Page 1

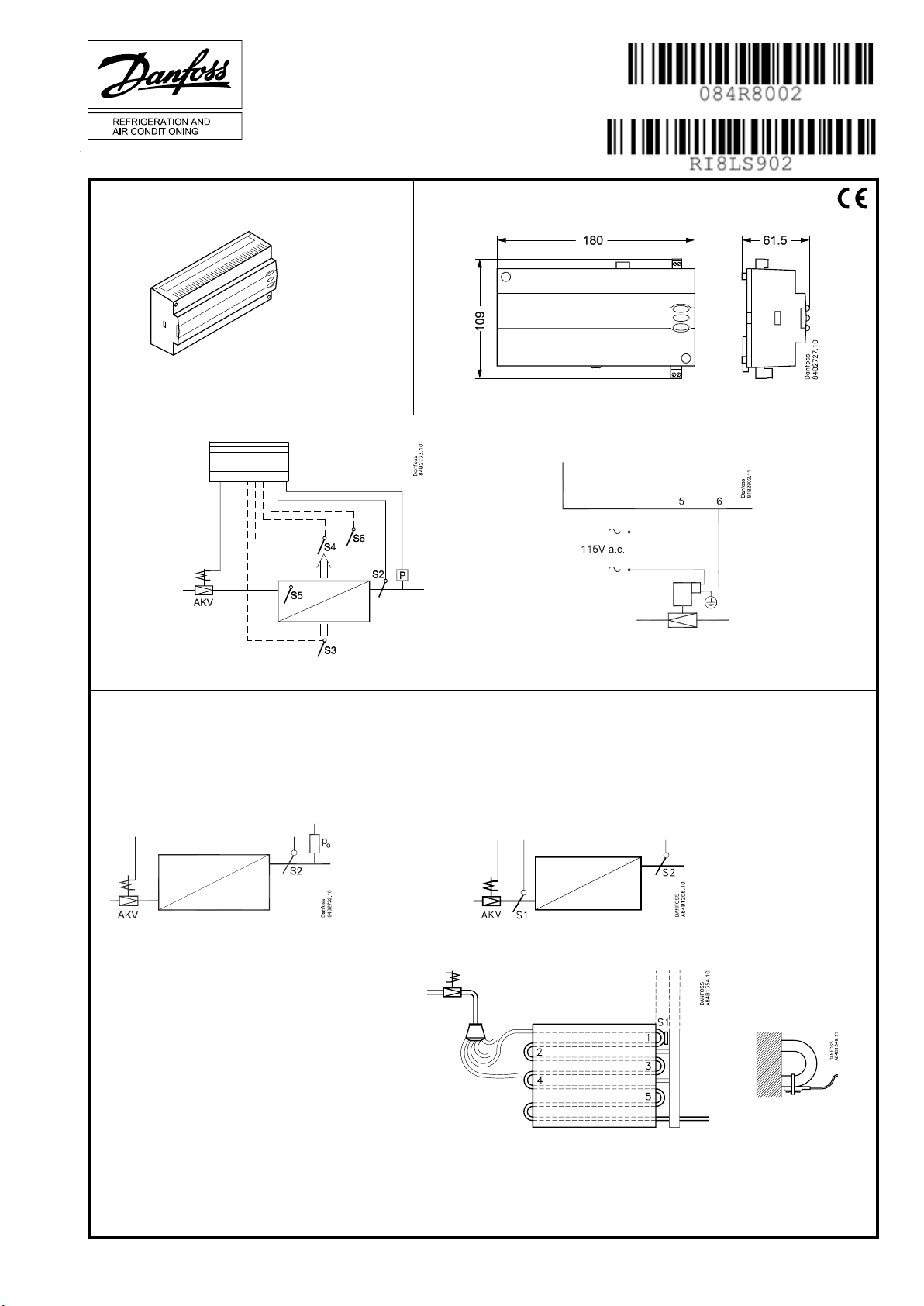

Instructions

AK-CC 550

115 V

Identication

Principle

Dimensions

084B8024

AKV:

115 V a.c. coil

115 V c.a. Bobine

Selection of signal to superheat measurement. Pressure transmitter or temperature sensor S1

S1, S2:

