Page 1

Data sheet

Direct-operated 2/2-way solenoid valves

Type EV210B and EV210BW

EV210B and EV210BW covers a wide range of

direct-operated 2/2-way solenoid valves for

universal use.

EV210B and EV210BW are a very robust valves

program with high performance and can be used

in all kind of tough working conditions in

demanding industrial applications such as

control and closage.

Features and versions:

y For water, oil, compressed air and similar

neutral media.

y Flow range: 0 – 8 m3/h

y Differential pressure: 0 – 30 bar

y Media temperature: -30 – 140 °C

y Ambient temperature: up to 80 °C

y Coil enclosure : up to IP67

y Tread connections: G 1⁄8 – G 1

y DN 1.5 – 25

y Viscosity: up to 50 cSt

y The valves can be used for vacuum

y EV210B brass version for water, oil,

compressed air and similar neutral media

y EV210B stainless steel version for neutral and

aggressive liquids and gasses

y EV210BW brass and Stainless steel versions,

EPDM seal and WRAS approved for drinking

water

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 1

Page 2

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

EV210B

brass valve body, NC

y ACS (only EPDM 1.5 to 10)

y PZH (only EPDM 1.5 to 3.0)

y In accordance with:

- Low Voltage Directive 2014/35/EU

- EN60730-1

- EN60730-2-8

- Pressure Equipment Directive

2014/68/EU

- RoHS Directive 2011/65/EU

Conn.

Seal

ISO

228/1

G 1⁄8

G 1⁄4

G 3⁄8

G 1⁄2

G 3⁄4

G 1

1

) 140 °C / 3.6 bar low pressure steam, orifice DN 1.5 – 4.5.

- Low pressure steam: DN 1.5 – 3 Use coil type BB or BG

DN 4.5 Use coil type BG

2

) Pressure range can be extended to use in rough vacuum, typically up to 99% vacuum (10 mbar), depending on the application.

Orif.

size

value

[m³/h]

material

EPDM 1) 1.5 0.08 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 ACS, PZH -30 – 120 032U5701

FKM 1.5 0.08 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 -10 – 100 032U5702

FKM 2.0 0.15 0 – 30 0 – 20 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 -10 – 100 032U5704

EPDM 1) 3.0 0.30 0 – 15 0 – 9 0 – 24 0 – 20 0 – 13 0 – 30 0 – 25 ACS, PZH -30 – 120 032U5705

FKM 3.0 0.30 0 – 15 0 – 9 0 – 24 0 – 20 0 – 13 0 – 30 0 – 25 -10 – 100 032U5706

FKM 1.5 0.08 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 -10 – 100 032U3629

EPDM 1) 2.0 0.15 0 – 30 0 – 20 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 ACS, PZH -30 – 120 032U5707

FKM 2.0 0.15 0 – 30 0 – 20 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 -10 – 100 032U5708

