Page 1

Data sheet

Servo-operated 2/2-way solenoid valves

Type EV220B 6 - EV220B 22

EV220B 6 - EV220B 22 is a direct

servo-operated 2/2-way solenoid valve program

with connections from 1/4” to 1”.

This program is especially for OEM applications

demanding a robust solution and moderate flow

rates.

Features and versions:

y For water, oil, compressed air and similar

neutral media

y Flow range from 0.2 – 19 m³/h

y Differential pressure from 0.1 – 20 bar

y Media temperature from -30 – 100 °C

y Ambient temperature: Up to 80 °C

y Coil enclosure: Up to IP67

y Thread connections: From G ¼ – G 1

y DN 6 – 22

y Viscosity: Up to 50 cSt

y Brass version NC and NO

y DZR brass version NC

y FKM and EPDM

y Also available with NPT thread

© Danfoss | DCS (az) | 2017.06

IC.PD.200.2C.02 | 1

IC.PD.200.2C.02 | 1

Page 2

Data sheet | Solenoid valves, type EV220B 6 - EV220B 22

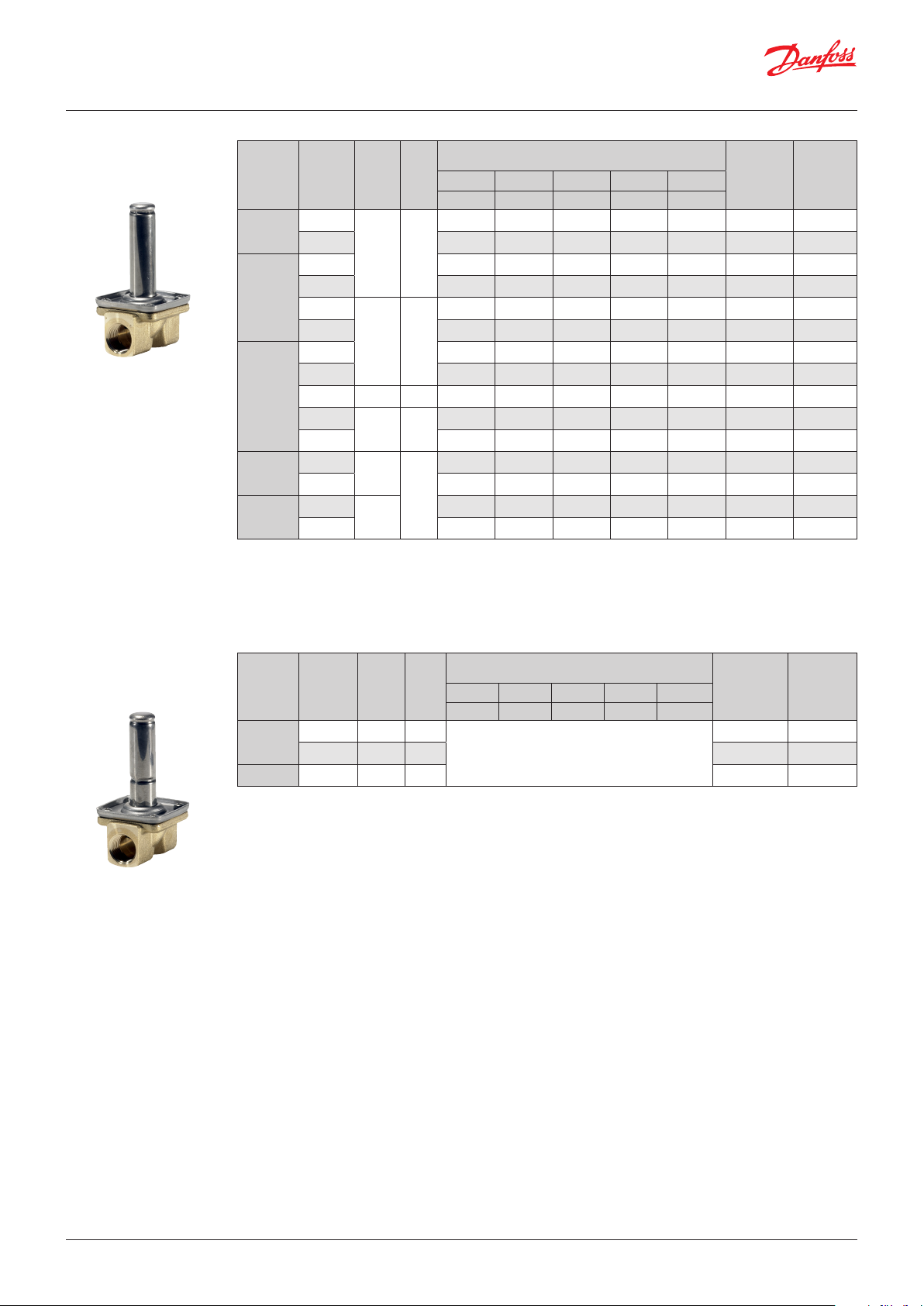

Brass valve body, NC

Differential pressure

Connection

ISO 228/1

G 1/4

G 3/8

G 1/2

G 3/4

G 1

1)

EPDM is recommended for water.

2)

FKM is suitable for oil and air. For water at max. 60 °C.

3)

In water applications, exercise the valves at least once every 24 hours, meaning change the state of the valve.

Seal

material

EPDM

FKM

EPDM

FKM

EPDM

FKM

EPDM

FKM

EPDM 1)

EPDM

FKM

EPDM

FKM

EPDM

FKM

Orifice

1)

2)

1)

2)

1)

2)

1)

2)

1)

2)

1)

