Page 1

Data sheet

Plate Heat Exchanger

XGM050

Description

Micro Plate Heat Exchangers - a revolutionary

technology from Danfoss.

Characterized by their unique plate pattern,

MPHEs enable heat to be transferred more

efficient than any previous model of heat

exchangers.

Benefits:

• Energy and cost savings

• Better heat transfer

• Lower pressure loss

• Longer life time

more on: MPHE.danfoss.com

XGM050 is a gasketed plate heat exchanger,

which will be available in plate corrugation

H, M and L. It will be available in 1-pass (with

4 connections) and 2-pass version (with

6 connections). Heat exchangers can be

dimensioned in Danfoss calculation software

“Hexact” which can be downloaded from

MPHE.danfoss.com.

Main data:

• Min. temperature −10 °C

• Max. temperature 150 °C

• Max. working pressure 16 bar

(10&25 bar on request)

• Circulation water / glycolic water up to 50 %

• Connection size G 2A or DN 50

Approvals:

• Pressure Equipment Directive (PED)

• GOST/Russia

Ordering

XGM 050 H – 1 – 10

Number of plates

Number of Passes (1 = 1-pass)

Channel type (L-M-H)

Connection size (DN 50)

Micro plate™ plates

Gasketed heat exchanger

Tailor made ordering

1-pass/2-pass gasketed heat exchanger type XGM050

• The heat exchanger shall be ordered at a Danfoss sales company or at Danfoss Kamnik.

• Tailor Made orders: the code will created when contacting Danfoss Kamnik.

• With the order please attach the Hexact Datasheet, Punchlist, Plate Arrangement Drawing and

BOM.

For further details please contact Danfoss sales representative.

© Danfoss | 2019.11

AI160986475761en-000401 | 1

Page 2

Data sheet XGM050

Ordering (continuous) 1-pass gasketed heat exchanger XGM050

Picture

Note: brackets has to be o rdered separately

1-pass gasketed heat exchanger XGM050

Picture

Note: brackets has to be o rdered separately, linings are no t included, counter flang e is included.

No of plates

(n)

20

30 079B00 51 079B0070 079B0089

40 079B0052 079B0071 079B0090

50 079B0053 079B0072 079 B0091

60 079B0054 079B0073 079 B0092

70 079B0055 079B0 074 079B0 093

80 079B0056 079 B0075 079B0094

90 079B0057 079B0 076 079B0 095

100 079B0058 079B0077 079B0096

110 079B0059 079B0 078 079B0097

120 079B0 060 079B 0079 079B0098

No of plates

(n)

20

30 079 B1032 079B1051 079B1070

40 079 B1033 079B10 52 079B1071

50 079 B1034 079B1053 079B1072

60 079 B1035 079B1054 079B1073

70 07 9B1036 079B1055 079B1074

80 079 B1037 079B10 56 079B1075

90 079B1038 079B10 57 079 B1076

100 079B103 9 079B1058 079B1077

110 079B10 40 07 9B1059 079B1078

120 079B10 41 079B10 60 079B1079

Connection

Thread G2"

Connection

Flange DN50

XGM05 0H XGM05 0M XG M050L

Code no.

079B0050 079B0069 079B0088

XGM05 0H XGM05 0M XG M050L

Code no.

079 B1031 079B10 50 07 9B1069

Accessories - Insulation

(Aluminium stucco and mineral wool)

Type coverage (p late number)

L H&M

10-20 10-28 004H4230

21-4 8 29 -70 004H4231

49-76 71- 110 004H4232

77-10 4 112-15 0 004H4233

105 -132 152-19 0 004H4234

Note: Aluminium st ucco and mineral wool insulation ca n be used

for 1-pass and 2-pa ss version

Code No

Accessories - Insulation

(Coated steel sheet and polyester insulation)

Type coverage (p late number)

L H&M

10-20 10-28 004H4270

21-4 8 29 -70 0 04H4271

49-76 71- 110 004H4272

77-10 4 111- 150 004H4273

105 -132 152-19 0 004 H4274

Note: Coated s teel sheet and polester insu lation can be used for

1-pass. (2-pass ver sions are available on enqui ry)

Code No

2 | AI160986475761en-000401

© Danfoss | 2019.11

Page 3

Data sheet XGM050

Ordering (continuous) Accessories - Tailpieces

Picture Description Connection Code No.

