Page 1

Data sheet

ELIMINATOR® filter drier with replaceable solid core

Type DCR

Danfoss ELIMINATOR® lter driers with

replaceable solid core, type DCR, are for use

in liquid and / or suction lines in refrigeration,

freezing and air-conditioning systems.

Besides being able to meet the demanding

requirements of high working pressure

levels when operating with R410A thanks to

replaceable solid cores the DCR programme

oers exibility with respect to dierent

applications.

Available with steel and copper connections.

Features DCR housing:

• PED approved for PS up to 46 bar

• DCR housing (incl. core holder) are made

entirely of steel and are thus compatible with

all refrigerants

• DCR housings have undergone phosphate

pre-treatment and have a corrosion-resistant

powder-paint nish

• DCR housings are helium leak tested

Top covers for DCR housings:

• Zinc-chromated steel top covers with or

without external access connection

Inserts for DCR housings - strainer

48 - F strainer - compatible with all refrigerants:

• Retains dirt particles larger than 15 μm

• For use direct in DCR housings

• Utilised in the suction or liquid line

Inserts for DCR housings - solid cores

48 - DM - 100% molecular sieve solid core

suitable for HFC (R134a, R404A, R507, R407C and

R410A) refrigerants:

• Provides high moisture adsorption at low and

high condensing temperatures

• Eective protection against impurities

48 - DC - 80% molecular sieve and 20% activated

alumina solid core suitable for HCFC (R22)

refrigerants and compatible with HFC (R134a,

R404A, R507, R407C and R410A) refrigerants:

• Adsorbs moisture and acid in the system

throughout the entire temperature range

48 - DA - 30% molecular sieve and 70% activated

alumina solid core suitable after compressor

burnout and compatible with

HCFC (R22) / HFC (R134a, R404A, R507, R407C

and R410A) refrigerants:

• High acid adsorption and standard water

adsorption

All solid cores have an optimised uniform grain

size ensuring eective dirt removal and low

pressure drop. The robust solid cores withstand

pressure surge and vibration.

