Page 1

Application guidelines

Danfoss scroll compressors

VZH088-117-170

Single

R410A

www.danfoss.com

Page 2

Page 3

Content

GENERAL INFORMATION ........................ 4

PRODUCT INFORMATION .......................5

Features..................................................... 5

Compressor model designation ............. 6

Technical specifications ........................... 7

Dimensions ............................................... 9

Electrical data, connections and wiring 23

Supply voltage ........................................................ 23

Phase sequence and reverse rotation

protection ................................................................. 26

IP rating ...................................................................... 27

Motor protection.................................................... 27

Approval and certificates ......................28

SYSTEM DESIGN ..................................... 29

Drive installation .................................... 29

Direct and indirect exposure of

drive to water ......................................................... 29

Condensation .......................................................... 29

Dust Exposure ......................................................... 29

Mechanical Mounting .......................................... 29

Ambient temperature .......................................... 30

EMC installation ..................................... 31

EMC ..............................................................................31

EMC best practices .................................................31

Unit Architecture .................................... 32

Design piping ......................................... 33

General requirements .......................................... 33

Design compressor mounting ..............34

General requirements .......................................... 34

Single requirements.............................................. 34

Manage oil in the circuit ........................ 35

Requirement ............................................................ 35

System evaluation ................................................. 35

Test, criteria and solutions .................................. 35

Manage sound and vibration ................ 36

Compressor sound radiation ............................. 36

Mechanical vibrations ...........................................37

Gas pulsation ............................................................37

Speed limit requirement ..................................... 38

Start/Stop/Ramp setting ..................................... 38

Manage superheat .................................39

Requirement ............................................................ 39

System evaluation ................................................. 39

Test, criteria and solutions .................................. 40

Manage off cycle migration ................... 41

Requirement .............................................................41

System evaluation .................................................41

Manage operating envelope ................. 43

Requirement ............................................................ 43

System evaluation ................................................. 44

Control logic ........................................... 47

Safety control logic requirements ....................47

Short cycle protection .........................................47

Defrost cycle logic ................................................. 48

Pump-down logic recommendations ............ 48

Oil management logic ......................................... 49

Oil sensor logic in single configuration 50

1. Oil management logic for single system .. 50

2. Oil management description .........................51

Reduce moisture in the system ............. 54

Requirements .......................................................... 54

Solutions.................................................................... 54

INTEGRATION INTO SYSTEMS .............. 55

Assembly line procedure ....................... 55

Compressor storage ...............................................55

Compressor holding charge ...............................55

Handling ....................................................................55

Piping assembly...................................................... 56

System pressure test and leak detection ...... 56

Vacuum evacuation and moisture removal 57

Refrigerant charging ............................................. 57

Dielectric strength and insulation resistance

tests ............................................................................. 57

Commissioning ....................................... 58

Preliminary check................................................... 58

Initial start-up .......................................................... 58

System monitoring ................................................ 58

Oil level checking and top-up ........................... 58

Troubleshooting ..................................... 59

Dismantal and disposal ......................... 62

ORDERING INFORMATION ................... 63

Packaging ............................................... 63

Ordering codes ....................................... 64

Accessories .............................................. 67

3AB221086441234en-001101

Page 4

General Information

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Danfoss scroll compressors are designed and

manufactured according to the state of the

art and to valid European and US regulations.

Particular emphasis has been placed on

safety and reliability. Related instructions are

highlighted with the following icons:

This icon indicates instructions to avoid

safety risk.

R

This icon indicates instructions to avoid

reliability risk.

The purpose of this guideline is to help

customers qualify compressors in the unit.

You are strongly advise to follow these

instructions. For any deviation from the

guidelines, please contact Danfoss Technical

Support. In any case, Danfoss accepts no

liability as a result of the improper integration

of the compressor into the unit by the system

manufacturer.