1)

One set conta ins 2 tailpieces with union nuts a nd gaskets.

Accessories - Plates for XGM050,

(Material 1.4404) PN16

Typ e Code No.

Plates XGM050H 1.4404, I-p* 10 pcs 004H4242

Plates XGM050M 1.4404, I-p* 10 pcs 004H4243

Plates XGM050L 1.4404, I-p* 10 pcs 004H4244

Plates XGM050H 1.4404, I-p* 250 pcs 00 4H4245

Plates XGM050M 1.4404, I-p* 250 pcs 004H4246

Plates XGM050L 1.4404, I-p* 250 pcs 004 H4247

1)

sets of 10 & 250

* I-p: I ndustrial pack

Accessories - Special plate set

(Material: 1.4404) PN16

Typ e Description Code No.

XGM050H: spec. plates 1-pass versions, including gaskets

XGM050M: spec. plates 1-pass versions, including gaskets 079H904 0

XGM050L: spec. plates 1-pass versions, including gaskets 079 H9041

XGM050H: spec. plates 2-pass versions, including gaskets

XGM050M: spec. plates 2-pass versions, including gaskets 079H904 6

XGM050L: spec. plates 2-pass versions, including gaskets 079H9 047

Solder tailpieces

Weld-on tailpieces

G 2 / 28 mm 004B2 910

G 2 / 35 mm 0 04B 2911

G 2 / 42 mm 00 4B2912

G 2 / DN 32 004B2907

G 2 / DN 40 004B2908

G 2 / DN 50 004B2909

Accessories - EPDM Gasket

1)

Typ e Code No.

Gasket for XGM050L, I-p* 10 pcs 079H9032

Gasket for XGM050L, I-p* 250 pcs 079H9033

Gasket for XGM050H&M, I-p* 10 pcs 079H9034

Gasket for XGM050H&M, I-p* 250 pcs 079H9035

1)

sets of 10 & 250

* I-p: Indust rial pack

Sets of 1 front and 1 back plate for 1 pass

versions including EPDM gaskets

Sets of 1 front, 1 back and 1 middle plates

for 2 pass versions including EPDM gaskets

1)

1)

079H9039

079H9045

Accessories - Other spare parts

Typ e Code No.

Linings XGM050 PN16 EPDM I-Pack, 4 Pcs 004H4263

Linings XGM050 PN25 EPDM I-Pack, 4 Pcs 004H4266

O-rings for XGM050 flanges I-Pack 10Pcs 004 H4265

Accessories - Bracket

Picture Code No.

004H4237

NOTE: Bracket set is not inclu ded in HEX please order it

separately. Set contai n 2 pcs of bracket/legs .

© Danfoss | 2019.11

AI160986475761en-000401 | 3

Page 4

Data sheet XGM050

Technical data

Heat exchanger XGM050

Typ e XGM05 0L XG M050M XGM050 H

Max. working pressure PN (bar) 10, 16, 25

Max. operating temperature

Min. operating temperature −10

Flow medium Circulation water/glycolic water up to 50 %

Volume / Channel Ltr 0. 395 0.254 0.254

Connection type

Connection size G 2 or DN 50

Materials

Plate Stainless steel, EN 1.4404 (AISI 316L) & EN 1.4301 (AISI 304)

Liners in connections EPDM

Gasket type Glue free

Gasket material EPDM

1)

Counter flang e is included.

o

C

Cylindrical external thread acc. to DIN ISO 228/1 or

Compact f langes DN 50 EN 1.4404

150

1)

Insulation properties

Typ e Aluminium stucco and mineral wool

Heat conductivity, λ W/mK 0.035 0.045

Max

temperature

Wall thickness mm 65 25

Permanent

Short term peak 180 18 0

°C

150 150

Coated st eel sheet and po lyester

insulation

Design and function

Danfoss 2 pass heat exchanger are made with 6

connections, as they are primarily used to heat

tap water.

