Page 1

Data sheet

ELIMINATOR® Hermetic receiver filter drier

Types DMC and DCC

DMC and DCC are combined receivers and filter

driers for use in small hermetic refrigeration

systems.

Under operating conditions where the condenser

cannot contain the total quantity of refrigerant, a

receiver might be necessary.

This extra receiver capacity can be provided by

using a DCC or a DMC combined receiver and

filter drier.

There are two types of ELIMINATOR® cores.

Type DMC driers have a core composition of

100% Molecular Sieve, while type DCC contain

80% Molecular Sieve with 20% activated alumina.

ELIMINATOR® type DMC driers are designed

for applications requiring the highest moisture

capacity.

ELIMINATOR® type DCC driers are designed for

applications requiring high moisture capacity

and acid adsorption capacity.

Features The Core Type DMC

• 100% Molecular Sieve core

• High drying capacity minimizing the risk of

acid formation (hydrolysis)

• Recommended for use with HFO, HC, HFC and

HCFC refrigerants

• Will not deplete oil additives

The Core Type DCC

• 80% Molecular Sieve with 20% activated

alumina

• Recommended for use with HFO, HC, HFC and

HCFC refrigerants

• Perfect core blend for A/C systems that operate

at high condensing temperatures and require

high drying capacity

Available with solder (cu-plated steel)

connections.

The Shell

• PED/UL approved for PS 42 bar

• Available with solder

(cu-plated steel connectors)