2)

1)

2)

Kv -

BA / BD BB / BE BB / BE BG BG

value

size

[m³/h]

9 [W a.c] 10 [W AC] 18 [W DC] 12 [W AC] 20 [W DC]

0.1 – 20 0.1 – 20 0.1 – 10 0.1 – 20 0.1 – 20 -30 – 100 032U1236

6 0.7

0.1 – 20 0.1 – 20 0.1 – 10 0.1 – 20 0.1 – 20 0 – 100 032U1237

0.1 – 20 0.1 – 20 0.1 – 10 0.1 – 20 0.1 – 20 -30 –100 032U1241

0.1 – 20 0.1 – 20 0.1 – 10 0.1 – 20 0.1 – 20 0 – 100 032U1242

0.1 – 20 0.1 – 20 0.1 – 10 0.1 – 20 0.1 – 20 -30 – 100 032U1246

10 1.5

0.1 – 20 0.1 – 20 0.1 – 10 0.1 – 20 0.1 – 20 0 – 100 032U1247

0.1 – 20 01. – 20 0.1 – 10 0.1 – 20 0.1 – 20 -30 – 100 032U1251

0.1 – 20 0.1 – 20 0.1 – 10 0.1 – 20 0.1 – 20 0 – 100 032U1252

11.5 2.3 0.1 – 10 0.1 – 10 0.1 – 10 0.1 – 10 0.1 – 10 -30 – 100 032U1279

12 2.5

18

22

0.3 – 10 0.3 – 10 – 0.3 – 10 0.3 – 10 -30 – 100 032U1256

0.3 – 10 0.3 – 10 – 0.3 – 10 0.3 – 10 0 – 100 032U1255

0.3 – 10 0.3 – 10 – 0.3 – 10 0.3 – 10 -30 – 100 032U1261

0.3 – 10 0.3 – 10 – 0.3 – 10 0.3 – 10 0 – 100 032U1260

6.0

0.3 – 10 0.3 – 10 – 0.3 – 10 0.3 – 10 -30 – 100 032U1263

0.3 – 10 0.3 – 10 – 0.3 – 10 0.3 – 10 0 – 100 032U1266

min. to max. [bar] /coil type

Media

temperature

min. to max.

[°C]

The valve exercise will minimize the risk of the valve sticking due to calcium carbonate, zinc or iron oxide build-up.

Code

number

Brass valve body, NO

Differential pressure

Connection

ISO 228/1

G 3/8

G 1/2

1)

EPDM is recommended for water.