EPDM 1) 3.0 0.30 0 – 15 0 – 9 0 – 24 0 – 20 0 – 13 0 – 30 0 – 25 ACS, PZH -30 – 120 032U5709

FKM 3.0 0.30 0 – 15 0 – 9 0 – 24 0 – 20 0 – 13 0 – 30 0 – 25 -10 – 100 032U5710

EPDM 1) 4.5 0.55 0 – 8 0 – 3.5 0 – 12 0 – 10 0 – 4.5 0 – 13 0 – 9 ACS -30 – 120 032U3600

FKM 4.5 0.55 0 – 8 0 – 3.5 0 – 12 0 – 10 0 – 4.5 0 – 13 0 – 9 -10 – 100 032U3601

EPDM 6.0 0.70 0 – 2.5 0 – 1 0 – 3.3 0 – 4 0 – 2 0 – 6 0 – 4.5 ACS -30 – 120 032U3602

FKM 6.0 0.70 0 – 2.5 0 – 1 0 – 3.3 0 – 4 0 – 2 0 – 6 0 – 4.5 -10 – 100 032U3603

EPDM 1) 3.0 0.30 0 – 15 0 – 9 0 – 24 0 – 20 0 – 13 0 – 30 0 – 25 ACS, PZH -30 – 120 032U3642

FKM 3.0 0.30 0 – 15 0 – 9 0 – 24 0 – 20 0 – 13 0 – 30 0 – 25 -10 – 100 032U3643

EPDM 1) 4.5 0.55 0 – 8 0 – 3.5 0 – 12 0 – 10 0 – 4.5 0 – 13 0 – 9 ACS -30 – 120 032U3605

FKM 4.5 0.55 0 – 8 0 – 3.5 0 – 12 0 – 10 0 – 4.5 0 – 13 0 – 9 -10 – 100 032U3606

EPDM 6.0 0.70 0 – 2.5 0 – 1 0 – 3.3 0 – 4 0 – 2 0 – 6 0 – 4.5 ACS -30 – 120 032U3607

FKM 6.0 0.70 0 – 2.5 0 – 1 0 – 3.3 0 – 4 0 – 2 0 – 6 0 – 4.5 -10 – 100 032U3608

EPDM 8.0 1.00 0 – 1.5 0 – 0.5 0 – 2 0 – 2 0 – 1.2 0 – 3 0 – 2.5 ACS -30 – 120 032U3609

FKM 8.0 1.00 0 – 1.5 0 – 0.5 0 – 2 0 – 2 0 – 1.2 0 – 3 0 – 2.5 -10 – 100 032U3610

EPDM 10.0 1.50 0 – 0.8 0 – 0.3 0 – 1.1 0 – 1.2 0 – 0.6 0 – 1.6 0 – 1.3 ACS -30 – 120 032U3611

FKM 10.0 1.50 0 – 0.8 0 – 0.3 0 – 1.1 0 – 1.2 0 – 0.6 0 – 1.6 0 – 1.3 -10 – 100 032U3612

EPDM 15.0 2.50 0 – 0.25 – 0 – 0.4 0 – 0.3 0 – 0.15 0 – 0.45 0 – 0.4 -30 – 120 032U3613

FKM 15.0 2.50 0 – 0.25 – 0 – 0.4 0 – 0.3 0 – 0.15 0 – 0.45 0 – 0.4 -10 – 100 032U3614

EPDM 8.0 1.00 0 – 1.5 0 – 0.5 0 – 2 0 – 2 0 – 1.2 0 – 3 0 – 2.5 ACS -30 – 120 032U3615

FKM 8.0 1.00 0 – 1.5 0 – 0.5 0 – 2 0 – 2 0 – 1.2 0 – 3 0 – 2.5 -10 – 100 032U3616

EPDM 10.0 1.50 0 – 0.8 0 – 0.3 0 – 1.1 0 – 1.2 0 – 0.6 0 – 1.6 0 – 1.3 ACS -30 – 120 032U3617

FKM 10.0 1.50 0 – 0.8 0 – 0.3 0 – 1.1 0 – 1.2 0 – 0.6 0 – 1.6 0 – 1.3 -10 – 100 032U3618

EPDM 15.0 2.85 0 – 0.25 – 0 – 0.4 0 – 0.3 0 – 0.15 0 – 0.45 0 – 0.4 -30 – 120 032U3619

FKM 15.0 2.85 0 – 0.25 – 0 – 0.4 0 – 0.3 0 – 0.15 0 – 0.45 0 – 0.4 -10 – 100 032U3620

EPDM 20.0 4.50 – – – 0 – 0.28 0 – 0.12 0 – 0.4 0 – 0.35 -30 – 120 032U3621

FKM 20.0 4.50 – – – 0 – 0.28 0 – 0.12 0 – 0.4 0 – 0.35 -10 – 100 032U3622

EPDM 25.0 8.00 – – – 0 – 0.25 0 – 0.09 0 – 0.35 0 – 0.2 -30 – 120 032U3623

FKM 25.0 8.00 – – – 0 – 0.25 0 – 0.09 0 – 0.35 0 – 0.2 -10 – 100 032U3624

Dierential pressure min. to max. [bar] /coil type 2)

K

v

BA

[AC]BA[DC]BD[AC]BB[AC]BB[DC]BG[AC]BG[DC]

Drinking water

approval

Media

temperature

min. to max.

[°C]

Code no.