Insulate sensors

Sensores aislados

Place S1 on the rst U-bend of the second-lowest evaporator passage

Montar S1 en la primera curva en U del serpentín correspondiente a la penúltima

tubería del distribuidor

RI8LS902 06-2015

Page 2

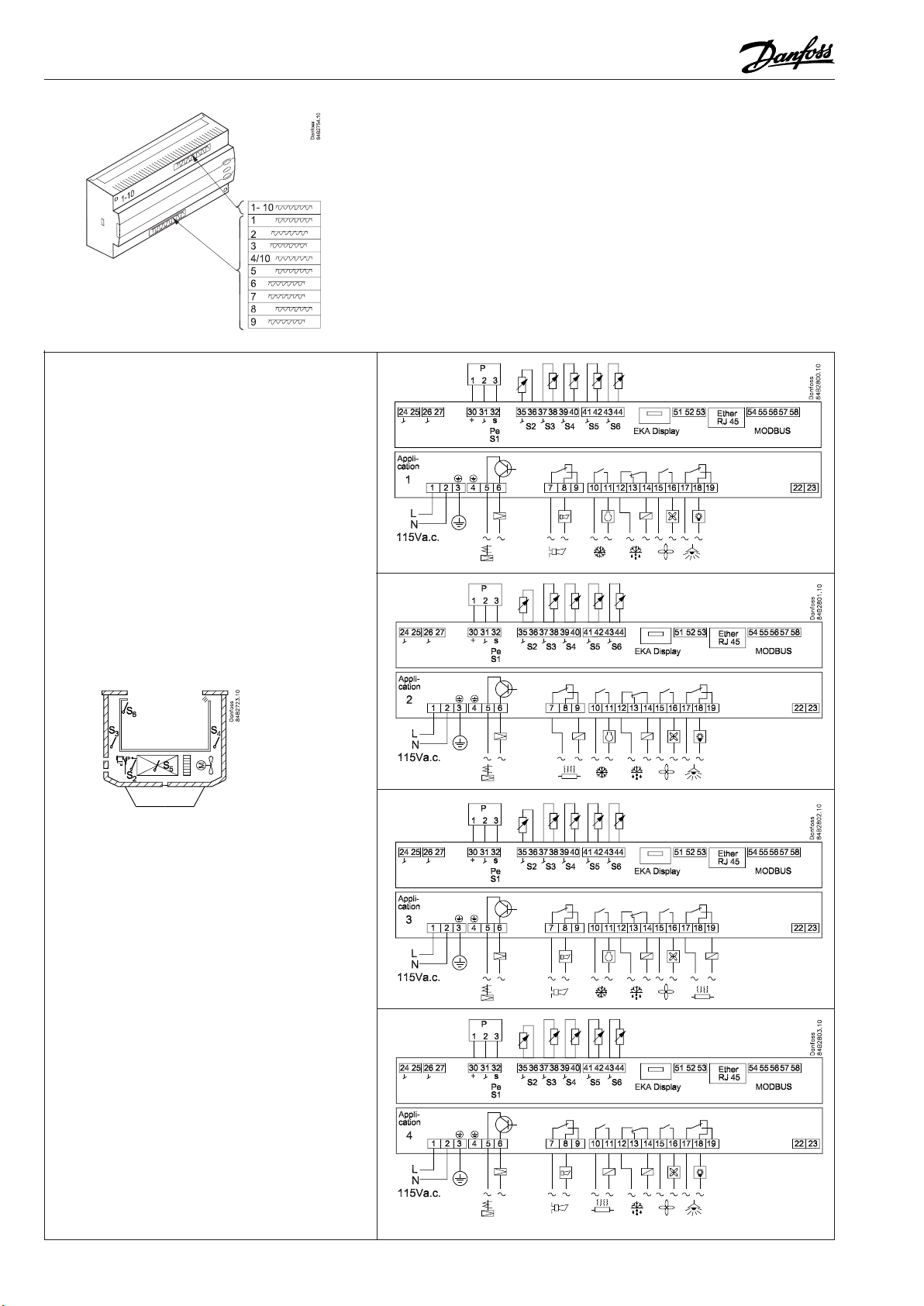

The controller is provided with signs from the factory indicating application 1.

If you employ another use, signs are provided so that you can mount the relevant one.

1

1 - 8

2

3

4

2 Instructions RI8LS902 © Danfoss 06/2015 AK-CC 550 - 115 V

Page 3

5

6

7

9

8

9

10

10

AK-CC 550 - 115 V Instructions RI8LS902 © Danfoss 06/2015 3

Page 4

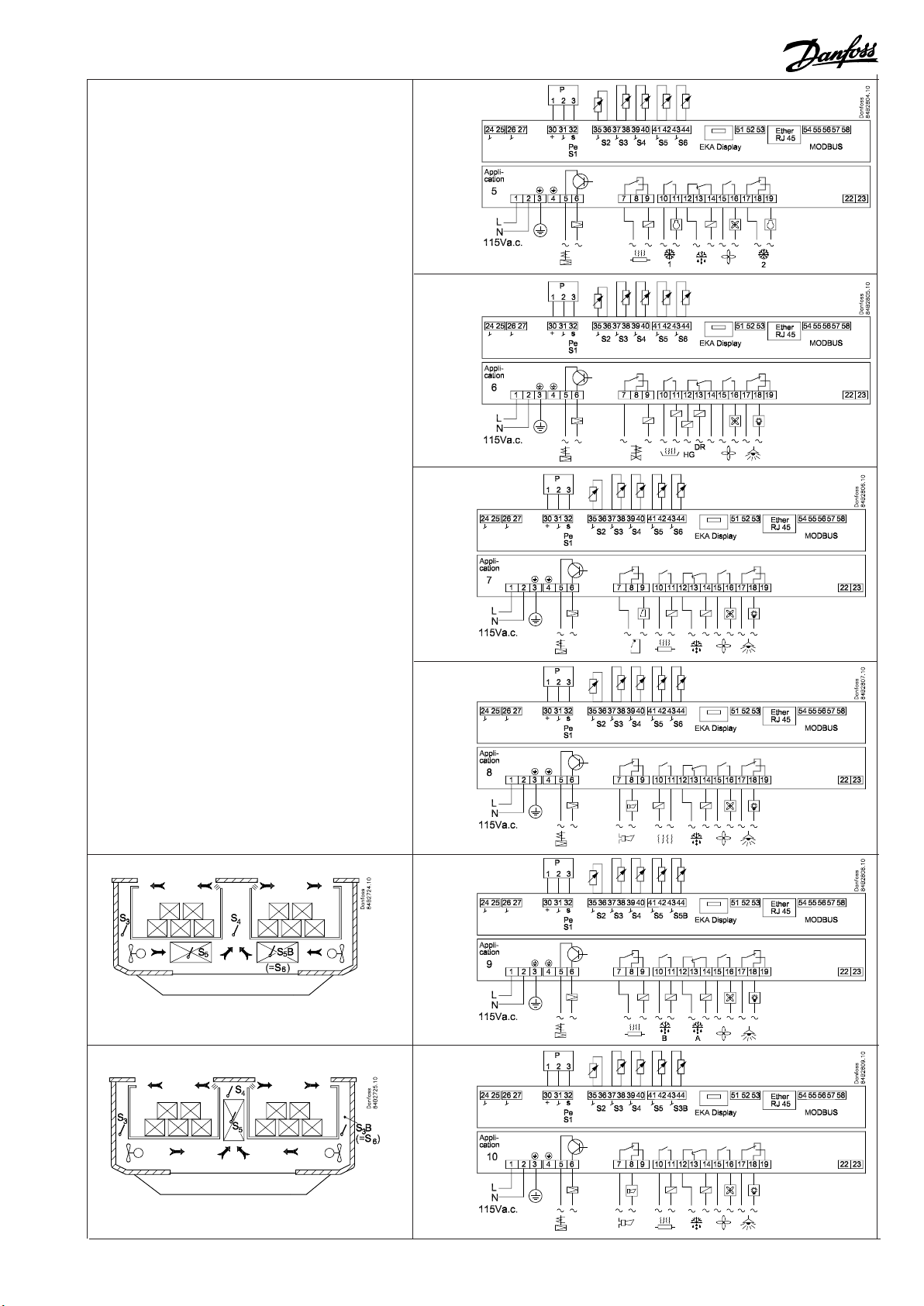

Data communication

Important All connections to the data communication MODBUS and RS 485 must comply

with the requirements for data communication cables. See literature: RC8AC.

System manager

/ Gateway

Display EKA 163 / 164

L < 15 m

L > 15 m

AK-SM.... AKA 245 version 6.20+ /

AK-SM...

