Page 1

W895A

Proportional Grade/Steering Controller

BLN-95-8973-2 Issued: April 1996

DESCRIPTION

The W895A Proportional Rotary Position Controller is used to provide grade or steering

control of paving, trenching, curbing or similar construction machines. The Controller

uses a follower to sense the grade level or steering direction from a stringline or other

reference surface. When a grade or steering error is sensed, an electrical signal is

provided to the servovalve, such as the KVF, to reposition the machine.

The W895A consists of a microsyn transducer and an amplifier in a single housing.

Modular design with plug-in electrical interconnection allows easy component troubleshooting or replacement.

The W895A may be used with either a right angle stringline follower or a straight tubular

wand. The right angle follower is used for grade control with a stringline; when used with

a firm surface, a skate and ski assembly is attached to a grid arm follower. The straight

tubular wand is used for steering control.

FEATURES

• Easy to install

• Modular design with replacement modules

• Easy to service - single plug-in connector between modules

• May be mounted on either side of equipment

• Adjustable tracking force

• Rugged aluminum housing

• Operator can override with manual control

ORDERING INFORMATION

SPECIFY

1. Model Number W895A. See Table A.

2. Accessories

3. Spare Parts

TABLE A.

ORDER NUMBER DESCRIPTION

W895A1038 12 Vdc, Drives KVF

W895A1053 Without Amp

ACCESSORIES

Order the necessary parts from the list below. See the

following pages for part pictures.

1. KG07002 Steering Follower Wand

2. KG04003 Right Angle Grade Follower

3. K09274 Grid Arm

• Zero-center meter shows deviation from setpoint in RUN

or STANDBY operation

• Shock and vibration resistant

• Reverse polarity and short circuit protection

• Moisture and corrosion resistant

• Adjustable sensitivity

• Dithered output

5. KG06001 Skate Assembly (must be used with the

K09274 Grid Arm)

6. KVF Servovalve

7. ACX104C Rotary Position Sensor

8. KW01013 Cable (two-foot coiled cable that extends to

ten feet. Has right angle connector on one end and

straight connector on the other. Mates with the ten-pin

W895A Connector and an MS3102A18-1P plug (Part

Number K03989)).

9. KW01017 Cable (two-foot coiled cable that extends to

ten feet. Has straight connector on one end and spade

lugs on the other. Mates with the ten-pin W895A Connector and a terminal strip.)

10. KW01001 Cable (two-foot coiled cable that extends to

five feet. Has straight connector on one end and spade

lugs on the other. Mates with the five-pin W895A

Connector and a terminal strip)

4. KG02001 Ski Runner (must be used with the KG06001

Skate Assembly)

© Danfoss, 2013-09 BLN-95-8973-2 1

.

.

