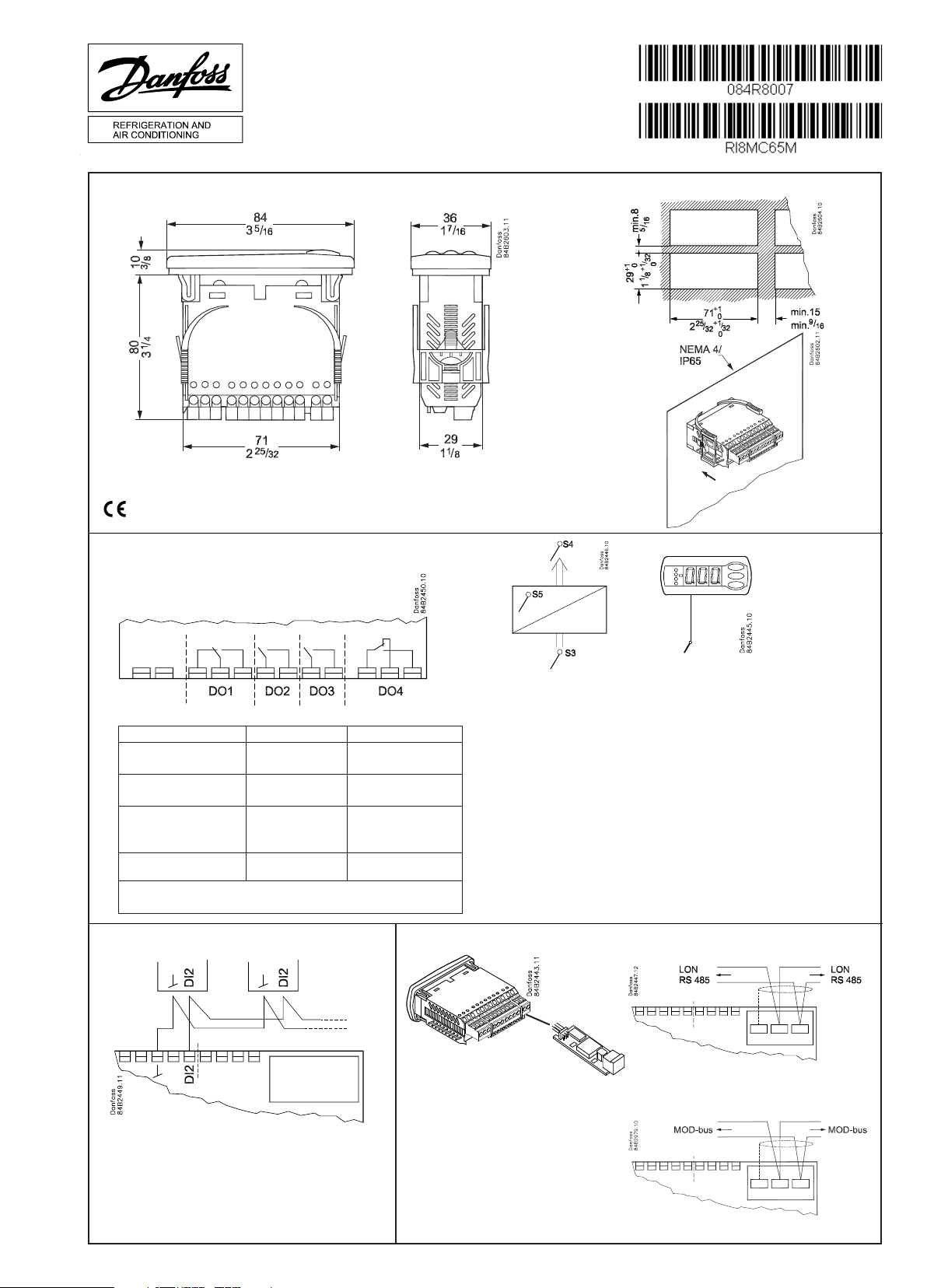

Page 1

INSTRUCTIONS

AK-CC 210 (115 V)

084R8007

t

= 0 - +55°C, 32 - +131°F

amb

115 V a.c., 50/60 Hz

2.5 VA

10 V < U < 256 V

084R8007

CE (250 V a.c.) UL *** (240 V a.c.)

DO1. Refrigeration * 10 (6) A

DO2. Defrost * 10 (6) A

DO3. Fan or

refrigeration 2 *

DO4. Alarm, light, rail heat

or hotgas defrost *

* DO1 and DO2 are 16 A relays. DO3 and DO4 are 8 A relays. Max. load must be keept.