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 2

Page 3

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

EV210B

Brass valve body, NC

Technical data

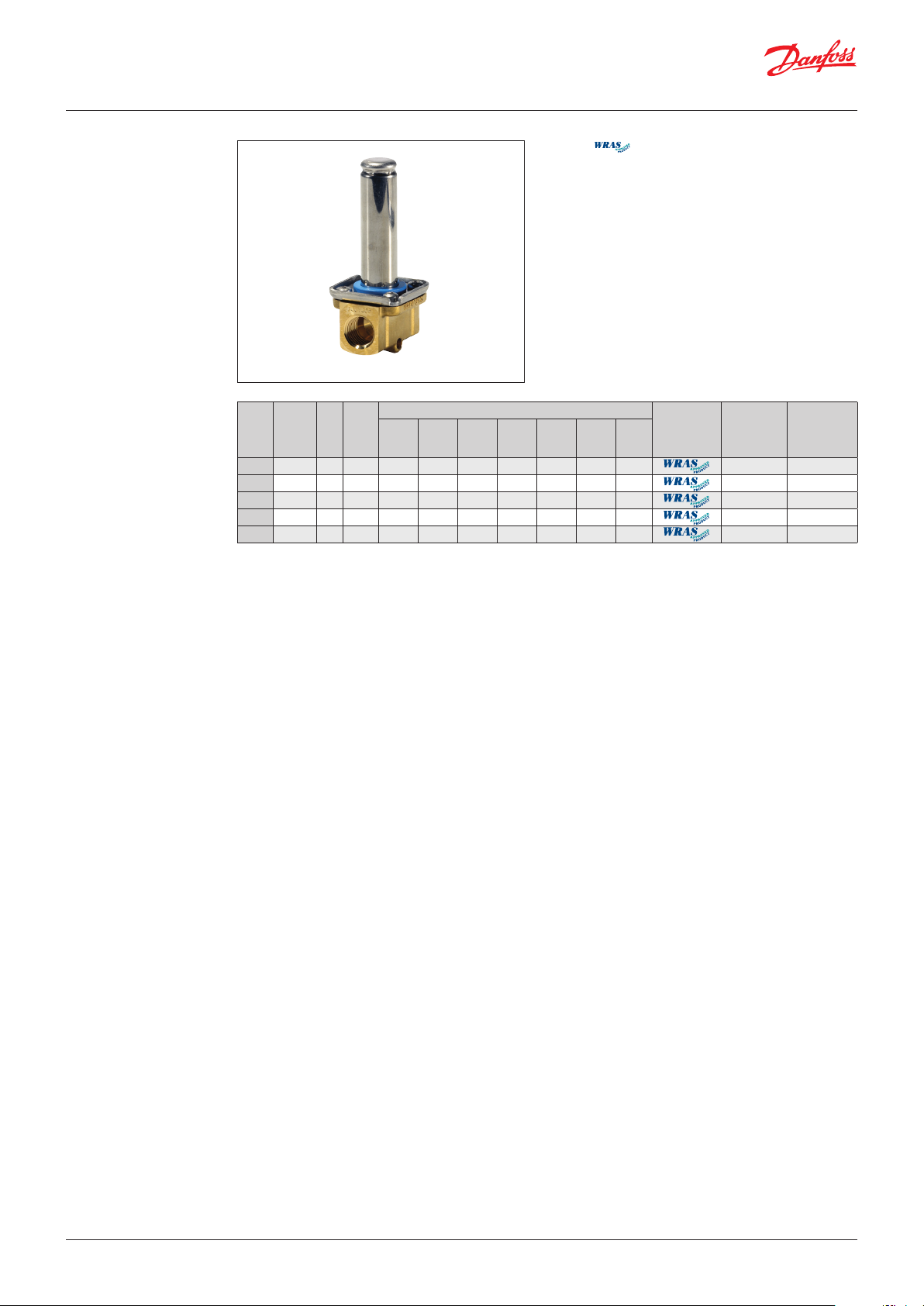

Dimensions and weight

Type

Time to open [ms] 1) 10 20 20 20 30 40 40

Time to close [ms] 1) 20 20 20 30 50 50 70

Max test pressure [bar] EV210B 52.5 52.5 37.5 37.5 24 24 24

1)

The times are indicative and apply to water. The exact times will depend on the pressure conditions.

Installation Optional, but vertical solenoid system is recommended

Ambient temperature Max. 80 °C (depending on coil type)

Viscosity Max. 50 cSt

Materials

Type

EV210B 1.5 / EV210B 2B, NC 0.15 35 34 32 46 67 12 70

EV210B 3 / EV210B 4.5, NC 0.20 38 34 32 46 67 11 70

EV210B 6B, NC 0.22 46 34 32 46 67 16 73

EV210B 8 / EV210B 10B, NC 0.29 49 34 32 46 67 16 73

EV210B 15B, NC 0.45 58 53 32 46 67 13 93

EV210B 20B, NC 1.10 90 58 32 46 67 18 92

EV210B 25B, NC 1.10 90 58 32 46 67 23 96

EV210B

1.5 - 2

Valve body Brass W.no. 2.0402

Armature Stainless steel W.no. 1.4105 / ASIS 430FR

Armature tube Stainless steel W.no. 1.4306 / ASIS 304L

Armature stop Stainless steel W.no. 1.4105 / ASIS 430FR

Springs Stainless steel W.no. 1.4306 / ASIS 301

Seal material: see specic data in table

Weight gross valve

body without coil

EV210B

3-4.5

[kg] [mm] [mm]

EV210B 6EV210B

L B

8 – 10

Coil type

BA / BD

EV210B 15EV210B 20EV210B

B

1

[mm]

Coil type

BB / BE

Coil type

BG

[mm] [mm]

25

H

1

H

Dimensions

Danfoss

32U1769.11

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 3

Page 4

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

EV210BW

brass valve body, NC

y WRAS

y In accordance with:

- Low Voltage Directive 2014/35/EU

- EN60730-1

- EN60730-2-8

- Pressure Equipment Directive

2014/68/EU

- RoHS Directive 2011/65/EU

Conn.