Page 2

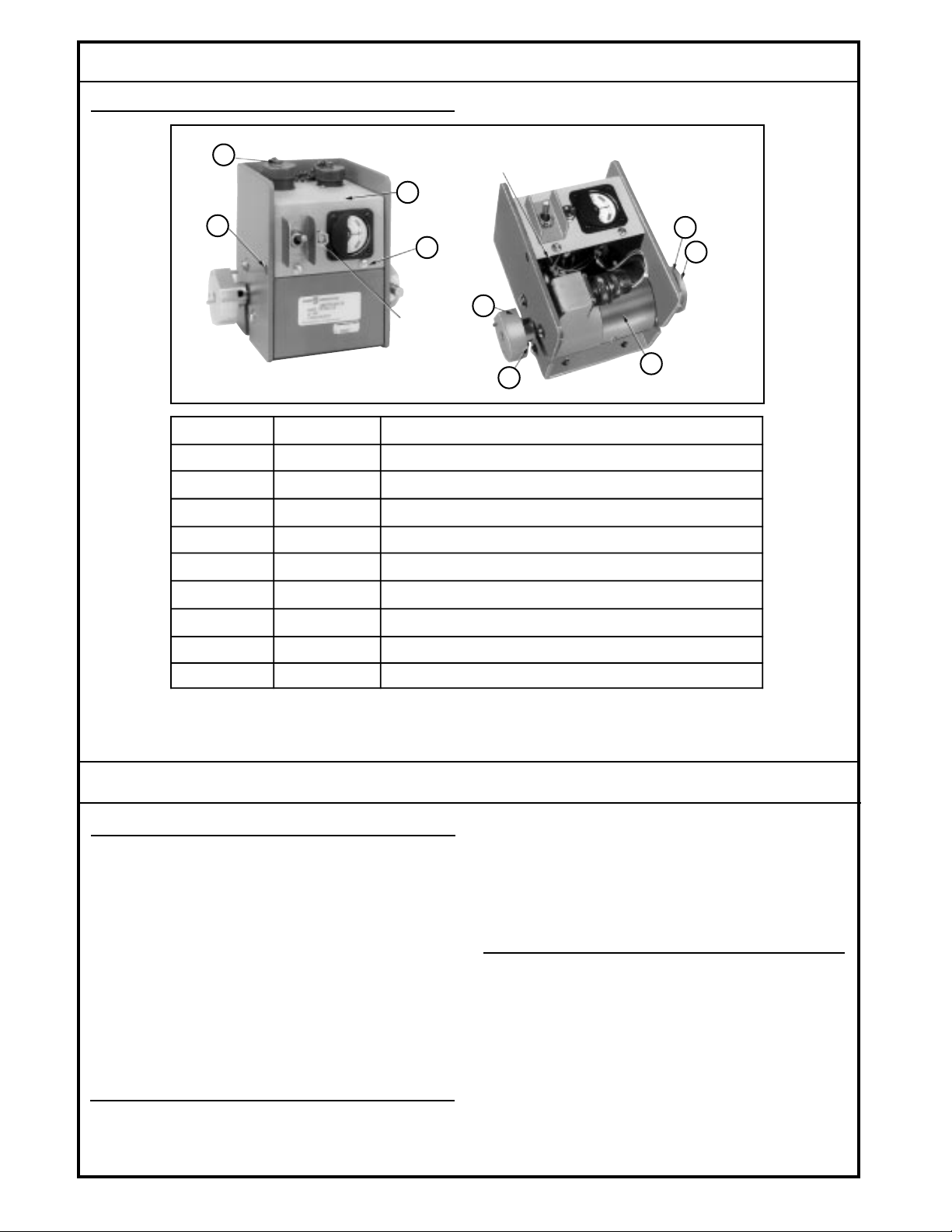

ORDERING INFORMATION

SPARE PARTS IDENTIFICATION

(continued)

4

1

3

GAIN

ADJUSTMENT

ITEM NUMBER PART NUMBER DESCRIPTION

1 K04463 Amplifier Module

2 † Cover Screw (2) 8-32, 1/2 inch

3 † Cover Retaining Bar Mounting Screw (2) Pan Head 8-32, 1/4 inch

4 † Cap and Chain Mounting Screw (2) Round Head 6-32, 5/16 inch

5 K03368 Spring Bias Assembly

6 K04232 Hub Assembly With Channel

GRADE/SLOPE

SWITCH

2

9

7

8

5

6

1181A

7 K04224 Transducer Including MS Connector

8 † Stop Screw, Fillister Head 10-32, 1/2 inch

9 K04228 Hub Assembly With Stop Pins

† Standard hardware items. Obtain locally. Only those parts listed by Part Number should be

ordered from Danfoss. Return the devices for repair if replacing individual parts is

insufficient.

TECHNICAL DATA

ELECTRICAL

INPUT VOLTAGE

11 to 15 Vdc

RATED OUTPUT VOLTAGE

5.8 Vdc (12 Vdc input, 32 ohm, .5 henry load)

GAIN

(with six-inch right angle follower at 45° trailing angle)

1. At minimum gain (full counter-clockwise) no output

voltage for any error input.

