Page 1

Technical Information

D Series and XD Series

Fixed Displacement Gear Pumps

www.danfoss.com

Page 2

Technical Information

D Series and XD Series Gear Pumps

Revision history Table of revisions

Date Changed Rev

April 2020 Corrected XD Model Code Information 0202

December 2019 0201

October 2019 First edition 0101

2 | © Danfoss | April 2020 BC319684134607en-000202

Page 3

Technical Information

D Series and XD Series Gear Pumps

Contents

General Information

Overview..............................................................................................................................................................................................6

Features and benefits..................................................................................................................................................................... 6

Quick chart overview...................................................................................................................................................................... 6

Typical applications.........................................................................................................................................................................7

Design...................................................................................................................................................................................................7

System schematic.............................................................................................................................................................................8

Product features................................................................................................................................................................................9

Technical Specifications

Technical specifications...............................................................................................................................................................10

Fluid specifications........................................................................................................................................................................10

Inlet pressure...................................................................................................................................................................................10

Operating Parameters

Sizing equations.............................................................................................................................................................................11

Pressure............................................................................................................................................................................................. 11

Temperature and viscosity......................................................................................................................................................... 12

Speed..................................................................................................................................................................................................12

Hydraulic fluid.................................................................................................................................................................................13

Filtration............................................................................................................................................................................................ 13

Filters.............................................................................................................................................................................................13

Selecting a filter.........................................................................................................................................................................13

Reservoir...................................................................................................................................................................................... 13

Line sizing......................................................................................................................................................................................... 14

Pump life........................................................................................................................................................................................... 14

Pump shaft connection................................................................................................................................................................14

Radial and axial loading...............................................................................................................................................................15

D Series Model Code

Single pump order code..............................................................................................................................................................16

DE1: D series cast iron gear pump, single section........................................................................................................ 16

A Rotation - viewed from drive shaft........................................................................................................................... 16

B1 Displacement..................................................................................................................................................................16

B2 Input shaft........................................................................................................................................................................17

C Mounting flange..............................................................................................................................................................17

D Rear cover: Port options, integrated valves, and auxillary flange................................................................. 18

E Flow control valve setting............................................................................................................................................ 19

F Pressure control valve setting.....................................................................................................................................20

H Assembly Screws - depending on rear cover........................................................................................................21

J Nameplates.........................................................................................................................................................................23

K Special feature.................................................................................................................................................................. 23

Two section (tandem) pump order code.............................................................................................................................. 23

A Rotation - viewed from drive shaft.................................................................................................................................23

B1 Displacement.......................................................................................................................................................................24

B2 Input shaft.............................................................................................................................................................................24

C Mounting flange................................................................................................................................................................... 25

R Ports - First section............................................................................................................................................................... 25

S Displacement - Second section........................................................................................................................................26

D Rear cover: Port options, integrated valves and auxillary flange........................................................................26

E Flow control valve.................................................................................................................................................................28

F Pressure control valve..........................................................................................................................................................29

H Assembly screws...................................................................................................................................................................30

J Nameplate................................................................................................................................................................................33

K Special features......................................................................................................................................................................33

Three section (triple) pump order code.................................................................................................................................33

A Rotation - viewed from drive shaft.................................................................................................................................34

B1 Displacement - First section........................................................................................................................................... 34

B2 Input shaft.............................................................................................................................................................................34

C Mounting flange................................................................................................................................................................... 35

L Ports - First section................................................................................................................................................................35

©

Danfoss | April 2020 BC319684134607en-000202 | 3

Page 4

Technical Information

D Series and XD Series Gear Pumps

Contents

M Displacement - Second section......................................................................................................................................36

R Ports - Second section.........................................................................................................................................................37

S Displacement - Third section............................................................................................................................................ 37

D Rear cover: Port options, integrated valves and auxiliary......................................................................................38

E Flow control valve.................................................................................................................................................................40

F Pressure control valve..........................................................................................................................................................40

H Assembly screws...................................................................................................................................................................41

J Nameplate................................................................................................................................................................................41

K Special feature........................................................................................................................................................................42

Four section (quad) pump order code...................................................................................................................................42

A Rotation - viewed from drive shaft.................................................................................................................................42

B1 Displacement - First section........................................................................................................................................... 43

B2 Input shaft.............................................................................................................................................................................43

C Mounting flange................................................................................................................................................................... 44

L Ports - First section................................................................................................................................................................44

M Displacement - Second section......................................................................................................................................45

N Ports - Second section........................................................................................................................................................ 45

P Displacement - Third section............................................................................................................................................46

R Ports - Third Section.............................................................................................................................................................47

S Displacement - Fourth section.........................................................................................................................................47

D Rear cover: Port options, integrated valves and auxiliary flange........................................................................48

E Flow control valve.................................................................................................................................................................50

F Pressure control valve..........................................................................................................................................................51

H Assembly screws...................................................................................................................................................................51

J Nameplate................................................................................................................................................................................52

K Special feature........................................................................................................................................................................52

D Series Options

Shaft options....................................................................................................................................................................................53

Mounting flanges...........................................................................................................................................................................54

Multiple pump port options...................................................................................................................................................... 56

Rear cover - port options.............................................................................................................................................................58

Integrated Priority Flow Divider..........................................................................................................................................62

Integrated Priority Flow Divider..........................................................................................................................................64

Integrated Steering Cover.....................................................................................................................................................64

Integrated Steering Cover.....................................................................................................................................................65

Load Sense Priority Flow Valve............................................................................................................................................66

Pumps with Load Sense Priority Flow Valves.................................................................................................................67

D Series Dimension Drawings

One Section - Single......................................................................................................................................................................69

Two section - Tandem..................................................................................................................................................................70

Three Section - Triple....................................................................................................................................................................71

Four Section - Quad...................................................................................................................................................................... 72

D Series Performance Data

Flow performance..........................................................................................................................................................................73

XD Model Code Information

A Rotation - viewed from drive shaft...................................................................................................................................... 78

B1 Displacement - front section............................................................................................................................................... 78

B2 Input shaft.................................................................................................................................................................................. 78

C Mounting flange.........................................................................................................................................................................79

R Ports - first section......................................................................................................................................................................79

S Displacement - rear section....................................................................................................................................................79

D Rear cover.....................................................................................................................................................................................79

E Flow control valve...................................................................................................................................................................... 80

F Pressure control valve...............................................................................................................................................................80

H Assembly screws........................................................................................................................................................................ 80

J Name plate.................................................................................................................................................................................... 80

K Special features...........................................................................................................................................................................80

4 | © Danfoss | April 2020 BC319684134607en-000202

Page 5

Technical Information

D Series and XD Series Gear Pumps

Contents

XD Options

XD Shaft options.............................................................................................................................................................................81

XD Mounting flanges....................................................................................................................................................................81

XD Dimension Drawings Information

Dimensions.......................................................................................................................................................................................84

©

Danfoss | April 2020 BC319684134607en-000202 | 5

Page 6

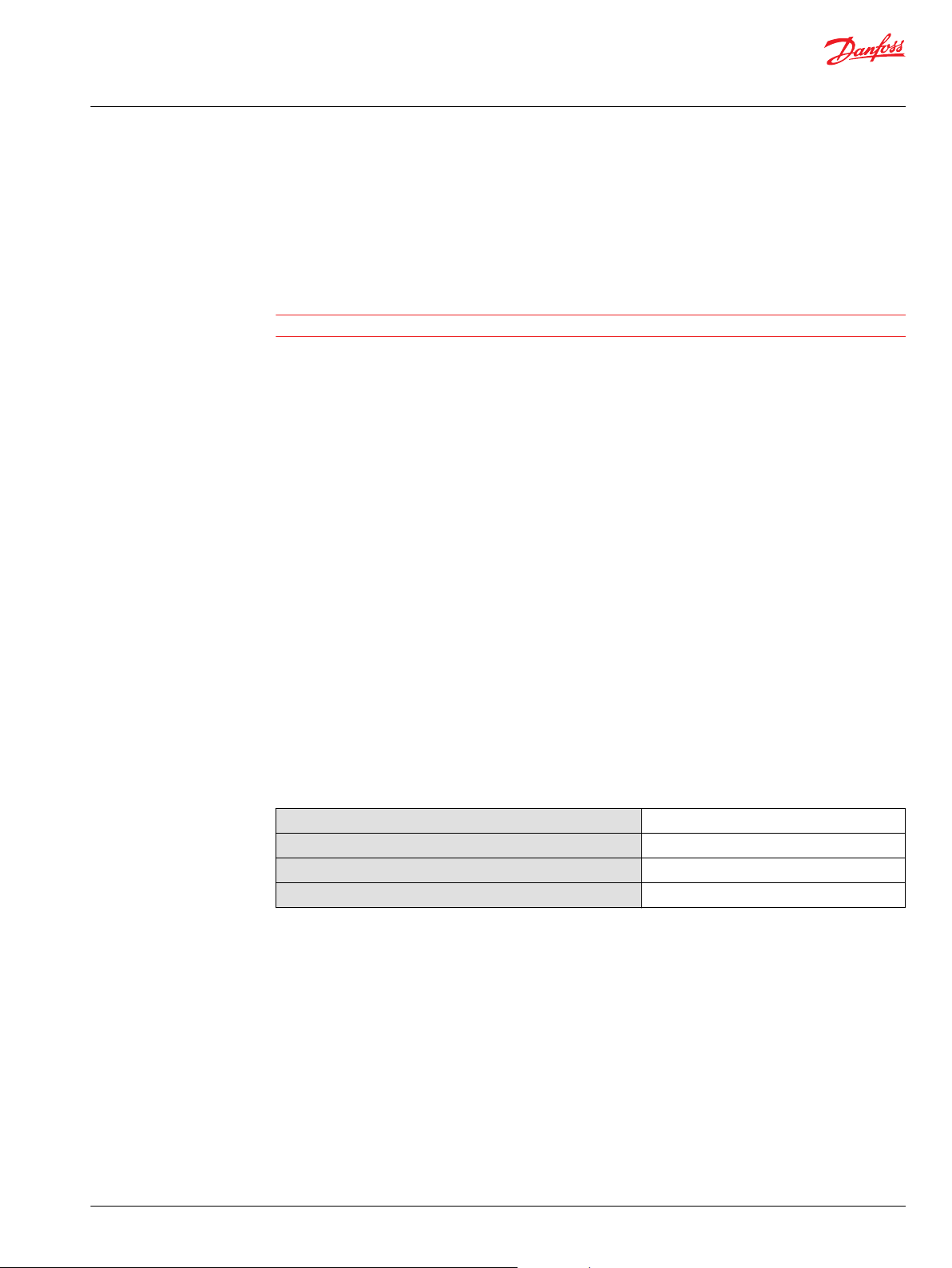

300

250

200

150

100

50

0

0

10

20

30 40 50

Displacement

cm

3

/rev

P

ressure

psi

P107 949E

Group 3 Gear Pump

D SERIES Cast Iron Gear Pump

Group 2 Gear Pump

Bar

in3/rev

4000

3000

2000

1000

0

1.0

0

3.0

3.0

4.0 5.0

6.0

60 70

80 90 100

Group 1 Gear Pump

XD SERIES Cast Iron Gear Pump

Technical Information

D Series and XD Series Gear Pumps

General Information

Overview

The D Series fixed displacement gear pump has been specifically designed for demanding mobile

equipment applications where maximum performance is required at peak power levels and operating

temperatures.

The design integrates cast iron construction with pressure balanced thrust plates to deliver consistent

efficiency across the entire operating range of pressure, speed, and temperature; all in an industryleading package size that maximizes power density.

Features and benefits

•

High strength cast iron construction allows consistently efficient performance and long life in

continuous operation at 276 bar [4000 psi] and peak conditions of 303 bar [4400 psi].

•

Custom engineered bearings, pressure-balanced load plates, and viton seals optimize internal

lubircation allowing for long life with intermittent fluid temperatures up to 115 °C [239 °F] and fluid

viscosities as low as 8 mm2/sec (cSt) [36 SUS].

•

Compact three-piece design maximizes power density and creates one of the shortest multisection

pumps (with up to four pumping sections) in the global marketplace.

•

Bearings located in the front flange increase radial/axial load carrying capability and eliminate the

need for most bolt-on outrigger bearings.