4 AB221086441234en-001101

Page 5

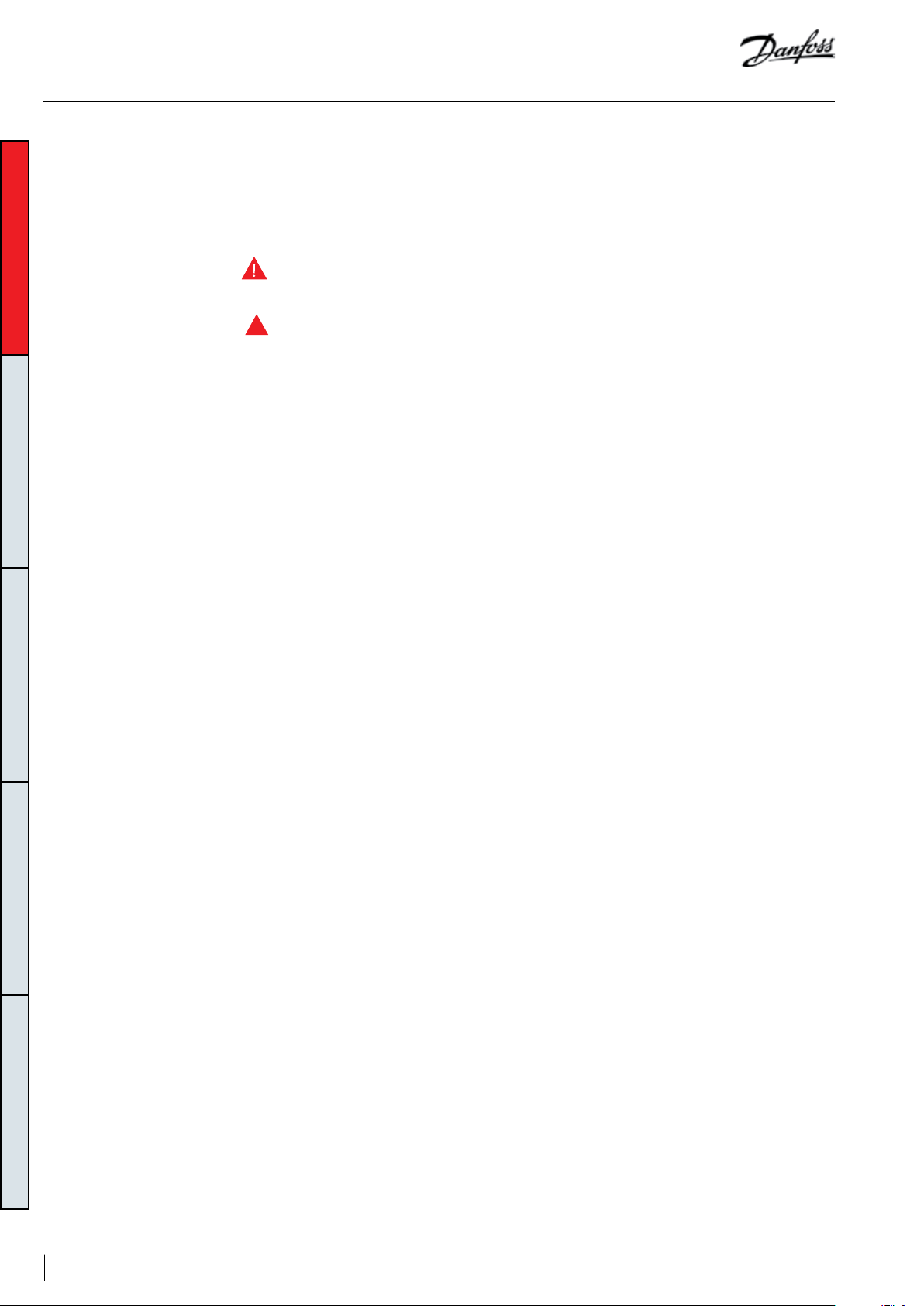

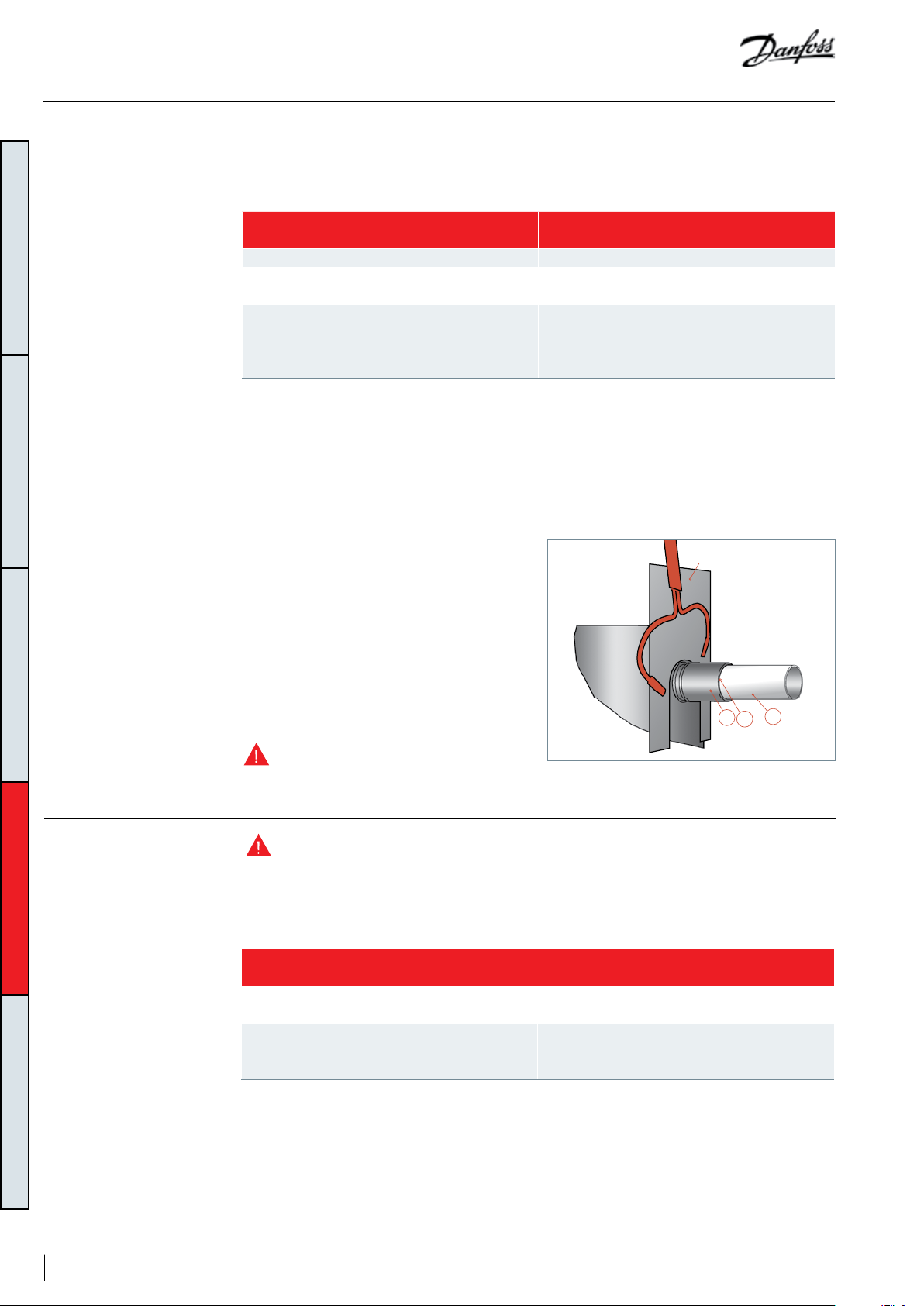

Features

High speed oil circulation

minimized by separating

oil and gas flows with a

sump oil return tube

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Reinforced high grade cast

iron scroll set. 2 ranges for

high and low pressure ratio

A patented oil injection

system ensures optimal

efficiency at low speed by

improving scroll set sealing

Oil injection control

optimizes the oil

circulation

Gearotor oil pump

ensures low speed

bearing lubrication

Lead free polymer bearing

with excellent performance

under diverse loads and

speeds

Permanent magnet motor

with high efficiency at all

speeds

Oil strainer controls the

risk of system debris in

the oil injection circuit

5AB221086441234en-001101

Page 6

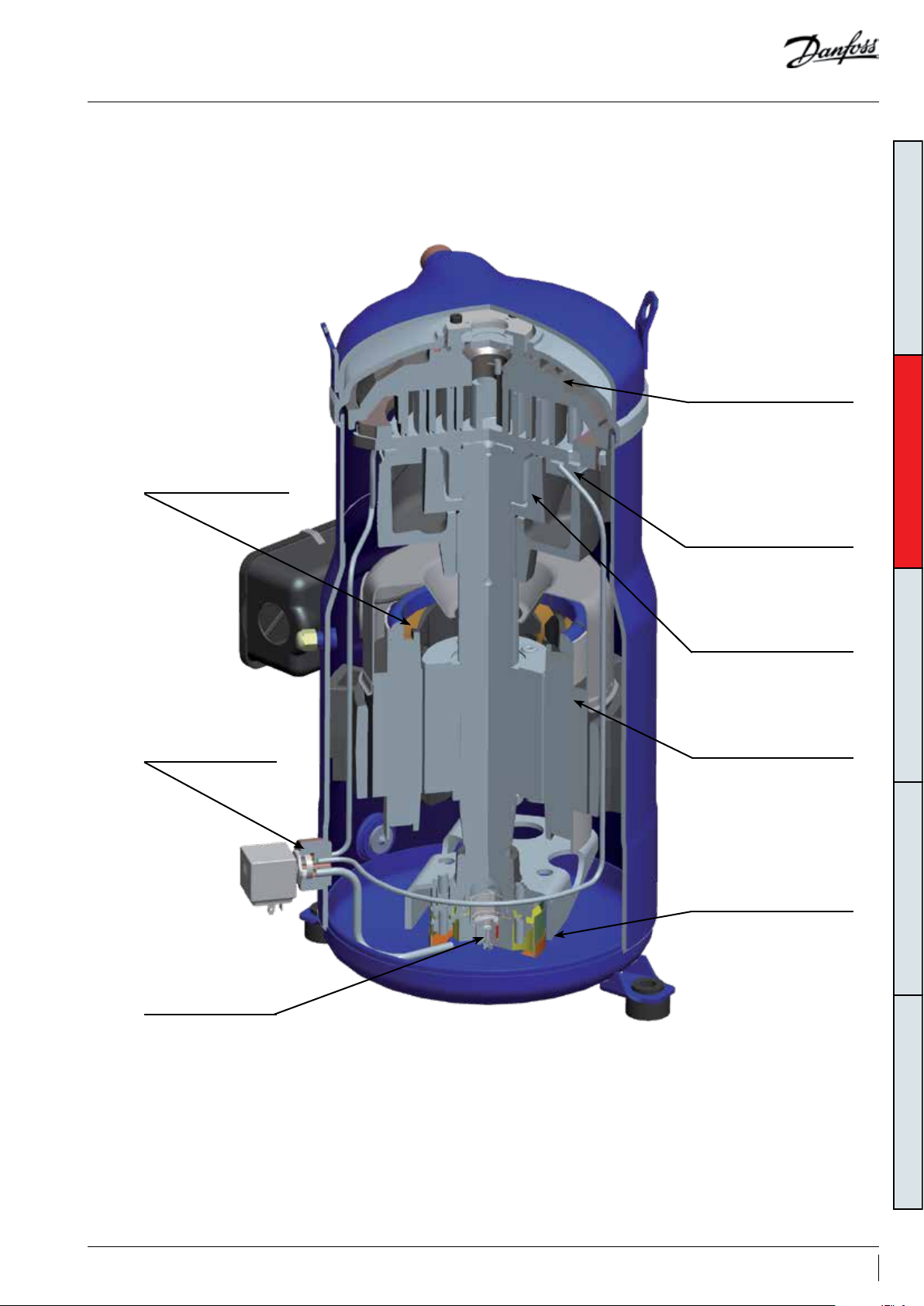

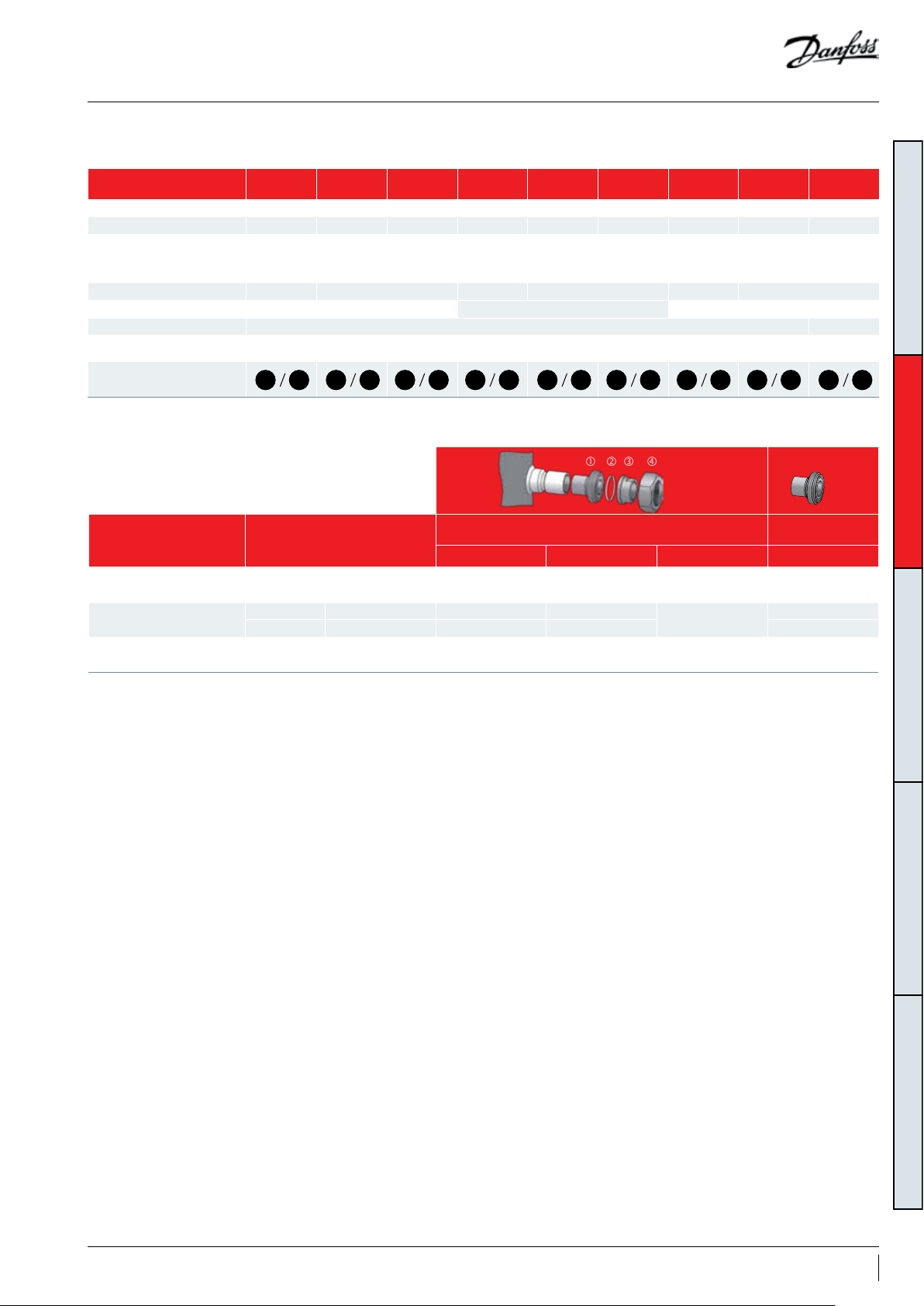

Compressor model designation

Compressor

nomenclature

ANAGA117ZHV

Variable speed

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Lubricant

POE lubricant, R410A

refrigerant

Swept volume

in cm³/rev

Design pressure ratio

A: high PR,

Frequency converter

nomenclature

Family

VZH scroll

B: low PR

Evolution index

Motor protection type

N: no internal motor protection

(protection by drive)

Equipement version

A: brazed connections, single version

B: brazed connections, manifold version

D: brazed connections, unified version

Oil sight glass Oil level switch

Single version Threaded None

Manifold version None Threaded

Unified version Threaded Threaded

Motor voltage code to CDS303 *

G: 380-480V/3~/50 & 60Hz

H: 525-600V/3~/50&60Hz

J: 200-240V/3~/50 & 60Hz

* main supply voltage to frequency converter

H2E20T4P15K303CDS

Dedicated compressor

drive for VZH/VSH scroll

Serie 303

High overload

output power

in kW

Note:

High overload output power: output power @160% Torque

RFI class

Enclosure protection

IP rating

Main supply voltage

T2: 200-240V/3 ph/50-60 Hz

T4: 380-480V/3 ph/50-60 Hz

T6: 525-600V/3 ph/50-60 Hz

6 AB221086441234en-001101

Page 7

Technical specifications

Compressor size

Frequency converter

variants

Compressor and

frequency converter

combinations

To have the optimum compressor selection,

select a compressor size which achieves the

peak load system cooling capacity demand at its

maximum speed.

