Page 1

Data sheet

VZL valve - 2/3/4-way

Description

Stem

extension

plug

VZL 4VZL 3VZL 2

Ordering

VZL valves provide a high quality, cost effective

solution for the control of hot and/or chilled

water for fan coil units, small reheaters, and

recoolers in temperature control systems.

The valves are used in combination with:

- AMV(E) 130(H)/140(H) ABNM A5 with

extension plug;

- AMV(E) 13 (SU) and TWA-ZL actuators.

Note:

TWA-ZL thermal a ctuator does not close po rt B.

In case that stem e xtension plug is not used tog ether with AMV(E)

130(H)/140(H) dea d zone in valve close position wil l occur.

2-way valve VZL 2

Picture

DN k

(mm) (m3/h) (bar) Flat End Conex

15

20

VS

0.25 2.5 065Z2070 065Z2040

0.4 2.5 065Z2071 065Z2041

0.63 2.5 065Z2072 065Z2042

1.0 2.0 065Z2073 065Z2043

1.6 2.0 065Z2074 065Z2044

2.5 1.0 065Z2075 065Z2045

3.5 1.0 065Z2076 065Z2046

Main data:

• DN 15, 20

• kVS 0.25-3.5 m3/h

• PN 16

• Temperature:

- Circ. water / glycolic water up to 50 %:

2 … 120 °C

• Reduced kVS on B port (VZL 3 & VZL 4 only)

• Linear characteristic

• Linear bypass on 3 and 4 port valves

• Valves are supplied with screwed plastic

cover for manual operation

• Connections: flat end or conex

• Water quality acc. to VDI 2035 requirements

max. ∆p Code No.

3-way valve VZL 3

Picture

DN

(mm)

15

20

kVS (A - AB) kVS (B - AB)

m3/h

0.25 0.25 2.5 065Z2080

0.4 0. 25 2.5 065Z2081

0.63 0.40 2.5 065Z20 82

1.0 0.63 2.0 065Z2083

1.6 1.0 2.0 065Z 2084

2.5 1.6 1. 0 065Z2085

3.5 2.5 1.0 065Z2086

max. ∆p Code No.

(bar) Flat End

© Danfoss | 2021.11 AI191686478067en-011002 | 1

Page 2

Data sheet VZL valve

Ordering (continued)

Technical data

4-way valve VZL 4

Picture

DN

(mm)

15

20

k

(A - AB) k

VS

0.25 0.25 2.5 065Z2090 065Z2060

0.4 0.25 2.5 065Z2091 065Z2061

0.63 0.4 2.5 065Z2092 065Z2062

1.0 0.63 2.0 065Z 2093 065Z2063

1.6 1.0 2.0 065Z2094 065Z2064

2.5 1.6 1.0 065Z2095 065Z2065

3.5 2.5 1.0 065Z2096 065Z2066

m3/h

(B - AB)

VS

max. Δp

(bar)

Code No.

Flat End Conex

Accessories

Typ e Pipe size DN Description Code No.

Tailpieces with

external thread

Tailpieces for

soldering

Stuffing box 065F0006

Spindle ex tension adapter, 2 mm (5 pieces) 003Z0249

Control characteristic Linear

Control range min. 30:1

Leakage loss, closed valve

Medium Circulation water / Glycolic water up to 50 %

Medium temperature °C 2 … 120

Max. operating pressure bar 16

Stroke mm 2.8

Connection External thread (flat connection (MS 58) or conex)

Materials

Body Brass CuZn40Pb2

Seat cone and stem Brass CuZn39Pb3

Stuffing box EPDM

R /” 15

R ½” 20 003H6902

12 m m 15

15 mm 20 06 5Z7017

Consist of 2 union nuts,

2 tailpieces and 2 gaskets (Ms 58)

Consist of 2 union nuts, 2 solder bushes

and 2 gaskets (Ms 58)