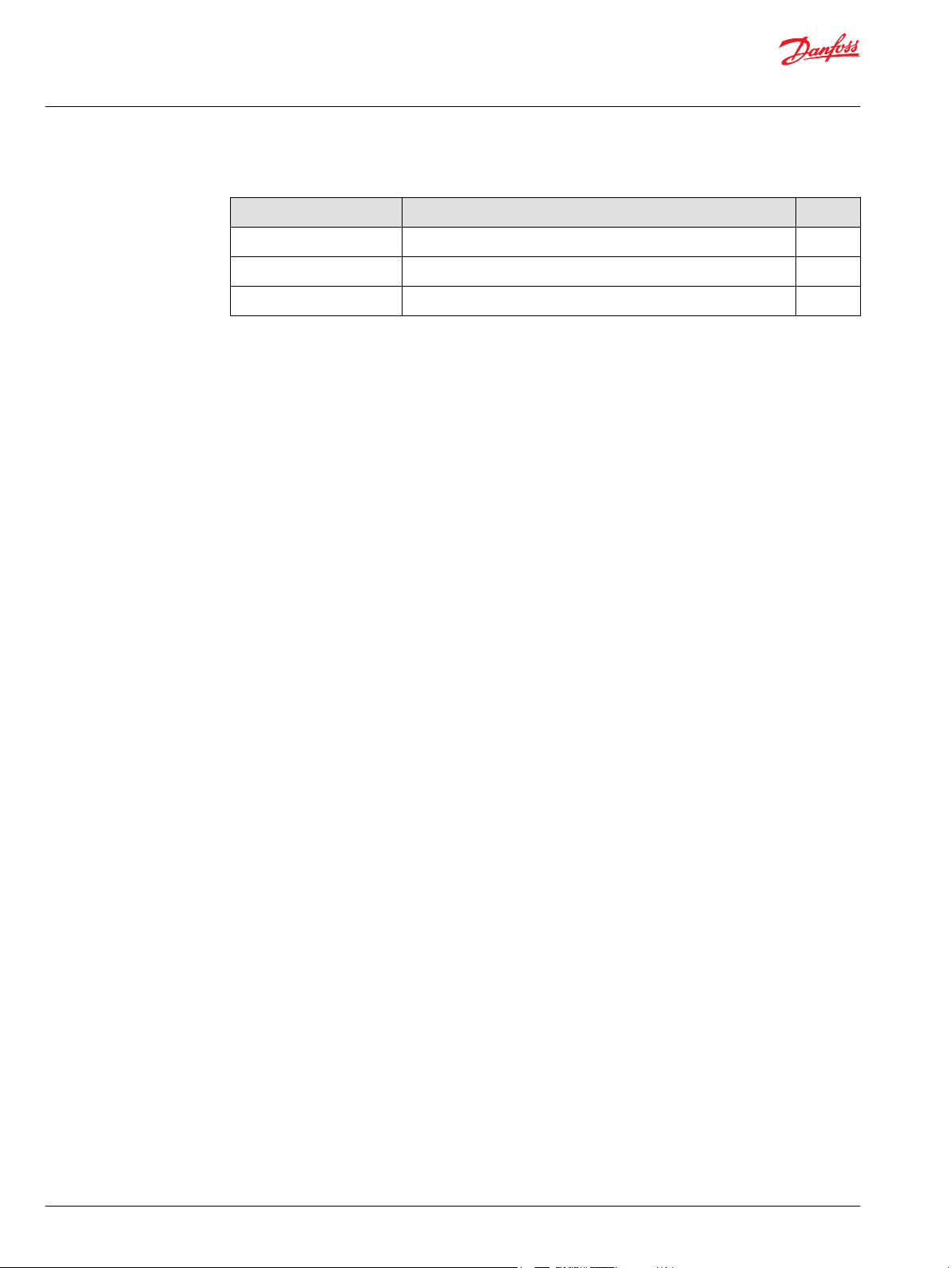

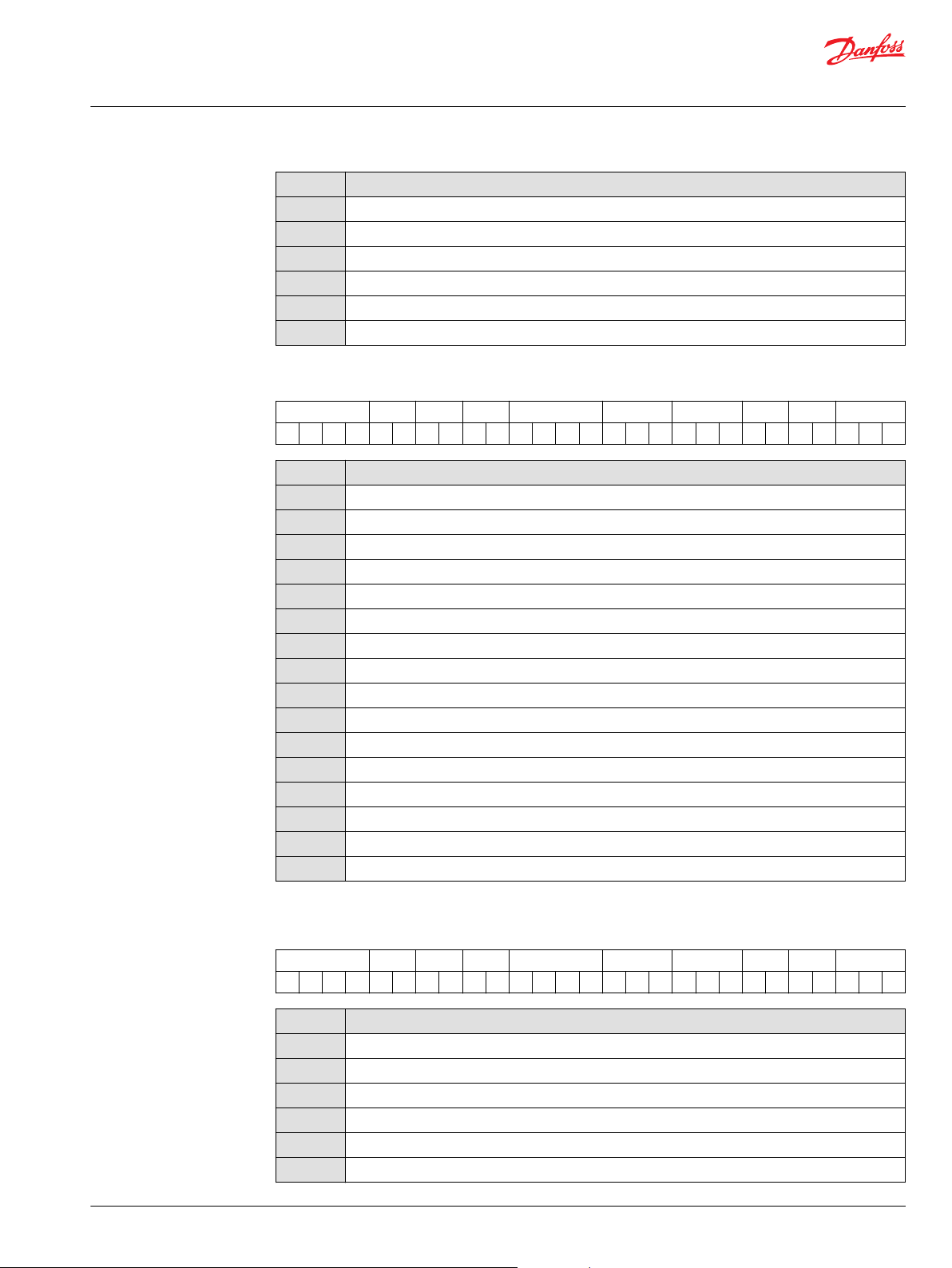

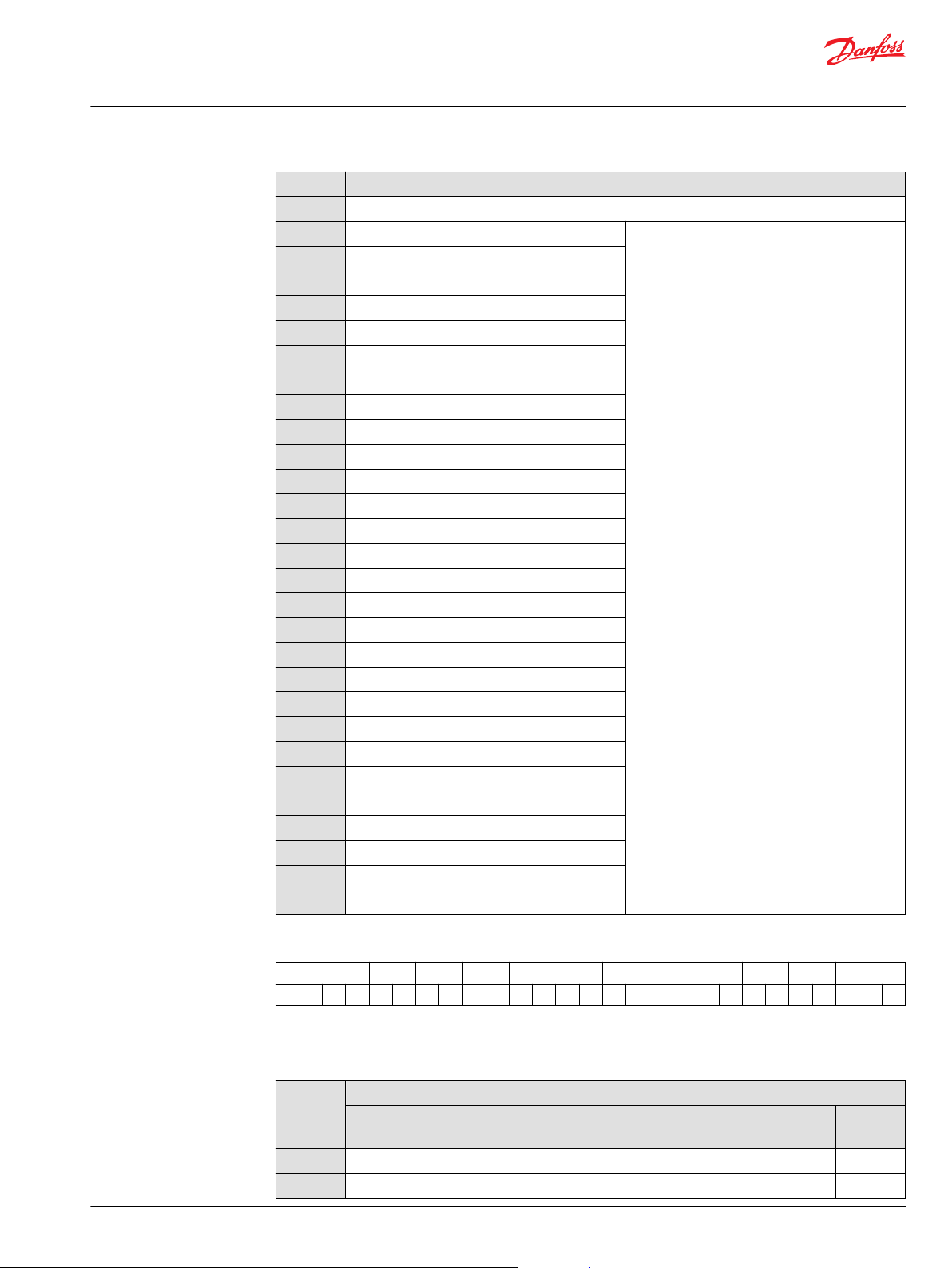

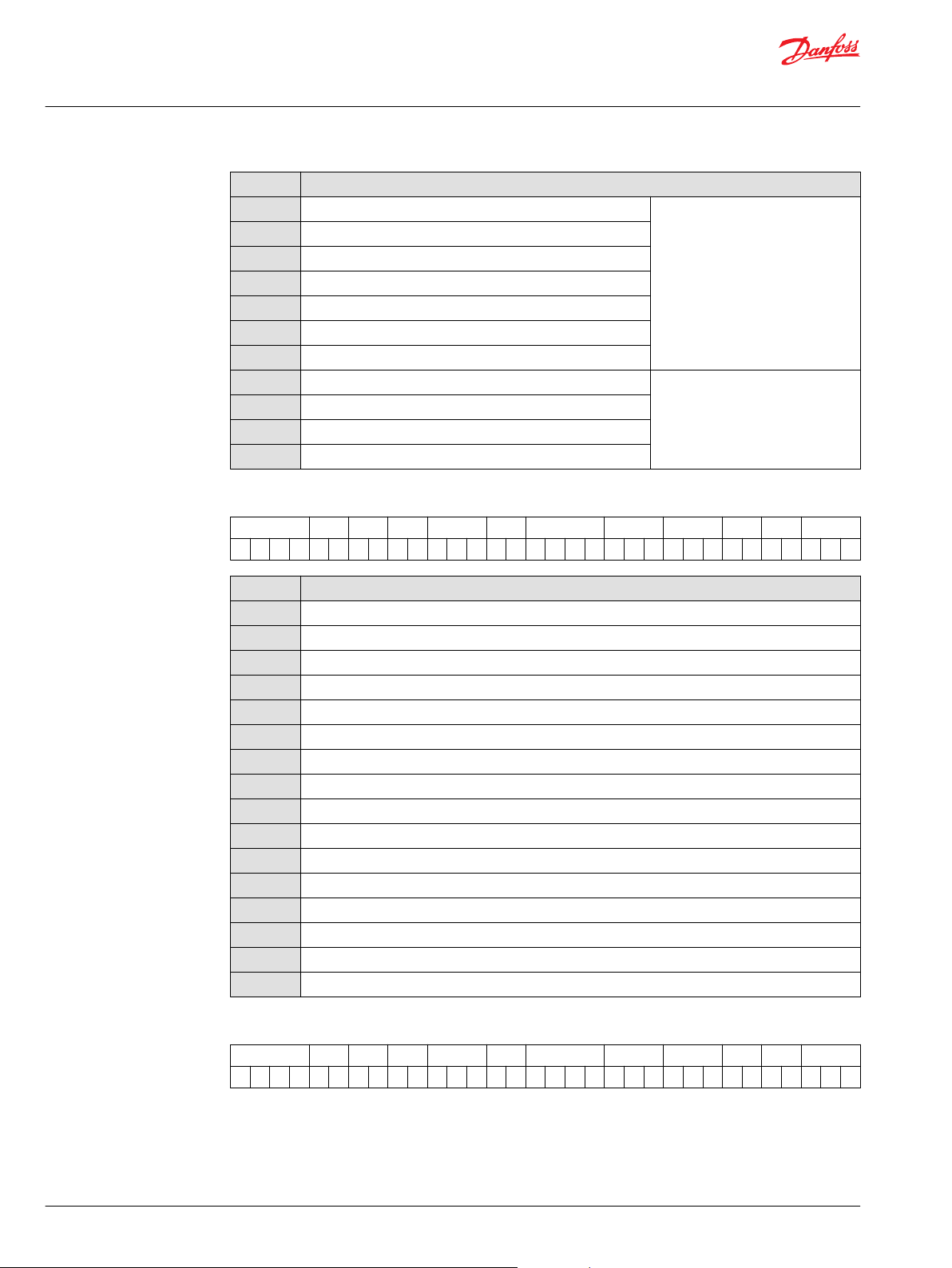

Quick chart overview

The D Series pump blends the traditional Group 2 (SAE-A) and Group 3 (SAE-B) frame sizes in a single

package with displacements from 7 to 45 cm3 (0.43 to 2.75 in3).

These displacements, in addition to a wide variety of shafts, flanges, ports, and integrated valve options

can be used in virtually any combination to offer greater design flexibility and meet specific application

requirements.

Gear pumps quick chart overview

6 | © Danfoss | April 2020 BC319684134607en-000202

Page 7

1

3

2

7

5

4

6

8

Technical Information

D Series and XD Series Gear Pumps

General Information

Typical applications

The D Series gear pump is commonly applied in the following type of applications:

•

Wheel loader - Aggressive duty cycles with continuous working pressures above 250 bar [3600 psi]

•

Mining equipment - Increased exposure to system contamination in a corrosive environment

•

Skid steer loaders - Multiple pump combinations with short length and common inlets

•

Work function attachments - Rapid loading of cylinders/motors in high bulk modulus systems

causing pressure rise rates greater than 3000 bar/sec

•

Agricultural sprayers - Pumps with integrated valves including priority flow dividers and load sense

steering

•

Pavers - D pumps integrated with other Turolla components including variable displacement piston

pumps, aluminum gear pumps and cartridge valves

•

Fan drives - High levels of performance with elevated temperatures and minimal oil viscosities and