OEM

Address o03 > 0

4 Instructions RI8LS902 © Danfoss 06/2015 AK-CC 550 - 115 V

Page 5

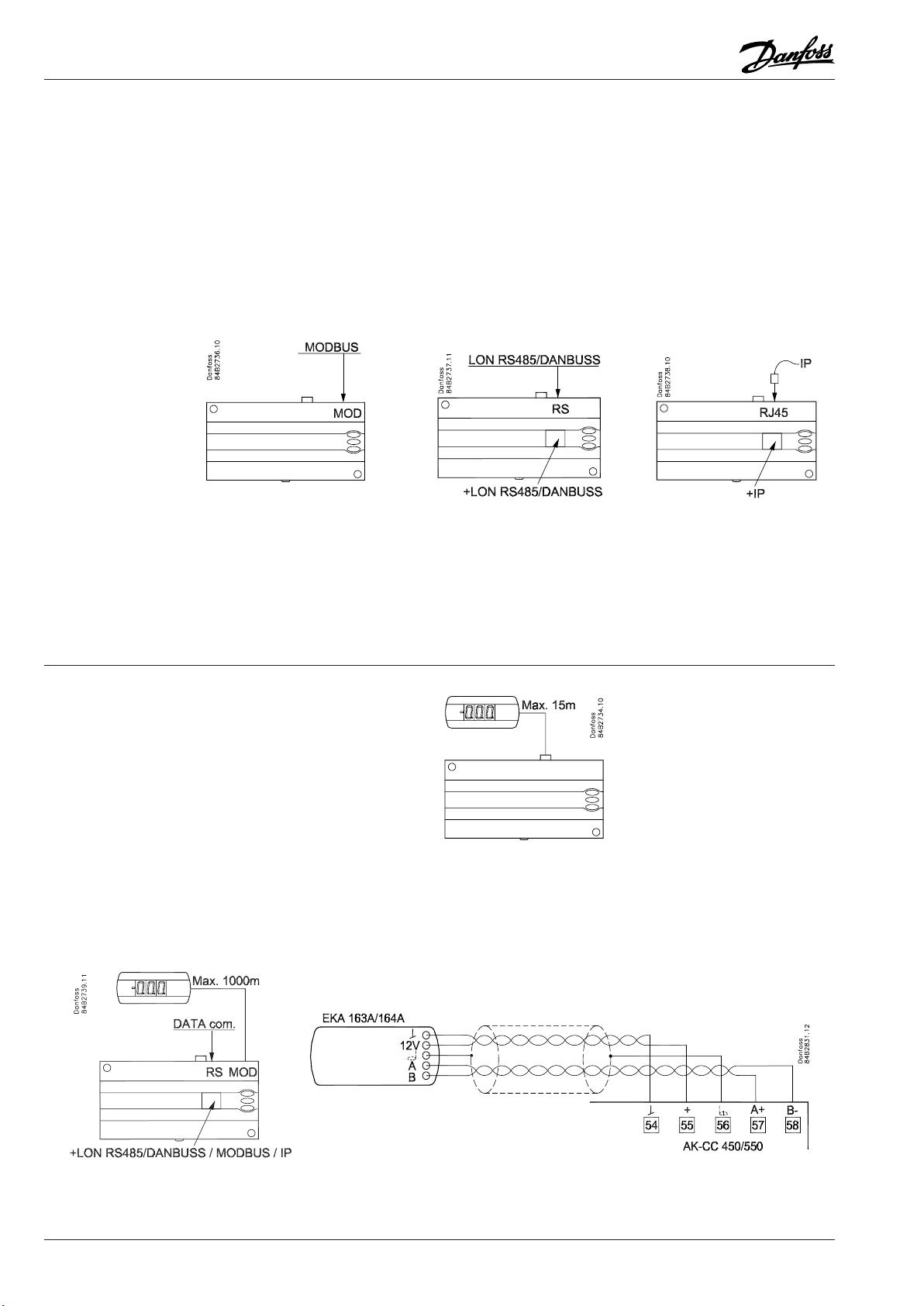

Connections

English

Overview of outputs and

applications.

See also electrical diagrams earlier

in the instruction

DI1

Digital input signal.

The dened function is active when the input is short-circuited/

opened. The function is dened in o02.

DI2

Digital input signal.

The dened function is active when the input is short-circuited/

opened. The function is dened in o37.

Pressure transmitter or temperature sensor S1

Pe / AKS 32R (pressure measurement recommended)

Connect to terminal 30, 31 and 32.

The signal from one pressure transmitter can be received by up

to 10 controllers. But only if there are no signicant pressure

decreases between the evaporators to be controlled.

If use with 060G1034 cable, 1=black, 2=blue, 3=brown

S1 (correct location is important to ensure correct measurements)

Pt 1000 ohm sensor

Connect to terminal 31 and 32.

S2

Pt 1000 ohm sensor

S3, S4, S5, S6

Pt 1000 ohm sensor or PTC 1000 ohm sensor. All have to be of

the same type.

S3, air sensor, placed in the warm air before the evaporator

S4, air sensor, placed in the cold air after the evaporator

(the need for either S3 or S4 can be deselected in the

conguration)

S5, defrost sensor, placed on the evaporator

S6, product sensor or defrost sensor B or air sensor B.

The conguration determines which.

Application DO1 DO2 DO3 DO4 DO5 DO6 DI1 DI2 DI3 AI1 AI2 AI3 AI4 AI5 AI6

1

2

3

4

5

6

7

8

9

10

• • •

• • •

• • •

• • •

• • •

suction

Blinds

heat

hotgas

2 1

• • •

• • •

• • •

• • •

• • •

EKA Display

If there is be external reading/operation of the controller, display

type EKA 163B or EKA 164B can be connected.

RS485 (terminal 51, 52, 53)

For data communication, but only if a data communication

module is inserted in the controller. The module can be a LON

RS485 or a MODBUS.

Terminal 51 = screen

Terminal 52 = A (A+)

Terminal 53 = B (B-)

(For LON RS485 and gateway type AKA 245 the gateway must be

version 6.20 or higher.)

RJ45

For data communication, but only if a TCP/IP module is inserted in

the controller. (OEM)

MODBUS

For data communication.

Terminal 56 = screen

Terminal 57 = A+

Terminal 58 = B(Alternatively the terminals can be connected to an external

display type EKA 163A or 164A, but then they cannot be used

for data communication. Any data communication must then be

carried out by one of the other methods.)

Supply voltage

115 V a.c., 50/60 Hz

P0/S1 S2 S3 S4 S5 S6

P0/S1 S2 S3 S4 S5 S6

P0/S1 S2 S3 S4 S5 S6

P0/S1 S2 S3 S4 S5 S6

P0/S1 S2 S3 S4 S5 S6

P0/S1 S2 S3 S4 S5 S6

P0/S1 S2 S3 S4 S5 S6

P0/S1 S2 S3 S4 S5 S6

P0/S1 S2 S3 S4 S5 S5B

P0/S1 S2 S3 S4 S5 S3B

AK-CC 550 - 115 V Instructions RI8LS902 © Danfoss 06/2015 5

Page 6

DO1

Connection of expansion valve type AKV or AKVA. The coil must

be a 115 V a.c. coil.