© Danfoss A/S | DCS (sw) | 2017.02

DKRCC.PD.EJ0.1A.02 | 1

Page 2

Danfosss

R64-8039

Data sheet | ELIMINATOR® lter drier with replaceable solid core, type DCR

Approvals

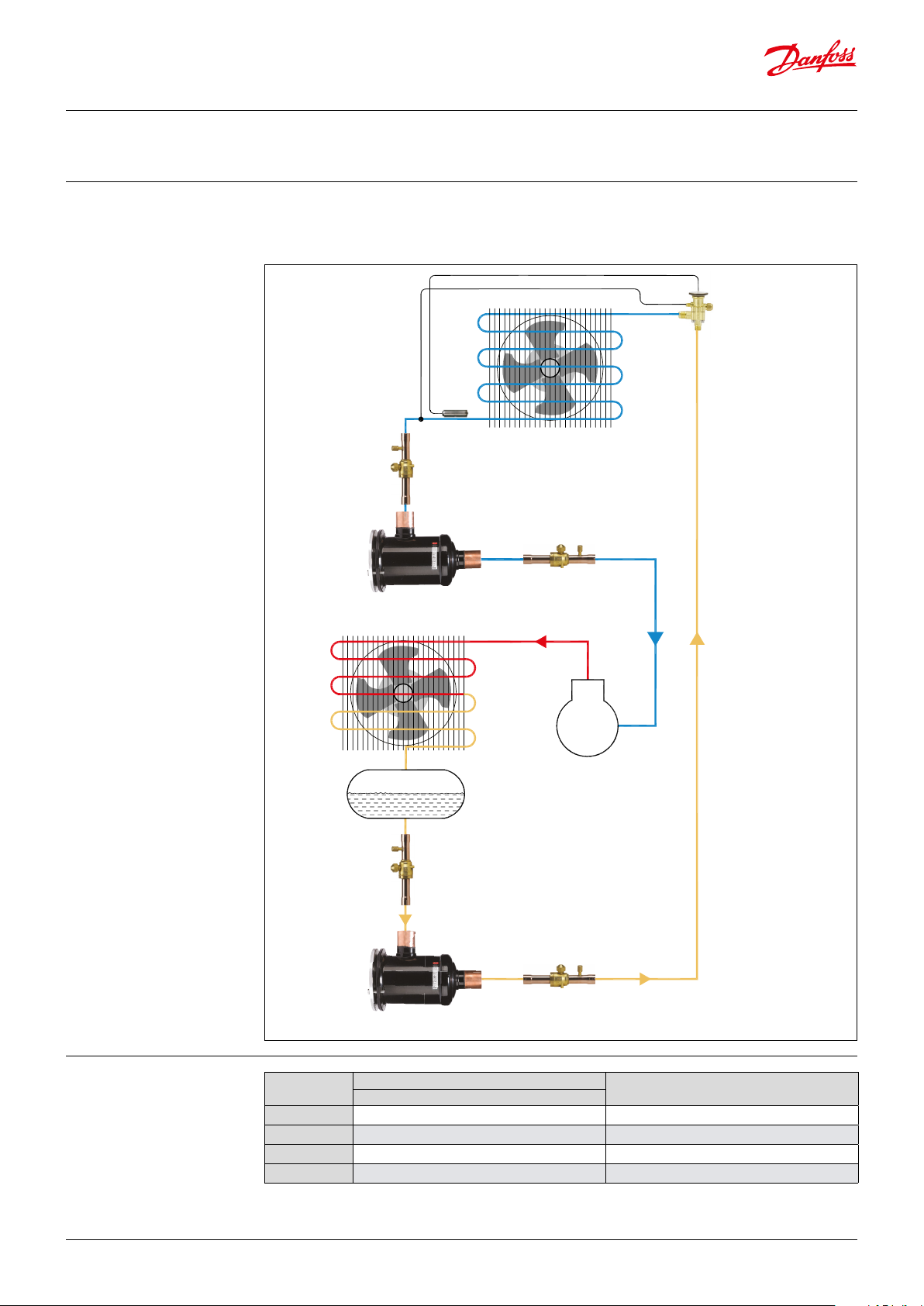

Introduction

CE marked in accordance with the European

Pressure Equipment Directive - 97/23/EC

Danfoss ELIMINATOR® lter driers with

replaceable solid core, type DCR, protect

refrigeration, freezing and air-conditioning

systems from moisture, acids, and solid particles.

UL US listed 207 and C22.2 no. 140.3

EN 12284

With these contaminants eliminated, systems are

safer from harmful chemical reactions and from

abrasive impurities.

TE

DCR, suction line lter drier

DCR, liquid line lter drier

Technical data

© Danfoss A/S | DCS (sw) | 2017.02

Type

DCR 048

DCR 096

DCR 144

DCR 192

1

) For usage with strainer or as a receiver application

2

) For “drier” application using all the permissible cores

Maximum working pressure PS

[bar]

46 - 40 – 70 °C

46 - 40 – 70 °C

351) / 462) - 40 – 70 °C

281) / 402) - 40 – 70 °C

Temperature range

DKRCC.PD.EJ0.1A.02 | 2

Page 3

Data sheet | ELIMINATOR® lter drier with replaceable solid core, type DCR

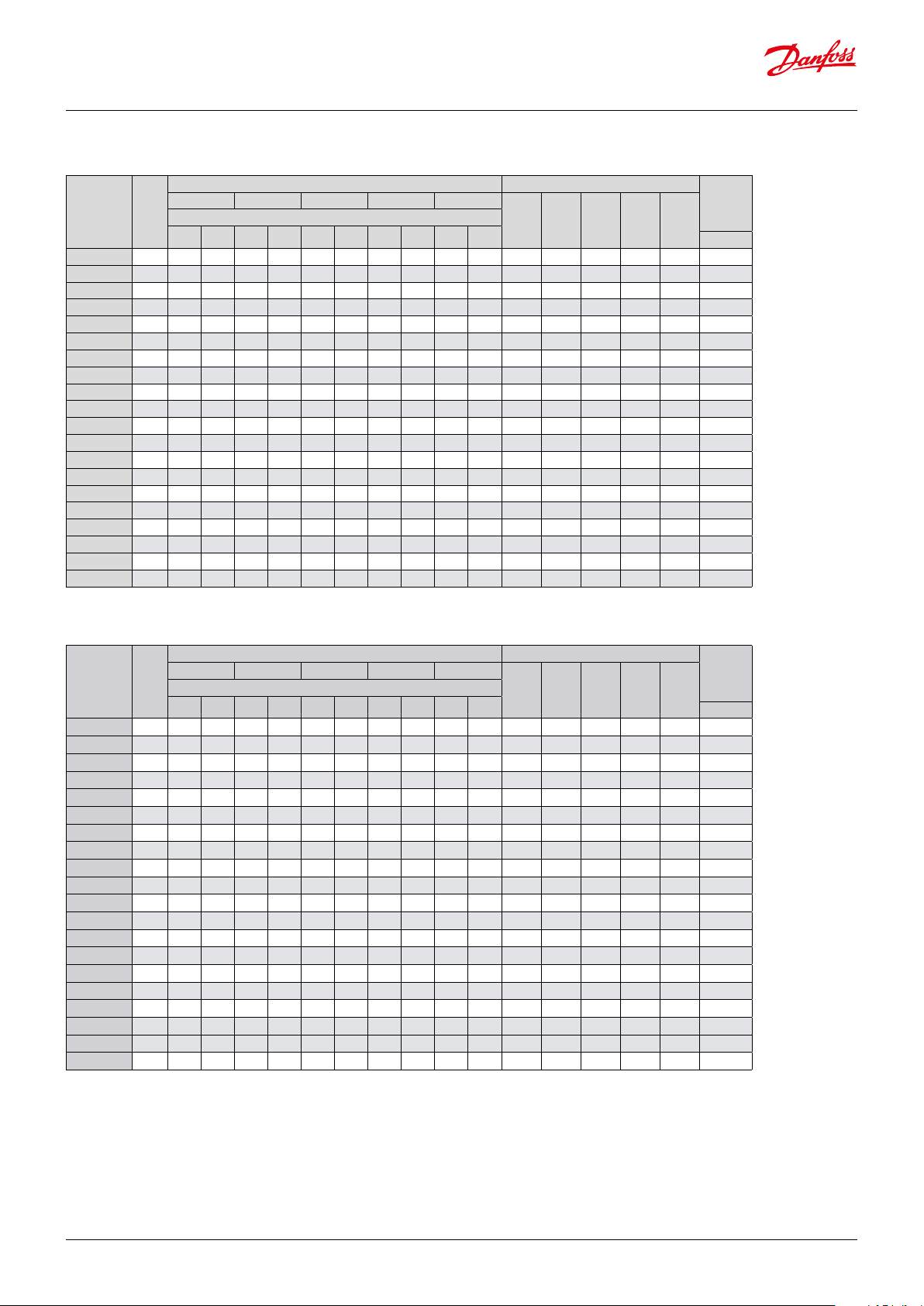

Capacitiy

Drying and liquid capacity , type 48-DM

Drying capacity [kg refrigerant] 1) Liquid capacity [kW] 2) Max.