restrictive envelope dimensions

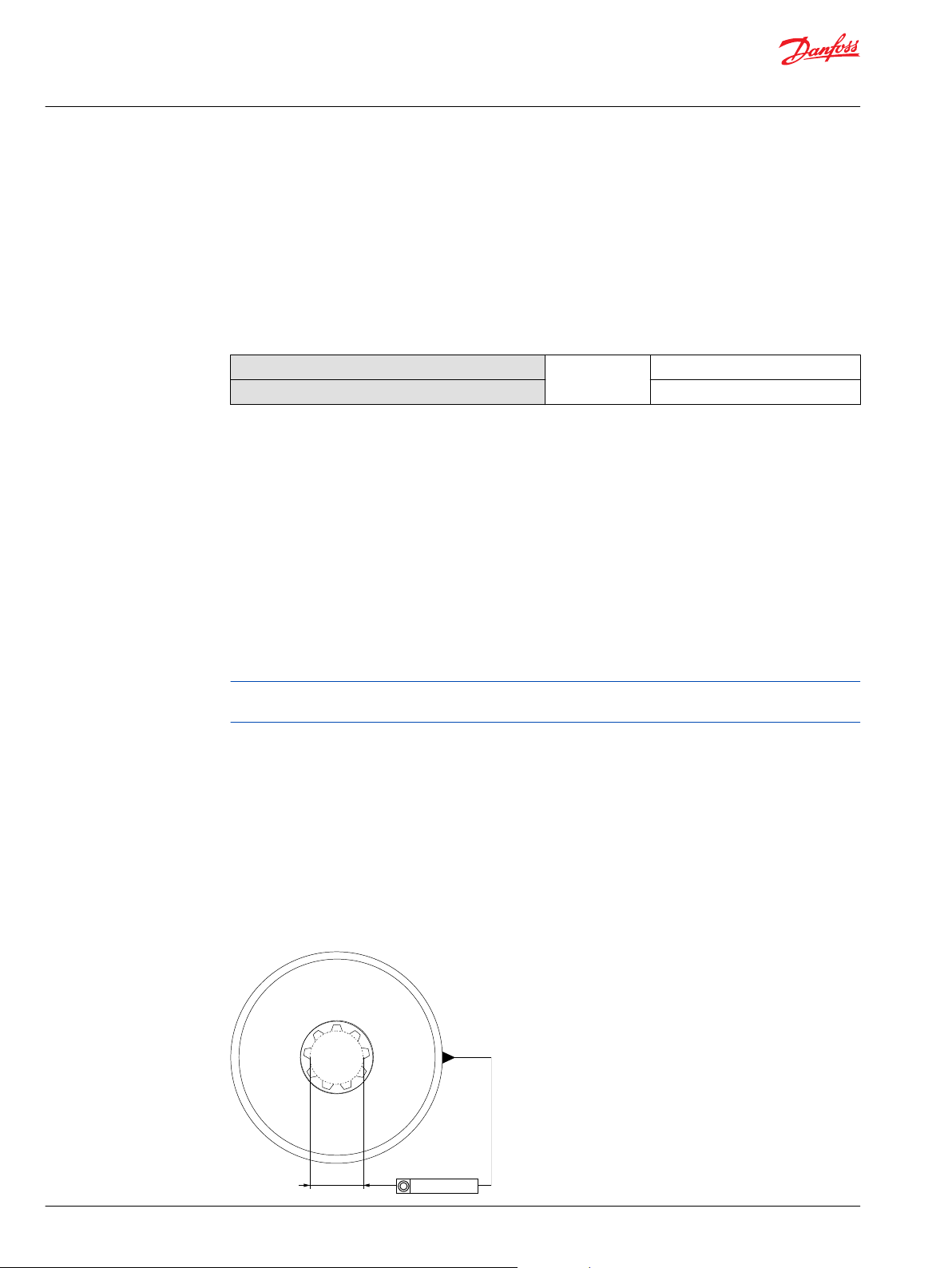

Design

1. High-quality, heat-treated alloy steel integral gears and shaft

2. High-strength ductile iron body and covers

©

Danfoss | April 2020 BC319684134607en-000202 | 7

3. Heavy-duty low-friction sleeve bushings

4. Pressure balanced bronze-on-steel thrust plates

5. High temperature Viton seals

6. Optional: flow control with load sensing priority flow or factory preset fixed priority flow divider valve

7. SAE-A/SAE-B 2-bolts mounting flange

8. Optional: Side or rear port options

Cast iron housings, bearings

The three piece structural members of the pump are made of high-strength cast ductile iron. Cast iron

provides contamination resistance, thermal stability and the strength needed for consistently high levels

of performance and durability needed in demanding off highway applications.

Heavy-duty low friction PTFE-lined sleeve bushings are optimized to provide long life in low viscosity,

high pressure conditions. The bearings are located in the front mounting flange, rear cover, and bearing

plate (for multiple section pumps) and allow the D pump to be 20% shorter than a typical bearing block

Page 8

Microcontroller

(PLUS+1TM)

Filter

T3

T2

T1

Temperature

sensors

D Series

gear pump

D Series

gear motor

RESERVOIR

DIESEL ENGINE

P107 929E

case drain

CANBUS J1939

Technical Information

D Series and XD Series Gear Pumps

General Information

design pump. In addition, the proximity of the front bearing to the mounting flange increases the radial

load capacity of the pump, eliminating the need for most bolt-on outrigger requirements.

Pressure balance, sealing

The pump incorporates two steel-backed bronze thrust plates seated in depressions in the mounting

flange, rear cover, and bearing plate (for multiple section pumps). Underneath the front plate (known as

the deflecting plate) is the load seal.

The E-shaped load seal distributes system pressure underneath the plate and enables the plate to deflect

and maintain a tight sealing surface against the side face of the gears.

The tight sealing action allows the pump to maintain very high levels of volumetric efficiency, even when

operating in extreme temperature, pressure and speed conditions.

One-piece gear design

All D Series pump gear shafts are of one-piece design. This enables the shaft to provide uniform high

strength and accurate gear profile relative to the journals for smooth mesh operation. The integral gear

shafts are made of heat treated AISI 8620 steel, manufactured to precise tolerances and surface finishes,

for maximal life and minimal leakage. This integral design eliminates the potential problems of fatigue

stress and gear face mismatch often associated with two-piece gear shaft designs.

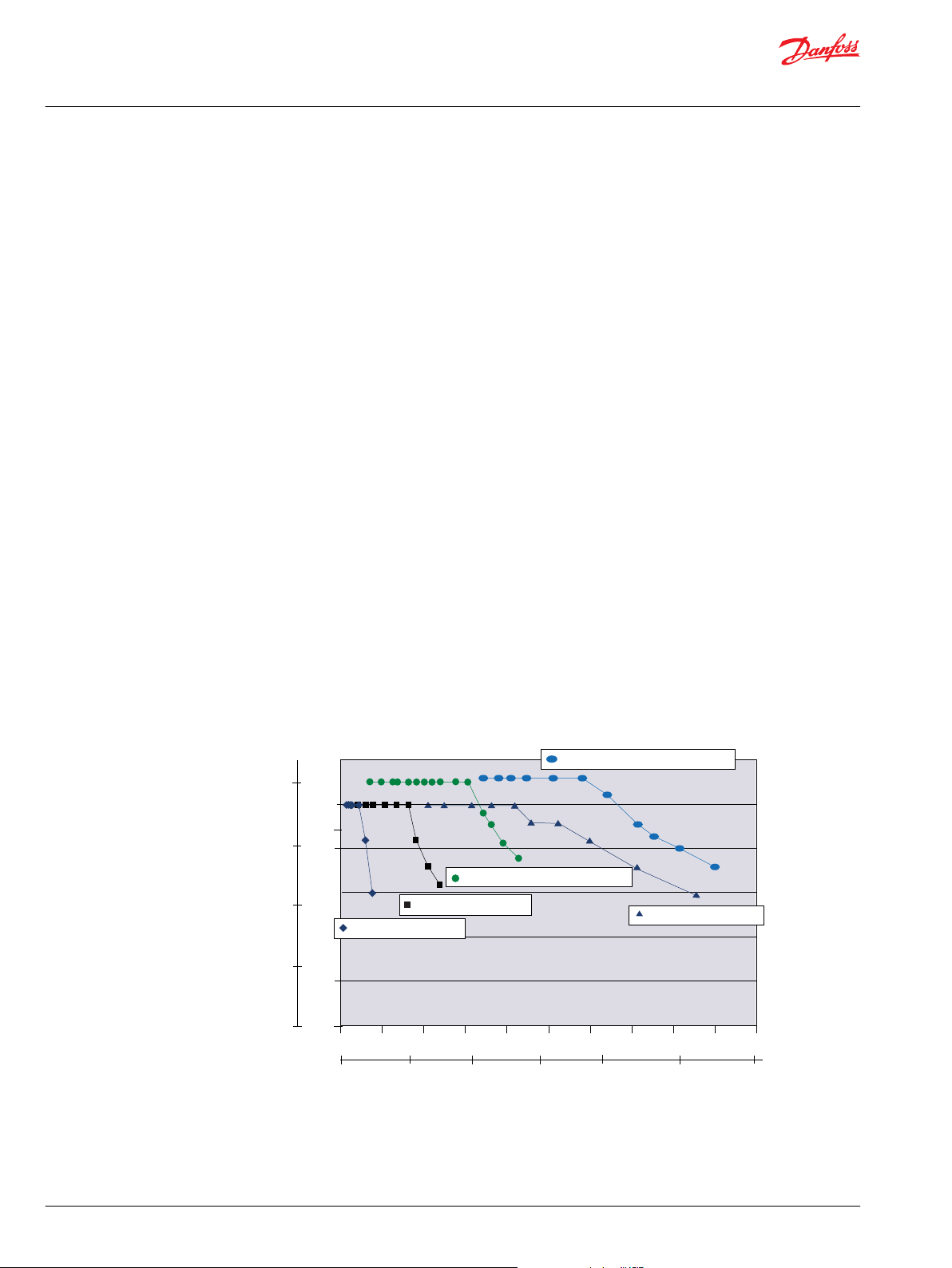

System schematic

Multiple pump configuration

D Series pumps can be coupled together to produce tandem, triple and even quadruple section units.

The interconnecting chambers accommodate fluid flow between sections and allow the number of inlet

connections to be minimized. Systems that require operation with different fluids and/or reservoirs can

be accommodated with sealed auxiliary covers between sections.

Gear Pump/Gear Motor Fan Drive System with Electronic Control

8 | © Danfoss | April 2020 BC319684134607en-000202

Page 9

Technical Information

D Series and XD Series Gear Pumps

General Information

Product features

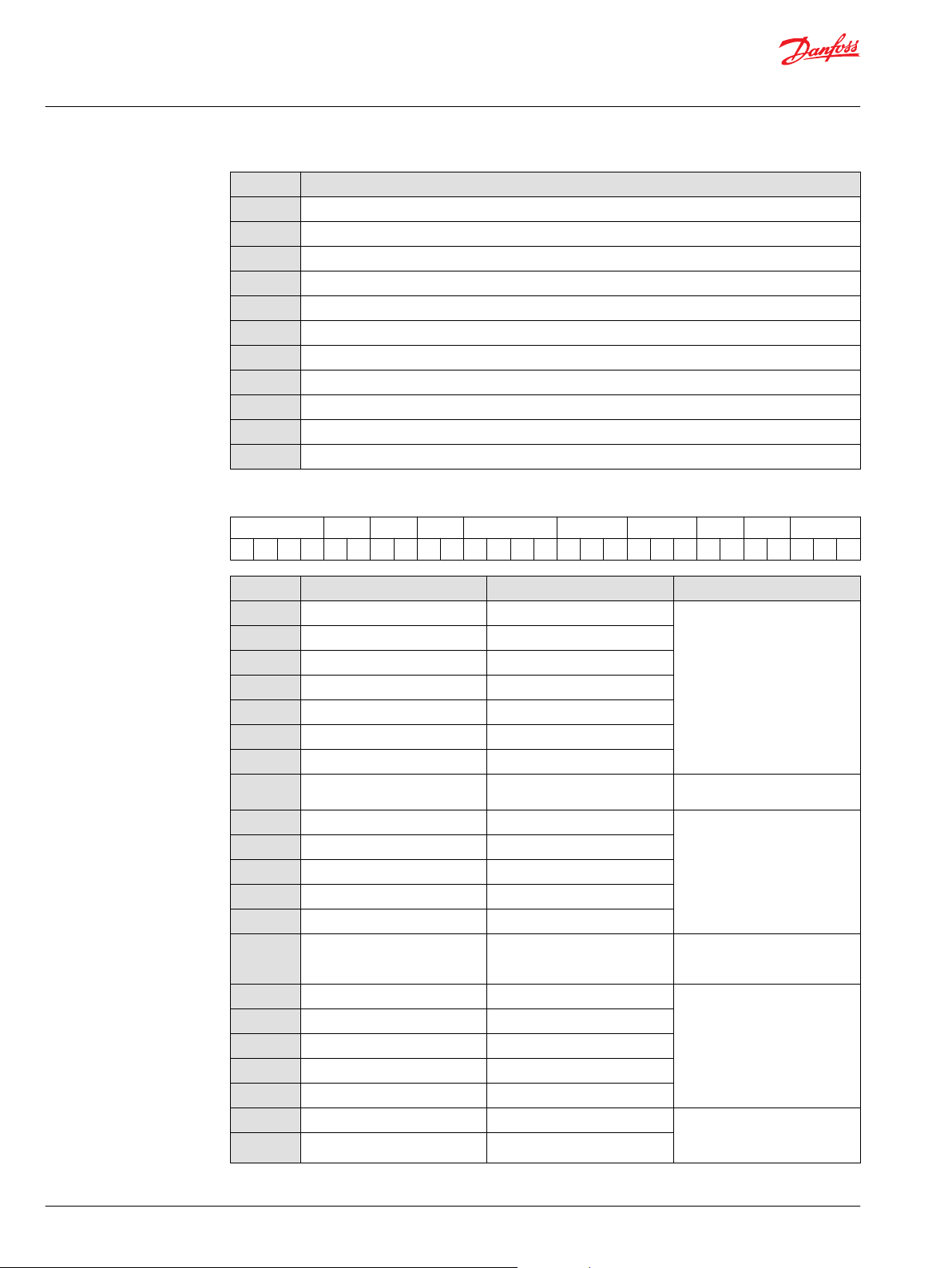

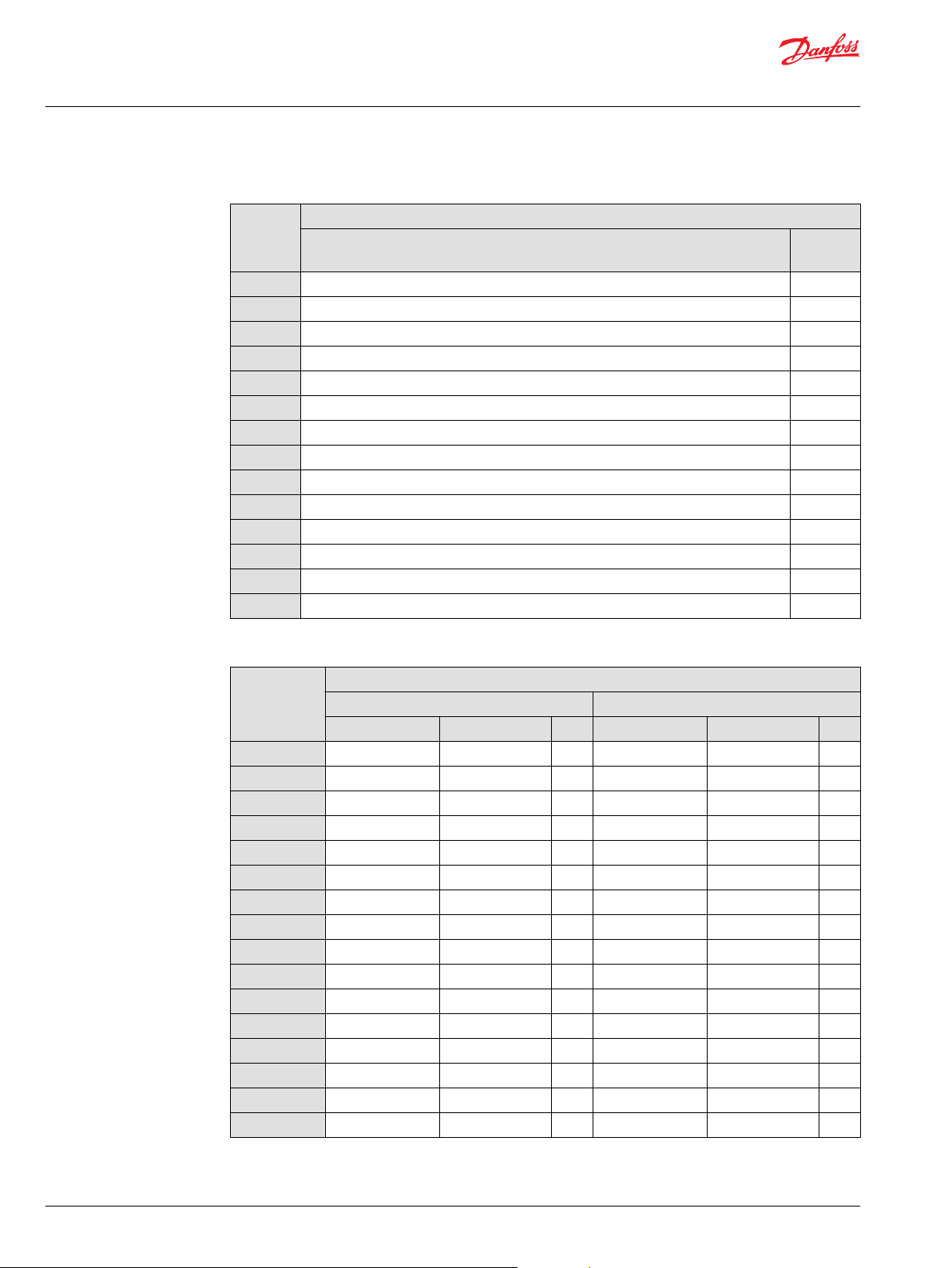

Features Description

Construction

Displacements

Continuous Pressure

Peak Pressure

Speed

Mounting

Shaft (types)

Ports

Fluid viscosity

Filtration requirement

Fluids

Operating

temperature*

Configurations

Integrated valve

options

*

Temperature and viscosity requirements must be satisfied concurrently.