2)

FKM is suitable for oil and air. For water at max. 60 °C.

3)

In water applications, exercise the valves at least once every 24 hours, meaning change the state of the valve.

Seal

material

EPDM

FKM

FKM

Orifice

1)

2)

2)

Kv-

BA / BD BB / BE BB / BE BG BG

value

size

[m³/h]

9 [W AC] 10 [W AC] 18 [W DC] 12 [W AC] 20 [W d.c].

6 0.7

6 0.7 0–100 032U1239

10 1.0 0–100 032U1249

min. to max. [bar] / coil type

0.1 – 10

Media

temperature

min. to max.

[°C]

-30–100 032U1238

The valve exercise will minimize the risk of the valve sticking due to calcium carbonate, zinc or iron oxide build-up.

Code

number

© Danfoss | DCS (az) | 2017.06

IC.PD.200.2C.02 | 2

Page 3

Data sheet | Solenoid valves, type EV220B 6 - EV220B 22

Technical data,

NC and NO

Type EV220B 6 EV220B 10 EV220B 12 EV220B 18 EV220B 22

Time to open [ms]

Time to close [ms]

1)

The times are indicative and apply to water. The exact times will depend on the pressure conditions.

Installation Vertical solenoid system is recommended.

Max. working pressure

Max. test pressure

Ambient temperature

Viscosity Max. 50 cSt

Materials Valve body Brass W.no. 2.0402

1)

1)