Seal

ISO

material

228/1

G 1⁄8 EPDM 1.5 0.08 0 – 16 0 – 16 0 – 16 0 – 16 0 – 16 0 – 16 0 – 16 -30 – 901) 132U2102

G 1⁄4 EPDM 3.0 0.30 0 – 15 0 – 9 0 – 16 0 – 16 0 – 13 0 – 16 0 – 16 -30 – 901) 132U3004

G 1⁄4 EPDM 4.5 0.55 0 – 8 0 – 3.5 0 – 12 0 – 10 0 – 4.5 0 – 13 0 – 9 -30 – 901) 132U4408

G 3⁄8 EPDM 3.0 0.30 0 – 15 0 – 9 0 – 16 0 – 16 0 – 13 0 – 16 0 – 16 -30 – 901) 132U3006

G 3⁄8 EPDM 4.5 0.55 0 – 8 0 – 3.5 0 – 12 0 – 10 0 – 4.5 0 – 13 0 – 9 -30 – 901) 132U4404

1

) WRAS approved to 23 °C

Orif.

size

K

v

value

[m³/h]

Dierential pressure min. to max. [bar]

BA

[AC]BA[DC]BD[AC]BB[AC]BB[DC]BG[AC]BG[DC]

Drinking

Water

Approval

Media

temperature

min. to max.

[°C]

Code no.

