INSTRUCTIONS

INSTRUCTIONS

EC FAN SPEED CONTROLLER

EC FAN SPEED CONTROLLER

Type

Type

IMPORTANT

IMPORTANT

Failure to read and follow all instructions carefully before installing or operating this Fan Speed

Failure to read and follow all instructions carefully before installing or operating this Fan Speed

Controller could cause personal injury and/or property damage. Save these instructions for future use.

Controller could cause personal injury and/or property damage. Save these instructions for future use.

NOTES FOR SAFETY

NOTES FOR SAFETY

!

!

WARNING

WARNING

Before wiring and service, be sure to turn off power supply. Otherwise, may cause electrical shock.

Before wiring and service, be sure to turn off power supply. Otherwise, may cause electrical shock.

Before F.V.S. adjusting, connection of a plug and disassembly of a plug, be sure to turn off power

Before F.V.S. adjusting, connection of a plug and disassembly of a plug, be sure to turn off power

supply as it may cause electrical shock.

supply as it may cause electrical shock.

Do not touch the main body during driving. Otherwise, it may burn a hands.

Do not touch the main body during driving. Otherwise, it may burn a hands.

OUTLINE

OUTLINE

The XGE-*SE fan speed controllers are designed for speed control of electronically commutated (EC) fan motors.

The XGE-*SE fan speed controllers are designed for speed control of electronically commutated (EC) fan motors.

The XGE controls Fan Motor Speed of air cooled condenser of general purpose cold/cooling unit, and keeps a definite condensing

The XGE controls Fan Motor Speed of air cooled condenser of general purpose cold/cooling unit, and keeps a definite condensing

pressure and makes it to drive stably.

pressure and makes it to drive stably.