40 50 60 200 200

250 300 300 500 500

NC

NO DN 6 - 10 0.1 - 10 bar

EV220B 6 – EV220B 10 50 bar

EV220B 11.5 – EV220B 22 16 bar

BA Up to 40 °C

BD / BE DC / BB DC Up to 50 °C

BB / BE AC / BG Up to 80 °C

Armature Stainless steel W.no. 1.4105 / AISI 430FR

Armature tube Stainless steel W.no. 1.4306 / AISI 304L

Armature stop Stainless steel W.no. 1.4105 / AISI 430FR

Springs Stainless steel W.no. 1.4310 / AISI 301

O-rings EPDM or FKM

Valve plate EPDM or FKM

Diaphragm EPDM or FKM

DN 6 - 10

DN 11.5 - 22

0.1 - 20 bar

0.3 - 10 bar

© Danfoss | DCS (az) | 2017.06

IC.PD.200.2C.02 | 3

Page 4

Data sheet | Solenoid valves, type EV220B 6 - EV220B 22

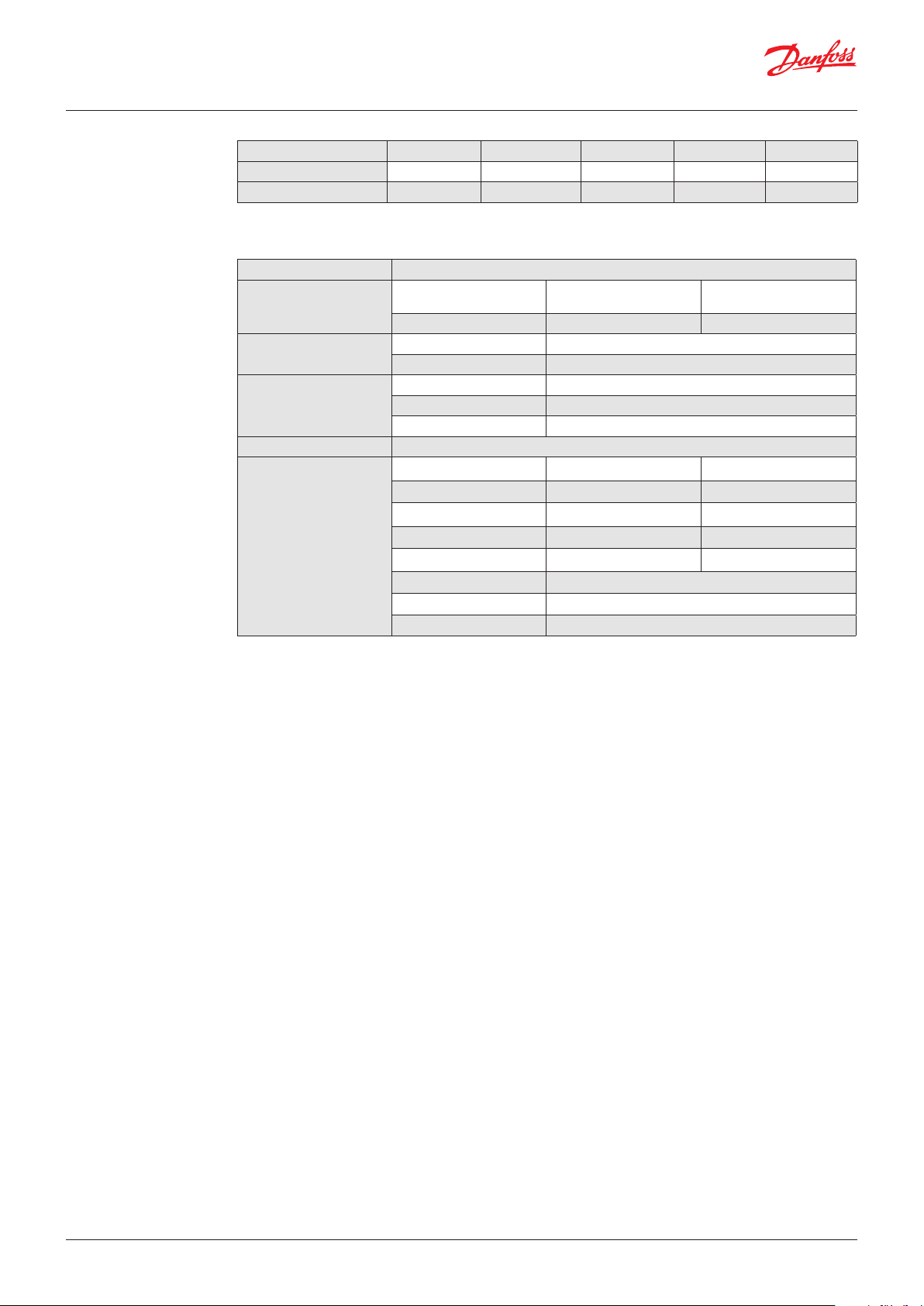

Dezincification resistant

brass (DZR) brass valve

body NC

Technical data NC,

Dezincification resistant

brass (DZR)

Differential pressure

Connection

ISO

228/1

G 3/8

G 1/2

1)

EPDM is recommended for water.

2)

In water applications, exercise the valves at least once every 24 hours, meaning change the state of the valve.

Seal

material

EPDM

EPDM

EPDM

Orifice

1)

1)

1)

Kv-

value

size

[m³/h]

0.7 0.1–20 0.1–20 0.1–10 0.1–20 0.1–20

6

1.5 0.1–20 0.1–20 0.1–10 0.1–20 0.1–20

10

1.5 0.1–20 0.1–20 0.1–10 0.1–20 0.1–20

10

BA BB / BE BG

9 [W AC] 10 [ W AC] 18 [W DC] 12 [W AC] 20 [W DC]

min. to max. [bar] /coil type

Media

temperature

min. to max.

[°C]

-30 – 100

-30 – 100

-30 – 100

The valve exercise will minimize the risk of the valve sticking due to calcium carbonate, zinc or iron oxide build-up.

Main type EV220B 6 EV220B 10 EV220B 12

Time to open [ms]

Time to close [ms]

1)

The times are indicative and apply to water. The exact times will depend on the pressure conditions.

