Page 1

DESCRIPTION

The W894A Proportional Level Controller provides automatic slope control of paving, curbing, grading and similar

mobile equipment. The Controller measures deviation from

a gravity reference and supplies a two-wire output for driving

a servovalve such as the MCV113. The W894A operates in

12 Volt electrical systems.

Two modules are housed in the case of the Controller with

plug-in electrical interconnections. The transducer sensing

module electromagnetically measures the deviation of the

equipment it is mounted on from a gravity reference. The

amplifier module accepts the signals from the slope sensing

module and uses the deviation to provide a corrective output

to keep the equipment at the prescribed slope.

FEATURES

W894A

Proportional Level Controller

BLN-95-8974-5 Issued: March 1992

• Rugged aluminum housing

• Adjustable sensitivity

• RUN/STANDBY switch permits operator to switch to

manual control

• Deviation meter with zero center shows deviation from

setpoint in RUN or STANDBY positions

ORDERING INFORMATION

SPECIFY

1. Model Number W894A. See Table A.

2. Accessories

TABLE A.

ORDER NUMBER DESCRIPTION

W894A1053 12Vdc, Drives MCV113

Hot Side Switching

• Reverse polarity and short circuit protection

• Moisture and corrosion resistant

• Accepts a remote slope setpoint adjuster

• Withstands vibration and shock

ACCESSORIES

Order the necessary parts from the list below:

1. MCV113 Servovalve

2. Q625A Remote Setpoint (hand-held setpoint with integral coiled cord and MS connector).

3. Q625A Remote Setpoint (panel-mount setpoint with terminal strip).

4. KW01001 Cable (two-foot coiled cable that extends to

ten feet. Has straight connector on one end and spade

lugs on the other. Mates with the five-pin W894A connector and the panel-mount Q625A Remote Setpoint)

5. KW01013 Cable (two-foot coiled cable that extends to

ten feet. Has right angle connector on one end and

straight connector on the other. Mates with the ten-pin

W894A connector and an MS3102A18-1P plug).

6. KW01012 Cable (four-foot coiled cable that extends to

twenty feet. Has right angle connector on one end and

straight connector on the other. Mates with the ten-pin

W894A connector and an MS3102A18-1P plug).

© Danfoss, 2013-09 BLN-95-8974-5 1

Page 2

TECHNICAL DATA

ELECTRICAL

INPUT VOLTAGE

11 to 15 Vdc

OUTPUT VOLTAGE

5.4 to 6.2 Vdc with a 12 Vdc input into a 32 ohm load. A

null meter reading at the red/white division indicates a 3

Vdc output.