MOUNTING

MOUNTING

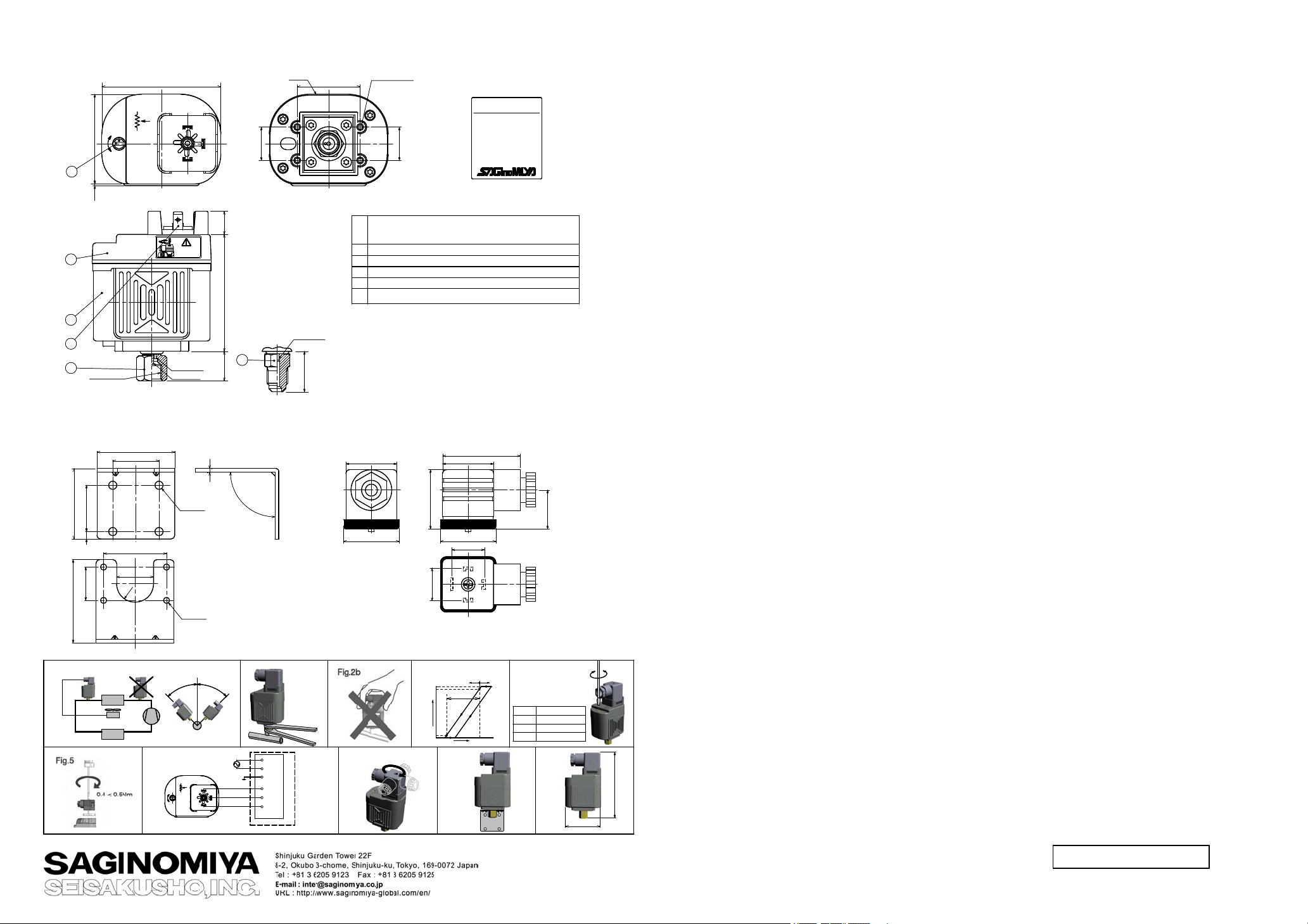

Directly mount onto the pressure line (see Fig.1a) in a location where pressure can be detected accurately (e, g. After the

Directly mount onto the pressure line (see Fig.1a) in a location where pressure can be detected accurately (e, g. After the

condenser) Alternatively it is possible to remote mount to a side panel using the optional fixing bracket (see Fig.8) and

condenser) Alternatively it is possible to remote mount to a side panel using the optional fixing bracket (see Fig.8) and

connect to the pressure line with a refrigeration pipe (not supplied).

connect to the pressure line with a refrigeration pipe (not supplied).

!

!

CAUTION

CAUTION

Don’t install at the place to require degrees of protection over IP65 Category 2 enclosures.

Don’t install at the place to require degrees of protection over IP65 Category 2 enclosures.

Don’t tighten with excessive force whilst holding the unit, since this can result in deformation of the controller.

Don’t tighten with excessive force whilst holding the unit, since this can result in deformation of the controller.

For direct mounting, tighten the connection using an appropriately sized spanner and a torque of 12.7-15Nm (see Fig.2).

For direct mounting, tighten the connection using an appropriately sized spanner and a torque of 12.7-15Nm (see Fig.2).

The mounting position should be in the vertical axis and should not be fitted more than 45°from the vertical (see Fig.1b).

The mounting position should be in the vertical axis and should not be fitted more than 45°from the vertical (see Fig.1b).

Failure to install the Copper Packing at the connection portion cause leak of refrigerant gas.

Failure to install the Copper Packing at the connection portion cause leak of refrigerant gas.

Provide adequate ventilation space so that heat doesn’t build up. At least 50mm clearance above the top and below the bottom

Provide adequate ventilation space so that heat doesn’t build up. At least 50mm clearance above the top and below the bottom

of XGE is necessary. Don’t mount this instrument directly above equipment that generates large amount of heat. (heaters,

of XGE is necessary. Don’t mount this instrument directly above equipment that generates large amount of heat. (heaters,

transformers, large-wattage resistors.)

transformers, large-wattage resistors.)

Don’t give strong impact over 100G. This may result changing in properties and breakage.

Don’t give strong impact over 100G. This may result changing in properties and breakage.