** Gold plating ensures make function with small contact loads

*** UL-approval based on 30000 couplings

6 (3) A

4 (1) A

Min. 100 mA**

10 A Resistive

5FLA, 30LRA

10 A Resistive

5FLA, 30LRA

6 A Resistive

3FLA, 18LRA

131 VA Pilot duty

4 A Resistive

131 VA Pilot duty

Coordinated defrost

Data communication

Type: Pt 1000 (1000 Ω /0°C ) /

Ptc 1000 (1000 Ω /25°C ) /

NTC-M2020 (5000 Ω / 25°C)

( o06)

LON RS485

MOD-bus

RI8MC65M 08-2011

Page 2

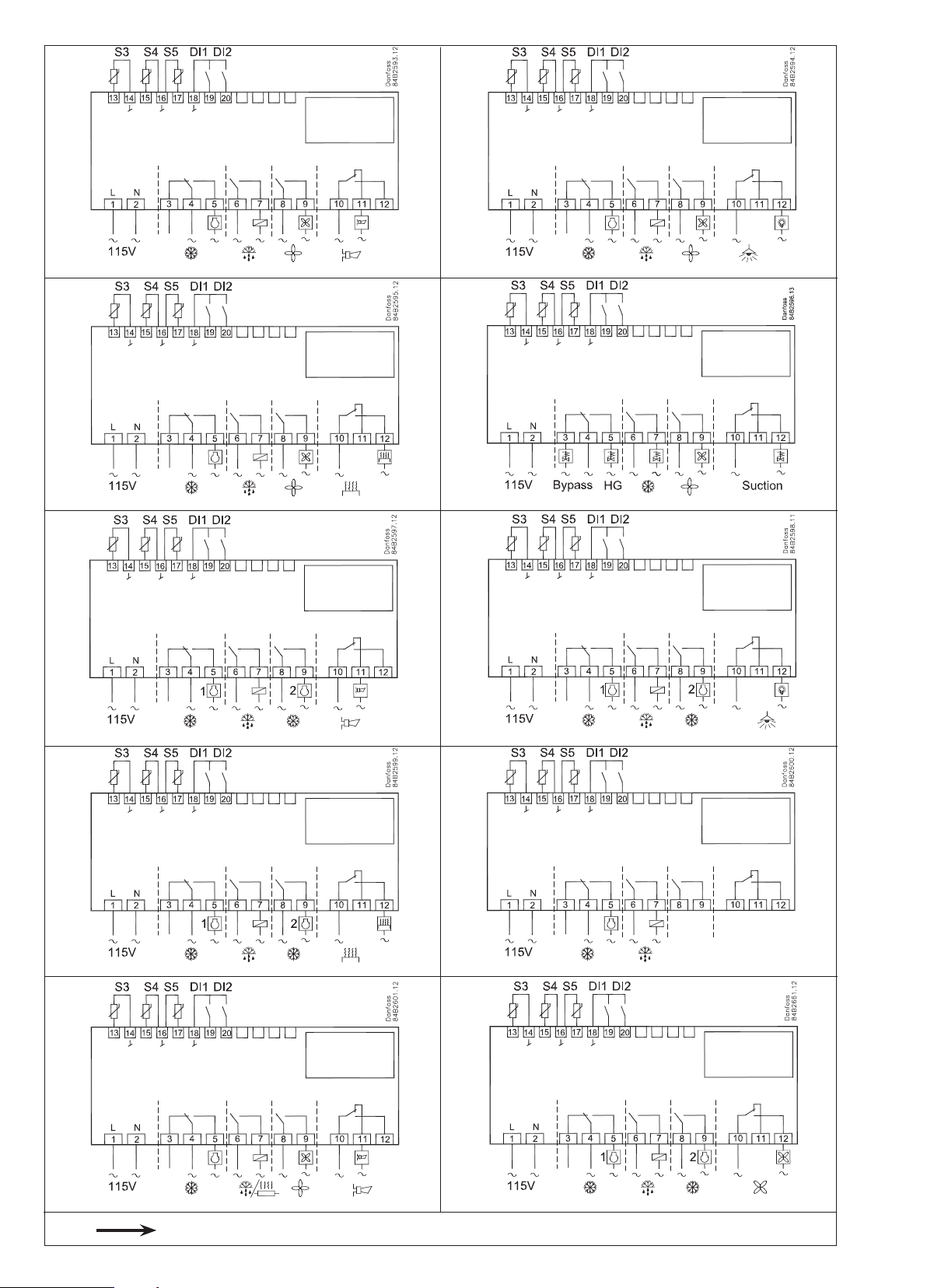

o61 — Electrical connections

1 2

*)

*)

3 4

5 6

*)

*) *)

*)

7 8

9 10

*)

*)*)

*)

! ! !