DO2

Alarm

There is a connection between terminal 7 and 8 in alarm

situations and when the controller is without power.

Rail heat and heating element in drip tray

There is connection between terminal 7 and 9 when heating

takes place.

Night blind

There is connection between terminal 7 and 9 when the night

blind is up.

Suction line valve

There is connection between terminal 7 and 9 when the

suction line must be open.

DO6

Light relay

There is connection between terminal 17 and 18 when the

light must be on.

Rail heat, Compressor 2

There is connection between terminal 17 and 19 when the

function must be active.

DI3

Digital indput signal.

The signal must have a voltage of 0 / 115 V AC.

The function is dened in o84.

Data communication

If data communication is used, it is important that the installation

of the data communication cable is performed correctly.

See separate literature No. RC8AC…

DO3

Refrigeration, Rail heat, Heat function, Defrost 2

There is connection between terminal 10 and 11 when the

function must be active.

Heating element in drip tray

There is connection between terminal 10 and 11 when heating

takes place.

DO4

Defrost

There is connection between terminal 12 and 14 when

defrosting takes place.

Hot gas / drain valve

There is connection between terminal 13 and 14 during normal

operation.

There is connection between terminal 12 and 14 when the hot

gas valves must open.

DO5

Fan

There is connection between terminal 15 and 16 when the fan

is on.

Coordinated defrost via

cable connections

Electric noise

Cables for sensors, DI inputs and data communication must be

kept separate from other electric cables:

- Use separate cable trays

- Keep a distance between cables of at least 10 cm

- Long cables at the DI input should be avoided

Installation considerations

Accidental damage, poor installation, or site conditions, can give

rise to malfunctions of the control system, and ultimately lead to a

plant breakdown.

Every possible safeguard is incorporated into our products to

prevent this. However, a wrong installation, for example, could still

present problems. Electronic controls are no substitute for normal,

good engineering practice.

Danfoss wil not be responsible for any goods, or plant components, damaged as a result of the above defects. It is the installer's

responsibility to check the installation thoroughly, and to t the

necessary safety devices.

Special reference is made to the necessity of signals to the

controller when the compressor is stopped and to the need of

liquid receivers before the compressors.

Your local Danfoss agent will be pleased to assist with further

advice, etc.

Max. 10

The following controllers can be connected

up in this way:

EKC 204A, AK-CC 210, AK-CC 250,

AK-CC 450, AK-CC 550,

Refrigeration is resumed when all

controllers have “released” the signal for

defrost.

Coordinated defrost via

data communication

The setting of controllers to coordinate

their defrosting takes place in the

gateway/system manager.

Refrigeration is resumed when all

controllers have “released” the signal for

defrost.

6 Instructions RI8LS902 © Danfoss 06/2015 AK-CC 550 - 115 V

Page 7

Operation

Display

The values will be shown with three digits, and with a setting you

can determine whether the temperature is to be shown in °C or in

°F.

Light-emitting diodes (LED) on front panel

The LED’s on the front panel will light up when the relevant relay

is activated.

= Refrigeration

= Defrost

= Fan running

The light-emitting diodes will ash when there is an alarm.

In this situation you can download the error code to the display

and cancel/sign for the alarm by giving the top button a brief

push.

The buttons

When you want to change a setting, the upper and the lower

buttons will give you a higher or lower value depending on the

button you are pushing. But before you change the value, you

must have access to the menu. You obtain this by pushing the

upper button for a couple of seconds - you will then enter the column with parameter codes. Find the parameter code you want to

change and push the middle buttons until value for the parameter

is shown. When you have changed the value, save the new value

by once more pushing the middle button.

Examples

Set menu

1. Push the upper button until a parameter r01 is shown

2. Push the upper or the lower button and nd that parameter you

want to change

3. Push the middle button until the parameter value is shown

4. Push the upper or the lower button and select the new value

5. Push the middle button again to freeze the value.

Cutout alarm relay / receipt alarm/see alarm code

• A short press of the upper button

If there are several alarm codes they are found in a rolling stack.

Push the uppermost or lowermost button to scan the rolling

stack.

Get a good start

With the following procedure you can start regulation very quickly:

1 Open parameter r12 and stop the regulation (in a new and not

previously set unit, r12 will already be set to 0 which means

stopped regulation.)

2 Select electrical connection based on the drawings on page 2

and 3

3 Open parameter o61 and set the electric connection number in

it

4 Now select one of the preset settings from the table

Auxillary schedule for

settings (quick-setup)

Preset settings (o62) 1 2 3 4 5 6

Temperature (SP)

Max. temp. setting (r02)

Min. temp. setting (r03)

Sensor signal for thermostat. S4% (r15)

Alarm limit high (A13)

Alarm limit low (A14)

Sensor signal for alarm

funct.S4% (A36)

Interval between defrost

(d03)

Defrost sensor: 0=time,

1=S5, 2=S4 (d10)

DI1 cong. (o02)

Sensor signal for display

view S4% (017)

Note: For applications 9 and 10 the sensor weighting for the S3/S4 sensors is not used for the

thermostat, alarm thermostat and display readings as the sensor uses are predened.

Case Room

Defrost stop on Defrost stop on

time S5 time S5

2°C -2°C -28°C 4°C 0°C -22°C

6°C 4°C -22°C 8°C 5°C -20°C

0°C -4°C -30°C 0°C -2°C -24°C

100% 0%

8°C 6°C -15°C 10°C 8°C -15°C

-5°C -5°C -30°C 0°C 0°C -30°C

0% 100% 0%

6 h 6h 12h 8h 8h 6h

0 1 1 0 1 1

Case cleaning (=10) Door function (=2)

0%

5 Open parameter o62 and set the number for the array of preset-

tings. The few selected settings will now be transferred to the

menu.

6 Open parameter n57 and select method for measuring of

evaporator pressure Pe or S1 (factory setting is Pe pressure

transmitter)

7 If pressure transmitter Pe is used you must select refrigerant via

parameter o30

8 Open parameter r12 and start the regulation

Set temperature

1. Push the middle button until the temperature value is shown

2. Push the upper or the lower button and select the new value

9 Go through the survey of factory settings. The values in the grey

cells are changed according to your choice of settings. Make any

necessary changes in the respective parameters.