WIRING

WIRING

Please refer wiring diagram (Fig.6) to connect the plug (supplied). When the plug has wired, refer Fig.5 to mount the plug,

Please refer wiring diagram (Fig.6) to connect the plug (supplied). When the plug has wired, refer Fig.5 to mount the plug,

and fix by screw (supplied). The plug can wire so that orientation is possible in 4 directions as desired. (see Fig. 7)

and fix by screw (supplied). The plug can wire so that orientation is possible in 4 directions as desired. (see Fig. 7)

XGE

XGE

RESTRICTIONS OF USE

RESTRICTIONS OF USE

This Product is designed and manufactured for the purpose of using them for cooling and heating and refrigerating

This Product is designed and manufactured for the purpose of using them for cooling and heating and refrigerating

appliances and air conditioning equipment or various industrial equipment, but is not designed and manufactured for the

appliances and air conditioning equipment or various industrial equipment, but is not designed and manufactured for the

purpose of using this Product for any instrument or system related to human life or health purposes.

purpose of using this Product for any instrument or system related to human life or health purposes.

Therefore, the use of this Product in fields related to items (1) through (3) below is not intended whatsoever. Saginomiya

Therefore, the use of this Product in fields related to items (1) through (3) below is not intended whatsoever. Saginomiya

shall be held harmless and be indemnified from any and all damages incurred by use of this Product under item (3).

shall be held harmless and be indemnified from any and all damages incurred by use of this Product under item (3).

(1) In any field related to nuclear power and radiation;

(1) In any field related to nuclear power and radiation;

(2) In any field related to space or seafloor equipment;

(2) In any field related to space or seafloor equipment;

(3) In any equipment or device requiring a high degree of reliance on such equipment or device with respect to which it

(3) In any equipment or device requiring a high degree of reliance on such equipment or device with respect to which it

is reasonably foreseeable that failure or malfunction of the equipment or device would either directly or indirectly

is reasonably foreseeable that failure or malfunction of the equipment or device would either directly or indirectly

cause serious damage to human life, health or property;

cause serious damage to human life, health or property;

Also, when using this Product under the fields related to items (1) through (9) , (except for item (3),in relation to which

Also, when using this Product under the fields related to items (1) through (9) , (except for item (3),in relation to which

this Product must never be used), please be sure to notify our Saginomiya’s contact desk in charge of sales and obtain

this Product must never be used), please be sure to notify our Saginomiya’s contact desk in charge of sales and obtain

Saginomiya’s prior written approval for such use.

Saginomiya’s prior written approval for such use.

Saginomiya shall be held harmless and be indemnified from any and all damages incurred by use of this Product in relation to

Saginomiya shall be held harmless and be indemnified from any and all damages incurred by use of this Product in relation to

these fields if the Customers do not notify Saginomiya's contact desk and obtain Saginomiya's

these fields if the Customers do not notify Saginomiya's contact desk and obtain Saginomiya's

prior written approval.

prior written approval.

(4) Transportation device (railroad, aviation, ship or vessel, vehicle equipment, etc.);

(4) Transportation device (railroad, aviation, ship or vessel, vehicle equipment, etc.);

(5) Disaster-prevention or crime-prevention device;

(5) Disaster-prevention or crime-prevention device;

(6) Facility or application directly related to medical equipment, burning appliances, electro thermal

(6) Facility or application directly related to medical equipment, burning appliances, electro thermal

equipment, amusement rides and devices, facilities/applications associated directly with billing, or

equipment, amusement rides and devices, facilities/applications associated directly with billing, or

device using flammable fluid;

device using flammable fluid;

(7) Equipment requiring high reliance on supply systems such as electricity, gas, water, etc., in large-scale

(7) Equipment requiring high reliance on supply systems such as electricity, gas, water, etc., in large-scale

communication system, or in transportation or air traffic control system;

communication system, or in transportation or air traffic control system;

(8) Facilities that are to comply with regulations of governmental / public agencies or specific industries or

(8) Facilities that are to comply with regulations of governmental / public agencies or specific industries or

(9) Other machineries or equipment equivalent to those set forth in the above items (4) to (8) which require

(9) Other machineries or equipment equivalent to those set forth in the above items (4) to (8) which require

for high reliability and safety.

for high reliability and safety.