Different frequency converter variants are

available according to:

1. Mains supply voltage

2. IP class (CDS303 drives are available in IP20 or

IP55 housings)

When the compressor size and mains voltage

have been defined in the above selection criteria,

the code number tables from the “Ordering

information and packaging” section provides the

appropriate frequency converter sizes and up

to eight corresponding code numbers for each

compressor model.

Detailed performances can be found in

datasheets and in selection programs.

3. RFI (Radio Frequency Interference) class H2/H3

or HX

4. Printed Circuit Board (PCB) coated or not

coated.

Note this compressor is equipped with

a four poles electrical motor so the applied

frequency from the inverter will be 50 Hz for

25 rps (1500 rpm) up to 200 Hz for 100 rps

(6000 rpm).

Please refer to the table below

min max

Compressor speed

Drive output frequency Hz 50 200

rps 25 100

rpm 150 0 6000

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

7AB221086441234en-001101

Page 8

Technical specifications

Compressor

specifications

Displacement Oil charge

Compressor

model

VZH088 88.4 5.39 7.9 6 281 15.91 562 19.09 675 31.82 1125 3.3 112 3.8 12 8 55 121

VZH117 116 .9 7.13 10.52 372 21.04 744 25.25 892 42.08 1487 3.6 122 4.1 139 61 134

VZH170 170 .2 10.38 15.32 541 30.64 1083 36.76 129 9 61.27 2165 6.7 227 7.7 260 112 247

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Swept volume

cm³/re v cu.in/rev m³/h cu.ft/h m³/h cu.ft/h m³/ h cu.ft/h m³/ h cu.ft/h dm³ oz dm³ oz kg lbs

25 rps 50 rps 60 rps 100 rps

Single and

manifold

version

Unified

version

Net weight

Frequency converter

specifications

Oil injection control

Bearings lubrication

T2: 200 - 240 V ±10% (3-phase)

Mains supply voltage

Supply frequency 50 / 60 Hz

Output voltage 0 - 100 % of supply voltage

Inputs 6 digital (0-24V), 2 analog (0/±10V or 4-20mA, scalable)

Programmable outputs 2 digital (0-24V), 1 analog (0/4-20mA), 2 relay

Protection functions Over-current protection, low / high current handling

Compressor functions Motor protection, compressor ramp up/down control

VZH compressors are equipped with an oil

injection system that makes the compression

pockets more tight thus improving the isotropic

efficiency of the compressor as well as controls

T4: 380 - 480 V ±10% (3-phase)

T6: 525 - 600V ±10% (3-phase)

The compressors are delivered with no coils.

208V-240V / 110V-120V / 24V coils are available

as accessory (refer to “Accessories” section). The

coil must be installed for oil injection control.

the oil circulation ratio, at all running speeds.

The frequency converter via an oil injection valve

controls this system. The oil injection valve is a

normally closed valve. At low speed, the valve

Control parameters are factory preset but

accessible on the parameter list as read only

values.

is closed and the oil is injected to the scroll set

suction ports.

Optimal bearings lubrication is ensured by a

gearotor oil pump at all compressor speeds.