3. Push the middle button again to conclude the setting.

10 For network. Set the address in o03

Reading the temperature at defrost sensor (Or product sensor, if

selected in o92.)

• A short press of the lower button

11 Send address to system unit:

• MODBUS: Activate scan function in system unit

• If another data communication card is used in the controller:

Manuel start or stop of a defrost

- LON RS485: Activate the function o04

• Push the lower button for four seconds.

AK-CC 550 - 115 V Instructions RI8LS902 © Danfoss 06/2015 7

Page 8

Menu survey

Parameter EL-diagram page 2 or 3

Function Code 1 2 3 4 5 6 7 8 9 10

Normal operation

Temperature (setpoint) - - - 1 1 1 1 1 1 1 1 1 1 -50°C 50°C 2

Thermostat

Dierential r01 1 1 1 1 1 1 1 1 1 1 0.1 K 20 K 2

Max. limitation of setpoint setting

Min. limitation of setpoint setting

Adjustment of temperature indication

Temperature unit (°C/°F)

Correction of the signal from S4

Correction of the signal from S3

Manual service, stop regulation, start regulation (-1, 0, 1)

Displacement of reference during night operation

Dene thermostat function

1=ON/OFF, 2=Modulating

Denition and weighting, if applicable, of thermostat sen-

sors - S4% (100%=S4, 0%=S3)

Time between melt periods

Duration of melt periods

Temperature setting for thermostat band 2 . As dierential

r02 1 1 1 1 1 1 1 1 1 1 -49°C 50°C 50

r03 1 1 1 1 1 1 1 1 1 1 -50°C 49°C -50

r04 1 1 1 1 1 1 1 1 1 1 -10 10 0

r05 1 1 1 1 1 1 1 1 1 1 0/°C 1/F 0/°C

r09 1 1 1 1 1 1 1 1 1 1 -10 K 10 K 0

r10 1 1 1 1 1 1 1 1 1 1 -10 K 10 K 0

r12 1 1 1 1 1 1 1 1 1 1 -1 1 0

r13 1 1 1 1 1 1 1 1 1 1 -50 K 50 K 0

r14 1 1 1 1 1 1 1 1 1 1 1 2 1

r15 1 1 1 1 1 1 1 1 0 % 100 % 100

r16 1 1 1 1 1 1 1 1 1 1 0 hrs 10 hrs 1

r17 1 1 1 1 1 1 1 1 1 1 0 min. 30 min. 5

r21 1 1 1 1 1 1 1 1 1 1 -50°C 50°C 2

use r01

Correction of the signal from S6 r59 1 1 1 1 1 1 1 1 1 -10 K 10 K 0

Denition and weighting, if applicable, of thermostat sensors when night cover is on. (100%=S4, 0%=S3)

Heat function

r61 1 0 % 100 % 100

r62 1 0 K 50 K 2

Neutral zone between refrigeration and heat function

Time delay at switch between refrigeration and heat

r63 1 0 min. 240 min. 0

function

Alarms

Delay for temperature alarm

Delay for door alarm

Delay for temperature alarm after defrost

High alarm limit for thermostat 1

Low alarm limit for thermostat 1

High alarm limit for thermostat 2

Low alarm limit for thermostat 2

High alarm limit for sensor S6 at thermostat 1

Low alarm limit for sensor S6 at thermostat 1

High alarm limit for sensor S6 at thermostat 2

Low alarm limit for sensor S6 at thermostat 2

S6 alarm time delay

With setting = 240 the S6 alarm will be omitted

Alarm time delay or signal on the DI1 input

Alarm time delay or signal on the DI2 input

Signal for alarm thermostat. S4% (100%=S4, 0%=S3)

A03 1 1 1 1 1 1 1 1 1 1 0 min. 240 min. 30

A04 1 1 1 1 1 1 1 1 1 1 0 min. 240 min. 60

A12 1 1 1 1 1 1 1 1 1 1 0 min. 240 min. 90

A13 1 1 1 1 1 1 1 1 1 1 -50°C 50°C 8

A14 1 1 1 1 1 1 1 1 1 1 -50°C 50°C -30

A20 1 1 1 1 1 1 1 1 1 1 -50°C 50°C 8

A21 1 1 1 1 1 1 1 1 1 1 -50°C 50°C -30

A22 1 1 1 1 1 1 1 1 1 -50°C 50°C 8

A23 1 1 1 1 1 1 1 1 1 -50°C 50°C -30

A24 1 1 1 1 1 1 1 1 1 -50°C 50°C 8

A25 1 1 1 1 1 1 1 1 1 -50°C 50°C -30

A26 1 1 1 1 1 1 1 1 1 0 min. 240 min. 240

A27 1 1 1 1 1 1 1 1 1 1 0 min. 240 min. 30

A28 1 1 1 1 1 1 1 1 1 1 0 min. 240 min. 30

A36 1 1 1 1 1 1 1 1 0 % 100 % 100

Delay for S6 (product sensor alarm) after defrost A52 1 1 1 1 1 1 1 1 1 0 min. 240 min. 90

Compressor

Min. ON-time c01 1 1 1 1 0 min. 30 min. 0

Min. OFF-time c02 1 1 1 1 0 min. 30 min. 0

Time delay for cutin of comp.2

c05 1 0 sec 999 sec 5

Defrost

Defrost method: 0=none, 1= EL, 2= Gas d01 1 1 1 1 1 1 1 1 1 1 0/No 2/GAs 1/EL

Defrost stop temperature

Interval between defrost starts

Max. defrost duration

Displacement of time on cutin of defrost at start-up

Drip o time

Delay for fan start after defrost

Fan start temperature

Fan cutin during defrost

d02 1 1 1 1 1 1 1 1 1 1 0°C 50°C 6

d03 1 1 1 1 1 1 1 1 1 1 0 hrs/O 240 hrs 8

d04 1 1 1 1 1 1 1 1 1 1 0 min. 360 min. 45

d05 1 1 1 1 1 1 1 1 1 1 0 min. 240 min. 0

d06 1 1 1 1 1 1 1 1 1 1 0 min. 60 min. 0

d07 1 1 1 1 1 1 1 1 1 1 0 min. 60 min. 0

d08 1 1 1 1 1 1 1 1 1 1 -50 °C 0 °C -5

d09 1 1 1 1 1 1 1 1 1 1 0 2 1

0: Stopped

1: Running

2: Running during pump down and defrost

Defrost sensor: 0 =Stop on time, 1=S5, 2=S4, 3=Sx

d10 1 1 1 1 1 1 1 1 1 1 0 3 0

(Application 1-8 and 10: both S5 and S6.