2. At maximum gain (full clockwise) .09 inches vertical

deviation yields full drive current to the KVF

Servovalve.

MECHANICAL

SHAFT TORQUE

6.0 inch-grams within 5° of null

NULL

Electrical null is located with the flat edge of the hub at

90 ± 5° from the back (mounting stud) side of the case.

ENVIRONMENTAL

TEMPERATURE RANGE

-40° to 77° C (-40° to 170° F) storage

0° to 77° C (32° to 170° F) operating

SHOCK

50 g for 11 milliseconds. Three shocks in both directions

of the three mutually perpendicular axes for a total of 18

shocks.

SHAFT ROTATION

± 20°

2

BLN-95-8973-2

Page 3

TECHNICAL DATA

(continued)

VIBRATION

Withstands a vibration test designed for mobile equipment controls consisting of two parts:

1. Cycling from 5 to 2000 Hz in each of the three axes.

2. Resonance dwell for one million cycles for each

resonance point in each of the three axes.

Run from 1 g to 46 g's. Acceleration level varies with frequency.

HUMIDITY

After being placed in a controlled atmosphere of 95%

humidity at 49° C (120° F) for 10 days, the sensor will

perform within specification limits.

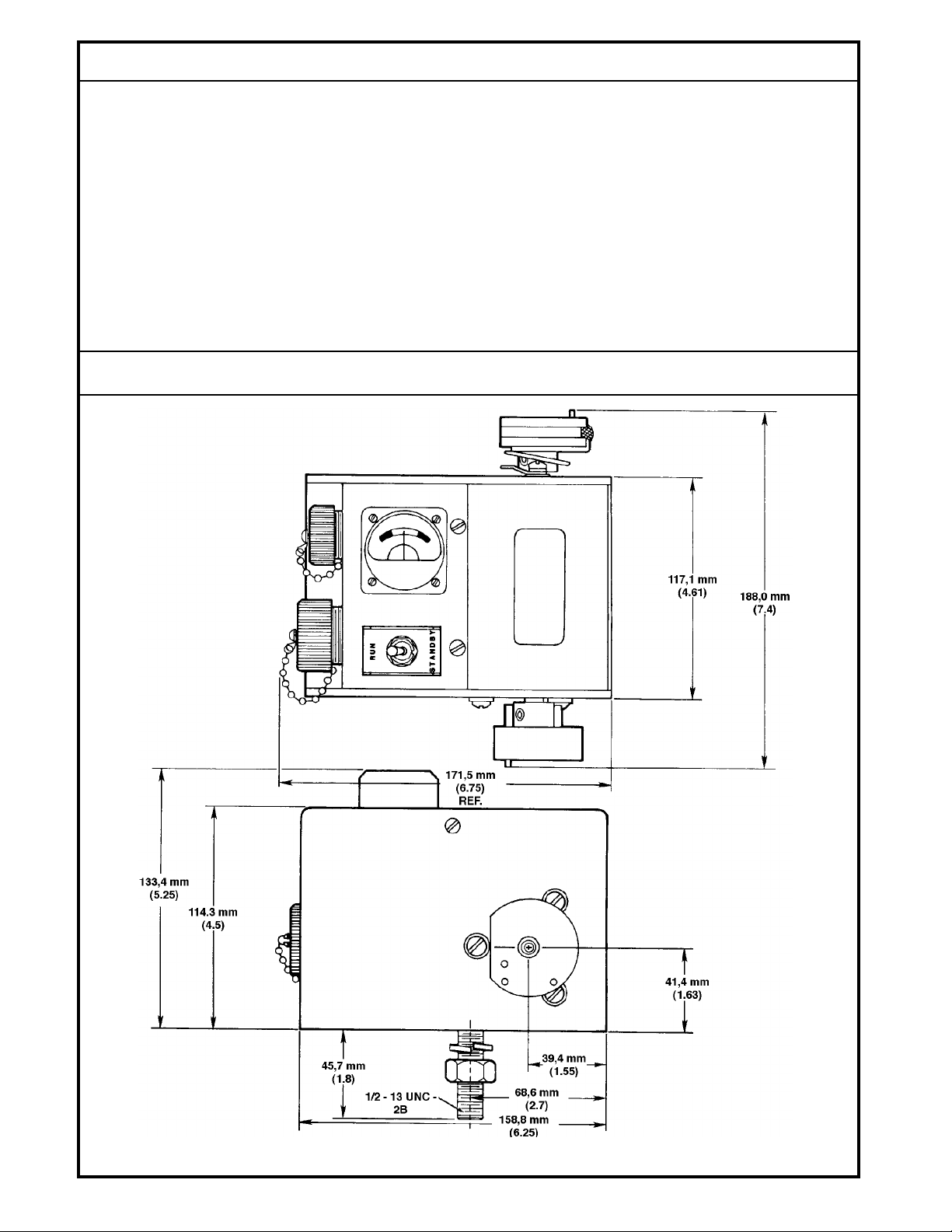

DIMENSIONS

DUST

After being placed in a controlled atmosphere of dust

simulating outdoor conditions for 24 hours, the W895A will

perform within specification limits.

WEIGHT

3.2 kg (7 lbs.)

DIMENSIONS

See Dimension Drawing.

Dimensions of the W895A in Millimeters (Inches).

3

1174

BLN-95-8973-2

Page 4

THEORY OF OPERATION

The amplifying section of the W895A supplies an excitation

of 0.7 Vac (440 Hz square wave) across Pins A and B of the

W895A’s internal MS connector to the transducer. See the

Block Diagram. As the command signal from the stringline or

reference surface moves up/down (grade) or in/out (steering), the W895A’s follower is moved, resulting in rotation of its

shaft. As the rotor moves toward one secondary and away

from the other, the voltage induced in the coil toward the rotor

is increased, the opposite being true of the other secondary.