Type

DCR 0485 1 82.5 78.0 88.7 84.0 90.3 83.4 82.7 76.4 75.2 69.3 80.6 59.4 57.5 84.5 87.9 46

DCR 0487 1 82.5 78.0 88.7 84.0 90.3 83.4 82.7 76.4 75.2 69.3 128.0 92.5 89.6 132.6 136.8 46

DCR 0489 1 82.5 78.0 88.7 84.0 90.3 83.4 82.7 76.4 75.2 69.3 184.3 132.6 128.4 190.4 195.9 46

DCR 04811 1 82.5 78.0 88.7 84.0 90.3 83.4 82.7 76.4 75.2 69.3 249.3 180.5 174.8 258.5 266.8 46

DCR 04813 1 82.5 78.0 88.7 84.0 90.3 83.4 82.7 76.4 75.2 69.3 304.1 222.0 215.1 317.1 328.5 46

DCR 04817 1 82.5 78.0 88.7 84.0 90.3 83.4 82.7 76.4 75.2 69.3 434.3 324.1 314.3 459.4 480.7 46

DCR 04821 1 82.5 78.0 88.7 84.0 90.3 83.4 82.7 76.4 75.2 69.3 320.4 234.4 227.1 334.5 346.8 46

DCR 0967 2 165.0 155.0 177.3 168.1 180.5 166.8 165.3 152.8 150.5 138.7 119.6 85.7 83.0 123.2 126.6 46

DCR 0969 2 165.0 155.0 177.3 168.1 180.5 166.8 165.3 152.8 150.5 138.7 189.5 136.4 131.9 195.6 201.2 46

DCR 09611 2 165.0 155.0 177.3 168.1 180.5 166.8 165.3 152.8 150.5 138.7 259.7 187.2 181.4 268.6 276.7 46

DCR 09613 2 165.0 155.0 177.3 168.1 180.5 166.8 165.3 152.8 150.5 138.7 331.9 240.8 233.3 344.7 356.1 46

DCR 09617 2 165.0 155.0 177.3 168.1 180.5 166.8 165.3 152.8 150.5 138.7 477.2 349.1 338.3 498.2 516.6 46

DCR 1449 3 247.5 233.9 266.0 252.7 270.8 250.1 248.0 229.1 225.7 208.0 184.4 132.7 128.5 190.5 196.0 353) / 464)

DCR 14411 3 247.5 233.9 266.0 252.7 270.8 250.1 248.0 229.1 225.7 208.0 272.5 196.9 190.7 282.2 290.9 353) / 464)

DCR 14413 3 247.5 233.9 266.0 252.7 270.8 250.1 248.0 229.1 225.7 208.0 340.1 246.8 239.1 353.2 364.9 353) / 464)

DCR 14417 3 247.5 233.9 266.0 252.7 270.8 250.1 248.0 229.1 225.7 208.0 442.3 323.0 313.0 461.3 478.0 353) / 464)

DCR 19211 4 329.9 311.9 354.7 336.2 361.0 333.5 330.6 305.5 300.9 277.0 290.0 211.6 205.0 302.3 313.1 283) / 404)

DCR 19213 4 329.9 311.9 354.7 336.2 361.0 333.5 330.6 305.5 300.9 277.0 359.8 261.7 253.6 374.2 387.0 283) / 404)

DCR 19217 4 329.9 311.9 354.7 336.2 361.0 333.5 330.6 305.5 300.9 277.0 442.5 321.7 311.7 460.2 475.8 283) / 404)

DCR 19221 4 329.9 311.9 354.7 336.2 361.0 333.5 330.6 305.5 300.9 277.0 505.6 366.0 354.6 524.3 541.0 283) / 404)

№ of

cores

R134a R404A R507 R22/R407C R410A

[°C]

24 52 24 52 24 52 24 52 24 52

R134a R404A R507

R22 /

R407C

R410A

working

pressure

PS

[bar]

Drying and liquid capacity , type 48-DC

Drying capacity [kg refrigerant] 1) Liquid capacity [kW] 2) Max.