Application 9: S5 and S5B)

Min.-value Max.-value

Factory

setting

SW = 1.5x

Actual

setting

8 Instructions RI8LS902 © Danfoss 06/2015 AK-CC 550 - 115 V

Page 9

Continued Code 1 2 3 4 5 6 7 8 9 10 Min. Max. Fac. Actual

Pump down delay

d16 1 1 1 1 1 1 1 1 1 1 0 min. 60 min. 0

Drain delay (used at hot gas defrost only) d17 1 0 min. 60 min. 0

Max. aggregate refrigeration time between two defrosts

Heat in drip tray. Time from defrosting stops to heating

d18 1 1 1 1 1 1 1 1 1 1 0 hrs 48 hrs 0/OFF

d20 1 0 min. 240 min. 30

in the drip tray is switched o

Extra defrost with adaptive function allowed:

d21 1 1 1 1 1 1 1 1 1 1 0 4 0

0=none, 1=monitoring only, 2=Day only, 3=Both day

and night, 4=Night only

Reset of the "Adaptive defrosting function" (starts a

d22 1 1 1 1 1 1 1 1 1 1 0/OFF 1/ON 0/OFF

defrost and starts subsequent new tuning)

Injection control function

Injection algorithm

n05 1 1 1 1 1 1 1 1 1 1 30 sec 600 sec 150

Only for trained personnel

Max. value of superheat reference

Min. value of superheat reference

n09 1 1 1 1 1 1 1 1 1 1 3°C 20°C 12

n10 1 1 1 1 1 1 1 1 1 1 3°C 20°C 3

MOP temperature. O if MOP temp. = 15.0 °C n11 1 1 1 1 1 1 1 1 1 1 -50°C 15°C 15

Glide for Ezotrope refrigerant (at S1-measurement only) n12 1 1 1 1 1 1 1 1 1 1 0 K 10 K 0

Period time of AKV pulsation

Only for trained personnel

Injection algorithm

Only for trained personnel

Injection algorithm

Only for trained personnel

Injection algorithm

Only for trained personnel

Injection algorithm

Only for trained personnel

Injection algorithm

Only for trained personnel

Injection algorithm

Only for trained personnel

Selection of signal to superheat measurement: 1=

n13 1 1 1 1 1 1 1 1 1 1 3 sec 6 sec 6

n15 1 1 1 1 1 1 1 1 1 1 30 sec 600 sec 180

n16 1 1 1 1 1 1 1 1 1 1 10 % 75 % 30

n17 1 1 1 1 1 1 1 1 1 1 5 % 70 % 30

n18 1 1 1 1 1 1 1 1 1 1 0 10 4

n23 1 1 1 1 1 1 1 1 1 1 1 50 6

n24 1 1 1 1 1 1 1 1 1 1 100 sec 1800 sec 900

n57 1 1 1 1 1 1 1 1 1 1 1 2 1

pressure transmitter AKS32R, 2= Temperature sensor S1

Fan

Fan stop temperature (S5)

Pulse operation on fans: 0=No pulse operation, 1=At

F04 1 1 1 1 1 1 1 1 1 1 -50°C 50°C 50

F05 1 1 1 1 1 1 1 1 1 1 0 2 0

thermostat cuts out only, 2= Only at thermostat cut

outs during night operation

Period time for fan pulsation (on-time + o-time) F06 1 1 1 1 1 1 1 1 1 1 1 min. 30 min. 5

On-time in % of period time F07 1 1 1 1 1 1 1 1 1 1 0 % 100 % 100

Real time clock

Six start times for defrost.

Setting of hours.

0=OFF

Six start times for defrost.

Setting of minutes.

0=OFF

Clock - Setting of hours

Clock - Setting of minute

Clock - Setting of date

Clock - Setting of month

Clock - Setting of year

Miscellaneous

Delay of output signals after start-up

Input signal on DI1. Function:

0=not used. 1=status on DI1. 2=door function with alarm

when open. 3=door alarm when open. 4=defrost start

(pulse-signal). 5=ext.main switch. 6=night operation

7=thermostat band changeover (activate r21). 8=alarm

function when closed. 9=alarm function when open.

10=case cleaning (pulse signal). 11=forced cooling at hot

gas defrost, 12=night cover

Network address (0=o)

On/O switch (Service Pin message)

IMPORTANT! o61 must be set prior to o04

t01 -

1 1 1 1 1 1 1 1 1 1 0 hrs 23 hrs 0

t06

t11 -

1 1 1 1 1 1 1 1 1 1 0 min. 59 min. 0

t16

t07 1 1 1 1 1 1 1 1 1 1 0 hrs 23 hrs 0

t08 1 1 1 1 1 1 1 1 1 1 0 min. 59 min. 0

t45 1 1 1 1 1 1 1 1 1 1 1 day 31 day 1

t46 1 1 1 1 1 1 1 1 1 1 1 mon. 12 mon. 1

t47 1 1 1 1 1 1 1 1 1 1 0 year 99 year 0

o01 1 1 1 1 1 1 1 1 1 1 0 sec 600 sec 5

o02 1 1 1 1 1 1 1 1 1 1 0 12 0

o03 1 1 1 1 1 1 1 1 1 1 0 240 0

o04 1 1 1 1 1 1 1 1 1 1 0/O 1/On 0/O

(used at LON 485 only)

Access code 1 (all settings)

Used sensor type : 0=Pt1000, 1=Ptc1000, o06 1 1 1 1 1 1 1 1 1 1 0/Pt 1/Ptc 0/Pt

Max hold time after coordinated defrost

Select signal for display view. S4% (100%=S4, 0%=S3)

Pressure transmitter working range – min. value

Pressure transmitter working range – max. value

o05 1 1 1 1 1 1 1 1 1 1 0 100 0

o16 1 1 1 1 1 1 1 1 1 1 0 min. 360 min. 20

o17 1 1 1 1 1 1 1 1 0 % 100 % 100

o20 1 1 1 1 1 1 1 1 1 1 -1 bar 5 bar -1

o21 1 1 1 1 1 1 1 1 1 1 6 bar 200 bar 12

AK-CC 550 - 115 V Instructions RI8LS902 © Danfoss 06/2015 9

Page 10

Continued Code 1 2 3 4 5 6 7 8 9 10 Min. Max. Fac. Actual

Refrigerant setting:

o30 1 1 1 1 1 1 1 1 1 1 0 31 0

1=R12. 2=R22. 3=R134a. 4=R502. 5=R717. 6=R13.

7=R13b1. 8=R23. 9=R500. 10=R503. 11=R114.

12=R142b. 13=User dened. 14=R32. 15=R227.