2 Instructions RI8MC65M © Danfoss 8/2011 AK-CC 210

*) DI1, DI2: AU: Guld, Gold, Or, Oro l = max. 15 m

Page 3

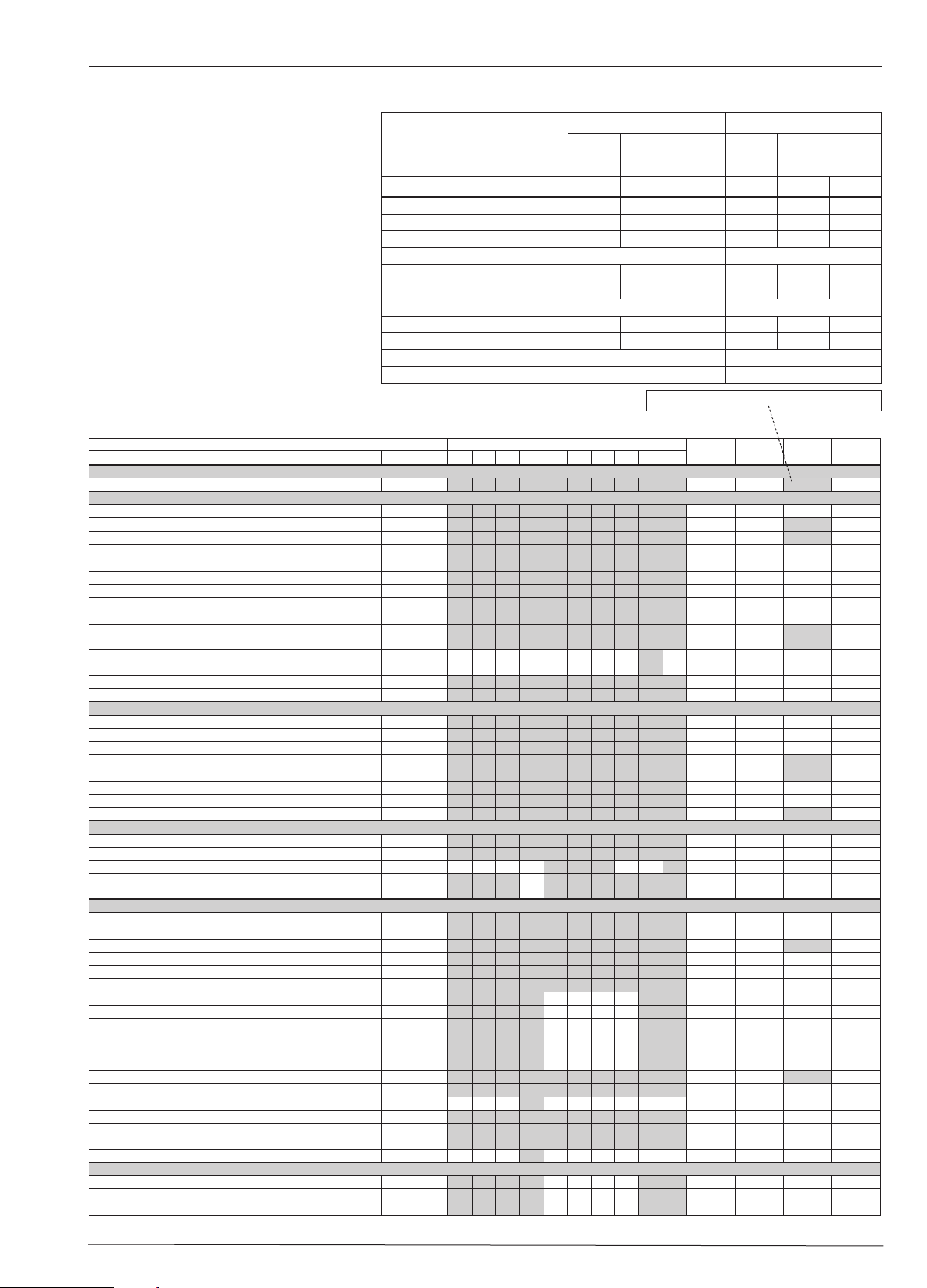

Setting:

1 Open parameter r12 and stop the regulation

2 Select electric connection based on the draw-

ings on page 2

3 Open parameter o61 and set the electric con-

nection number in it

4 Now select one of the preset settings from the

table on the right-hand side

5 Open parameter o62 and set the number for

the array of presettings

6 Open parameter r12 and start the regulation

7 Go through the survey of factory settings.

Make any necessary changes in the respective

parameters.

8 For network. Set the address in o03 and then

transmit it to the gateway/system unit with

setting o04.