A - AB ≤ 0.05 % of k

B - AB ≤ 1 % of k

VS

VS

065Z7015

065 Z7016

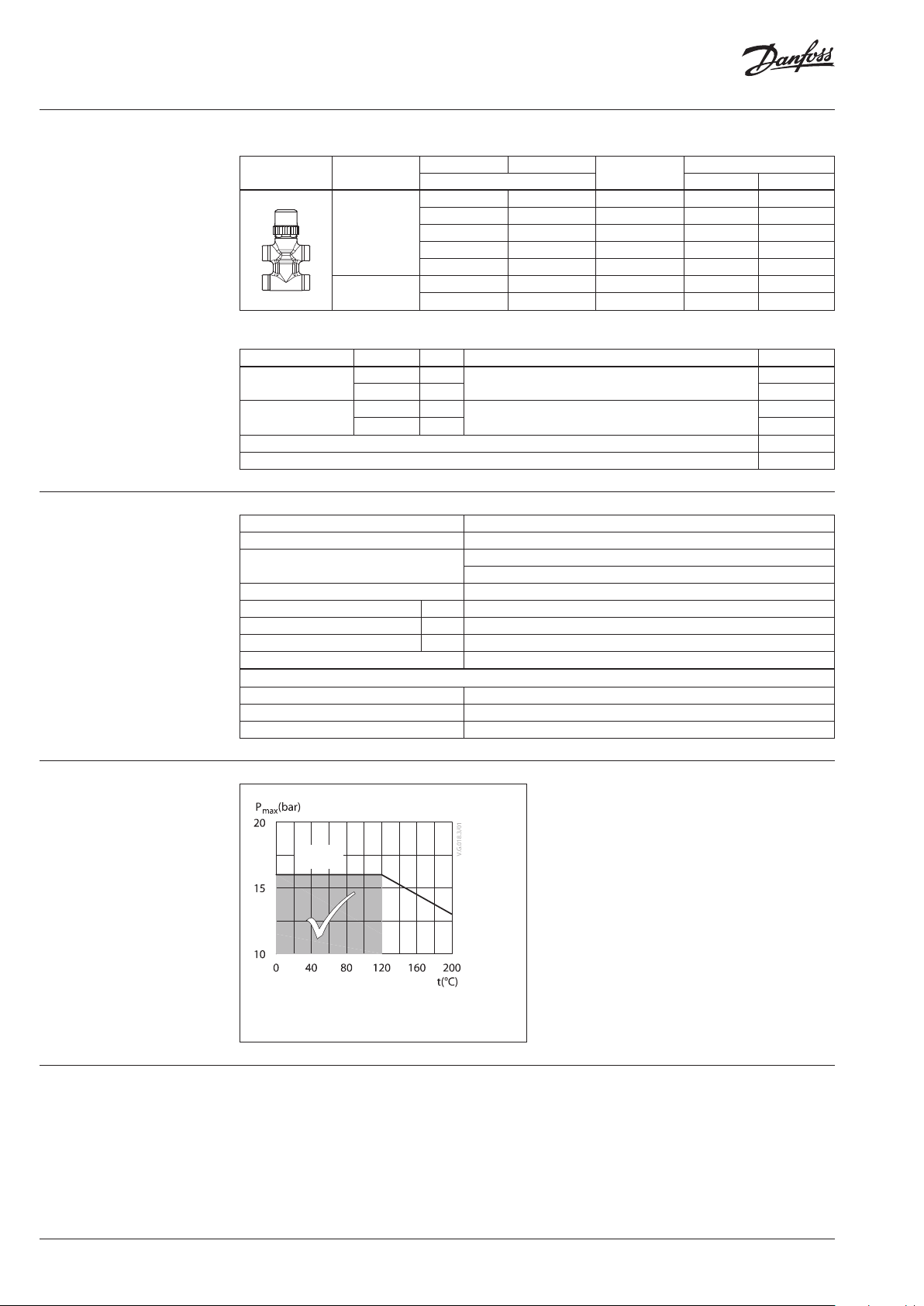

Pressure temperature

diagram

Disposal

PN 16

CuZn4 0Pb2

Maximum allowed operating pressure as a function of

medium temperature (according to EN1092-3)

The valve must be dismantled and the elements

sorted into various material groups before

disposal.

