Page 1

Technical Information

WD, WP and WR Series

Orbital Motors

www.danfoss.com

Page 2

Technical Information

Orbital Motors Type WD, WP and WR

Revision history Table of revisions

Date Changed Rev

December 2019 Conversion to CMS/ET Danfoss layout. 0201

June 2017 First edition 0101

2 | © Danfoss | December 2019 BC267362166283en-000201

Page 3

Technical Information

Orbital Motors Type WD, WP and WR

Contents

Technical Information

Operating Recommendations..................................................................................................................................................... 4

Oil Type...........................................................................................................................................................................................4

Fluid Viscosity and Filtration...................................................................................................................................................4

Installation and Start-up...........................................................................................................................................................4

Motor Protection.........................................................................................................................................................................4

Hydraulic Motor Safety Precaution.......................................................................................................................................4

Motor/Brake Precaution........................................................................................................................................................... 5

Motor Connections..........................................................................................................................................................................6

Product Testing.................................................................................................................................................................................7

Allowable Bearing and Shaft Loading.......................................................................................................................................7

Vehicle Drive Calculations.............................................................................................................................................................9

Induced Side Load.........................................................................................................................................................................12

Hydraulic Equations......................................................................................................................................................................13

Shaft Nut Information...................................................................................................................................................................14

Optional Motor Features

Speed Sensor Options..................................................................................................................................................................16

Freeturning Rotor Option........................................................................................................................................................... 19

Valve Cavity Option.......................................................................................................................................................................19

Slinger Seal Option........................................................................................................................................................................20

WD Product Line

WD Introduction.............................................................................................................................................................................21

WD Functional Charts...................................................................................................................................................................22

WD 145/146 Series.........................................................................................................................................................................28

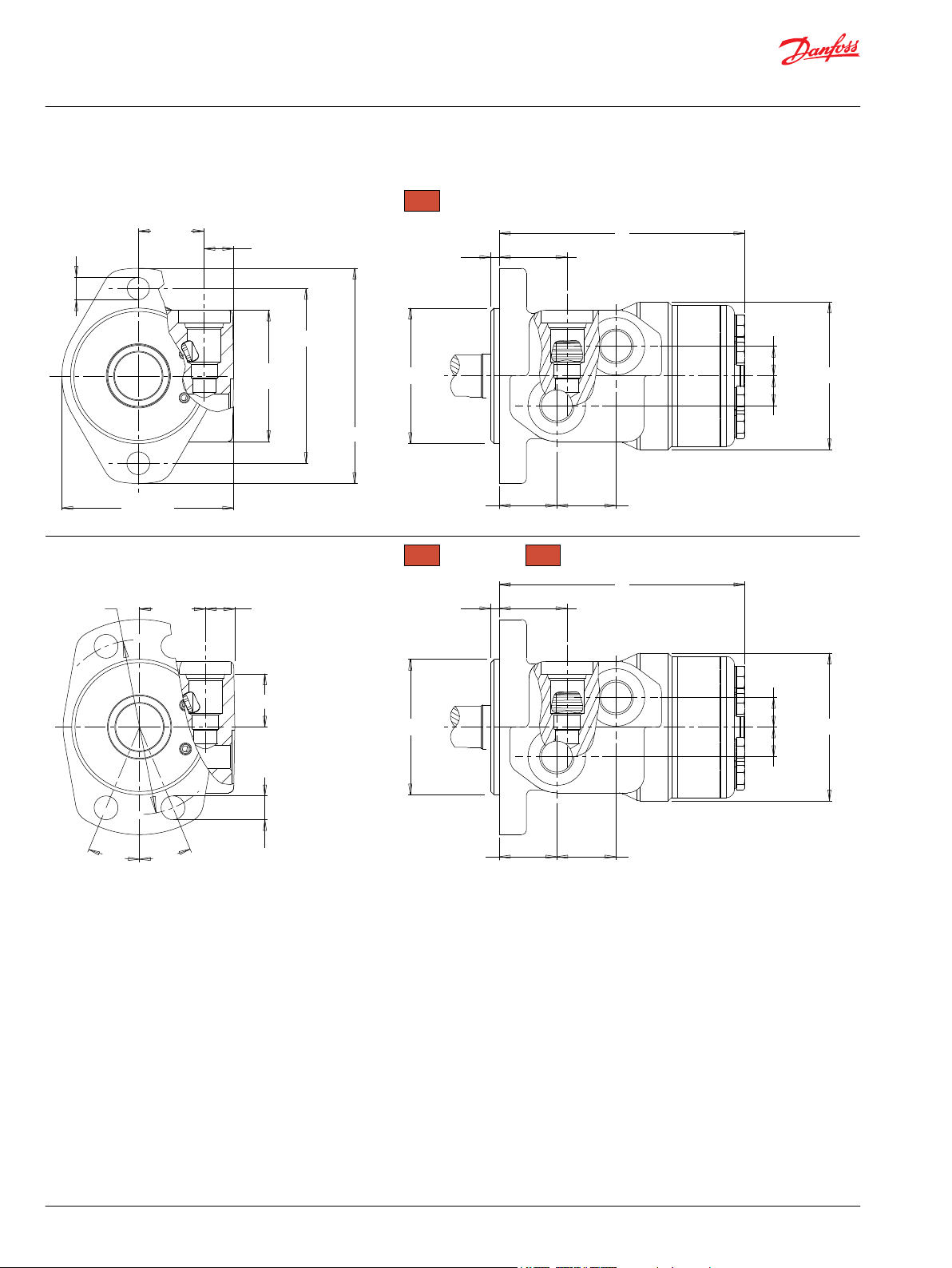

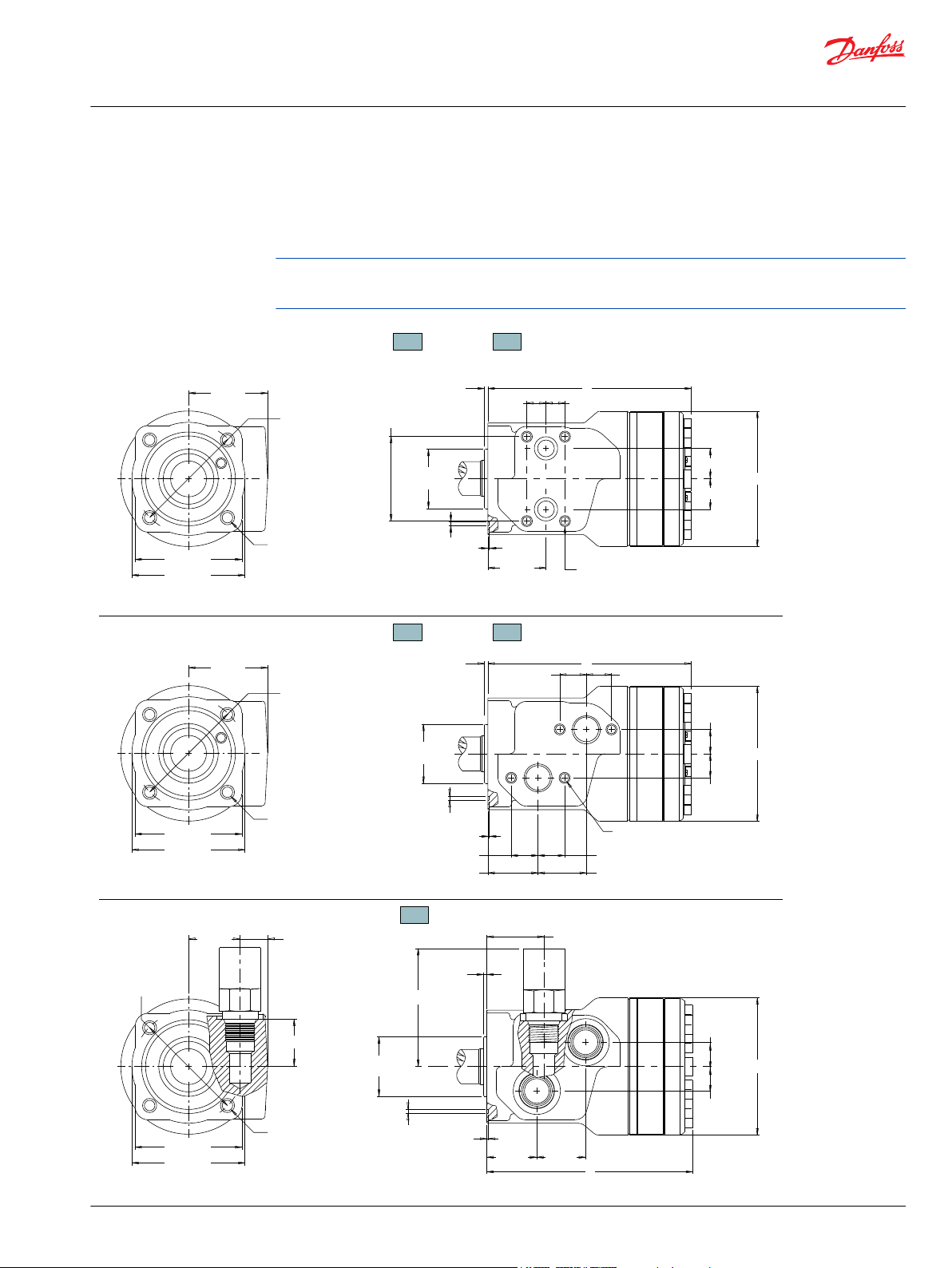

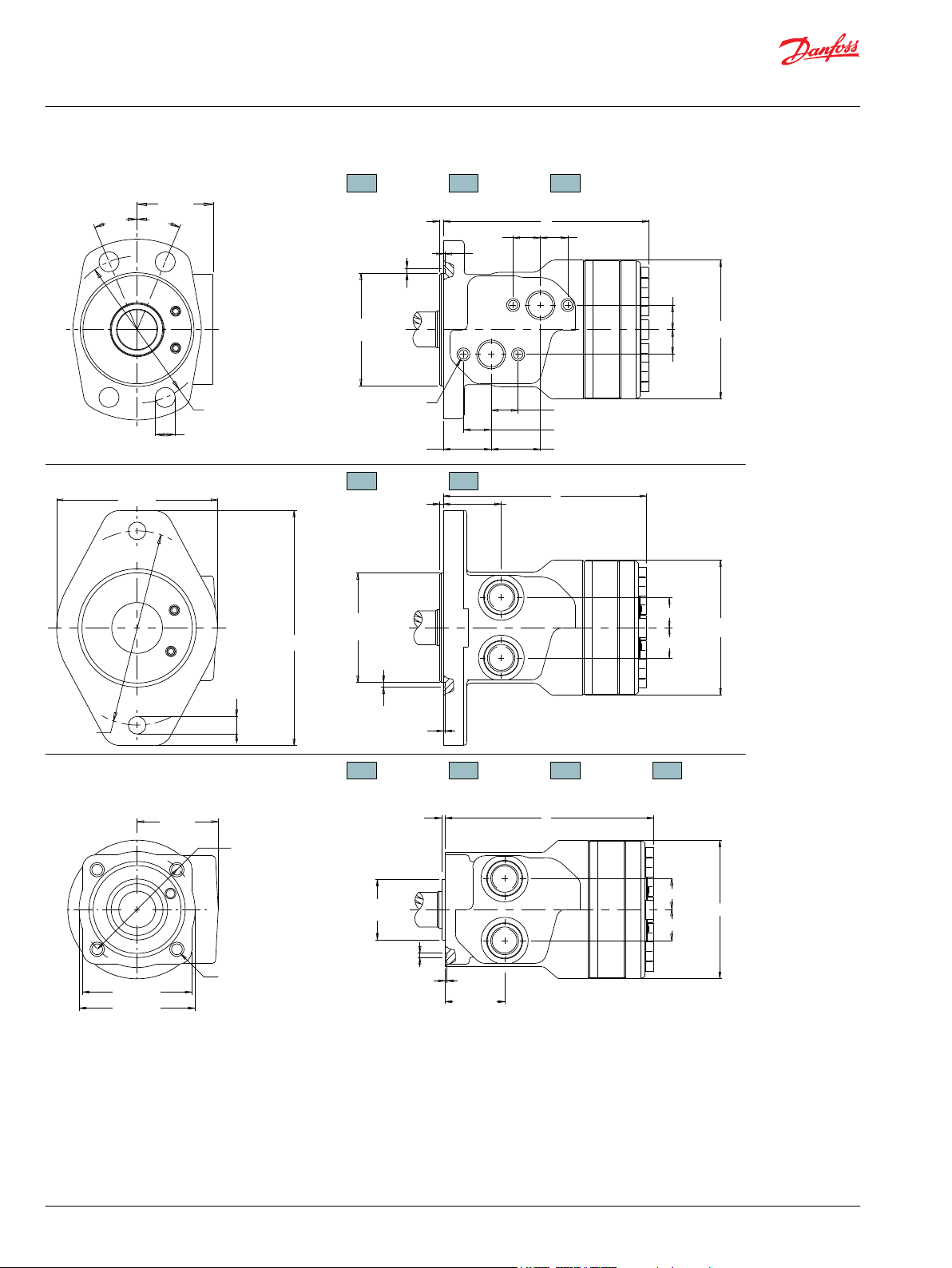

145/146 Series Housings........................................................................................................................................................28

145/146 Series Technical Data.............................................................................................................................................30

145/146 Series Shafts.............................................................................................................................................................. 33

145/146 Series Order Codes................................................................................................................................................. 35

WP Product Line

WP Introduction............................................................................................................................................................................. 36

WP Functional Charts................................................................................................................................................................... 37

155/156 Series.................................................................................................................................................................................45

155/156 Series Housings........................................................................................................................................................45

155/156 Series Technical Data.............................................................................................................................................51

155/156 Series Shafts.............................................................................................................................................................. 55

155/156 Order Codes.............................................................................................................................................................. 57

WP 157 and 158 Series................................................................................................................................................................. 60

WP 157 and 158 Series Housings........................................................................................................................................60

WP 157 and 158 Series Technical Information...............................................................................................................60

WP 157 and 158 Series Shafts.............................................................................................................................................. 62

WP 157 and 158 Series Ordering Information................................................................................................................64

WR Product Line

WR Product Line Introduction...................................................................................................................................................65

WR Displacement Performance................................................................................................................................................66

WR 251 and 252 Series.................................................................................................................................................................75

WR 251 and 252 Series Housings........................................................................................................................................75

WR 251 and 252 Series Technical Information...............................................................................................................76

WR 251 and 252 Series Shafts.............................................................................................................................................. 79

WR 251 and 252 Series Ordering Information................................................................................................................80

WR 255 and 256 Series.................................................................................................................................................................81

WR 255 and 256 Series Housings........................................................................................................................................81

WR 255 and 256 Series Technical Information...............................................................................................................85

WR 255 and 256 Series Shafts.............................................................................................................................................. 89

WR 255 and 256 Series Ordering Information................................................................................................................91

©

Danfoss | December 2019 BC267362166283en-000201 | 3

Page 4

Technical Information

Orbital Motors Type WD, WP and WR

Technical Information

Operating Recommendations

Oil Type

Hydraulic oils with anti-wear, anti-foam and demulsifiers are recommended for systems incorporating

Danfoss motors. Straight oils can be used but may require VI (viscosity index) improvers depending on

the operating temperature range of the system. Other water based and environmentally friendly oils may

be used, but service life of the motor and other components in the system may be significantly

shortened. Before using any type of fluid, consult the fluid requirements for all components in the system

for compatibility. Testing under actual operating conditions is the only way to determine if acceptable

service life will be achieved.

Fluid Viscosity and Filtration

Fluids with a viscosity between 20 - 43 cSt [100 - 200 S.U.S.] at operating temperature is recommended.

Fluid temperature should also be maintained below 85°C [180° F]. It is also suggested that the type of

pump and its operating specifications be taken into account when choosing a fluid for the system. Fluids

with high viscosity can cause cavitation at the inlet side of the pump. Systems that operate over a wide

range of temperatures may require viscosity improvers to provide acceptable fluid performance.

Danfoss recommends maintaining an oil cleanliness level of ISO 17-14 or better.

Installation and Start-up

When installing a Danfoss motor it is important that the mounting flange of the motor makes full contact

with the mounting surface of the application. Mounting hardware of the appropriate grade and size must

be used. Hubs, pulleys, sprockets and couplings must be properly aligned to avoid inducing excessive

thrust or radial loads. Although the output device must fit the shaft snug, a hammer should never be

used to install any type of output device onto the shaft. The port plugs should only be removed from the

motor when the system connections are ready to be made. To avoid contamination, remove all matter

from around the ports of the motor and the threads of the fittings. Once all system connections are

made, it is recommended that the motor be run-in for 15-30 minutes at no load and half speed to remove

air from the hydraulic system.

Motor Protection

Over-pressurization of a motor is one of the primary causes of motor failure. To prevent these situations,

it is necessary to provide adequate relief protection for a motor based on the pressure ratings for that

particular model. For systems that may experience overrunning conditions, special precautions must be

taken. In an overrunning condition, the motor functions as a pump and attempts to convert kinetic

energy into hydraulic energy. Unless the system is properly configured for this condition, damage to the

motor or system can occur.

To protect against this condition a counterbalance valve or relief cartridge must be incorporated into the

circuit to reduce the risk of overpressurization. If a relief cartridge is used, it must be installed upline of

the motor, if not in the motor, to relieve the pressure created by the over-running motor. To provide

proper motor protection for an over-running load application, the pressure setting of the pressure relief

valve must not exceed the intermittent rating of the motor.

Hydraulic Motor Safety Precaution

A hydraulic motor must not be used to hold a suspended load. Due to the necessary internal tolerances,

all hydraulic motors will experience some degree of creep when a load induced torque is applied to a

motor at rest. All applications that require a load to be held must use some form of mechanical brake

designed for that purpose.

4 | © Danfoss | December 2019 BC267362166283en-000201

Page 5

C

C

P109317

Technical Information

Orbital Motors Type WD, WP and WR

Technical Information

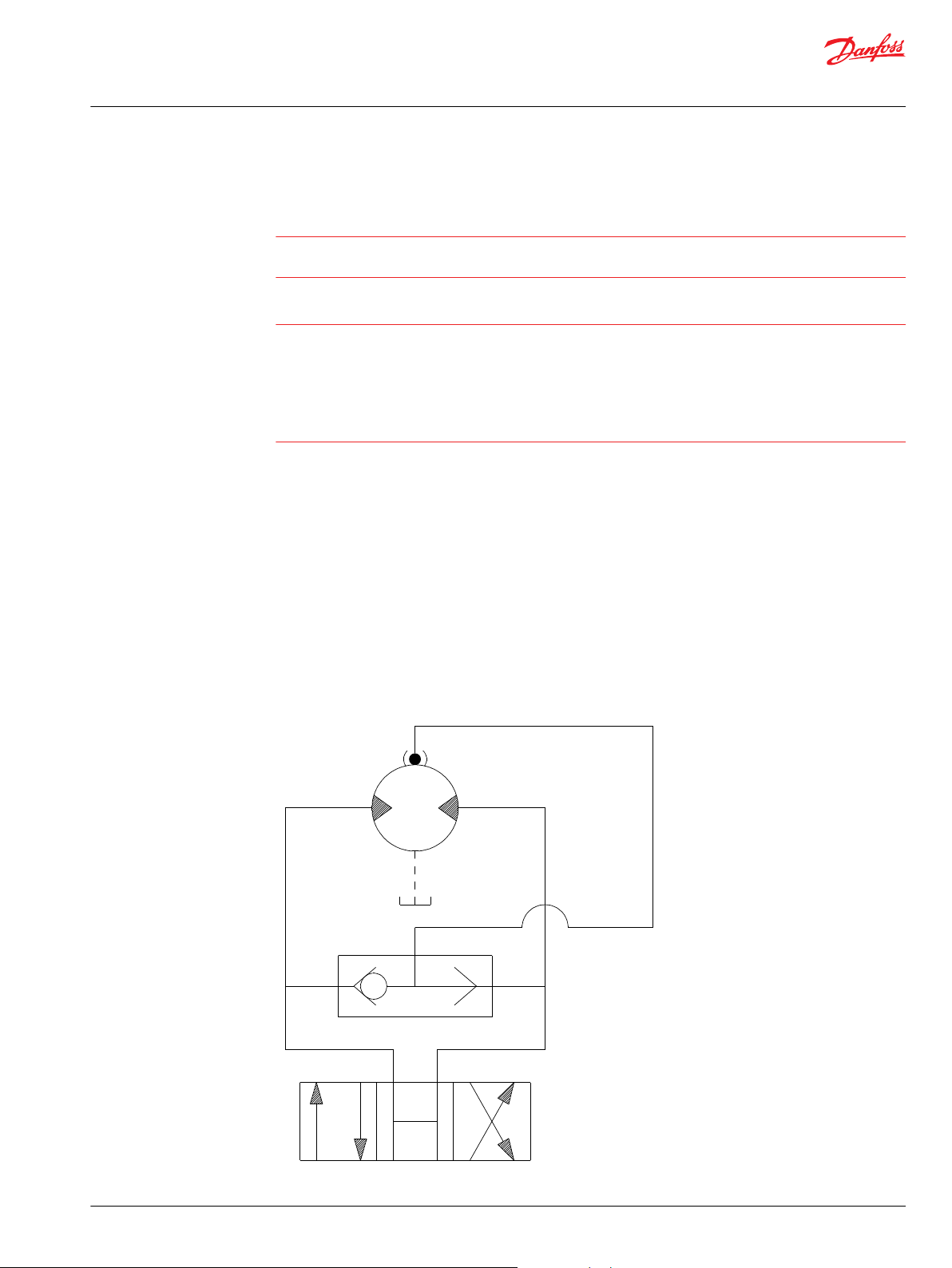

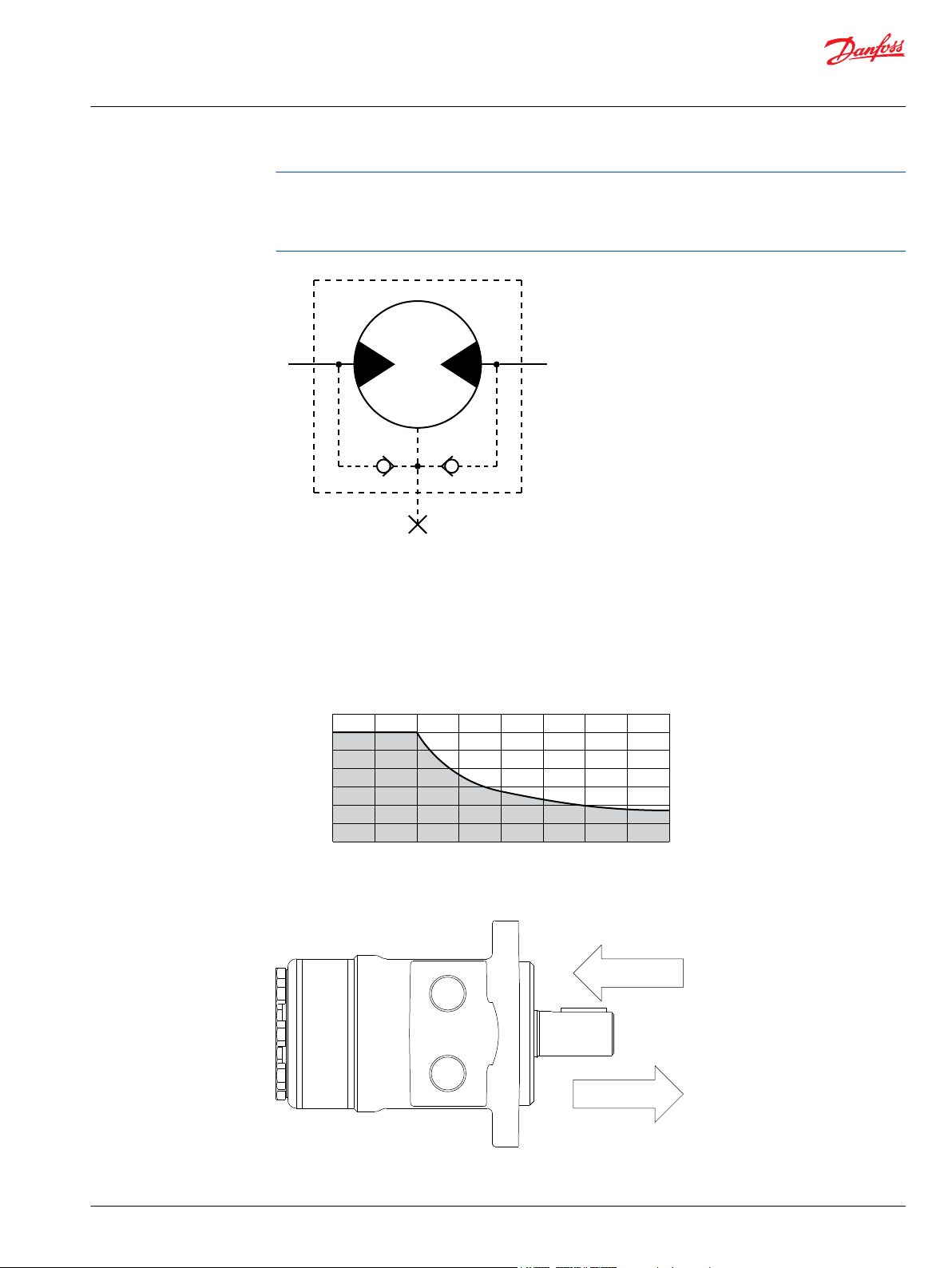

Motor/Brake Precaution

Caution

Danfoss’ motors/brakes are intended to operate as static or parking brakes. System circuitry must be

designed to bring the load to a stop before applying the brake.

Caution

Because it is possible for some large displacement motors to overpower the brake, it is critical that the

maximum system pressure be limited for these applications. Failure to do so could cause serious injury or

death. When choosing a motor/brake for an application, consult the performance chart for the series and

displacement chosen for the application to verify that the maximum operating pressure of the system

will not allow the motor to produce more torque than the maximum rating of the brake. Also, it is vital

that the system relief be set low enough to insure that the motor is not able to overpower the brake.

To ensure proper operation of the brake, a separate case drain back to tank must be used. Use of the

internal drain option is not recommended due to the possibility of return line pressure spikes. A simple

schematic of a system utilizing a motor/brake is shown in Typical Motor/Brake Schematic on page 5.

