Page 1

Data sheet

Plate heat exchanger

XGF100 -034, -035, -050, -066

Description

Design and function

The heat exchangers are made of shape-pressed

heat plates between which the ow channels are

created. Gaskets between the plates separate

the ow channels from each other so that the

ows do not mix. The heavy turbulence and

counter-ow principle enables ecient heat

transfer. The task of the heat exchanger is to

transfer heat from the primary to secondary ow

through a heat transfer plate thus preventing

the ows from mixing with each other. The plate

heat exchanger with gaskets can be opened

for cleaning and for replacement of plates and

gaskets. The heat output can be changed by

adding or removing plates.

The choice of heat exchanger is determined by

the desired heat output, required temperatures

and the permitted pressure losses.

The XGF100 gasketed hex range include 4 plate

types in dierent length and same width.

All plates are available in L and H type which can

be combined to M type. This datasheet include

a range of types, where standard code no’s

have been prepared, all in PN 16 variants in 1

pass. Standard codes have not been created for

XGF100 -06 6.

Danfoss XGF plate heat exchanger has been

developed specically for District Energy

applications like District Heating and Cooling

ensuring you a reliable high ecient plate heat

exchanger fullling your needs.

Among others the XGF range include following

features:

- Improved plate alignment system;

- Glue free gaskets with a robust attachment

system;

- Enforced distribution area;

- Optimized distribution area ensures high

eciency and reduced risk of fouling.

T11

T22

1-pass heat exchanger

T11 - Primary side in

T12 - Primary side out

T12

T21

T21 - Secondary side in

T22 - Secondary side out

The complete range can be supplied in PN 25

and 2 pass variants. All variants can be calculated

in Danfoss Calculation software “Hexact”, where

they will be shown without a standard code no.

Unique code no’s for these variants will be

created when they are ordered. Please contact

your local Danfoss Sales Oce for oering and

ordering.

DEN-SMT/SI

VD.GS.L4.02 © Danfoss 01/2015

1

Page 2

Data sheet Plate heat exchanger XGF100

Ordering

1-pass gasketed heat exchangers type XGF100

Picture

No. of plates 100-034H 100-034M 100-034L 100-035H 100-035M 100-035L 100-050H

(n) Code No.

50 004H7001 0 04H 7012 004H7023 004H703 4 004H7045 004H7056 004H7067

60 004H7002 0 04H7013 0 04H7024 0 04H7035 004H7046 00 4H7057 004H7068

70 004H7003 00 4H7014 004H7025 0 04H7036 004H7047 004H7058 004H7069

80 004H7004 0 04H 7015 004H7026 004H7037 004H7048 004H7059 004H7070

90 004H7005 0 04H7016 0 04H7027 0 04H7038 004H7049 004H7060 004 H7071

100 004H7006 00 4H7 017 004H7028 004H7039 004H7050 004H7061 00 4H7072

110 004H7007 00 4H7018 00 4H7029 004H7040 00 4H7051 004H7062 004H7073

120 004H7008 00 4H7019 004H7030 004H7041 004H7052 004H7063 004H 7074

130 004H7009 004H7020 004H7031 004H7042 004H70 53 004H7064 004H 7075

140 0 04H7010 0 04H7021 004H7032 004H7043 00 4H7054 004H7065 00 4H7076

150 00 4H7 011 004H7022 004 H7033 004H7044 004H7055 004H7066 00 4H7077

Accessories - Insulations

Type coverage (plate nos) No. of plates Code No.

Insulation set

XGF10 0-034 20 ->54

XGF10 0-035 20 ->34

XGF10 0-034 5 6->14 4

XGF10 0-035 36 ->92

XGF10 0-034 14 6->2 66

XGF10 0-035 9 4->16 8

004H710 5

004H7106

004H710 7

Type coverage (plate nos) No. of plates Code No.

Insulation set XGF100-050

Insulation set XGF100-066

Accessories - EPDM Gasket, sets of 10 & 250 (Pricelist is per 1 pc.)

Typ e Code No.

Gasket for XGF100-034, I-pack 10 pcs 00 4H712 0

Gasket for XGF100-034, I-pack 250 pcs 00 4H7121

Gasket for XGF100-035, I-pack 10 pcs 00 4H712 2

Gasket for XGF100-035, I-pack 250 pcs 00 4H7123

Typ e Code No.