It is recommended to replace this Product within 5 to 10 years of delivery if no other duration of use is provided in the

It is recommended to replace this Product within 5 to 10 years of delivery if no other duration of use is provided in the

applicable specifications or instruction manual because the conditions and environment of use also have an impact on this

applicable specifications or instruction manual because the conditions and environment of use also have an impact on this

Product.

Product.

SCOPE OF WARRANTY

SCOPE OF WARRANTY

SAGINOMIYA WILL PROVIDE THE CUSTOMERS WITH REPLACEMENT OR REPAIRED THIS PRODUCT DELIVERED, FREE OF COST, ONLY WITHIN ONE YEAR

SAGINOMIYA WILL PROVIDE THE CUSTOMERS WITH REPLACEMENT OR REPAIRED THIS PRODUCT DELIVERED, FREE OF COST, ONLY WITHIN ONE YEAR

OF DELIVERY TO THE CUSTOMER, IF FAILURE OCCURS IN THE CUSTOMERS’ EQUIPMENT USING THIS PRODUCT DUE TO A DEFECT OF THIS PRODUCT;

OF DELIVERY TO THE CUSTOMER, IF FAILURE OCCURS IN THE CUSTOMERS’ EQUIPMENT USING THIS PRODUCT DUE TO A DEFECT OF THIS PRODUCT;

PROVIDED, HOWEVER, THAT IN ANY EVENT THE RATIO OF THE AMOUNT THAT SAGINOMIYA BEARS FOR THE DAMAGES INCURRED BY THE FAILURE OF

PROVIDED, HOWEVER, THAT IN ANY EVENT THE RATIO OF THE AMOUNT THAT SAGINOMIYA BEARS FOR THE DAMAGES INCURRED BY THE FAILURE OF

THIS PRODUCT OR CUSTOMERS’ EQUIPMENT SHALL NOT EXCEED THE PRICE OF THIS PRODUCT WE DELIVERED. IN ADDITION, SAGINOMIYA SHALL

THIS PRODUCT OR CUSTOMERS’ EQUIPMENT SHALL NOT EXCEED THE PRICE OF THIS PRODUCT WE DELIVERED. IN ADDITION, SAGINOMIYA SHALL

BE HELD HARMLESS AND BE INDEMNIFIED FROM ANY AND ALL DAMAGES INCURRED WHEN THE FAILURE OF THE CUSTOMERS’ EQUIPMENT OCCURRED

BE HELD HARMLESS AND BE INDEMNIFIED FROM ANY AND ALL DAMAGES INCURRED WHEN THE FAILURE OF THE CUSTOMERS’ EQUIPMENT OCCURRED

DUE TO ANY CAUSE SET FORTH BELOW.

DUE TO ANY CAUSE SET FORTH BELOW.

(1) WHEN CAUSED BY INAPPROPRIATE HANDLING OR USE OF THIS PRODUCT BY THE CUSTOMERS (SUCH AS NOT COMPLYING WITH THE CONDITIONS,

(1) WHEN CAUSED BY INAPPROPRIATE HANDLING OR USE OF THIS PRODUCT BY THE CUSTOMERS (SUCH AS NOT COMPLYING WITH THE CONDITIONS,

ENVIRONMENTAL SPECIFICATIONS OR CAUTIONS INDICATED IN ANY APPLICABLE CATALOGUE, SPECIFICATIONS, INSTRUCTION MANUAL, ETC.);

ENVIRONMENTAL SPECIFICATIONS OR CAUTIONS INDICATED IN ANY APPLICABLE CATALOGUE, SPECIFICATIONS, INSTRUCTION MANUAL, ETC.);

(2) WHEN FAILURE OCCURRED DUE TO ANY REASON OTHER THAN THIS PRODUCT;

(2) WHEN FAILURE OCCURRED DUE TO ANY REASON OTHER THAN THIS PRODUCT;

