Page 1

Data sheet

Gasketed heat exchanger XG

Description / application

The XG is a heat exchanger with gaskets and it

has been developed for use with district heating

and cooling systems. The heat exchangers can

be opened for cleaning and for replacement

of plates and gaskets. The XG plate heat

exchangers with gaskets are manufactured with

dierent plate sizes.

Main data:

- Min. temperature -10 °C

- Max. temperature +150 °C

- Max. working pressure 16 bar

- Circulation water / glycolic water up to 50%

- Connection size DN (thread or anged)

25…125

Approvals:

• Pressure Equipment Directive (PED) 97/23/EC

• GOST/Russia

DEN-SMT/SI

VD.KA .F6.02 © Danfoss 09/ 2014

1

Page 2

Gasketed heat exchanger, XGData sheet

Ordering Explanation, XG types

XG 10L – 1 – 10

Plate types L - H

Number of plates

Pass of the heat exchanger

1 = 1-pass

Plate type

Plate size

G=Gasketed heat exchanger

Special versions for dierent mediums,

connections / couplings, max. operating

pressures, materials and capacities are available

on request. Please contact the local sales

representative for details.

The heat exchanger can consist of plates type L

or plates type H.

The H- type plate has larger herring bone angle

than the L- type plate. H- type plate ts better

for certain temperatures than L- type. H- type

heat exchangers have better heating capacity,

but they also have higher pressure loss.

L- type H- type

The same principal dierence can be obtained with

other plate patterns as well.

Gasketed heat exchangers type XG

Typ e XG 10 -1 XG 14H-1 XG18 H-1 XG 20L-1 XG 20 H-1

Thread Thread Thread Thread Thread

Connection

G 1 A G 1¼ A G 1¼ A G 2 A G 2 A

No of plates, n

8 - 00 4B126 0 004B1276 - 10 004B5005 00 4B1261 00 4B1277 004B2954 004B5205

20 004B5010 004 B1262 004B1278 004B2955 004 B5210

30 004B5015 004 B1263 004B1279 004B2956 004B5215

40 004B5020 00 4B126 4 0 04B1280 004B2957 004B5220

50 004B5025 004B1265 0 04B1281 004B2958 004B5225

60 004B5030 0 04B1266 004 B1282 004B2959 004B5230

70 004B5035 004 B1267 004 B1283 004B2960 004B5235

80 - 004B1268 0 04B12 84 004 B2961 004B5240

90 - 00 4B1269 004 B1285 004B2962 004B5245

100 - 004 B1270 004 B1286 004B2963 004B5250

110 - 00 4B1271 00 4B1287 004B2964 004B5255

120 - 0 04B1272 004B128 8 004B2965 004B5260

130 - - - - 140 - - - 004B2966 004B5270

150 - - - - 160 - - - - 180 - - - - 200 - - - - -

* Available on request

¹ Primary / secondary

XG 31L-1 XG 31H-1 XG 40-1 XG 50 -1 XG 60 -1* XG 70 -1*

Flange Flange

DN 65 DN 65

- - - - - -

00 4B1375 00 4B1389 - - - -

004B1376 004B1390 - - - -

00 4B1377 004 B1391 - - - -

00 4B1378 004 B1392 - - - -

004B379 0 04B1393 004B1045 004B1091 - -

00 4B138 0 0 04B13 94 004B1046 004B1092 - -

00 4B1381 00 4B1395 004B1047 004B10 93 - -

004B1382 0 04B1396 004B1049 004B1094 - -

00 4B1383 004B1397 004B1083 004B1095 - -

00 4B138 4 0 04B1398 004 B1084 004B1096 - -

004B1385 0 04B1399 0 04B1085 004B1097 - -

00 4B138 6 004B1400 004B1086 0 04B1098 - -

00 4B1387 004B1401 - - - -

00 4B138 8 0 04B14 02 004B1087 00 4B1099 - -

- - - - - -

- - 004 B1088 004B1100 - -

- - 004 B1089 004B1101 - -

- - 004B1090 0 04 B1102 - -

Place for

ange

DN

100/125¹

Place for

ange

DN

100/125¹

- -

2

VD.KA .F6.02 © Danfoss 09/ 2014

DEN-SMT/SI

Page 3

Data sheet

Gasketed heat exchanger, XG

Accessories Accessories for gasketed heat exchanger type XG

Typ e Code No.

