Page 1

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

L

N

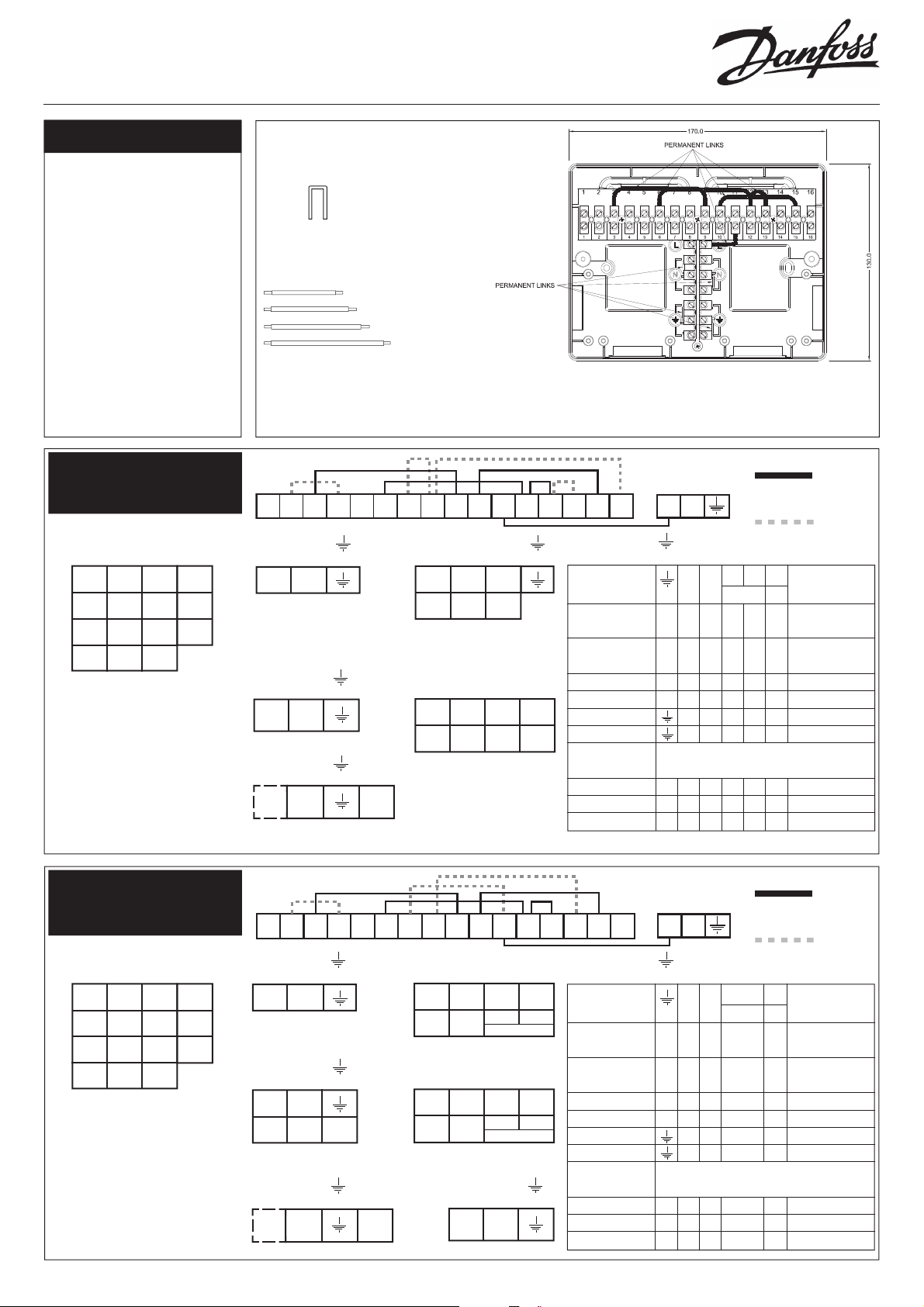

WC4/B Wiring Centre

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

L

N

Wiring Guide

Specifi cation

Terminals: 23 way

Voltage Rating: 230 V 50/60Hz

Current Rating: 10A