• Corrosion resistant powder-painted finish

The Filter

• Combination of filter drier and receiver

• Available in sizes 4 – 40 cubic inches

• High drying capacity at high and low liquid

temperatures

• Space-saving

• Fast installation

• 25 μm (0.001 in.) filter provides high retention

with minimal pressure drop

• Thermally stable up to 120 °C

© Danfoss | DCS (az) | 2016.04

DKRCC.PD.EF0.A6.02 | 520H10988 | 1

Page 2

Data sheet | ELIMINATOR® Hermetic receiver filter drier, types DMC and DCC

Approvals

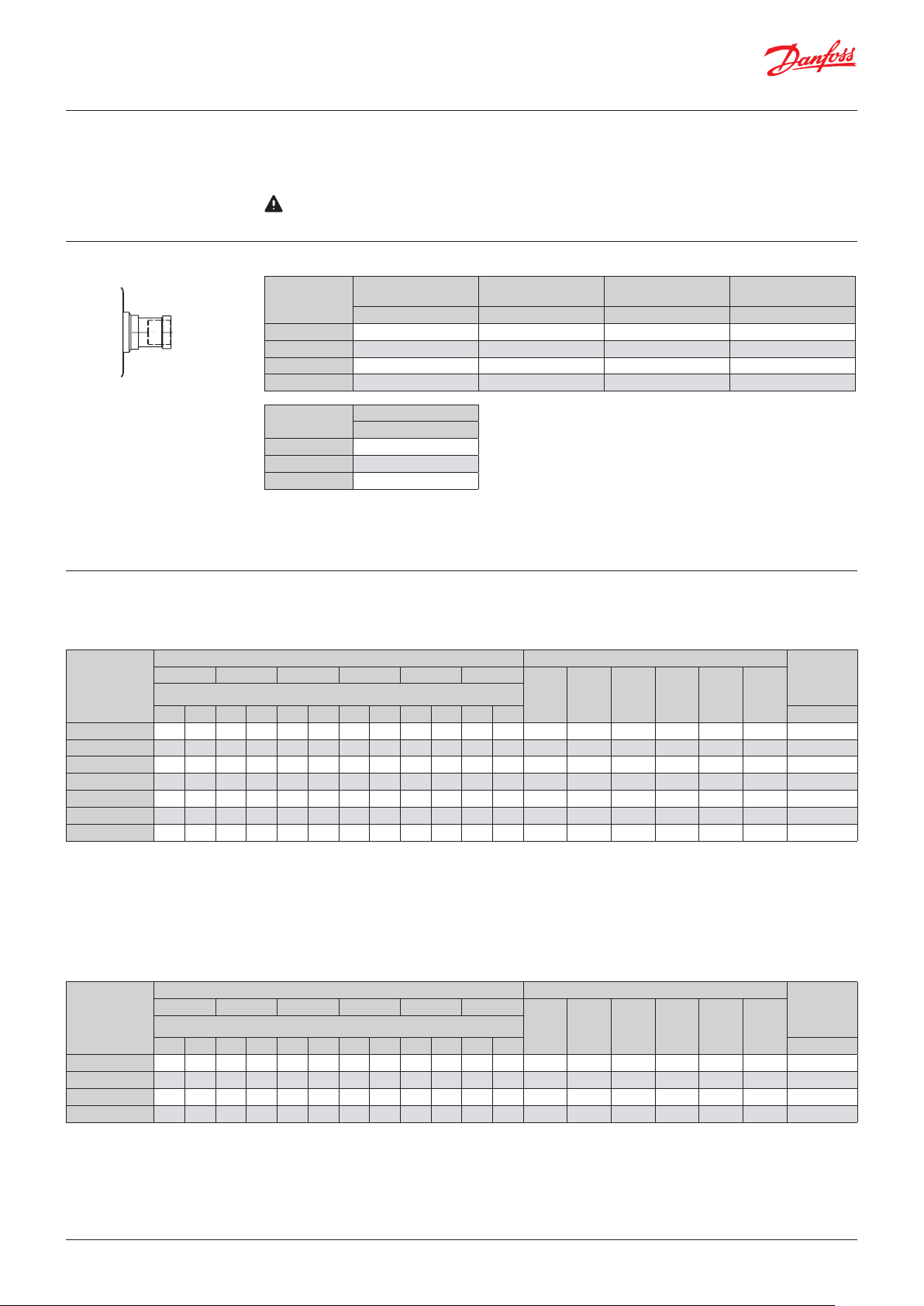

Technical data

Solder connection

(cu-plated steel connectors)

Technical data

and capacities

UL US, file no. SA 6398

PED 97/23/EC - a3p3

Compliant with ATEX hazard zone 2

Note: Only solder versions (cu-plated / pure copper)

and connection sizes below 25 mm are approved for

flammable refrigerants now.

Surface and volume

Filter

DMC / DCC 04 83 53 0.14 0.09

DMC / DCC 07 83 53 0.19 0.14

DMC / DCC 20 83 53 0.35 0.30

DMC 40 220 234 0.77 0.54

Filter

DCC 04 0.71

DCC 07 0.71

DCC 20 0.71

1

) Adsorption capacity of oleic acid at

0.05 TAN (Total Acid Number).

Temperature range:

-40 – 70 °C

Solid core surface Solid core volume

[cm2] [cm3] [l] [l]

Acid capacity

[g] 1)

Filter drier volume

(shell volume)

Filter drier volume

(net volume)

Drying and liquid capacity , type DMC

Drying capacity [kg] refrigerant 1) Liquid capacity [kW] 2) Max.

Type

DMC 0432s 5.0 4.7 5.3 5.1 5.4 5.0 5.0 4.7 5.0 4.6 4.5 4.2 7.71 5.52 5.36 8.44 7.96 8.21 42

DMC 0732s 5.0 4.7 5.3 5.1 5.4 5.0 5.0 4.7 5.0 4.6 4.5 4.2 7.71 5.52 5.36 8.44 7.96 8.21 42

DMC 2032s 5.0 4.7 5.3 5.1 5.4 5.0 5.0 4.7 5.0 4.6 4.5 4.2 7.71 5.52 5.36 8.44 7.96 8.21 42

DMC 2033s 5.0 4.7 5.3 5.1 5.4 5.0 5.0 4.7 5.0 4.6 4.5 4.2 15.69 11.17 10.84 17.14 16.14 16.61 42

DMC 2034s 5.0 4.7 5.3 5.1 5.4 5.0 5.0 4.7 5.0 4.6 4.5 4.2 32.65 25.73 25.05 37.42 35.85 38.68 42

DMC 40163s 27.7 26.2 29.8 28.3 30.4 28.0 28.1 26.0 27.8 25.7 25.3 23.3 15.69 11.17 10.84 17.14 16.14 16.61 42

DMC 40164s 27.7 26.2 29.8 28.3 30.4 28.0 28.1 26.0 27.8 25.7 25.3 23.3 32.65 25.73 25.05 37.42 35.85 38.68 42

1

) Drying capacity is based on following moisture content test standards before

and after drying:

– R134a: 1050 – 50 ppm W

– R404A, R507: 1020 – 50 ppm W

– R407C: 1020 – 50 ppm W

– R410A: 1050 – 50 ppm W

– R22: 1050 – 60 ppm W

In accordance with ARI 710-2004

R134a R404A R507 R22 R407C R410A

R134a R404A R507 R22 R407C R410A[°C]

24 52 24 52 24 52 24 52 24 52 24 52 [bar]

2

) Given in accordance with ARI 710-2004 for

– te= -15 °C

– tc= 30 °C

– Δp = 0.07 bar

For technical data on other refrigerants, please contact your Danfoss Sales

Representative

Working

Pressure

Drying and liquid capacity , type DCC

Drying capacity [kg] refrigerant 1) Liquid capacity [kW] 2) Max.