Gasket for XGF100-050H, I-pack 10 pcs 00 4H712 4

Gasket for XGF100-050H, I-pack 250 pcs 00 4H712 5

Gasket for XGF100-066H, I-pack 10 pcs 00 4H712 6

Gasket for XGF100-066H, I-pack 250 pcs 00 4H7127

20 ->54 00 4H7 111

56 ->14 4 00 4H7 112

146->26 6 004 H7113

20 ->54 00 4H7 114

56 ->14 4 00 4H7 115

146->26 6 00 4H 7116

Accessories - Plates for XG100 PN16, sets of 10 & 250 (Material 1.4404) (Pricelist is per 1 pc.)

Type coverage (plate nos) Code No.

Plates for XGF100- 034H PN16, I-pack 10 pcs 00 4H713 0

Plates for XGF100- 034L PN16, I-pack 10 pcs 00 4H7131

Plates for XGF100- 034H PN16, I-pack 250 pcs 00 4H7132

Plates for XGF100- 034L PN16, I-pack 250 pcs 00 4H7133

Plates for XGF100- 035H PN16, I-pack 10 pcs 00 4H713 4

Plates for XGF100- 035L PN16, I-pack 10 pcs 00 4H7135

Plates for XGF100- 035H PN16, I-pack 250 pcs 00 4H7136

Plates for XGF100- 035L PN16, I-pack 250 pcs 00 4H7137

Type coverage (plate nos) Code No.

Plates for XGF100- 050H PN16, I-pack 10 pcs 00 4H713 8

Plates for XGF100- 050L PN16, I-pack 10 pcs 004H7139

Plates for XGF100- 050H PN16, I-pack 250 pcs 004H7140

Plates for XGF100- 050L PN16, I-pack 250 pcs 00 4H7141

Plates for XGF100- 066H PN16, I-pack 10 pcs 0 04H 7134

Plates for XGF100- 066L PN16, I-pack 10 pcs 004 H7135

Plates for XGF100- 066H PN16, I-pack 250 pcs 004H7136

Plates for XGF100- 066L PN16, I-pack 250 pcs 004H 7137

Accessories - PN16, sets of 1 front and 1 back plate for 1 pass versions incl EPDM gaskets

Typ e Code No.

XGF100-034H: spec. plates 1-pass versions,

including gaskets. PN16

XGF100-034L: spec. plates 1-pass versions,

including gaskets. PN16

XGF100-035H: spec. plates 1-pass versions,

including gaskets. PN16

XGF100-035L: spec. plates 1-pass versions,

including gaskets. PN16

00 4H714 6

00 4H714 8

00 4H714 9

00 4H7151

Typ e Code No.

XGF100-050H: spec. plates 1-pass versions,

including gaskets. PN16

XGF100-050L: spec. plates 1-pass versions,

including gaskets. PN16

XGF100-066H: spec. plates 1-pass versions,

including gaskets. PN16

XGF100-066L: spec. plates 1-pass versions,

including gaskets. PN16

00 4H7152

00 4H7154

00 4H7155

00 4H7157

Accessories - PN16, sets of 1 front, 1 back and 1 middle plates for 2 pass versions incl EPDM gaskets

Typ e Code No.

XGF100-034H: spec. plates 2-pass version,

including gaskets PN16

00 4H7158

Typ e Code No.

XGF100-050H: spec. plates 2-pass version,

including gaskets PN16

004H7164

2

VD.GS.L4.02 © Danfoss 01/2015

DEN-SMT/SI

Page 3

Data sheet Plate heat exchanger XGF100

Ordering (continuous)

Accessories - Plates for XG100 PN25, sets of 10 & 250 (Material 1.4404) (Pricelist is per 1 pc.)

Type coverage (plate nos) Code No.

Plates for XGF100- 034H PN25, I-pack 10 pcs 00 4H717 0

Plates for XGF100- 034L PN25, I-pack 10 pcs 004H7171

Plates for XGF100- 034H PN25, I-pack 250 pcs 00 4H7172

Plates for XGF100- 034L PN25, I-pack 250 pcs 004H7173

Plates for XGF100- 035H PN25, I-pack 10 pcs 00 4H7174

Plates for XGF100- 035L PN25, I-pack 10 pcs 00 4H7175

Plates for XGF100- 035H PN25, I-pack 250 pcs 00 4H7176

Plates for XGF100- 035L PN25, I-pack 250 pcs 00 4H717 7

Type coverage (plate nos) Code No.

