Page 1

Installation Instructions

Wall Mount Plate

®

VLT

DriveMotor FCP 106

These installation instructions provide information on how to

mount the VLT

Only Danfoss authorized,

install this equipment. The personnel must be familiar with the

instructions and safety measures described in the

®

DriveMotor FCP 106 & FCM 106 Service Guide.

VLT

®

DriveMotor FCP 106 on a wall.

qualied

personnel is allowed to

Items Supplied

Wall mount plate

•

Accessory bag

•

- Motor plug

- Gasket

- Wall mount plug housing

- Wall mount plug housing gasket

- Wall mount cover for plug housing

- Screws

- Crimp terminals

-

134B0497 (1–2.5 mm

14], MH1

-

134B0498 (2.5–4 mm

12], MH2 and MH3

Enclosure size Ordering number

MH1 134B0341

MH2 134B0391

MH3 134B0441

Tab le 1.1 Ord er in g Nu mb er s, Wa ll Mou nt Pla te

2

) [AWG 17–

2

) [AWG 14–

Additional Items Required

- Crimp die for MH2, 600 V, 9 A, 14 AWG: TE

ordering number 539734-2.

- Crimp die for MH3, 600 V, 15.5 A, 12 AWG:

TE ordering number 539734-2

Safety Instructions

For important information about safety precautions for instal-

lation, refer to VLT

Instructions.

®

DriveMotor FCP 106/FCM 106 Operating

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors, which

can remain charged even when the frequency converter is

not powered. High voltage can be present even when the

warning LED indicator lights are o. Failure to wait the

specied time after power has been removed before

performing service or repair work can result in death or

serious injury.

Stop the motor.

•

Disconnect AC mains and remote DC-link power

•

supplies, including battery back-ups, UPS, and DClink connections to other frequency converters.

Disconnect or lock PM motor.

•

Wait for the capacitors to discharge fully. The

•

minimum duration of waiting time is specied in

Tabl e 1.2 .

Before performing any service or repair work, use

•

an appropriate voltage measuring device to make

sure that the capacitors are fully discharged.

FCP 106 frequency converter.

•

Motor cable, suitable for Type 4X.

•

Cable gland, suitable for Type 4X.

•

Grabber tool, TE ordering number 1-1579007-6.

•

- Gripper for all crimp contacts: TE ordering

number 539635-1.

- Crimp die for MH1, 600 V, 3.7 A, 16 AWG: TE

ordering number 539733-2.

Volt age

[V]

3x400 0.55–7.5 (0.75–10) 4

Tab le 1.2 Dis ch ar ge Time

1) Power ratings relate to normal overload, see VLT

106/FCM 106 Operating Instructions.

Danfoss A/S © 02/2016 All rights reserved. MI03P102

Power Range

[kW (hp)]

1)

Minimum waiting

time

(minutes)