(3) WHEN CAUSED BY MODIFICATION OR REPAIR OF THIS PRODUCT MADE BY ANYONE OTHER THAN SAGINOMIYA OR DESIGNEE OF SAGINOMIYA;

(3) WHEN CAUSED BY MODIFICATION OR REPAIR OF THIS PRODUCT MADE BY ANYONE OTHER THAN SAGINOMIYA OR DESIGNEE OF SAGINOMIYA;

(4) WHEN CAUSED BY THE USE OF THIS PRODUCT IN VIOLATION OF THE ABOVE “RESTRICTIONS OF USE” OR “CONFIRMATION OF OPERATION”;

(4) WHEN CAUSED BY THE USE OF THIS PRODUCT IN VIOLATION OF THE ABOVE “RESTRICTIONS OF USE” OR “CONFIRMATION OF OPERATION”;

(5)

(5)

WHEN SUCH FAILURE WAS NOT REASONABLY FORESEEABLE AT THE TIME OF SAGINOMIYA'S SHIPMENT; OR

WHEN SUCH FAILURE WAS NOT REASONABLY FORESEEABLE AT THE TIME OF SAGINOMIYA'S SHIPMENT; OR

(6) BY ANY OTHER CAUSE NOT ATTRIBUTABLE TO SAGINOMIYA, SUCH AS AN ACT OF GOD, DISASTER, OR ACT OF ANY THIRD PARTY.

(6) BY ANY OTHER CAUSE NOT ATTRIBUTABLE TO SAGINOMIYA, SUCH AS AN ACT OF GOD, DISASTER, OR ACT OF ANY THIRD PARTY.

PLEASE NOTE THAT THE CUSTOMERS WILL NOT BE ENTITLED TO ANY OF THE ABOVE WARRANTY IF THE CUSTOMERS PURCHASED THIS PRODUCT FROM

PLEASE NOTE THAT THE CUSTOMERS WILL NOT BE ENTITLED TO ANY OF THE ABOVE WARRANTY IF THE CUSTOMERS PURCHASED THIS PRODUCT FROM

INTERNET AUCTION, ETC.

INTERNET AUCTION, ETC.

!

!

CAUTION

CAUTION

For connecting motor, use Fan Motor (SELV circuit) that isolated the primary circuit(Fan Motor main AC) and the secondary

For connecting motor, use Fan Motor (SELV circuit) that isolated the primary circuit(Fan Motor main AC) and the secondary

circuit(Fan Speed Controller).

circuit(Fan Speed Controller).

Cable length for connecting the Fan Speed Controller and Fan Motor should be less than 10m.

Cable length for connecting the Fan Speed Controller and Fan Motor should be less than 10m.

Fix the plug onto the XGE, using the gasket provided and securely tighten with the screw (also provided) using a torque of

Fix the plug onto the XGE, using the gasket provided and securely tighten with the screw (also provided) using a torque of

0.4-0.6Nm (see Fig.5).

0.4-0.6Nm (see Fig.5).

CAUTION: It is important to use the gasket (DIN 43650) between the plug and controller as well as tightening the screw

CAUTION: It is important to use the gasket (DIN 43650) between the plug and controller as well as tightening the screw

sufficiently to avoid the risk of electrical shock or short circuit.

sufficiently to avoid the risk of electrical shock or short circuit.

ADJUSTING(see Fig.4)

ADJUSTING(see Fig.4)

Turn the Range Adjusting Screw to clockwise (+) for increasing the

Turn the Range Adjusting Screw to clockwise (+) for increasing the

setting value, and to counterclockwise (-) for decreasing the setting value.

setting value, and to counterclockwise (-) for decreasing the setting value.

!

!

CAUTION

CAUTION

Do not move the screw other than the Range Adjusting Screw.

Do not move the screw other than the Range Adjusting Screw.

Please do not apply more than 0.35Nm torque to the range adjusting screw.

Please do not apply more than 0.35Nm torque to the range adjusting screw.

If applied torque excess over 0.35Nm, a part of resin-made case may be brokenand

If applied torque excess over 0.35Nm, a part of resin-made case may be brokenand

it may be impossible to adjust the range.

it may be impossible to adjust the range.