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 4

Page 5

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

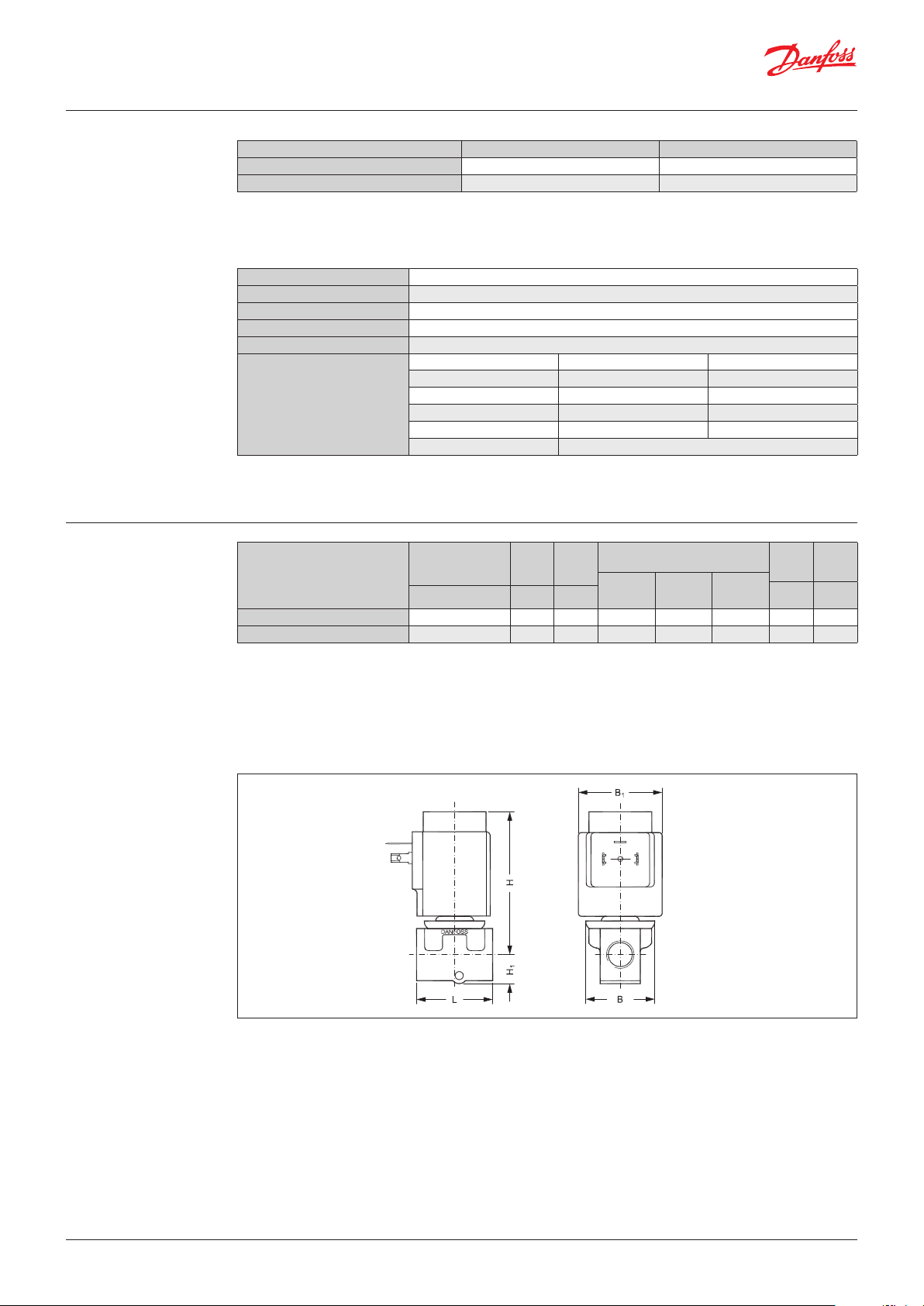

EV210 BW

Brass valve body, NC

Technical data

Dimensions and weight

Type EV210BW 1.5 EV210BW 3-4.5

Time to open [ms] 1) 10 20

Time to close [ms] 1) 20 20

1)

The times are indicative and apply to water. The exact times will depend on the pressure conditions.

Installation Optional, but vertical solenoid system is recommended

Max. test pressure 24 bar

Max working pressure 16 bar

Ambient temperature Max. 80 °C (depending on coil type)

Viscosity Max. 50 cSt

Valve body Brass W.no. 2.0402

Armature Stainless steel W.no. 1.4105 / AISI 430FR

Materials

Type

EV210BW 1.5 0.15 35 34 32 46 67 12 70

EV210BW 3 – 4.5 0.20 38 34 32 46 67 11 70

Armature tube Stainless steel W.no. 1.4306 / AISI 304L

Armature stop Stainless steel W.no. 1.4105 / AISI 430FR

Springs Stainless steel W.no. 1.4310 / AISI 301

Seal material: EPDM

B

Weight gross valve

body without coil

[kg] [mm] [mm]

L B

Coil type

BA / BD

1

[mm]

Coil type

BB / BE

Coil type

BG

H

1

[mm] [mm]

H

Dimensions

Danfoss

32U1769.11

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 5

Page 6

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

EV210B

Brass valve body, NO

y ACS (only EPDM 1.5 to 4.5)

y PZH (only EPDM 1.5 to 3)

y In accordance with:

- Low Voltage Directive 2014/35/EU

- EN60730-1

- EN60730-2-8

- Pressure Equipment Directive

2014/68/EU

- RoHS Directive 2011/65/EU

Conn.

228/1

1

) 140 °C / 3.6 bar low pressure steam, orifice DN 1.5 – 4.5.

- Low pressure steam: DN 1.5 – 3 Use coil type BB or BG

DN 4.5 Use coil type BG

2

) Pressure range can be extended to use in rough vacuum, typically up to 99% vacuum (10 mbar), depending on the application.

Seal

ISO

material

EPDM 1) 1.5 0.08 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 ACS, PZH -30 – 120 032U3630

G 1⁄8

EPDM 1) 2.0 0.15 0 – 12 0 – 12 0 – 12 0 – 12 0 – 12 0 – 12 0 – 12 ACS, PZH -30 – 120 032U3632

EPDM 1) 2.0 0.15 0 – 12 0 – 12 0 – 12 0 – 12 0 – 12 0 – 12 0 – 12 ACS, PZH -30 – 120 032U3636

EPDM 1) 3.0 0.3 0 – 5 0 – 5 0 – 5 0 – 5 0 – 5 0 – 5 0 – 5 ACS, PZH -30 – 120 032U3638

G 1⁄4

EPDM 1) 4.5 0.55 0 – 2 0 – 2 0 – 2 0 – 2 0 – 2 0 – 2 0 – 2 ACS -30 – 120 032U3640

Orif.

value

size

[m³/h]

FKM 1.5 0.08 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 -10 – 100 032U3631

FKM 2.0 0.15 0 – 12 0 – 12 0 – 12 0 – 12 0 – 12 0 – 12 0 – 12 -10 – 100 032U3633

FKM 2.0 0.15 0 – 12 0 – 12 0 – 12 0 – 12 0 – 12 0 – 12 0 – 12 -10 – 100 032U3637

FKM 3.0 0.3 0 – 5 0 – 5 0 – 5 0 – 5 0 – 5 0 – 5 0 – 5 -10 – 100 032U3639

FKM 4.5 0.55 0 – 2 0 – 2 0 – 2 0 – 2 0 – 2 0 – 2 0 – 2 -10 – 100 032U3641

Dierential pressure min. to max. [bar] /coil type 2)

K

v

BA

[AC]BA[DC]BD[AC]BB[AC]BB[DC]BG[AC]BG[DC]

Drinking

Water

Approval

Media

temperature

min. to max.