8 AB221086441234en-001101

Page 9

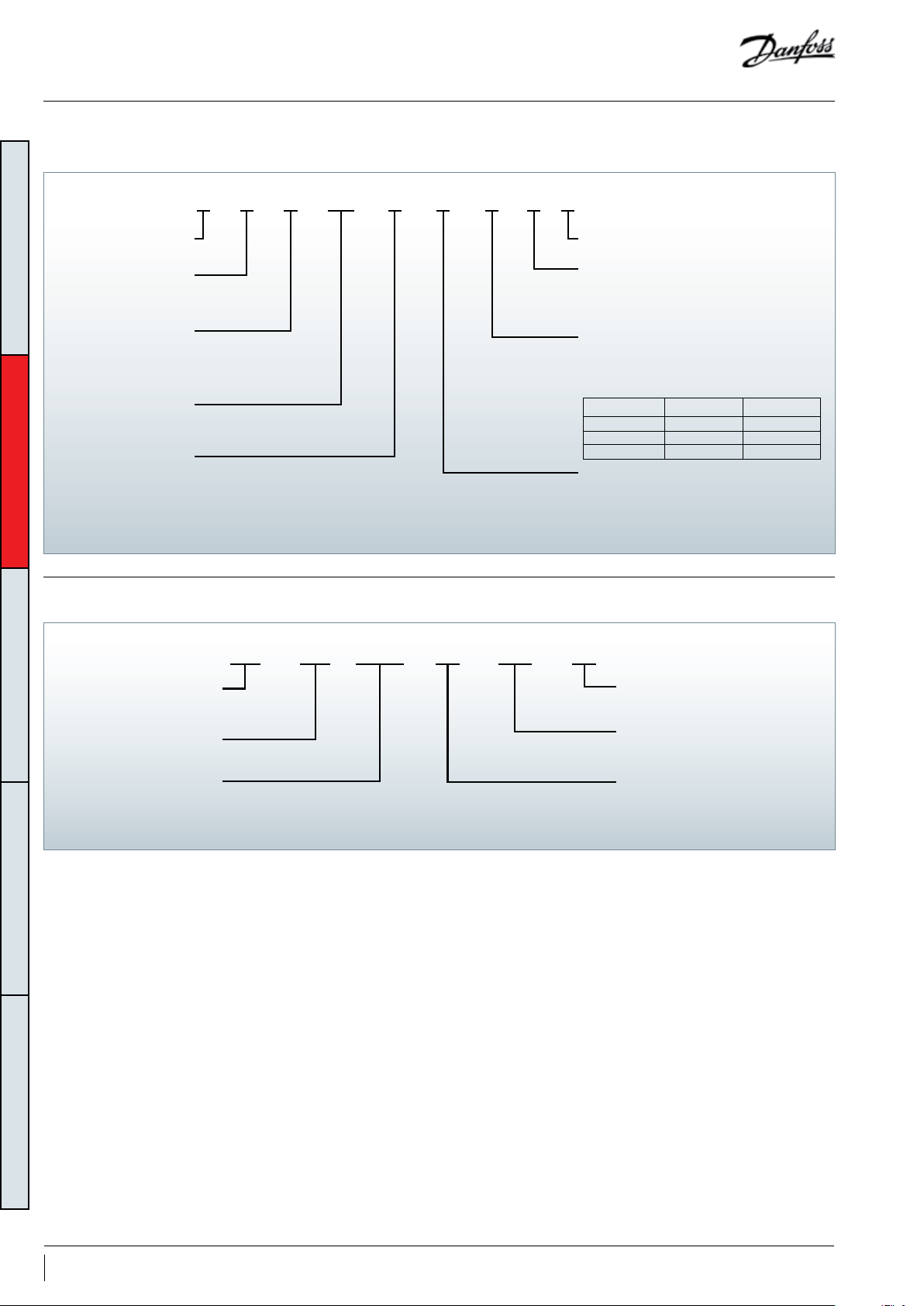

Dimensions

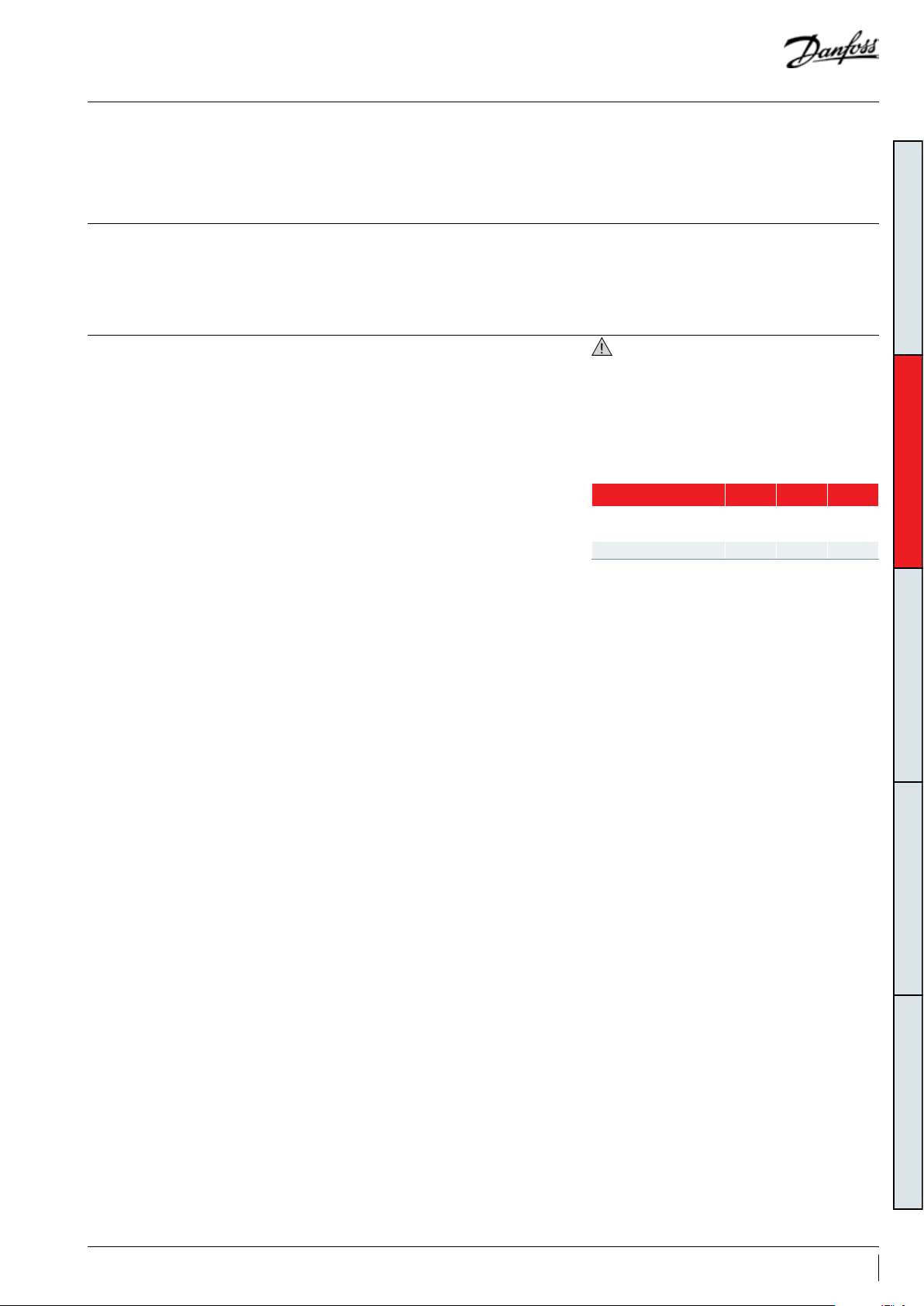

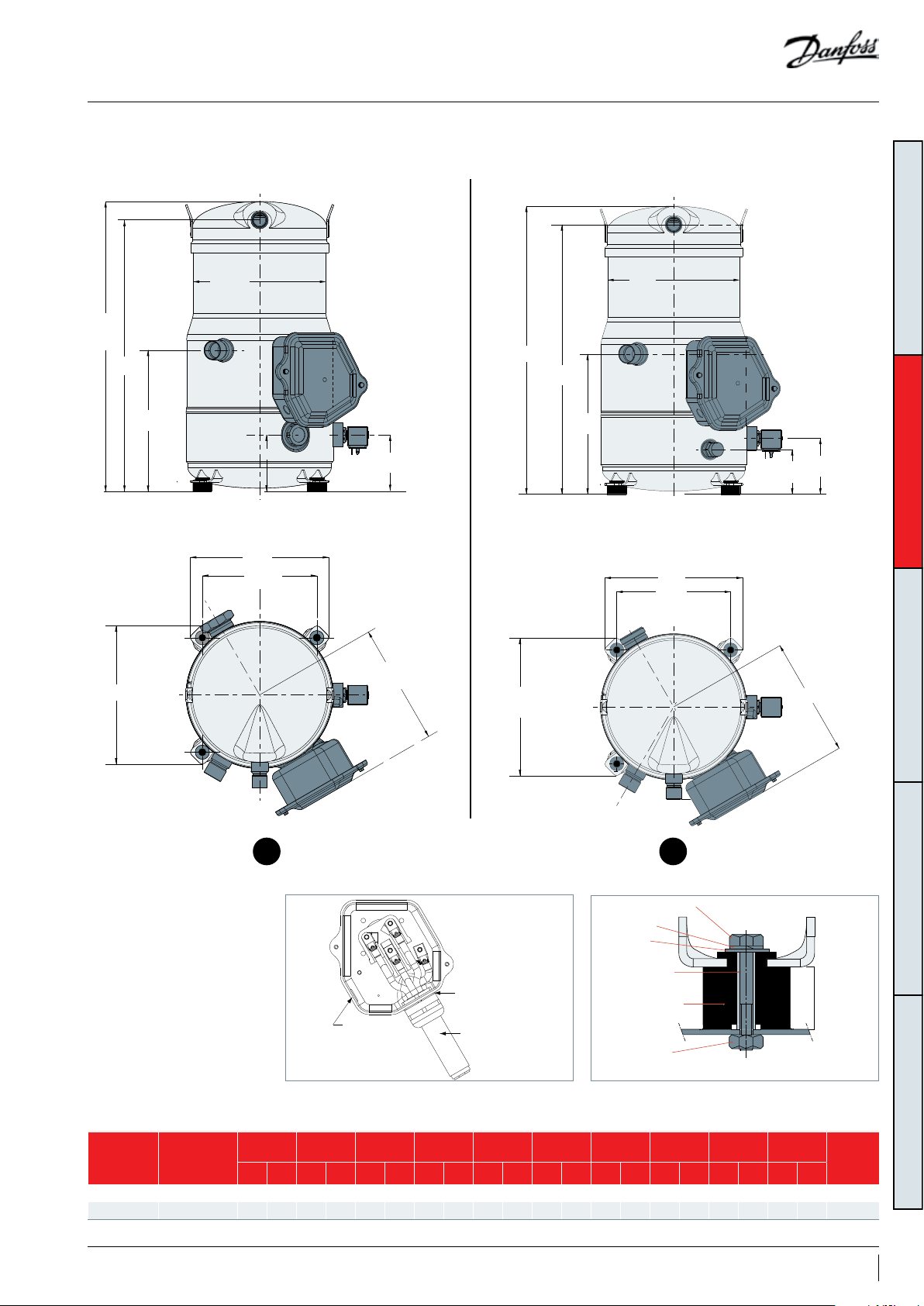

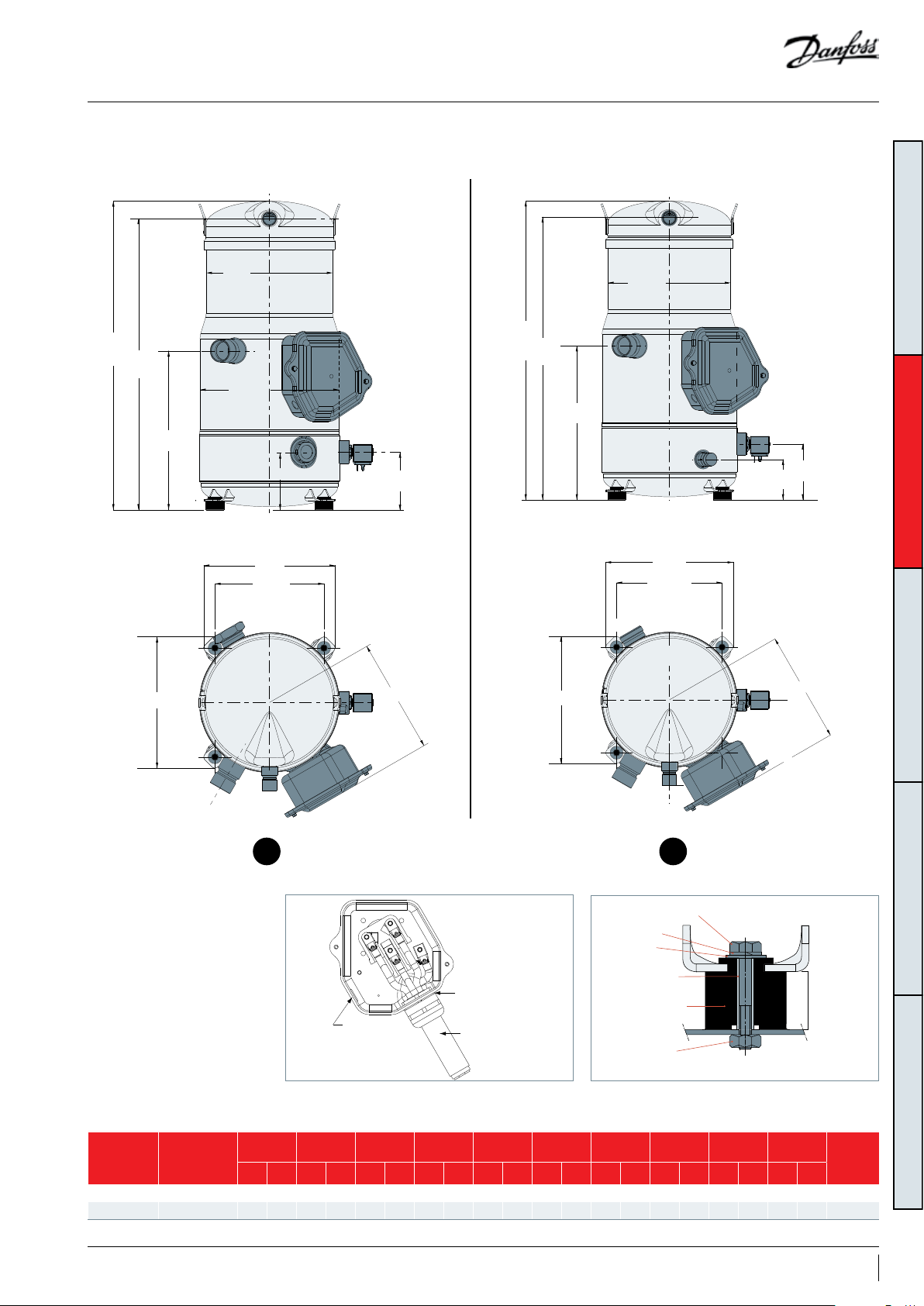

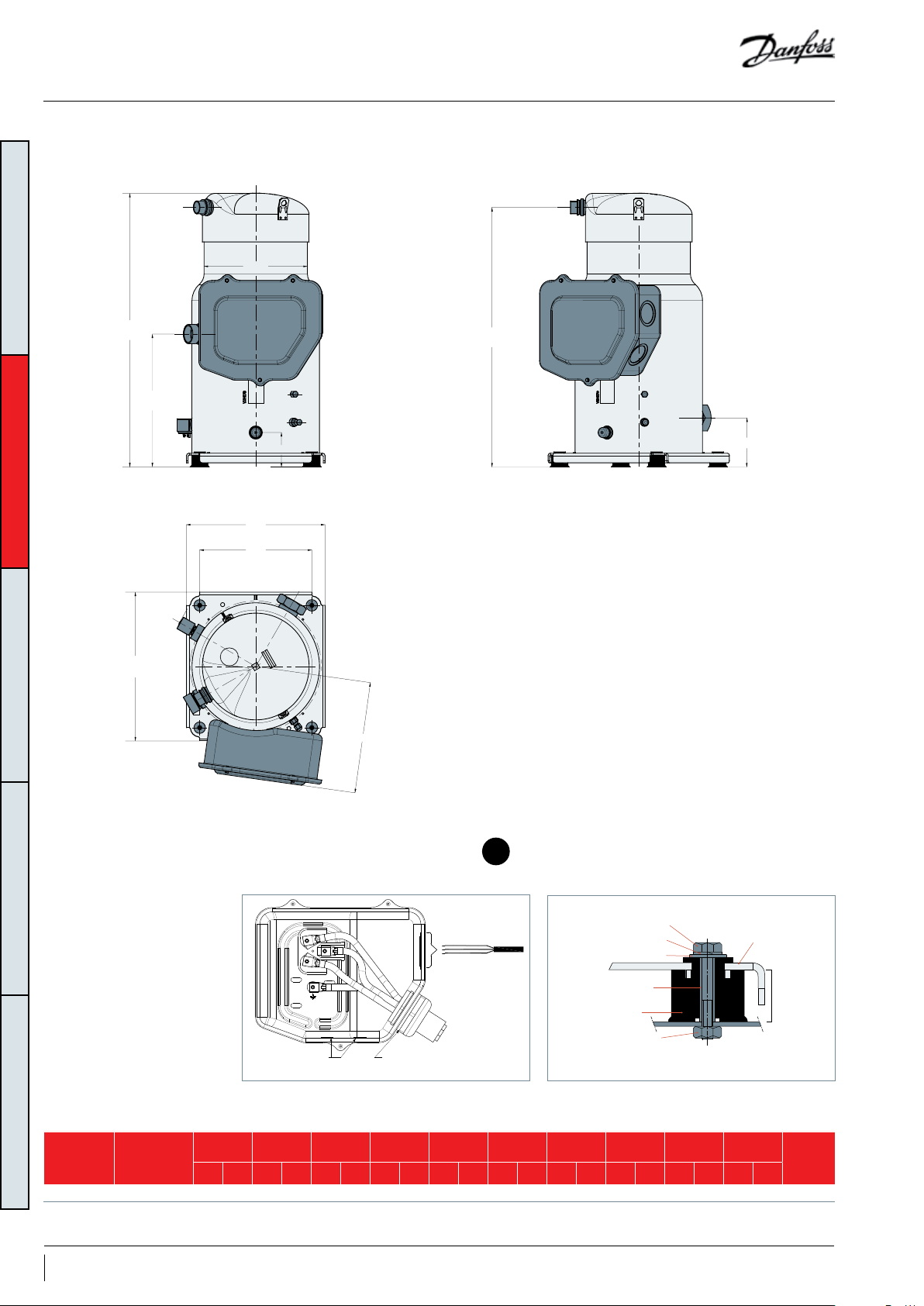

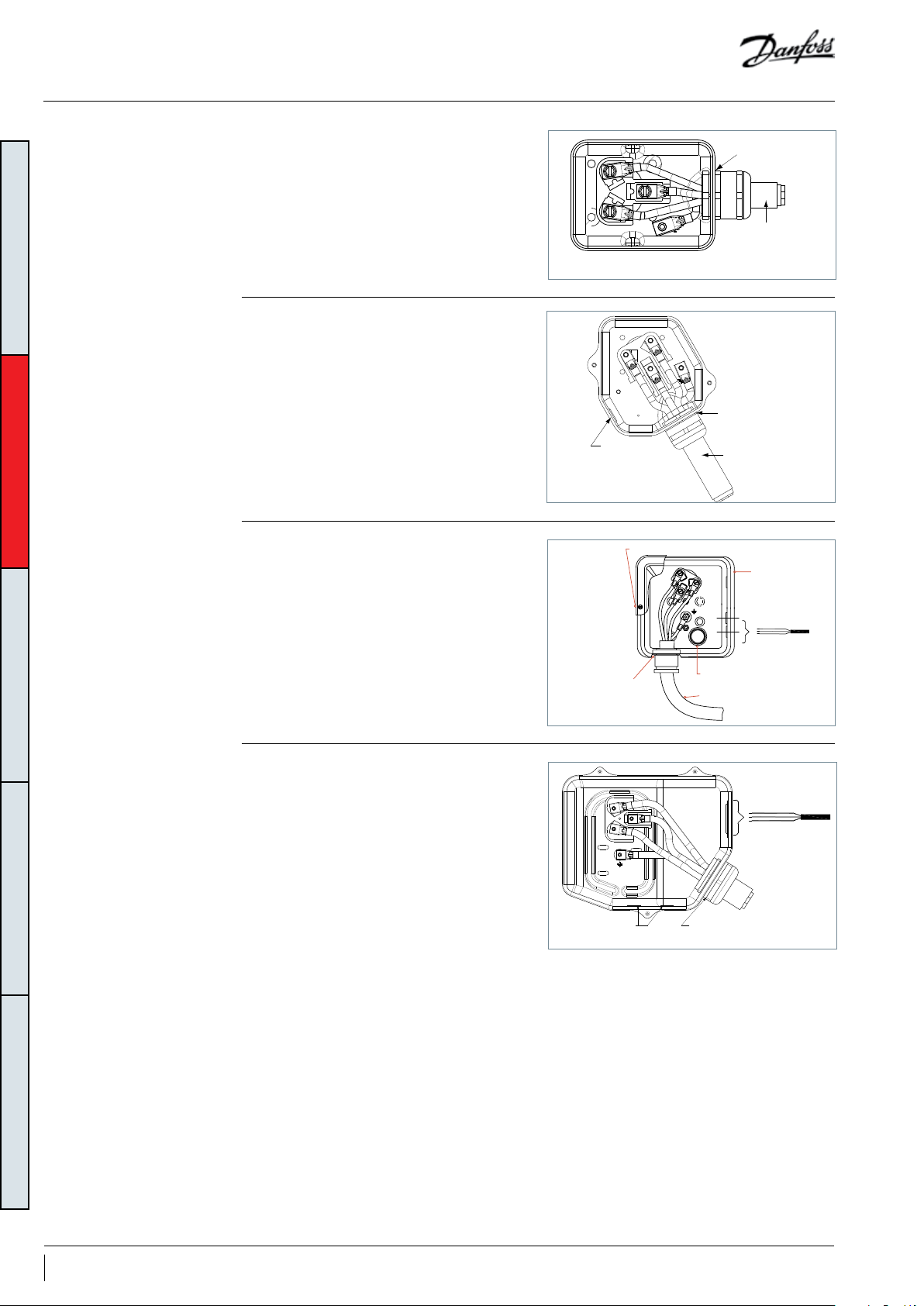

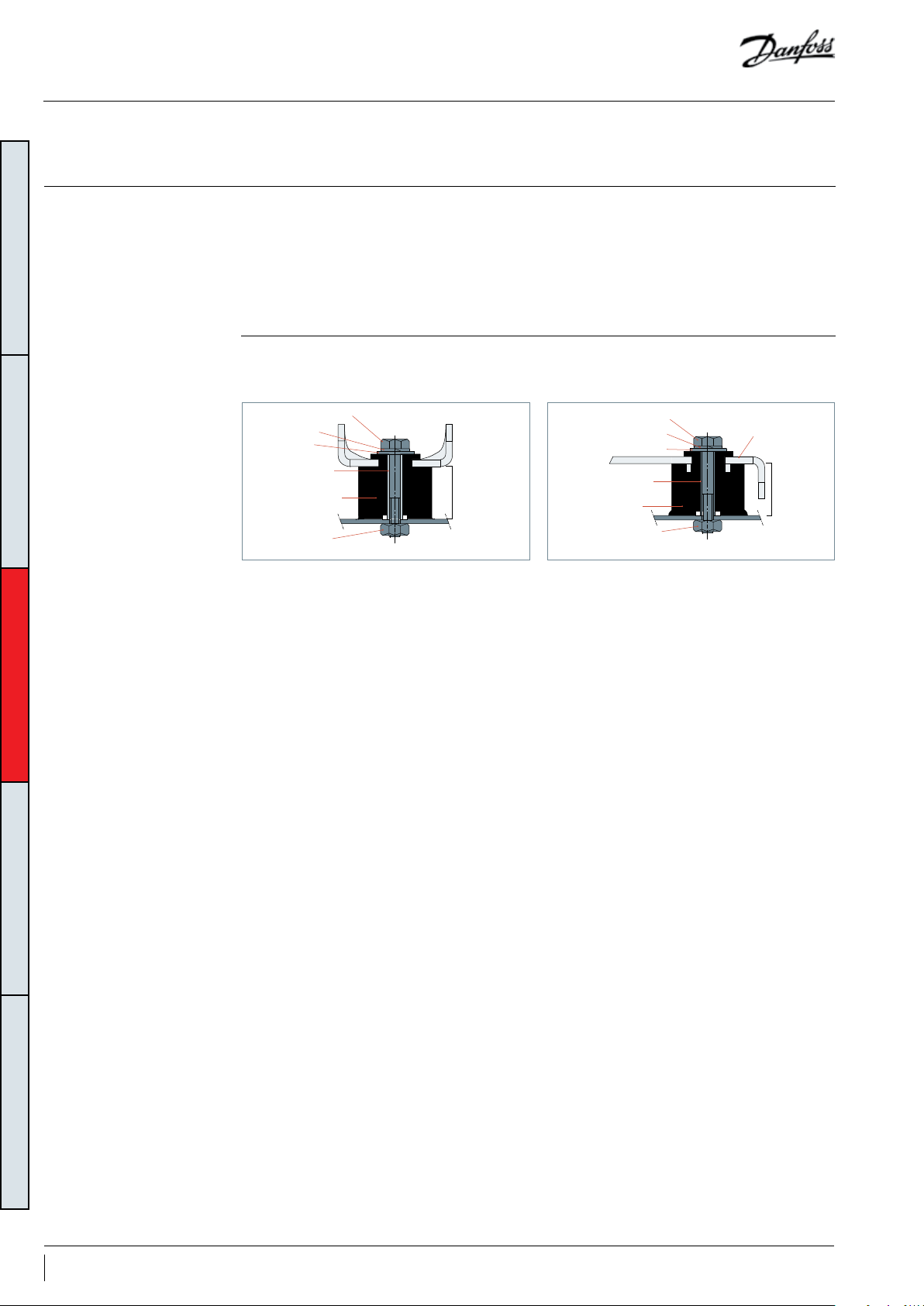

VZH088-G/H single

version

H3

H2

H1

ØD

L1

L3

H4

H5

VZH088-G/H manifolded version

ØD

H3

H2

H1

H4

L1

L3

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