CONFIRMATION OF OPERATION

CONFIRMATION OF OPERATION

All customers using this Product (hereinafter referred to as “Customers”) are requested to, after properly installing this

All customers using this Product (hereinafter referred to as “Customers”) are requested to, after properly installing this

Product, test the operation of this Product to confirm that all the systems in connection with this Product fully function.

Product, test the operation of this Product to confirm that all the systems in connection with this Product fully function.

In order to prevent the occurrence of bodily injury, fire accidents, serious damage, etc., in connection with the Customers’

In order to prevent the occurrence of bodily injury, fire accidents, serious damage, etc., in connection with the Customers’

machinery or equipment due to improper installation of this Product, Saginomiya kindly requests the Customers to take the

machinery or equipment due to improper installation of this Product, Saginomiya kindly requests the Customers to take the

necessary safety measures by preparing safe designs such as a fail-safe design (*1) and a fire spread prevention design,

necessary safety measures by preparing safe designs such as a fail-safe design (*1) and a fire spread prevention design,

as well as to make the proper adjustments for product reliability necessary for fault-tolerance (*2).

as well as to make the proper adjustments for product reliability necessary for fault-tolerance (*2).

(*1) Fail-safe design: Design to ensure safety in the event of any mechanical failure

(*1) Fail-safe design: Design to ensure safety in the event of any mechanical failure

(*2) Fault-tolerance: Utilization of redundancy technology

(*2) Fault-tolerance: Utilization of redundancy technology

Periodic Inspection of this Product

Periodic Inspection of this Product

Be sure to confirm the proper operation of this Product and keep records of such operation at least once a year. Saginomiya

Be sure to confirm the proper operation of this Product and keep records of such operation at least once a year. Saginomiya

shall be held harmless and be indemnified by the Customers from any damages incurred due to the Customers failing to conduct

shall be held harmless and be indemnified by the Customers from any damages incurred due to the Customers failing to conduct

the above operational procedures, provided, however, that, this shall not apply if the damages which the Customer sincurred

the above operational procedures, provided, however, that, this shall not apply if the damages which the Customer sincurred

due to the defect of this Product caused by Saginomiya.

due to the defect of this Product caused by Saginomiya.

!

!

CAUTION

CAUTION

It can not be used for ammonia refrigeration system.

It can not be used for ammonia refrigeration system.

This product is not available for the system which apply pressure more than 4.7MPa [ 47bar] because the rated maximum working

This product is not available for the system which apply pressure more than 4.7MPa [ 47bar] because the rated maximum working

pressure of this product is 4.7MPa [47bar] if the pressure more than the rated maximum working pressure is applied to this

pressure of this product is 4.7MPa [47bar] if the pressure more than the rated maximum working pressure is applied to this

product, it causes transformation of characteristics or the destruction. Operation will became unstable when using other than

product, it causes transformation of characteristics or the destruction. Operation will became unstable when using other than

sine waves for the power supply. In this case, proper control may be achieved.

sine waves for the power supply. In this case, proper control may be achieved.

Catalog No.

Catalog No.

XGE-2SE*-*

XGE-2SE*-*

XGE-4SE*-*

XGE-4SE*-*

XGE-6SE*-*

XGE-6SE*-*

1 Turn

1 Turn

Approx. 0.8bar

Approx. 0.8bar

Approx. 1.5bar

Approx. 1.5bar

Approx. 2.5bar

Approx. 2.5bar

SPECIFICATIONS

SPECIFICATIONS

E.P.B.

F.V.S.Setting bar[Psi]

F.V.S.Setting bar[Psi]

Factory

Catalog No.

Catalog No.