Although maximum brake release pressure may be used for an application, a 34 bar [500 psi] pressure

reducing valve is recommended to promote maximum life for the brake release piston seals. However, if

a pressure reducing valve is used in a system which has case drain back pressure, the pressure reducing

valve should be set to 34 bar [500 psi] over the expected case pressure to ensure full brake release.

To achieve proper brake release operation, it is necessary to bleed out any trapped air and fill brake

release cavity and hoses before all connections are tightened. To facilitate this operation, all motor/

brakes feature two release ports. One or both of these ports may be used to release the brake in the unit.

Motor/brakes should be configured so that the release ports are near the top of the unit in the installed

position.

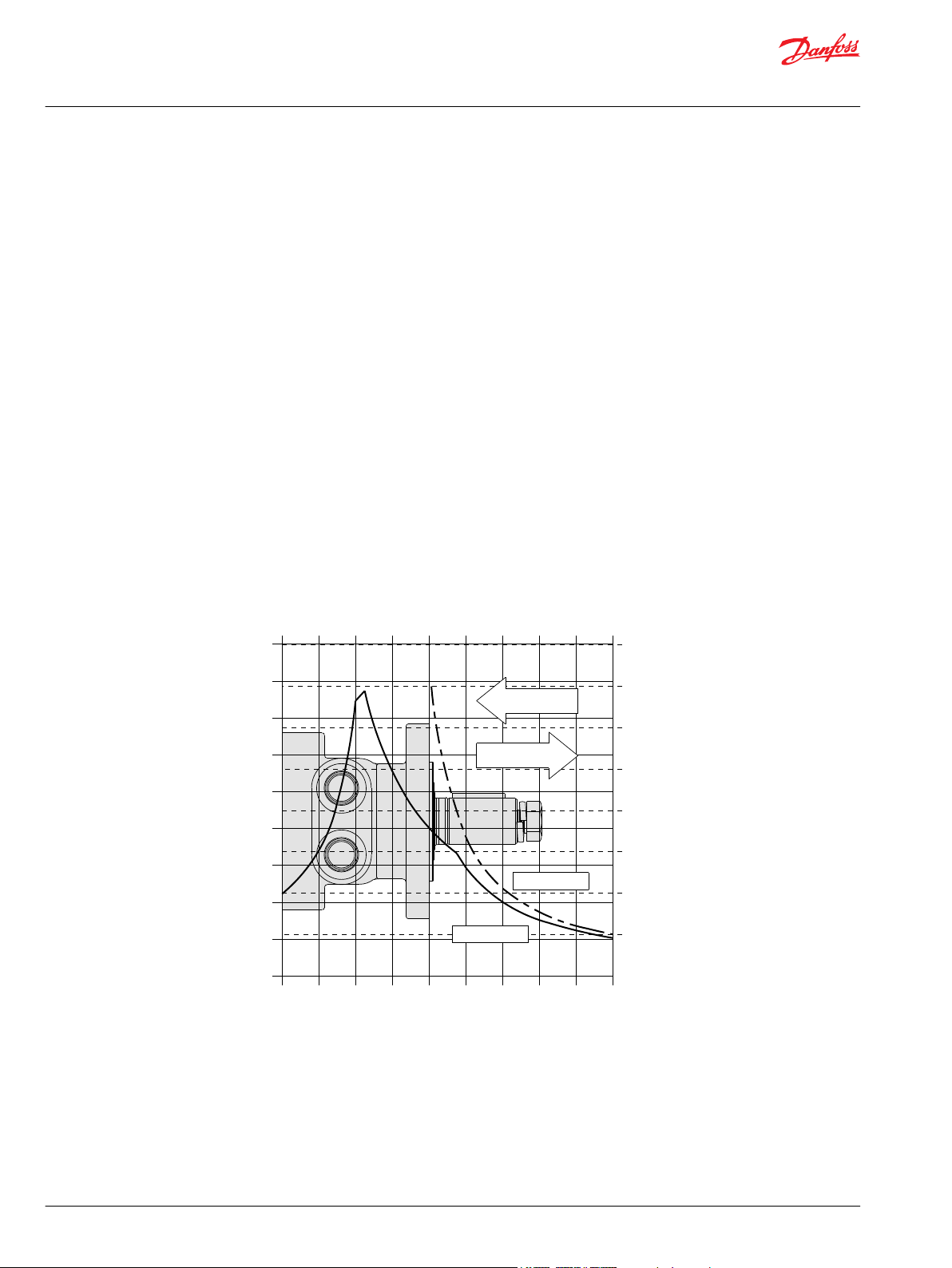

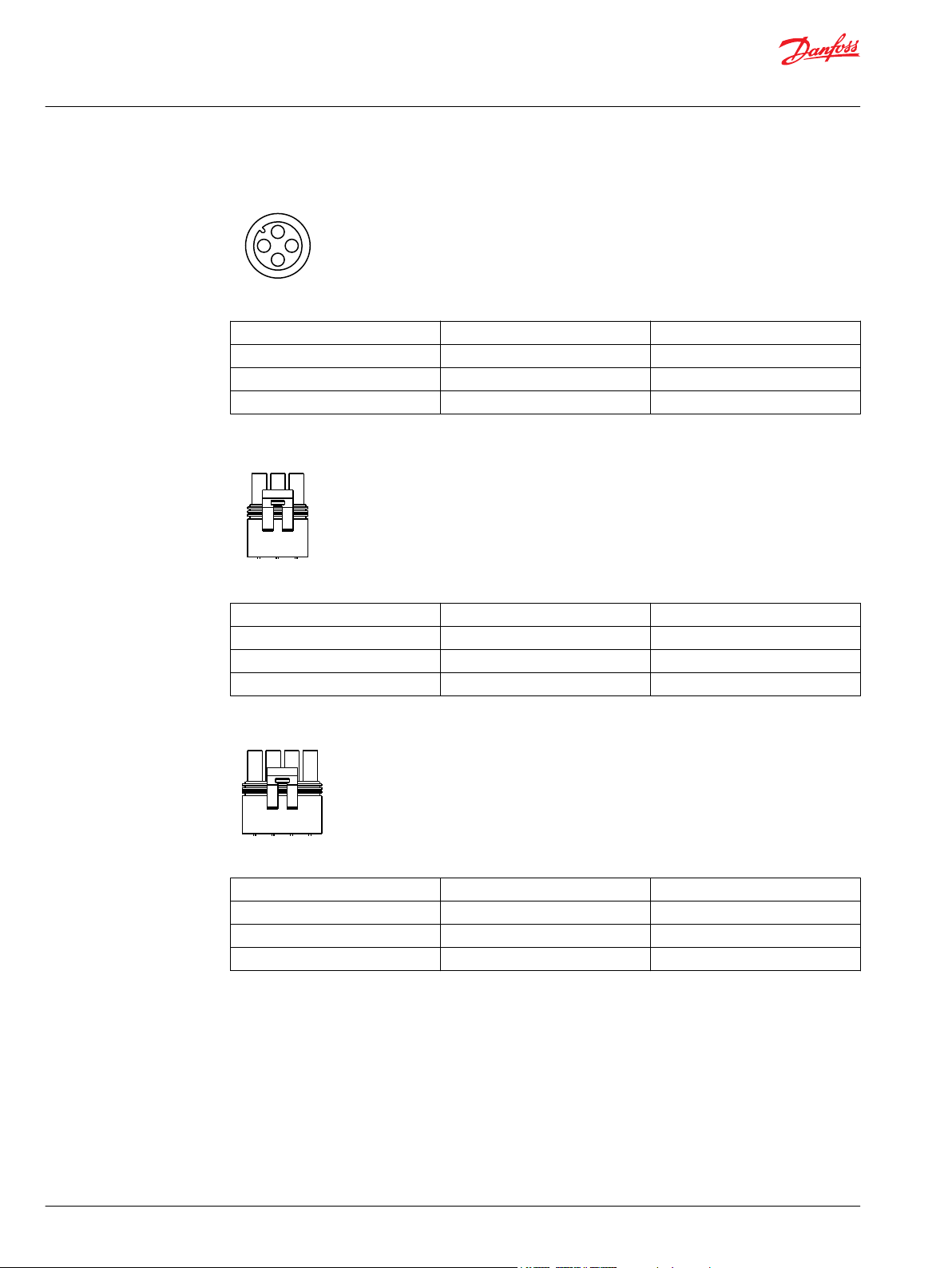

Typical Motor/Brake Schematic

©

Danfoss | December 2019 BC267362166283en-000201 | 5

Page 6

W

P109318

P109319

Technical Information

Orbital Motors Type WD, WP and WR

Technical Information

Once all system connections are made, one release port must be opened to atmosphere and the brake

release line carefully charged with fluid until all air is removed from the line and motor/brake release

cavity. When this has been accomplished the port plug or secondary release line must be reinstalled. In

the event of a pump or battery failure, an external pressure source may be connected to the brake release

port to release the brake, allowing the machine to be moved.

Warning

It is vital that all operating recommendations be followed. Failure to do so could result in injury or death.

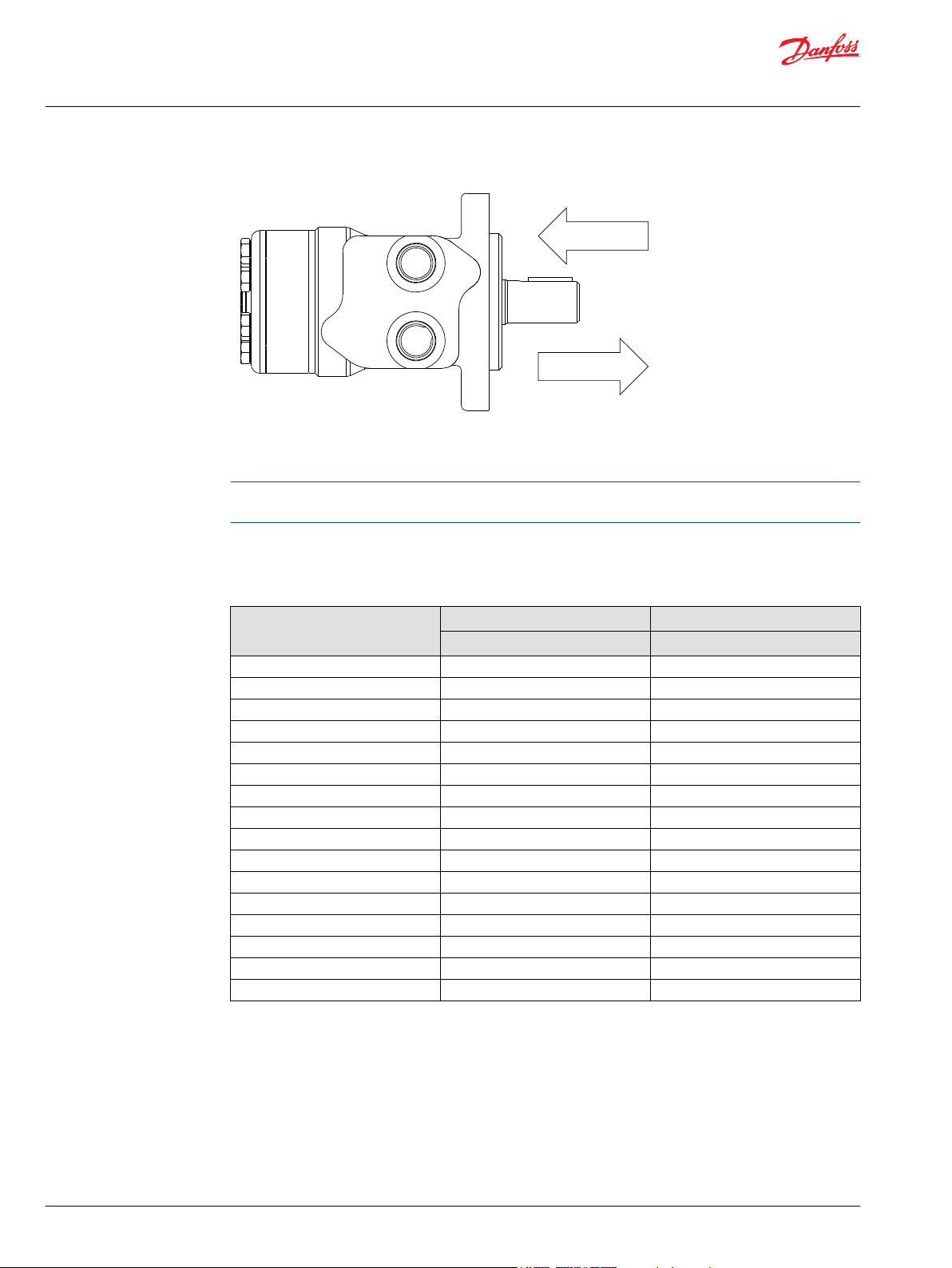

Motor Connections

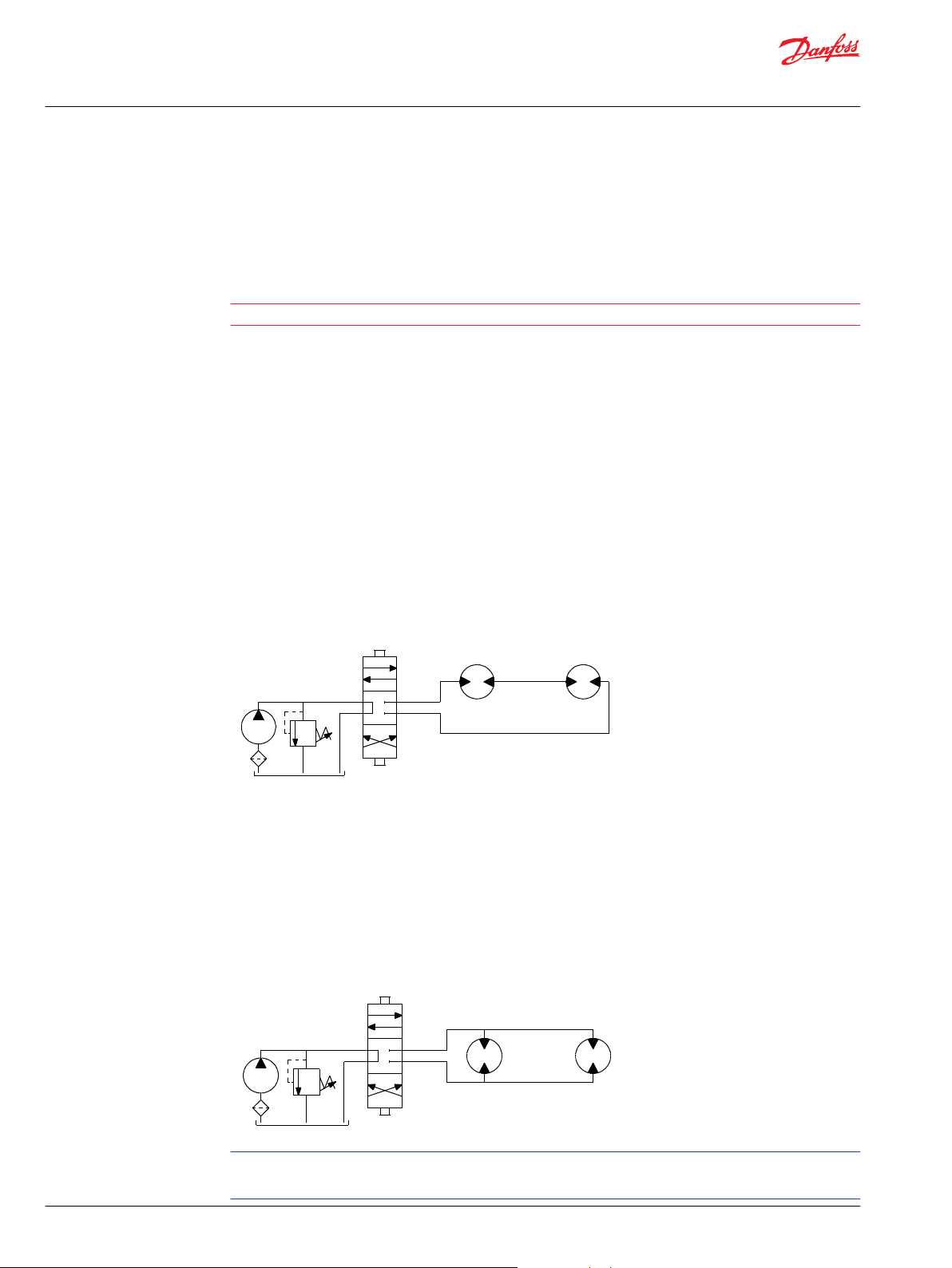

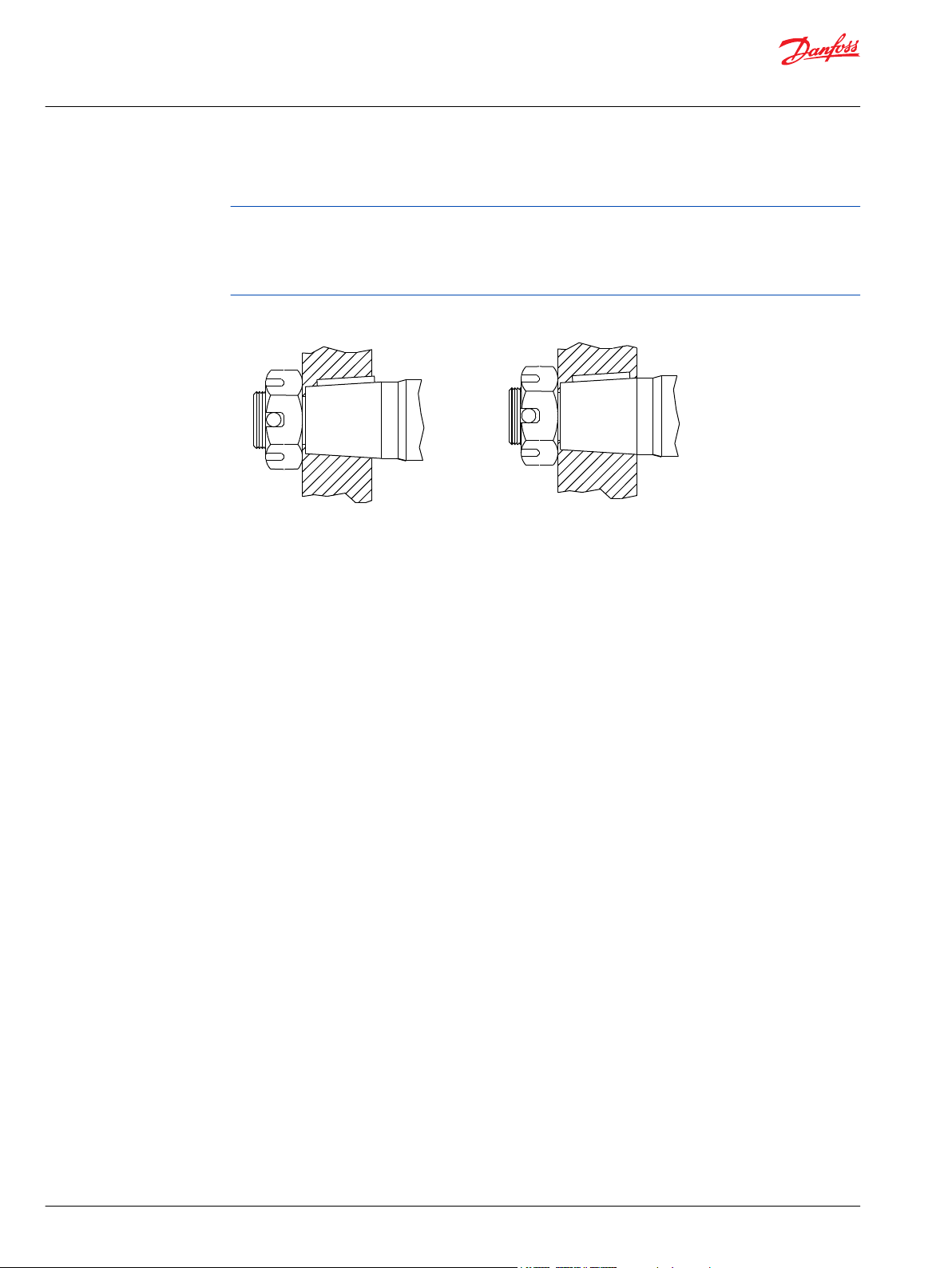

There are two common types of circuits used for connecting multiple numbers of motors – series

connection and parallel connection.

Series Connection

When motors are connected in series, the outlet of one motor is connected to the inlet of the next motor.

This allows the full pump flow to go through each motor and provide maximum speed. Pressure and

torque are distributed between the motors based on the load each motor is subjected to. The maximum

system pressure must be no greater than the maximum inlet pressure of the first motor. The allowable

back pressure rating for a motor must also be considered. In some series circuits the motors must have an

external case drain connected. A series connection is desirable when it is important for all the motors to

run the same speed such as on a long line conveyor.

Series Circuit

Parallel Connection

In a parallel connection all of the motor inlets are connected. This makes the maximum system pressure

available to each motor allowing each motor to produce full torque at that pressure. The pump flow is

split between the individual motors according to their loads and displacements. If one motor has no load,

the oil will take the path of least resistance and all the flow will go to that one motor. The others will not

turn. If this condition can occur, a flow divider is recommended to distribute the oil and act as a

differential.

Parallel Circuit

The motor circuits shown above are for illustration purposes only. Components and circuitry for actual

applications may vary greatly and should be chosen based on the application.

6 | © Danfoss | December 2019 BC267362166283en-000201

Page 7

25

50

100

200

301

401

24

50

100

200

300

400

502

602

690

21

43

99

199

297

398

500

601

689

18

43

92

191

295

390

499

600

688

17

34

87

181

284

384

498

597

658

11

32

79

174

271

372

485

540

644

11

32

78

160

253

346

443

526

631

9

31

77

154

245

339

433

510

613

[127]

[140]

[139]

[127]

[113]

[91]

14

16

16

14

13

10

[262]

[286]

[280]

[275]

[262]

[243]

[212]

[177]

[127]

30

32

32

31

30

27

24

20

14

[543]

[559]

[563]

[572]

[557]

[536]

[511]

[482]

[445]

61

63

64

65

63

61

58

54

50

[806]

[839]

[857]

[872]

[853]

[826]

[790]

[767]

[741]

91

95

97

99

96

93

89

87

84

[1062]

[1099]

[1139]

[1155]

[1149]

[1125]

[1087]

[1060]

[1098]

120

124

129

131

130

127

123

120

124

[1285]

[1340]

[1390]

[1420]

[1420]

[1409]

[1379]

[1451]

[1369]

145

151

157

160

160

159

156

164

155

[1496]

[1579]

[1652]

[1643]

[1646]

[1654]

[1638]

[1711]

[1640]

169

178

187

186

186

187

185

193

185

[1693]

[1796]

[1865]

[1911]

[1930]

[1945]

[1883]

[2021]

[1918]

191

203

211

216

218

220

213

228

217

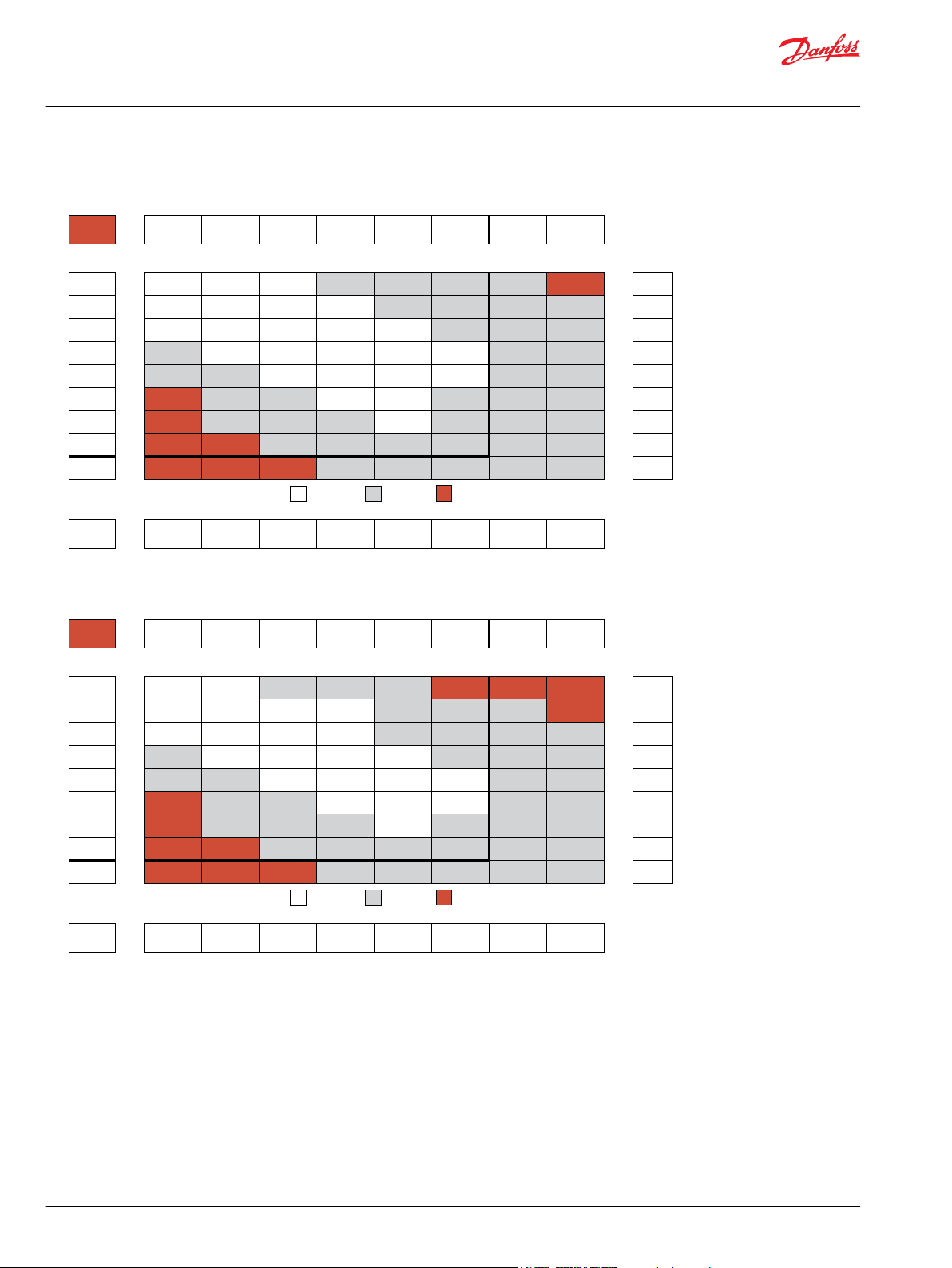

Flow - lpm [gpm]

17 [250] 35 [500] 69 [1000] 104 [1500] 138 [2000] 173 [2500] 207 [3000] 242 [3500]

Pressure - bars [psi]

21 [183] 41 [366] 83 [732] 124 [1099] 166 [1465] 207 [1831] 248 [2197] 290 [2564]

Theoretical Torque - Nm [lb-in]

Max.