Max cable size: 1.5mm

Max. Ambient Temperature: 55°C

Enclosure Rating: IP30

Pollution Control Situation: Normal

Dimensions: 170 mm wide

130 mm high

39 mm deep

Complies with BS6220

2

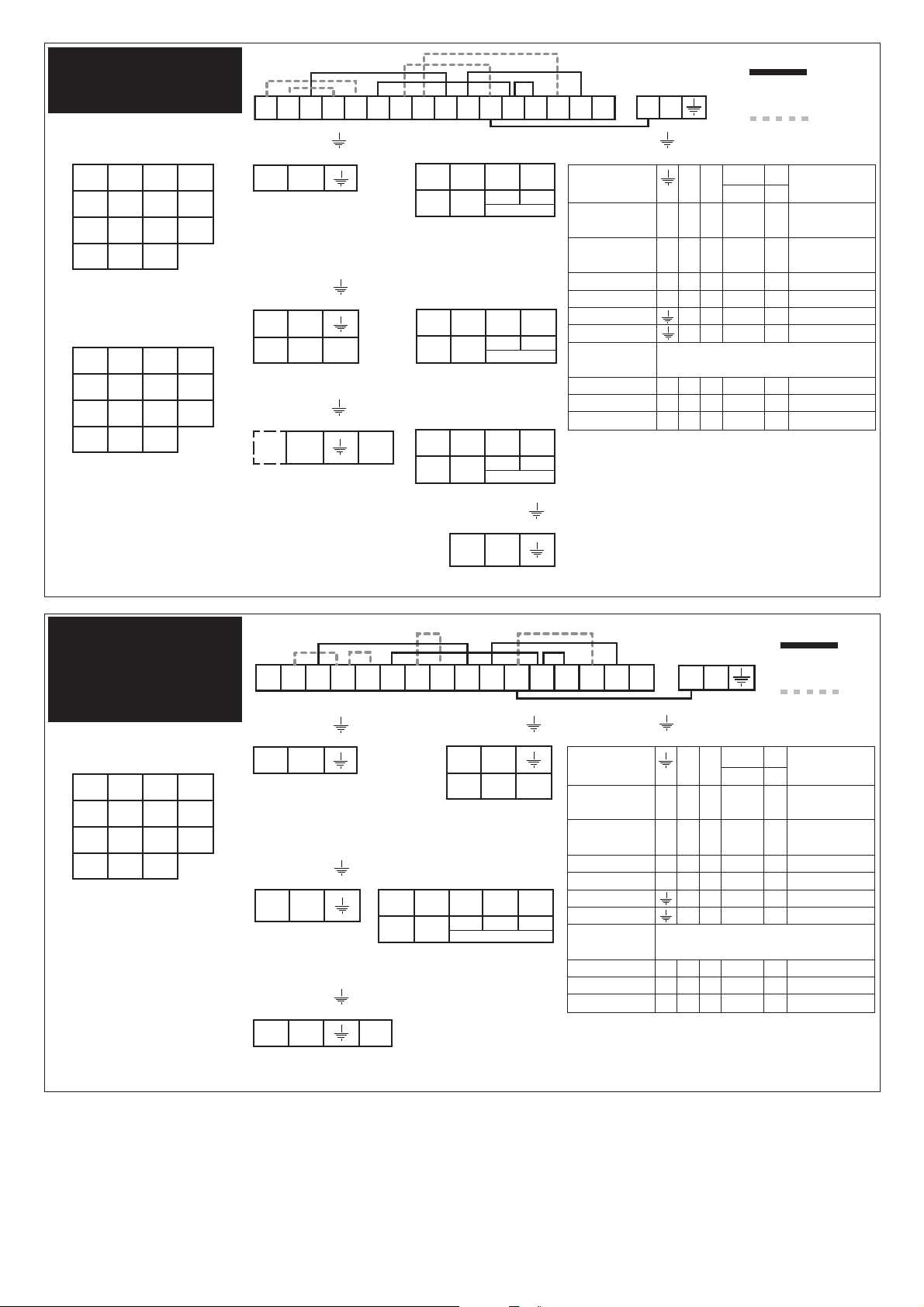

1. Fully Pumped System,

3-Port Mid-Position

Valve.