XGE-2SE*-*

XGE-2SE*-*

XGE-4SE*-*

XGE-4SE*-*

XGE-6SE*-*

XGE-6SE*-*

Ambient Temperature of Fan Speed Controller Housing:-20 to 55℃ / Vibration:2G or less in normal use. /

Ambient Temperature of Fan Speed Controller Housing:-20 to 55℃ / Vibration:2G or less in normal use. /

Shock:100G or less / Altitube:2000m / Humidity:0 to 90%RH

Shock:100G or less / Altitube:2000m / Humidity:0 to 90%RH

Special specification: F.V.S.Factory setting can be set the different points within the Adjusting

Special specification: F.V.S.Factory setting can be set the different points within the Adjusting

Range on demand.

Range on demand.

These model were approved UL Recognition (US):File E43867 , CCN SDFY2

These model were approved UL Recognition (US):File E43867 , CCN SDFY2

[Selection of Catalog number] Example:XGE-2SEBI-US

[Selection of Catalog number] Example:XGE-2SEBI-US

①Refrigerants select

①Refrigerants select

②EC Fan Model

②EC Fan Model

③Pressure connections

③Pressure connections

④Type of packing

④Type of packing

⑤Standard

⑤Standard

Factory

Adjusting Range

Adjusting Range

Min.

Min.

Set

Set

19

19

[145]

[145]

[276]

[276]

28 3922

28 3922

UL Recognition (Canada):File E43867 , CCN SDFY8

UL Recognition (Canada):File E43867 , CCN SDFY8

2:R134a、4:R22,R407C,R404A、6:R410A

2:R134a、4:R22,R407C,R404A、6:R410A

Fixed.

Fixed.

No symbol:7/16-20UNF Female Flare Fitting with Schroeder

No symbol:7/16-20UNF Female Flare Fitting with Schroeder

B :7/16-20UNF Male Flare Fitting

B :7/16-20UNF Male Flare Fitting

No symbol:Packed by small box, I: Packed by Big box

No symbol:Packed by small box, I: Packed by Big box

US:UL Standard

US:UL Standard

E.P.B.

bar

bar

[Psi]

[Psi]

Max.

Max.

Fixed 4.5

Fixed 4.5

1888

1888

[261][116][116] [65]

[261][116][116] [65]

2510

2510

Fixed 6

Fixed 6

[87]

[87]

[362]

[362]

Fixed 7

Fixed 7

[101][319][406] [566]

[101][319][406] [566]

Refrigerants

Refrigerants

R134a

R134a

R22,R404A,R407C

R22,R404A,R407C

R410A

R410A

Pressure

[VDC]

[VDC]

Pressure

Connections

Connections

7/16-20UNF

7/16-20UNF

Female Flare

Female Flare

Fitting with

Fitting with

Schrader

Schrader

or

or

7/16-20UNF

7/16-20UNF

male Flare

male Flare

Fitting

Fitting

Output

Supply

Supply

Voltage

Voltage

[VDC]

[VDC]

Supplied Voltage

Supplied Voltage

()

()

from EC Fan Motor

from EC Fan Motor

⑤③④①②

⑤③④①②

Output

Voltage

Voltage

10

10

0to10

0to10

Mass of the

Mass of the

Equipment

Equipment

[g]

[g]

140

140

F.V.S. : Full Voltage Set point

F.V.S. : Full Voltage Set point

This is pressure that output voltage

This is pressure that output voltage

output 95% of supply voltage.

output 95% of supply voltage.

E.P.B. : Effective Proportional Band

E.P.B. : Effective Proportional Band

This is difference of pressure

This is difference of pressure

between output voltage output 5% and

between output voltage output 5% and

95% of supply voltage.

95% of supply voltage.