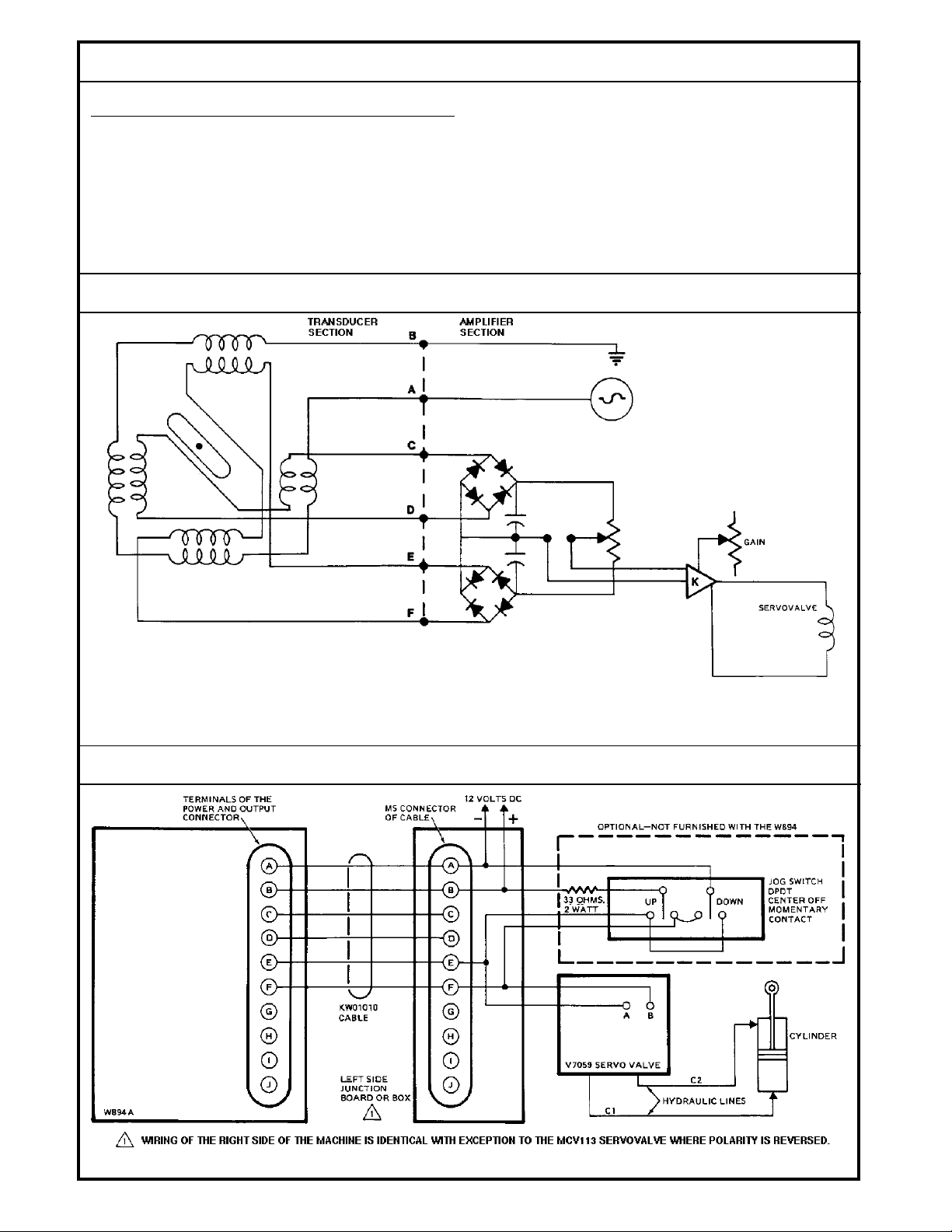

BLOCK DIAGRAM

POWER CONSUMPTION

4.5 watts maximum

PROPORTIONAL GAIN

With gain potentiometer set to maximum, gain will be 1.7

to 2.7 Vdc per 0.3% slope error input.

Schematic of Transducer and Amplifier Sections of the W894A.

CONNECTION DIAGRAM

1183

BLN-95-8974-5

Typical System Connections.

2

206C

Page 3

DIMENSIONS

1182

Dimensions of the W894A in Millimeters (Inches).

THEORY OF OPERATION

The amplifier section of the W894A supplies an excitation of

1.4 V-ac (440 Hz square wave) across Pins A and B of the

W894A’s internal MS connector to the transducer. See the

Block Diagram. As the machine is tilted off the proper slope,

the rotor rotates with respect to the secondary coils. As the

rotor moves toward one secondary and away from the other,

the voltage induced in the coil toward the rotor is increased,

the opposite being true of the other secondary. At the full

10%-from-null slope (the rated maximum range), the voltage

across the secondary closer to the rotor is 5.3 V-ac, while the

other voltage is 4.2 V-ac.

ENVIRONMENTAL

OPERATING TEMPERATURE

-18° to 77° C (0° to 170° F)

STORAGE TEMPERATURE

-40° to 77° C (-40° to 170° F)

HUMIDITY

After being placed in a controlled atmosphere of 95%

humidity at 49° C (120° F) for 10 days, the W894A will

perform within specification limits.

RAIN

After being showered from all directions by a high

pressure hose down, the W894A will perform within

specification limits. This test fulfills NEMA 4 specifications.

The ac signals from the secondaries are applied to two

bridge rectifiers in the amplifier section, where each is

converted to dc. At null the voltages across both capacitors

are equal. When a change in secondary voltage is introduced, the voltages across the capacitors are offset,

inducing a differential between the reference (which may be

a remote setpoint command) and the junction between the

capacitors. This differential serves as the positive or negative correction signal that is amplified and then supplied to

the servovalves to close the control loop. Control action

drives the machine to a position such that the sensor error

signal to the amplifier section is reduced to null.

VIBRATION

Withstands a vibration test designed for mobile equipment consisting of two parts:

1. Cycling from 5 to 2000 Hz in each of the 3 axes.

2. Resonance dwell for one million cycles for each

resonance point in each of the 3 axes.

SHOCK

50 g's for 11 milliseconds. Three shocks in both directions of the 3 mutually perpendicular axes for a total of

18 shocks.

WEIGHT

3.4 Kg (7 pounds, 8 ounces)

DIMENSIONS

See the Dimension Drawing.

3

BLN-95-8974-5

Page 4

CUSTOMER SERVICE

NORTH AMERICA

ORDER FROM

Danfoss (US) Company

Customer Service Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

Phone: (763) 509-2084

Fax: (763) 559-0108

DEVICE REPAIR

For devices in need of repair or evaluation, include a

description of the problem and what work you believe

needs to be done, along with your name, address and

telephone number.

RETURN TO

Danfoss (US) Company

Return Goods Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

EUROPE

ORDER FROM

Danfoss (Neumünster) GmbH & Co.

Order Entry Department

Krokamp 35

Postfach 2460

D-24531 Neumünster

Germany

Phone: 49-4321-8710

Fax: 49-4321-871-184

4

BLN-95-8974-5

Loading...

Loading...