Plates for XGF100- 050H PN25, I-pack 10 pcs 00 4H717 8

Plates for XGF100- 050L PN25, I-pack 10 pcs 004H 7179

Plates for XGF100- 050H PN25, I-pack 250 pcs 004 H7180

Plates for XGF100- 050L PN25, I-pack 250 pcs 0 04H7181

Plates for XGF100- 066H PN25, I-pack 10 pcs 0 04H718 2

Plates for XGF100- 066L PN25, I-pack 10 pcs 004H7183

Plates for XGF100- 066H PN25, I-pack 250 pcs 004 H7184

Plates for XGF100- 066L PN25, I-pack 250 pcs 004H7185

Accessories - PN25, sets of 1 front and 1 back plate for 1 pass versions incl EPDM gaskets

Typ e Code No.

XGF100-034H: spec. plates 1-pass versions,

including gaskets. PN25

XGF100-034L: spec. plates 1-pass versions,

including gaskets. PN25

XGF100-035H: spec. plates 1-pass versions,

including gaskets. PN25

XGF100-035L: spec. plates 1-pass versions,

including gaskets. PN25

00 4H7192

00 4H7194

00 4H7195

00 4H7197

Typ e Code No.

XGF100-050H: spec. plates 1-pass versions,

including gaskets. PN25

XGF100-050L: spec. plates 1-pass versions,

including gaskets. PN25

XGF100-066H: spec. plates 1-pass versions,

including gaskets. PN25

XGF100-066L: spec. plates 1-pass versions,

including gaskets. PN25

00 4H7198

004H7200

004 H7201

004H7203

Accessories - PN25, sets of 1 front, 1 back and 1 middle plates for 2 pass versions incl EPDM gaskets

Typ e Code No.

XGF100-034H: spec. plates 2-pass version,

including gaskets PN25

004H7207

Typ e Code No.