DIMENSIONS

DIMENSIONS

1

1

(1) (48.4)

(1) (48.4)

2

2

3

3

4

4

5

5

7/16-20UNF

7/16-20UNF

+

+

-

-

2

2

1

1

1:+ 10V DC

1:+ 10V DC

2:GND

2:GND

3:0-10V DC

3:0-10V DC

±0.3

±0.3

64.2

64.2

3

3

SEE INSTRUCTIONS

SEE INSTRUCTIONS

2

2

1

1

Rated Torque

Rated Torque

:

:

[Nm]

[Nm]

0,4~0,6

0,4~0,6

Pressure

Pressure

admission

admission

port

port

Schrader

Schrader

Label

Label

34 ±0.3

34 ±0.3

3

3

(15.9) 63.2 12.5

(15.9) 63.2 12.5

5

5

14

14

Case of

Case of

XGE-*SEB*-* type

XGE-*SEB*-* type

Pressure

Pressure

admission

admission

port

port

(22)

(22)

4-φ2.6 Hole

4-φ2.6 Hole

XGE-AE01(Mounting bracket)

XGE-AE01(Mounting bracket)

for mounting screws

for mounting screws

MADE IN JA PAN

MADE IN JAPAN

18 ±0.3

18 ±0.3

7/16-20UNF Female Flare Fitting with Schroeder

7/16-20UNF Female Flare Fitting with Schroeder

⑤

⑤

7/16-20UNF Male Flare Fitting

7/16-20UNF Male Flare Fitting

Fasten terminal

④

Fasten terminal

④

Case

③

Case

③

Cover

②

Cover

②

Range adjusting screw

Range adjusting screw

①

①

No.

No.

or

or

Parts Name

Parts Name

FAN SPEED CONTROLLER

FAN SPEED CONTROLLER

EC

EC

TYPE:XGE-2SE

TYPE:XGE-2SE

LOT No.:2017

LOT No.:2017

Supply voltage:10VDC

Supply voltage:10VDC

Output voltage:0-10VDC

Output voltage:0-10VDC

Setting:8bar

Setting:8bar

RANGE:8 t o 18bar

RANGE:8 t o 18bar

[116 to 261Psi]

[116 to 261Psi]

Label

Label

CONDENSER

CONDENSER

Option

Option

Mounting Bracket(XGE-AE01)

Mounting Bracket(XGE-AE01)

38

38

25 ±0.24

25 ±0.24

18

18

38

38

42

42

25 ±0.2

25 ±0.2

34

34

20

20

0

0

1

1

R

R

+

+

-

-

2

2

4-φ4.4

4-φ4.4

For wall mounting

For wall mounting

4-φ3.2

4-φ3.2

For XGE mounting

For XGE mounting

Fig.1bFig.1a

Fig.1bFig.1a

4

4

5

5

゚

゚

゚

゚

5

5

4

4

2

2

3

3

2

2

1

1:+ 10V DC

1:+ 10V DC

2:GND

2:GND

3:0-10V DC

3:0-10V DC

1

1

1

SEE INSTRUCTIONS

SEE INSTRUCTIONS

0-10V

0-10V

3

3

+10V

+10V

Accessory (Furnished)

Accessory (Furnished)

Plug

Plug

27.5 27.5

27.5 27.5

9

9

0

0

゚

゚

30 30

30 30

Fig.2a

Fig.2a

Fig.7

L

L

N

N

PE

PE

GND

GND

GND

GND

INPUT

INPUT

OUTPUT

OUTPUT

TERMINAL

TERMINAL

EC FAN MOTOR

EC FAN MOTOR

Fig.7

10V

10V

95%(9.5V)

95%(9.5V)

5%(0.5V)

5%(0.5V)

32

32

18

18

Output Voltage

Output Voltage

0V

0V

Fig.3

Fig.3

E.P.B

E.P.B

(Fixed)

(Fixed)

42

42

18

18

F.V.S.(Adjustable)

F.V.S.(Adjustable)

Pressure

Pressure

Range

Range

8~18

8~18

10~25

10~25

22~39

22~39

Fig.4

Fig.4

Approx.0.8bar

Approx.0.8bar

Approx.1.5bar

Approx.1.5bar

Approx.2.5bar

Approx.2.5bar

Fig.9Fig.8Fig.6

Fig.9Fig.8Fig.6

21

21

-

-

+

+

360°

360°

113.6

113.6

64.2

64.2

XGE-X1E MAR.2017

XGE-X1E MAR.2017

REFERENCE DRAWING

REFERENCE DRAWING

Loading...

Loading...