Inter.

Max.

Cont.

76 cc [4.6 in3/rev.]

080

2 [0.5]

4 [1]

8 [2]

15 [4]

23 [6]

30 [8]

38 [10]

45 [12]

53 [14]

61 [16]

64 [17]

26

51

101

201

302

402

503

603

704

804

904

Theoretical rpm

Overall Efficiency -

70 - 100%

40 - 69%

0 - 39%

Intermittent Ratings - 10% of Operation

Displacement tested at 54°C [129°F] with an oil viscosity of 46cSt [213 SUS]

Max. Inter.Max. Cont.

1

2

3

4

5

8

7

Torque - Nm [lb-in], Speed rpm

6

P109395

Technical Information

Orbital Motors Type WD, WP and WR

Technical Information

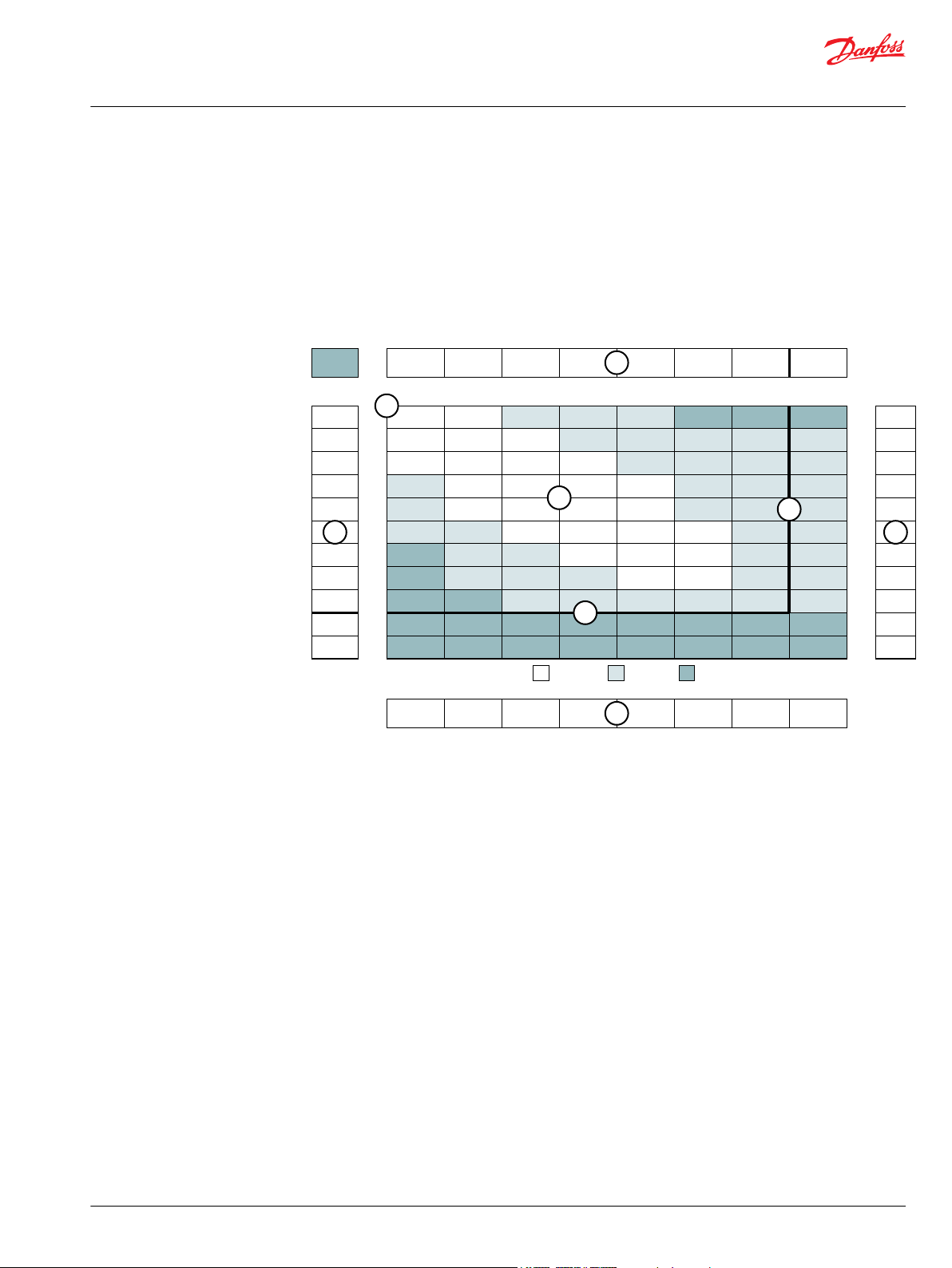

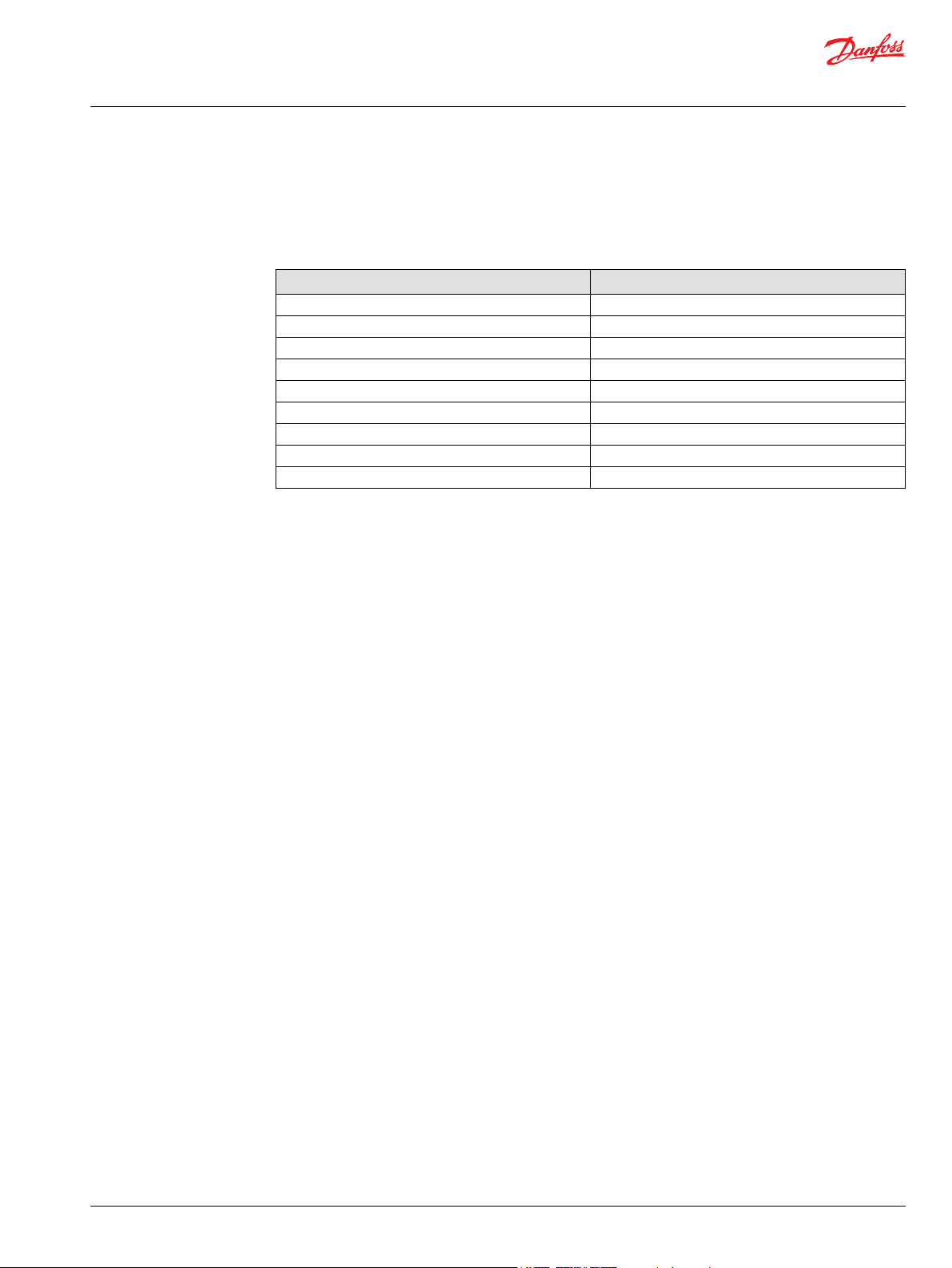

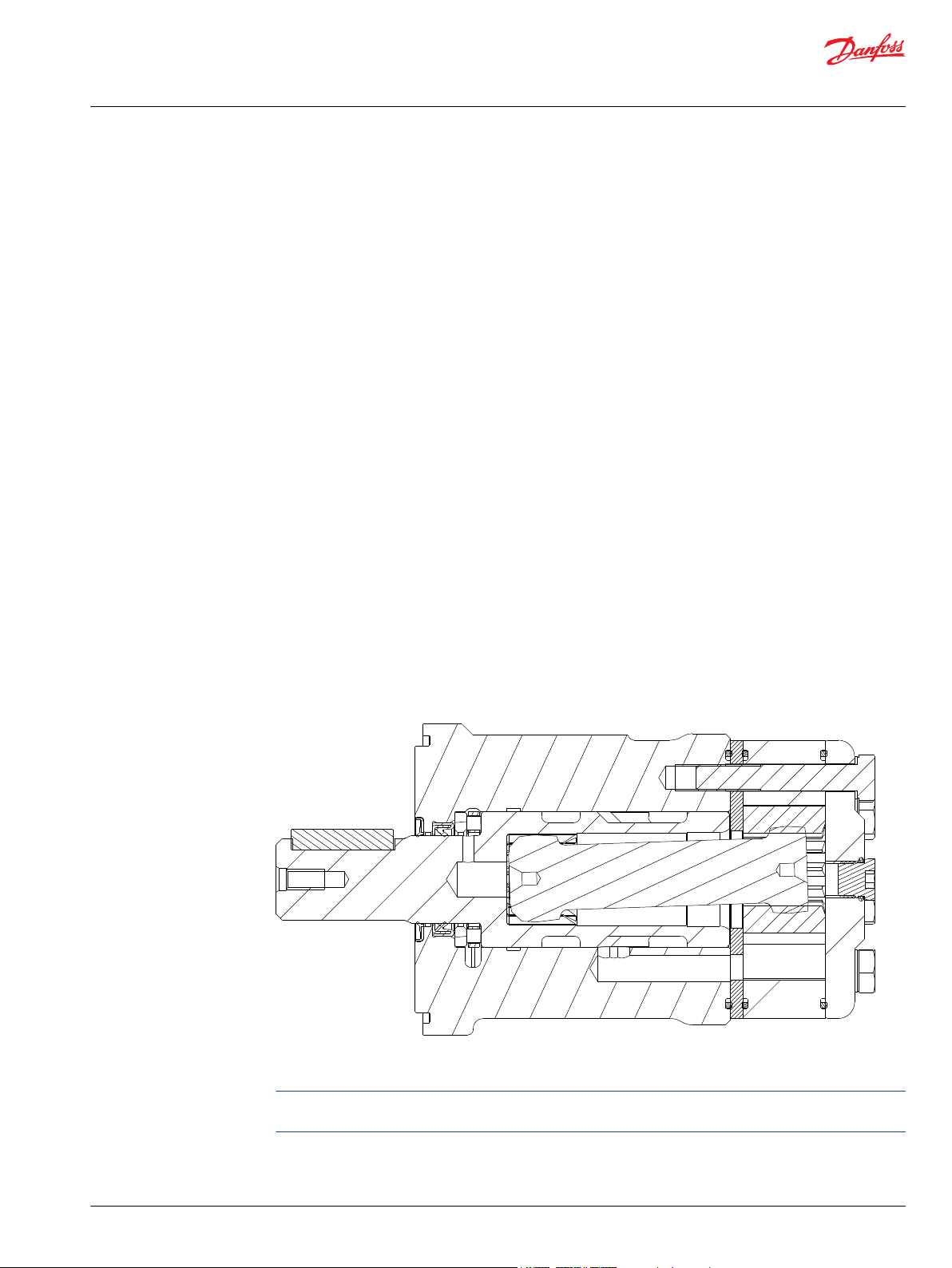

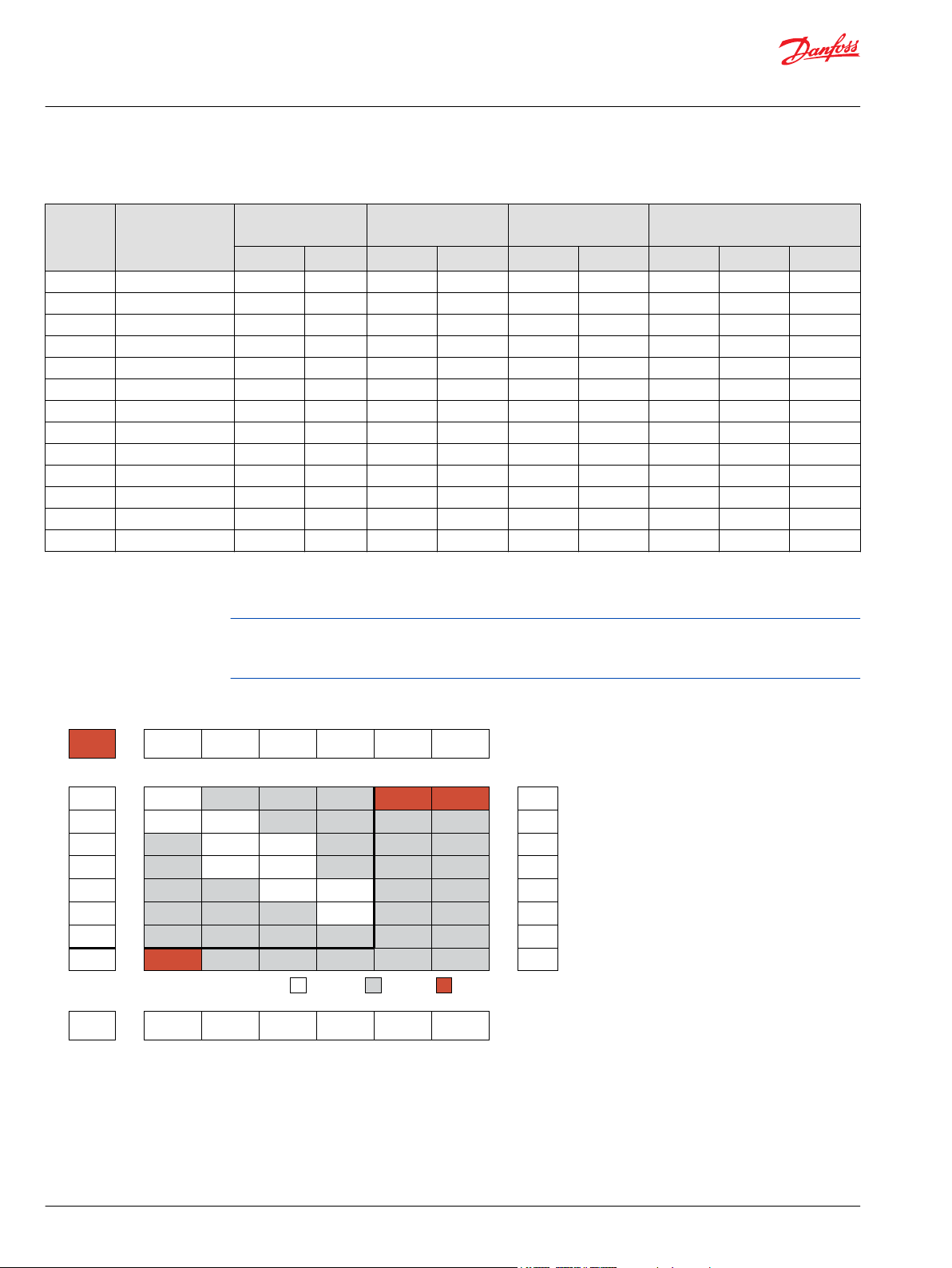

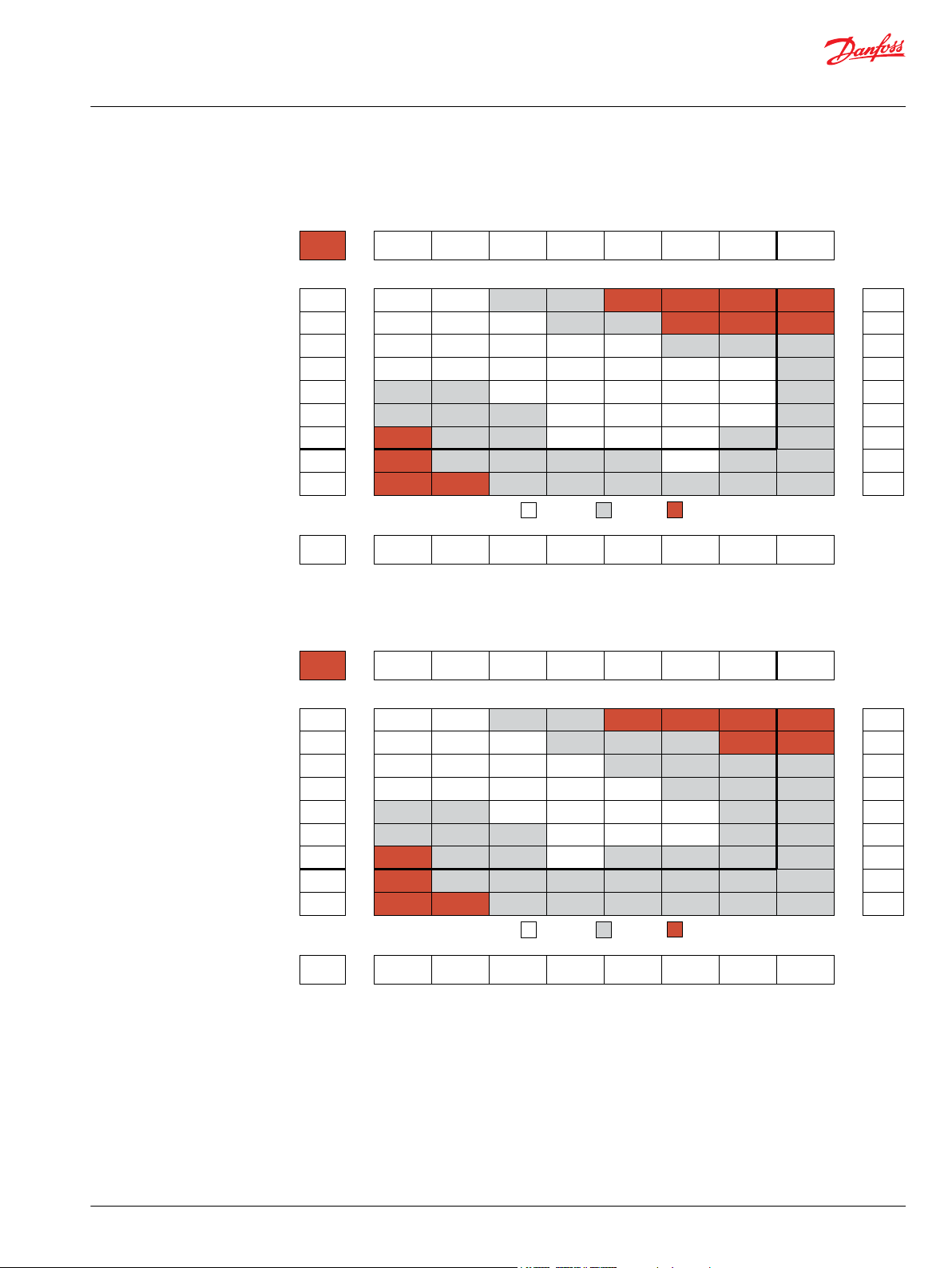

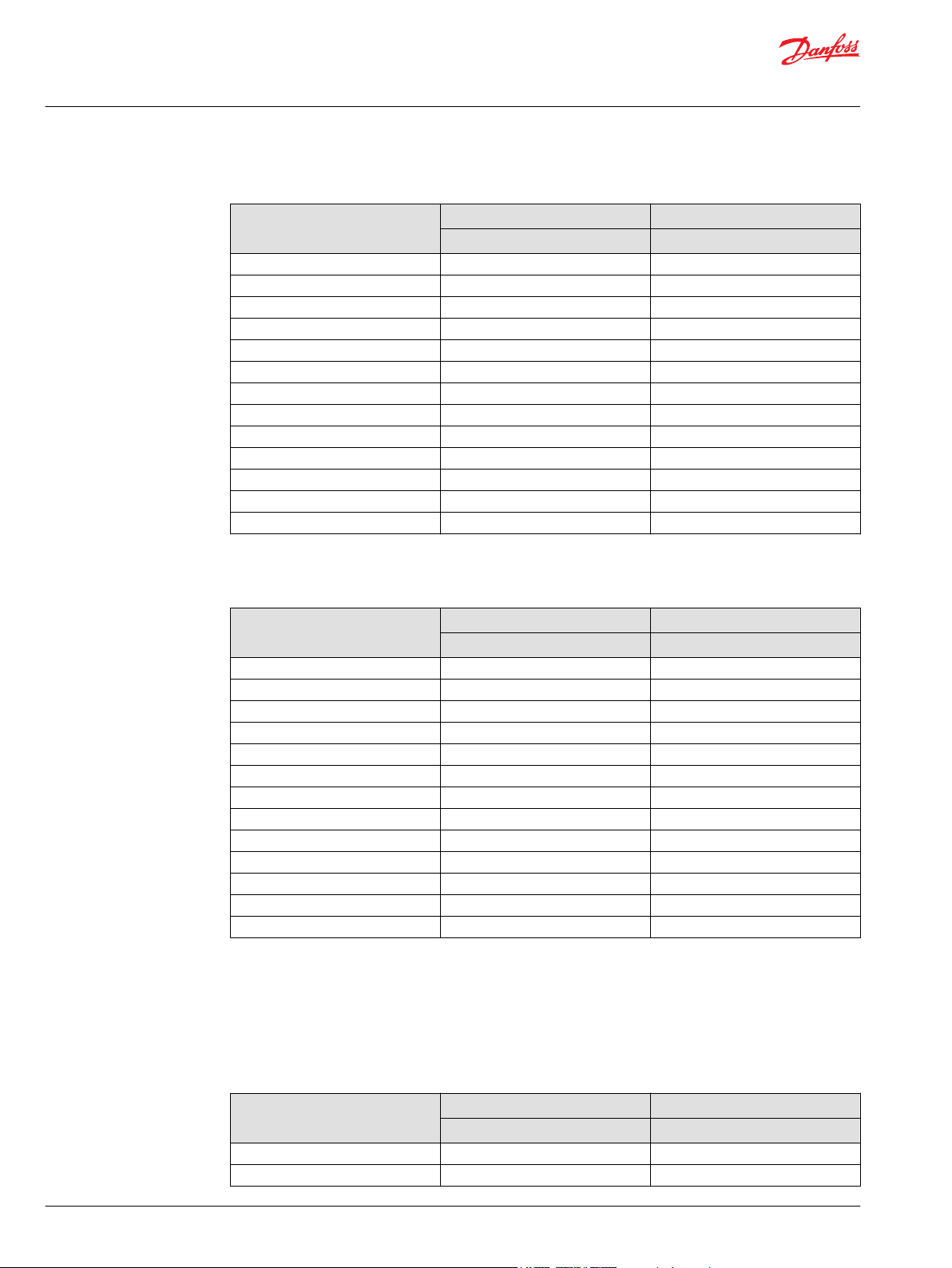

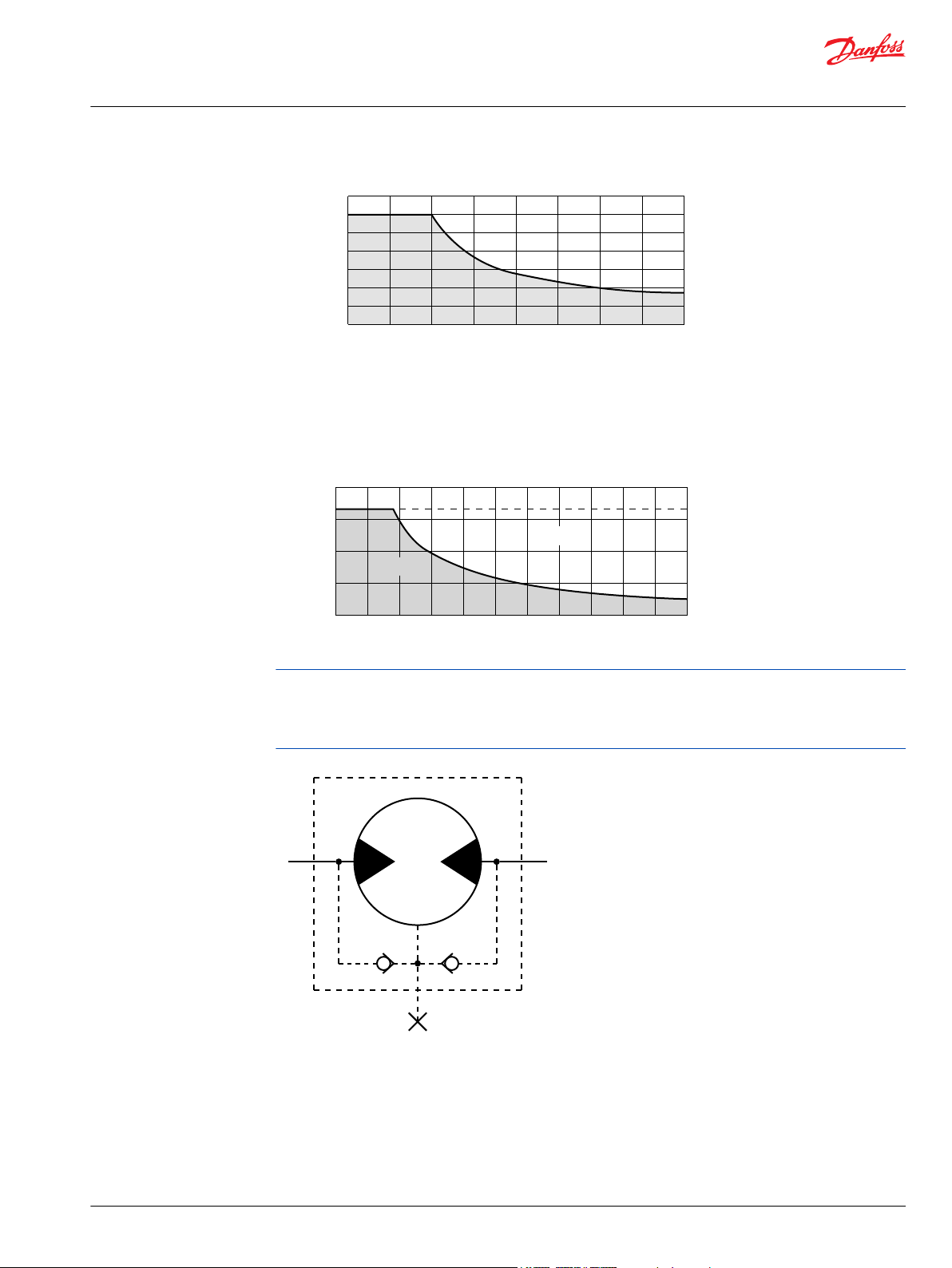

Product Testing

Performance testing is the critical measure of a motor’s ability to convert flow and pressure into speed

and torque. All product testing is conducted using Danfoss’ state of the art test facility. This facility utilizes

fully automated test equipment and custom designed software to provide accurate, reliable test data.