English (°C)

Auxiliary table for settings

(quick-setup)

Preset settings (o62) 1 2 3 4 5 6

Temperature (SP)

Max. temp. setting (r02)

Min. temp. setting (r03)

Sensor signal for thermostat. S4% (r15)

Alarm limit high (A13)

Alarm limit low (A14)

Sensor signal for alarm funct.S4% (A36)

Interval between defrost (d03)

Defrost sensor: 0=time, 1=S5, 2=S4 (d10)

DI1 config. (o02)

Sensor signal for display view S4% (017)

Defrost

stop on

time

4°C 2°C -24°C 6°C 3°C -22°C

6°C 4°C -22°C 8°C 5°C -20°C

2°C 0°C -26°C 4°C 1°C -24°C

10°C 8°C -15°C 10°C 8°C -15°C

-5°C -5°C -30°C 0°C 0°C -30°C

6 h 6h 12h 8h 8h 12h

Case Room

Defrost stop

on S5

100% 0%

100% 0%

0 1 1 0 1 1

Case cleaning =10 Door function =3

100% 0%

Array 1-6: The settings in the grey fields will be changed

Defrost

stop on

time

Defrost stop

on S5

Function Codes 1 2 3 4 5 6 7 8 9 10

Normal operation

Temperature (set point) --- -50.0°C 50.0°C 2.0°C

Thermostat

Differential *** r01 0.0 K 20.0K 2.0 K

Max. limitation of setpoint setting *** r02 -49.0°C 50°C 50.0°C

Min. limitation of setpoint setting *** r03 -50.0°C 49.0°C -50.0°C

Adjustment of temperature indication r04 -20.0 K 20.0 K 0.0 K

Temperature unit (°C/°F) r05 °C °F °C

Correction of the signal from S4 r09 -10.0 K +10.0 K 0.0 K

Correction of the signal from S3 r10 -10.0 K +10.0 K 0.0 K

Manual service, stop regulation, start regulation (-1, 0, 1) r12 -1 1 0

Displacement of reference during night operation r13 -10.0 K 10.0 K 0.0 K

Definition and weighting, if applicable, of thermostat sensors

- S4% (100%=S4, 0%=S3)

The heating function is started a number of degrees below the

thermostats cutout temperature

Activation of reference displacement r40 r39 OFF ON OFF

Value of reference displacement (activate via r39 or DI) r40 -50.0 K 50.0 K 0.0 K

Alarm

Delay for temperature alarm A03 0 min 240 min 30 min

Delay for door alarm *** A04 0 min 240 min 60 min

Delay for temperature alarm after defrost A12 0 min 240 min 90 min

High alarm limit *** A13 -50.0°C 50.0°C 8.0°C

Low alarm limit *** A14 -50.0°C 50.0°C -30.0°C

Alarm delay DI1 A27 0 min 240 min 30 min

Alarm delay DI2 A28 0 min 240 min 30 min

Signal for alarm thermostat. S4% (100%=S4, 0%=S3) A36 0% 100% 100%

Compressor

Min. ON-time c01 0 min 30 min 0 min

Min. OFF-time c02 0 min 30 min 0 min

Time delay for cutin of comp.2 c05 0 sec 999 sec 0 sec

Compressor relay 1 must cutin and out inversely

(NC-function)

Defrost

Defrost method (none/EL/GAS/BRINE) d01 no bri EL

Defrost stop temperature d02 0.0°C 25.0°C 6.0°C

Interval between defrost starts d03 0 hours

Max. defrost duration d04 0 min 180 min 45 min

Displacement of time on cutin of defrost at start-up d05 0 min 240 min 0 min

Drip off time d06 0 min 60 min 0 min

Delay for fan start after defrost d07 0 min 60 min 0 min

Fan start temperature d08 -15.0°C 0.0°C -5.0°C

Fan cutin during defrost

0: Stopped

1: Running

2: Running during pump down and defrost

Defrost sensor (0=time, 1=S5, 2=S4) d10 0 2 0

Pump down delay d16 0 min 60 min 0 min

Drain delay d17 0 min 60 min 0 min

Max. aggregate refrigeration time between two defrosts d18 0 hours 48 hours 0 hours

Defrost on demand - S5 temperature’s permitted variation during frost build-up. On central plant choose 20 K (=off)

Delay of hot gas injection d23 0 min 60 min 0 min

Fan

Fan stop at cutout compressor F01 no yes no

Delay of fan stop F02 0 min 30 min 0 min

Fan stop temperature (S5) F04 -50.0°C 50.0°C 50.0°C

Parameters EL-diagram number (page 2)

r15 0% 100% 100%

r36 -15.0 K -3.0 K -15.0 K

c30 0

d09 0 2 1

d19 0.0 K 20.0 k 20.0 K

Min.value

OFF

Max.value

1

ON

240 hours

Factory

setting

0

OFF

8 hours

Actual

setting

AK-CC 210 Instructions RI8MC65M © Danfoss 8/2011 3

Page 4

HACCP

Actual temperature measurement for the HACCP function h01

Last registered peak temperature h10

Selection of function and sensor for the HACCP function. 0 = no

HACCP function. 1 = S4 used (maybe also S3). 2 = S5 used

Alarm limit for the HACCP function h12 -50.0°C 50.0°C 8.0°C

Time delay for the HACCP alarm h13 0 min. 240 min. 30 min.