16=R401A. 17=R507. 18=R402A. 19=R404A. 20=R407C.

21=R407A. 22=R407B. 23=R410A. 24=R170. 25=R290.

26=R600. 27=R600a. 28=R744. 29=R1270. 30=R417A.

31=R422A.

Input signal on DI2. Function:

(0=not used. 1=status on DI2. 2=door function with alarm

when open. 3=door alarm when open. 4=defrost start

(pulse-signal). 5=ext. main switch 6=night operation

7=thermostat band changeover (activate r21). 8=alarm

function when closed. 9=alarm function when open.

10=case cleaning (pulse signal). 11=forced cooling at hot

gas defrost.). 12=night cover, 13=coordinated defrost)

Conguration of light function: 1=Light follows day /night

o37 1 1 1 1 1 1 1 1 1 1 0 13 0

o38 1 1 1 1 1 1 1 1 1 4 1

operation, 2=Light control via data communication

via ‘o39’, 3=Light control with a DI-input, 4=As "2", but

light switch on and night cover will open if the network

cut out for more than 15 minutes.

Activation of light relay (only if o38=2) On=light o39 1 1 1 1 1 1 1 1 0/O 1/On 0/O

Rail heat On time during day operations

Rail heat On time during night operations

Rail heat period time (On time + O time)

Case cleaning. 0=no case cleaning. 1=Fans only. 2=All

output O.

Selection of EL diagram. See overview page 2 and 3

Download a set of predetermined settings. See overview

page 7.

Access code 2 (partial access)

Replace the controllers factory settings with the present

settings

Input signal on DI3. Function: (high voltage input)

(0=not used. 1=status on DI2. 2=door function with alarm

when open. 3=door alarm when open. 4=defrost start

(pulse-signal). 5=ext. main switch 6=night operation,

o41 1 1 1 1 1 1 1 0 % 100 % 100

o42 1 1 1 1 1 1 1 0 % 100 % 100

o43 1 1 1 1 1 1 1 6 min. 60 min. 10

*** o46 1 1 1 1 1 1 1 1 1 1 0 2 0

* o61 1 1 1 1 1 1 1 1 1 1 1 10 1

* o62 1 1 1 1 1 1 1 1 1 1 0 6 0

*** o64 1 1 1 1 1 1 1 1 1 1 0 100 0

o67 1 1 1 1 1 1 1 1 1 1 0/O 1/On 0/O

o84 1 1 1 1 1 1 1 1 1 1 0 14 0

7=thermostat band changeover (activate r21). 8=Not used.

9=Not used. 10=case cleaning (pulse signal). 11=forced

cooling at hot gas defrost, 12=night cover. 13=Not used.

14=Refrigeration stopped (forced closing))

Rail heat control

o85 1 1 1 1 1 1 1 0 2 0

0=not used, 1=pulse control with timer function (o41

and o42), 2=pulse control with dew point function

Dew point value where the rail heat is minimum o86 1 1 1 1 1 1 1 -10°C 50°C 8

Dew point value where the rail heat is 100% on o87 1 1 1 1 1 1 1 -9°C 50°C 17

Lowest permitted rail heat eect in % o88 1 1 1 1 1 1 1 0 % 100 % 30

Time delay from "open door” refrigeration is started o89 1 1 1 1 1 1 1 1 1 1 0 min. 240 min. 30

Fan operation on stopped refrigeration (forced closing):

o90 1 1 1 1 1 1 1 1 1 1 0/no 1/yes 1/yes

no/0=Fan O, yes/1=Fan On

Denition of readings on lower button:

o92 1 1 1 1 1 1 1 1 1 1 1 3 1

1=defrost stop temperature, 2=S6 temperature,

3=S5_B temperature

Display of temperature

o97 1 1 1 1 1 1 1 1 1 1 1 2 1

1= u56 Air temperature

2= u36 product temperature

Light and night blinds dened

o98 1 1 1 1 1 1 1 1 1 1 0 1 0

0: Light is switch o and night blind is open when the

main switch is o

1: Light and night blind is independent of main switch

Conguration of alarm relay

P41 1 1 1 1 1 0 127 111

The alarm relay will be activated upon an alarm signal

from the following groups:

1 - High temperature alarms

2 - Low temperature alarms

4 - Sensor error

8 - Digital input enabled for alarm

16 - Defrosting alarms

32 - Miscellaneous

64 - Injection alarms

The groups that are to activate the alarm relay must be

set by using a numerical value which is the sum of the

groups that must be activated.

(E.g.: a value of 5 will activate all high temperature

alarms and all sensor error. 0 will cancel relay function)

10 Instructions RI8LS902 © Danfoss 06/2015 AK-CC 550 - 115 V

Page 11

Continued Code 1 2 3 4 5 6 7 8 9 10 Min. Max. Fac. Actual

Service

Temperature measured with S5 sensor

Status on DI1 input. on/1=closed

u09 1 1 1 1 1 1 1 1 1 1

u10 1 1 1 1 1 1 1 1 1 1

Actual defrost time (minutes) u11 1 1 1 1 1 1 1 1 1 1

Temperature measured with S3 sensor

Status on night operation (on or o) 1=on

Temperature measured with S4 sensor

u12 1 1 1 1 1 1 1 1 1 1

u13 1 1 1 1 1 1 1 1 1 1

u16 1 1 1 1 1 1 1 1 1 1

Thermostat temperature u17 1 1 1 1 1 1 1 1 1 1

Run time of thermostat (cooling time) in minutes u18 1 1 1 1 1 1 1 1 1 1

Temperature of evaporator inlet temp u19 1 1 1 1 1 1 1 1 1 1

Temperature of evaporator outlet temp. u20 1 1 1 1 1 1 1 1 1 1

Superheat across evaporator u21 1 1 1 1 1 1 1 1 1 1

Reference of superheat control u22 1 1 1 1 1 1 1 1 1 1

Opening degree of AKV valve u23 1 1 1 1 1 1 1 1 1 1

Evaporating pressure Po (relative) u25 1 1 1 1 1 1 1 1 1 1

Evaporator temperature To (Calculated) u26 1 1 1 1 1 1 1 1 1 1

Temperature measured with S6 sensor

u36 1 1 1 1 1 1 1 1 1

(product temperature)