H5

L2

L4

L2

Ø 33 mm

(1.30 inch) hole

Power supply

GrommetElectrical box

HM 8 bolt

Lock washer

Flat washer

Steel mounting

sleeve

Rubber grommet

Nut

L4

21

15 mm

(0.59 inch)

Version

Single VZH088-G/H 220.8 8.69 234.6 9.23 451.2 17.7 6 484.8 19.08 93.8 3.69 93.8 3.69 230 9.05 230 9.05 190 .5 7. 5 18 0.7 7.11 8560025

Manifolding VZH088-G/H 220.8 8.69 234.6 9.23 451.2 17. 76 484.8 19.0 8 74. 8 2.94 93.8 3.69 230 9.05 230 9.05 19 0.5 7. 5 180.7 7. 11 8560055

Compressor

model

D H1 H2 H3 H4 H5 L1 L2 L3 L4

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

Outline

drawing

number

9AB221086441234en-001101

Page 10

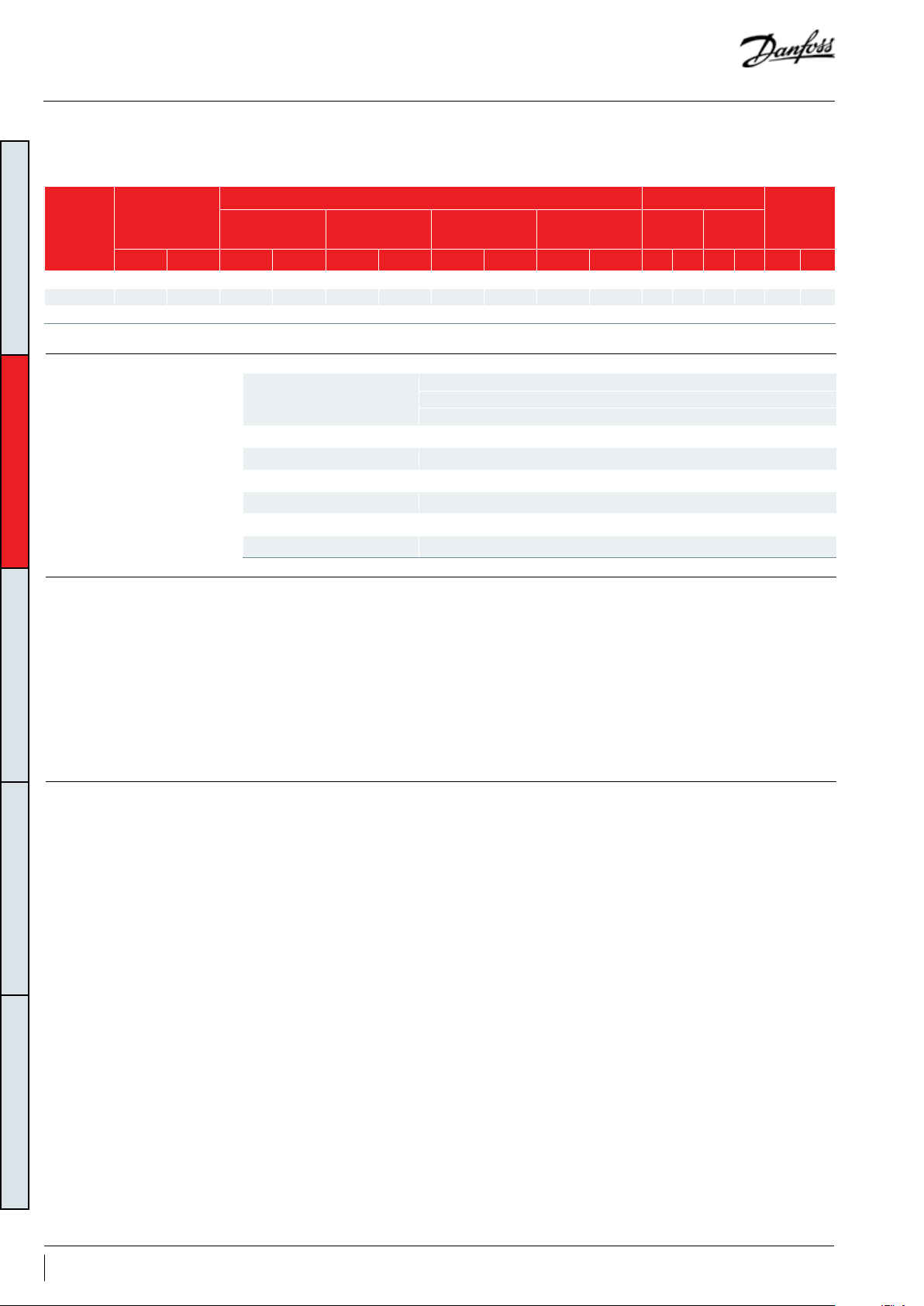

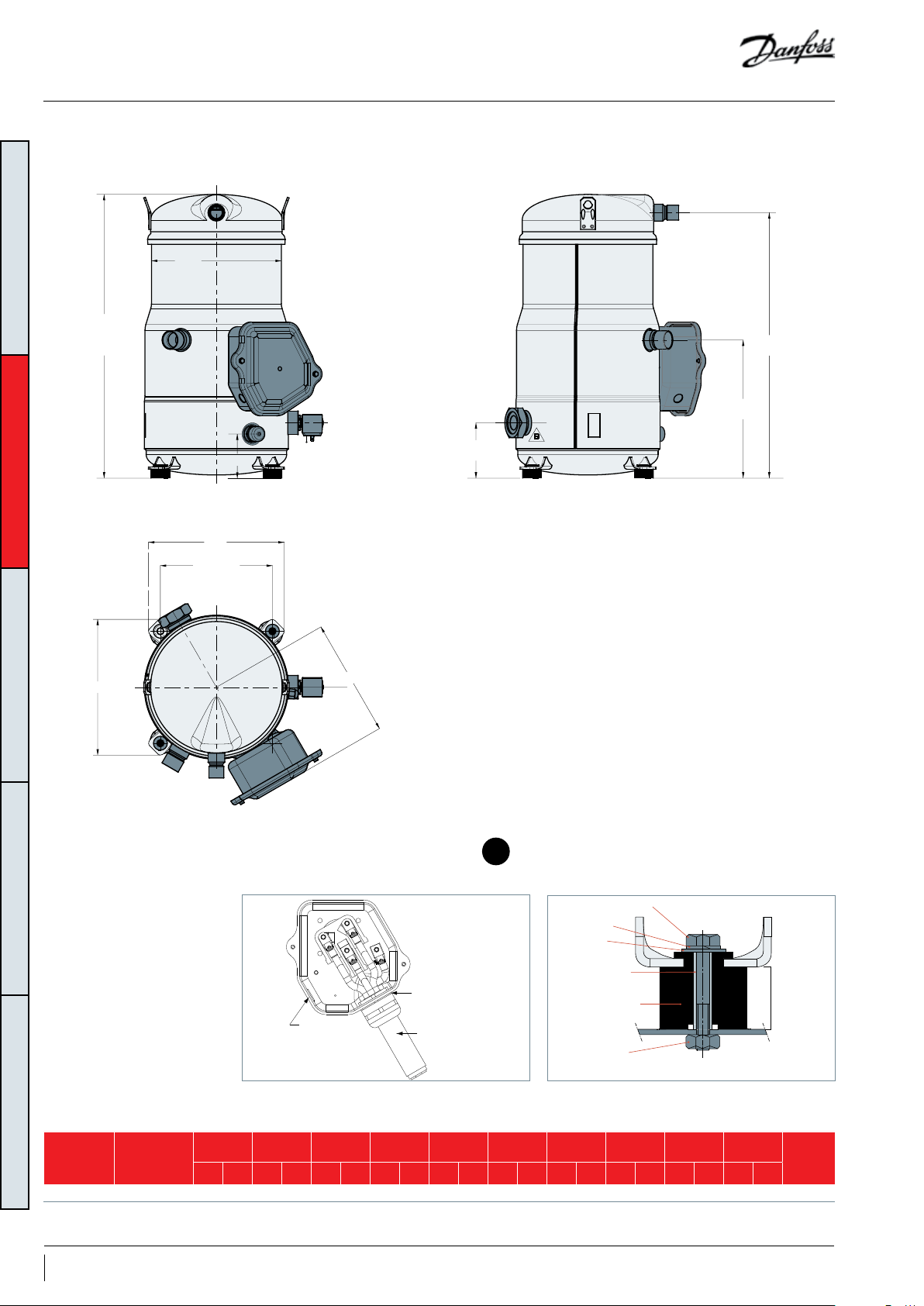

Dimensions

VZH088 -G/H unified version

ØD

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

H3

H2

H1

L2

L1

L3

H4

L4

H5

Ø 33 mm

(1.30 inch) hole

Power supply

3

GrommetElectrical box

HM 8 bolt

Lock washer

Flat washer

Steel mounting

sleeve

Rubber grommet

15 mm

(0.59 inch)