1)

1)

40 50 60

250 300 300

Installation Vertical solenoid system is recommended

Max. working pressure 20 bar 20 bar 10 bar

Max. test pressure 50 bar 50 bar 16 bar

Ambient temperature BA: Up to 40 °C

BD / BE DC / BB DC: Up to 50 °C

BB / BE AC / BG: Up to 80 °C

Viscosity Max. 50 cSt

Valve body Dezincification resistant brass (DZR) CuZn36 Pb2As / CZ132

Armature Stainless Steel W.no. 1.4105 / AISI 430FR

Armature tube Stainless Steel W.no. 1.4306 / AISI 304L

Armature stop Stainless Steel W.no. 1.4105 / AISI 430FR

Materials

Springs Stainless Steel W.no. 1.4310 / AISI 301

Valve seat Stainless Steel W.no. 1.4404 / AISI 316L

O-rings EPDM

Valve plate EPDM

Diaphragm EPDM

Code

number

032U5807

032U5809

032U5810

© Danfoss | DCS (az) | 2017.06

IC.PD.200.2C.02 | 4

Page 5

Data sheet | Solenoid valves, type EV220B 6 - EV220B 22

Dimensions and weight: Brass, DZR brass, NC and NO

Weight gross

Type

EV220B 6B 0.22 45.5 43.5 32 46 68 78 13

EV220B 10B /

EV220B11.5B

EV220B 12B 0.35 58.0 54.0 32 46 68 81 13

EV220B 18B 0.65 90.0 60.0 32 46 68 87 22

EV220B 22B 0.65 90.0 60.0 32 46 68 91 22

valve body without coil

[kg]

0.29 51.5 48.0 32 46 68 81 13

L

[mm]

B

[mm]

B1 [mm] / Coil type

H

[mm]

Dimensions

H1

[mm]BA BB / BE BG

Mounting angle

© Danfoss | DCS (az) | 2017.06

IC.PD.200.2C.02 | 5

Page 6

Data sheet | Solenoid valves, type EV220B 6 - EV220B 22

Below coils can be used with EV220B 6 - EV220B 22

Coil

Type

Power consumption Enclosure Features

BA / BD, screw on

BB, clip on

BE, clip on

BF, clip on

9 W AC

15 W AC

10 W AC

18 W DC

10 W AC

18 W DC

10 W AC

18 W DC

IP00

with spade connector

IP00

with spade connector

IP67 With terminal box

IP67 With 1 m cable

IP20 with protective cap,

IP20 with protective cap,

IP65 with cable plug

IP65 with cable plug

BG, clip on

BN, clip on

BO, screw on

For further information and for ordering, see separate data sheet for coils.

12 W AC

20 W DC

20 W

26 VA

10 W

21 VA

IP67 With terminal box

IP67

IP67

only including seal kit

018Z0090

With terminal box and 1

With terminal box and 5 m

Hum free

m cable

For explosion-risk

environment zone 1.

cable

© Danfoss | DCS (az) | 2017.06

IC.PD.200.2C.02 | 6

Page 7

Data sheet | Solenoid valves, type EV220B 6 - EV220B 22

Accessories: Cable plug

Universal electronic multi-timer,

type ETM

Application Code number

GDM 2011 (grey) cable plug according to DIN 43650-A PG11 042N0156

ø

Ambient

temperature

[°C] Code number

Application

External adjustable timing from 1 to 45 minutes

with 1 to 15 seconds drain open. With manual

override (test button). Electrical connection DIN

43650 A / EN 175 301-803-A

y Outside adjustments

y Light weight and small size

y External adjustable timing from 1 min-

ute to 45

Voltage

[V AC ]

24 – 240. BA, BD, BB -10 – 50 042N0185

To use

with coil

from 24-240 V AC

y Light diodes for indication

y All in one unit

y Manual override (test button)

minutes with 1 to 15 seconds drain open

y One solid state timer fits all coil voltages

Technical data

Dimensions

Type ET 20 M

Voltage 24 – 240 V AC/ 50 – 60 Hz

Power rating Max. 20 Watt

Enclosure IP 00, IP65 with cable plug

Electrical connection DIN connector ( DIN 43650-A)

Ambient operating temperature range -10°C – 50°C

Function Start with pulse

Interval timer 1 – 45 min.

“On” timer 1 – 15 sec.