Heavy duty ductile iron 3-piece construction with pressure balance load plates and

viton seals

7 to 45 cm³ [0.43 to 2.75 in3/rev]

276 bar [4000 psi] up to 32 cm³ [1.94 in3/rev]

303 bar [4400 psi] up to 32 cm³ [1.94 in3/rev]

600 to 3400 min-1 (rpm) - up to 25cm³ [1.55 in3/rev]

SAE A two bolt, SAE B two bolt, Perkins engine mount

Straight keyed, 1:8 tapered keyed, 9T, 11T, 13T and 15T splined

SAE O-ring boss, SAE split flange, beaded tube inlet (axial and radial)

*

8 mm²/sec (cSt) [36 SUS] minimum, 1600 mm²/sec (cSt) [7500 SUS] maximum

22/18/13 ISO 4406 at motor inlet

Petroleum/mineral based

-40°C [-40°F] minimum for cold start

110°C [230°F] normal operating conditions 115°C [239°F] peak intermittent

Single, tandem, triple, and quadruple multisection pumps available with common inlets.

Integrated auxiliary cover for through drive applications.

Priority flow divider with priority relief Priority steering with steering relief

Load sense priority flow divider

©

Danfoss | April 2020 BC319684134607en-000202 | 9

Page 10

Technical Information

D Series and XD Series Gear Pumps

Technical Specifications

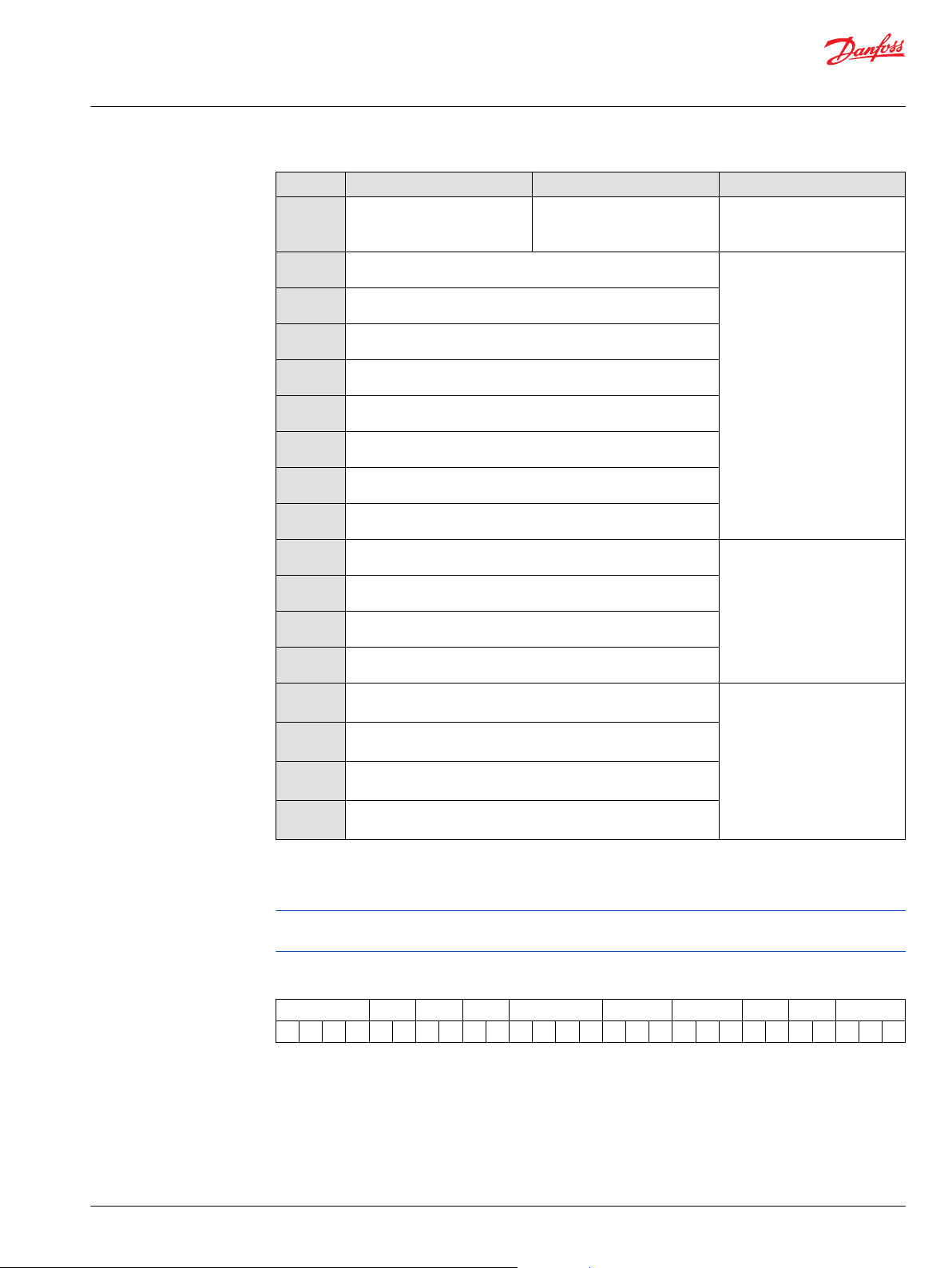

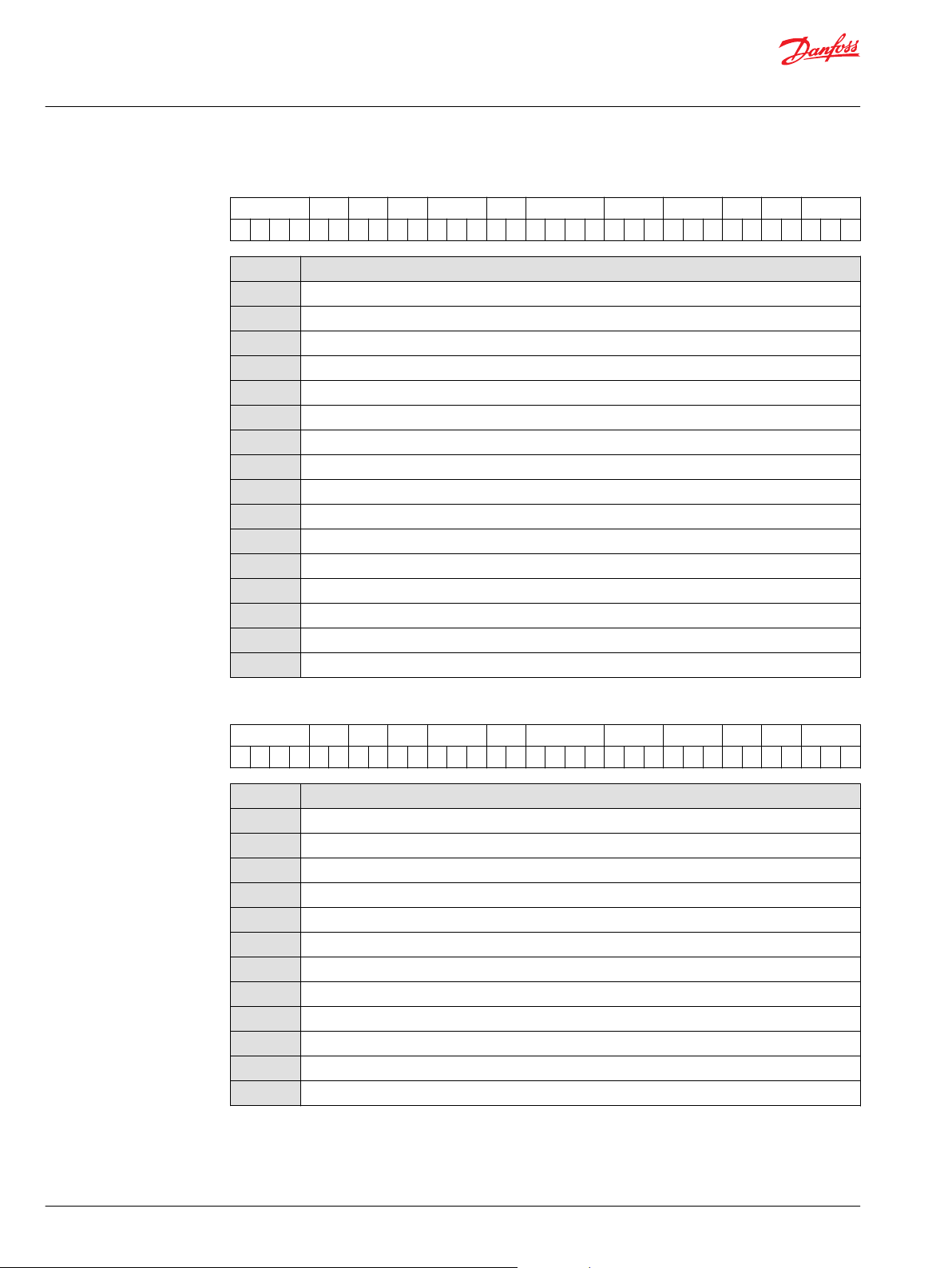

Technical specifications

Ratings Units 07 10 11 13 14 17 19 21 23 25 29 32 36 38 41 45

Displacement

Rated pressure

Peak pressure

Speed min

(rpm)

Theoretical flow at max

speed

Weight

Mass moment of inertia

*

minimum speed at maximum pressure

-1

cm3/rev 7.0 9.5 10.8 12.6 14.3 17.0 19.0 20.5 22.5 25.4 29.0 31.8 36.1 38.0 41.0 45.1

in3/rev

bar 276 276 276 276 276 276 276 276 276 276 276 276 241 228 207 190

psi

bar 303 303 303 303 303 303 303 303 303 303 303 303 265 250 228 209

psi

maximum 3400 3400 3400 3400 3400 3400 3400 3400 3400 3400 3200 3000 2750 2750 2500 2500

minimum

l/min 24.0 32.3 36.7 42.9 48.5 57.9 64.6 69.6 76.3 86.4 92.8 95.4 99.0 104.5 102.4 112.7

US gal/min

kg 7.2 7.3 7.4 7.5 7.6 7.8 7.9 7.9 8.1 8.3 8.4 8.6 8.8 9.0 9.1 9.4

lb

x10-6 kg•m² 60 71 77 85 92 104 105 119 128 141 157 170 188 197 218 228

x10-6 slug•ft²

0.43 0.58 0.66 0.77 0.87 1.04 1.16 1.25 1.37 1.55 1.77 1.94 2.20 2.32 2.50 2.75

4000 4000 4000 4000 4000 4000 4000 4000 4000 4000 4000 4000 3500 3300 3000 2750

4400 4400 4400 4400 4400 4400 4400 4400 4400 4400 4400 4400 3850 3630 3300 3025

*

1200 900 900 700 700 600 600 600 600 600 600 600 600 600 600 600

6.3 8.5 9.7 11.3 12.8 15.3 17.1 18.4 20.2 22.8 24.5 25.2 26.2 27.6 27.1 29.8

15.8 16.1 16.3 16.5 16.7 17.1 17.4 17.5 17.8 18.2 18.6 19.0 19.6 19.8 20.2 20.7

44 53 57 63 68 77 77 88 95 104 116 125 139 145 155 168

Fluid specifications

Inlet pressure

Parameter Unit Minimum Continuous Maximum

Viscosity

Temperature*

Cleanliness

Filtration efficiency, charge filtration

*

Temperature and viscosity requirements must be satisfied concurrently

*

mm2/sec (cSt)[SUS]

°C [°F] -40 [-40] 110 [230] 115 [239]

8

[52]

ISO 4406 Class 22/18/13 or better

b15-20 =75 (b10³10)

10 - 100

[59-456]

1600

[7500]

Ratings are based on operation with premium petroleum-based hydraulic fluids containing oxidation,

rust, and foam inhibitors.

Maximum continuous vacuum

Maximum intermittent vacuum

Maximum charged inlet pressure

bar atmospheric [inches mercury vacuum]

bar atmospheric [psi] 3.0 [44]

0.8 [5.9]

0.6 [11.8]

10 | © Danfoss | April 2020 BC319684134607en-000202

Page 11

Peak pressure

Rated pressure

Reaction time (100 ms max)

Time

Pressure

Technical Information

D Series and XD Series Gear Pumps

Operating Parameters

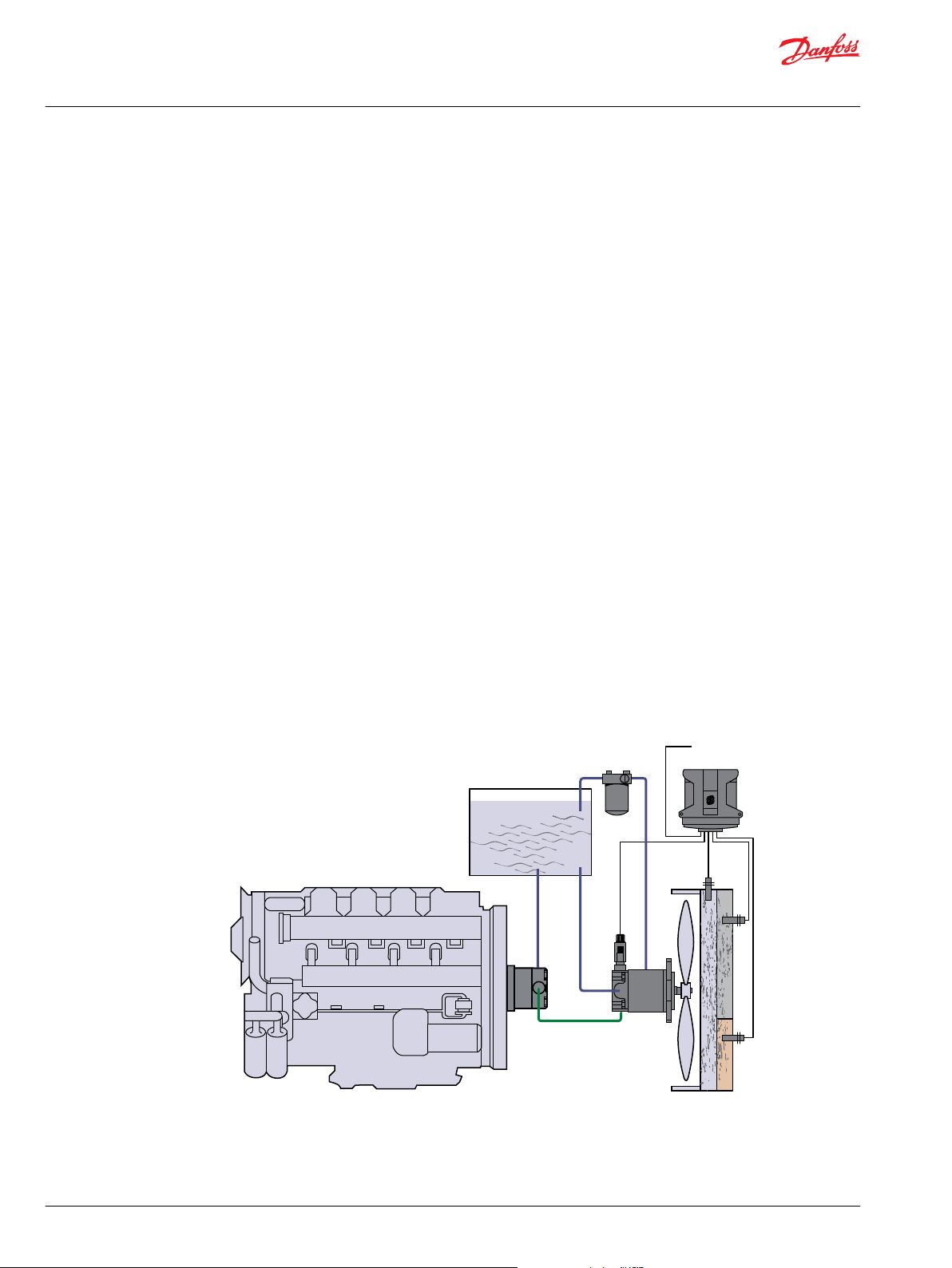

Sizing equations

Use these formulas to determine the nominal pump size for a specific application.