3 2 N

¨

¨

¨

1 2 4

L 3 N

L* 1 N

COM CALL N

ROOM THERMOSTAT

* Link terminals L and

Com in the RET230P for

correct operation. (See

thermostat instructions

for further information).

** Refer to Boiler wiring

information for boilers

with pump overrun.

RMT

230

RET

230

RET

230P*

Movable Links

Preformed (2 off )

Straight Solid Core (1 off each)

- 1.5mm2 (BS6004),

ends trimmed 7mm.

45mm

70mm

80mm

105mm

The Danfoss Randall 23-way WC4/B Wiring Centre, suited to most popular heating/hot water systems, provides a systemised

and tidy approach to wiring, particularly in respect of cable links and terminal numbers. It has some fi xed and some movable

links and is designed to be wall mounted, with cable entry from either the rear or through knock-outs in the rear. The following

wiring connection information covers most popular domestic heating control systems.

A. Permanent Links

B. Links to be made by

installer

L N

¨

¨

¨

L N

MAINS SUPPLY

(Fuse 3A)

13 N

¨

¨

¨

L N

** PUMP

L N 12

¨

¨

¨

Perm N Sw.

L L

** BOILER

15 14 16

¨

1 2 3

COM CALL SAT

ATC CYLINDER

THERMOSTAT

4 N 7 6

¨

Wh/ Blue Gr. Or.

Br.

HTG. N HW. Sw.

L OFF L

HS3 MID-POS. VALVE

¨

¨

¨

¨

¨

¨

PROGRAMMER N L OFF ON ON LINKS

WATER HTG

CP715 Si, FP715 Si - N L 1 3 4 -

& TP9000

SET3M, SET 3E - N L 3 1 4 L, 2 & 5

& FP975

SET2E - N L - 1 4 L-2, 1-5

¨

102, 102E5, 102E7 - N L - 1 2 L-3

4033 7 6 5 4 2 1-6

3060 & 3020P 7 6 - 4 2 -

TIMESWITCH N.B. WHEN USING UNITS BELOW LINK 11-9 ON

WIRING CENTRE

103, 103E5, 103E7 - N L - 1 - L-3

TS715 Si - N L - 4 - L-1

SET1E & TS975 - N L - 4 - L-5

N 11 8 10 9

¨¨¨¨¨

¨

2. Fully Pumped System,

2 x 2-Port Spring Return

¨

ller

¨

RMT

230

RET

230

RET

230P*

L N

¨

¨

L N

MAINS SUPPLY

(Fuse 3A)

15 14

¨

¨

1 2

COM CALL

ATC CYLINDER

THERMOSTAT

L N 12

¨

¨

Perm N Sw.

L L

** BOILER

Zone Valves.

3 2 N

¨

1 2 4

L 3 N

L* 1 N

COM CALL N

ROOM THERMOSTAT

* Link terminals L and

Com in the RET230P for

correct operation. (See

thermostat instructions

for further information).

** Refer to Boiler wiring

information for boilers

with pump overrun.

¨

¨

¨

4 N 6 7

¨

Brn. Blue Or. Gr.

Motor N OUT IN.

L Aux. Sw.

HP22, 2-PORT HTG VALVE

8 N 6 7

¨

Brn. Blue Or. Gr.

Motor N OUT IN.

L Aux. Sw.

HP22, 2-PORT DHW VALVE

13 N

¨

L N

** PUMP

¨

¨

¨

¨

¨

¨

A. Permanent Links

B. Links to be made by

installer

N 11 10 9

¨

PROGRAMMER N L ON ON LINKS

WATER HTG

CP715 Si, FP715 Si - N L 3 4 -

& TP9000

SET3M, SET 3E - N L 1 4 L, 2 & 5

& FP975

¨

SET2E - N L 1 4 L-2, 1-5

102, 102E5, 102E7 - N L 1 2 L-3

4033 7 6 4 2 1-6

3060 & 3020P 7 6 4 2 -

TIMESWITCH N.B. WHEN USING UNITS BELOW LINK 11-9 ON

WIRING CENTRE

103, 103E5, 103E7 - N L 1 - L-3

¨

TS715 Si - N L 4 - L-1

SET1E & TS975 - N L 4 - L-5

¨

¨

¨

¨

¨

1

Page 2

3. Fully Pumped System,

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

L

N

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

L

N

3 x 2-Port Spring Return

Zone Valves.