Gasket (set of 10) Plates (set of 10) Special plate set¹ Special plate set

XG 10 004B 6931³ 004B6938 004B2930 00 4B2931

XG 14 H 004B1301 0 04B13 03 00 4B130 9 004 B1311

XG 18H 0 04B1302 004B1304 004 B1310 0 04B1312

XG 20L

XG 20H 004B6939 004B2932 004B2933

XG 31L

XG 31H 00 4B1370 004B1404 0 04B14 07

XG 40 004B6934 004B69 41 004B2936 004B2937

XG 50 004B6935 004B6942 004B2938 004B2939

XG 60 004B6936 004B6943 004B2940 004B29 41

XG 70 004B6937 004B6944 004B2942 004B2943

¹ The set contains front plate, end plate and matching gaskets for 1-pass versions

² The set contains front plate, end plate, middle plate and matching gaskets for 2-pass versions

³ Non-glued gasket

Clip-on gasket

Glued gasket

Min. order size 10 pieces = 1 set (I-pack). Sets of 250 pieces available on inquiry.

004B6932

00 4B1367

004B2967 004B2968 004B2969

004B1368 0 04B14 03 004B1406

2-pass ²

Tailpieces for gasketed heat exchanger type XG

Description Suitable for Connection Code No.¹

XG10

Solder tailpieces

Weld-on tailpieces

Threaded tailpieces XG10

¹ One set contains 2 tailpieces with unionnuts and gaskets

XG14, XG18

XG20

XG10

XG14, XG18

XG20

G 1 A / 15 mm 004B2904

G 1 A / 18 mm 004B2905

G 1 A / 22 mm 004B2906

G 1 ¼ A /

22mm, 28 mm

G 2 A / 28 mm 004B2910

G 2 A / 35 mm 0 04 B2911

G 2 A / 42 mm 0 04B2912

G 1 A / DN 15 004B2901

G 1 A / DN 20 003H6909

G 1 A / DN 25 004B2903

G 1¼ A / DN 25 003H6910

G 1¼ A / DN 32 004B1343

G 2 A / DN 32 004B2907

G 2 A / DN 40 004B2908

G 2 A / DN 50 004B2909

G 1 A / G 3/4 A 00 4B2913

- -

00 4B1358

DEN-SMT/SI

VD.KA .F6.02 © Danfoss 09/ 2014

3

Page 4