Test routines are standardized, including test stand calibration and stabilization of fluid temperature and

viscosity, to provide consistent data. The example below provides an explanation of the values pertaining

to each heading on the performance chart.

1. Flow represents the amount of fluid passing through

the motor during each minute of the test.

2. Pressure refers to the measured pressure differential

between the inlet and return ports of the motor during

the test.

3. The maximum continuous pressure rating and

Allowable Bearing and Shaft Loading

maximum intermittent pressure rating of the motor are

separated by the dark lines on the chart.

5. The maximum continuous flow rating and maximum

intermittent flow rating of the motor are separated by the

dark line on the chart.

7. Areas within the white shading represent maximum

motor efficiencies.

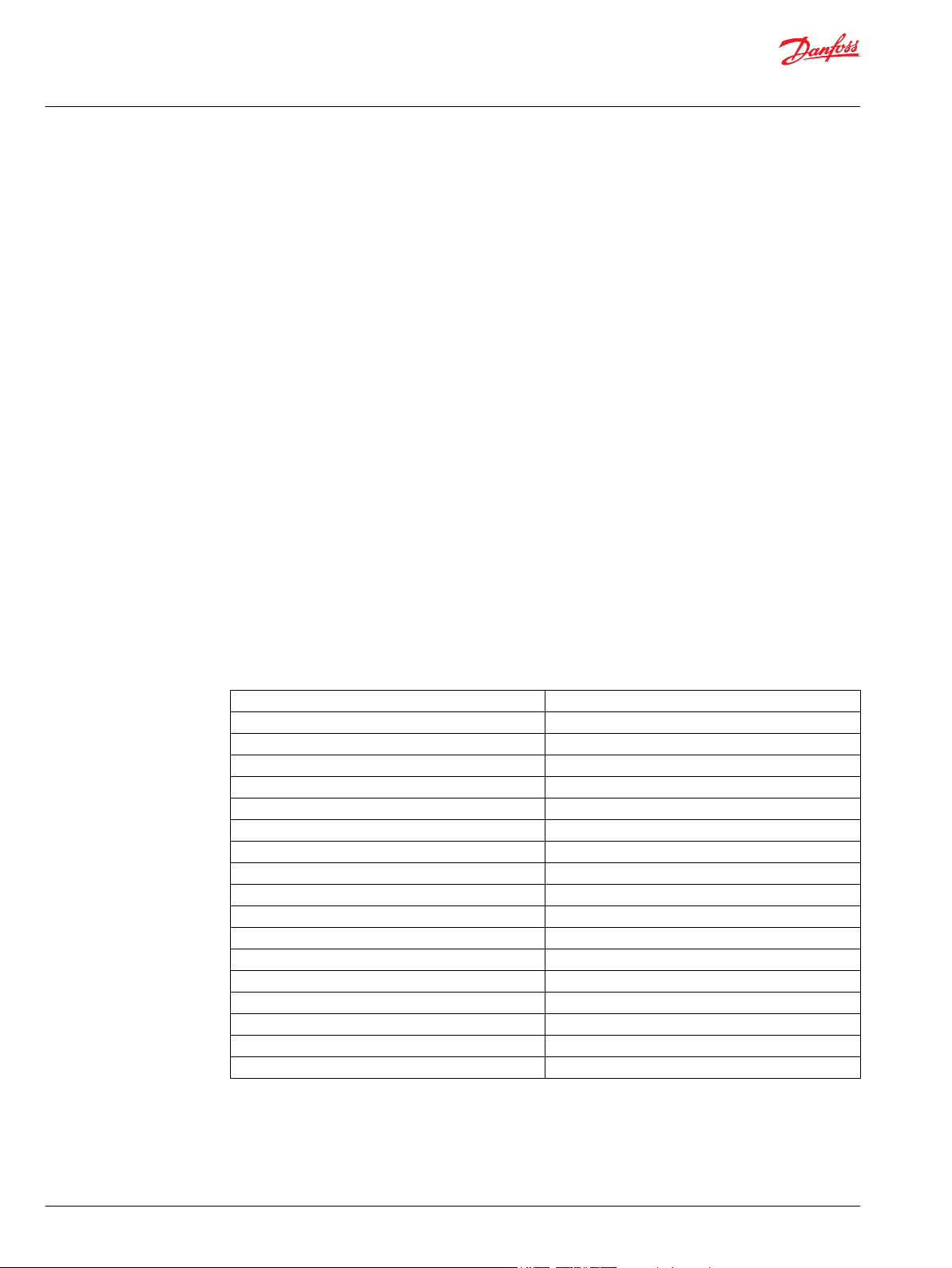

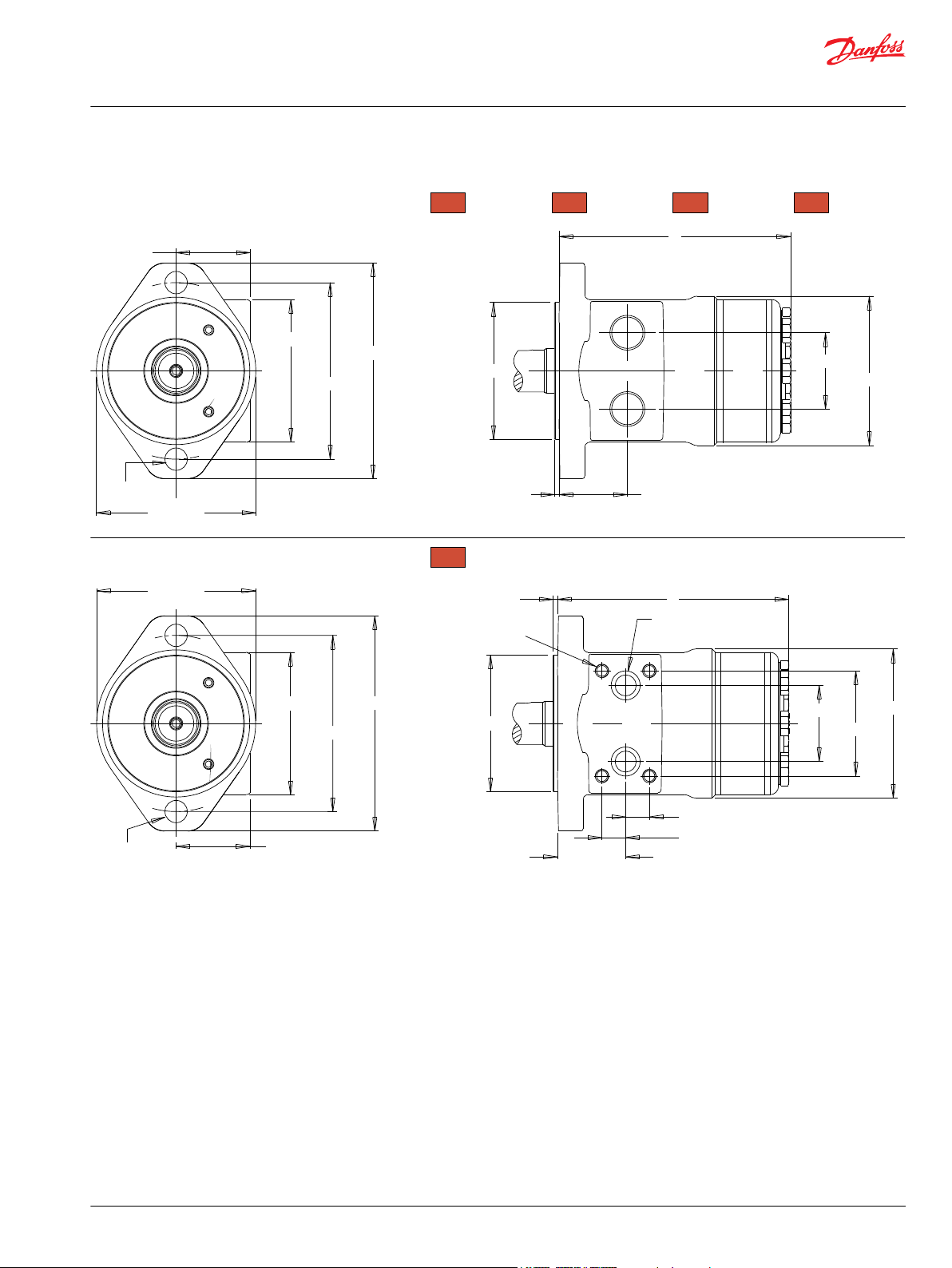

This catalog provides curves showing allowable radial loads at points along the longitudinal axis of the

motor. They are dimensioned from the mounting flange. Two capacity curves for the shaft and bearings

are shown. A vertical line through the centerline of the load drawn to intersect the x-axis intersects the

©

Danfoss | December 2019 BC267362166283en-000201 | 7

curves at the load capacity of the shaft and of the bearing.

4. Theoretical RPM represents the RPM that the motor

would produce if it were 100% volumetrically efficient.

Measured RPM divided by the theoretical RPM give the

actual volumetric efficiency of the motor.

6. Performance numbers represent the actual torque and

speed generated by the motor based on the

corresponding input pressure and flow. The numbers on

the top row indicate torque as measured in Nm [lb-in],

while the bottom number represents the speed of the

output shaft.

8. Theoretical Torque represents the torque that the

motor would produce if it were 100% mechanically

efficient. Actual torque divided by the theoretical torque

gives the actual mechanical efficiency of the motor.

Page 8

9000

8000

7000

6000

5000

4000

3000

2000

1000

lb

4000

3500

3000

2500

2000

1500

1000

500

daN

445 daN [1000 lb]

445 daN [1000 lb]

BEARING

SHAFT

-100

-50 -25 0 25 50 75 100

mm

-75

-100

-50 -25 0 25 50 75 100

mm

-75

P109320

Technical Information

Orbital Motors Type WD, WP and WR

Technical Information

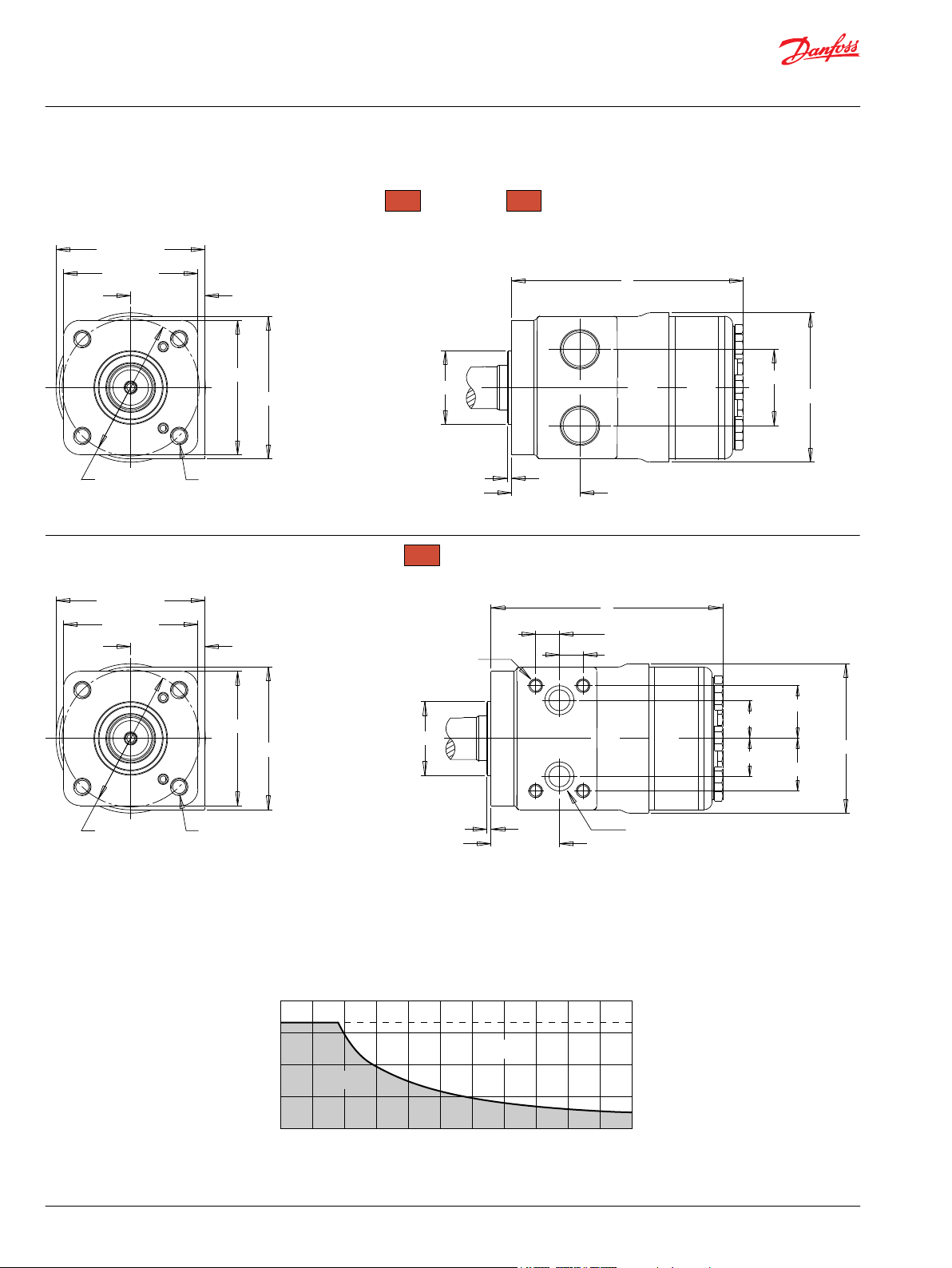

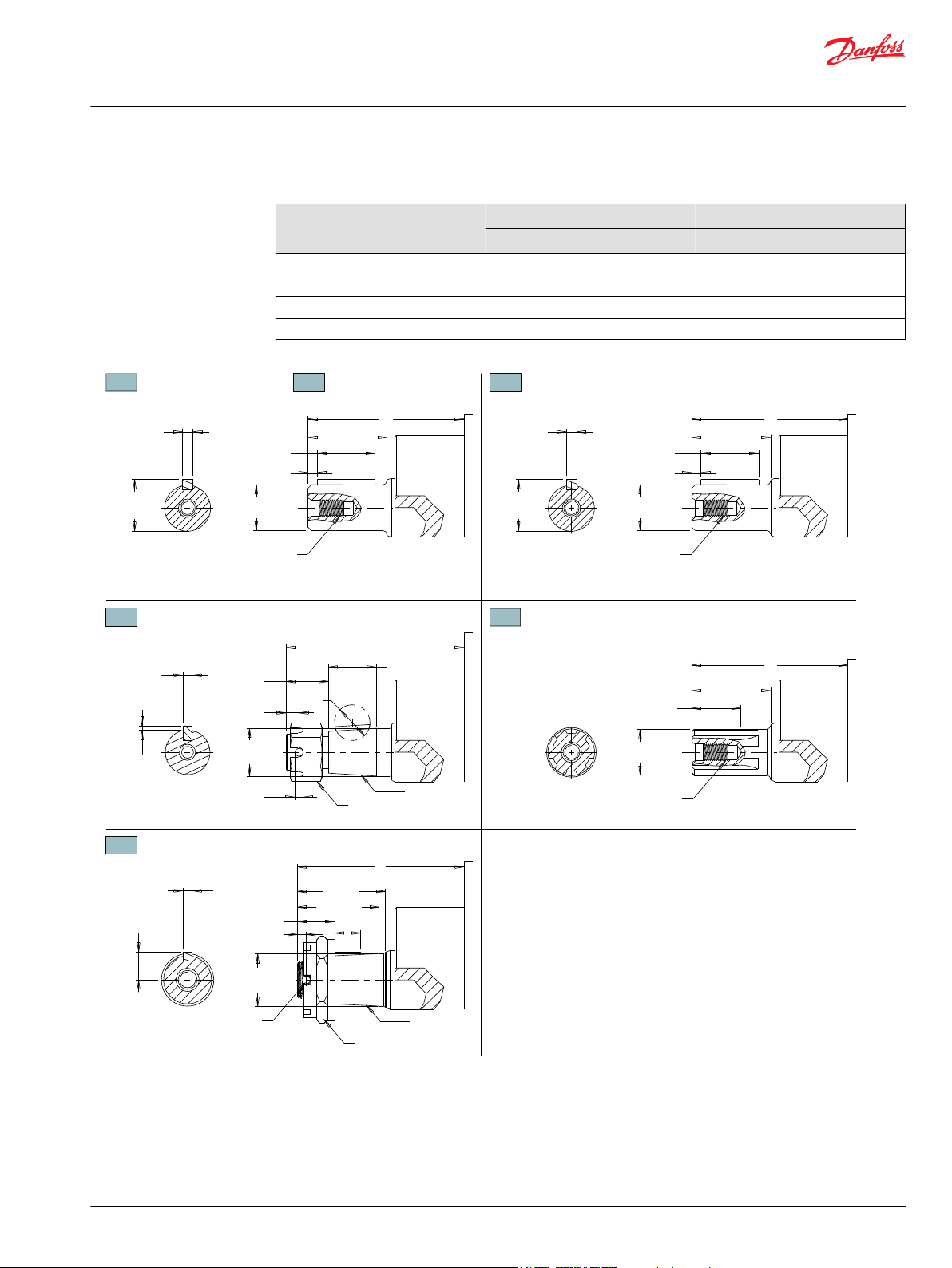

In the example below, the maximum radial load bearing rating is between the internal roller bearings

illustrated with a solid line. The allowable shaft rating is shown with a dotted line.

The bearing curves for each model are based on laboratory analysis and testing conducted at Danfoss.

The shaft loading is based on a 3:1 safety factor and 330 Kpsi tensile strength. The allowable load is the

lower of the curves at a given point. For instance, one inch in front of the mounting flange the bearing

capacity is lower than the shaft capacity. In this case, the bearing is the limiting load. The motor user

needs to determine which series of motor to use based on their application knowledge.

ISO 281 Ratings vs. Manufacturer's Ratings

Published bearing curves can come from more than one type of analysis. The ISO 281 bearing rating is an

international standard for the dynamic load rating of roller bearings. The rating is for a set load at a speed

of 33 1/3 RPM for 500 hours (1 million revolutions). The standard was established to allow consistent

comparisons of similar bearings between manufacturers. The ISO 281 bearing ratings are based solely on

the physical characteristics of the bearings, removing any manufacturers specific safety factors or

empirical data that influences the ratings.

Manufacturers’ ratings are adjusted by diverse and systematic laboratory investigations, checked

constantly with feedback from practical experience. Factors taken into account that affect bearing life are

material, lubrication, cleanliness of the lubrication, speed, temperature, magnitude of the load and the

bearing type.

The operating life of a bearing is the actual life achieved by the bearing and can be significantly different

from the calculated life. Comparison with similar applications is the most accurate method for bearing life

estimations.

8 | © Danfoss | December 2019 BC267362166283en-000201

Example Load Rating for Mechanically Retained Needle Roller Bearings

Bearing Life L

L

10

C dynamic load rating

10

(C/P)p [106 revolutions]

nominal rating life

Page 9

Technical Information

Orbital Motors Type WD, WP and WR

Technical Information

P equivalent dynamic load

Life Exponent p 10/3 for needle bearings

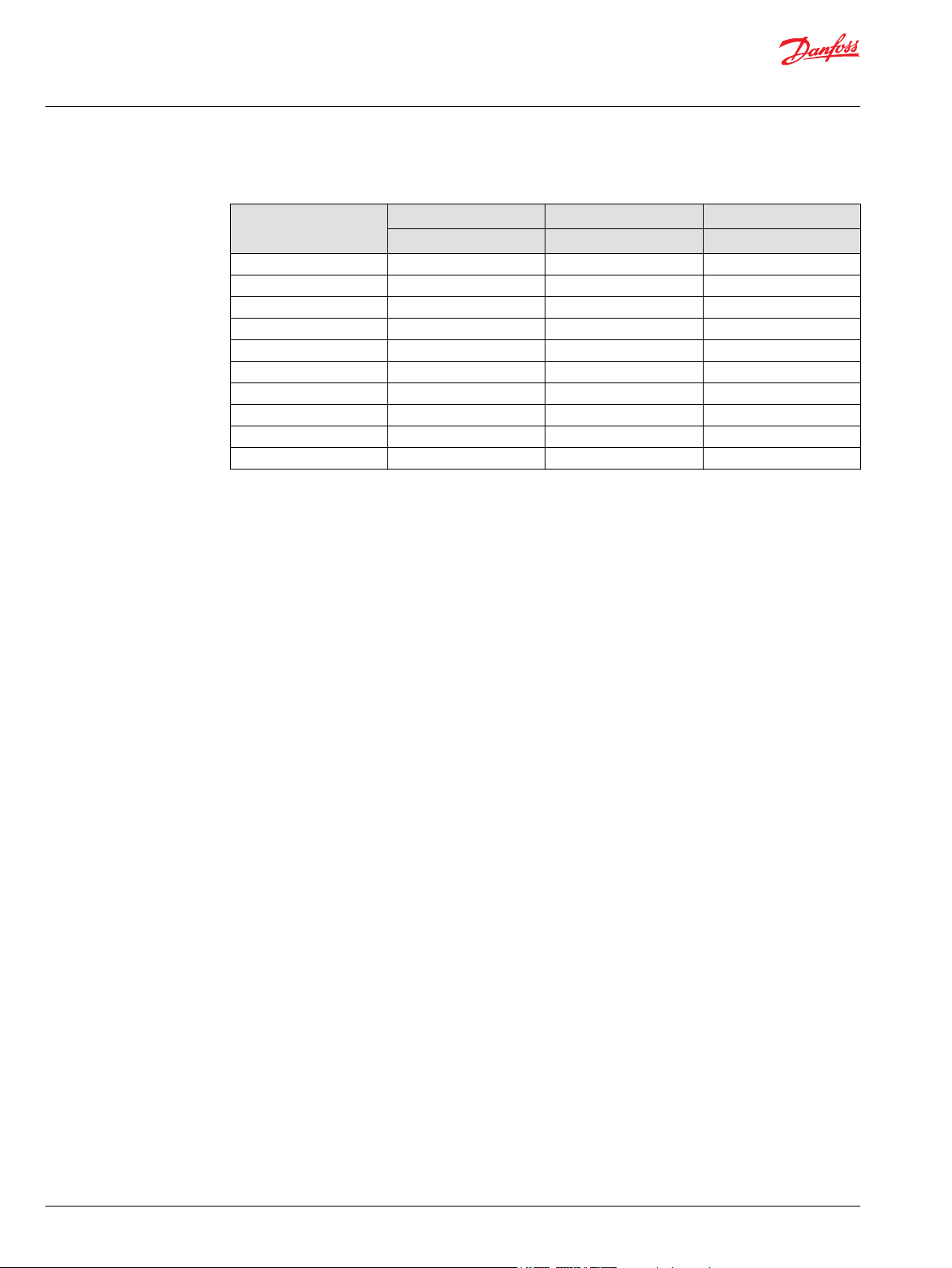

Bearing Load Multiplication Factor Table

RPM Factor

50 1.23

100 1.00

200 0.81

300 0.72

400 0.66

500 0.62

600 0.58

700 0.56

800 0.50

Vehicle Drive Calculations

When selecting a wheel drive motor for a mobile vehicle, a number of factors concerning the vehicle

must be taken into consideration to determine the required maximum motor RPM, the maximum torque

required and the maximum load each motor must support. The following sections contain the necessary

equations to determine this criteria. An example is provided to illustrate the process.

Sample application (vehicle design criteria)

vehicle description 4 wheel vehicle

vehicle drive 2 wheel drive

GVW 1,500 lbs.

weight over each drive wheel 425 lbs.

rolling radius of tires 16 in.

desired acceleration 0-5 mph in 10 sec.

top speed 5 mph

gradability 20%

worst working surface poor asphalt

To determine maximum motor speed

RPM = (2.65 x KPH x G) / rm or RPM = (168 x MPH x G) / ri

KPH max. vehicle speed (kilometers/hr)

MPH max. vehicle speed (miles/hr)

G gear reduction ratio (if none, G = 1)

rm rolling radius of tire (meters)

ri rolling radius of tire (inches)

RPM = (168 x 5 x 1) / 16 = 52.5

©

Danfoss | December 2019 BC267362166283en-000201 | 9

Page 10

Technical Information

Orbital Motors Type WD, WP and WR

Technical Information

To determine maximum torque requirement of motor

To choose a motor(s) capable of producing enough torque to propel the vehicle, it is necessary to

determine the Total Tractive Effort (TE) requirement for the vehicle. To determine the total tractive effort,

the following equation must be used:

TE = RR + GR + FA + DP (lbs or N)

TE Total tractive effort

RR Force necessary to overcome rolling resistance

GR Force required to climb a grade

FA Force required to accelerate

DP Drawbar pull required

The components for this equation may be determined using the following steps.