Select signal for the HACCP function. S4% (100% = S4, 0% = S3) h14 0% 100% 100%

Real time clock

Six start times for defrost.

Setting of hours.

0=OFF

Six start times for defrost.

Setting of minutes.

0=OFF

Clock - Setting of hours *** t07 0 hours 23 hours 0 hours

Clock - Setting of minute *** t08 0 min 59 min 0 min

Clock - Setting of date *** t45 1 31 1

Clock - Setting of month *** t46 1 12 1

Clock - Setting of year *** t47 0 99 0

Miscellaneous

Delay of output signals after start-up o01 0 s 600 s 5 s

Input signal on DI1. Function:

0=not used. 1=status on DI1. 2=door function with alarm when

open. 3=door alarm when open. 4=defrost start (pulse-pressure). 5=ext.main switch. 6=night operation 7=change reference (activate r40). 8=alarm function when closed. 9=alarm

function when open. 10=case cleaning (pulse pressure).

11=forced cooling at hot gas defrost.

Network address (0=off) o03 0 240 0

On/Off switch (Service Pin message)

IMPORTANT! o61 must be set prior to o04

Access code 1 (all settings) o05 0 100 0

Used sensor type (Pt /PTC/NTC) o06 Pt ntc Pt

Display step = 0.5 (normal 0.1 at Pt sensor) o15 no yes no

Max hold time after coordinated defrost o16 0 min 60 min 20

Select signal for display view. S4% (100%=S4, 0%=S3) o17 0% 100% 100%

Input signal on DI2. Function:

(0=not used. 1=status on DI2. 2=door function with alarm when

open. 3=door alarm when open. 4=defrost start (pulse-pressure). 5=ext. main switch 6=night operation 7=change reference (activate r40). 8=alarm function when closed. 9=alarm

function when open. 10=case cleaning (pulse pressure).

11=forced cooling at hot gas defrost.). 12=coordinated defrost)

Configuration of light function (relay 4)

1=ON during day operation. 2=ON / OFF via data communication. 3=ON follows the DI-function, when DI is selected to door

function or to door alarm

Activation of light relay (only if o38=2) o39 OFF ON OFF

Rail heat On time during day operations o41 0% 100% 100

Rail heat On time during night operations o42 0% 100% 100

Rail heat period time (On time + Off time) o43 6 min 60 min 10 min

Case cleaning. 0=no case cleaning. 1=Fans only. 2=All output

Off.

Selection of EL diagram. See overview page 2 * o61 1 10 1

Download a set of predetermined settings. See overview

previous page.

Access code 2 (partly access) *** o64 0 100 0

Save the controllers present settings to the programming key.

Select your own number.

Load a set of settings from the programming key (previously

saved via o65 function)

Replace the controllers factory settings with the present settings

Service

Status codes are shown on page 5 S0-S33

Temperature measured with S5 sensor *** u09

Status on DI1 input. on/1=closed u10

Temperature measured with S3 sensor *** u12

Status on night operation (on or off) 1=closed *** u13

Temperature measured with S4 sensor *** u16

Thermostat temperature u17

Read the present regulation reference u28

Status on DI2 output. on/1=closed u37

Temperature shown on display u56

Measured temperature for alarm thermostat u57

Status on relay for cooling ** u58

Status on relay for fan ** u59

Status on relay for defrost ** u60

Status on relay for railheat ** u61

Status on relay for alarm ** u62

Status on relay for light ** u63

Status on relay for valve in suction line ** u64

Status on relay for compressor 2 ** u67

*** o46 0 2 0

* o62 0 6 0

1 2 3 4 5 6 7 8 9 10

h11 0 2 0

t01-t06 0 hours 23 hours 0 hours

t11-t16 0 min 59 min 0 min

o02 1 11 0

o04 OFF ON OFF

o37 0 12 0

o38 1 3 1

o65 0 25 0

o66 0 25 0

o67 OFF On OFF

*) Can only be set when regulation is stopped (r12=0)

**) Can be controlled manually, but only when r12=-1

***) With access code 2 the access to these menus will be limited

Factory settings are indicated for standard units. Other code numbers have customized settings.

SW = 2.3x

4 Instructions RI8MC65M © Danfoss 8/2011 AK-CC 210

Page 5

The buttons

LED

Set menu

1. Push the upper button until a parameter

r01 is shown

2. Push the upper or the lower button and

find that parameter you want to change

3. Push the middle button until the

parameter value is shown

4. Push the upper or the lower button and

select the new value

5. Push the middle button again to enter

the value.

