Page 1

Data sheet

Plate Heat Exchanger

XGM032

Description

Ordering

Micro Plate Heat Exchangers - a revolutionary

technology from Danfoss. Characterized by their

unique plate pattern, MPHEs enable heat to be

transferred more efficient than any previous

model of heat exchangers.

XGM 032 H – 1 – 10

Benefits:

• Energy and cost savings

• Better heat transfer

• Lower pressure loss

• More flexible design

• Longer life time

more on:

MPHE.danfoss.com

XGM032 is gasketed plate heat exchanger,

designed and configured for District Heating and

other Heating applications.

Heat exchanger XGM032 will be available in plate

corrugation H, M and L. It will be available in

1-pass version (with 4 connections) and 2-pass

version (with 6 connections). Heat exchanger can

be dimensioned in Danfoss calculation software

“Hexact” which can be downloaded from hexact.

danfoss.com.

Approvals:

• Pressure Equipment Directive (PED)

• GOST/Russia

Number of plates

Number of Passes (1 = 1-pass)

Channel type (L-M-H)

Connection size (DN 32)

Micro plate™ plates

Gasketed heat exchanger

1-pass gasketed heat exchangers type XGM032 (PN 16)

Picture

No. of plates

(n)

20

30 004H7097 004H7088 004H7079

40 004H709 8 004H7089 004H7080

50 004H7099 004H70 90 004H7081

60 004H7100 004H7091 004H70 82

70 0 04H7101 00 4H7092 004 H7083

80 004H7102 004 H7093 004H7084

90 004H710 3 004H7094 004H70 85

100 004H7104 0 04H7095 004H7086

Connection

Thread

G 1¼

XGM032 L XGM032 M XGM032 H

004H7096 004H7087 004H7078

Code No.

© Danfoss | 2019.02

VD.GS.U6.02 | 1

Page 2

Data sheet Micro Plate Heat Exchanger (MPHE) XGM032

Ordering - continuous

Accessories - Insulations

Type coverage (p late nos) Code N o.

20-40 079G0 052

41-70 079G0053

71-10 0 079G0054

Accessories - EPDM Gasket

Typ e Code No.

Gasket for XGM032, I-p * 10 pcs 079H9030

Gasket for XGM032, I-p * 250 pcs 079 H9031

* I-p: Indust rial pack

Accessories for gasketed heat exchanger type XGM

Typ e Code No.

Plates 4H 0.4 XGM032H 1.4404 I-P 10 079 B0416

Plates 4H 0.4 XGM032L 1.4404 I-P 10 079B 0417

Plates 4H 0.4 XGM032L 1.4404 I-P 10 079 B0418

XGM032H: spec. plates 1-pass versions, including gaskets 0,4 079H9036

XGM032M: spec. plates 1-pass versions, including gaskets 0,4 079H9037

XGM032L: spec. plates 1-pass versions, including gaskets 0,4 079H9038

XGM032H: spec. plates 2-pass versions, including gaskets 0,4 079H9 042

XGM032M: spec. plates 2-pass versions, including gaskets 0,4 079H9043

XGM032L: spec. plates 2-pass versions, including gaskets 0,4 079H 9044

Tailpieces for gasketed heat exchanger type XG

Picture Description Connection Co de No.¹ ⁾

Solder tailpieces G 1¼ A/22 mm, 28 mm 00 4B1358

Weld-on tailpieces

1)

One set contains 2 tail pieces with union nuts and gask ets

G 1¼ A/DN 25 003 H6910

G 1¼ A/DN 32 00 4B134 3

Technical data

Max. working pressure PN (bar) 16 & 25

Max. operating temperature

Min. operating temperature

Flow medium Circulation water / glycolic water up to 50 %

Volume / Channel

Primary side volume (n/2) -1 x volume/channel

Secondary side volume (n/2) x volume/channel

Connection type Cylindrical external thread acc. to DIN ISO 228/1

Connection size G 1¼

Plate material Stainless steel, mat. no. EN 1.4404

Plate thickness mm 0.4

Gasket type Glue free

Gasket material, rubber EPDM

1)

At flow temp. b elow 2 °C glycolic water must be use d

1)

150

o

C

−10

0.097

Ltr

Insulation properties

Typ e

Heat conductivity, λ W/mK 0.042

Max

temperature

Wall thickness mm 40

Note:

For more details ab out insulation please contac t your Danfoss

sales representative.

Permanent

Short term peak 180

Aluminium stucco

and mineral wool

°C

150

2 | © Danfoss | 2019.02

VD.GS.U6.02

Page 3

Data sheet Micro Plate Heat Exchanger (MPHE) XGM032

Design and function

Sizing

T11

T22

1-pass heat exchanger

T11 - Primary side in

T12 - Primary side out

T21 - Secondary side in

T22 - Secondary side out

T12

T21

XGM032 will be available as standard and tailor

made unit. It can be calculated in latest version

of Danfoss calculation software “Hexact”

ver. 2.1.3 which can be downloaded from

hexact.danfoss.com.

The heat exchangers are made of shape-pressed

heat plates between which the flow channels are

created. Gaskets between the plates separate

the flow channels from each other so that the

flows do not mix. The heavy turbulence and

counter-flow principle enables efficient heat

transfer. The task of the heat exchanger is to

transfer heat from the primary to secondary flow

through a heat transfer plate thus preventing

the flows from mixing with each other. The plate

heat exchanger with gaskets can be opened

for cleaning and for replacement of plates and

gaskets. A steeples output adjustment can be

carried out by changing the number of plates.

The choice of heat exchanger is determined by

the desired heat output, required temperatures

and the permitted pressure losses.