Nut

Version

Unified VZH088-G/H 220.8 8.69 234.6 9.23 451. 2 17.76 484.8 19. 08 74 .8 2.94 93.8 3.69 230 9.05 230 9.05 19 0.5 7. 5 180 .7 7.11 8560097

Compressor

model

D H1 H2 H3 H4 H5 L1 L2 L3 L4

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

10 AB221086441234en-001101

Outline

drawing

number

Page 11

Dimensions

VZH088-J single version VZH088-J manifolded version

H3

ØD

ØD

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

H2

H1

H4

H5

H3

H2

H1

H4

H5

L1

L3

L1

L3

L4

L2

L2

L4

54

GrommetElectrical box

HM 8 bolt

Lock washer

Flat washer

Steel mounting

Ø 40.5 mm

(1.59 inch) hole

Ø 16.5 mm

(0.65 inch)

knockout

Version

Single VZH088-J 220.8 8.69 234.6 9.23 451.2 17. 76 484.8 19.0 8 93.8 3.69 93.8 3.69 230 9.05 230 9.05 19 0.5 7. 5 200.4 7.81 8560 030

Manifolding VZH088-J 220.8 8.69 234.6 9.23 451.2 17. 76 484.8 19.0 8 74. 8 2.94 93.8 3.69 230 9.05 230 9.05 19 0.5 7. 5 200.4 7. 81 8560056

Compressor

model

D H1 H2 H3 H4 H5 L1 L2 L3 L4

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

Power supply

sleeve

Rubber grommet

Nut

15 mm

(0.59 inch)

Outline

drawing

number

11AB221086441234en-001101

Page 12

Dimensions

VZH088 -J unified version

ØD

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

H3

H2

H1

H4

H5

L1

L3

L2

L4

6

GrommetElectrical box

HM 8 bolt

Lock washer

Flat washer

Steel mounting

Ø 40.5 mm

(1.59 inch) hole

Ø 16.5 mm

(0.65 inch)

knockout

Version

Unified VZH088-J 220.8 8.69 234.6 9.23 451. 2 17. 76 484.8 19.0 8 74. 8 2.94 93.8 3.69 230 9.05 230 9.05 19 0.5 7. 5 200.4 7.81 8560098

Compressor

model

D H1 H2 H3 H4 H5 L1 L2 L3 L4

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

Power supply

sleeve

Rubber grommet

Nut

12 AB221086441234en-001101

15 mm

(0.59 inch)