®

DriveMotor FCP

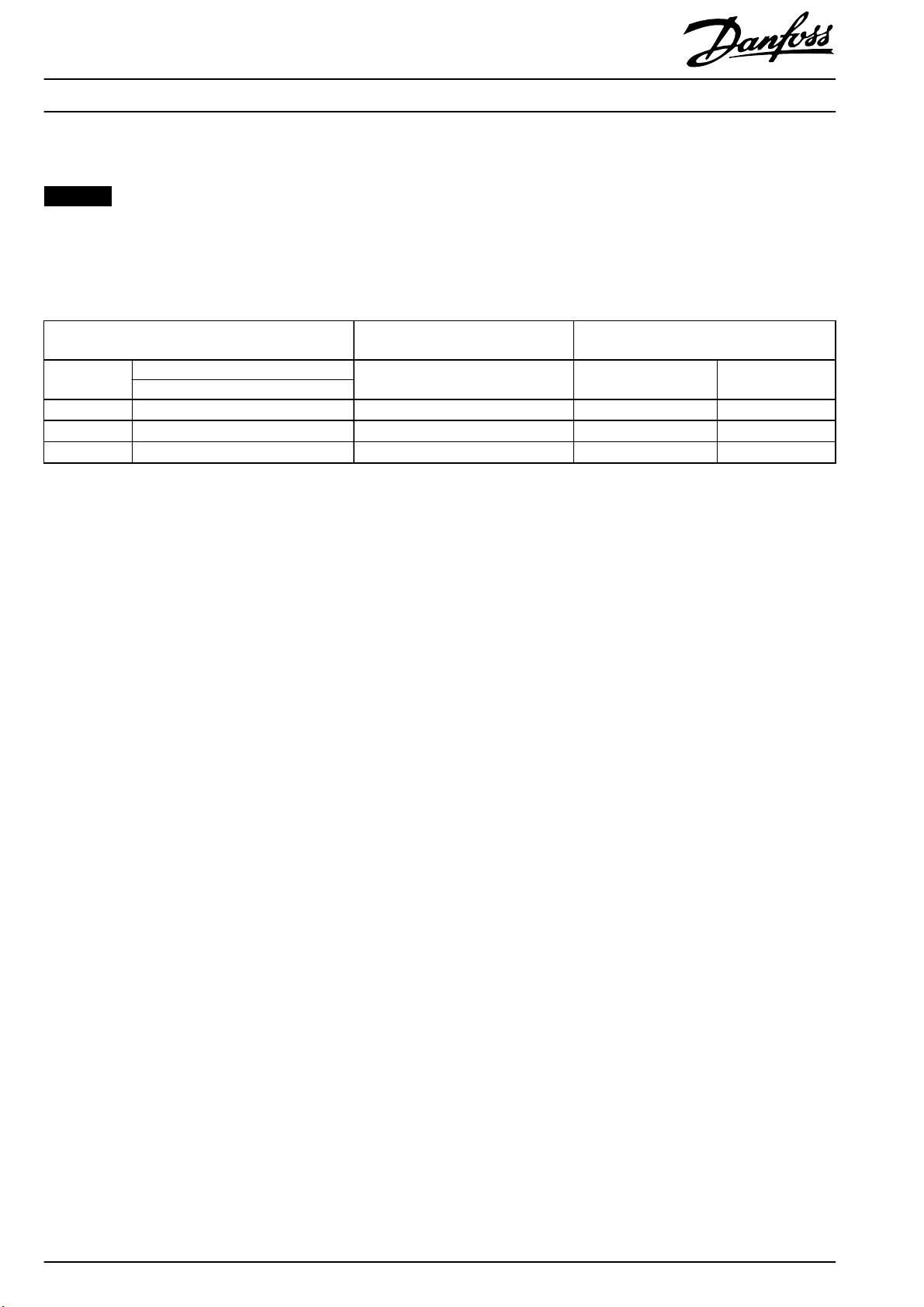

Page 2

Installation Instructions

Wall Mount Plate

®

DriveMotor FCP 106

VLT

Preparing for Wall Mounting

NOTICE

Improper mounting can result in overheating and reduced performance.

Cooling

To ensure

When air

sucient

ow

air

for the frequency converter, observe the minimum clearances listed in Table 1.3.

ow

is obstructed close to the frequency converter, ensure adequate inlet of cool air and exhaust of hot air from the unit.

Enclosure

Enclosure size Protection rating

FCP 106 with wall mount plate

MH1

MH2

MH3

Table 1.3 Minimum Clearance for Cooling

1) Power ratings relate to NO, see chapter Electrical Data in the VLT

2) The stated IP and Type rating only apply when the FCP 106 is mounted on a wall mount plate. When mounted on a wall mount plate, the standalone

frequency converter has enclosure rating IP00 and Open type.

IP66/Type 4X

IP66/Type 4X

IP66/Type 4X

2)

2)

2)

3x380–480 V Terminal end Cooling fan end

0.55–1.5 (0.75–2.0) 30 (1.2) 100 (4.0)

2.2–4.0 (3.0–5.0) 40 (1.6) 100 (4.0)

5.5–7.5 (7.5–10) 50 (2.0) 100 (4.0)

®

DriveMotor FCP 106/FCM 106 Design Guide.

Power

[kW (hp)]

1)

Clearance at ends

[mm (in)]

Lifting

To determine a safe lifting method, check the weight

•

of the unit, see chapter Specications in the VLT

®

DriveMotor FCP 106/FCM 106 Design Guide.

Ensure that the lifting device is suitable for the task.

•

If necessary, plan for a hoist, crane, or forklift with

•

the appropriate rating to move the unit.

For lifting, use the hoist rings on the unit, when

•

provided.

2

Danfoss A/S © 02/2016 All rights reser ved. MI03P102

Page 3

Installation Instructions

Wall Mount Plate

®

DriveMotor FCP 106

VLT

Mounting

1. Ensure that the strength of the mounting location

supports the unit weight. The frequency converter

allows side-by-side installation.

2. Locate the unit as near to the motor as possible.

Keep the motor cables as short as possible.

3. Use the slotted mounting holes on the unit for wall

mounting, when provided.

4. Crimp wires according to Illustration 1.1 to

Illustration 1.4.

Illustration 1.3 F-crimp - Insulation Securely Held, Crimp Barrel

Closed

1 Conductor present

2Insulation present

3 Bellmouth must always be present

4 Bellmouth allowed

5 Locking lances and terminal body not deformed

6 Cut-o tabs present

Illustration 1.1 Correct Selection of Wire, Terminal, and Applicator

1 Crimp barrel closed - legs support each other

2 Sucient gap between legs and bottom of crimp

Illustration 1.2 Correct Wire Crimp

Illustration 1.4 Overlap Crimp - Insulation Securely Held, Legs

overlap

MI03P102 Danfoss A/S © 02/2016 All rights reserved.

3

Page 4

1 Wall mount plate 8 Motor connector

2 Cover screws 9 Motor wires and crimp terminals

3 Plug housing cover 10 Motor thermistor wires

4Plug cover gasket 11PE wire

5 Plug housing 12 Motor cable

6 Plug housing screws 13 Cable gland

7 Motor connector gasket 14 Wall mount plate screws

Illustration 1.5 Exploded View

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on

order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective companies. Danfoss

and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

MI03P102130R0561 02/2016

*MI03P102*

Loading...

Loading...