There is one additional connection to allow

circulation of hot water and one connection to

connect and extract heat from return water from

heating heat exchanger.

T11

T22

T12

T21

Connections T112 and T212 can be blocked if

they are not used.

T12

T21

T11

T22

T112

T212

4 | AI160986475761en-000401

T11 - Primary side in

T12 - Primary side out

T112 - Primary side second inlet (2-pass)

T21 - Secondary side in

T22 - Secondary side out

T212 - Secondary side second inlet (2- pass)

© Danfoss | 2019.11

Page 5

Data sheet XGM050

Sizing XGM050 can be calculated in latest version of

Danfoss calculation software “Hexact” which can

be downloaded from hexact.danfoss.com.

Mounting

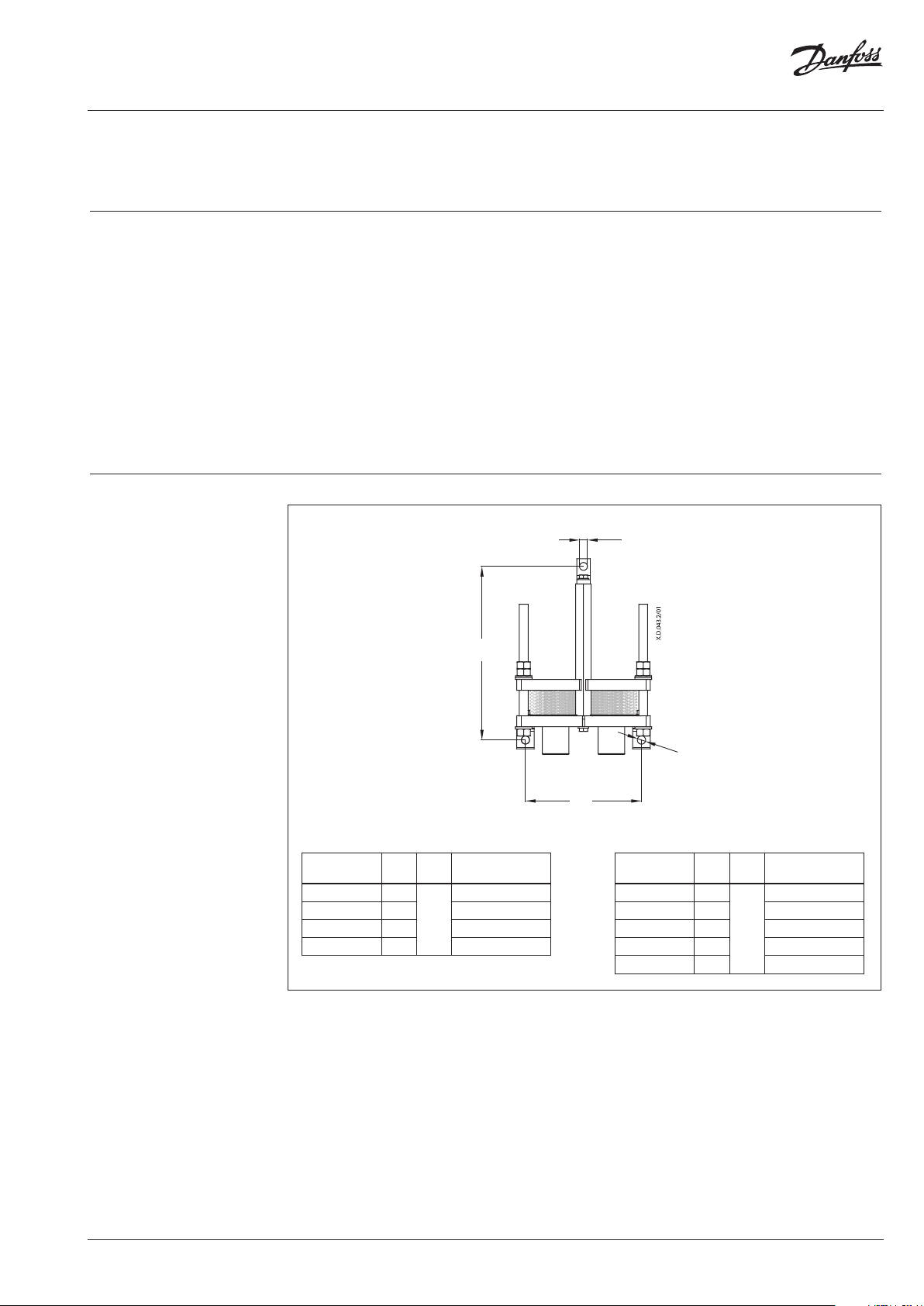

Dimensions

The heat exchanger must be mounted in vertical

position. Prepare the foundation for the heat

exchanger if necessary, always according to local

regulations. It is recommended that all pipes

connected to the heat exchanger are equipped

with shut-off valves for maintenance purposes.

The pipes to be connected must be mounted so

that the strain caused by the thermal expansion,

for instance, does not harm the heat exchanger.

The pipes must be equipped with brackets to

prevent any torsional stress concentration at the

heat exchanger’s pipe connections.

It is recommended that the heat exchanger is

equipped with insulation.

A safety valve must be installed between the

heat exchanger and the shut-off valves on the

secondary side of the heat exchanger. If the

safety valve is not installed, thermal expansion of

fluid might destroy the heat exchanger when the

shut-off valves are closed.

1)

18±0.5

L±5

18±0.5

B±2

395

545

695

845

1)

264

Weight

(kg)

89.3 + 0.44 4 × n

90.6 + 0.444 × n

91.9 + 0.444 × n

93.2 + 0.44 4 × n

XGM050L PN16

Plate range L B

10-20

21-4 8

49-76

77-10 4

105 -132

XGM050H&M PN16

Plate range L B

10-28

29 -70

71 -110

111-14 0

1)

Dimensions for PN 10 & 25 version can be extract from Hexact in tab “Dimensional data”.

395

545

695

845

995

1)

Weight

(kg)