Step One: Determine Rolling Resistance

Rolling Resistance (RR) is the force necessary to propel a vehicle over a particular surface. It is

recommended that the worst possible surface type to be encountered by the vehicle be factored into the

equation.

RR = (GVW / 1000) x R (lb or N)

GVW gross (loaded) vehicle weight (lb or kg)

R surface friction (value from Rolling Resistance on page 10)

Rolling Resistance

Concrete (excellent) 10

Concrete (good) 15

Concrete (poor) 20

Asphalt (good) 12

Asphalt (fair) 17

Asphalt (poor) 22

Macadam (good) 15

Macadam (fair) 22

Macadam (poor) 37

Cobbles (ordinary) 55

Cobbles (poor) 37

Snow (2 inch) 25

Snow (4 inch) 37

Dirt (smooth) 25

Dirt (sandy) 37

Mud 37 to 150

Sand (soft) 60 to 150

Sand (dune) 160 to 300

Step Two: Determine Grade Resistance

Grade Resistance (GR) is the amount of force necessary to move a vehicle up a hill or “grade.” This

calculation must be made using the maximum grade the vehicle will be expected to climb in normal

operation.

10 | © Danfoss | December 2019 BC267362166283en-000201

Page 11

Technical Information

Orbital Motors Type WD, WP and WR

Technical Information

To convert incline degrees to % Grade:

% Grade = [tan of angle (degrees)] x 100

GR = (% Grade / 100) x GVW (lb or N)

Example: GR = (20 / 100) x 1500 lbs = 300 lbs

Step Three: Determine Acceleration Force

Acceleration Force (FA) is the force necessary to accelerate from a stop to maximum speed in a desired

time.

FA = (KPH x GVW (N)) / (35.32 x t) or FA = (MPH x GVW (lb)) / (22 x t)

t time to maximum speed (seconds)

Example: FA = (5 x 1500 lbs) / (22 x 10) = 34 lbs

Step Four: Determine Drawbar Pull

Drawbar Pull (DP) is the additional force, if any, the vehicle will be required to generate if it is to be used

to tow other equipment. If additional towing capacity is required for the equipment, repeat steps one

through three for the towable equipment and sum the totals to determine DP.

Step Five: Determine Total Tractive Effort

The Tractive Effort (TE) is the sum of the forces calculated in steps one through three above. On low

speed vehicles, wind resistance can typically be neglected. However, friction in drive components may

warrant the addition of 10% to the total tractive effort to insure acceptable vehicle performance.

TE = RR + GR + FA + DP (lb or N)

Example: TE = 33 + 300 + 34 + 0 (lbs) = 367 lbs

Step Six: Determine Motor Torque

The Motor Torque (T) required per motor is the Total Tractive Effort divided by the number of motors

used on the machine. Gear reduction is also factored into account in this equation.

T = (TE x rm) / (M x G) Nm per motor or T = (TE x ri) / (M x G) lb-in per motor

M number of driving motors

Example: T = (367 x 16) / (2 x 1) lb-in/motor = 2936 lb-in

Step Seven: Determine Wheel Slip

To verify that the vehicle will perform as designed in regards to tractive effort and acceleration, it is

necessary to calculate wheel slip (TS) for the vehicle. In special cases, wheel slip may actually be desirable

to prevent hydraulic system overheating and component breakage should the vehicle become stalled.

TS = (W x f x rm) / G (Nm per motor) or TS = (W x f x ri) / G (lb-in per motor)

f coefficient of friction (see Coefficient of friction (f) on page 11)

W loaded vehicle weight over driven wheel (lb or N)

Example: TS = (425 x .06 x 16) / 1 = lb-in/motor = 4080 lbs

Coefficient of friction (f)

Steel on steel 0.3

Rubber tire on dirt 0.5

©

Danfoss | December 2019 BC267362166283en-000201 | 11

Page 12

Radius 76 mm [3.00 in]

Torque

1129 Nm

[10000 lb-in]

P109321

Technical Information

Orbital Motors Type WD, WP and WR

Technical Information

Coefficient of friction (f) (continued)

Rubber tire on a hard surface 0.6 - 0.8

Rubber tire on cement 0.7

To determine radial load capacity requirement of motor

When a motor used to drive a vehicle has the wheel or hub attached directly to the motor shaft, it is

critical that the radial load capabilities of the motor are sufficient to support the vehicle. After calculating

the Total Radial Load (RL) acting on the motors, the result must be compared to the bearing/shaft load

charts for the chosen motor to determine if the motor will provide acceptable load capacity and life.

RL = sqrt(W2 + (T / ri)2) lb or RL = sqrt(W2 + (T / rm)2) kg

Example: RL = sqrt(4252 + (2936 / 16)2) = 463 lbs

Once the maximum motor RPM, maximum torque requirement, and the maximum load each motor must

support have been determined, these figures may then be compared to the motor performance charts

and to the bearing load curves to choose a series and displacement to fulfill the motor requirements for

the application.

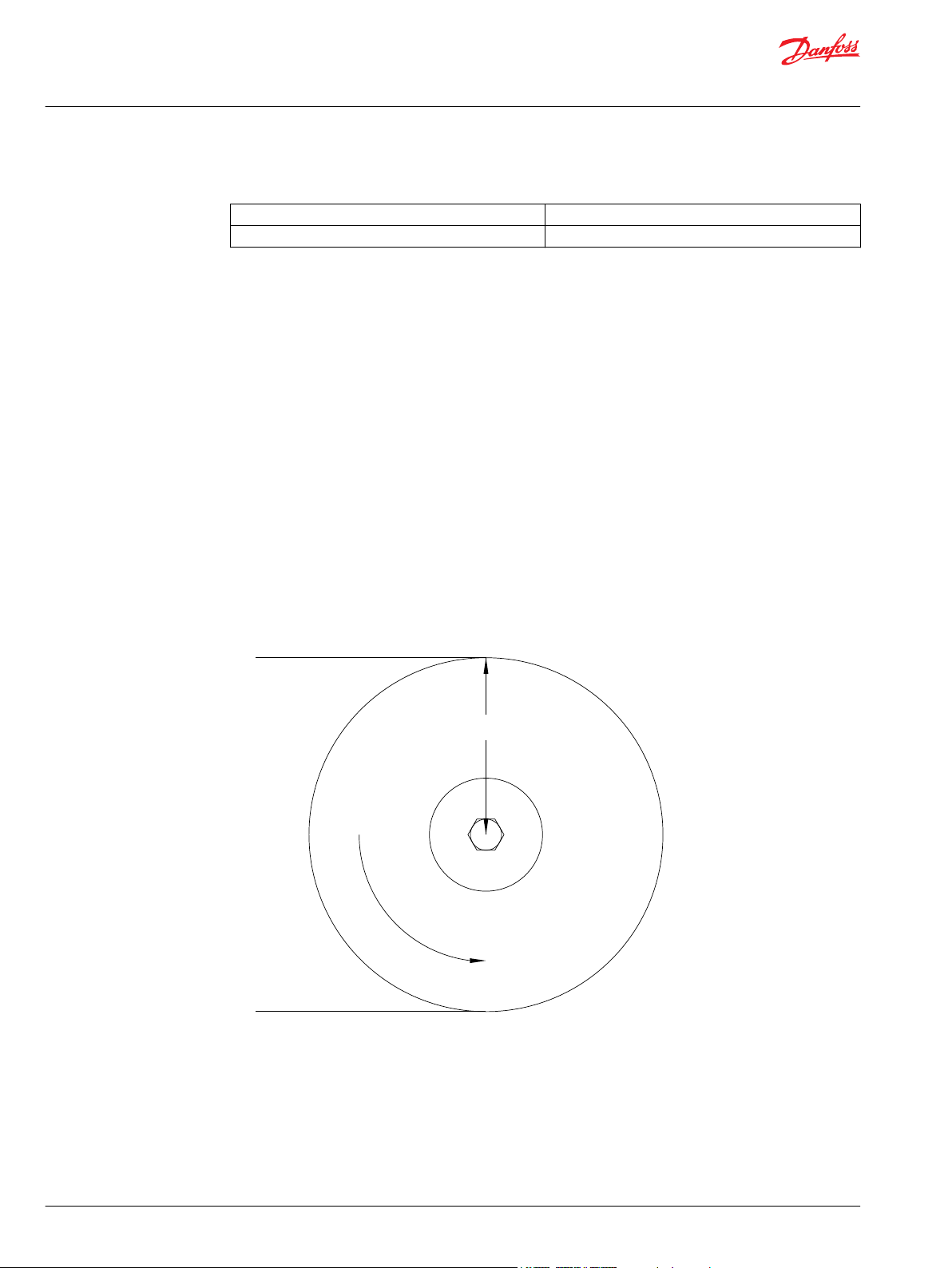

Induced Side Load

In many cases, pulleys or sprockets may be used to transmit the torque produced by the motor. Use of

these components will create a torque induced side load on the motor shaft and bearings. It is important

that this load be taken into consideration when choosing a motor with sufficient bearing and shaft

capacity for the application.

To determine the side load, the motor torque and pulley or sprocket radius must be known. Side load

may be calculated using the formula below. The distance from the pulley/sprocket centerline to the

mounting flange of the motor must also be determined. These two figures may then be compared to the

bearing and shaft load curve of the desired motor to determine if the side load falls within acceptable

load ranges.

12 | © Danfoss | December 2019 BC267362166283en-000201

Page 13

Distance

Side Load =

Side Load = 14855 Nm [3333 lbs]

Torque

Radius

P109322

Technical Information

Orbital Motors Type WD, WP and WR

Technical Information

Hydraulic Equations

Multiplication Factor Abbreviation Prefix

12

10

10

10

10

10

10

10

10

9

6

3

2

1

-1

-2

T tera

G giga

M mega

K kilo

h hecto

da deka

d deci

c centi

Theo. Speed (RPM) (1000 x LPM) / Displacement (cm3/rev)

(231 x GPM) / Displacement (in3/rev)

Theo. Torque (lb-in) (Bar x Disp. (cm3/rev)) / 20 pi

(PSI x Disp. (in3/rev) / 6.28

Power In (HP) (Bar x LPM) / 600

(PSI x GPM) / 1714

Power Out (HP) (Torque (Nm) x RPM) / 9543

(Torque (lb-in) x RPM) / 63024

©

Danfoss | December 2019 BC267362166283en-000201 | 13

Page 14

Incorrect

Correct

P109323

Technical Information

Orbital Motors Type WD, WP and WR

Technical Information

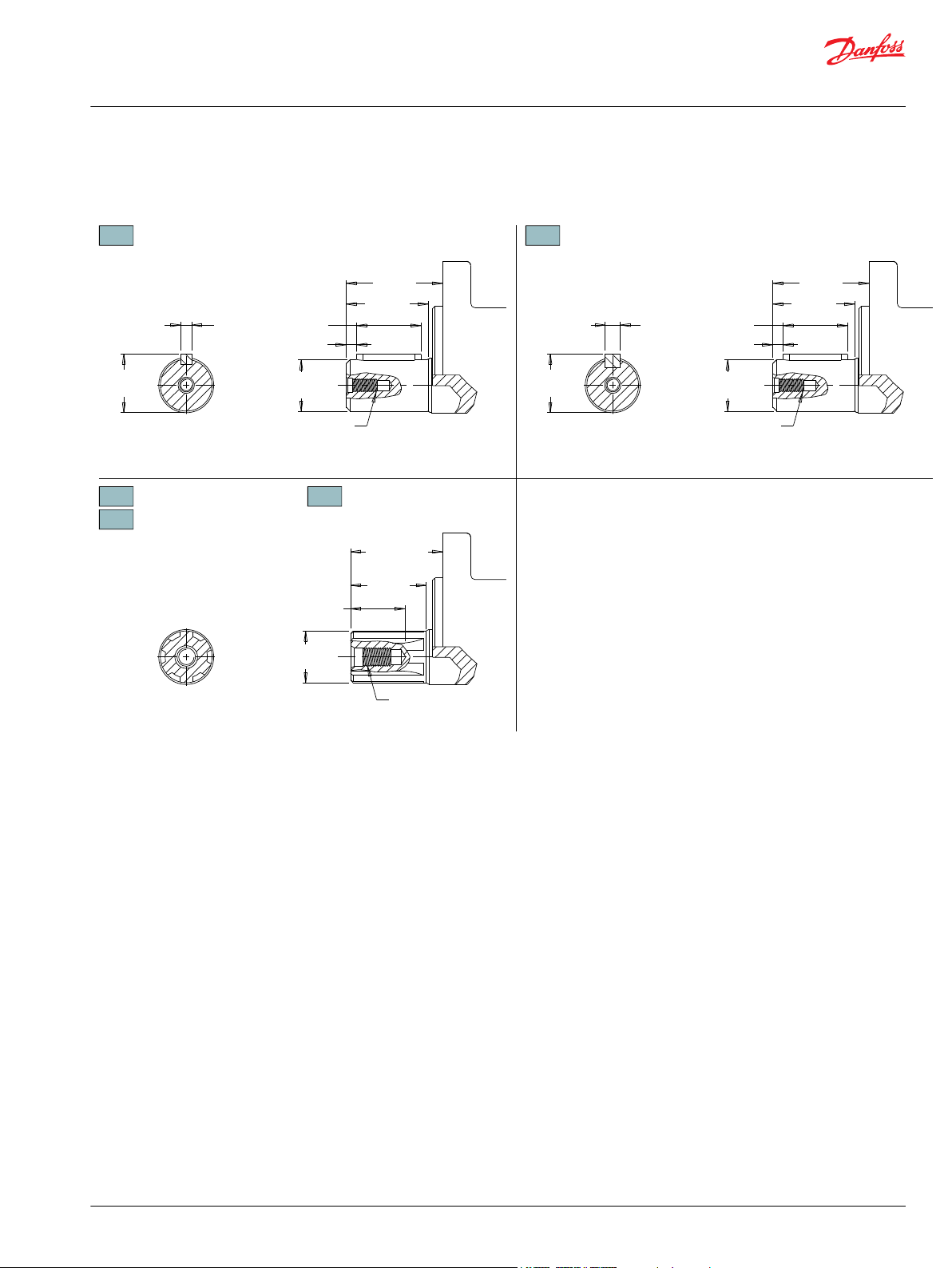

Shaft Nut Information

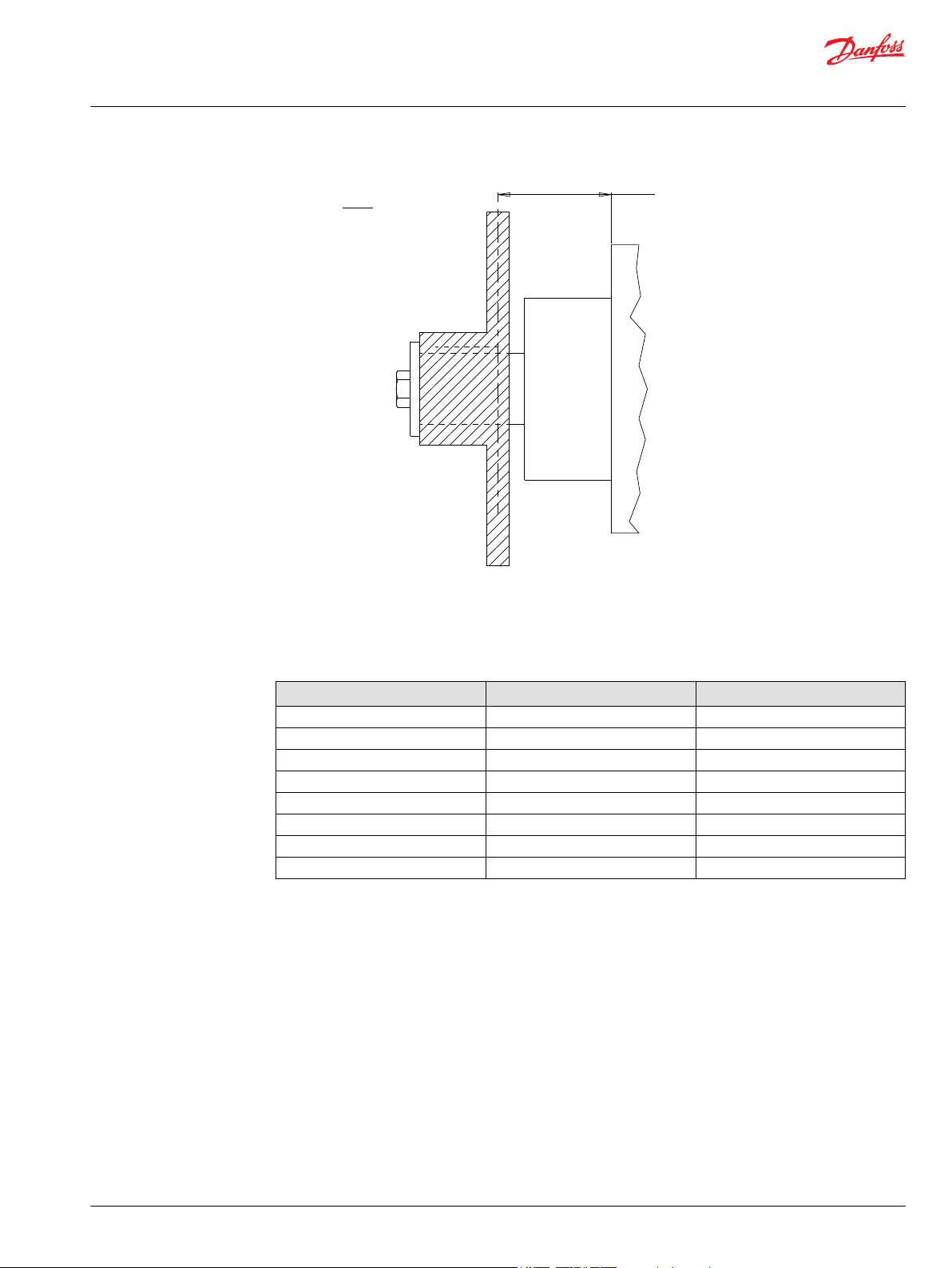

The tightening torques listed with each nut should only be used as a guideline. Hubs may require higher

or lower tightening torque depending on the material. Consult the hub manufacturer to obtain

recommended tightening torque. To maximize torque transfer from the shaft to the hub, and to

minimize the potential for shaft breakage, a hub with sufficient thickness must fully engage the taper

length of the shaft.

Hub engagement

14 | © Danfoss | December 2019 BC267362166283en-000201

Page 15

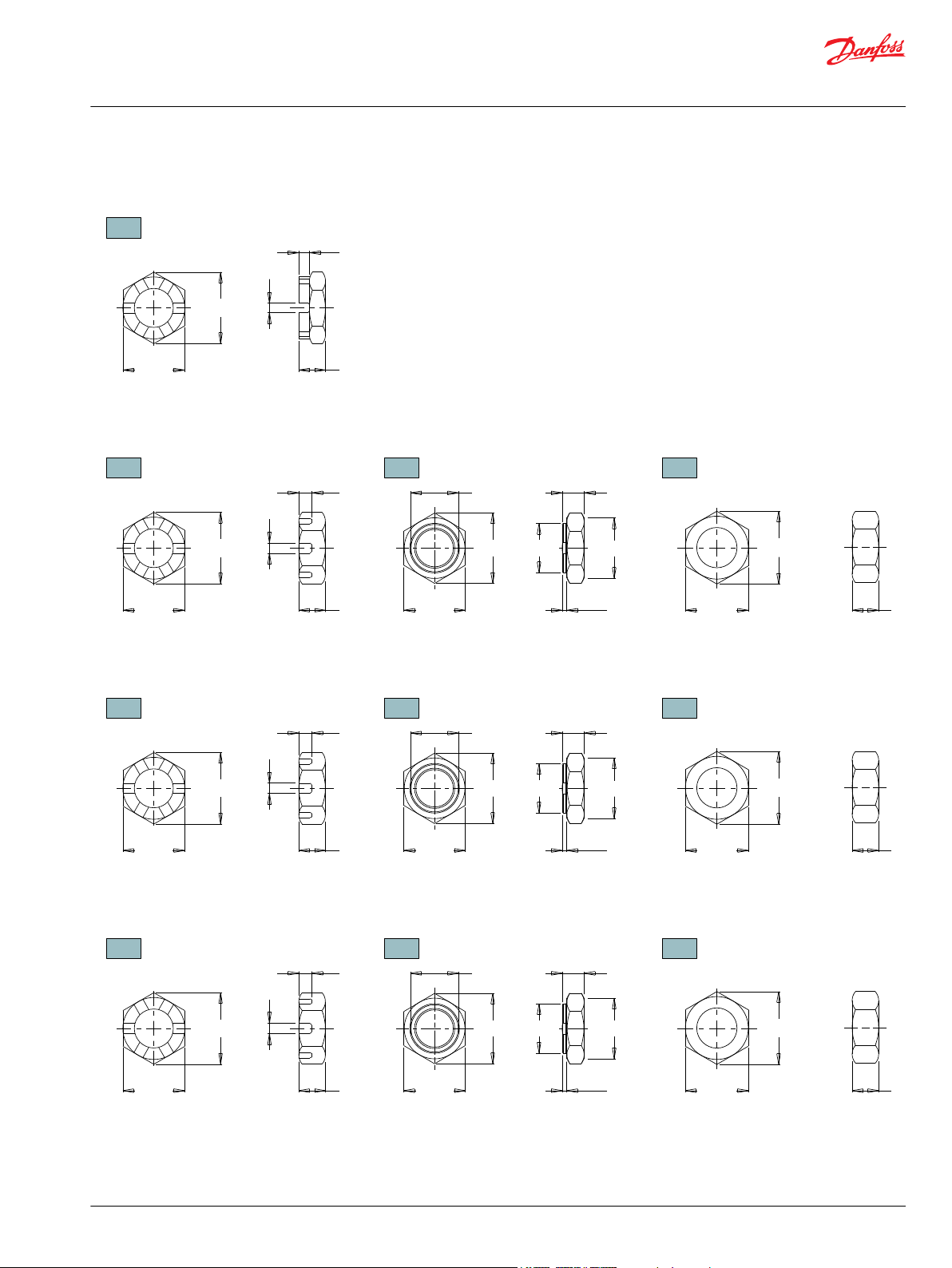

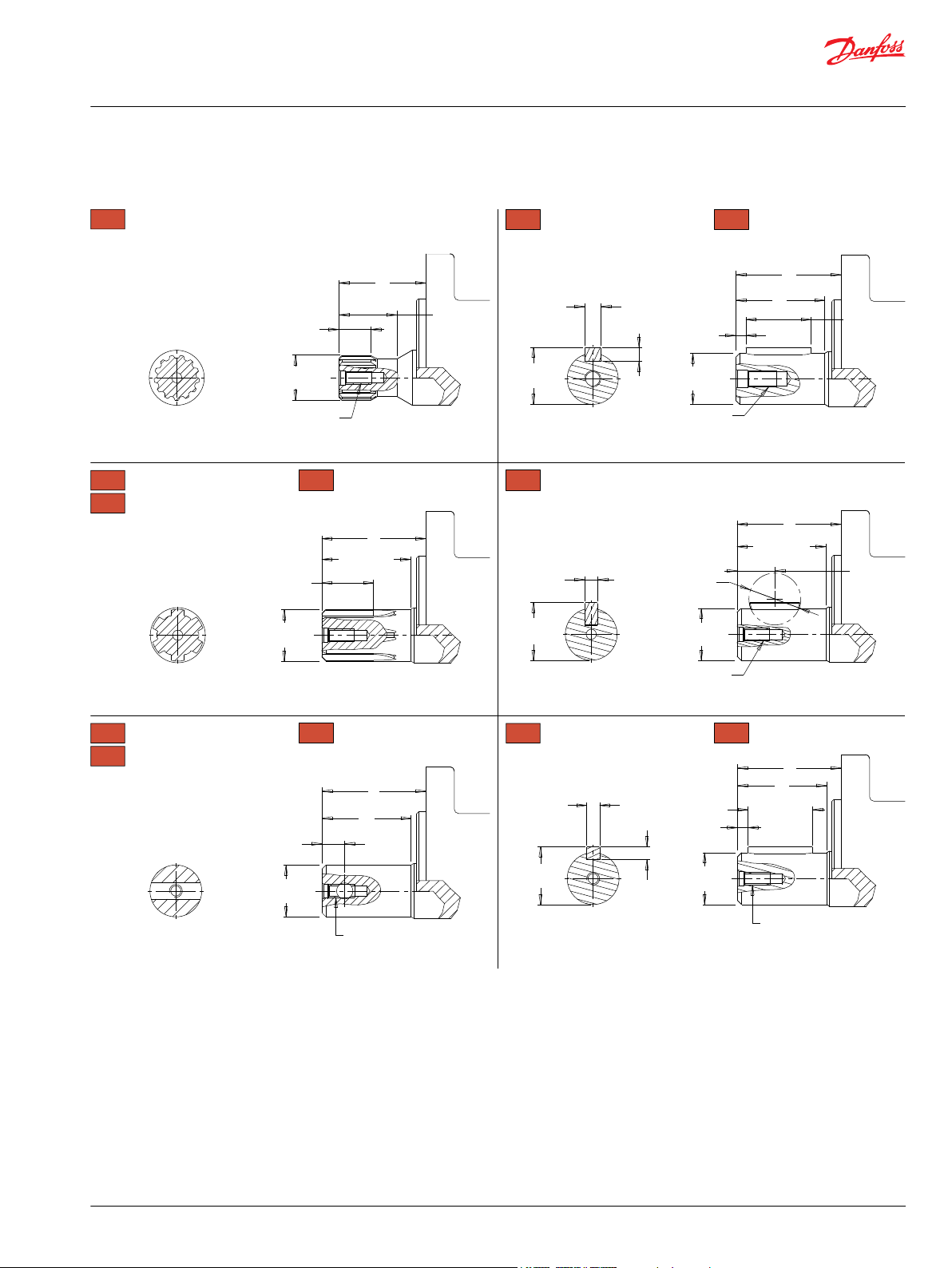

A Slotted Nut

35MM TAPERED SHAFTS

B Lock Nut

B Lock Nut

B

Lock Nut

C

Solid Nut

C

Solid Nut

C Solid Nut

M24 x 1.5 Thread

A

Slotted Nut

1” TAPERED SHAFTS

3/4-28 Thread

A Slotted Nut

1-1/4” TAPERED SHAFTS

1-20 Thread

A Slotted Nut

1-3/8” & 1-1/2” TAPERED SHAFTS

1 1/8-18 Thread

33 [1.29]

5 [.19]

6 [.24]

12 [.48]

Torque Specifications: 20 - 23 daNm [150 - 170 ft.lb.]