Pressure

Definitions of the D Series operating parameters appear below. Consult Danfoss technical support for

applications running outside of these parameters.

Peak pressure

Peak pressure is the highest intermittent pressure allowed. The relief valve overshoot (reaction time)

determines peak pressure. It is assumed to occur for less than 100 ms. The illustration to the right shows

peak pressure in relation to rated pressure and reaction time (100 ms maximum).

Rated pressure

Rated pressure is the average, regularly occurring operating outlet pressure that should yield satisfactory

product life. The maximum machine load demand determines rated pressure. For all systems, the load

should move below this pressure.

©

Danfoss | April 2020 BC319684134607en-000202 | 11

Page 12

Technical Information

D Series and XD Series Gear Pumps

Operating Parameters

System pressure

System pressure is the differential between the inlet and outlet ports. It is a dominant operating variable

affecting hydraulic unit life. High system pressure reduces expected pump life. System pressure must

remain at, or below, rated pressure during normal operation to achieve expected life.

Inlet vacuum

Inlet vacuum must be controlled in order to realize expected performance and pump life. System design

must meet inlet vacuum requirements during all modes of operation. Expect lower inlet vacuums during

cold start situations. Low vacuum condition should improve quickly as fluid warms.

Pressure rise rate

The maximum pressure rise rate is the rate of increase in system pressure as measured at the outlet port

of the pump. High pressure rise rates are commonly seen on work function applications during motor

start-up, completion of cylinder stroke, and during rapid shifting of control valves. The maximum

pressure rise rate of the D pump is 11,720 bar/sec [170,000 psi/sec]. During rapid rise rate situations, the

system pressure must not exceed the rated pressure of the pump.

Temperature and viscosity

Temperature

High temperature limits apply at the inlet port of the pump. The pump should run at or below the

maximum continuous temperature.

Minimum (cold start) temperature relates to the physical properties of component materials.

Cold oil, generally, doesn’t affect the durability of pump components. It may affect the ability of oil to

flow and transmit power. For this reason, keep the temperature at 16°C [29 °F] above the pour point of

the hydraulic fluid.

Continuous temperature is the temperature at or below the temperature which normal pump life can

be expected.

Maximum temperature is the highest temperature that is tolerable by the machine for a transient/

limited time (duty cycle 1% or less). At maximum temperature, oil viscosity must not go lower than

minimum recommended viscosity.

Viscosity

Continuous viscosity: Recommended viscosity range for maximum efficiency and pump life.

Minimum viscosity occurs only during brief occasions of maximum fluid temperature and severe duty

cycle operation. It’s the minimum acceptable viscosity to guarantee the pump life. (Duty

cycle 1% or less)

Maximum viscosity occurs only during cold start at very low temperatures. It is the upper limit of

viscosity that allows the pump to start. During this condition, limit speeds until the system warms up.

Temperature and viscosity requirements must be concurrently satisfied.

Speed

Maximum speed is the limit recommended for operation at rated pressure. It is the highest speed at

which normal life can be expected.

The lower limit of operating speed is the minimum speed.

12 | © Danfoss | April 2020 BC319684134607en-000202

Page 13

C

Technical Information

D Series and XD Series Gear Pumps

Operating Parameters

Hydraulic fluid

Ratings and data for gear pumps are based on operation with premium hydraulic fluids containing

oxidation, rust, and foam inhibitors. These fluids must possess good thermal and hydrolytic stability to

prevent wear, erosion, and corrosion of internal components.

Use only clean fluid in the pump and hydraulic circuit.

Caution

Never mix hydraulic fluids.

Filtration

Filters

Use a filter that conforms to Class 22/18/13 of ISO 4406 (or better). It may be on the pump outlet

(pressure filtration), inlet (suction filtration), or reservoir return (return-line filtration).

Selecting a filter

When selecting a filter, please consider:

•

contaminant ingression rate (determined by factors such as the number of actuators used in the

system)

•

generation of contaminants in the system

•

required fluid cleanliness

•

desired maintenance interval

•

filtration requirements of other system components

Measure filter efficiency with a Beta ratio (βX). For:

•

suction filtration, with controlled reservoir ingression, use a β

•

return or pressure filtration, use a pressure filtration with an efficiency of β10 = 75

βx ratio is a measure of filter efficiency defined by ISO 4572. It is the ratio of the number of particles

greater than a given diameter ( “X“ in microns) upstream of the filter to the number of these particles

downstream of the filter.

Fluid cleanliness level and βx ratio

Fluid cleanliness level (per ISO 4406)

βx ratio (suction filtration)

βx ratio (pressure or return filtration)

Recommended inlet screen size

The filtration requirements for each system are unique. Evaluate filtration system capacity by monitoring

and testing prototypes.

Reservoir

The reservoir provides clean fluid, dissipates heat, removes entrained air, and allows fluid volume

changes associated with fluid expansion and cylinder differential volumes. A correctly sized reservoir

accommodates maximum volume changes during all system operating modes. It promotes deaeration of

the fluid as it passes through, and accommodates a fluid dwell-time between 60 and 180 seconds,

allowing entrained air to escape.

Minimum reservoir capacity depends on the volume required to cool and hold the oil from all retracted

cylinders, allowing for expansion due to temperature changes. A fluid volume of 1 to 3 times the pump

output flow (per minute) is satisfactory. The minimum reservoir capacity is 125% of the fluid volume.

Install the suction line above the bottom of the reservoir to take advantage of gravity separation and

prevent large foreign particles from entering the line. Cover the line with a 100-125 micron screen. The

= 75 filter

35-45

Class 22/18/13 or better

β

= 75 and β10 = 2

35-45

β10 = 75

100-125 µm [0.004-0.005 in]

©

Danfoss | April 2020 BC319684134607en-000202 | 13

Page 14

Pilot cavity

Ø 0.1 [0.004]

Mating spline

Technical Information

D Series and XD Series Gear Pumps

Operating Parameters

pump should be below the lowest expected fluid level. Put the return-line below the lowest expected

fluid level to allow discharge into the reservoir for maximum dwell and efficient deaeration. A baffle (or

baffles) between the return and suction lines promotes deaeration and reduces fluid surges.

Line sizing

Choose line sizes that accommodate maximum fluid velocity to reduce system noise, pressure drops, and

overheating in order to maximize system life and performance. Line velocities shown in the following

table provide a general rule of thumb. Final selection of line sizing and fittings must comply with all

pressure ratings.

Pump life

Pump shaft connection

Inlet

Outlet 6-9 [20-30]

m/sec [ft/sec]

2.4-4.3 [8-14]

Most systems use hydraulic oil containing 10% dissolved air by volume. Over-areation, or entrained air is

the result of flow line restrictions, where the dissolved air comes out of solution, or when air is allowed to

leak into the hydraulic circuit. These include inadequate pipe sizes, sharp bends, or elbow fittings,

causing reduction of flow-line cross-sectional area. This problem will not occur if these circuit

recommendations are followed, rated speed requirements are maintained, and reservoir size and

location are adequate.

Pump life is a function of speed, system pressure, and other system parameters (such as fluid quality and

cleanliness).

All Danfoss gear pumps use hydrodynamic journal bearings with an oil film between the gear/shaft and

bearing surfaces. If the oil film is sufficiently sustained through proper system maintenance and

operating within recommended limits, long life can be expected.

ß10 life expectancy number is generally associated with rolling element bearings. It does not exist for

hydrodynamic bearings.

When submitting an application for review, provide machine duty cycle data including percentage of

time at various loads and speeds. We strongly recommend a prototype testing program to verify

operating parameters and their impact on life expectancy before finalizing any system design.

Shaft options for gear pumps include tapered, splined, or parallel shafts.

Plug-in drives, with a splined shaft, can impose severe radial loads when the mating spline is rigidly

supported. Increasing spline clearance does not alleviate this condition.

Pump shaft connection

14 | © Danfoss | April 2020 BC319684134607en-000202

Page 15

C

P107 928E

3:00

12:00

9:00

6:00

Shaft loading

• All values measured 25.4 mm [1 inch]

from the mounting flange

• For other orientations and distances,

higher radial loads at lower pressures

contact your S-D representative

25.4 mm

[1 inch]

Recommended loading position

CW Rotation

CCW Rotation

Technical Information

D Series and XD Series Gear Pumps

Operating Parameters

Lubricate all shaft couplings. Failure to do so will result in premature shaft failure.

Use plug-in drives if the concentricity between the mating spline and pilot diameter is within 0.1 mm

[0.004 in]. Lubricate the drive by flooding it with oil. A 3-piece coupling minimizes radial or thrust shaft

loads.

Caution

To avoid spline shaft damages it is recommended to use carburized and hardened steel couplings with

80-82 HRA surface hardness.