Type

DCR 0485 1 64.7 61.2 69.6 65.9 70.8 65.4 64.9 59.9 59.0 54.4 80.6 59.4 57.5 84.5 87.9 46

DCR 0487 1 64.7 61.2 69.6 65.9 70.8 65.4 64.9 59.9 59.0 54.4 128.0 92.5 89.6 132.6 136.8 46

DCR 0489 1 64.7 61.2 69.6 65.9 70.8 65.4 64.9 59.9 59.0 54.4 184.3 132.6 128.4 190.4 195.9 46

DCR 04811 1 64.7 61.2 69.6 65.9 70.8 65.4 64.9 59.9 59.0 54.4 249.3 180.5 174.8 258.5 266.8 46

DCR 04813 1 64.7 61.2 69.6 65.9 70.8 65.4 64.9 59.9 59.0 54.4 304.1 222.0 215.1 317.1 328.5 46

DCR 04817 1 64.7 61.2 69.6 65.9 70.8 65.4 64.9 59.9 59.0 54.4 434.3 324.1 314.3 459.4 480.7 46

DCR 04821 1 64.7 61.2 69.6 65.9 70.8 65.4 64.9 59.9 59.0 54.4 320.4 234.4 227.1 334.5 346.8 46

DCR 0967 2 129.4 122.3 139.1 131.9 141.6 130.8 129.7 119.9 118.1 108.8 119.6 85.7 83.0 123.2 126.6 46

DCR 0969 2 129.4 122.3 139.1 131.9 141.6 130.8 129.7 119.9 118.1 108.8 189.5 136.4 131.9 195.6 201.2 46

DCR 09611 2 129.4 122.3 139.1 131.9 141.6 130.8 129.7 119.9 118.1 108.8 259.7 187.2 181.4 268.6 276.7 46

DCR 09613 2 129.4 122.3 139.1 131.9 141.6 130.8 129.7 119.9 118.1 108.8 331.9 240.8 233.3 344.7 356.1 46

DCR 09617 2 129.4 122.3 139.1 131.9 141.6 130.8 129.7 119.9 118.1 108.8 477.2 349.1 338.3 498.2 516.6 46

DCR 1449 3 194.1 183.5 208.7 197.8 212.4 196.2 194.6 179.8 177.1 162.2 184.4 132.7 128.5 190.5 196.0 353) / 464)

DCR 14411 3 194.1 183.5 208.7 197.8 212.4 196.2 194.6 179.8 177.1 162.2 272.5 196.9 190.7 282.2 290.9 353) / 464)

DCR 14413 3 194.1 183.5 208.7 197.8 212.4 196.2 194.6 179.8 177.1 162.2 340.1 246.8 239.1 353.2 364.9 353) / 464)

DCR 14417 3 194.1 183.5 208.7 197.8 212.4 196.2 194.6 179.8 177.1 162.2 442.3 323.0 313.0 461.3 478.0 353) / 464)

DCR 19211 4 258.9 244.7 278.3 263.8 283.2 261.7 259.4 239.7 236.1 217.6 290.0 211.6 205.0 302.3 313.1 283) / 404)

DCR 19213 4 258.9 244.7 278.3 263.8 283.2 261.7 259.4 239.7 236.1 217.6 359.8 261.7 253.6 374.2 387.0 283) / 404)

DCR 19217 4 258.9 244.7 278.3 263.8 283.2 261.7 259.4 239.7 236.1 217.6 442.5 321.7 311.7 460.2 475.8 283) / 404)

DCR 19221 4 258.9 244.7 278.3 263.8 283.2 261.7 259.4 239.7 236.1 217.6 505.6 366.0 354.6 524.3 541.0 283) / 404)

1

) Drying capacity is based on following moisture content test standards before and

after drying:

– R134a: 1050 – 50 ppm W

– R404A, R507: 1020 – 50 ppm W

– R407C: 1020 – 50 ppm W

– R410A: 1050 – 50 ppm W

– R22: 1050 – 60 ppm

In accordance with ARI 710-2004

№ of

cores

R134a R404A R507 R22/R407C R410A

[°C]

24 52 24 52 24 52 24 52 24 52

2

) Given in accordance with ARI 710-2004 for:

3

) For usage with strainer or as a receiver application

4

) For “drier” application using all the permissible cores

R134a R404A R507

– te= -15 °C

– tc= 30 °C

– Δp = 0.07 bar

R22 /

R407C

R410A

working

pressure

PS

[bar]

Refrigerants other than specied in the table please contact Danfoss for the approval.

© Danfoss A/S | DCS (sw) | 2017.02

DKRCC.PD.EJ0.1A.02 | 3

Page 4

Data sheet | ELIMINATOR® lter drier with replaceable solid core, type DCR

Capacitiy (continued)

Drying and acid capacity , type 48-DA

Drying capacity [g of water] 1)

Type

DCR 048 1 28 19 12 45 38 27 47 30 19 42 35 25 26.6

DCR 096 2 56 37 24 90 77 54 94 60 37 84 70 50 53.3

DCR 144 3 84 56 36 135 115 81 142 90 56 126 105 75 79.9

DCR 192 4 112 74 48 180 153 108 189 120 75 168 140 100 106.5

1

) Drying capacity is expressed during drying in:

– R22: EPD = 10 ppm W, corresponding to a dew point temperature = -50 °C

– R134a: EPD = 50 ppm W, corresponding to a dew point temperature = -37 °C

– R404A: EPD = 10 ppm W, corresponding to a dew point temperature = -40 °C

– R407C: EPD = 10 ppm W, corresponding to a dew point temperature = -40 °C

2

) Adsorption capacity of oleic acid at 0.05 TAN (Total Acid Number)

Number

of cores

-40 -20 4.4 -30 -20 4.4 -40 -20 4.4 -40 -20 4.4

R22 / R407C R134a R404A / R507 R410A [g]

Evaporating temperature te [°C]

Acid

capacity 2)

Recommended plant capacity in suction line - burn-out, type 48-DA

Recommended plant capacity [kW]

Evaporating temperature te [°C]