[°C]

Code no.

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 6

Page 7

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

EV210B

Brass valve body, NO

Technical data

Dimensions and weight

Type EV210B 1.5 – EV210B 4.5

Time to open [ms] 1) 20

Time to close [ms] 1) 20

1)

The times are indicative and apply to water. The exact times will depend on the pressure conditions.

Installation Optional, but vertical solenoid system is recommended

Max. test pressure 52,5 bar

Ambient temperature Max. 80 °C (depending on the coil type, see data for the coil selected)

Viscosity Max. 50 cSt

Valve body Brass W.no. 2.0402

Armature Stainless steel W.no. 1.4105 / AISI 430FR

Materials

Type

EV210B 1.5 / EV210B 2B, NO 0.15 35 34 32 46 67 12 70

EV210B 3 / EV210B 4.5, NO 0.20 38 34 32 46 67 11 70

Armature tube Stainless steel W.no. 1.4306 / AISI 304L

Armature stop Stainless steel W.no. 1.4105 / AISI 430FR

Springs Stainless steel W.no. 1.4310 / AISI 301

Seal material See specic valve data

B

Weight gross valve

body without coil

[kg] [mm] [mm]

L B

Coil type

BA / BD

1

[mm]

Coil type

BB / BE

Coil type

BG

H

1

[mm] [mm]

H

Dimensions

Danfoss

32U1769.11

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 7

Page 8

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

EV210B

stainless steel body, NC

y ACS

y PZH (only EPDM 2 and 3)

y In accordance with:

- Low Voltage Directive 2014/35/EU

- EN60730-1

- EN60730-2-8

- Pressure Equipment Directive

2014/68/EU

- RoHS Directive 2011/65/EU

Conn.

Seal

ISO

material

228/1

EPDM 1) 2 0.15 0 – 30 0 – 20 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 ACS, PZH -30 – 120 032U3647

EPDM 1) 3 0.30 0 – 15 0 – 9 0 – 24 0 – 20 0 – 13 0 – 30 0 – 25 ACS, PZH -30 – 120 032U3649

G 1⁄8

EPDM 1) 4.5 0.55 0 – 8 0 – 3.5 0 – 12 0 – 10 0 – 4.5 0 – 13 0 – 9 ACS -30 – 120 032U3655

EPDM 1) 2 0.15 0 – 30 0 – 20 0 – 30 0 – 30 0 – 30 0 – 30 0 – 30 ACS, PZH -30 – 120 032U3651

G 1⁄4

EPDM 1) 3 0.30 0 – 15 0 – 9 0 – 24 0 – 20 0 – 13 0 – 30 0 – 25 ACS, PZH -30 – 120 032U3653

1

) 140 °C / 3.6 bar low pressure steam, orifice DN 1.5 – 4.5.

- Low pressure steam: DN 1.5 – 3 Use coil type BB or BG

DN 4.5 Use coil type BG

Orif.

size

K

v

value

[m³/h]

[W AC ]

Permissible dierential pressure [bar]

BA 9

BA 15

BD 15

[W AC ]

BB 10

[W AC ]

[W DC]

BB 18

[W DC]

BG 12

[W AC ]

BG 20

[W DC]

Drinking

Water

Approval

Media

temperature

min. to max.

[°C]

Code no.

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 8

Page 9

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

EV210B

Stainless steel body, NC

Technical data

Dimensions and weight

Type EV210B 2 EV210BW 3 – 4.5

Time to open [ms] 1) 10 20

Time to close [ms] 1) 20 20

1)

The times are indicative and apply to water. The exact times will depend on the pressure conditions.