Type

DCC 0432s 3.9 3.6 4.2 3.9 4.2 3.9 3.9 3.6 3.9 3.6 3.5 3.2 7.71 5.52 5.36 8.44 7.96 8.21 42

DCC 0732s 3.9 3.6 4.2 3.9 4.2 3.9 3.9 3.6 3.9 3.6 3.5 3.2 7.71 5.52 5.36 8.44 7.96 8.21 42

DCC 2032s 3.9 3.6 4.2 3.9 4.2 3.9 3.9 3.6 3.9 3.6 3.5 3.2 7.71 5.52 5.36 8.44 7.96 8.21 42

DCC 2033s 3.9 3.6 4.2 3.9 4.2 3.9 3.9 3.6 3.9 3.6 3.5 3.2 15.69 11.17 10.84 17.14 16.14 16.61 42

1

) Drying capacity is based on following moisture content test standards before

and after drying:

– R134a: 1050 – 50 ppm W

– R404A, R507: 1020 – 50 ppm W

– R407C: 1020 – 50 ppm W

– R410A: 1050 – 50 ppm W

– R22: 1050 – 60 ppm W

In accordance with ARI 710-2004

R134a R404A R507 R22 R407C R410A

R134a R404A R507 R22 R407C R410A[°C]

24 52 24 52 24 52 24 52 24 52 24 52 [bar]

2

) Given in accordance with ARI 710-2004 for

– te= -15 °C

– tc= 30 °C

– Δp = 0.07 bar

For technical data on other refrigerants, please contact your Danfoss Sales

Representative

Working

Pressure

PS

PS

© Danfoss | DCS (az) | 2016.04

DKRCC.PD.EF0.A6.02 | 520H10988 | 2

Page 3

Data sheet | ELIMINATOR® Hermetic receiver filter drier, types DMC and DCC

Ordering

Technical data

and capacities

Type DMC

Industrial pack

Type Connection

for OEM only

Qty. Code no. Qty. Code no.

DMC 0432s 6 mm 16 023Z7012 24 023Z7019

DMC 0732s 6 mm 16 023Z7013 24 023Z7020

DMC 0732s

1

⁄4 in. 16 023Z7045 – –

DMC 2032s 6 mm 10 023Z7007 18 023Z7021

DMC 2032s

1

⁄4 in. 10 023Z7008 18 023Z7022

Multi pack

Type DCC

Type Connection

DCC 0432s 6 mm 16 023Z7000

DCC 0732s 6 mm 16 023Z7001

DCC 2032s 6 mm 10 023Z7002

DCC 2032s

1

⁄4 in. 10 023Z7003

DCC 2033s 10 mm 10 023Z7004

Industrial pack for OEM only

Qty. Code no.

DMC 2032.5s5⁄16 in. 10 023Z7044 – –

DMC 2033s 10 mm 10 023Z7014 18 023Z7023

DMC 2033s

3

⁄8 in. 10 023Z7009 18 023Z7024

DMC 2034s 12 mm 10 023Z7015 – –

DMC 2034s

1

⁄2 in. 10 023Z7010 18 023Z7026

DMC 40163s 10 mm 6 023Z7016 8 023Z7027

DMC 40163s3⁄8 in. 6 023Z7017 8 023Z7028

DMC 40164s 12 mm 6 023Z7018 8 023Z7029

DMC 40164s1⁄2 in. 6 023Z7011 8 023Z7030

Type codes

Type Codes Description

Filter drier D Drier

Solid core

Application C Combined filter drier/receiver

Filter housing volume (approx.)

Solid core size

Connection

(filter connection in 1/8 of an inch increments)

Connection type s Solder connection (cu-plated steel connectors)

M 100% Molecular Sieve core

C 80% Molecular Sieve / 20% activated alumina

04 4 in.

07 7 in.

20 20 in.

40 40 in.

03 3 in.

16 16 in.

2

3

4

3

3

3

3

3

3

1

⁄4 in. / 6 mm

3

⁄8 in. / 10 mm

1

⁄2 in. / 12 mm

Example for type codes

D M C 20 03 2 s

Solid core

Filter drier

Application

Solid core size

Filter housing volume (approx.)