2 | AI191686478067en-011002 © Danfoss | 2021.11

Page 3

Data sheet VZL valve

Installation

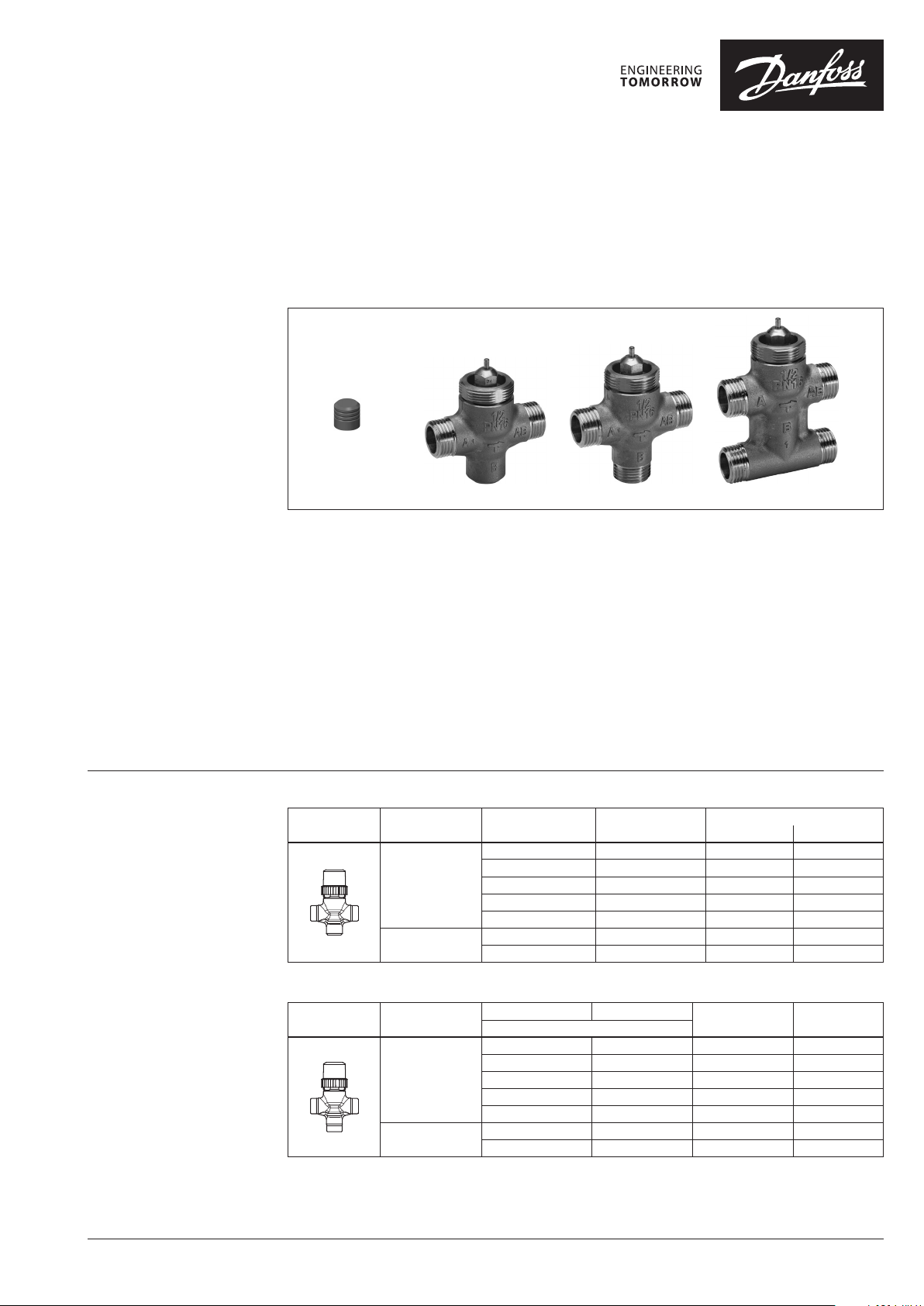

AMV(E) 130/140,

AMV(E) 130H/140H

AMV(E) 13 (SU)

Valve mounting

Before valve mounting the pipes have to be

cleaned and free from abrasion. Valve must

be mounted according to flow direction as

indicated on valve body. Mechanical loads of the

valve body caused by the pipes are not allowed.

Valve should be free of vibrations as well.