Cutout alarm relay / receipt alarm/see alarm

code

Set temperature

1. Push the middle button until the

temperature value is shown

2. Push the upper or the lower button and

select the new value

3. Push the middle button to select the

setting.

Reading the temperature at defrost sensor

• Push briey the lower button

Manuel start or stop of a defrost

• Push the lower button for four seconds.

Light emitting diode

= refrigeration

= defrost

= fan running

Flashes fast at alarm

HACCP

HACCP function is active

• Push short the upper button

See HACCP registration

1. Give the middle button a long push until

h01 appears

2. Select required h01-h10

3. See value by giving the middle button a

short push

Fault code display Alarm code display Status code display

E 1 Fault in controller A 1 High temperature alarm S0 Regulating

E 6 Change battery + check clock A 2 Low temperature alarm S 1 Waiting for end of the coordinated defrost

E 25 S3 sensor error A 4 Door alarm S 2 ON-time Compressor

E 26 S4 sensor error A 5 Max. Hold time S 3 OFF-time Compressor

E 27 S5 sensor error A 15 DI 1 alarm S 4 Drip-off time

A 16 DI 2 alarm S 10 Refrigeration stopped by main switch

A 45 Standby mode S 11 Refrigeration stopped by thermostat

A 59 Case cleaning S 14 Defrost sequence. Defrosting

A 60 HACCP alarm S 15 Defrost sequence. Fan delay

S 17 Door open (open DI input)

S 20 Emergency cooling

S 25 Manual control of outputs

S 29 Case cleaning

S 30 Forced cooling

S 32 Delay of output at start-up

S33 Heat function r36 is active

non The defrost temperature cannot be dis-

played. There is stop based on time

-d- Defrost in progress

PS Password required

AK-CC 210 Instructions RI8MC65M © Danfoss 8/2011 5

Page 6

English (° F)

Setting:

1 Open parameter r12 and stop the regulation

2 Select electric connection based on the draw-

ings on page 2

3 Open parameter o61 and set the electric con-

nection number in it

4 Now select one of the preset settings from the

table on the right-hand side

5 Open parameter o62 and set the number for

the array of presettings

6 Open parameter r12 and start the regulation

7 Go through the survey of factory settings.

Make any necessary changes in the respective

parameters.

8 For network. Set the address in o03 and then

Auxiliary table for settings

(quick-setup)

Preset settings (o62) 1 2 3 4 5 6

Temperature (SP)

Max. temp. setting (r02)

Min. temp. setting (r03)

Sensor signal for thermostat. S4% (r15)

Alarm limit high (A13)

Alarm limit low (A14)

Sensor signal for alarm funct.S4% (A36)

Interval between defrost (d03)

Defrost sensor: 0=time, 1=S5, 2=S4 (d10)

DI1 config. (o02)

Sensor signal for display view S4% (017)

Defrost

stop on

time

39°F 36°F -11°F 43°F 37°F -8°F

43°F 39°F -8°F 46°F 41°F -4°F

36°F 32°F -15°F 39°F 34°F -11°F

50°F 46°F 5°F 50°F 46°F 5°F

23°F 23°F -22°F 32°F 32°F -22°F

6 h 6h 12h 8h 8h 12h

transmit it to the gateway/system unit with

setting o04.

Function Codes 1 2 3 4 5 6 7 8 9 10

Normal operation

Temperature (set point) --- -58.0°F 122.0°F 36.0°F

Thermostat

Differential *** r01 0°F 36.0°F 36.0°F

Max. limitation of setpoint setting *** r02 -56.0°F 122°F 122°F

Min. limitation of setpoint setting *** r03 -58.0°F 120°F -58.0°F

Adjustment of temperature indication r04 -4.0°F 68.0°F 32.0°F

Temperature unit (°C/°F) r05 °C °F °F

Correction of the signal from S4 r09 -18.0°F +18.0°F 0.0°F

Correction of the signal from S3 r10 -18.0°F +18.0°F 0.0°F

Manual service, stop regulation, start regulation (-1, 0, 1) r12 -1 1 0

Displacement of reference during night operation r13 -18.0°F +18.0°F 0.0°F

Definition and weighting, if applicable, of thermostat sensors

- S4% (100%=S4, 0%=S3)

The heating function is started a number of degrees below the

thermostats cutout temperature

Activation of reference displacement r40 r39 OFF ON OFF

Value of reference displacement (activate via r39 or DI) r40 -90.0°F 90.0°F 0.0°F