Type

DCR 0485 3.1 8.9 21.0 3.0 5.4 13.0 2.4 7.1 17.5 3.1 8.9 21.0

DCR 0487 5.8 16.1 37.8 5.6 9.9 23.4 4.5 12.9 31.2 5.8 16.1 37.8

DCR 0489 7.8 21.6 50.7 7.5 13.3 31.5 6.0 17.2 41.8 7.8 21.6 50.7

DCR 04811 10.0 27.3 63.3 9.6 16.8 39.5 7.7 21.8 51.9 10.0 27.3 63.3

DCR 04813 10.0 27.3 63.3 9.6 16.8 39.5 7.7 21.8 51.9 10.0 27.3 63.3

DCR 04817 10.0 27.3 63.3 9.6 16.8 39.5 7.7 21.8 51.9 10.0 27.3 63.3

DCR 04821 10.0 27.3 63.3 9.6 16.8 39.5 7.7 21.8 51.9 10.0 27.3 63.3

DCR 0965 3.3 9.1 21.4 3.2 5.7 13.4 2.5 7.4 18.0 3.3 9.2 21.6

DCR 0967 5.8 16.2 38.1 5.6 9.9 23.6 4.5 12.9 31.4 5.8 16.2 38.1

DCR 0969 8.7 24.6 58.3 8.4 15.0 35.9 6.8 19.7 48.1 8.7 24.6 58.3

DCR 09611 11.9 33.4 79.3 11.4 20.4 48.9 9.3 26.8 65.4 11.9 33.4 79.3

DCR 09613 14.1 39.9 95.2 13.6 24.3 58.5 11.0 32.0 78.7 14.1 39.9 95.2

DCR 09617 14.1 39.9 95.2 13.6 24.3 58.5 11.0 32.0 78.7 14.1 39.9 95.2

DCR 09621 14.1 39.9 95.2 13.6 24.3 58.5 11.0 32.0 78.7 14.1 39.9 95.2

DCR 1445 3.5 10.0 22.8 3.4 6.0 14.0 2.7 7.7 18.9 3.5 10.0 22.8

DCR 1447 6.6 18.9 42.9 6.3 11.2 26.4 5.1 14.5 35.6 6.6 18.9 42.9

DCR 1449 8.8 25.1 57.2 8.4 15.0 35.2 6.8 19.4 47.5 8.8 25.1 57.2

DCR 14411 13.2 38.1 92.2 12.7 23.0 56.2 10.3 30.7 76.6 13.2 38.1 92.2

DCR 14413 13.2 38.1 92.2 12.7 23.0 56.2 10.3 30.7 76.6 13.2 38.1 92.2

DCR 14417 13.2 38.1 92.2 12.7 23.0 56.2 10.3 30.7 76.6 13.2 38.1 92.2

DCR 14421 13.2 38.1 92.2 12.7 23.0 56.2 10.3 30.7 76.6 13.2 38.1 92.2

DCR 1925 4.2 11.5 27.3 4.0 7.1 16.8 3.2 9.2 22.7 4.2 11.5 27.3

DCR 1927 7.9 21.6 51.4 7.6 13.4 31.6 6.1 17.4 42.7 7.9 21.6 51.4

DCR 1929 10.6 28.9 68.9 10.2 18.0 42.1 8.2 23.3 57.2 10.6 28.9 68.9

DCR 19211 14.8 41.8 99.4 14.3 25.5 61.2 11.6 33.6 82.2 14.8 41.8 99.4

DCR 19213 18.0 51.1 122.1 17.4 31.1 75.0 14.1 41.1 101.0 18.0 51.1 122.1

DCR 19217 18.0 51.1 122.1 17.4 31.1 75.0 14.1 41.1 101.0 18.0 51.1 122.1

DCR 19221 18.0 51.1 122.1 17.4 31.1 75.0 14.1 41.1 101.0 18.0 51.1 122.1

Data given in accordance with ARI-Standard 710-2004 for te = 4.4 °C and tc = 32.2 °C

-40 -20 4.4 -30 -20 4.4 -40 -20 4.4 -40 -20 4.4

Pressure drop ∆p [bar]

0.04 0.10 0.21 0.04 0.07 0.14 0.04 0.10 0.21 0.04 0.10 0.21

R22 / R407C R134a R404A / R507 R410A

© Danfoss A/S | DCS (sw) | 2017.02

Strainer mounted in suction line, type 48-F

Refrigerant R22 / R407C R134a R404A / R507 R410A

Evaporating temperature [°C] -40 -20 4.4 -30 -20 4.4 -40 -20 4.4 -40 -20 4.4

Pressure drop ∆p [bar] 0.04 0.10 0.21 0.04 0.07 0.14 0.04 0.10 0.21 0.04 0.10 0.21

Recommended system capacity [kW] 15 47 113 15 28 69 12 38 93 15 47 113

Strainer mounted in liquid line

Refrigerant R22 / R407C R134a R404A / R507 R410A

Recommended system capacity [kW] 390 350 260 390

The data given apply to DCR 04811 with 48-F core Liquid capacity is given in accordance with ARI 710-2004 for:

– te= -15 °C

– tc= 30 °C

– Δp = 0.07 bar

DKRCC.PD.EJ0.1A.02 | 4

Page 5

Data sheet | ELIMINATOR® lter drier with replaceable solid core, type DCR

Type of connector and

recommended soldering

material

Copper ODF solder connector

Copper pipe

Steel ODF solder connector

Copper pipe

Steel butt weld connector

Steel pipe

Ordering DCR housing and insert are ordered separately.