A. Permanent Links

B. Links to be made by

installer

3 2 N

¨

¨

¨

¨

RMT

230

RET

230

RET

230P*

RMT

230

RET

230

RET

230P*

1 2 4

L 3 N

L* 1 N

COM CALL N

ROOM THERMOSTAT

(Zone 1)

3 1 N

¨

¨

1 2 4

L 3 N

L* 1 N

COM CALL N

ROOM THERMOSTAT

(Zone 2)

* Link terminals L and

Com in the RET230P for

correct operation. (See

thermostat instructions

for further information).

L N

¨

¨

¨

L N

MAINS SUPPLY

(Fuse 3A)

15 14

¨

¨

¨

1 2

COM CALL

ATC CYLINDER

THERMOSTAT

L N 12

¨

¨

¨

Perm N Sw.

L L

** BOILER

** Refer to Boiler wiring

information for boilers

with pump overrun.

4 N 6 7

¨

Brn. Blue Or. Gr.

Motor N OUT IN.

L Aux. Sw.

HP22, 2-PORT HTG VALVE

(Zone 1)

5 N 6 7

Brn. Blue Or. Gr.

Motor N OUT IN.

L Aux. Sw.

HP22, 2-PORT HTG VALVE

(Zone 2)

8 N 6 7

¨

Brn. Blue Or. Gr.

Motor N OUT IN.

L Aux. Sw.

HP22, 2-PORT DHW VALVE

¨

¨

¨

¨

¨

13 N

¨

L N

** PUMP

¨

¨

¨

¨

N 11 10 9

¨

PROGRAMMER N L ON ON LINKS

WATER HTG

CP715 Si, FP715 Si - N L 3 4 -

& TP9000

SET3M, SET 3E - N L 1 4 L, 2 & 5

& FP975

SET2E - N L 1 4 L-2, 1-5

102, 102E5, 102E7 - N L 1 2 L-3

¨

4033 7 6 4 2 1-6

3060 & 3020P 7 6 4 2 -

TIMESWITCH N.B. WHEN USING UNITS BELOW LINK 11-9 ON

WIRING CENTRE

103, 103E5, 103E7 - N L 1 - L-3

TS715 Si - N L 4 - L-1

SET1E & TS975 - N L 4 - L-5

¨

¨

¨

¨

¨

¨

¨

4. Gravity DHW and

Pumped Heating,

one 2-Port Spring

Return Zone Valve in

DHW.

3 2 N

¨

¨

¨

1 2 4

L 3 N

L* 1 N

COM CALL N

ROOM THERMOSTAT

(Zone 1)

* Link terminals L and

Com in the RET230P for

correct operation. (See

thermostat instructions

for further information).

230P*

RMT

230

RET

230

RET

L N

¨

¨

L N

MAINS SUPPLY

(Fuse 3A)

5 N

¨

¨

L N

PUMP

L

N 12

¨

¨

Perm

N L

L

BOILER

15 8

¨

1 2

COM CALL

ATC CYLINDER

THERMOSTAT

7 N 4 14 13

¨

¨

¨

Brn. Blue Wh. Gr. Or.

Motor N N/C N/O COM

L Aux. Sw.