At the full 20° of travel, the voltage across the secondary

closer to the rotor is 2.3 Vac, while the other voltage is 1.7

Vac.

The ac signals from the secondaries are applied to two bridge

rectifiers in the amplifying section, where each is converted

to dc. At null the voltages across both capacitors are equal.

CONNECTION DIAGRAM

When a change in secondary voltage is introduced, the

voltages across the capacitors are offset, inducing a differential between the reference and lead between the capacitors.

This differential serves as the positive or negative correction

signal that is amplified and then supplied to the servovalves

to close the control loop. Control action drives the machine

to a position such that the sensor error signal to the amplifying section is reduced to null.

Typical Grade Hookup for the W895A Rotary Position Controller.

4

954F

BLN-95-8973-2

Page 5

BLOCK DIAGRAM

Schematic of the Transducer and Amplifier Sections of the W895A.

MOUNTING

The W895A can be mounted on either side of the machine

and in any orientation, depending upon the location of the

grade or steering reference. With the W895A at null and a

follower equivalent to a six-inch radius arm attached to the

sensor at a 45° angle down as referenced to the top surface

of the sensor, the null touch point of the follower will be

approximately 5.5 inches below the center line of the mounting bolt. Figure 1 illustrates the dimension. When the arm is

at a 45° angle up, the touch point is approximately 3.25 inches

above the mounting stud. The follower may also be attached

so that it is parallel to the top surface of the W895A.

Once the mounting location is determined, drill a 14 mm

(9/16-inch) clearance hole for the mounting bolt. Remove the

nut and lockwasher from the mounting bolt through the

clearance hole. Replace the lockwasher and nut and tighten

the nut firmly.

NOTE: W895A must be mounted with connectors up.

1175

The follower may be attached to either hub of the W895A.