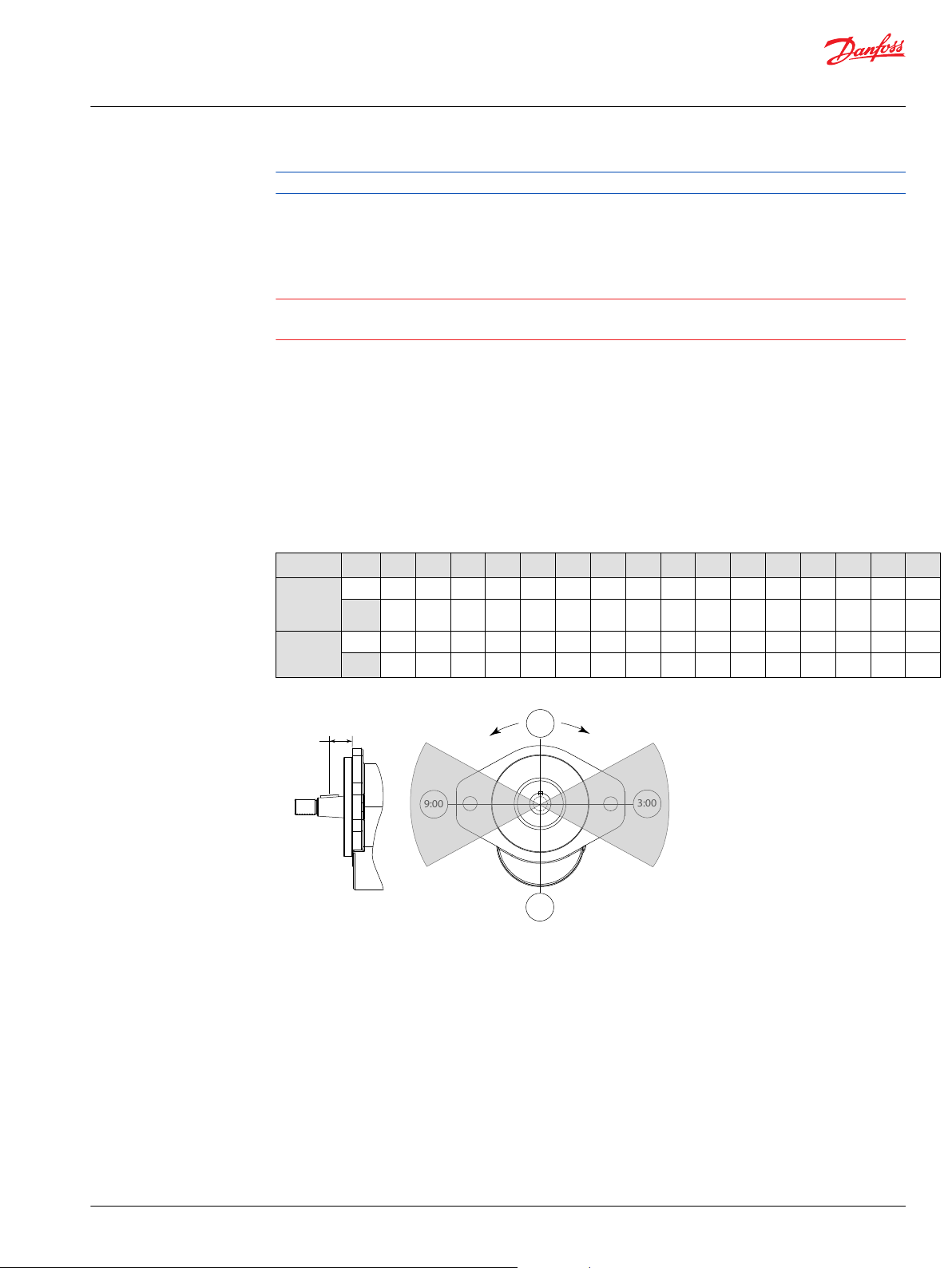

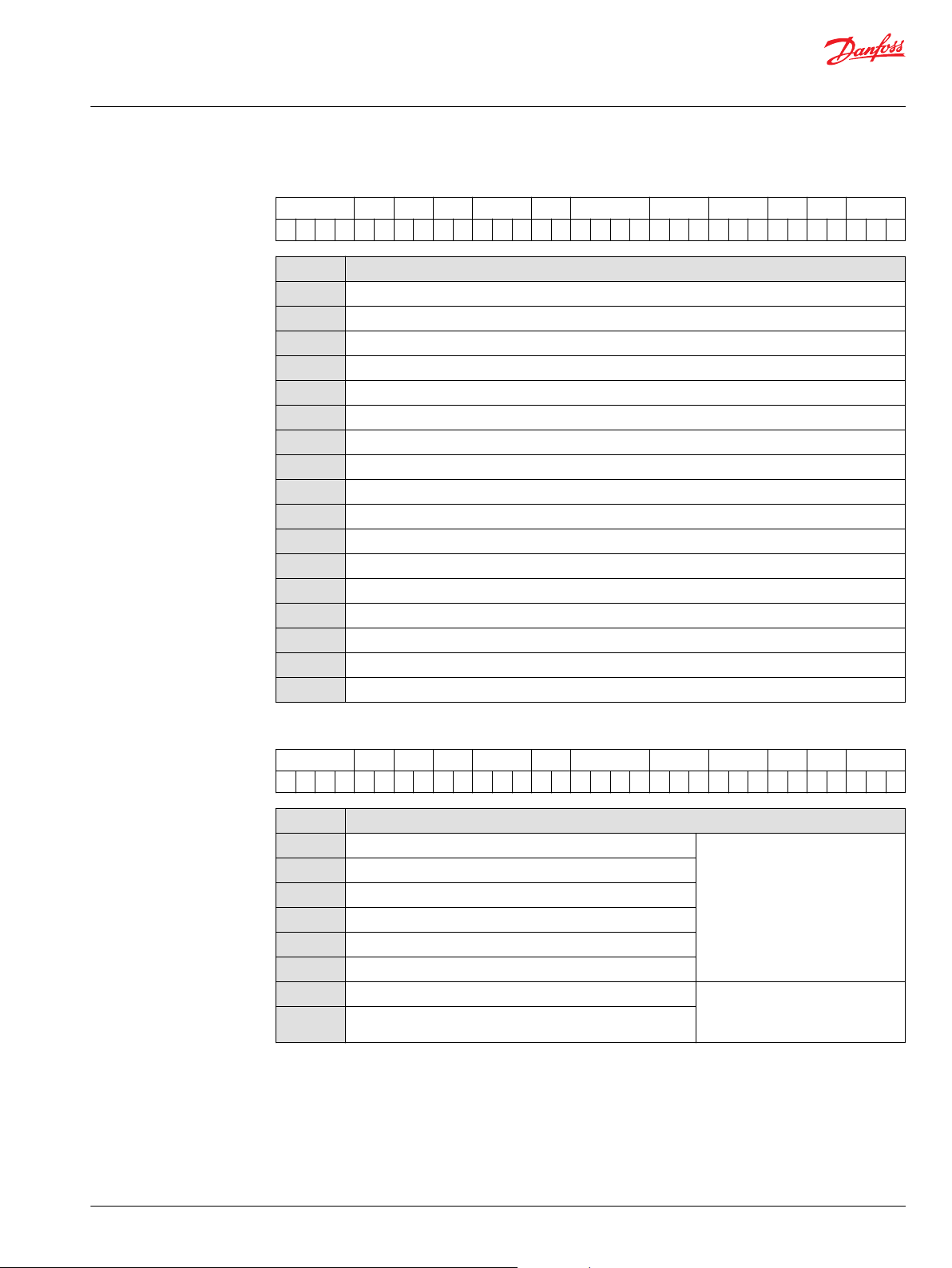

Radial and axial loading

Allowable radial shaft loads are a function of the load position, load orientation, and operating pressure.

All external shaft loads have an effect on bearing life, and may affect pump performance.

In applications where external shaft loads cannot be avoided, minimize the impact on the pump by

optimizing the orientation and magnitude of the load. Use tapered input shafts for applications with

radial shaft loads. The table below shows the preferred orientation for radial loads assuming maximum

pressure. For assistance concerning shaft loading, contact your Danfoss representative.

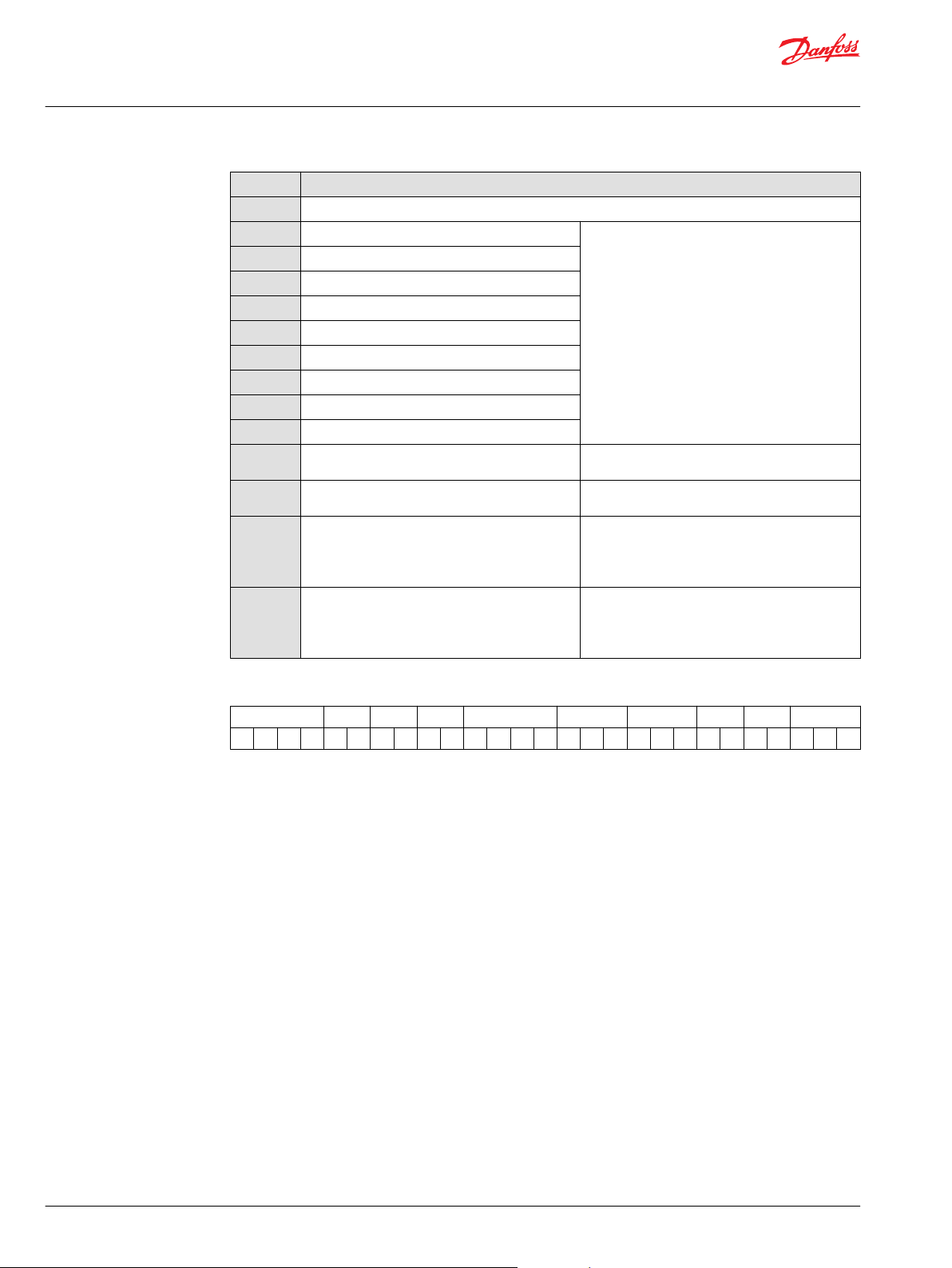

Maximum radial and axial loads

Ratings Units 7 10 11 13 14 17 19 21 23 25 29 32 36 38 41 45

Maximum

radial

load

Push/Pull

axial load

lbf 1430 1430 1430 1430 1430 1430 1360 1300 1210 1070 870 700 420 270 450 620

6361 6361 6361 6361 6361 6361 5943 5783 5382 4760 3870 3114 1868 1201 2002 2758

N

lbf 350 350 350 350 350 350 350 350 350 350 350 350 350 350 350 350

1557 1557 1557 1557 1557 1557 1557 1557 1557 1557 1557 1557 1557 1557 1557 1557

N

©

Danfoss | April 2020 BC319684134607en-000202 | 15

Page 16

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Single pump order code

Example

A B1 B2 C D E F H J K

D E 1 R 2 1 S H A C F 0 9 A 1 5 X 1 7 2 C Z A N N N N

Code Position Description

DE1R

21

SH

AC

F09A

15X

172

CZ

AN

NNN

A D Series pump, single section, right hand rotation

B1 21 cm³ displacement

B2 13 tooth spline input shaft

C SAE A two bolt mounting flange

D Integrated priority flow divider with cartridge style priority relief, 1 5/16-12 side inlet,

3/14-16 side priority, 7/8-14 side secondary

E 15.1 l/min[4 US gal/min] priority flow setting

F 172 bar [2495 psi] priority relief setting

H Assembly screws

J Standard Nameplate

K No special features, black paint

DE1: D series cast iron gear pump, single section

A Rotation - viewed from drive shaft

A B1 B2 C D E F H J K

D E 1 ●

Code Description

L Lefthand (counterclockwise)

R Right hand (clockwise)

B1 Displacement

A B1 B2 C D E F H J K

D E 1 ● ●

Code Description

07

10

11

13

14

17

19

21

23

25

7.0 cm³/rev [0.43 in3/rev]

9.5 cm³/rev [0.58 in3/rev]

10.8cm³/rev [0.66 in3/rev]

12.6cm³/rev [0.77 in3/rev]

14.3cm³/rev [0.87 in3/rev]

17.0cm³/rev [1.04 in3/rev]

19.0cm³/rev [1.16 in3/rev]

20.5cm³/rev [1.25 in3/rev]

22.5 cm³/rev [1.37 in3/rev]

25.4 cm³/rev [1.55 in3/rev]

16 | © Danfoss | April 2020 BC319684134607en-000202

Page 17

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Code Description

29

32

36

38

41

45

B2 Input shaft

A B1 B2 C D E F H J K

D E 1 ● ●

Code Description

*

SE

SC

SF

SH

SV

PB

PD

PZ

TA

TG

TH

TX

WT

AB

AC

AH

*

Contact factory for units with SE (9T spline) to verify torque limits

29.0 cm³/rev [1.77 in3/rev]

31.8 cm³/rev [1.94 in3/rev]

36.1 cm³/rev [2.20 in3/rev]

38.0 cm³/rev [2.32 in3/rev]

41.0 cm³/rev [2.50 in3/rev]

45.1 cm³/rev [2.75 in3/rev]

SAE 9 tooth spline, 31.8 mm [1.25 in] length

SAE 11 tooth spline, 38.1 mm [1.5 in] length

11 tooth spline, 31.8 mm [1.25 in] length (special modified length)

SAE 13 tooth spline, 41 mm [1.62 in] length

15 tooth spline, 46 mm [1.81 in] length (use with mounting flange AR or BR)

22 mm [7/8 in] diameter, 41 mm [1.62 in] length, with 1/4 key

19 mm [3/4 in] diameter, 51 mm [2 in] length, with 3/16 key

25.4 mm [1 in] diameter, 46 mm [1.81 in] length with 1/4 key

1:5taper, 25mm [1 in] dia, 58mm [2.30 in] length, 5/8 thread, M5 key with locknut and washer

1:8taper, 22mm [7/8 in] dia, 50mm [1.95 in] length, 5/8 thread with key, locknut and washer

1:8taper, 22mm [7/8 in] dia, 49mm [1.94 in] length, 9/16 thread with key, locknut and washer

1:4 taper, 22mm [7/8 in] dia, 50mm [1.98 in] length, 5/16 internal thread with key

Input shaft similar to TH option with 34 tooth helical gear for Perkins engine mount

22mm[7/8 in] diameter, 41mm [1.62] length with 1/4 key with 9T spline through drive

SAE 11 tooth spline, 38.1 mm [1.5 in] length with 9T spline through drive

SAE 13 tooth spline, 41 mm [1.62 in] length with 9T spline through drive

C Mounting flange

A B1 B2 C D E F H J K

D E 1 ● ●

Code Description

AA

AC

AL

AM

AP

AR

©

Danfoss | April 2020 BC319684134607en-000202 | 17

SAE A 2-bolt

SAE A 2-bolt, use with integral PFD/Steering Cover

SAE A 2-bolt, two shaft seals with weep hole

SAE A 2-bolt, with T seal

SAE A 2-bolt, with T seal, use with integral PFD/Steering cover

SAE A 2-bolt, use with 15 T spline input drive

Page 18

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Code Description

AS

AT

BB

BC

BM

BP

BR

BS

BT

BW

PP

D Rear cover: Port options, integrated valves, and auxillary flange

A B1 B2 C D E F H J K

D E 1 ● ● ● ●

SAE A 2-bolt, use with integral PFD/Steering cover and 15 T input spline

SAE A 2-bolt, two shaft seals with weep hole, use with integral PFD/Steering cover

SAE B 2-bolt

SAE B 2-bolt, use with integral PFD/Steering cover

SAE B 2-bolt, with T seal

SAE B 2-bolt, with T seal, use with integral PFD/Steering cover

SAE B 2-bolt, use with 15 T spline input drive

SAE B 2-bolt, use with integral PFD/Steering cover and 15 T input spline

SAE B 2-bolt, two shaft seals with weep hole, use with integral PFD/Steering Cover

SAE B 2-bolt, two shaft seals with weep hole

Perkins 6 bolt flange with (2) seals (use with WT input shaft and clockwise rotation)

Code Inlet Outlet Description

N101

N103

N104

N125

N501

N503

N504

N252

N402

N403

N404

N407

N408

N342

N704

N708

N715

N716

N720

B103

B104*

1 1/16-12 side inlet 7/8-14 side outlet

1 5/16-12 side inlet 7/8-14 side outlet

1 5/16-12 side inlet 1 1/16-12 side outlet

1 5/8-12 side inlet 1 1/16-12 side outlet

1 1/16-12 rear inlet 7/8-14 rear outlet

1 5/16-12 rear inlet 7/8-14 rear outlet

1 5/16-12 rear inlet 1 1/16-12 rear outlet

M33x2-6H rear inlet M22x1.5-6H side outlet SAE Metric Ports – No Integrated

3/4-14 side inlet 1/2-14 side outlet

1-11 side inlet 1/2-14 side outlet

1 1/4-11 side inlet 1/2-14 side outlet

1-11 side inlet 3/4-14 side outlet

1 1/4-11 side inlet 3/4-14 side outlet

1 1/4 side split flange inlet 3/4side split flange outlet (SAE

code 61)

1 1/4 side tube inlet 7/8-14 side ORB outlet

1 1/4 side tube inlet 1 1/16-12 side ORB outlet

1 1/4 REAR tube inlet 1 1/16-12 REAR ORB outlet

1 1/2 side tube inlet 1 1/16-12 side ORB outlet

1 1/4 REAR tube inlet 7/8-14 REAR ORB outlet

*

1 5/16-12 side inlet 7/8-14 side outlet

1 5/16-12 side inlet 1 1/16-12 side outlet

SAE O-ring boss ports No

integrated valves No auxiliary

flange

Valves

British Standard Pipe Parallel

(BSPP) threads - No integrated

valves

SAEsplit flange ports No

integrated valves Noauxiliary

flange

Beaded tube inlet port, SAE Oring boss outlet port No

integrated valves

No auxiliary flange

SAE-A2-Bolt Auxiliary Flange

SAEO-ring boss ports

No integrated valves

18 | © Danfoss | April 2020 BC319684134607en-000202

Page 19

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Code Inlet Outlet Description