Weight 0.084 kg

© Danfoss | DCS (az) | 2017.06

IC.PD.200.2C.02 | 7

Page 8

Data sheet | Solenoid valves, type EV220B 6 - EV220B 22

Spare parts kit for

EV220B 6 - EV220B 22 B, NC

(brass body)

EV220B 6 - EV220B 10B

Type

EV220B 6B

EV220B 6B

EV220B 10B - EV220B 11.5B

EV220B 10B

EV220B 12B

EV220B 12B

EV220B 18B - EV220B 22B

EV220B 18B - EV220B 22B

1)

EPDM is recommended for water.

2)

FKM is suitable for oil and air. For water at max. 60 °C.

Seal

material Code number

1)

EPDM

FKM

EPDM

FKM

EPDM

FKM

EPDM

FKM

032U1062

2)

032U1063

1)

032U1065

2)

032U1066

1)

032U1068

2)

032U1067

1)

032U1070

2)

032U1069

EV220B 6 – EV220B 11.5 spare parts

kit comprises:

Locking button

Nut for the coil

Armature with valve plate and spring

Diaphragm

O-ring

EV220B 12 – EV220B 22 spare parts

kit comprises:

Locking button

Nut for the coil

Armature with valve plate and spring

Diaphragm

EV220B 12 - EV220B 22B

Assembled NO unit

Type Seal

EV220B 6B

EV220B 6B

EV220B 10B

1)

EPDM is recommended for water.

2)

FKM is suitable for oil and air. For water at max. 60 °C.

material

EPDM

FKM

FKM

1)

2)

2)

Code number

032U0165

032U0166

032U0167

Spare part kit comprises:

NO actuator unit

Locking button

Nut for coil

O-ring

© Danfoss | DCS (az) | 2017.06

IC.PD.200.2C.02 | 8

Page 9

Data sheet | Solenoid valves, type EV220B 6 - EV220B 22

Function, NC

1. Armature spring

2. Armature

3. Valve plate

4. Equalizing orifice

5. Main orifice

6. Pilot orifice

7. Diaphragm

8. Coil

Coil voltage disconnected (closed):

When the supply voltage to the coil (8)

is disconnected, the valve plate (3) is

pressed down against the pilot orifice (6)

by the armature spring (1). The pressure

across the diaphragm (7) is built up via the

equalizing orifice (4). The diaphragm closes

the main orifice (5) as soon as the pressure

across the diaphragm is equivalent to the

inlet pressure. The valve will be closed

for as long as the voltage to the coil is

disconnected.

Coil voltage connected (open):

When voltage is applied to the coil, the

pilot orifice (6) is opened. As the pilot

orifice is larger than the equalizing orifice

(4), the pressure across the diaphragm (7)

drops and therefore it is lifted clear of the

main orifice (5). The valve is now open and

will be open for as long as the minimum

differential pressure across the valve is

maintained, and for as long as there is

voltage to the coil.

Function, NO Coil voltage disconnected (open):

When the voltage to the coil (8) is

disconnected, the pilot orifice (6) is open.

As the pilot orifice is larger than the

equalizing orifice (4), the pressure across

the diaphragm (7) drops and therefore it is

lifted clear of the main orifice (5). The valve

will be open for as long as the minimum

differential pressure across the valve is

maintained, and for as long as the voltage

to the coil is disconnected.

Coil voltage connected (closed):

When voltage is applied to the coil, the

valve plate (3) is pressed down against the

1. Opening spring

2. Armature

3. Valve plate

4. Equalizing orifice

5. Main orifice

6. Pilot orifice

7. Diaphragm

8. Coil

pilot orifice (6). The pressure across the

diaphragm (7) is built up via the equalizing

orifice (4). The diaphragm closes the main

orifice (5) as soon as the pressure across

the diaphragm is equivalent to the inlet

pressure. The valve will be closed for as

long as there is voltage to the coil.

© Danfoss | DCS (az) | 2017.06

IC.PD.200.2C.02 | 9

Page 10

Capacity diagram:

Example, water: EV220B 10 NC,

at 4 bar diff. pressure: Approx: 3 m3/h

EV220B 18-22

© Danfoss | DCS (az) | 2017.06

IC.PD.200.2C.02 | 10

Loading...

Loading...