89.3 + 0.495 × n

90.6 + 0.495 × n

91.9 + 0.495 × n

264

93.2 + 0.495 × n

94.5 + 0.495 × n

© Danfoss | 2019.11

AI160986475761en-000401 | 5

Page 6

Data sheet XGM050

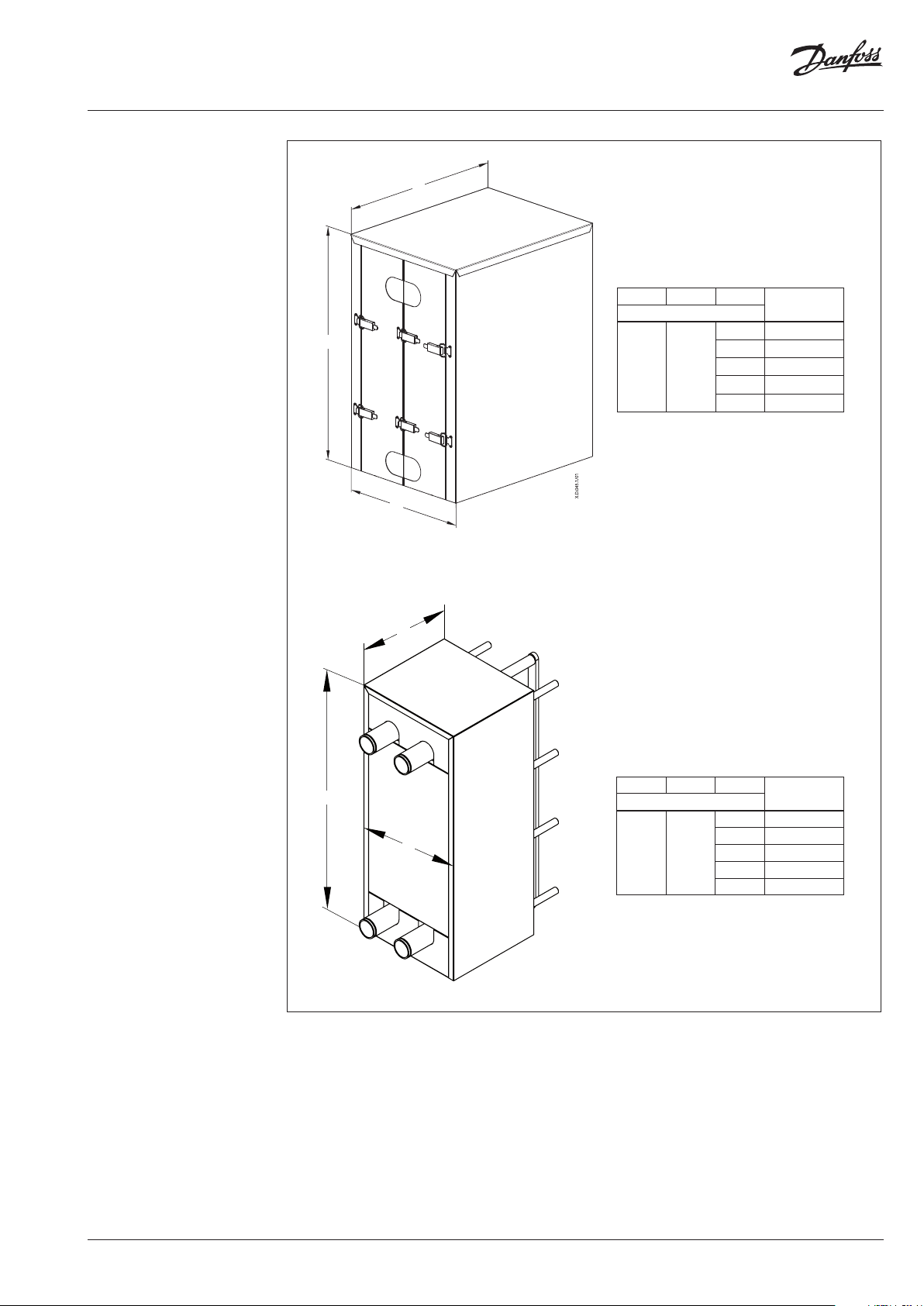

Dimensions (continuous)

Lmax

A

E

C

G

D

B

E

Pass

Typ e PN

XGM050 H&M

16

XGM050L

Note: For bl ock mix solution please ref er to Hexact.

Connection

no.

1 Thread G 2" 2 + 2.37 × n

1 Flange DN 50 0 + 2.37 × n

2 Thread G 2" 5 + 2.37 × n

2 Flange DN 50 1 + 2.37 × n

1 Thread G 2" 2 + 3.57 × n

1 Flange DN 50 0 + 3.57 × n

2 Thread G 2" 5 + 3.57 × n

2 Flange DN 50 1 + 3.57 × n

type

A B C D E G L

mm

304 127 576 73 765 43 7.5 -133 7.5

max

6 | AI160986475761en-000401

© Danfoss | 2019.11

Page 7

Data sheet XGM050

Dimensions (continuous)

G

H

Insulation

(Aluminium stucco and mineral wool)

G B H

mm

572.5 004H4230

722.5 0 04H4231

835 444

B

872.5 004H4232

1022.5 004 H4233

1172. 5 00 4H4234

Code No

H

Insulation

Coated steel sheet and polyester insulation

G

B

G B H

mm

795 364

167 0 04H4270

263 00 4H4271

354 00 4H4272

447 0 04H4273

539 0 04H 4274

Code No

© Danfoss | 2019.11

AI160986475761en-000401 | 7

Page 8

Danfos

produc

Al

Danfoss A/S

Heating Segment • heating

Data sheet XGM050

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its products w ithout notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are p roperty of the respective companies. Danfoss and all D anfoss logotypes are trademarks of Danfoss A/S. All rights reser ved.

8 | AI160986475761en-000401

.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

© Danfoss | DHS-SRMT/SI | 2019.11

Loading...

Loading...