XGF100-050H: spec. plates 2-pass version,

including gaskets PN25

00 4H7213

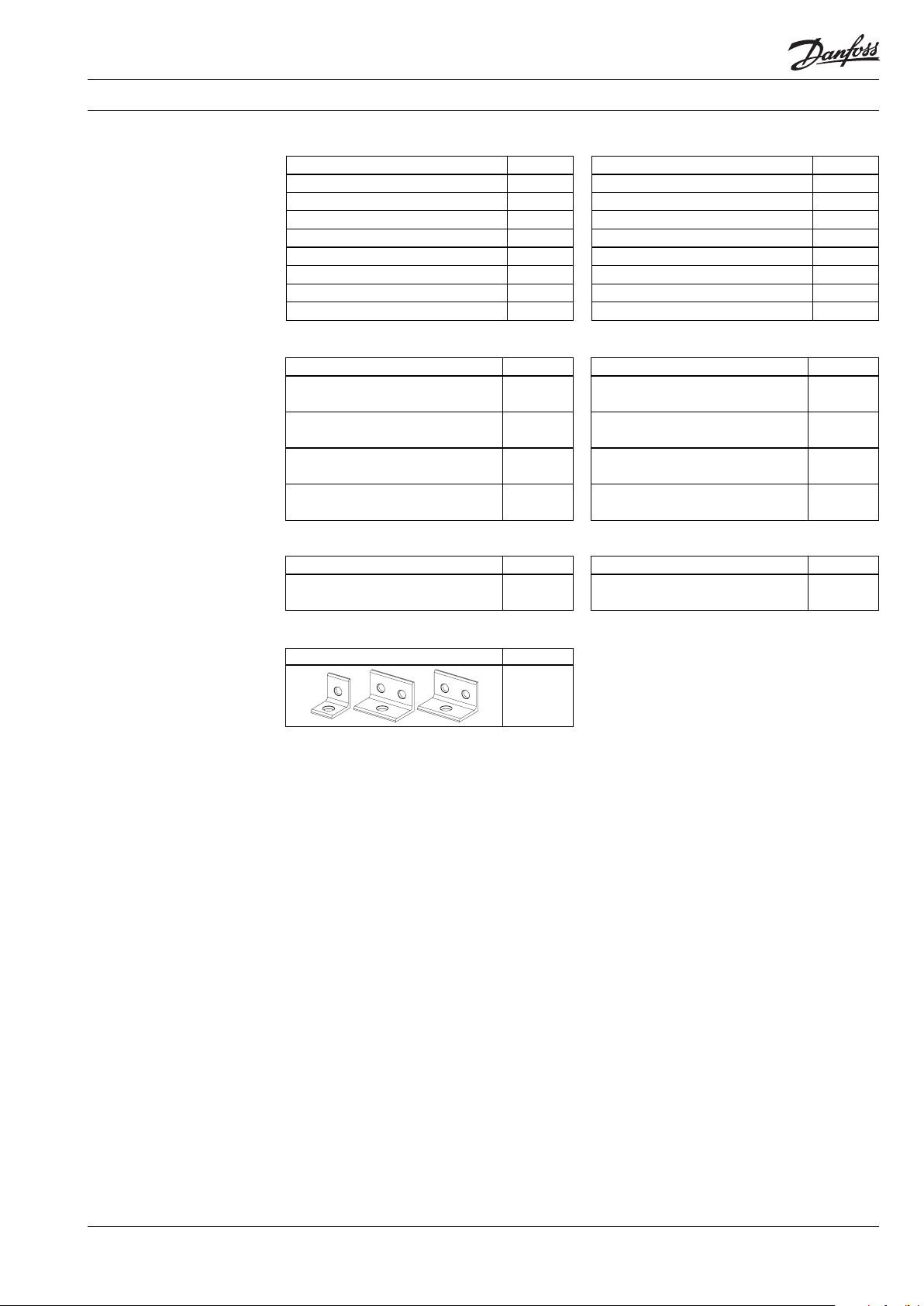

Accessories - Bracket

Picture Code No.

004H7223

NOTE:

Bracket set is not i ncluded in HEX please o rder it separately.

Set contain 3 die rent pcs of bracket/leg s with screws.

DEN-SMT/SI

VD.GS.L4.02 © Danfoss 01/2015

3

Page 4

Data sheet Plate heat exchanger XGF100

Technical data

Note:

For more details a bout insulation please

contact your Danfoss sales representative.

Typ e XGF10 0-34 XGF100 -35 XGF100 -50 XGF10 0-6 6

Max. working pressure PN bar 16

Max. operating temperature

Min. operating temperature −10

Flow medium Circulation water/glycolic water up to 50 %

Heat transfer area per plate, HTA m

Max. no of plates 500 250

Volume/channel

Primary side volume (n/2) -1 × volume/channel

Secondary side volume (n/2) × volume/channel

Connection type Studded for anges according to EN1092, directly on endplates

Connection size DN 10 0

Plate thickness mm 0,5 for PN16

Materials

Plate Stainless steel EN1.4401

Liners in connections Stainless steel EN1.4401

Gasket type Glue free

Gasket material EPDM

o

C

2

ltr

0,306 0,306 0,4 67 0,628

0,3 0,7 0,7 1,5

150

Insulation properties

Typ e

Heat conductivity, λ W/mK 0,042

Max

temperature

Wall thickness mm 65

Permanent

Short term peak

Aluminium stucco and

mineral wool

°C

150

180

Sizing Dimensioning and selection of heat exchangers

should be carried out in the Danfoss calculation

software “Hexact”. The software can be

downloaded from hexact.danfoss.com.

4

VD.GS.L4.02 © Danfoss 01/2015

DEN-SMT/SI

Page 5

Data sheet Plate heat exchanger XGF100

Mounting The heat exchanger must be mounted in vertical

position. Prepare the foundation for the heat

exchanger if necessary, always according to local

regulations. It is recommended that all pipes

connected to the heat exchanger are equipped

with shut-o valves for maintenance purposes.

The pipes to be connected must be mounted so

that the strain caused by the thermal expansion,

for instance, does not harm the heat exchanger.

The pipes must be equipped with brackets to

prevent any torsional stress concentration at the

heat exchanger’s pipe connections.

It is recommended that the heat exchanger is

equipped with insulation.

PN 16 mounting, dimensions and weight

L±5

A safety valve must be installed between the

heat exchanger and the shut-o valves on the

secondary side of the heat exchanger. If the

safety valve is not installed, thermal expansion of

uid might destroy the heat exchanger when the

shut-o valves are closed.

All XGF100 are supplied with brackets for

mounting.