R104

**

F09A

‡

F09B

F13A**

F13B‡

F21A**

F21B‡

F25A**

F25B‡

D23A*

D23B**

D24A*

D24B**

L01A**

L01B‡

L08A**

L08B‡

*

Integrated auxilliary flange requires use of input shaft option AH or AC

**

Requires use of mounting flange option AC or AP

‡

Requires use of mounting flange option BC or BP

1 5/16-12 side inlet 1 1/16-12 side outlet Integrated Relief Valve Internally

Drained

Maximum Displacement 23cc

15/16-12 side inlet, 3/4-16 side priority, 7/8-14side secondary (SAE A

flange)

1 5/8-12 rear inlet, 3/4-16 rear priority, 7/8-14 rear secondary (SAE A

flange)

1 5/8-12 rear inlet, 3/4-16 rear priority, 7/8-14 rear secondary (SAE A

flange)

1 5/8-12 rear inlet, 3/4-16 rear priority, 7/8-14 rear secondary (SAE B

flange)

15/8-12 side inlet, 3/4-16 side priority, 7/8-14 side secondary (SAE A

flange)

15/8-12 side inlet, 3/4-16 side priority, 7/8-14 side secondary (SAE B

flange)

1 5/16-12 rear inlet, 3/4-16 rear priority, 7/8-14 rear secondary (SAE A

flange)

1 5/16-12 rear inlet, 3/4-16 rear priority, 7/8-14 rear secondary (SAE B

flange)

15/16-12 side inlet, 3/4-16 side priority, nosecondary port (SAE A

flange)

15/16-12 side inlet, 3/4-16 side priority, nosecondary port (SAE B

flange)

1 5/16-12 rear inlet, 3/4-16 rear priority, no secondary port (SAE A

flange)

1 5/16-12 rear inlet, 3/4-16 rear priority, no secondary port (SAE B

flange)

1 5/16-12 side inlet, 3/4-16 side priority, 7/8-14 side secondary,

7/16-20 side LS (SAE-A flange)

1 5/16-12 side inlet, 3/4-16 side priority, 7/8-14 side secondary,

7/16-20 side LS (SAE-B flange)

1 5/16-12 rear inlet, 3/4-16 rear priority, 7/8-14 rear secondary,

7/16-20 rear LS (SAE-A flange)

1 5/16-12 rear inlet, 3/4-16 rear priority,

7/8-14 rear secondary, 7/16-20 rear LS (SAE-B flange)

Integrated Priority Flow Divider,

cartridge style relief

for settings up to: 221barand

34.3 l/min

[3200 psi and 9 US gal/min]

Integrated Steering Cover,

Priority Relief Valve

(Cartridge Style) for settings up

to: 221 bar and 34.3 l/min

[3200 psi and 9 US gal/min]

Integrated Load Sense Divider

(Dynamic), Priority Relief Valve

A variety of integrated load sense priority flow divider covers are available from Danfoss. Please contact

your technical representative to determine which hardware best suits specific application needs.

E Flow control valve setting

A B1 B2 C D E F H J K

D E 1 ● ● ●

©

Danfoss | April 2020 BC319684134607en-000202 | 19

Page 20

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Code Description

NNN Noflow control setting, standard for units without integrated flow control valves

04X 3.8 l/min [1 US gal/min]

08X 7.6 l/min [2 US gal/min]

11X 11.4 l/min [3 US gal/min]

15X 15.1 l/min [4 US gal/min]

19X 18.9 l/min [5 US gal/min]

23X 22.7 l/min [6 US gal/min]

27X 26.5 l/min [7 US gal/min]

30X 30.3 l/min [8 US gal/min]

34X 34.3 l/min [9 US gal/min]

38A 10 bar standby

38L 10 bar standby

R1N

R2N

Maximum flow not to exceed 75 l/min, pressure

rangefrom 7-55bar

Maximum flow not to exceed 75 l/min, pressure

rangefrom 41-248bar

For integrated PFD

Steering cover with cartridge style relief valve

(Cover options F09A, F09B, F13A, F13B, F21A, F21B,

F25A or F25B)

Forintegrated load sense divider (use with L08A or

L08B rear ports)

Forintegrated load sense divider (use with L01A or

L01B side ports)

For integrated relief valve, internally drained

(without flow control)

Use with R104 cover option

23cc and under

For integrated relief valve, internally drained

(without flow control)

Use with R104 cover option

23cc and under

F Pressure control valve setting

A B1 B2 C D E F H J K

D E 1 ● ● ●

20 | © Danfoss | April 2020 BC319684134607en-000202

Page 21

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Code Description

000 Nopressure control settings, standard for units without integrated pressure control valves

034 34 bar [500 psi]

041 41 bar [600 psi]

048 48 bar [700 psi]

055 55 bar [800 psi]

062 62 bar [900 psi]

069 69 bar [1000 psi]

076 76 bar [1100 psi]

083 83 bar [1200 psi]

090 90 bar [1300 psi]

097 97 bar [1400 psi]

103 103 bar [1500 psi]

110 110 bar [1600 psi]

117 117 bar [1700 psi]

124 124 bar [1800 psi]

131 131 bar [1900 psi]

138 138 bar [2000 psi]

145 145 bar [2100 psi]

152 152 bar [2200 psi]

159 159 bar [2300 psi]

165 165 bar [2400 psi]

172 172 bar [2500 psi]

179 179 bar [2600 psi]

186 186 bar [2700 psi]

193 193 bar [2800 psi]

200 200 bar [2900 psi]

207 207 bar [3000 psi]

214 214 bar [3100 psi]

221 221 bar [3200 psi]

For integrated priority flow divider (PFD) cover

with cartridge style relief valve

(Cover optionsF09A, F09B, F13A, F13B, F21A, F21B,

F25A, F25B)

For integrated steering cover with cartridge style

relief valve (Cover options D23A, D23B, D24A,

D24B)

For integrated load sense (LS) cover with cartridge

relief valve (Cover options L01A, L01B, L08A, L08B)

H Assembly Screws - depending on rear cover

A B1 B2 C D E F H J K

D E 1 ● ●

(Choose Table 1 or Table 2)

Table 1. Single pumps without auxiliary cover or integrated valves

Displacem

ent

(Module

B)

07 AF AJ

10 AG AJ

©

Danfoss | April 2020 BC319684134607en-000202 | 21

N101, N103, N104, N501, N503, N504, N704, N708 N125

Rear Cover - Controls & Ports (Module D)

Page 22

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Table 1. Single pumps without auxiliary cover or integrated valves (continued)

Displacem

ent

(Module

B)

11 AG AJ

13 AG AJ

14 AG AK

17 AH AK

19 AH AK

21 AH AL

23 AJ AL

25 AJ AL

29 AK AM

32 AK AM

36 AL AN

38 AL AN

41 AM AP

45 AM AR

Rear Cover - Controls & Ports (Module D)

N101, N103, N104, N501, N503, N504, N704, N708 N125

Table 2. Single pumps with auxiliary cover or integrated valves, dependent on rotation

Rear Cover - Controls & Ports (Module D)

Displacement

(Module B)

F09A F13A, F21A F09B F13B, F21B B104 F09A F13A, F21A F09B F13B, F21B B104

07 CV DG AG EM DG AG

10 CV DG AH EM DG AH

11 CV DG AH EM DG AH

13 CX DJ AH EP DJ AH

14 CX DJ AH EP DJ AH

17 CY DK AJ ER DK AJ

19 CZ DL AJ ES DL AJ

21 CZ DL AJ ES DL AJ

23 CZ DM AJ ES DM AJ

25 DA DN AK ET DN AK

29 DB DP AK EY DP AK

32 DC DR AL EU DR AL

36 DD DS AM EV DS AM

38 DE DT AM EW DT AM

41 DE DT AM EW DT AM

45 DF DU AN EX DU AN

Right Hand (CW) Rotation Left Hand (CCW) Rotation

22 | © Danfoss | April 2020 BC319684134607en-000202

Page 23

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

J Nameplates

A B1 B2 C D E F H J K

D E 1 ● ●

Code Description

AN Standard nameplate

K Special feature

A B1 B2 C D E F H J K

D E 1 ● ● ●

Code Description

NNN No special features, standard black paint

Two section (tandem) pump order code

Example

The order code below provides an example of a single section pump with integrated priority flow divider

A B1 B2 C R S D E F H J K

D E 2 R 2 3 S H B B 1 0 4 1 3 N 1 1 3 N N N O O O A V A N N N N

Code Position Description

DE2R

23

SH

BB

104

13

N113

NNN

000

AV

AN

NNN

A D Series pump with two pumping sections, right hand rotation

B1 23 cm³ displacement on first section

B2 13 tooth spline input shaft

C SAE B two bolt mounting flange

R 1 5/16-12 side inlet, 1 1/16 side outlet on first section

S 13 cm³ displacement on second section

D No inlet and 7/8-14 side outlet on second section

E No flow control setting

F No pressure control setting

H Assembly screws

J Standard Nameplate

K No special features, black paint

A Rotation - viewed from drive shaft

A B1 B2 C R S D E F H J K

D E 2 ●

Code Description

L

R

©

Danfoss | April 2020 BC319684134607en-000202 | 23

Lefthand (counterclockwise)

Right hand (clockwise)

Page 24

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

B1 Displacement

A B1 B2 C R S D E F H J K

D E 2 ● ●

Code Description

07

10

11

13

14

17

19

21

23

25

29

32

36

38

41

45

7.0 cm³/rev [0.43 in3/rev]

9.5 cm³/rev [0.58 in3/rev]

10.8cm³/rev [0.66 in3/rev]

12.6cm³/rev [0.77 in3/rev]

14.3cm³/rev [0.87 in3/rev]

17.0cm³/rev [1.04 in3/rev]

19.0cm³/rev [1.16 in3/rev]

20.5cm³/rev [1.25 in3/rev]

22.5cm³/rev [1.37 in3/rev]

25.4cm³/rev [1.55 in3/rev]

29.0cm³/rev [1.77 in3/rev]

31.8cm³/rev [1.94 in3/rev]

36.1cm³/rev [2.20 in3/rev]

38.0cm³/rev [2.32 in3/rev]

41.0cm³/rev [2.50 in3/rev]

45.1cm³/rev [2.75 in3/rev]

B2 Input shaft

A B1 B2 C R S D E F H J K

D E 2 ● ●

Code Description

*

SE

SC

SF

SH

SV

PB

PD

PZ

TA

TG

TH

WT

*

Contact factory for units with SE (9T spline) to verify torque limits

SAE 9 tooth spline, 31.8 mm [1.25 in] length

SAE 11 tooth spline, 38.1 mm [1.50 in] length

11 tooth spline, 31.8 mm [1.25 in] length (special modified length)

SAE 13 tooth spline, 41 mm [1.62 in] length

15 tooth spline, 46 mm [1.81 in] length (requires mounting flange AR or BR)

22 mm [7/8 in] diameter x 41 mm [1.62 in] length, with 1/4 inch key

19 mm [3/4 in] diameter x 51 mm [2.0 in] length, with 3/16 inch key

25.4 mm [1 inch] diameter x 46 mm [1.81 in] length, with 1/4 inch key

1:5taper, 25mm [1 in] dia, 58mm [2.30 in] length, 5/8 thread, M5 key with locknut and washer

1:8taper, 22mm [7/8 in] dia, 50mm [1.95 in] length, 5/8 thread with key, locknut and washer

1:8taper, 22mm [7/8 in] dia, 49mm [1.94 in] length, 9/16 thread with key, locknut and washer

Input shaft similar to TH option with 34 tooth helical gear for Perkins engine mount

24 | © Danfoss | April 2020 BC319684134607en-000202

Page 25

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

C Mounting flange

A B1 B2 C R S D E F H J K

D E 2 ● ●

Code Description

AA

AC

AM

AP

AR

AS

AL

AT

BB

BC

BM

BP

BR

BS

BT

BW

PP

SAE A 2-bolt

SAE A 2-bolt, use with integral PFD/Steering Cover

SAE A 2-bolt, with T seal

SAE A 2-bolt, with T seal, use with integral PFD/Steering cover

SAE A 2-bolt, use with 15 T spline input drive

SAE A 2-bolt, use with integral PFD/Steering cover and 15 T input spline

SAE A 2-bolt, two shaft seals with weep hole

SAE A 2-bolt, two shaft seals with weep hole, use with integral PFD/Steering cover

SAE B 2-bolt

SAE B 2-bolt, use with integral PFD/Steering cover

SAE B 2-bolt, with T seal

SAE B 2-bolt, with T seal, use with integral PFD/Steering cover

SAE B 2-bolt, use with 15 T spline input drive

SAE B 2-bolt, use with integral PFD/Steering cover and 15 T input spline

SAE B 2-bolt, two shaft seals with weep hole, use with integral PFD/Steering Cover

SAE B 2-bolt, two shaft seals with weep hole

Perkins 6 bolt flange with (2) seals (use with WT input shaft and clockwise rotation)

R Ports - First section

A B1 B2 C R S D E F H J K

D E 2 ● ● ●

Code Description

101 1 1/16-12 side inlet, 7/8-14 side outlet

103 1 5/16-12 side inlet, 7/8-14 side outlet

104 1 5/16-12 side inlet, 1 1/16-12 side outlet

113 No inlet, 7/8-14 side outlet

125 1 5/8-12 side inlet, 1 1/16-12 side outlet

126 No inlet, 1 1/16-12 side outlet

341 Noinlet, 3/4 side split flange outlet (SAE Code 61)

342

11/4 side split flange inlet, 3/4 side split flange outlet(SAE Code

61)

SAE O-ring boss ports No integrated

SAESplit Flange Ports - No

integratedvalves

valves

©

Danfoss | April 2020 BC319684134607en-000202 | 25

Page 26

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Code Description

401 No inlet, 1/2-14 side outlet

402 3/4-14 side inlet, 1/2-14 side outlet

403 1-11 side inlet, 1/2-14 side outlet

404 1 1/4-11 side inlet, 1/2-14 side outlet

405 No inlet, 3/4-14 side outlet

407 1-11 side inlet, 3/4-14 side outlet

408 1 1/4-11 side inlet, 3/4-14 side outlet

704 1 1/4 side tube inlet, 7/8-14 side ORB outlet

708 11/4 side tube inlet, 1 1/16-12 side ORB outlet

716 11/2 side tube inlet, 1 1/16-12 side ORB outlet

717 1 1/2 side tube inlet, 7/8-14 side ORB outlet

S Displacement - Second section

A B1 B2 C R S D E F H J K

D E 2 ● ●

British Standard Pipe Parallel (BSPP)

threads - No integrated valves

Beaded tube inlet port

SAE O-ring boss outlet port No

integrated valves

Code Description

07

10

11

13

14

17

19

21

23

25

29

32

36

38

41

45

7.0 cm³/rev [0.43 in3/rev]

9.5 cm³/rev [0.58 in3/rev]

10.8cm³/rev [0.66 in3/rev]

12.6cm³/rev [0.77 in3/rev]

14.3cm³/rev [0.87 in3/rev]

17.0cm³/rev [1.04 in3/rev]

19.0cm³/rev [1.16 in3/rev]

20.5 cm³/rev [1.25 in3/rev]

22.5 cm³/rev [1.37 in3/rev]

25.4 cm³/rev [1.55 in3/rev]

29.0 cm³/rev [1.77 in3/rev]

31.8 cm³/rev [1.94 in3/rev]