Select housing and top cover with all internal

Table 1. Housing with copper connectors + top cover

Type

DCR 0485s 1

DCR 0487s 1

DCR 0487s 1

DCR 0489s 1 – 28 Plug 46 023U7252

DCR 0489s 1 11⁄8 – Plug 46 023U7253

DCR 0489s 1 – 28 – 46 023U7268

DCR 04811s 1 13⁄8 35 Plug 46 023U7254

DCR 04813s 1 15⁄8 – Plug 46 023U7255

DCR 04813s 1 – 42 Plug 46 023U7256

DCR 04813s 1 – 42 – 46 023U7303

DCR 04817s 1 21⁄8 54 Plug 46 023U7257

DCR 04821s 1 25⁄8 – Plug 46 023U7276

DCR 0967s 2

DCR 0969s 2 – 28 Plug 46 023U7259

DCR 0969s 2 11⁄8 – Plug 46 023U7260

DCR 0969s 2 11⁄8 – – 46 023U7278

DCR 09611s 2 13⁄8 35 Plug 46 023U7261

DCR 09613s 2 15⁄8 – Plug 46 023U7262

DCR 09613s 2 – 42 Plug 46 023U7263

DCR 09613s 2 – 42 – 46 023U7463

DCR 09617s 2 21⁄8 54 Plug 46 023U7264

DCR 09617s 2 21⁄8 54 – 46 023U7290

DCR 09621s 2 25⁄8 – Plug 46 023U7281

DCR 1449s 3 – 28 Plug 351) / 462) 023U7265

DCR 14411s 3 13⁄8 35 Plug 351) / 462) 023U7267

DCR 14411s 3 13⁄8 – – 351) / 462) 023U7275

DCR 14413s 3 15⁄8 – Plug 351) / 462) 023U7282

DCR 14413s 3 – 42 Plug 351) / 462) 023U7269

DCR 14413s 3 15⁄8 42 – 351) / 462) 023U7297

DCR 14417s 3 21⁄8 54 Plug 351) / 462) 023U7270

DCR 19211s 4 13⁄8 – – 281) / 402) 023U7083

DCR 19213s 4 15⁄8 – Plug 281) / 402) 023U7272

DCR 19213s 4 – 42 Plug 281) / 402) 023U7273

DCR 19213s 4 15⁄8 – – 281) / 402) 023U7082

DCR 19217s 4 21⁄8 54 Plug 281) / 402) 023U7274

1

) For usage with strainer or as a receiver application

2

) For “drier” application using all the permissible cores

Number of

cores

Copper connectors

Solder ODF

[in.] [mm]

5

⁄8 16 Plug 46 023U7250

7

⁄8 22 Plug 46 023U7251

7

⁄8 22 – 46 023U7571

7

⁄8 22 Plug 46 023U7258

Solder connector Recommended soldering material

Copper Min. 5% Ag

Steel Silver-o 55 + Easy-ow ux

parts assembled from table 1 or 2 and required

number of inserts from table 3.

Max. working

Cover type

pressure PS

[bar]

Code number

© Danfoss A/S | DCS (sw) | 2017.02

DKRCC.PD.EJ0.1A.02 | 5

Page 6

Data sheet | ELIMINATOR® lter drier with replaceable solid core, type DCR

Ordering

(continued)

Table 2. Housing with steel connectors + top cover

Type

Number of

cores

DCR 0485 1

DCR 0487 1

DCR 0487 1

Solder ODF

[in.] [mm]

5

⁄8 16

7

⁄8 22

7

⁄8 22

Butt weld

Cover type

[in.] [bar]

1

⁄2 Plug 46 023U7050

3

⁄4 Plug 46 023U7051

3

⁄4 – 46 023U7151

DCR 0489 1 – 28 1 Plug 46 023U7052

DCR 0489 1 11⁄8 – 1 Plug 46 023U7053

DCR 04811 1 13⁄8 35 11⁄4 Plug 46 023U7054

DCR 04813 1 15⁄8 – 11⁄2 Plug 46 023U7055

DCR 04813 1 – 42 11⁄2 Plug 46 023U7056

DCR 04817 1 21⁄8 54 2 Plug 46 023U7057

DCR 04821 1 25⁄8 – 21⁄2 Plug 46 023U7076

Steel connectors

DCR 0967 2

7

⁄8 22

3

⁄4 Plug 46 023U7058

DCR 0969 2 – 28 1 Plug 46 023U7059

DCR 0969 2 11⁄8 – 1 Plug 46 023U7060

DCR 09611 2 13⁄8 35 11⁄4 Plug 46 023U7061

DCR 09611 2 13⁄8 35 11⁄4 – 46 023U7161

DCR 09613 2 15⁄8 – 11⁄2 Plug 46 023U7062

DCR 09613 2 – 42 11⁄2 Plug 46 023U7063

DCR 09617 2 21⁄8 54 2 Plug 46 023U7064

DCR 1449 3 – 28 1 Plug 35 1) / 46 2) 023U7065

DCR 1449 3 11⁄8 – 1 Plug 35 1) / 46 2) 023U7066

DCR 14411 3 13⁄8 35 11⁄4 Plug 35 1) / 46 2) 023U7067

DCR 14413 3 15⁄8 – 11⁄2 Plug 35 1) / 46 2) 023U7068

DCR 14413 3 – 42 11⁄2 Plug 35 1) / 46 2) 023U7069

DCR 14417 3 21⁄8 54 2 Plug 35 1) / 46 2) 023U7070

DCR 19211 4 13⁄8 35 11⁄4 Plug 28 1) / 40 2) 023U7071

DCR 19213 4 15⁄8 – 11⁄2 Plug 28 1) / 40 2) 023U7072

DCR 19213 4 – 42 11⁄2 Plug 28 1) / 40 2) 023U7073

DCR 19217 4 21⁄8 54 2 Plug 28 1) / 40 2) 023U7074

DCR 19221 4 25⁄8 – 21⁄2 Plug 28 1) / 40 2) 023U7086

1

) For usage with strainer or as a receiver application

2

) For “drier” application using all the permissible cores

Max.