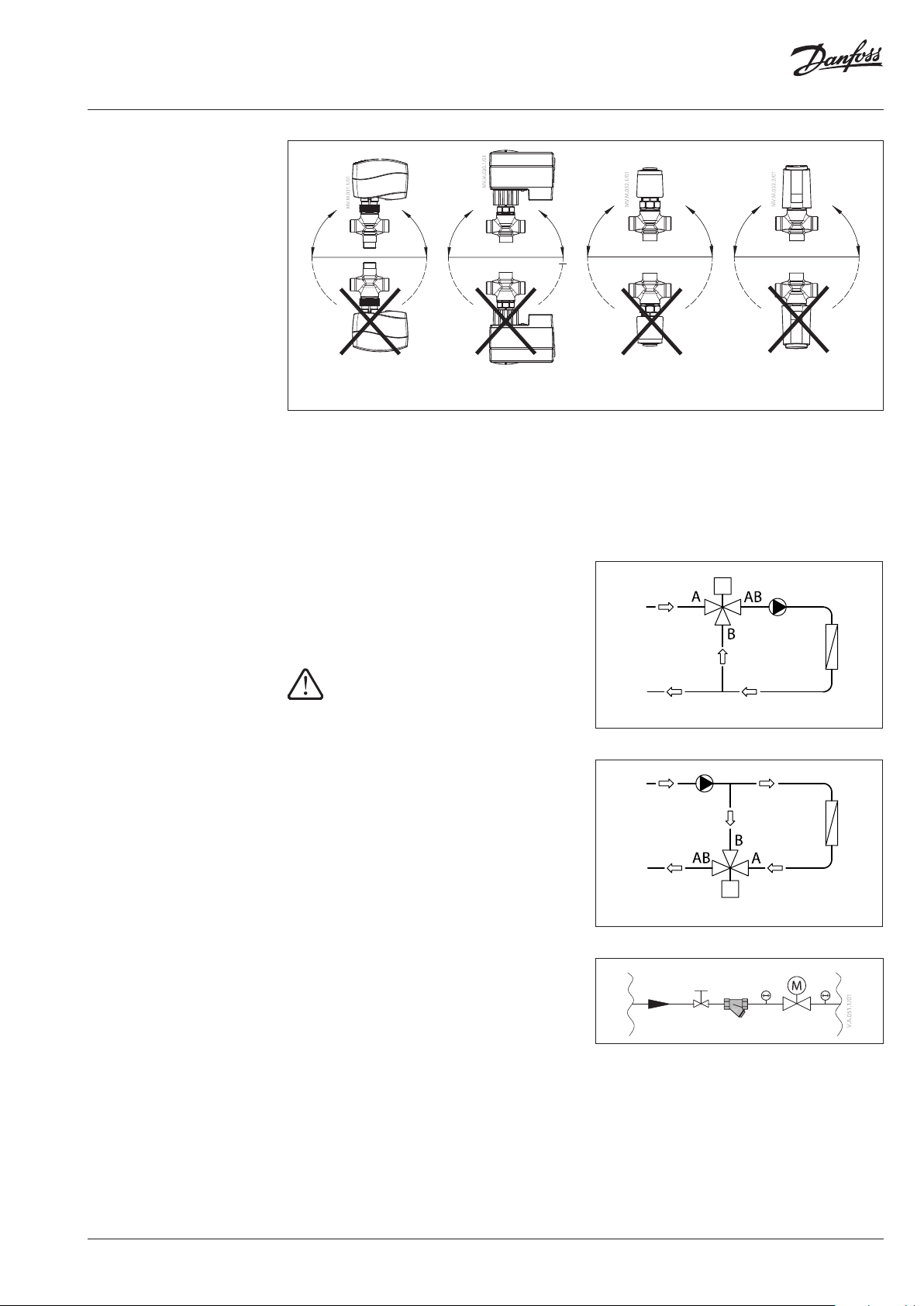

Application schemes for 3-way and 4-way

mixing valves

3-way and 4-way valves are mixing valves

meaning that A and B ports are inlet ports, and

AB port is outlet port (f ig. 1). In case valve should

be used as diverting valve it is a solution to install

valve in return pipe (f ig. 2).

To prevent damages, starting max. p must not

exceed 1 bar for DN 20 and 2/2.5 bar for DN 15,

when installing the valve.

TWA -ZL ABNM-A5

Installation of the valve with the actuator is

allowed in horizontal position or upwards.

Installation downwards is not allowed.