Alarm

Delay for temperature alarm A03 0 min 240 min 30 min

Delay for door alarm *** A04 0 min 240 min 60 min

Delay for temperature alarm after defrost A12 0 min 240 min 90 min

High alarm limit *** A13 -58.0°F 122.0°F 46.0°F

Low alarm limit *** A14 -58.0°F 122.0°F -22.0°F

Alarm delay DI1 A27 0 min 240 min 30 min

Alarm delay DI2 A28 0 min 240 min 30 min

Signal for alarm thermostat. S4% (100%=S4, 0%=S3) A36 0% 100% 100%

Compressor

Min. ON-time c01 0 min 30 min 0 min

Min. OFF-time c02 0 min 30 min 0 min

Time delay for cutin of comp.2 c05 0 sec 999 sec 0 sec

Compressor relay 1 must cutin and out inversely

(NC-function)

Defrost

Defrost method (none/EL/GAS/BRINE) d01 no bri EL

Defrost stop temperature d02 32.0°F 77.0°F 43.0°F

Interval between defrost starts d03 0 hours

Max. defrost duration d04 0 min 180 min 45 min

Displacement of time on cutin of defrost at start-up d05 0 min 240 min 0 min

Drip off time d06 0 min 60 min 0 min

Delay for fan start after defrost d07 0 min 60 min 0 min

Fan start temperature d08 5.0°F 32.0°F 23.0°F

Fan cutin during defrost

0: Stopped

1: Running

2: Running during pump down and defrost

Defrost sensor (0=time, 1=S5, 2=S4) d10 0 2 0

Pump down delay d16 0 min 60 min 0 min

Drain delay d17 0 min 60 min 0 min

Max. aggregate refrigeration time between two defrosts d18 0 hours 48 hours 0 hours

Defrost on demand - S5 temperature’s permitted variation during frost build-up. On central plant choose 20 K (=off)

Delay of hot gas injection d23 0 min 60 min 0 min

Fan

Fan stop at cutout compressor F01 no yes no

Delay of fan stop F02 0 min 30 min 0 min

Fan stop temperature (S5) F04 -58.0°F 122.0°F 122.0°F

Parameters EL-diagram number (page 2)

r15 0% 100% 100%

r36 -27.0°F -5.0°F -22.0°F

c30 0

d09 0 2 1

d19 0°F 36.0°F 36.0° F

Case Room

Defrost stop

on S5

100% 0%

100% 0%

0 1 1 0 1 1

Case cleaning =10 Door function =3

100% 0%

Array 1-6: The settings in the grey fields will be changed

Min.value

OFF

Defrost

stop on

time

Max.value

1

ON

240 hours

Defrost stop

Factory

setting

0

OFF

8 hours

on S5

Actual

setting

6 Instructions RI8MC65M © Danfoss 8/2011 AK-CC 210

Page 7

HACCP

Actual temperature measurement for the HACCP function h01

Last registered peak temperature h10

Selection of function and sensor for the HACCP function. 0 = no

HACCP function. 1 = S4 used (maybe also S3). 2 = S5 used

Alarm limit for the HACCP function h12 -58.0°F 122.0°F 46.0°F

Time delay for the HACCP alarm h13 0 min. 240 min. 30 min.

Select signal for the HACCP function. S4% (100% = S4, 0% = S3) h14 0% 100% 100%

Real time clock

Six start times for defrost.

Setting of hours.

0=OFF

Six start times for defrost.

Setting of minutes.

0=OFF

Clock - Setting of hours *** t07 0 hours 23 hours 0 hours

Clock - Setting of minute *** t08 0 min 59 min 0 min

Clock - Setting of date *** t45 1 31 1

Clock - Setting of month *** t46 1 12 1

Clock - Setting of year *** t47 0 99 0

Miscellaneous

Delay of output signals after start-up o01 0 s 600 s 5 s

Input signal on DI1. Function:

0=not used. 1=status on DI1. 2=door function with alarm when

open. 3=door alarm when open. 4=defrost start (pulse-pressure). 5=ext.main switch. 6=night operation 7=change reference (activate r40). 8=alarm function when closed. 9=alarm

function when open. 10=case cleaning (pulse pressure).

11=forced cooling at hot gas defrost.

Network address (0=off) o03 0 240 0

On/Off switch (Service Pin message)

IMPORTANT! o61 must be set prior to o04

Access code 1 (all settings) o05 0 100 0

Used sensor type (Pt /PTC/NTC) o06 Pt ntc Pt

Display step = 0.5 (normal 0.1 at Pt sensor) o15 no yes no

Max hold time after coordinated defrost o16 0 min 60 min 20

Select signal for display view. S4% (100%=S4, 0%=S3) o17 0% 100% 100%

Input signal on DI2. Function:

(0=not used. 1=status on DI2. 2=door function with alarm when

open. 3=door alarm when open. 4=defrost start (pulse-pressure). 5=ext. main switch 6=night operation 7=change reference (activate r40). 8=alarm function when closed. 9=alarm

function when open. 10=case cleaning (pulse pressure).