The KG04003 Right Angle Grade Follower adapts to almost

any grade application. The attachment can follow a stringline

at a 45° angle above or below the W895A, or it can follow the

stringline horizontally. Figure 2 exhibits one possible way of

attaching the Right Angle Grade Follower. Note the direction

of travel for each.

RIGHT

HUB

Figure 1. Relative Distance to Stringline.

1176

TRAVEL

BREAKAWAY

JOINT

STRINGLINE

Figure 2. Right Angle Grade Follower at Horizontal

Trailing or Leading.

5

1948

BLN-95-8973-2

Page 6

MOUNTING

(continued)

Guide holes on the KG07002 Steering Follower are identified

in Figure 3. This follower may also be attached to either hub

of the W895A. Unlike the Right Angle Grade Follower, it is

mounted vertically for steering applications. See Figure 4.

BREAKAWAY JOINT

STEERING

LEFT HUB

GRADE

RIGHT

1

HUB

THE RIGHT HUB IS DEFINED AS THE ONE WITH

1

THE SPRING BIAS ADJUSTMENT THUMBSCREW

STEERING

RIGHT HUB

LEFT

HUB

1

952B

Figure 3. Guide Hole Identification for the KG07001

Steering Follower.

Other followers include a ski and skate that attach to the

K09274 Grid Arm; Figure 5 shows the ski and a skate

assembly. These followers are used to follow hard reference

surfaces for grade applications. See the Ordering Information for Part Numbers.

After the follower has been installed, adjust the spring bias

adjustment on the right hub so that the follower exerts a slight

tension on the stringline at null. The bias setting controls both

the left and right hub. Note that when the flat of the hub is

parallel to the top surface of the case, the W895A is at null.

RIGHT

HUB

TRAVEL

RIGHT

HUB

1950

Figure 5. Skate and Ski Assembly.

1949

Figure 4. Typical Steering Application. Shaft of the

W895A Must Run Parallel to the Stringline.

6

BLN-95-8973-2

Page 7

WIRING

When used in grade applications, all wiring connections are

made through the larger ten-pin MS connector on the top of

the W895A. It mates with cable number KW01013 as shown

in Connection Diagram. An MS3102A18-1P (Part Number

K03989) connector mates at the other end of this cable to

terminate at the junction board. Another cable, the KW01017,

needs no MS connector interface.

START-UP PROCEDURE

1. Place the RUN/STANDBY switch in the STANDBY

position and energize the electrical system.

2. With the equipment at the correct grade or steering

position, adjust the position of the W895A until the

deviation meter nulls. Lock in position.

3. Adjust the gain potentiometer. Turn the gain potentiometer, located in the face of the W895A, fully clockwise.

Place a nickel between the grade reference surface and

the follower. Adjust the gain potentiometer until the

deviation meter deflects to the red/white division. For

some applications, it may be advantageous to increase

or decrease the gain. Turning the adjustment screw

clockwise will increase the gain, and vice-versa. If the

system oscillates, the gain is too high. If the system is

sluggish and slow to respond, the gain is too low.

If the steering controller is remote from the steering mechanism, electric sensing or steering post position is necessary.

The smaller five-pin connector makes connection to the

steering feedback transducer. The larger ten-pin connector

is used for voltage input and servovalve connections. If the

W895A is attached to the steering mechanism (mechanical

feedback), only the ten-pin connector is used. A KW01001

cable mates with the five-pin connector and terminates in

spade lugs at a junction board. The electrical feedback is

provided by the ACX104C Potentiometer Transducer.

TROUBLESHOOTING

When preliminary investigation of a system malfunction

indicates trouble in the W895A, the following facts should be

kept in mind to determine the specific malfunction:

1. The deviation meter will indicate deviations in grade or

steering whenever power is supplied to the W895A,

regardless of the RUN/STANDBY switch position.

2. In the RUN mode, the amplifier output is connected to

the servovalve. In the STANDBY mode, the amplifier is

not connected to the servovalve.