29 [1.13]28 [1.12]

42 [1.64]

6 [.22]

6 [.24]

15 [.59]

Torque Specifications: 32.5 daNm [240 ft.lb.]

36 [1.42]

16 [.63]

3.5 [.14]

33 [1.29]

28 [1.11]

12 [.47]

33 [1.28]

23 [.92]

24 [.95]

28 [1.10]

Torque Specifications: 24 - 27 daNm [180 - 200 ft.lb.]

Torque Specifications: 20 - 23 daNm [150 - 170 ft.lb.]

44 [1.73]

5 [.19]

6 [.25]

14 [.55]

Torque Specifications: 38 daNm [280 ft.lb.] Max.

35 [1.38]38 [1.48]

16 [.63]

4 [.16]

40 [1.57]

38 [1.48]

14 [.55]

44 [1.73]

29 [1.14]

30 [1.18]

34 [1.34]

Torque Specifications: 33 - 42 daNm [240 - 310 ft.lb.] Torque Specifications: 38 daNm [280 ft.lb.] Max.

48 [1.90]

5 [.19]

6 [.22]

15 [.61]

Torque Specifications: 41 - 54 daNm [300 - 400 ft.lb.]

44 [1.73]42 [1.66]

16 [.63]

4 [.16]

51 [2.00]

42 [1.66]

15 [.61]

48 [1.90]

35 [1.38]

36 [1.42]

44 [1.73]

Torque Specifications: 34 - 48 daNm [250 - 350 ft.lb.]

Torque Specifications: 41 - 54 daNm [300 - 400 ft.lb.]

P109324

Technical Information

Orbital Motors Type WD, WP and WR

Technical Information

©

Danfoss | December 2019 BC267362166283en-000201 | 15

Page 16

P109325

Technical Information

Orbital Motors Type WD, WP and WR

Optional Motor Features

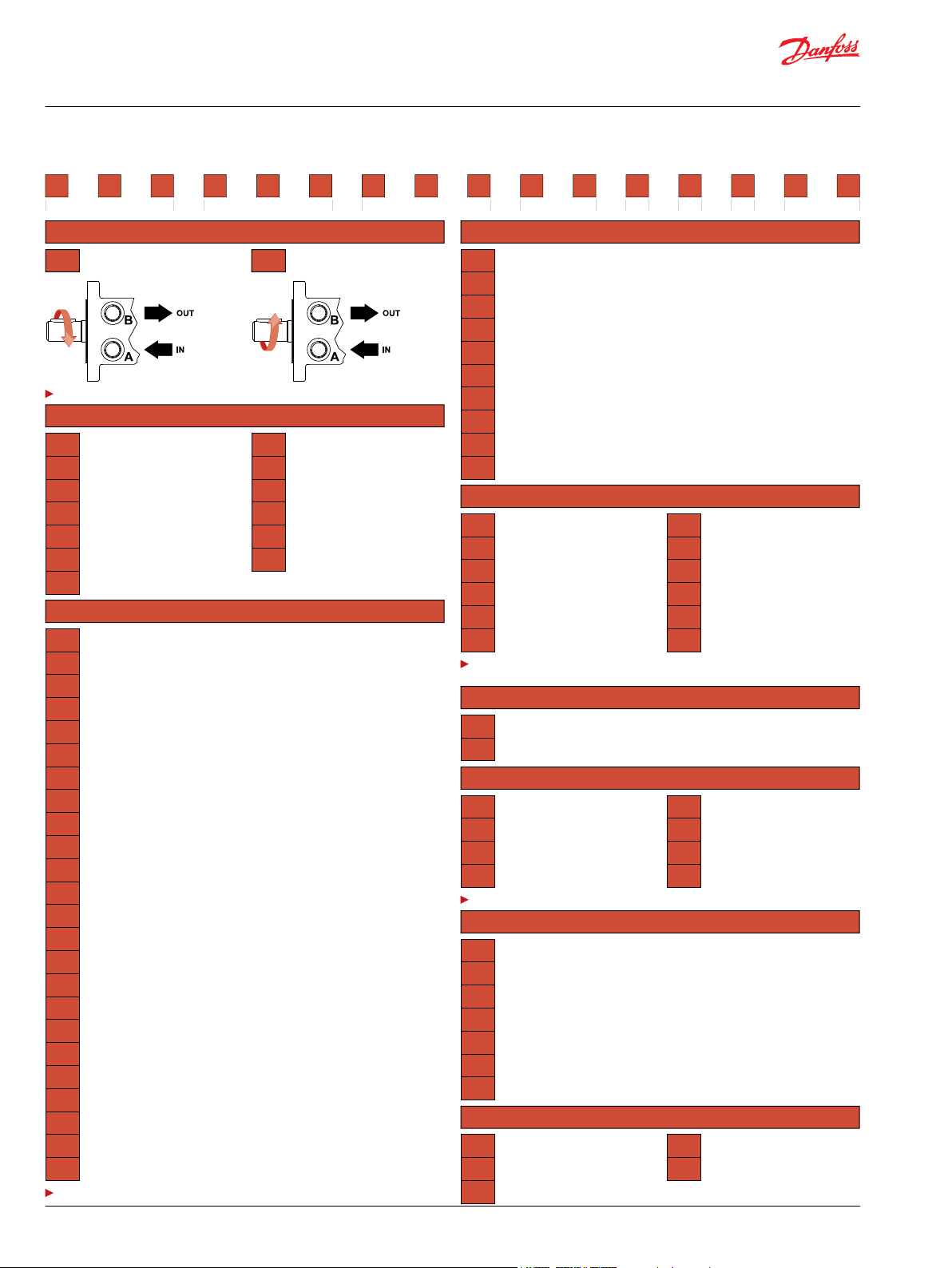

Speed Sensor Options

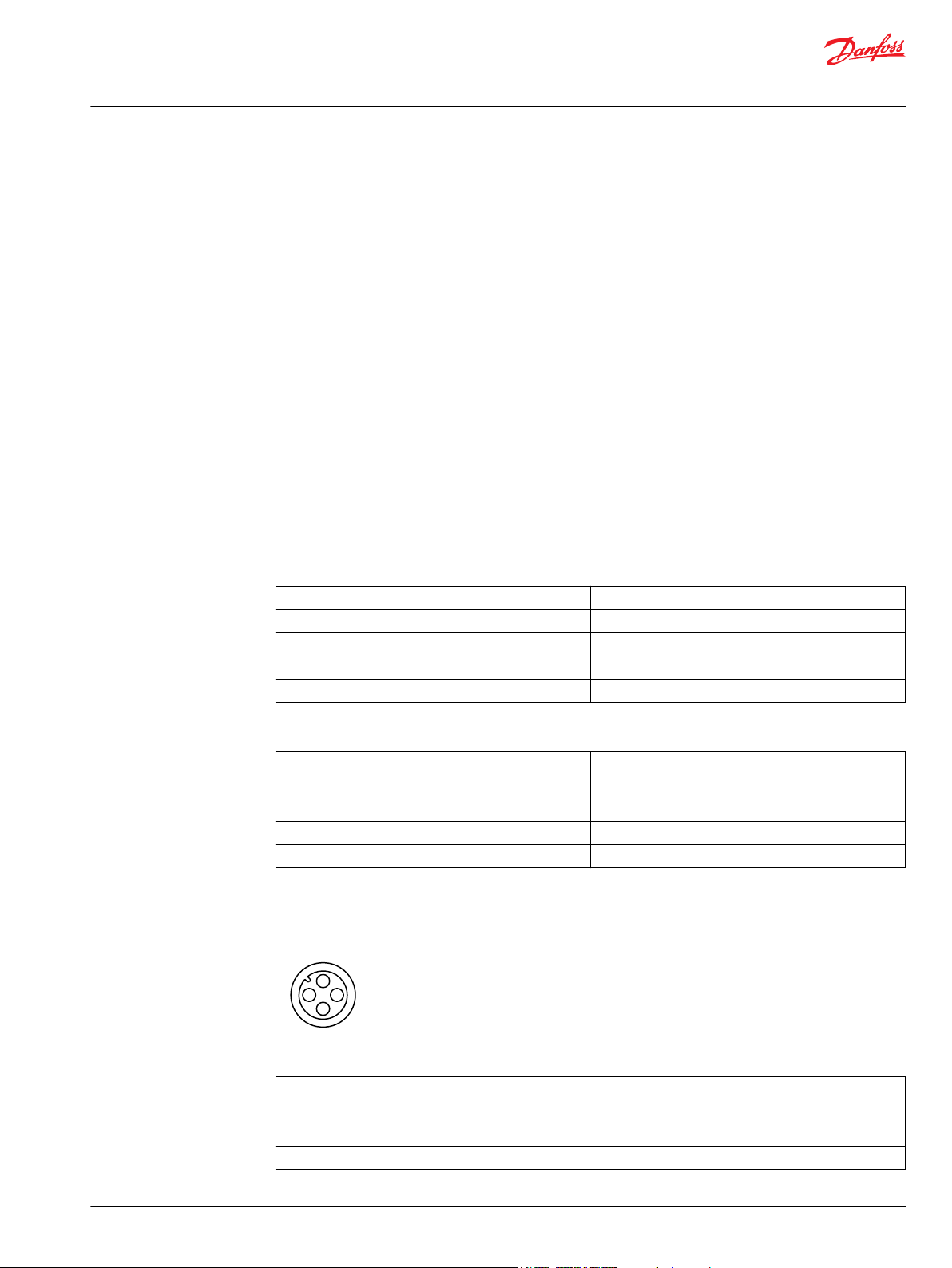

Danfoss offers both single and dual element speed sensor options providing a number of benefits to

users by incorporating the latest advancements in sensing technology and materials. The 700 & 800

series motors single element sensors provide 60 pulses per revolution with the dual element providing

120 pulses per revolution, with all other series providing 50 & 100 pulses respectively. Higher resolution is

especially beneficial for slow speed applications, where more information is needed for smooth and

accurate control. The dual sensor option also provides a direction signal allowing end-users to monitor

the direction of shaft rotation .

Unlike competitive designs that breach the high pressure area of the motor to add the sensor, the

Danfoss speed sensor option utilizes an add-on flange to locate all sensor components outside the high

pressure operating environment. This eliminates the potential leak point common to competitive

designs. Many improvements were made to the sensor flange including changing the material from cast

iron to acetal resin, incorporating a Buna-N shaft seal internal to the flange, and providing a grease zerk,

which allows the user to fill the sensor cavity with grease. These improvements enable the flange to

withstand the rigors of harsh environments.

Another important feature of the new sensor flange is that it is self-centering, which allows it to remain

concentric to the magnet rotor. This produces a consistent mounting location for the new sensor

module, eliminating the need to adjust the air gap between the sensor and magnet rotor. The oring

sealed sensor module attaches to the sensor flange with two small screws, allowing the sensor to be

serviced or upgraded in the field in under one minute. This feature is especially valuable for mobile

applications where machine downtime is costly. The sensor may also be serviced without exposing the

hydraulic circuit to the atmosphere. Another advantage of the self-centering flange is that it allows users

to rotate the sensor to a location best suited to their application. This feature is not available on

competitive designs, which fix the sensor in one location in relationship to the motor mounting flange.

Features / Benefits

•

Grease fitting allows sensor cavity to be filled with grease for additional protection.

•

Internal extruder seal protects against environmental elements.

•

M12 or weatherpack connectors provide installation flexibility.

•

Dual element sensor provides up to 120 pulses per revolution and directional sensing.

•

Modular sensor allows quick and easy servicing.

16 | © Danfoss | December 2019 BC267362166283en-000201

Page 17

1

2

3

4

P109326

Technical Information

Orbital Motors Type WD, WP and WR

Optional Motor Features

•

Acetal resin flange is resistant to moisture, chemicals, oils, solvents and greases.

•

Self-centering design eliminates need to set magnetto-sensor air gap.

•

Protection circuitry

Sensor Options

•

Z - 4-pin M12 male connector

This option has 50 pulses per revolution on all series except the DT which has 60 pulses per

revolution. This option will not detect direction.

•

Y - 3-pin male weatherpack connector

This option has 50 pulses per revolution on all series except the DT which has 60 pulses per

revolution. This option will not detect direction. Includes a 610 mm [2 ft] cable.

•

X - 4-pin M12 male connector

This option has 100 pulses per revolution on all series except the DT which has 120 pulses per

revolution. This option will detect direction.

•

W - 4-pin male weatherpack connector

This option has 100 pulses per revolution on all series except the DT which has 120 pulses per

revolution. This option will detect direction. Includes a 610 mm [2 ft] cable.

Single Element Sensor - Y & Z

Supply voltages 7.5-24 Vdc

Maximum output off voltage 24 V

Maximum continuous output current < 25 ma

Signal levels (low, high) 0.8 to supply voltage

Operating Temp -30°C to 83°C [-22°F to 181°F]

Dual Element Sensor - X & W

Supply voltages 7.5-18 Vdc

Maximum output off voltage 18 V

Maximum continuous output current < 20 ma

Signal levels (low, high) 0.8 to supply voltage

Operating Temp -30°C to 83°C [-22°F to 181°F]

Sensor Connectors

Z Option

Pin 1 positive brown or red

Pin 2 n/a white

Pin 3 negative blue

Pin 4 pulse out black

©

Danfoss | December 2019 BC267362166283en-000201 | 17

Page 18

1

2

3

4

P109327

C B A

P109328

CD B A

P109329

Technical Information

Orbital Motors Type WD, WP and WR

Optional Motor Features

X Option

Pin 1 positive brown or red

Pin 2 direction out white

Pin 3 negative blue

Pin 4 pulse out black

Y Option

Pin A positive brown or red

Pin B negative blue

Pin C pulse out black

Pin D n/a white

W Option

Pin A positive brown or red

Pin B negative blue

Pin C pulse out black

Pin D direction out white

Protection Circuitry

The single element sensor has been improved and incorporates protection circuitry to avoid electrical

damage caused by:

•

reverse battery protection

•

overvoltage due to power supply spikes and surges (60 Vdc max.)

•

power applied to the output lead

The protection circuit feature will help “save” the sensor from damage mentioned above caused by:

18 | © Danfoss | December 2019 BC267362166283en-000201

Page 19

P109330

Technical Information

Orbital Motors Type WD, WP and WR

Optional Motor Features

•

faulty installation wiring or system repair

•

wiring harness shorts/opens due to equipment failure or harness damage resulting from accidental

conditions (i.e. severed or grounded wire, ice, etc.)

•

power supply spikes and surges caused by other electrical/electronic components that may be

intermittent or damaged and “loading down” the system.

While no protection circuit can guarantee against any and all fault conditions. The single element sensor

from Danfoss with protection circuitry is designed to handle potential hazards commonly seen in real

world applications.

Unprotected versions are also available for operation at lower voltages down to 4.5V.

Freeturning Rotor Option

The ‘AC’ option or “Free turning” option refers to a specially prepared rotor assembly. This rotor assembly

has increased clearance between the rotor tips and rollers allowing it to turn more freely than a standard

rotor assembly. For spool valve motors, additional clearance is also provided between the shaft and

housing bore. The ‘AC’ option is available for all motor series and displacements.

There are several applications and duty cycle conditions where ‘AC’ option performance characteristics

can be beneficial. In continuous duty applications that require high flow/high rpm operation, the benefits

are twofold. The additional clearance helps to minimize internal pressure drop at high flows. This

clearance also provides a thicker oil film at metal to metal contact areas and can help extend the life of

the motor in high rpm or even over speed conditions. The ‘AC’ option should be considered for

applications that require continuous operation above 57 LPM [15 GPM] and/ or 300 rpm. Applications

that are subject to pressure spikes due to frequent reversals or shock loads can also benefit by specifying

the ‘AC’ option. The additional clearance serves to act as a buffer against spikes, allowing them to be

bypassed through the motor rather than being absorbed and transmitted through the drive link to the

output shaft. The trade-off for achieving these benefits is a slight loss of volumetric efficiency at high

pressures.

Valve Cavity Option

The valve cavity option provides a cost effective way to incorporate a variety of cartridge valves integral

to the motor. The valve cavity is a standard 10 series (12 series on the 800 series motor) 2-way cavity that

accepts numerous cartridge valves, including overrunning check valves, relief cartridges, flow control

valves, pilot operated check fuses, and high pressure shuttle valves. Installation of a relief cartridge into

the cavity provides an extra margin of safety for applications encountering frequent pressure spikes.

Relief cartridges from 69 to 207 bar [1000 to 3000 psi] may also be factory installed.

©

Danfoss | December 2019 BC267362166283en-000201 | 19

Page 20

P109331

Technical Information

Orbital Motors Type WD, WP and WR

Optional Motor Features

For basic systems with fixed displacement pumps, either manual or motorized flow control valves may be

installed into the valve cavity to provide a simple method for controlling motor speed. It is also possible

to incorporate the speed sensor option and a programmable logic controller with a motorized flow

control valve to create a closed loop, fully automated speed control system. For motors with internal

brakes, a shuttle valve cartridge may be installed into the cavity to provide a simple, fully integrated

method for supplying release pressure to the pilot line to actuate an integral brake. To discuss other

alternatives for the valve cavity option, contact an authorized Danfoss distributor.

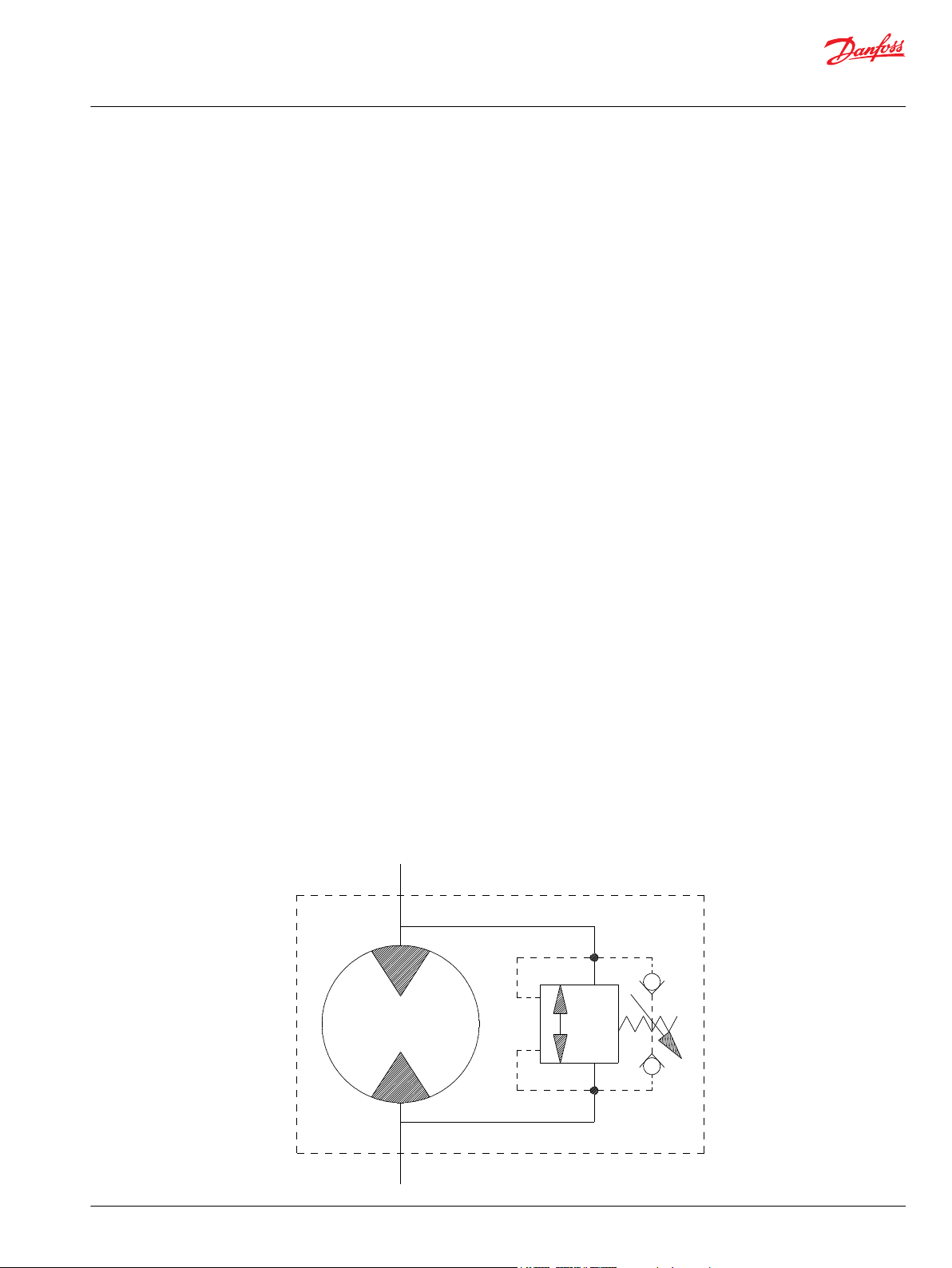

Slinger Seal Option

Slinger seals are available on select series offered by Danfoss. Slinger seals offer extendes shaft/shaft seal

protection by prevented a buildup of material around the circumference of the shaft which can lead to

premature shaft seal failures. The Danfoss slinger seals are designed to be larger in diameter than

competitive products, providing greater surface speed and ‘slinging action’.

Slinger seals are also available on 4-hole flange mounts on select series. Contact a Danfoss Customer

Service Representative for additional information.

20 | © Danfoss | December 2019 BC267362166283en-000201

Page 21

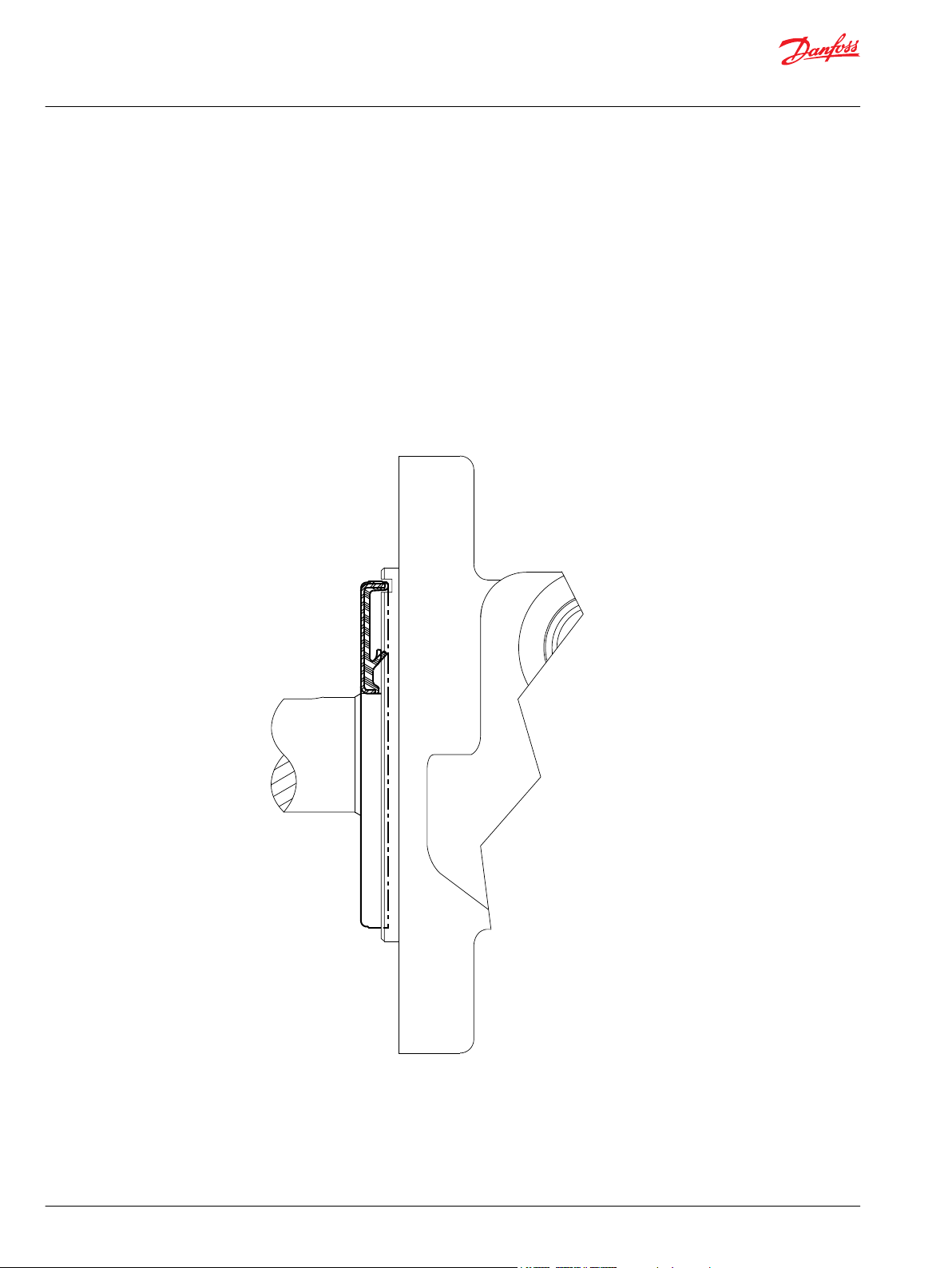

P109594

Technical Information

Orbital Motors Type WD, WP and WR

WD Product Line

WD Introduction

Overview

The WD motor series is an economical solution for light duty applications requiring high torque. It has a

smaller outline yet still provides high efficiency across a wide performance range. Its integral check valves

and a provision for a case drain reduce pressure on internal seals to improve product life. The compact

package is suitable for industrial and mobile applications including car wash brushes, food processing

equipment, conveyors, machine tools, agricultural equipment, sweepers, skid steer attachments, and

more.