Mounting The heat exchanger must be mounted in vertical

position. Prepare the foundation for the heat

exchanger if necessary, always according to local

regulations. It is recommended that all pipes

connected to the heat exchanger are equipped

with shut-off valves for maintenance purposes.

The pipes to be connected must be mounted so

that the strain caused by the thermal expansion,

for instance, does not harm the heat exchanger.

The pipes must be equipped with brackets to

prevent any torsional stress concentration at the

heat exchanger’s pipe connections.

It is recommended that the heat exchanger is

equipped with insulation.

A safety valve must be installed between the

heat exchanger and the shut-off valves on the

secondary side of the heat exchanger. If the

safety valve is not installed, thermal expansion of

fluid might destroy the heat exchanger when the

shut-off valves are closed.

VD.GS.U6.02

© Danfoss | 2019.02 | 3

Page 4

Danfos

produc

Al

Danfoss A/S

Heating Segment • heating

Data sheet Micro Plate Heat Exchanger (MPHE) XGM032

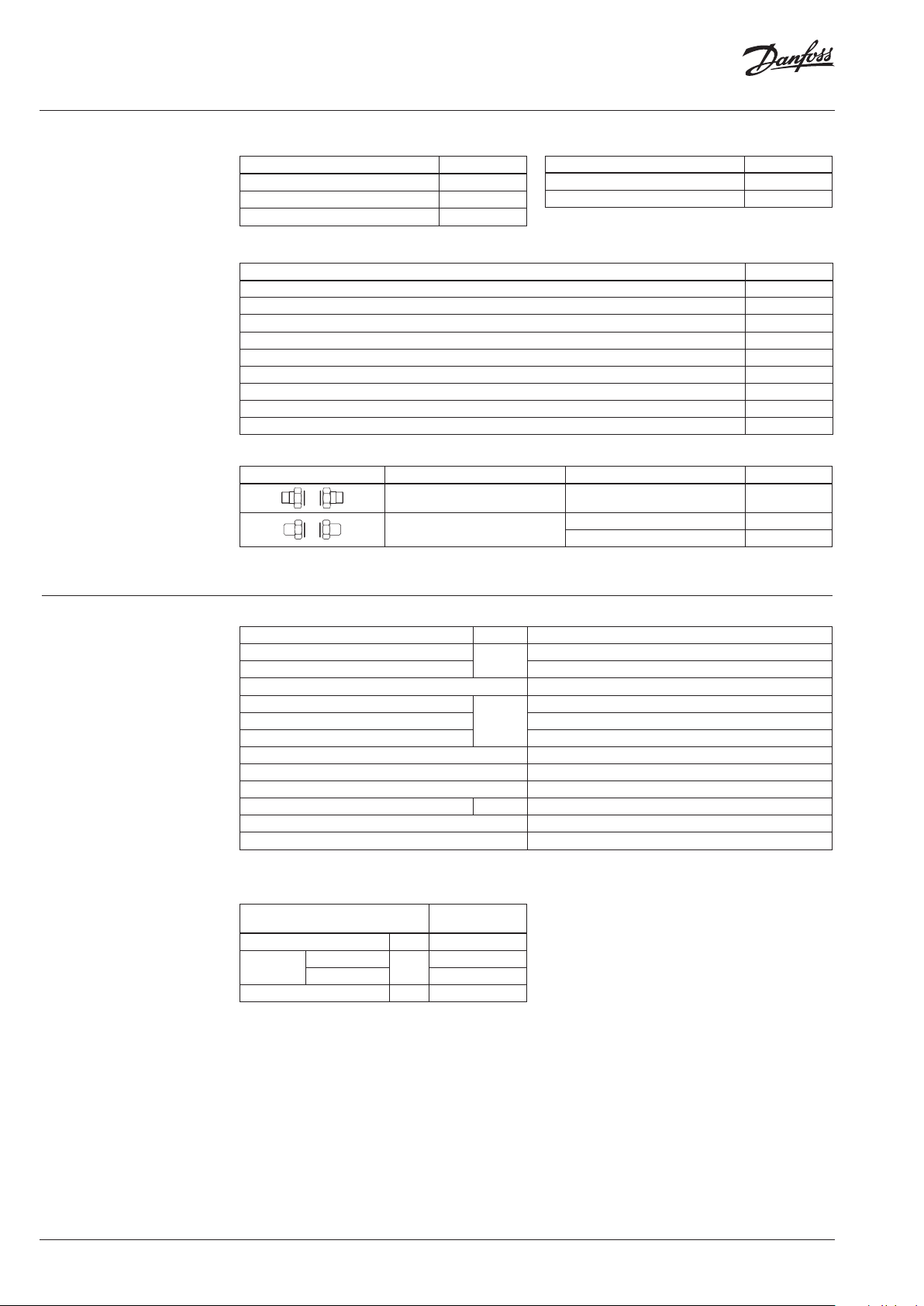

Dimensions

G

D

1)

A

E

C

Heat exchanger

E

B

H

No. of plates A B C D E G

10- 40

41-70

71-10 0

n = number of pl ates

2.4 x n 180 63 470 65 630

Weight

(kg)

0.21 x n + 36.14

0.21 x n + 43.51

0.21 x n + 50.88

1)

Dimensions for 2-pass and PN25 version can be ex tract from calculating software “Hexact” in tab “Dimensional data”.

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its products w ithout notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are p roperty of the respective companies. Danfoss and all D anfoss logotypes are trademarks of Danfoss A/S. All rights reser ved.

4 | © Danfoss | DHS-SRMT/SI | 2019.02

G

Insulation

B

.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

I

G B I H

633 276 55

Weight

(kg)

360 10 079G0 052

460 12 079G 0053

560 14 079G0054

Code No.

VD.GS.U6.02

Loading...

Loading...