Installation Optional, but vertical solenoid system is recommended

Max. test pressure 45 bar

Max working pressure 30 bar

Ambient temperature Max. 80 °C

Viscosity Max. 50 cSt

Valve body Stainless steel W.no. 1.4404 / AISI 316L

Armature Stainless steel W.no. 1.4105 / AISI 430FR

Materials

Type

EV210B 2 / 3 / 4.5 0.25 35 35 32 46 67 11.5 75

Armature tube Stainless steel W.no. 1.4306 / AISI 304L

Armature stop Stainless steel W.no. 1.4105 / AISI 430FR

Springs Stainless steel W.no. 1.4310 / AISI 301

Seal material EPDM

B

Weight gross valve

body without coil

[kg] [mm] [mm]

L B

Coil type

BA / BD

1

[mm]

Coil type

BB / BE

Coil type

BG

H

1

[mm] [mm]

H

Dimensions

Danfoss

32U1779.10

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 9

Page 10

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

EV210BW

stainless steel body, NC

y WRAS

y In accordance with:

- Low Voltage Directive 2014/35/EU

- EN60730-1

- EN60730-2-8

- Pressure Equipment Directive

2014/68/EU

- RoHS Directive 2011/65/EU

Conn.

Seal

ISO

material

228/1

EPDM 1.5 0.08 0 – 16 0 – 16 0 – 16 0 – 16 0 – 16 0 – 16 0 – 16 -30 – 901) 132U2154

G 1⁄4

EPDM 3 0.30 0 – 15 0 – 9 0 – 16 0 – 16 0 – 13 0 – 16 0 – 16 -30 – 901) 132U3054

EPDM 4.5 0.55 0 – 8 0 – 3.5 0 – 12 0 – 10 0 – 4.5 0 – 13 0 – 9 -30 – 901) 132U4452

1

) WRAS approved to 23°C

Orif.

size

K

v

value

[m³/h]

[W AC ]

Permissible dierential pressure [bar]

BA 9

BA 15

BD 15

[W AC ]

BB 10

[W AC ]

[W DC]

BB 18

[W DC]

BG 12

[W AC ]

BG 20

[W DC]

Drinking

Water

Approval

Media

temperature

min. to max.

Code no.

[°C]

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 10

Page 11

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

EV210BW

Stainless steel body, NC

Technical data

Dimensions and weight

Type EV210BW 1.5 EV210BW 3 – 4.5

Time to open [ms] 1) 10 20

Time to close [ms] 1) 20 20

1)

The times are indicative and apply to water. The exact times will depend on the pressure conditions.

Installation Optional, but vertical solenoid system is recommended

Max. test pressure 24 bar

Max working pressure 16 bar

Ambient temperature Max. 80 °C

Viscosity Max. 50 cSt

Valve body Stainless steel W.no. 1.4404 / AISI 316L

Armature Stainless steel W.no. 1.4105 / AISI 430FR

Materials

Type

EV210BW 1.5 / 3 / 4.5 0.25 35 35 32 46 67 11.5 75

Armature tube Stainless steel W.no. 1.4306 / AISI 304L

Armature stop Stainless steel W.no. 1.4105 / AISI 430FR

Springs Stainless steel W.no. 1.4310 / AISI 301

Seal material EPDM

B

Weight gross valve

body without coil

[kg] [mm] [mm]

L B

Coil type

BA / BD

1

[mm]

Coil type

BB / BE

Coil type

BG

H

1

[mm] [mm]

H

Dimensions

Danfoss

32U1779.10

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 11

Page 12

EV15-25EV15-25

EV1.5-3 EV1.5-3

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

Mounting angle

Below coils can be used for EV210B

Coil Type Power consumption Enclosure Features

BA / BD, screw on

BB, clip on

BE, clip on

BG, clip on

9 W AC

15 W DC

10 W AC

18 W DC

10 W AC

18 W DC

12 W AC

20 W DC

IP00

with spade connector

IP00

with spade connector

IP67 With terminal box

IP67 With terminal box

IP20 with protective cap,

IP20 with protective cap,

IP65 with cable plug

IP65 with cable plug

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 12

Page 13

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

Accessories:

Cable plug

Universal electronic

multi-timer, type ETM

Application Code no.

GDM 2011 (grey) cable plug according to DIN 43650-A PG11 042N0156

Application

External adjustable timing from 1 to 45 minutes with 1 to 15

seconds drain open. With manual override (test button). Electrical

connection DIN 43650 A / EN 175 301-803-A

y Outside adjustments

y Light weight and small size

y External adjustable timing from 1 minute to 45

Voltage

[V AC ] [°C]

24 – 240 BA, BD, BB -10 – 50 042N0185

To use

with coil

y Light diodes for indication

y All in one unit

y Manual override (test button)

Ambient

temperature

Code no.

minutes with 1 to 15 seconds drain open

y One solid state timer ts all coil voltages from

24 – 240 V AC

Technical data

Dimensions

Type ET 20 M

Voltage 24 – 240 V AC / 50/60 Hz

Power rating Max. 20 Watt

Enclosure IP00, IP65 with power connector (cable plug)

Electrical connection DIN connector ( DIN 43650-A)

Ambient operating temperature range -10 – 50 °C

Function Start with pulse

Interval timer 1 – 45 min.