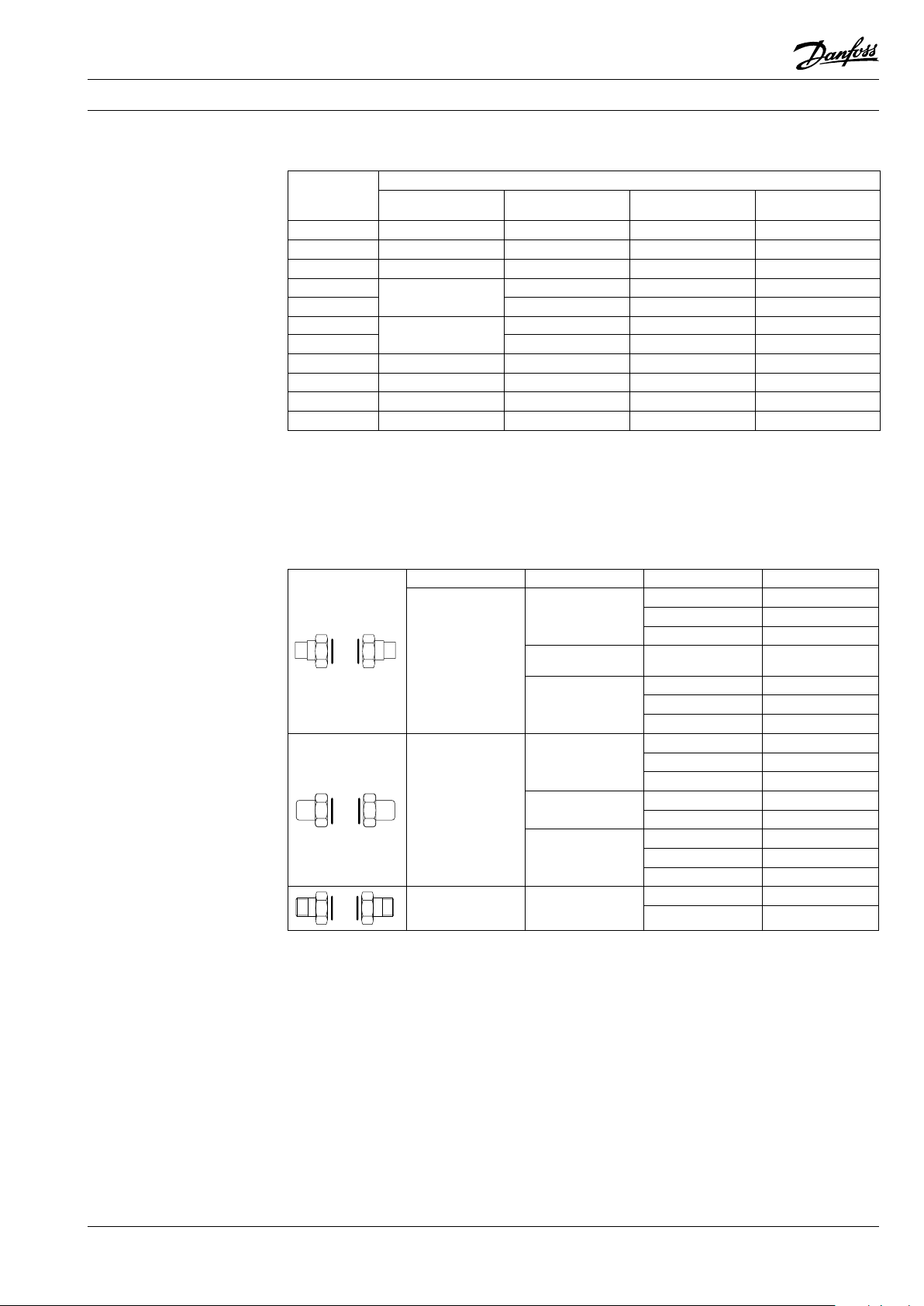

Accessories continued

Gasketed heat exchanger, XGData sheet

Insulation for gasketed heat exchanger type XG

Typ e XG 10-1 XG 14H-1 XG 18H-1

No of plates

8 10

20 - 30 - 40

50

60

70 00 4B5135

90 -

100 -

120 130 - - - 140 - - - 004B5370 004B5790 004B5990

150 - - - - - - 160 - - - - 180 - - - - 200 - - - - - 004B5799 004B5999

004B5115 00 4B5315 004 B1361

00 4B5130 004B1314 004B1319 004B5330 004 B1362

00 4B1338 004B1318

00 4B1315 00 4B1320 004B5345 0 04B1363 0 04B5745 004B594580 -

004B1316 004B1321 004B5360 00 4B1365 004B5760 004B5960110 -

XG 20 L-1

XG 20 H-1

- - - -

XG 31L-1

XG 31H-1

00 4B136 6

XG 40 -1 XG 50 -1

- -

- -

004B5730 004B5930

- -

004B5790 004B5790

Insulation properties

Technical data

Typ e Coated steel sheet and polyester insulation

Heatconductivity, λ [W/mK] 0.042

Max temperature, °C

-Permanent, °C 150

-Short term peak, °C 180

Wall thickness, mm 30

Typ e XG 10 -1 XG 14H -1 XG 18 H-1

Max. working pressure

(bar)

Max. operating temp. (°C) 150

Min. operating temp.² (°C) -10

Flow medium Circulation water / glycolic water up to 50%

Volume/channel (litres) 0.045 0.095 0.13 0.480 0.370 1. 370 1.710

Heat surface, m²/plate 0.021 0.049 0. 074 0.122 0.141 0.288 0.383

Connection type Thread³ Flange, DN Place for ange, DN

Connection size G 1 A G 1¼ A G 1¼ A G 2 A DN 65 DN 100/125

Plate material Stainless steel, mat. no. EN 1.4404

Gasket material, rubber EPDM

¹ PN25 versions are available on inquiry. PN25 versions must be ordered separately using special codes,

please contact your sales representative.