18±0 ,5

XGF100 -34

Plate range

10-54 614

56 -144 914 377 + 1,278 × n

146 -266 1314 395 + 1,278 × n

268-356 1614 415 + 1,278 × n

358-50 8 2114 436 + 1,278 × n

L B Weight

mm (kg)

363 + 1,278 × n

380

XGF100 -50

Plate range

10-54 604

56 -144 904 504 + 1,915 × n

146 -266 130 4 523 + 1,915 × n

268-356 16 04 54 4 + 1,915 × n

358-50 8 2104 566 + 1,915 × n

L B Weight

mm (kg)

493 + 1,915 × n

395

B±2

18±0 ,5

XGF100 -35

Plate range

10-34 614

36-92 914 377 + 1,337 × n

94 -168 1314 395 + 1,337 × n

170 -226 1614 415 + 1,337 × n

226-322 2114 436 + 1,337 × n

L B Weight

mm (kg)

363 + 1,337 × n

380

XGF100 -66

Plate range

10-54 604

56 -144 904 650 + 2,572 × n

146 -266 130 4 660 + 2,572 × n

268-356 16 04 673 + 2,572 × n

358-50 8 2104 687 + 2,572 × n

L B Weight

mm (kg)

634 + 2,572 × n

395

DEN-SMT/SI

VD.GS.L4.02 © Danfoss 01/2015

5

Page 6

Data sheet Plate heat exchanger XGF100

Dimensions

Lmax

H

A

E

C

D

G

B

Typ e PN

XGF10 0-034

XGF10 0-035 4 × n

XGF100-050 2,5 × n

XGF10 0-0 66 2,5 × n 1556 2021

XGF10 0-034

XGF10 0-035 4,1 × n

XGF100-050 2,6 × n

XGF10 0-0 66 2,6 × n 1556 2021

A H B C D E G L

2,5 × n

A + 90 495

16

A + 80 510

2,6 × n

A + 100 495

25

A + 100 510

Dimension for mounting anges on front end plate.

Counteranges for front and back end plate are not

supplied with the he x.

C

max

mm

720 184 110 8 65 4-2154

225

113 8

720 184 110 8 654-216 4

235

113 8

187

187

1603

1603

64 4-2144

64 4-2154

2 pass hex include 4 connections on the front end

plate and 2 connections on the back endplate. The

connections on the front end plate are same as

connections on back endplate, as specied here.

d2

k

6

VD.GS.L4.02 © Danfoss 01/2015

22,5°

45°

n

Typ e PN

XGF 100

Flanges accordin g to EN1092.

D

D k d2

mm

16 220 180 M16 8

25 235 190 M20 8

n

DEN-SMT/SI

Page 7

Data sheet Plate heat exchanger XGF100

Dimensions (continuous)

G

H

Insulation

Typ e PN

XGF10 0-034

XGF10 0-035

XGF100-050

XGF10 0-0 66

16 and 25

16

25

16

25

B

max

Isolation

NOP

54 004H710 5

144 004H7106 720 29

266 00 4H7107 1020 38

356 004H7900 124 0 44

508 004H7901 1640 52

34 004H710 5

92 004H7106 720 29

168 0 04H7107 1020 38

226 004H7900 12 40 44

322 004H7901 1640 52

54 0 04 H7111

144 0 04 H7112 720 55

266 0 04 H7113 1040 75

356 004H7902 1280 90

508 004H7903 168 0 100

54 004H7906 480 40

144 004H7907 720 55

266 004H7908 1040 75

356 004H7909 1280 90

508 004 H7910 1680 100

54 0 04 H7114

144 0 04 H7115 680 70

266 0 04 H7116 1000 95

356 004H7904 120 0 115

508 004H7905 160 0 145

54 0 04H7 911 480 55

144 00 4H7912 680 70

266 00 4H7913 1000 95

356 004 H7914 120 0 11 5

508 00 4H7915 1600 145

code

2080 650

L

G B H

mm (kg)

122 5 634

122 5 634

1670 650

Weight

490 25

490 25

480 40

480 55

DEN-SMT/SI

VD.GS.L4.02 © Danfoss 01/2015

7

Page 8

Data sheet Plate heat exchanger XGF100

8

VD.GS.L4.02 Produce d by Danfoss A/S © 01/2015

Loading...

Loading...