Speed Filter Time Const.

•

1-16 High Speed Filter Time Const.

•

1-17 Voltage filter time const.

•

1-24 Motor Current

•

1-25 Motor Nominal Speed

•

1-26 Motor Cont. Rated Torque

•

1-30 Stator Resistance (Rs)

•

1-37 d-axis Inductance (Ld)

•

1-39 Motor Poles

•

1-40 Back EMF at 1000 RPM

•

1-66 Min. Current at Low Speed

•

4-13 Motor Speed High Limit [RPM]

•

4-19 Max Output Frequency

•

Note concerning advanced motor data:

Stator resistance and d-axis inductance values are often

described differently in technical specifications. For

programming resistance and d-axis inductance values in

adjustable frequency drives, always use line to common