36.1 cm³/rev [2.20 in3/rev]

38.0 cm³/rev [2.32 in3/rev]

41.0 cm³/rev [2.50 in3/rev]

45.1 cm³/rev [2.75 in3/rev]

D Rear cover: Port options, integrated valves and auxillary flange

A B1 B2 C R S D E F H J K

D E 2 ● ● ● ●

26 | © Danfoss | April 2020 BC319684134607en-000202

Page 27

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Code Inlet Outlet Description

N101

N103

N104

N113

N125

N126

N501

N503

N504

N401

N402

N403

N404

N407

N408

N341

N342

N704

N708

N715

N716

N720

*

B103

B104*

R104

N252

*

Integrated auxilliary flange requires use of input shaft option AH or AC

1 1/16-12 side inlet 7/8-14 side outlet

1 5/16-12 side inlet 7/8-14 side outlet

1 5/16-12 side inlet 1 1/16-12 side outlet

No inlet 7/8-14 side outlet

1 5/8-12 side inlet 1 1/16-12 side outlet

No inlet 1 1/16-12 side outlet

1 1/16-12 rear inlet 7/8-14 rear outlet

1 5/16-12 rear inlet 7/8-14 rear outlet

1 5/16-12 rear inlet 1 1/16-12 rear outlet

No inlet 1/2-14 side oultet

3/4-14 side inlet 1/2-14 side outlet

1-11 side inlet 1/2-14 side outlet

1 1/4-11 side inlet 1/2-14 side outlet

1-11 side inlet 3/4-14 side outlet

1 1/4-11 side inlet 3/4-14 side outlet

No inlet 3/4side split flange outlet (SAE

code 61)

1 1/4 side split flange inlet 3/4side split flange outlet (SAE

code 61)

1 1/4 side tube inlet 7/8-14 side ORB outlet

1 1/4 side tube inlet 1 1/16-12 side ORB outlet

1 1/4 REAR tube inlet 1 1/16-12 REAR ORB outlet

1 1/2 side tube inlet 1 1/16-12 side ORB outlet

1 1/4 REAR tube inlet 7/8-14 REAR ORB outlet

1 5/16-12 side inlet 7/8-14 side outlet, SAE-A2-Bolt Auxiliary Flange

1 5/16-12 side inlet 1 1/16-12 side outlet Integrated Relief Valve Internally

1 5/16-12 side inlet 1 1/16-12 side outlet

M33x2-6H rear inlet M22x1.5-6H side outlet SAEMetric Ports – No Integrated

SAE O-ring boss ports No

integrated valves No auxiliary

flange

British Standard Pipe Parallel

(BSPP) threads - No integrated

valves

SAEsplit flange ports No

integrated valves Noauxiliary

flange

Beaded tube inlet port, SAE Oring boss outlet port No

integrated valves

No auxiliary flange

SAEO-ring boss ports

No integrated valves

Drained

Maximum Displacement 23cc

Valves

©

Danfoss | April 2020 BC319684134607en-000202 | 27

Page 28

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Code Inlet/Outlet Description

**

F09A

‡

F09B

F13A**

F13B‡

F21A**

F21B‡

F25A**

F25B‡

*

D23A

D23B**

D24A*

D24B**

L01A**

L01B***

L08A**

L08B***

**

Requires use of mounting flange option AC or AP

‡

Requires use of mounting flange option BC or BP

*

Integrated auxilliary flange requires use of input shaft option AH or AC

15/16-12 side inlet, 3/4-16 side priority, 7/8-14side

secondary (SAE A flange)

15/16-12 side inlet, 3/4-16 side priority, 7/8-14side

secondary (SAE B flange)

1 5/8-12 rear inlet, 3/4-16 rear priority, 7/8-14 rear

secondary (SAE A flange)

1 5/8-12 rear inlet, 3/4-16 rear priority, 7/8-14 rear

secondary (SAE B flange)

15/8-12 side inlet, 3/4-16 side priority, 7/8-14 side

secondary (SAE A flange)

15/8-12 side inlet, 3/4-16 side priority, 7/8-14 side

secondary (SAE B flange)

1 5/16-12 rear inlet, 3/4-16 rear priority, 7/8-14 rear

secondary (SAE A flange)

1 5/16-12 rear inlet, 3/4-16 rear priority, 7/8-14 rear

secondary (SAE B flange)

15/16-12 side inlet, 3/4-16 side priority,

nosecondary port (SAE A flange)

15/16-12 side inlet, 3/4-16 side priority,

nosecondary port (SAE B flange)

1 5/16-12 rear inlet, 3/4-16 rear priority, no

secondary port (SAE A flange)

1 5/16-12 rear inlet, 3/4-16 rear priority, no

secondary port (SAE B flange)

1 5/16-12 side inlet, 3/4-16 side priority,

7/8-14 side secondary, 7/16-20 side LS (SAE-A

flange)

1 5/16-12 side inlet, 3/4-16 side priority,

7/8-14side secondary, 7/16-20 side LS (SAE-B

flange)

1 5/16-12 rear inlet, 3/4-16 rear priority,

7/8-14 rear secondary, 7/16-20 rear LS (SAE-A

flange)

1 5/16-12 rear inlet, 3/4-16 rear priority,

7/8-14 rear secondary, 7/16-20 rear LS (SAE-B

flange)

Integrated Priority Flow Divider, cartridge style

relief

for settings up to: 221barand 34.3 l/min

[3200 psi and 9 US gal/min]

Integrated Steering Cover,

Priority Relief Valve

(CartridgeStyle) for settings up to: 221 bar and

34.3 l/min

[3200 psi and 9 US gal/min]

Integrated Load Sense Divider (Dynamic), Priority

Relief Valve

A variety of integrated valve options including PFD, Steering Covers, and Load sense priority flow dividers

covers are available with D Series multiple pumps. Please contact your technical representative to

determine which hardware best suits specific application needs.

E Flow control valve

A B1 B2 C R S D E F H J K

D E 2 ● ● ●

28 | © Danfoss | April 2020 BC319684134607en-000202

Page 29

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Code Description

NNN Noflow control setting, standard for units without integrated flow control valves

04X 3.8 l/min [1 US gal/min]

08X 7.6 l/min [2 US gal/min]

11X 11.4 l/min [3 US gal/min]

15X 15.1 l/min [4 US gal/min]

19X 18.9 l/min [5 US gal/min]

23X 22.7 l/min [6 US gal/min]

27X 26.5 l/min [7 US gal/min]

30X 30.3 l/min [8 US gal/min]

34X 34.3 l/min [9 US gal/min]

38A 10 bar standby

38L 10 bar standby

R1N

R2N

Maximum flow not to exceed 75 l/min, pressure

rangefrom 7-55bar

Maximum flow not to exceed 75 l/min, pressure

rangefrom 41-248bar

For integrated PFD

Steering cover with cartridge style relief valve

(Cover options F09A, F09B, F13A, F13B, F21A, F21B,

F25A or F25B)

Forintegrated load sense divider (use with L08A or

L08B rear ports)

Forintegrated load sense divider (use with L01A or

L01B side ports)

For integrated relief valve, internally drained

(without flow control)

Use with R104 cover option

23cc and under

For integrated relief valve, internally drained

(without flow control)

Use with R104 cover option

23cc and under

F Pressure control valve

A B1 B2 C R S D E F H J K

D E 2 ● ● ●

©

Danfoss | April 2020 BC319684134607en-000202 | 29

Page 30

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Code Description

000 Nopressure control settings

034 34 bar [500 psi]

041 41 bar [600 psi]

048 48 bar [700 psi]

055 55 bar [800 psi]

062 62 bar [900 psi]

069 69 bar [1000 psi]

076 76 bar [1100 psi]

083 83 bar [1200 psi]

090 90 bar [1300 psi]

097 97 bar [1400 psi]

103 103 bar [1500 psi]

110 110 bar [1600 psi]

117 117 bar [1700 psi]

124 124 bar [1800 psi]

131 131 bar [1900 psi]

138 138 bar [2000 psi]

145 145 bar [2100 psi]

152 152 bar [2200 psi]

159 159 bar [2300 psi]

165 165 bar [2400 psi]

172 172 bar [2500 psi]

179 179 bar [2600 psi]

186 186 bar [2700 psi]

193 193 bar [2800 psi]

200 200 bar [2900 psi]

207 207 bar [3000 psi]

214 214 bar [3100 psi]

221 221 bar [3200 psi]

For integrated priority flow divider (PFD) cover

with cartridge style relief valve

(Cover optionsF09A, F09B, F13A, F13B, F21A, F21B,

F25A, F25B)

For integrated steering cover with cartridge style

relief valve (Cover options D23A, D23B, D24A,

D24B)

For integrated load sense (LS) cover with cartridge

relief valve (Cover options L01A, L01B, L08A, L08B)

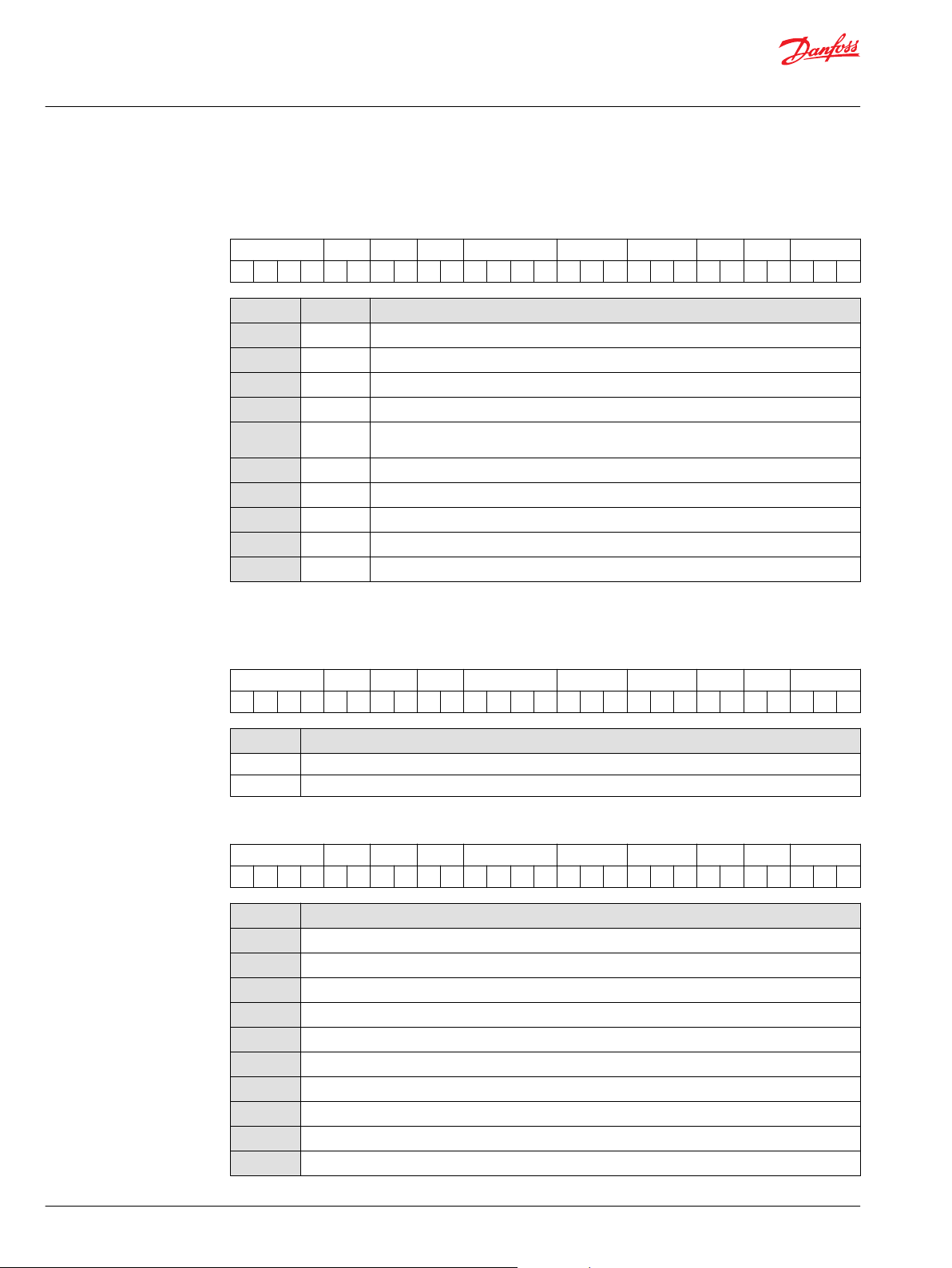

H Assembly screws

A B1 B2 C R S D E F H J K

D E 2 ● ●

1. Step 1 - Select the table corresponding to the port codes of the front and rear pump

2. Step 2 - Select the row corresponding to the displacement of the front pump

3. Step 3 - Select the column corresponding to the displacement of the rear pump

4. Step 4 - Select the 2 letter code where the two displacements meet

Example from Table 1: AW = 21+19 tandem

The following tables are only applicable to port codes shown. For all other port code options (including

PFD, LS and auxiliary cover), please consult factory.

30 | © Danfoss | April 2020 BC319684134607en-000202

Page 31

Technical Information

D Series and XD Series Gear Pumps

D Series Model Code

Table

number

1

2

3

4

Table 1

Displacement

front pump

(Module B)

07

10

13

14

17

19

21

23

25

29

32

36

38

41

45

Front pump port code Module R Rear pump port code Module D

101, 103, 104, 113, 126,

704 or 708

125, 716, 717

101, 103, 104, 113, 126,

704 or 708

125, 716, 717 N125

Frontpump port code, Module: R = 101, 103, 104, 113, 126, 704, or 708 Rearpump port code,

Module: D = N101, N103,

N104, N113, N126, N501, N503, N504, N704, or N708

Displacement rear pump, Module: S

07 10 13 14 17 19 21 23 25 29 32 36 38 41 45

AS AS AS AT AT AT AU AU AU AV AV AW AW AX AY

AS AS AT AT AU AU AU AU AV AV AW AX AX AX AY

AS AT AT AU AU AU AV AV AV AW AW AX AX AY AY

AT AT AU AU AU AV AV AV AW AW AX AX AY AY AZ

AT AU AU AU AV AV AV AW AW AX AX AY AY AY AZ

AT AU AU AV AV AV AW AW AW AX AX AY AZ AZ AZ

AU AU AV AV AV AW AW AW AX AX AY AY AZ AZ BA

AU AU AV AV AW AW AW AW AX AX AY AZ AZ AZ BA

AU AV AV AW AW AW AX AX AX AY AZ AZ AZ BA BA

AV AV AW AW AX AX AX AX AY AY AZ AZ BA BA BB

AV AW AW AX AX AX AY AY AY AZ AZ BA BA BB BB

AW AX AX AX AY AY AY AY AZ AZ BA BA BB BB BC

AW AX AX AY AY AY AZ AZ AZ BA BA BB BB BC BC

AX AX AY AY AY AZ AZ AZ BA BA BB BB BC BC BD

AY AY AY AZ AZ AZ BA BA BA BB BB BC BC BD BE

N101, N103, N104, N113, N126,

N501, N503, N504, N704, or N708

N101, N103, N104, N113, N126,

N501, N503, N504, N704, or N708

N125

Table 2

Displacement

front pump

(Module B)

07

10

13

14

17

19

21

23

25

©

Danfoss | April 2020 BC319684134607en-000202 | 31