Features / Benefits

•

Built-in check valves offer versatility and increased seal life.

•

A variety of mounts and shafts provide flexibility in application design.

•

Spool valve design gives superior performance and smooth operation over a wide speed and torque

range.

•

Integral rotor design provides smooth performance, compact volume and low weight.

•

Low port profiling is suitable for applications with limited space.

Typical Applications

agriculture equipment, conveyors, carwashes, sweepers, food processing, grain augers, spreaders, feed

rollers, augers, brush drives and more

Series Descriptions

145/146 - Hydraulic Motor (standard)

Specifications

Performance data is typical. Performance of production units varies slightly from one motor to another.

Running at intermittent ratings should not exceed 10% of every minute of operation.

©

Danfoss | December 2019 BC267362166283en-000201 | 21

Page 22

186

388

568

780

970

1172

1361

167

350

536

736

922

1120

1318

1502

138

316

206

688

885

1086

1285

1477

115

285

485

658

855

1046

1248

1439

106

255

447

628

830

1026

1212

1404

217

402

598

780

981

1172

1365

[80]

[80]

[71]

[71]

[62]

[53]

[44]

9

9

8

8

7

6

5

[159]

[177]

[168]

[168]

[159]

[142]

[115]

[97]

18

20

19

19

18

16

13

11

[221]

[230]

[239]

[230]

[230]

[212]

[195]

[177]

25

26

27

26

26

24

22

20

[283]

[301]

[292]

[292]

[292]

[283]

[266]

[248]

32

34

33

33

33

32

30

28

[310]

[327]

[336]

[336]

[327]

[319]

[319]

[310]

35

37

38

38

37

36

36

35

[407]

[416]

[416]

[407]

[398]

[381]

[372]

46

47

47

46

45

43

42

P109595

Torque - Nm [lb-in], Speed rpm

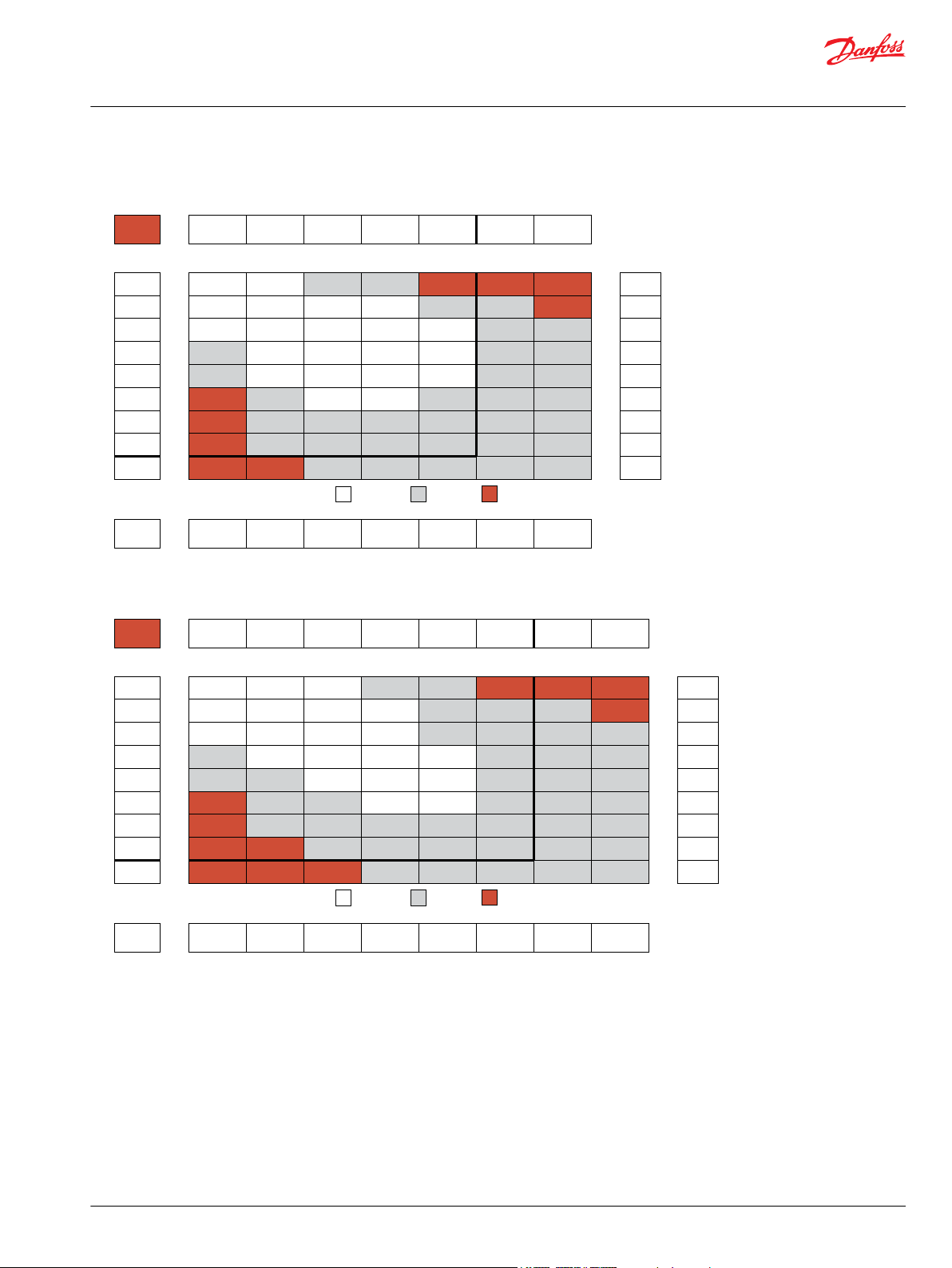

Flow - lpm [gpm]

30 [435] 60 [870] 80 [1160] 100 [1450] 120 [1740] 140 [2030]

Max. Inter.Max. Cont.

12 [104] 24 [208] 31 [277] 39 [347] 47 [416] 55 [485]

Theoretical Torque - Nm [lb-in]

Max.

Inter.

Max.

Cont.

025

5 [1.3]

10 [2.6]

15 [4.0]

20 [5.3]

25 [6.6]

30 [7.9]

35 [9.2]

40 [10.6]

203

407

610

813

1016

1220

1423

1626

Theoretical rpm

Overall Efficiency -

70 - 100%

40 - 69%

0 - 39%

Intermittent Ratings - 10% of Operation

Displacement tested at 45°C [113°F] with an oil viscosity of 46cSt [213 SUS]

Pressure - bar [psi]

mm [in]

Rotor

Width

4.1

[.160]

25 cm3 [1.5 in3] / rev

Technical Information

Orbital Motors Type WD, WP and WR

WD Product Line

Specifications

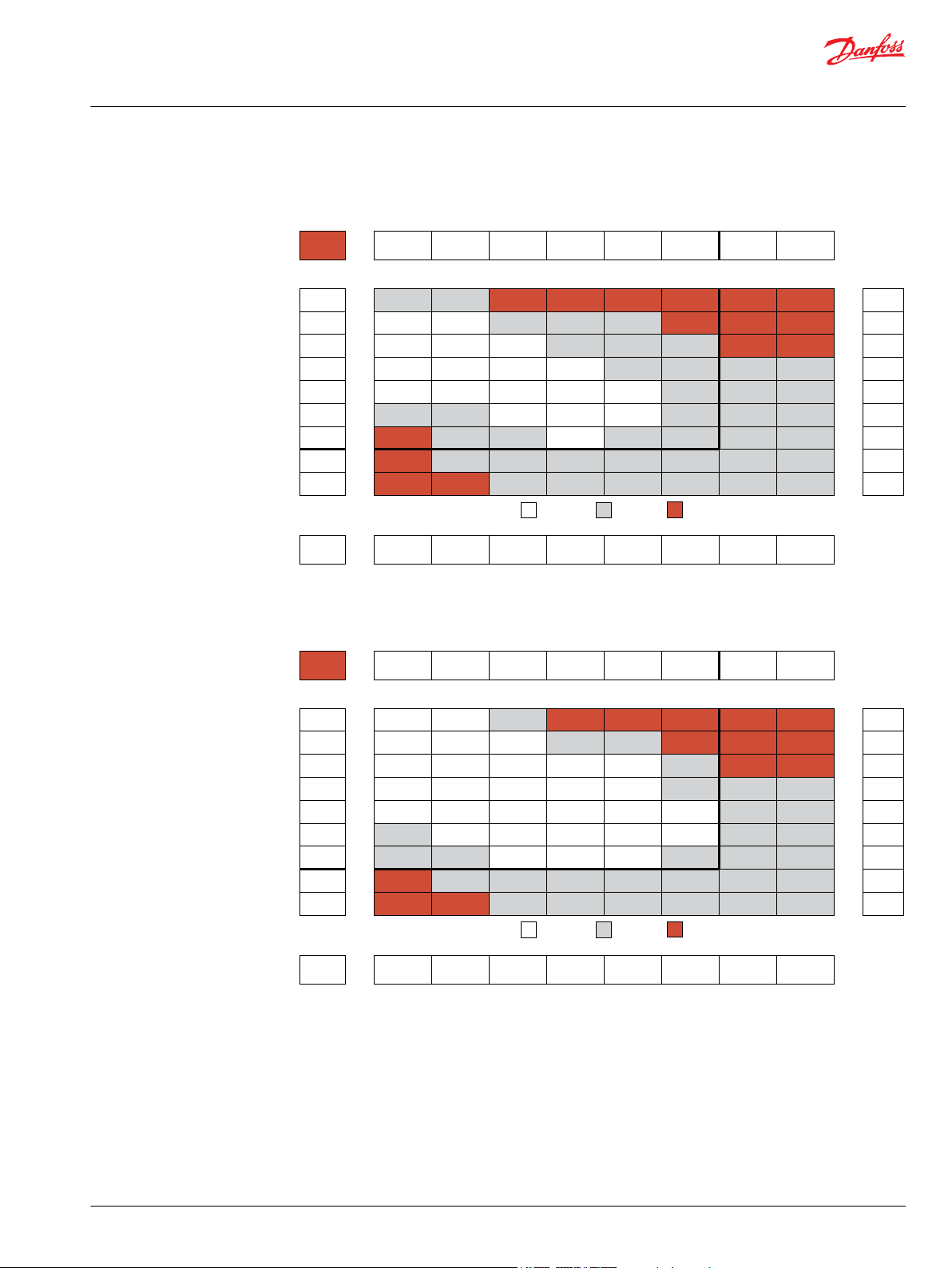

CODE

025 24.6 [1.5] 1361 1502 35 [9] 40 [11] 34 [301] 47 [416] 100 [1450] 140 [2030] 225 [3260]

032 30.8 [1.9] 1244 1388 40 [11] 45 [12] 42 [372] 57 [505] 100 [1450] 140 [2030] 225 [3260]

040 39.7 [2.4] 1124 1312 45 [12] 53 [14] 66 [584] 79 [699] 124 [1800] 155 [2250] 225 [3260]

050 48.2 [2.9] 900 1012 45 [12] 53 [14] 91 [805] 114 [1009] 138 [2000] 173 [2500] 225 [3260]

060 59.4 [3.6] 880 970 53 [14] 60 [16] 110 [974] 136 [1204] 138 [2000] 173 [2500] 225 [3260]

080 79.6 [4.9] 752 934 60 [16] 75 [20] 141 [1248] 175 [1549] 138 [2000] 173 [2500] 225 [3260]

100 96.0 [5.9] 628 786 60 [16] 75 [20] 170 [1505] 220 [1947] 138 [2000] 173 [2500] 225 [3260]

125 122.8 [7.5] 483 604 60 [16] 75 [20] 225 [1991] 274 [2425] 138 [2000] 173 [2500] 225 [3260]

160 158.0 [9.6] 383 479 60 [16] 75 [20] 284 [2513] 345 [3054] 138 [2000] 173 [2500] 225 [3260]

200 196.5 [12.0] 308 384 60 [16] 75 [20] 312 [2761] 411 [3638] 124 [1800] 166 [2400] 225 [3260]

250 240.5 [14.7] 248 312 60 [16] 75 [20] 317 [2806] 450 [3983] 103 [1500] 155 [2250] 225 [3260]

315 303.2 [18.5] 199 250 60 [16] 75 [20] 396 [3505] 576 [5098] 103 [1500] 155 [2250] 200 [2900]

400 385.8 [23.5] 150 189 60 [16] 75 [20] 480 [4248] 582 [5151] 97 [1400] 121 [1750] 180 [2610]

Displacement

cm3 [in3]

Max. Speed

rpm

Max. Flow

lpm [gpm]

Max. Torque

Nm [lb-in]

Max. Pressure

bar [psi]

cont. inter. cont. inter. cont. inter. cont. inter. peak

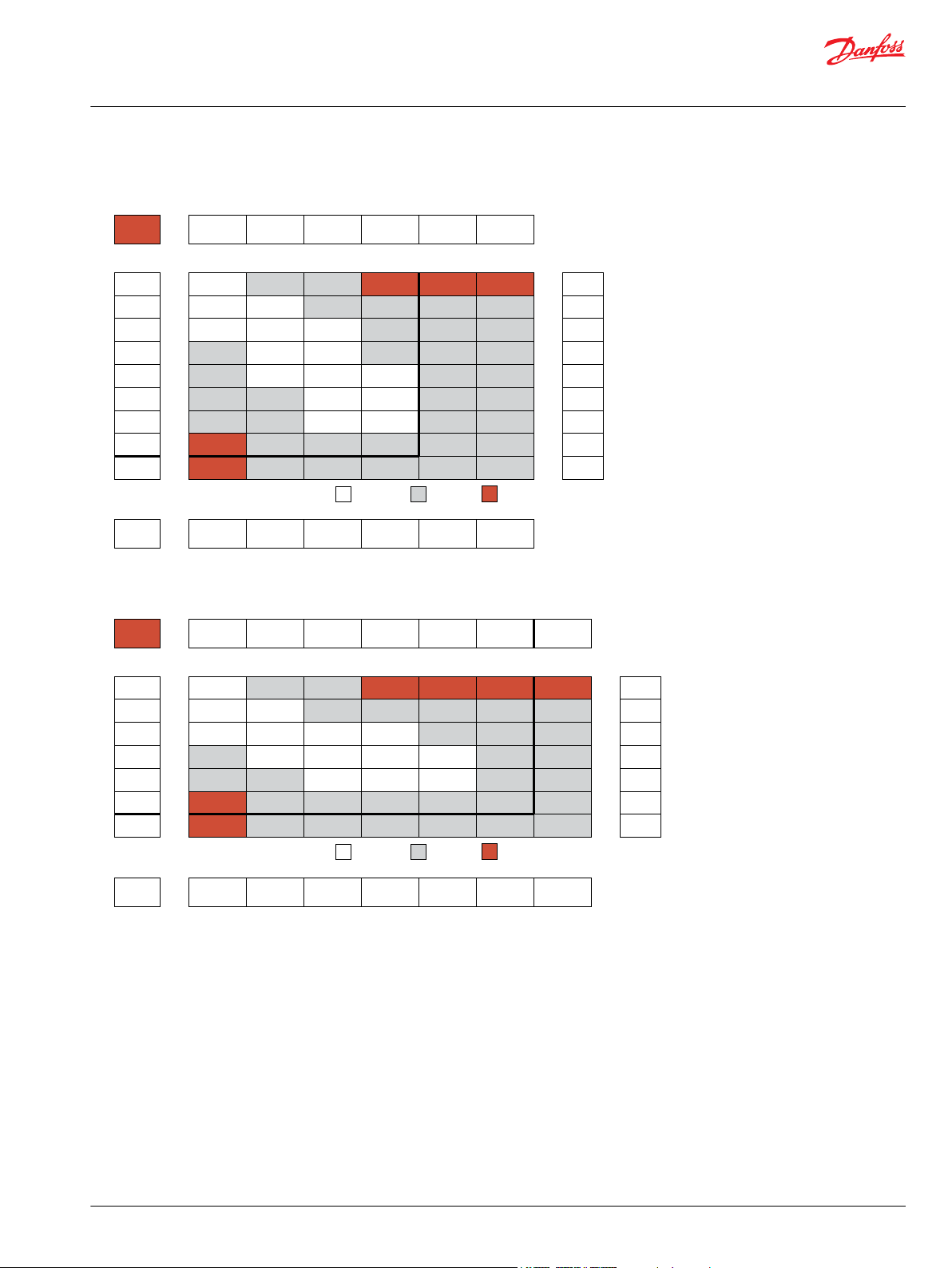

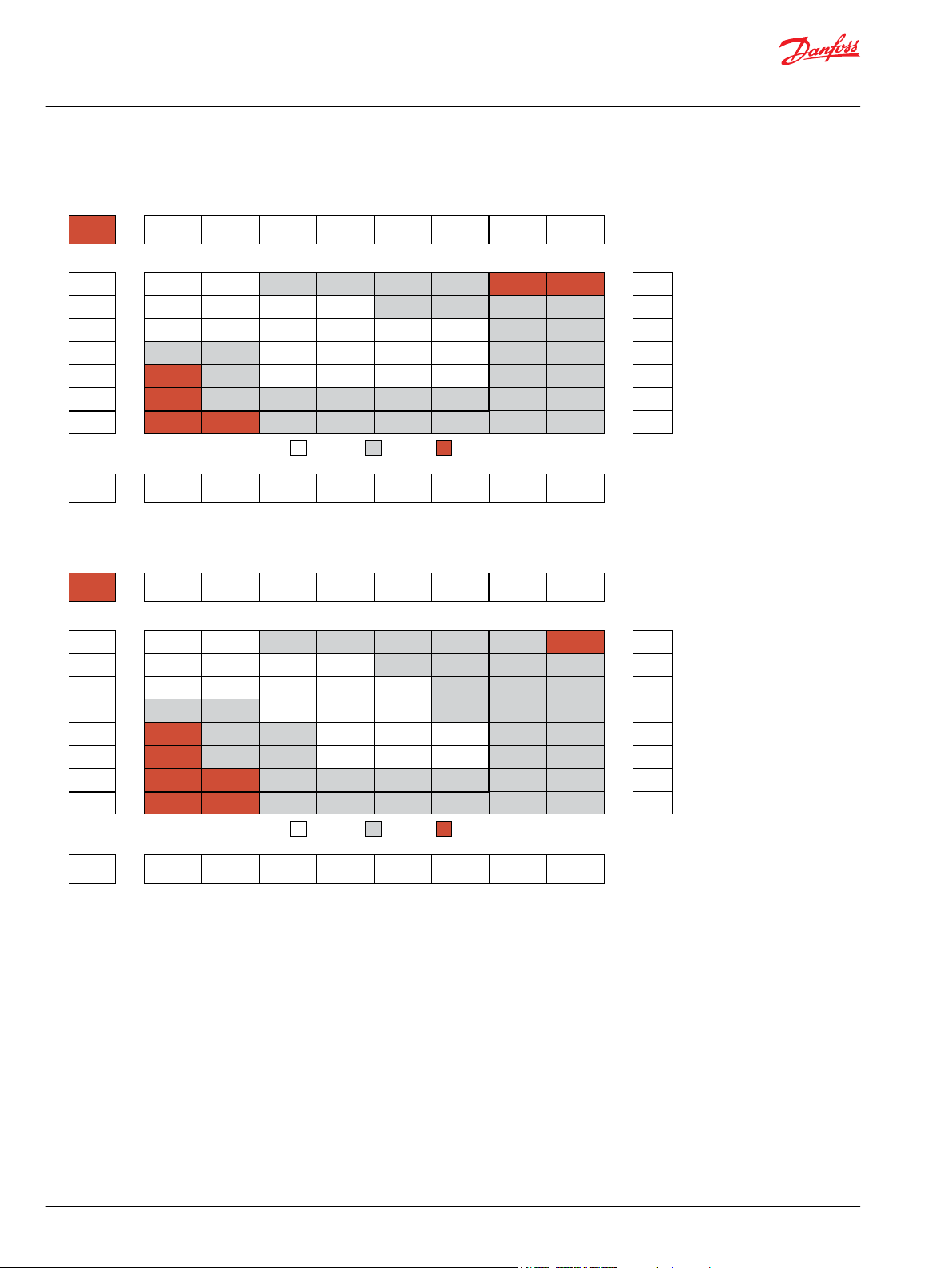

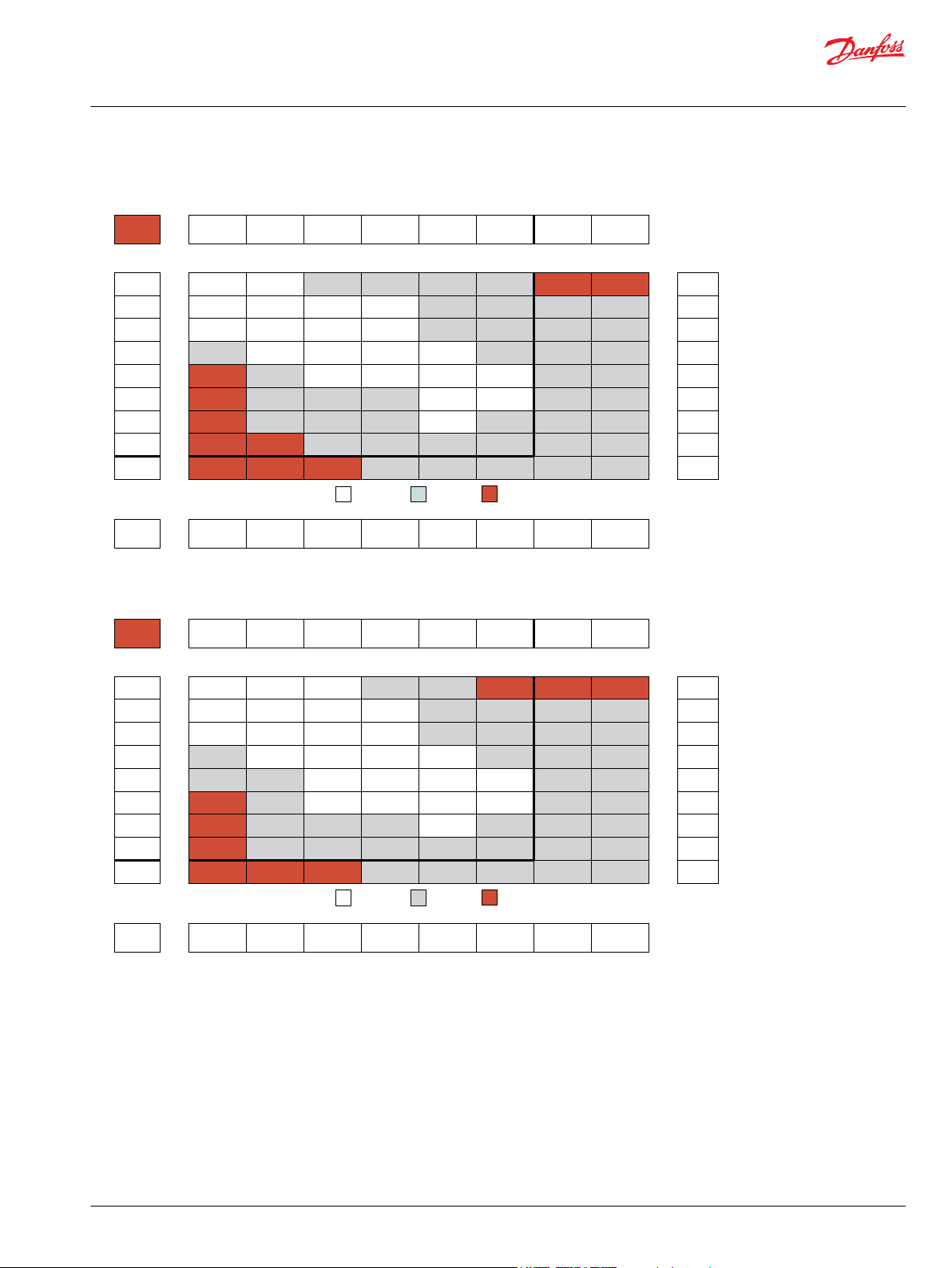

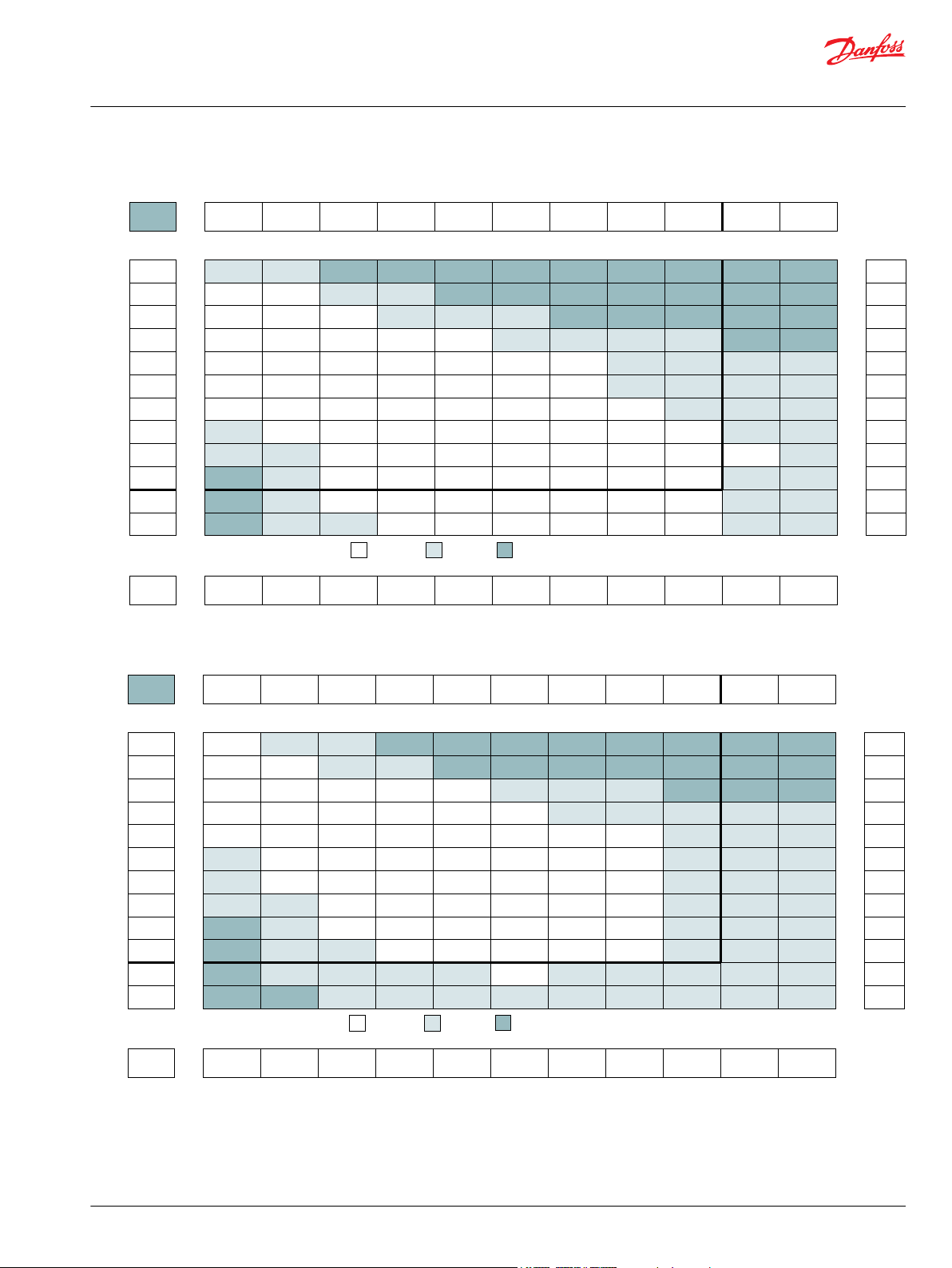

WD Functional Charts

Performance data is typical. Performance of production units varies slightly from one motor to another.