Fig. 1 Mixing valve used in mixing application

Note:

Install a strainer upstream of the valve

(e.g. Dan foss FVR/FV F)

Fig. 2 Mixing valve used in diverting application

AMV(E)

FVR/FVF

AI191686478067en-011002 | 3© Danfoss | 2021.11

Page 4

Data sheet VZL valve

Sizing

Example

Design data:

Flow rate: 0.3 m3/h

System pressure drop: 20 kPa

Locate the horizontal line representing a flow

rate of 0.3 m3/h (line A). The valve authority is

given by the equation:

ΔP

1

N authority, Valve

ΔPΔP

21

Where:

P1 = pressure drop across the fully open valve,

P2 = pressure drop across the rest of the circuit

with a fully open valve

The ideal valve would give a pressure drop equal

to the system pressure drop (i.e. an authority

of 0.5):

If P1 = P2,

ΔP

1

N

=

ΔPΔP

+

5.0

=

21

In this example an authority of 0.5 would be

given by a valve having a pressure drop of

20 kPa at that flow rate (point B).

The intersection of line A with a vertical line

drawn from B lies between two diagonal lines;

this means that no ideally-sized valve is available.

The intersection of line A with the diagonal

lines gives the pressure drops stated by real,

rather than ideal, valves. In this case, a valve with

kVS0.63 would give a pressure drop of 25 kPa

(point C):

authority valve hence

25

0.56

0252

The second-largerst valve, with kVS 1, would give

a pressure drop of 9 kPa (point D):

authority valve hence

9

0.31

0 29

Generally, for a 3 port application, the smaller

valve would be selected (resulting in a valve

authority higher than 0.5, and therefore

improved controllability). However, this will

increase the total pressure and should be

checked by the system designer for compatibility

with available pump head, etc.

The ideal authority is 0.5 with a preferred range

of between 0.4 and 0.7.

Design

to close

A AB

VZL 2 (2 Port)

A

to close A - AB

AB

B

to close A - AB

A AB

B B

VZL 4 (4 Port)VZL 3 (3 Port)

4 | AI191686478067en-011002 © Danfoss | 2021.11

Page 5

Data sheet VZL valve

Dimensions

92

Hh

d

L

AMV(E) 130/140 + VZL 2

+ stem extension plug

92

1

h

c

Hh

AMV(E) 130/140 + VZL 3

+ stem extension plug

121

4.7

Ø5

Stem extension

plug

92

d

L

92

Hh

L

AMV(E) 130/140 + VZL 4

+ stem extension plug

40.5

d

44 .1

1

H

L

AMV(E) 130H/140H + VZL

+ stem extension plug

Valve t ype d

VZL 2 DN 15 G ½” 65 111 117 140 88 93.5

VZL 2 DN 20* G ¾” 77 117 123 146 94 99.5 34.0 0. 47

VZL 3 DN 15 G ½” 65 111 117 140 88 93.5 35.0 0.28

VZL 3 DN 20 G ¾” 77 117 12 3 146 94 99.5 35.0 0.40

VZL 4 DN 15 G ½” 65 111 117 140 88 93.5 40 51.0 0. 39

VZL 4 DN 20* G ¾” 77 117 123 14 6 94 9 9.5 50 65.0 0.59

* conex valves DN 20 - G 1¹/₈” 14 TPI

Tailpieces for soldering

Ød L

G

½” 12 15 0 .11

¾” 15 20 0.17

mm

Weight

2

H

L

AMV(E) 13 SU + VZL

L H H1H2H3H4c h h

mm

3

H

TWA-ZL + VZL

L

-

Tailpieces with external thread

R L Weight

(kg)

G

L

G

Ød

(“) (mm) (kg)

½” ⁄ 23 0 .11

¾” ½ 26 0.17

29.5

4

H

ABNM A5 + VZL

+ stem extension plug

Valve weight

1

(kg)

0.27

47. 5

G

L

R

L

AI191686478067en-011002 | 5© Danfoss | 2021.11

Page 6

Data sheet VZL valve

6 | AI191686478067en-011002 © Danfoss | 2021.11

Page 7

Data sheet VZL valve

AI191686478067en-011002 | 7© Danfoss | 2021.11

Page 8

Data sheet VZL valve

© Danfoss | DCS-SGDPT/SI | 2021.118 | AI191686478067en-011002

Loading...

Loading...