“On” timer 1 – 15 sec.

Weight 0.084 kg

RĘCZNE

STEROWANIE

ZEWNĘTRZNE

MOC

WŁ

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 13

Page 14

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

Mounting bracket

Isolating diaphragm kit

for EV210B 1.5 – 4.5 NC

Description Code no.

Brackets 032U1040

Seal material

EPDM -20 - 50 042U1009

FKM 0 - 50 042U1010

Media temperature

[C°]

Code no.

For EV210B/BW 1.5 – 4.5B in connection with

synthetic tubes, pipes and similar.

Avoids build-up of contaminates that can block

movement of the armature. Permits use of more

aggressive media that would normally attack the

armature. Gel lled; guarantees operation after long

periods of inactivity. The kit is suitable for orice sizes

up to DN 4.5 mm.

The kit consist of:

Assembled isolating unit

O-ring

4 screws

Locking button

Nut for coil

Spare parts kit, NC The spare parts kit consists of:

Spare parts kit, NO

Valve type Seal material Code no.

EV210B 1.5, 2, 3, 4.5 FKM 032U2003

EV210B 6, 8, 10

EV210B 15

EV210B 20

EV210B 25

Valve type Seal material Code no.

EV210B 1.5, 2, 3, 4.5

FKM 032U2011

EPDM 032U2006

FKM 032U2012

EPDM 032U2013

FKM 032U2014

EPDM 032U2017

FKM 032U2018

EPDM 032U2019

FKM 032U2004

EPDM 032U2005

Locking button

Nut for the coil

Armature with valve plate and spring

O-ring

The spare parts kit consists of:

Armature tube

2 O-rings

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 14

Page 15

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

Function NC

Function NO

Coil voltage disconnected (closed):

When the voltage to the coil (5) is disconnected,

the armature (2) with the valve plate (3) is pressed

down against the valve orice (4) by the closing

spring (1) and the medium,s pressure.

The valve will be closed for as long as the voltage

to the coil is disconnected.

Coil voltage connected (open):

When voltage is applied to the coil(5), the armature (2) with the valve plate (3) is lifted clear of

the valve orice (4).

The valve is now open for unimpeded ow and

will be open for as long as there is voltage to the

coil.

Coil voltage connected (open):

When the voltage to the coil(8) is disconnected,

the valve orice (5) is open, the opening spring

(2) lifting the spindle (3) with the valve plate (4)

clear of the orice.

The valve will be open for as long as the supply

voltage to the coil is disconnected.

1.Closing spring

2.Armature

3.Valve plate

4.Valve orice

5.Coil

Coil voltage disconnected (closed):

When voltage is applied to the coil (8), the magnetic eld draws the valve,s armature (1) down to

touch the xed base(7). The spindle (3) with the

valve plate (4) is now pressed down against the

valve orice (5) by the closing spring (6).

The valve will be closed for as long as there is

voltage to the coil.

1.Armature

2.Opening spring

3.Spindle

4.Valve plate

5.Valve orice

6.Closing spring

7.Fixed base

8.Coil

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 15

Page 16

Data sheet | Direct-operated 2/2-way solenoid valves, Type EV210B and EV210BW

Capacity diagrams:

Example, water at low pressure:

Capacity for EV210B 1.5B at

dierential pressure of 10 mbar.

Approx. 0.08 l / min

EV210B / EV210BW 1.5B

EV210B / EV210BW 3B

EV210B / EV210BW 4.5B

Example, water at higher

pressure:

Capacity for EV210B 3B at

dierential pressure of 0.5 bar.

Approx. 0.21 m3 / h

EV210B / EV210BW 1.5B

EV210B / EV210BW 3B

EV210B / EV210BW 4.5B

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 16

Page 17

Example, air at lower pressure:

Capacity for EV210B 15B at dierential

pressure of 17 mbar. Approx. 10 Nm3 / h

EV210B / EV210BW 1.5

EV210B / EV210BW 4.5

EV210B / EV210BW 3

Example, air at higher pressure :

Capacity for EV210B 2B at inlet pressure

(p1) of 5 bar and outlet pressure (p2) of

3.25 bar. Approx. 9 Nm3 / h

EV210B / EV210BW 3

EV210B / EV210BW 2

EV210B / EV210BW 1.5

© Danfoss | DCS (az) | 2019.04

IC.PD.200.7A.02 | 17

Loading...

Loading...