11=forced cooling at hot gas defrost.). 12=coordinated defrost)

Configuration of light function (relay 4)

1=ON during night operation. 2=ON / OFF via data communication. 3=ON follows the DI-function, when DI is selected to door

function or to door alarm

Activation of light relay (only if o38=2) o39 OFF ON OFF

Rail heat On time during day operations o41 0% 100% 100

Rail heat On time during night operations o42 0% 100% 100

Rail heat period time (On time + Off time) o43 6 min 60 min 10 min

Case cleaning. 0=no case cleaning. 1=Fans only. 2=All output

Off.

Selection of EL diagram. See overview page 2 * o61 1 10 1

Download a set of predetermined settings. See overview

previous page.

Access code 2 (partly access) *** o64 0 100 0

Save the controllers present settings to the programming key.

Select your own number.

Load a set of settings from the programming key (previously

saved via o65 function)

Replace the controllers factory settings with the present settings

Service

Status codes are shown on page 8 S0-S33

Temperature measured with S5 sensor *** u09

Status on DI1 input. on/1=closed u10

Temperature measured with S3 sensor *** u12

Status on night operation (on or off) 1=closed *** u13

Temperature measured with S4 sensor *** u16

Thermostat temperature u17

Read the present regulation reference u28

Status on DI2 output. on/1=closed u37

Temperature shown on display u56

Measured temperature for alarm thermostat u57

Status on relay for cooling ** u58

Status on relay for fan ** u59

Status on relay for defrost ** u60

Status on relay for railheat ** u61

Status on relay for alarm ** u62

Status on relay for light ** u63

Status on relay for valve in suction line ** u64

Status on relay for compressor 2 ** u67

*) Can only be set when regulation is stopped (r12=0)

**) Can be controlled manually, but only when r12=-1

***) With access code 2 the access to these menus will be limited

Factory settings are indicated for standard units. Other code numbers have customized settings.

*** o46 0 2 0

* o62 0 6 0

1 2 3 4 5 6 7 8 9 10

h11 0 2 0

t01-t06 0 hours 23 hours 0 hours

t11-t16 0 min 59 min 0 min

o02 1 11 0

o04 OFF ON OFF

o37 0 12 0

o38 1 3 1

o65 0 25 0

o66 0 25 0

o67 OFF On OFF

SW = 2.3x

AK-CC 210 Instructions RI8MC65M © Danfoss 8/2011 7

Page 8

The buttons

LED

Set menu

1. Push the upper button until a parameter

r01 is shown

2. Push the upper or the lower button and

find that parameter you want to change

3. Push the middle button until the

parameter value is shown

4. Push the upper or the lower button and

select the new value

5. Push the middle button again to enter

the value.

Cutout alarm relay / receipt alarm/see alarm

code

Set temperature

1. Push the middle button until the

temperature value is shown

2. Push the upper or the lower button and

select the new value

3. Push the middle button to select the

setting.

Reading the temperature at defrost sensor

• Push briey the lower button

Manuel start or stop of a defrost

• Push the lower button for four seconds.

Light emitting diode

= refrigeration

= defrost

= fan running

Flashes fast at alarm

HACCP

HACCP function is active

• Push short the upper button

See HACCP registration

1. Give the middle button a long push until

h01 appears

2. Select required h01-h10

3. See value by giving the middle button a

short push

Fault code display Alarm code display Status code display

E 1 Fault in controller A 1 High temperature alarm S0 Regulating

E 6 Change battery + check clock A 2 Low temperature alarm S 1 Waiting for end of the coordinated defrost

E 25 S3 sensor error A 4 Door alarm S 2 ON-time Compressor

E 26 S4 sensor error A 5 Max. Hold time S 3 OFF-time Compressor

E 27 S5 sensor error A 15 DI 1 alarm S 4 Drip-off time

A 16 DI 2 alarm S 10 Refrigeration stopped by main switch

A 45 Standby mode S 11 Refrigeration stopped by thermostat

A 59 Case cleaning S 14 Defrost sequence. Defrosting

A 60 HACCP alarm S 15 Defrost sequence. Fan delay

S 17 Door open (open DI input)

S 20 Emergency cooling

S 25 Manual control of outputs

S 29 Case cleaning

S 30 Forced cooling

S 32 Delay of output at start-up

S33 Heat function r36 is active

non The defrost temperature cannot be dis-

played. There is stop based on time

-d- Defrost in progress

PS Password required

8 Instructions RI8MC65M © Danfoss 8/2011 AK-CC 210

Loading...

Loading...