Operating at maximum continuous pressure and maximum continuous flow simultaneously is not

recommended. For additional information on product testing please refer to Product Testing on page 7.

025 Displacement Performance

22 | © Danfoss | December 2019 BC267362166283en-000201

Page 23

150

300

460

616

780

928

1090

1244

133

276

433

586

754

910

1077

1214

1388

100

253

415

566

736

882

1057

1198

1362

68

236

398

543

712

860

1035

1177

1342

203

375

520

688

824

1008

1155

1326

186

346

500

658

806

980

1130

1300

[106]

[106]

[97]

[80]

[71]

[62]

[62]

[53]

12

12

11

9

8

7

7

6

[212]

[221]

[212]

[212]

[204]

[195]

[186]

[168]

[150]

24

25

24

24

23

22

21

19

17

[283]

[292]

[292]

[283]

[283]

[274]

[274]

[257]

[248]

32

33

33

32

32

31

31

29

28

[354]

[372]

[372]

[363]

[354]

[354]

[336]

[327]

[327]

40

42

42

41

40

40

38

37

37

[425]

[434]

[434]

[425]

[416]

[407]

[407]

[398]

48

49

49

48

47

46

46

45

[487]

[504]

[496]

[496]

[496]

[487]

[478]

[478]

55

57

56

56

56

55

54

54

Torque - Nm [lb-in], Speed rpm

Flow - lpm [gpm]

30 [435] 60 [870] 80 [1160] 100 [1450] 120 [1740] 140 [2030]

Max. Inter.Max. Cont.

15 [130] 29 [260] 39 [347] 49 [434] 59 [521] 69 [608]

Theoretical Torque - Nm [lb-in]

Max.

Inter.

Max.

Cont.

032

5 [1.3]

10 [2.6]

15 [4.0]

20 [5.3]

25 [6.6]

30 [7.9]

35 [9.2]

40 [10.6]

45 [11.9]

162

325

487

649

812

974

1136

1299

1461

Theoretical rpm

Overall Efficiency -

70 - 100%

40 - 69%

0 - 39%

Intermittent Ratings - 10% of Operation

Displacement tested at 45°C [113°F] with an oil viscosity of 46cSt [213 SUS]

Pressure - bar [psi]

mm [in]

Rotor

Width

5.1

[.200]

31 cm3 [1.9 in3] / rev

P109596

182

362

548

738

932

1124

169

344

535

729

914

1102

1312

128

334

519

706

896

1084

1290

90

320

502

688

878

1062

1266

304

488

670

856

1043

1242

284

468

648

834

1014

1218

254

428

614

798

976

1168

[89]

[97]

[89]

[62]

[53]

[27]

10

11

10

7

6

3

[177]

[186]

[177]

[168]

[142]

[124]

[124]

20

21

20

19

16

14

14

[257]

[274]

[283]

[274]

[266]

[248]

[221]

29

31

32

31

30

28

25

[354]

[381]

[372]

[363]

[354]

[336]

[336]

40

43

42

41

40

38

38

[478]

[469]

[460]

[451]

[434]

[425]

54

53

52

51

49

48

[575]

[584]

[566]

[549]

[531]

[531]

65

66

64

62

60

60

[690]

[699]

[690]

[681]

[673]

[673]

78

79

78

77

76

76

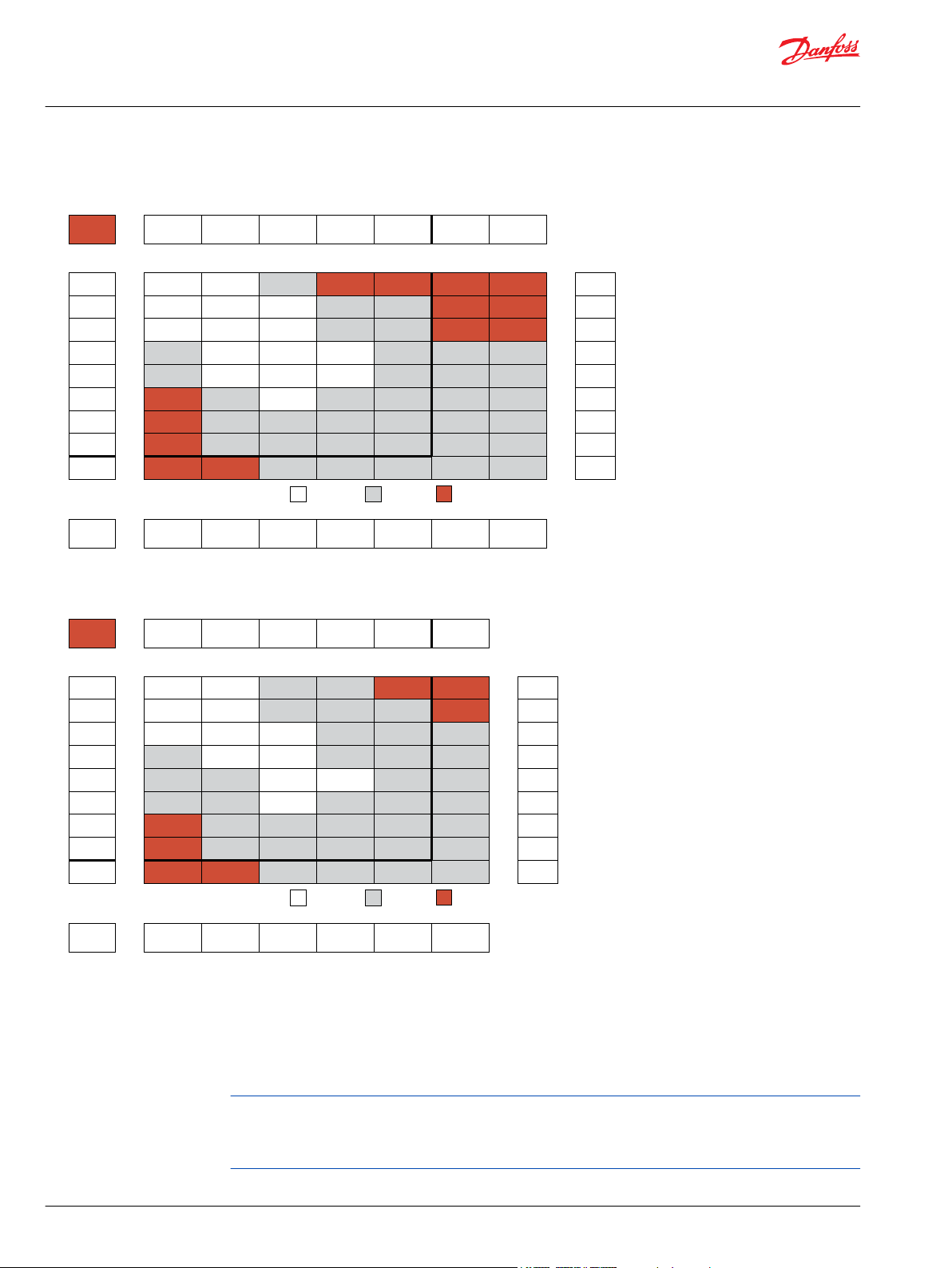

Torque - Nm [lb-in], Speed rpm

Flow - lpm [gpm]

21 [300] 41 [600] 62 [900] 83 [1200] 103 [1500] 124 [1800] 155 [2250]

Max. Inter.Max. Cont.

13 [117] 26 [229] 39 [347] 52 [464] 65 [576] 78 [694] 98 [867]

Theoretical Torque - Nm [lb-in]

Max.

Inter.

Max.

Cont.

040

8 [2]

15 [4]

23 [6]

30 [8]

38 [10]

45 [12]

53 [14]

191

380

572

763

955

1144

1335

Theoretical rpm

Overall Efficiency -

70 - 100%

40 - 69%

0 - 39%

Intermittent Ratings - 10% of Operation

Displacement tested at 45°C [113°F] with an oil viscosity of 46cSt [213 SUS]

Pressure - bar [psi]

mm [in]

Rotor

Width

6.6

[.260]

40 cm3 [2.4 in3] / rev

P109597

Technical Information

Orbital Motors Type WD, WP and WR

WD Product Line

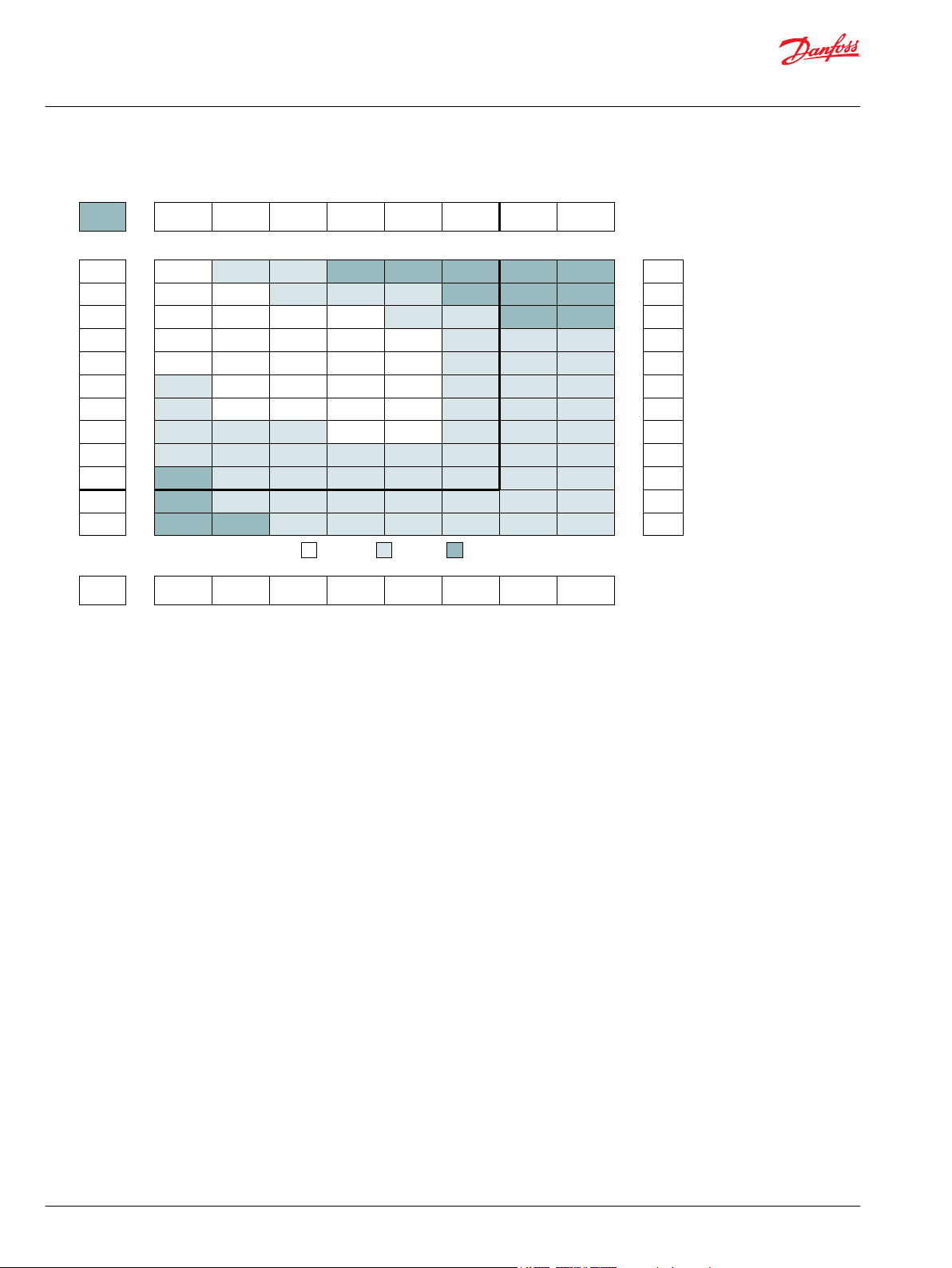

032cc Displacement Performance

040cc Displacement Performance

©

Danfoss | December 2019 BC267362166283en-000201 | 23

Page 24

148

298

450

602

750

143

289

438

590

732

900

130

276

423

580

722

885

1012

116

260

406

555

713

875

1000

102

245

388

540

693

860

986

86

229

374

523

681

848

972

75

214

352

508

669

830

960

166

314

475

635

794

924

[124]

[124]

[106]

[80]

[18]

14

14

12

9

2

[230]

[239]

[212]

[186]

[168]

[150]

26

27

24

21

19

17

[354]

[372]

[363]

[336]

[327]

[292]

[248]

40

42

41

38

37

33

28

[354]

[381]

[372]

[363]

[354]

[336]

[336]

55

56

54

52

51

46

42

[575]

[593]

[602]

[575]

[558]

[531]

[513]

65

67

68

65

63

60

58

[726]

[735]

[743]

[717]

[681]

[646]

[620]

82

83

84

81

77

73

70

[779]

[788]

[805]

[779]

[752]

[735]

[708]

88

89

91

88

85

83

80

[1009]

[991]

[974]

[947]

[929]

[885]

114

112

110

107

105

100

Torque - Nm [lb-in], Speed rpm

Flow - lpm [gpm]

21 [300] 41 [600] 62 [900] 83 [1200] 103 [1500] 124 [1800] 138 [2000]

Max. Inter.Max. Cont.

16 [143] 31 [278] 48 [422] 64 [564] 79 [700] 95 [842] 106 [937]

173 [2500]

133 [1175]

Theoretical Torque - Nm [lb-in]

Max.

Inter.

Max.

Cont.

050

8 [2]

15 [4]

23 [6]

30 [8]

38 [10]

45 [12]

53 [14]

158

313

471

629

786

942

1100

Theoretical rpm

Overall Efficiency -

70 - 100%

40 - 69%

0 - 39%

Intermittent Ratings - 10% of Operation

Displacement tested at 45°C [113°F] with an oil viscosity of 46cSt [213 SUS]

Pressure - bar [psi]

mm [in]

Rotor

Width

6.6

[.260]

48 cm3 [2.9 in3] / rev

P109598

122

247

371

496

626

752

119

243

367

492

618

744

880

970

113

236

360

484

608

735

870

958

107

223

347

470

596

727

862

944

94

209

330

457

582

716

847

932

77

192

315

436

567

696

830

924

65

180

304

425

558

680

800

902

142

266

386

500

628

740

842

[150]

[142]

[133]

[106]

[71]

[18]

17

16

15

12

8

2

[266]

[283]

[257]

[230]

[204]

[177]

[133]

[71]

30

32

29

26

23

20

15

8

[407]

[425]

[416]

[389]

[354]

[327]

[274]

[239]

46

48

47

44

40

37

31

27

[558]

[575]

[584]

[549]

[531]

[513]

[425]

[398]

63

65

66

62

60

58

48

45

[726]

[726]

[717]

[699]

[681]

[664]

[628]

[566]

82

82

81

79

77

75

71

64

[876]

[903]

[876]

[850]

[832]

[805]

[770]

[726]

99

102

99

96

94

91

87

82

[965]

[974]

[947]

[929]

[920]

[885]

[858]

[823]

109

110

107

105

104

100

97

93

[1204]

[1195]

[1151]

[1133]

[1124]

[1071]

[1035]

136

135

130

128

127

121

117

Torque - Nm [lb-in], Speed rpm

Flow - lpm [gpm]

21 [300] 41 [600] 62 [900] 83 [1200] 103 [1500] 124 [1800] 138 [2000]

Max. Inter.Max. Cont.

20 [176] 39 [343] 59 [520] 79 [695] 97 [862] 117 [1038] 131 [1155]

173 [2500]

164 [1448]

Theoretical Torque - Nm [lb-in]

Max.

Inter.

Max.

Cont.

060

8 [2]

15 [4]

23 [6]

30 [8]

38 [10]

45 [12]

53 [14]

61 [16]

128

254

382

510

638

764

892

1020

Theoretical rpm

Overall Efficiency -

70 - 100%

40 - 69%

0 - 39%

Intermittent Ratings - 10% of Operation

Displacement tested at 45°C [113°F] with an oil viscosity of 46cSt [213 SUS]

Pressure - bar [psi]

mm [in]

Rotor

Width

8.0

[.314]

59 cm3 [3.6 in3] / rev

P109599

Technical Information

Orbital Motors Type WD, WP and WR

WD Product Line

050cc Displacement Performance

060cc Displacement Performance

24 | © Danfoss | December 2019 BC267362166283en-000201

Page 25

90

187

286

378

474

564

85

182

276

372

469

558

662

752

934

78

176

268

364

460

550

658

734

929

70

167

257

354

448

540

648

724

914

62

154

248

342

440

530

637

716

904

52

143

237

334

430

519

633

700

890

42

136

227

324

416

504

609

690

876

112

202

297

370

472

576

663

814

[195]

[177]

[168]

[115]

[71]

[18]

22

20

19

13

8

2

[372]

[381]

[363]

[336]

[310]

[257]

[230]

[177]

[97]

42

43

41

38

35

29

26

20

11

[540]

[549]

[558]

[540]

[513]

[487]

[425]

[389]

[283]

61

62

63

61

58

55

48

44

32

[726]

[743]

[735]

[726]

[708]

[664]

[620]

[602]

[478]

82

84

83

82

80

75

70

68

54

[903]

[947]

[920]

[903]

[894]

[885]

[850]

[752]

[655]

102

107

104

102

101

100

96

85

74

[1097]

[1133]

[1106]

[1097]

[1089]

[1071]

[1018]

[929]

[832]

124

128

125

124

123

121

115

105

94

[1221]

[1248]

[1230]

[1212]

[1195]

[1177]

[1151]

[1089]

[956]

138

141

139

137

135

133

130

123

108

[1513]

[1549]

[1540]

[1460]

[1443]

[1425]

[1363]

[1310]

171

175

174

165

163

161

154

148

Torque - Nm [lb-in], Speed rpm

Flow - lpm [gpm]

21 [300] 41 [600] 62 [900] 83 [1200] 103 [1500] 124 [1800] 138 [2000]

Max. Inter.Max. Cont.

27 [236] 52 [460] 79 [697] 105 [931] 131 [1155] 157 [1391] 175 [1548]

173 [2500]

219 [1941]

Theoretical Torque - Nm [lb-in]

Max.

Inter.

Max.

Cont.

080

8 [2]

15 [4]

23 [6]

30 [8]

38 [10]

45 [12]

53 [14]

61 [16]

76 [20]

95

190

285

381

476

570

666

761

951

Theoretical rpm

Overall Efficiency -

70 - 100%

40 - 69%

0 - 39%

Intermittent Ratings - 10% of Operation

Displacement tested at 45°C [113°F] with an oil viscosity of 46cSt [213 SUS]

Pressure - bar [psi]

mm [in]

Rotor

Width

10.4

[.410]

80 cm3 [4.9 in3] / rev

P109600

76

154

235

313

392

470

71

147

226

307

389

465

550

628

65

140

219

299

384

458

545

622

786

54

132

212

291

375

449

532

611

770

45

122

203

281

364

437

518

598

758

33

113

193

270

353

429

510

584

732

104

185

264

346

426

500

575

716

84

162

240

314

398

473

552

670

[248]

[221]

[204]

[168]

[133]

[97]

28

25

23

19

15

11

[504]

[496]

[443]

[416]

[381]

[327]

[292]

[239]

57

56

50

47

43

37

33

27

[726]

[708]

[673]

[655]

[628]

[620]

[531]

[487]

[327]

82

80

76

74

71

70

60

55

37

[956]

[938]

[920]

[894]

[858]

[832]

[770]

[726]

[593]

108

106

104

104

97

94

87

82

67

[1168]

[1151]

[1133]

[1106]

[1080]

[1062]

[1044]

[1009]

[823]

132

130

128

125

122

120

118

114

93

[1398]

[1372]

[1354]

[1345]

[1319]

[1301]

[1266]

[1230]

[1089]

158

155

153

152

149

147

143

139

123

[1460]

[1505]

[1478]

[1478]

[1434]

[1416]

[1328]

[1221]

165

170

167

167

162

160

150

138

[1814]

[1876]

[1947]

[1929]

[1859]

[1832]

[1732]

[1682]

205

212

220

218

210

207

196

190

Torque - Nm [lb-in], Speed rpm

Flow - lpm [gpm]

21 [300] 41 [600] 62 [900] 83 [1200] 103 [1500] 124 [1800] 138 [2000]

Max. Inter.Max. Cont.

32 [284] 63 [555] 95 [840] 127 [1123] 157 [1393] 190 [1678] 211 [1867]

173 [2500]

264 [2340]

Theoretical Torque - Nm [lb-in]

Max.

Inter.

Max.

Cont.

100

8 [2]

15 [4]

23 [6]

30 [8]

38 [10]

45 [12]

53 [14]

61 [16]

76 [20]

79

157

236

316

395

473

552

631

789

Theoretical rpm

Overall Efficiency -

70 - 100%

40 - 69%

0 - 39%

Intermittent Ratings - 10% of Operation

Displacement tested at 45°C [113°F] with an oil viscosity of 46cSt [213 SUS]

Pressure - bar [psi]

mm [in]

Rotor

Width

13.0

[.510]

96 cm3 [5.9 in3] / rev

P109601

Technical Information

Orbital Motors Type WD, WP and WR

WD Product Line

080cc Displacement Performance

100cc Displacement Performance

©

Danfoss | December 2019 BC267362166283en-000201 | 25

Page 26

60

120

183

242

301

362

424

483

57

118

179

240

299

360

422

477

604

54

115

175

237

295

356

419

470

595

48

109

170

233

289

351

415

463

584

44

102

165

228

282

345

410

454

573

38

94

155

219

275

340

386

444

565

34

87

148

205

265

329

376

437

556

61

126

174

244

301

342

412

526

[274]

[266]

[266]

[248]

[195]

[133]

[80]

[18]

31

30

30

28

22

15

9

2

[566]

[558]

[549]

[522]

[478]

[425]

[363]

[283]

[133]

64

63

62

59

54

48

41

32

15

[903]

[894]

[876]

[850]

[823]

[761]

[708]

[620]

[425]

102

101

99

96

93

86

80

70

48

[1204]

[1221]

[1212]

[1186]

[1151]

[1097]

[1035]

[920]

[726]

136

138

137

134

130

124

117

104

82

[1425]

[1487]

[1478]

[1460]

[1425]

[1381]

[1319]

[1204]

[1080]

161

168

167

165

161

156

149

136

122

[1708]

[1779]

[1788]

[1761]

[1690]

[1628]

[1558]

[1460]

[1354]

193

201

202

199

191

184

176

165

153

[1947]

[1991]

[1974]

[1947]

[1903]

[1850]

[1805]

[1717]

[1575]

220

225

223

220

215

209

204

194

178

[2425]

[2407]

[2381]

[2328]

[2274]

[2151]

[2062]

[1982]

274

272

269

263

257

243

233

224

Torque - Nm [lb-in], Speed rpm

Flow - lpm [gpm]

21 [300] 41 [600] 62 [900] 83 [1200] 103 [1500] 124 [1800] 138 [2000]

Max. Inter.Max. Cont.

41 [363] 80 [710] 121 [1075] 162 [1436] 201 [1782] 242 [2146] 270 [2388]

173 [2500]

338 [2994]

Theoretical Torque - Nm [lb-in]

Max.

Inter.

Max.

Cont.

125

8 [2]

15 [4]

23 [6]

30 [8]

38 [10]

45 [12]

53 [14]

61 [16]

76 [20]

62

123

185

247

309

370

432

493

616

Theoretical rpm

Overall Efficiency -

70 - 100%

40 - 69%

0 - 39%

Intermittent Ratings - 10% of Operation

Displacement tested at 45°C [113°F] with an oil viscosity of 46cSt [213 SUS]

Pressure - bar [psi]

mm [in]

Rotor

Width

16.8

[.660]

123 cm3 [7.5 in3] / rev

P109602

47

94

143

191

238

287

335

45

92

140

188

236

285

334

383

479

42

89

136

184

233

283

332

382

478

36

85

130

178

229

281

329

378

475

28

79

124

171

224

276

324

372

469

20

72

116

162

218

270

319

363

460

64

107

154

205

261

311

358

455

35

84

134

183

235

281

333

434

[372]

[345]

[336]

[292]

[221]

[124]

[44]

42

39

38

33

25

14

5

[779]

[752]

[699]

[655]

[602]

[522]

[443]

[310]

[106]

88

85

79

74

68

59

50

35

12

[1062]

[1106]

[1089]

[1044]

[1000]

[929]

[814]

[664]

[487]

120

125

123

118

113

105

92

75

55

[1487]

[1505]

[1487]

[1451]

[1407]

[1328]

[1239]

[1062]

[814]

168

170

168

164

159

150

140

120

92

[1859]

[1867]

[1850]

[1832]

[1761]

[1699]

[1664]

[1416]

[1195]

210

211

209

207

199

192

188

160

135

[2177]

[2221]

[2195]

[2168]

[2133]

[2062]