3. If the gain adjustment on the front panel is turned fully

counter-clockwise (i.e., minimum gain), the position of

the follower will not affect the amplifier or servovalve.

The unit is effectively shut off.

4. Preliminary checks should include examination of the

cables and leads for damaged or broken wires. Examine areas where shorting may occur, and check the

power supply to be sure it is greater than 11 Vdc.

TROUBLESHOOTING PROCEDURE

1. With the W895A turned off, check to see if the meter

operates as the follower is slightly raised or lowered.

Raising or lowering the follower approximately the thickness of a nickel should deflect the indicator to the red/

white division on the meter when the gain potentiometer

is at full clockwise rotation.

2. If the meter operates correctly, check for power output at

the servovalve with the RUN/STANDBY switch in RUN

position. Raising or lowering the follower should cause

a voltage change to about 6 volts before the follower

reaches the stop.

3. If the meter of the W895A does not operate, recheck the

cable for damage or breaks. Replace cables that show

damage. Cables that have been badly pinched or kinked

may have shorted or broken leads.

5. A SLOPE/GRADE switch located on the printed circuit

board of the amplifier module must always be in the

GRADE position if connector Pins C and D are the valve

connections.

4. Check the power supply to be sure that voltage is more

than 11 Vdc. If the voltage supply is adequate, check

voltage at the W895A’s larger connector between Pins

A (-) and B (+) to be sure that cable wiring is not broken

(see Pin Identification Drawing).

5. If power is available, unplug the large connector and

check the meter by momentarily placing 12 Vdc across

Pins C and D on the W895A’s larger connector. The

meter should deflect fully to one side. Reverse polarity

and the meter should deflect to the other side. Be sure

the RUN/STANDBY switch is in the RUN position. If the

meter does not respond when 12 Vdc is applied to Pins

C and D, apply 12 Vdc to Pins E and F. If the meter

responds, the internal SLOPE/GRADE switch (see

Spare Parts Identification Drawing) is in the SLOPE

position and should be switched. If the meter does not

operate, replace the amplifier.

7

BLN-95-8973-2

Page 8

TROUBLESHOOTING PROCEDURE

(continued)

6. If power is available at the W895A and the meter

operates correctly, remove the cover and check the

wiring of the transducer (see Connection Diagram) for

continuity. Remove the plug from the socket on the

transducer so that the pins are accessible. A circuit

should be complete between Pins A and B, C and D, and

E and F on the transducer. There should be approximately 5 ohms between A and B, and 160 ohms between

C and D or E and F (see Pin Identification Drawing). The

circuit should be open between Pins A and F, A and D,

and D and F, as well as between each pin and ground.

If the transducer wiring has a short or break, the transducer should be replaced. If the transducer wiring is not

shorted or broken and the W895A does not function,

replace the amplifier.

C

D

B

A

F

E

JI

D

C

E

G

H

A

B

KEY

A

F

B

C

D

E

1180

Pin Identification for Large Connector On Top of W895A

(Ten-Pin), Small Connector On Top of W895A (Five-Pin)

and Transducer Connector. The Socket Connector

Leads are a Mirror Image of the Pin Identification (Lettered Counter-clockwise).

CUSTOMER SERVICE

NORTH AMERICA

ORDER FROM

Danfoss (US) Company

Customer Service Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

Phone: (763) 509-2084

Fax: (763) 559-0108

DEVICE REPAIR

For devices in need of repair or evaluation, include a

description of the problem and what work you believe

needs to be done, along with your name, address and

telephone number.

RETURN TO

Danfoss (US) Company

Return Goods Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

EUROPE

ORDER FROM

Danfoss (Neumünster) GmbH & Co.

Order Entry Department

Krokamp 35

Postfach 2460

D-24531 Neumünster

Germany

Phone: 49-4321-8710

Fax: 49-4321-871-184

8

BLN-95-8973-2

Loading...

Loading...