Connection (filter connection

Connection type

⁄8 of an inch increments)

1

in

© Danfoss | DCS (az) | 2016.04

DKRCC.PD.EF0.A6.02 | 520H10988 | 3

Page 4

Data sheet | ELIMINATOR® Hermetic receiver filter drier, types DMC and DCC

Selection

Type selection is made considering the application

Refrigerant and oil types DCC DMC

HFO Recommended Recommended

Refrigerant

Oil

1

) Only solder versions (cu-plated / pure copper) and connection sizes below 25 mm are approved for flammable refrigerants now

2

) DCC Hermetic filter driers contain activated alumina, which is a polar material used for acid adsorption.

Many oil additives are also polar substances and can be adsorbed by the activated alumina, rendering them useless, and

reducing the drier’s acid capacity, though this is not harmful to the system

HC 1) Recommended Recommended

HFC Recommended Recommended

HCFC Recommended Recommended

Mineral or AB Recommended Recommended

POE or PAG, pure Recommended Recommended

POE or PAG, with additives Not recommended 2) Recommended

Selection example Select the appropriate type (DMC or DCC) based

on refrigerant and oil type. Then select the drier

size based on the adsorption and liquid capacity

required.

a. Amount of charge: 4 kg R134a at tL = 24 °C

To dry 4 kg R134a at 24 °C from 1050 to 60 ppm

moisture, a DMC 20 is necessary

b. Cooling capacity: Qe = 15 kW

To obtain a mass flow corresponding to 15 kW

cooling capacity with a DMC 0 filter drier, a 3⁄8

inch connection must be chosen.

Larger connections can be chosen in

accordance with the liquid line dimension

c. Result

DMC 2033s or DMC 2034s can be used

If the initial moisture content is very small or a

planned change of the filter drier is considered, a

smaller filter drier size can be chosen.

During selection consider amount of the

refrigerant intended to keep in a reciever part of

the filter.

Drying capacity [kg] refrigerant 1) Liquid capacity [kW] 2) Max.

Type

DMC 0432s 4.9 4.6 5.2 5.0 5.3 4.9 4.9 4.6 4.9 4.5 4.4 4.1 7.71 5.52 5.36 8.44 7.96 8.21 42

DMC 0732s 4.9 4.6 5.2 5.0 5.3 4.9 4.9 4.6 4.9 4.5 4.4 4.1 7.71 5.52 5.36 8.44 7.96 8.21 42

DMC 2032s 4.9 4.6 5.2 5.0 5.3 4.9 4.9 4.6 4.9 4.5 4.4 4.1 7.71 5.52 5.36 8.44 7.96 8.21 42

DMC 2033s 4.9 4.6 5.2 5.0 5.3 4.9 4.9 4.6 4.9 4.5 4.4 4.1 15.69 11.17 10.84 17.14 16.14 16.61 42

DMC 2034s 4.9 4.6 5.2 5.0 5.3 4.9 4.9 4.6 4.9 4.5 4.4 4.1 32.65 25.73 25.05 37.42 35.85 38.68 42

DMC 40163s 25.6 24.2 27.5 26.1 28.0 25.9 25.9 24.0 25.6 23.7 23.3 21.5 15.69 11.17 10.84 17.14 16.14 16.61 42

DMC 40164s 25.6 24.2 27.5 26.1 28.0 25.9 25.9 24.0 25.6 23.7 23.3 21.5 32.65 25.73 25.05 37.42 35.85 38.68 42

R134a R404A R507 R22 R407C R410A

R134a R404A R507 R22 R407C R410A[°C]

24 52 24 52 24 52 24 52 24 52 24 52 [bar]

Working

Pressure

PS

© Danfoss | DCS (az) | 2016.04

DKRCC.PD.EF0.A6.02 | 520H10988 | 4

Page 5

Danf

already on order pro

All trademarks in this material are property of the respec

Design / function

Danfoss

23Z7008.10

23Z83.10

1. Inlet

2. Spring

3. Solid core

4. Polyester mat

5. Perforated plate

Dimensions and weights Solder connection (cu-plated steel connectors)

Danfoss

Type

L A B D

[mm] [mm] [mm]

1

[mm] [mm]

2

D

Net weight

[kg]

DMC / DCC 0432s 114 82 99 58 54 0.40

DMC / DCC 0732s 140 108 125 58 54 0.48

DMC / DCC 2032s 222 190 206 58 54 0.72

DMC / DCC 2033s 228 190 208 58 54 0.73

DMC / DCC 2034s 232 190 210 58 54 0.74

DMC 40163s 237 199 219 80 76 1.18

DMC 40164s 241 199 221 80 76 1.19

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

© Danfoss | DCS (az) | 2016.04

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

DKRCC.PD.EF0.A6.02 | 520H10988 | 5

Loading...

Loading...