HP28C DHW VALVE

¨

¨

¨

¨

¨

¨

A. Permanent Links

B. Links to be made

by installer

N 11 10 9

¨

¨

¨

PROGRAMMER N L ON ON LINKS

WATER HTG

CP715 Si, FP715 Si - N L 3 4 -

& TP9000

SET3M, SET 3E - N L 1 4 L, 2 & 5

& FP975

SET2E - N L 1 4 L-2, 1-5

102, 102E5, 102E7 - N L 1 2 L-3

¨

4033 7 6 4 2 1-6

3060 & 3020P 7 6 4 2 -

TIMESWITCH N.B. WHEN USING UNITS BELOW LINK 11-9 ON

WIRING CENTRE

103, 103E5, 103E7 - N L 1 - L-3

TS715 Si - N L 4 - L-1

SET1E & TS975 - N L 4 - L-5

¨

¨

¨

2

Page 3

5. Fully Pumped System,

3-port mid-position

valve with 2-channel

programmer and

wireless dial setting

room and hot water

thermostat

A. Permanent Links

WC4B

B. Links to be made by installer

123456789101112131415161718 LN

N L 3 15 2 14 16

¨

¨

NL123456

L N 12

¨

Perm N Sw.

L L

BOILER

RX Channel Assignment

Channel 1 Heating Channel 2 Hot Water

6. Fully Pumped System,

3-port mid-

position valve with

programmable

heating and hot water

thermostats.

¨

RX2C

¨

¨

¨

¨

WC4B

¨

¨

¨

NL8 109

¨

¨

¨

¨

¨

NL1234

FP715Si

13 N

¨

¨

¨

L N

PUMP

4N76

¨

White

Blue Grey Orange

Brown

Heating

N

L

L N

¨

L N

MAINS SUPPLY

A. Permanent Links

B. Links to be made by installer

123456789101112131415161718 LN

¨

HS3

¨

HW

Off SWL

¨

¨

¨

NL 2 1416

¨

¨

¨

¨

¨

NL123456

RX2C

L N 12

¨

¨

¨

¨

Perm N Sw.

L L

BOILER

RX Channel Assignment

Channel 1 Heating Channel 2 Hot Water

13 N

¨

¨

L N

PUMP

¨

4N76

¨

N

HS3

¨

HW

Off SWL

¨

¨

¨

White

Blue Grey Orange

Brown

Heating

L

L N

¨

L N

MAINS SUPPLY

(Fuse 3A)

¨

3

Page 4

7. Fully Pumped System,

2 x 2-port zone valves

with programmable

heating and hot water

thermostats

A. Permanent Links

WC4B

B. Links to be made by installer

123456789101112131415161718 LN

NL 2 14

¨

¨

NL123456

L N 12

¨

Perm N Sw.

L L

BOILER

RX Channel Assignment

Channel 1 Heating Channel 2 Hot Water

8. Fully Pumped System,

2 x 2-port zone

valves with 2-channel

programmer and

wireless dial setting

room and hot water

thermostats

RX2C

¨

8N67

¨

¨

Brown Blue Orange Grey

L N Aux Aux In

HP22 (Hot Water)

L N

¨

¨

L N

MAINS SUPPLY

(Fuse 3A)

A. Permanent Links

B. Links to be made by installer

¨

¨

WC4B

¨

¨

4N67

¨

¨

¨

¨

¨

Brown Blue Orange Grey

L N Aux Aux In

HP22 (Heating)

13 N

¨

L N

PUMP

¨

123456789101112131415161718 LN

¨

¨

¨

NL3152 14

¨

¨

¨

¨

¨

¨

NL123456

RX2C

4N67

¨

¨

Brown Blue Orange Grey

L N Aux Aux In

HP22 (Heating)

¨

N11 109

¨

¨

¨

¨

NL1234

FP715Si

RX Channel Assignment

Channel 1 Heating Channel 2 Hot Water

Danfoss Randall can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss Randall reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequent changes being necessary

in specifi cations already agreed.

L N 12

¨

¨

¨

Perm N Sw.

L L

BOILER

¨

13 N

¨

¨

L N

PUMP

¨

Danfoss Randall Ltd.,

Ampthill Road,

Bedford, MK42 9ER

Tel: (01234) 364621 Fax: (01234) 219705

Email: danfossrandall@danfoss.com

Website: www.danfoss-randall.co.uk

8N67

¨

¨

Brown Blue Orange Grey

L N Aux Aux In

HP22 (Hot Water)

L N

¨

L N

MAINS SUPPLY

(Fuse 3A)

¨

¨

¨

¨

¨

4

Part No: 39917v07 12/08

Loading...

Loading...