Status on DI2 output. on/1=closed

Air temperature . Weighted S3 and S4

Measured temperature for alarm thermostat

Status on relay for cooling

Status on relay for fan

Status on relay for defrost

Status on relay for railheat

Status on relay for alarm

Status on relay for light

Status on relay for valve in suction line

Status on relay for compressor 2

Temperature measured with S5B sensor

Status on relay for hot gas- / drain valve ** u80 1

Status on relay for heating element in drip tray

Status on relay for night blinds ** u82 1

Status on relay for defrost B ** u83 1

Status on relay for heat function

u37 1 1 1 1 1 1 1 1 1 1

u56 1 1 1 1 1 1 1 1 1 1

u57 1 1 1 1 1 1 1 1 1 1

** u58 1 1 1 1

** u59 1 1 1 1 1 1 1 1 1 1

** u60 1 1 1 1 1 1 1 1 1

** u61 1 1 1 1 1 1 1

** u62 1 1 1 1 1

** u63 1 1 1 1 1 1 1 1

** u64 1

** u67 1

u75 1

** u81 1

** u84 1

Readout of the actual rail heat eect u85 1 1 1 1 1 1 1

1: Thermostat 1 operating, 2: Thermostat 2 operating u86 1 1 1 1 1 1 1 1 1 1

Status on high voltage input DI3 u87 1 1 1 1 1 1 1 1 1 1

Readout of thermostats actual cut in value u90 1 1 1 1 1 1 1 1 1 1

Readout of thermostats actual cut out value u91 1 1 1 1 1 1 1 1 1 1

Readout of status on the adaptive defrost

U01 1 1 1 1 1 1 1 1 1 1

0: O. Function is not activated

1: Error. A reset must be carried out using d22

2: Reset is activated. New tuning is in progress

3: Normal

4: Light build-up of ice

5: Medium build-up of ice

6: Heavy build-up of ice

*) Can only be set when regulation is stopped (r12=0)

**) Can be controlled manually, but only when r12=-1

***) With access code 2 the access to these menus will be limited

Factory settings are indicated for standard units. Other code numbers have customized settings.

Factory setting

If you need to return to the factory-set values, it can be done in this way:

- Cut out the supply voltage to the controller

- Keep upper and lower button depressed at the same time as you recon nect the supply voltage

AK-CC 550 - 115 V Instructions RI8LS902 © Danfoss 06/2015 11

Page 12

Fault message

In an error situation the LED’s on the front will ash and the alarm relay will be

activated. If you push the top button in this situation you can see the alarm

report in the display.

There are two kinds of error reports - it can either be an alarm occurring during the daily operation, or there may be a defect in the installation.

A-alarms will not become visible until the set time delay has expired.

E-alarms, on the other hand, will become visible the moment the error occurs.

(An A alarm will not be visible as long as there is an active E alarm).

Here are the messages that may appear:

Code / Alarm text via

data communication

A1/--- High t.alarm High temperature alarm

A2/--- Low t. alarm Low temperature alarm

A4/--- Door alarm Door alarm

A5/--- Max hold time The ”o16” function is activated during

A10/--- Inject prob. Control problem

A11/--- No Rfg. sel. No refrigerant selected

A13/--- High temp S6 Temperature alarm. High S6

A14/--- Low temp S6 Temperature alarm. Low S6

A15/--- DI1 alarm DI1 alarm

A16/--- DI2 alarm DI2 alarm

A45/--- Standby mode Standby position (stopped refrigera-

A59/--- Case clean Case cleaning. Signal from DI input

A74/--- AD fault Error in the adaptive defrost function

A75/--- AD Iced Evaporator is iced up. Reduction of

A76/--- AD not defr. Defrost of evaporator is not

E1/--- Ctrl. error Faults in the controller

E6/--- RTC error Check clock

E20/--- Pe error Error on pressure transmitter Pe

E23/--- S1 error

E24/--- S2 error Error on S2 sensor 4

E25/--- S3 error Error on S3 sensor 4

E26/--- S4 error Error on S4 sensor 4

E27/--- S5 error Error on S5 sensor 4

E28/--- S6 error Error on S6 sensor 4

E37/--- S5 error B Error on S5B sensor

---/--- Max Def.Time Defrost stopped based on time instead

Description

a coordinated defrost

tion via r12 or DI input)

air ow

satisfactory

Error on S1 sensor 4

of, as wanted, on temperature

Alarm

relay

groups

(P41)

1

2

8

16

64

64

1

2

8

8

-

-

16

16

16

32

32

64

4

16

Operating status (Measurement)

The controller goes through some regulating situations where it is just waiting for the next point of the

regulation. To make these “why is nothing happening”

situations visible, you can see an operating status on

the display. Push briey (1s) the upper button. If there is

a status code, it will be shown on the display. The individual status codes have the following meanings:

Normal regulation S0 0

Waiting for end of the coordinated defrost S1 1

When the compressor is operating it must run for at least

x minutes.

When the compressor is stopped, it must remain stopped

for at least x minutes.

The evaporator drips o and waits for the time to run out S4 4

Refrigeration stopped by main switch. Either with r12 or

a DI-input

Refrigeration stopped by thermostat S11 11

Defrost sequence. Defrost in progress S14 14

Defrost sequence. Fan delay — water attaches to the

evaporator

Refrigeration stopped due to open ON input or stopped

regulation

Door is open. DI input is open S17 17

Melt function in progress. Refrigeration is interrupted S18 18

Modulating thermostat control S19 19

Emergency cooling due to sensor error S20 20

Regulation problem in the injections function S21 21

Start-up phase 2. Evaporator being charged S22 22

Adaptive control S23 23

Start-up phase 1. Signal reliability from sensors is

controlled

Manual control of outputs S25 25

No refrigerant selected S26 26

Case cleaning S29 29

Forced cooling S30 30

Delay on outputs during start-up S32 32

Heat function r36 is active S33 33

Other displays:

The defrost temperature cannot be displayed. There is

stop based on time

Defrost in progress / First cooling after defrost -d-

Password required. Set password PS

Reguleringen er stoppet via hovedafbryderen OFF

S2 2

S3 3

S10 10

S15 15

S16 16

S24 24

non

Ctrl. state:

(Shown in all

menu displays)

*) Emergency cooling will take eect when there is lack of signal from a dened

S3 or S4 sensor. The regulation will continue with a registered average cutin

frequency. There are two registered values – one for day operation and one for

night operation.

Data communication

The importance of individual alarms can be dened with a setting. The setting

must be carried out in the group "Alarm destinations"

Settings from

System manager

Settings from

AKM (AKM destination)

Log Alarm relay Send via

Non High Low-High

Network

High 1 X X X X

Middle 2 X X X

Low 3 X X X

Log only X

Disabled

Additional information:

Manual RS8EN

12 Instructions RI8LS902 © Danfoss 06/2015 AK-CC 550 - 115 V

DE-DB

Loading...

Loading...