² At flow temp. below 2 °C glycolic water must be used

³ Cylindrical external thread acc. to DIN ISO 228/1

Flanges PN16, acc. to EN 1092, facing type B (B1)

Primary side / Secondary side

XG 20 L-1

XG 20 H-1

16 / (25)¹

XG 31L-1

XG 31H-1

XG 40 -1 XG 50-1

4

VD.KA .F6.02 © Danfoss 09/ 2014

DEN-SMT/SI

Page 5

Data sheet

Gasketed heat exchanger, XG

Technical data continued

Design and function

Heat exchanger water volume

Primary side Secondary side

(n/2-1) * volume/channel

n = number of plates

XG 14..., XG 18...,XG 20 .., XG 31...,

XG 40..., XG 50...

1)

n/2* volume/channel

XG 10...

The heat exchangers are made of shapepressed heat plates between which the ow

channels are created. Gaskets between the

plates separate the ow channels from each

other so that the ows do not mix. The heavy

turbulence and counter-ow principle enables

ecient heat transfer. The task of the heat

exchanger is to transfer heat from the primary

to secondary ow through a heat transfer plate

thus preventing the ows from mixing with

each other.

Heat exchanger heat surface

(n-2) * heat surface/plate

1)

n= number of plates

1-pass heat exchanger

T11 - Primary side in

T12 - Primary side out

T21 - Secondary side in

T22 - Secondary side out

The plate heat exchanger with gaskets can

be opened for cleaning and for replacement

of plates and gaskets. A stepless output

adjustment can be carried out by changing the

number of plates.

The choice of heat exchanger is determined by

the desired heat output, required temperatures

and the permitted pressure losses.

Sizing Dimensioning and selection of heat exchangers

should be carried out with the support of

the Danfoss dimensioning program for heat

exchangers.

Mounting The heat exchanger must be mounted in vertical

position. Prepare the foundation for the heat

exchanger if necessary, always according to local

regulations. It is recommended that all pipes

connected to the heat exchanger are equipped

with shut-o valves for maintenance purposes.

The pipes to be connected must be mounted so

that the strain caused by the thermal expansion,

for instance, does not harm the heat exchanger.

The pipes must be equipped with brackets to

prevent any torsional stress concentration at the

heat exchanger’s pipe connections.

It is recommended that the heat exchanger is

equipped with insulation.

A safety valve must be installed between the

heat exchanger and the shut-o valves on the

secondary side of the heat exchanger. If the

safety valve is not installed, thermal expansion

of uid might destroy the heat exchanger when

the shut-o valves are closed.

DEN-SMT/SI

VD.KA .F6.02 © Danfoss 09/ 2014

5

Page 6

Gasketed heat exchanger, XGData sheet

Assembly dimensions

B

A

D

C

Example of XG40, XG50

Typ e A B C

XG10 158 100 15 9

XG14 200 92 12 10

XG18 200 92 12 10

XG20 300 234 20 13

XG31 360 234 20 13

XG40 540 430 30 20

XG50 540 430 30 20

View from above

Mounting bracket

End rear

Plate pack

End front

XG20, XG40, XG50, XG31

Number

of plates

8 - 118 118 - - 10 103,5 123 123 491 495 - 20 129 146 14 6 491 645 - 30 154,5 169 169 491 645 - 40 18 0 192 192 641 645 - 50 205,5 215 215 641 795 850 850