working

pressure PS

Code number

Table 3. Type DCR, inserts

Code number

Type Material

Industrial pack

(8 pcs.)

with gasket without gasket with gasket

48-DM solid core 100% molecular sieve 023U1392 023U1393 023U1391

48-DC solid core 80% molecular sieve & 20% Al

48-DA solid core 30% molecular sieve & 70% Al

O

3

2

O

3

2

023U4381 023U4382 023U4380

023U5381 023U5382 023U5380

48-F strainer Felt-gasket, 15 µm 023U1921 – –

1) Not for usage with DCR 048 – 192 housings

Core surface

DM 048, DC 048 and DA 048 = 612 cm

DM 096, DC 096 and DA 096 = 1225 cm

DM 144, DC 144 and DA 144 = 1837 cm

DM 192, DC 192 and DA 192 = 2450 cm

48-F = 405 cm

2

2

2

2

2

Core volume

DM 048, DC 048 and DA 048 = 727 cm

DM 096, DC 096 and DA 096 = 1454 cm

DM 144, DC 144 and DA 144 = 2181 cm

DM 192, DC 192 and DA 192 = 2908 cm

Multi pack

(3 pcs.)

3

3

3

3

© Danfoss A/S | DCS (sw) | 2017.02

DKRCC.PD.EJ0.1A.02 | 6

Page 7

Data sheet | ELIMINATOR® lter drier with replaceable solid core, type DCR

Core selection

Identication

Refrigerant and oil types DC DM DA

HFC (R134a, R404A, R507, R407C and R410A) Recommended Recommended Recommended

Refrigerant

HFO (R1234ze, R407F, R407A) Recommended Recommended Recommended

HCFC (R22) Recommended Recommended Recommended

Mineral or AB Recommended Recommended Recommended

Oil

POE or PAG, pure Recommended Recommended Recommended

POE or PAG, with additives Not recommended1) Recommended Recommended

1

) DC lter driers cores contain activated alumina, which is a polar material used for acid adsorption. Many oil additives are also

polar substances and can be adsorbed by the activated alumina, rendering them useless, and reducing the drier’s acid capacity,

though this is not harmful to the system.

Type codes

Type Code Description

Filter drier D Drier

Solid core

Size (volume)

Connection (lter connection

in 1/8 of an inch increments)

C Solid core

R Replaceable

048 48 in

096 96 in

144 144 in

192 192 in

5

7

3

3

3

3

5

⁄8 in. / 16 mm

7

⁄8 in. / 22 mm

9 11⁄8 in. / 28 mm

11 13⁄8 in. / 35 mm

13 15/8 in. / 42 mm

17 21⁄8 in. / 54 mm

21 2 5/8 in.

Connection type

(blank) Steel connectors

s Copper connectors

Example for type codes

D C R 096 9 s

Filter drier

Solid core

Replaceable

Size (volume)

Connection (lter connection

Connection type

⁄8 of an inch increments)

1

in

© Danfoss A/S | DCS (sw) | 2017.02

DKRCC.PD.EJ0.1A.02 | 7

Page 8

Danfoss

23M76.14

Dan

23M69.17

1

10

11

12

13

10

13

10

14

15

16

17

18

16

19

Data sheet | ELIMINATOR® lter drier with replaceable solid core, type DCR

Design / Function

Example:

2

3

4

5

6

7

8

9

9

1. Plug 1⁄4 in. NPT

2. Top cover bolts

M8 × 35, class 10.9

3. Top cover

4. Spring

5. Top cover gasket

ø121.8 × ø113.6 × 0.8 mm

6. Wing nut

M10 (torque max. 3 Nm)

7. Lock washer

8. Top plate

9. Felt gasket

ø95.5 × ø45.5 × 2 mm

10. Solid core

11. Extension rod

12. Extension nut

13. Core plate

14. Distance rod

15. Wire mesh

16. Felt gasket

ø95.5 × ø78 × 2 mm

17. Core holder

18. Hex socket head screw M6

19. Filter drier shell

9

9

9

9

foss

© Danfoss A/S | DCS (sw) | 2017.02

DKRCC.PD.EJ0.1A.02 | 8

Page 9

Danf

already on order pro

All trademarks in this material are property of the respec

Dimensions and weights DCR housing

Danfoss

23M93.13

Plug 1/4 in. NPT

Danfoss

23M92.11

138.4

42

93.5

Danfoss

23M18.16

DCR solid core

DCR top cover

48-DM, 48-DC and 48-DA

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

© Danfoss A/S | DCS (sw) | 2017.02

Type

Number

of cores

DCR with steel connectors DCR with copper connectors

L L1L2L3L4H1H5L L1L2L3L4H1H

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [Kg]