60 231 238 238 641 795 850 850

70 256,5 261 261 791 795 950 950

80 - 284 284 791 795 1150 1150

90 - 307 307 791 945 115 0 115 0

100 - 330 330 9 41 945 1150 1150

110 - 353 353 941 945 1150 1150

120 - 376 376 9 41 1095 1350 135 0

130 - - - - 1095 - 140 - - - 1091 1095 1350 1350

150 - - - - - - 160 - - - - - 1650 1650

180 - - - - - 1650 1650

200 - - - - - 1650 1650

XG10 XG14 XG18 XG20 XG31 XG40 XG50

Mounting bracket

XG10, XG14, XG18

Dimension-D mm

Dimensions

6

Typ e Connection

XG 10-… G 1 A

XG 14H-... G 1¼ A

XG 18H-... G 1¼ A

XG 20L-...

XG 20H-...

XG 31L-.. .

XG 31H-...

G 2 A

DN 65

External dimensions [mm]

A B C D G H F L

1)

2.55*n 158 65 235 310 A+30 460 500 0.2*n+16

1)

2.4*n 200 80 430 560 A+60 675 550 0.34*n+52

1)

2.4*n 200 80 630 760 A+60 875 550 0.46*n+72

1)

3.5*n 300 140 640 835 A+60 910 130 0 0.8*n+125

2)

2.95*n 360 150 665 910 A+60 965 160 0

max

Weight

empty

1.22*n+170

XG 40-… DN 100/125²) ³ 4.25*n 540 240 856 1198 A+10 0 1238 2500 2.2*n+550

)

XG 50-… DN 100/125²

³ 4.25*n 540 240 1096 1438 A+10 0 1478 2500 2.8*n+675

n = number of plates

L

max= Length of a heat exchanger with maximum number of heat plates

1)

Cylindrical external thread acc. to DIN ISO 228/1

2)

Flanges PN16, acc. to EN 1092, facing type B (B1)

³ Primary side / Secondary side

VD.KA .F6.02 © Danfoss 09/ 2014

[kg]

DEN-SMT/SI

Page 7

Data sheet

n

k

d₃

Gasketed heat exchanger, XG

Dimensions continued

Solder tailpieces Weld-on tailpieces Threaded tailpieces

G G 1 A G 1 ¼ A G 2 A

SW mm 41 47 71

1)

G

d

d

1

L2 117 - - - - -

- G ¾A - - - - - - 21,3 (DN 15) 26,9 (DN 20) 33,5 (DN 25) 33,5 (DN 25) 42,4 (DN 32) 42,4 (DN 32) 48,5 (DN 40) 60,3 (DN 50)

15 18 22 22 28 28 35 42

mm

L3 117 117 117 90 90 175 175 175

L4 117 117 117 90 90 175 175 175

1)

Cylindrical external thread acc. to DIN ISO 228/1

Flange connection

Flange dimensions

d₂

DN 65 10 0 125

L1¹

k 145 180 210

d

mm

2

n 4 8 8

d

3

1)

Flanges PN16, acc. to EN 1092, facing type B (B1)

2)

Primary / secondary

200/100² Place for ange Place for ange

18 18 18

M16 M16

Place for ange

DEN-SMT/SI

VD.KA .F6.02 © Danfoss 09/ 2014

7

Page 8

Gasketed heat exchanger, XGData sheet

Dimensions continued

Insulation for gasketed heat exchanger type XG

Typ e XG 10-1 XG 14H-1 XG 18 H-1

F (mm) 490 705 905 940 980 124 8 1488

B (mm) 218 260 260 360 420 600 600

No of plates H (mm)

8 10

20 - 30 - 40

50

60

70 272

90 -

100 -

120 130 - - - 140 - - - 610 925

150 - - - - - - 160 - - - - 180 - - - - 200 - - - - - 1010

168 225 203

246 264 330 285

192

336 435 368 54380 -

408 540 450 670110 -

XG 20 L-1

XG 20 H-1

- - - -

XG 31L-1

XG 31H-1

505

XG 40 -1 XG 5 0-1

- -

- -

415

- -

925

8

VD.KA.F6.02

Produce d by Danfoss A/S © 09/2014

Loading...

Loading...