5

Net

weight1)

DCR 0485(s) 1 242.9 162.7 170 12 12 96.8 21 259.9 179.7 170 12 12 112.8 19 5.2

DCR 0487(s) 1 237 156.8 170 17 17 90.3 27 259.5 179.3 170 17 17 112.8 25 5.2

DCR 0489(s) 1 240.4 160.2 170 22 22 94.3 34 261.9 181.7 170 20 20 115.8 32 5.2

DCR 0489(s) 1 240.4 160.2 170 22 22 94.3 34 261.9 181.7 170 20 20 115.8 32 5.2

DCR 04811(s) 1 242.8 162.6 170 25 25 97.3 42 264.3 184.1 170 25 25 118.8 39 5.2

DCR 04813(s) 1 248 167.8 170 29 29 103.3 48 265.5 185.3 170 29 29 120.8 46 5.2

DCR 04813(s) 1 248 167.8 170 29 29 103.3 48 265.5 185.3 170 29 29 120.8 46 5.2

DCR 04817(s) 1 253.7 173.5 170 33 33 110.8 60 267.7 187.5 170 34 34 124.8 58 5.2

DCR 04821(s) 1 256.5 176.3 170 38 38 115.8 73 269.5 189.3 170 34 34 128.8 71 5.2

DCR 0965(s) 2 381.9 301.7 310 12 12 96.8 21 398.9 318.7 310 12 12 112.8 19 6.6

DCR 0967(s) 2 376 295.8 310 17 17 90.3 27 398.5 318.3 310 17 17 112.8 25 6.6

DCR 0969(s) 2 379.4 299.2 310 22 22 94.3 34 400.9 320.7 310 20 20 115.8 32 6.6

DCR 0969(s) 2 379.4 299.2 310 22 22 94.3 34 400.9 320.7 310 20 20 115.8 32 6.6

DCR 09611(s) 2 381.8 301.6 310 25 25 97.3 42 403.3 323.1 310 25 25 118.8 39 6.6

DCR 09613(s) 2 387 306.8 310 29 29 103.3 48 404.5 324.3 310 29 29 120.8 46 6.6

DCR 09613(s) 2 387 306.8 310 29 29 103.3 48 404.5 324.3 310 29 29 120.8 46 6.6

DCR 09617(s) 2 392.7 312.5 310 33 33 110.8 60 406.7 326.5 310 34 34 124.8 58 6.6

DCR 09621(s) 2 395.5 315.3 310 38 38 115.8 73 408.5 328.3 310 34 34 128.8 71 6.6

DCR 1445(s) 3 523.9 443.7 310 12 12 96.8 21 540.9 460.7 310 12 12 112.8 19 7.8

DCR 1447(s) 3 518 437.8 310 17 17 90.3 27 540.5 460.3 310 17 17 112.8 25 7.8

DCR 1449(s) 3 521.4 441.2 310 22 22 94.3 34 542.9 462.7 310 20 20 115.8 32 7.8

DCR 1449(s) 3 521.4 441.2 310 22 22 94.3 34 542.9 462.7 310 20 20 115.8 32 7.8

DCR 14411(s) 3 523.8 443.6 310 25 25 97.3 42 545.3 465.1 310 25 25 118.8 39 7.8

DCR 14413(s) 3 529 448.8 310 29 29 103.3 48 546.5 466.3 310 29 29 120.8 46 7.8

DCR 14413(s) 3 529 448.8 310 29 29 103.3 48 546.5 466.3 310 29 29 120.8 46 7.8

DCR 14417(s) 3 534.7 454.5 310 33 33 110.8 60 548.7 468.5 310 34 34 124.8 58 7.8

DCR 14421(s) 3 537.5 457.3 310 38 38 115.8 73 550.5 470.3 310 34 34 128.8 71 7.8

DCR 1925(s) 4 663.9 583.7 310 12 12 96.8 21 680.9 600.7 310 12 12 112.8 19 9.1

DCR 1927(s) 4 658 577.8 310 17 17 90.3 27 680.5 600.3 310 17 17 112.8 25 9.1

DCR 1929(s) 4 661.4 581.2 310 22 22 94.3 34 682.9 602.7 310 20 20 115.8 32 9.1

DCR 1929(s) 4 661.4 581.2 310 22 22 94.3 34 682.9 602.7 310 20 20 115.8 32 9.1

DCR 19211(s) 4 663.8 583.6 310 25 25 97.3 42 685.3 605.1 310 25 25 118.8 39 9.1

DCR 19213(s) 4 669 588.8 310 29 29 103.3 48 686.5 606.3 310 29 29 120.8 46 9.1

DCR 19213(s) 4 669 588.8 310 29 29 103.3 48 686.5 606.3 310 29 29 120.8 46 9.1

DCR 19217(s) 4 674.7 594.5 310 33 33 110.8 60 688.7 608.5 310 34 34 124.8 58 9.1

DCR 19221(s) 4 677.5 597.3 310 38 38 115.8 73 690.5 610.3 310 34 34 128.8 71 9.1

1

) Without core.

For total weight add 0.7 kg per core for 48-DM and 48-DC, 0.8 kg per core for 48-DA or 0.4 kg per strainer 48-F

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

DKRCC.PD.EJ0.1A.02 | 9

Loading...

Loading...