Outline

drawing

number

Page 13

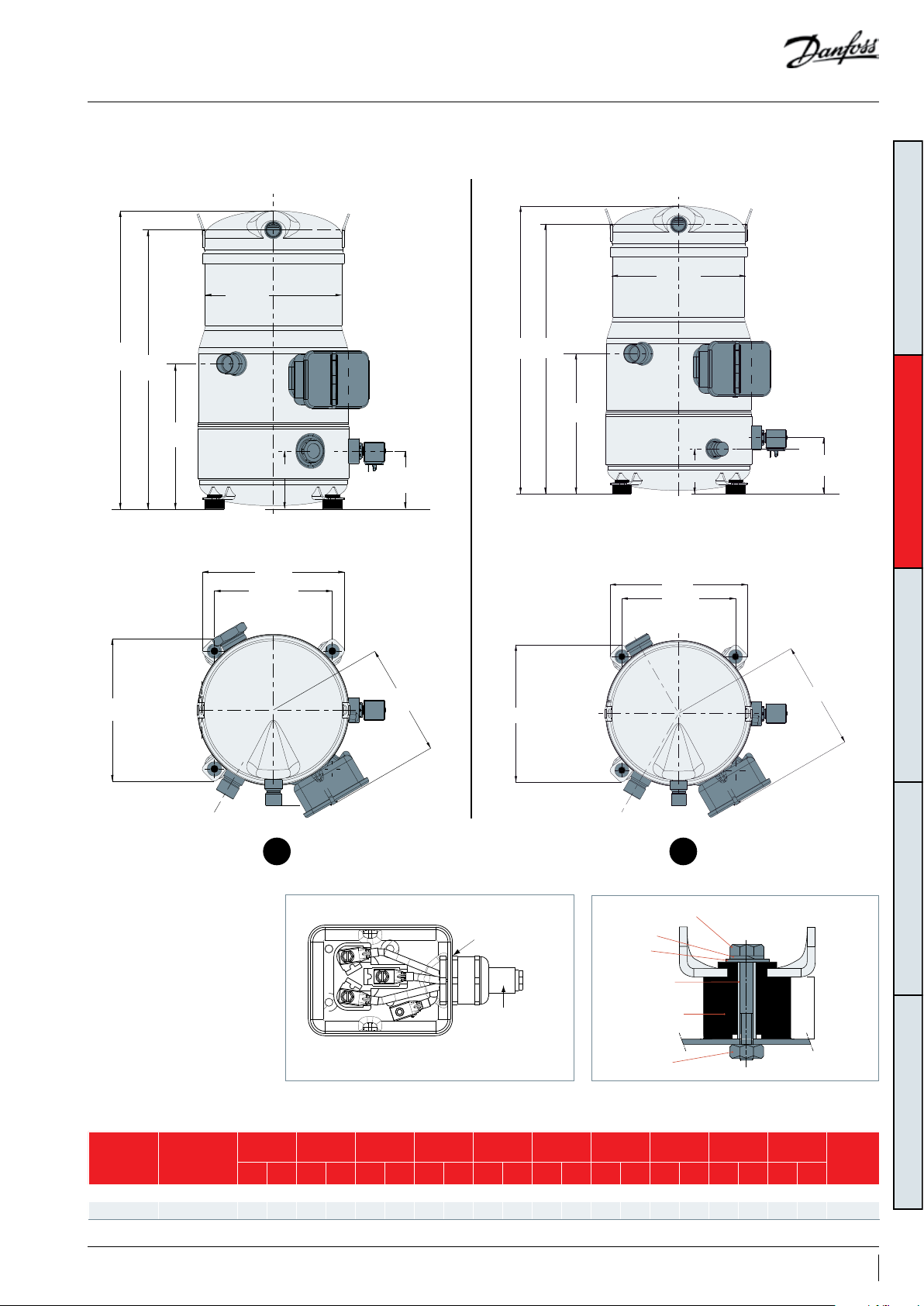

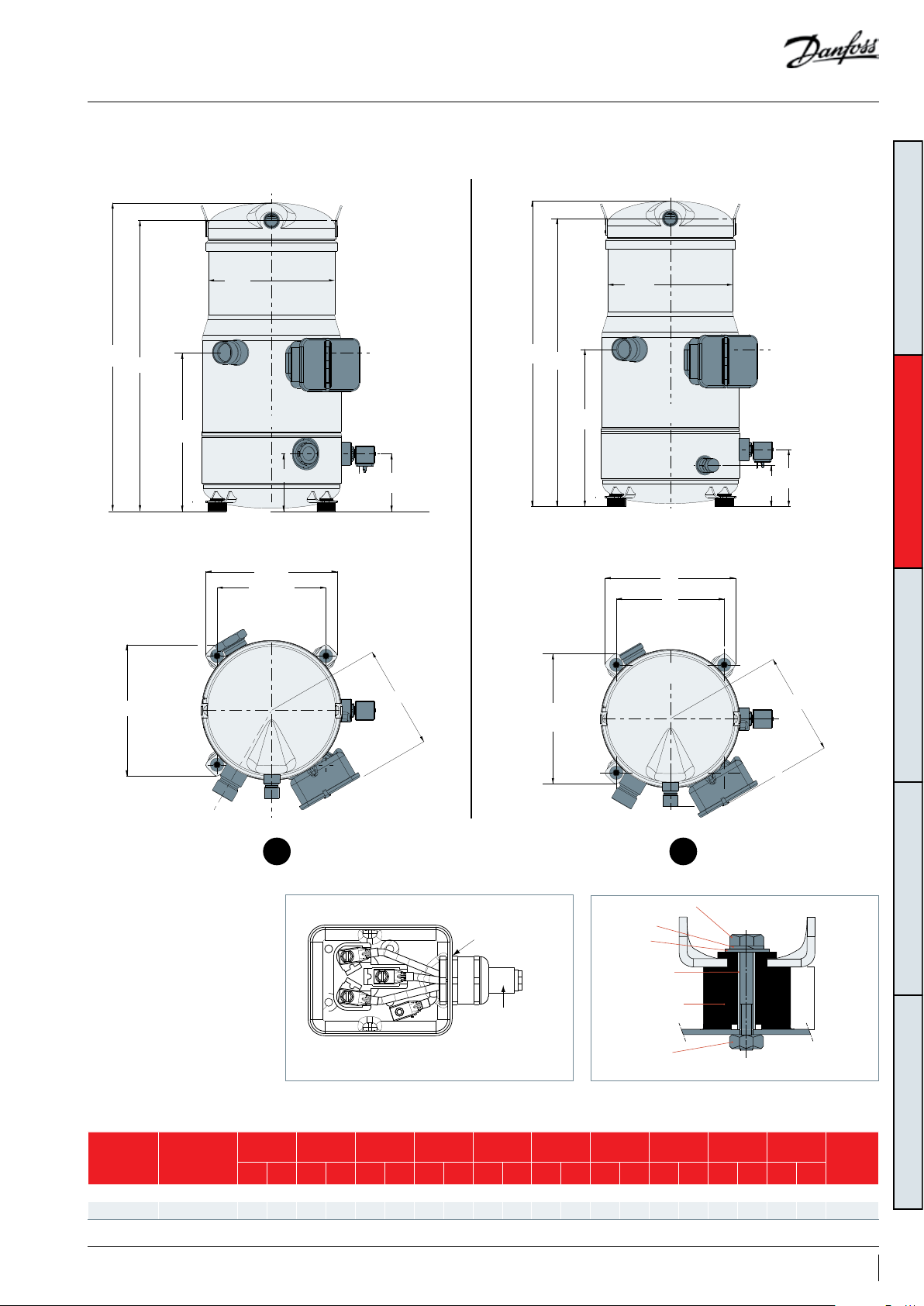

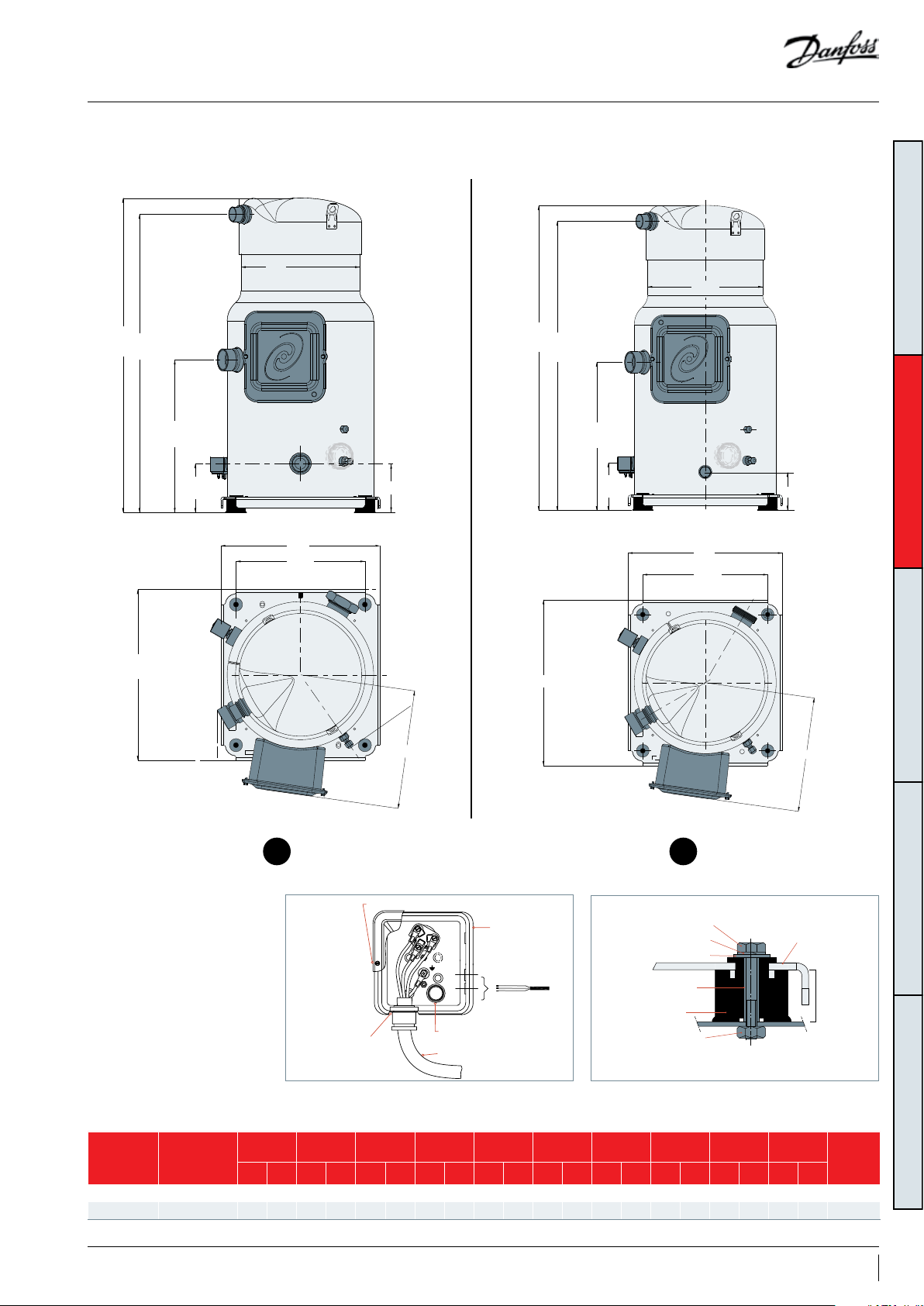

Dimensions

VZH117-G/H single version VZH117-G/H manifolded version

H3

ØD

ØD

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

H3

H2

H1

H4

L1

L3

L2

H5

L4

H2

H1

H5

H4

L1

L3

L2

L4

87

GrommetElectrical box

HM 8 bolt

Ø 33 mm

(1.30 inch) hole

Power supply

Version

Single VZH117- G /H 220.8 8.69 276.9 10.92 50 7.9 20.02 541.6 21.34 100 3.96 100 3.96 230 9.05 230 9.05 19 0.5 7. 5 180.7 7.13 8560026

Manifolding VZH117- G/ H 220.8 8.69 276 .9 10.92 507. 9 20.02 541.6 21. 34 72 2.86 100 3.96 230 9.05 230 9.05 19 0.5 7. 5 180 .7 7.13 8560057

Compressor

model

D H1 H2 H3 H4 H5 L1 L2 L3 L4

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

Lock washer

Flat washer

Steel mounting

sleeve

Rubber grommet

Nut

15 mm

(0.59 inch)

Outline

drawing

number

13AB221086441234en-001101

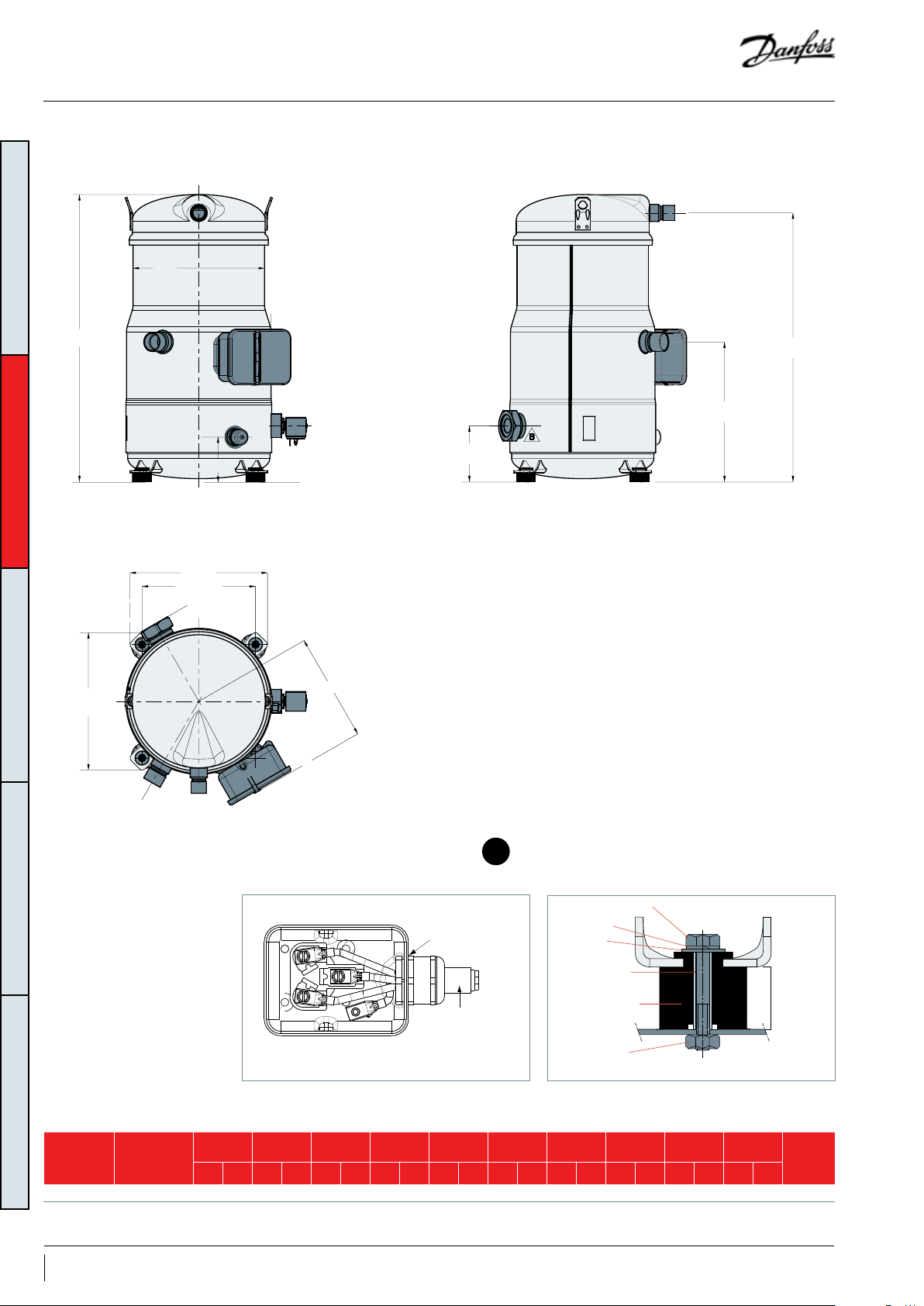

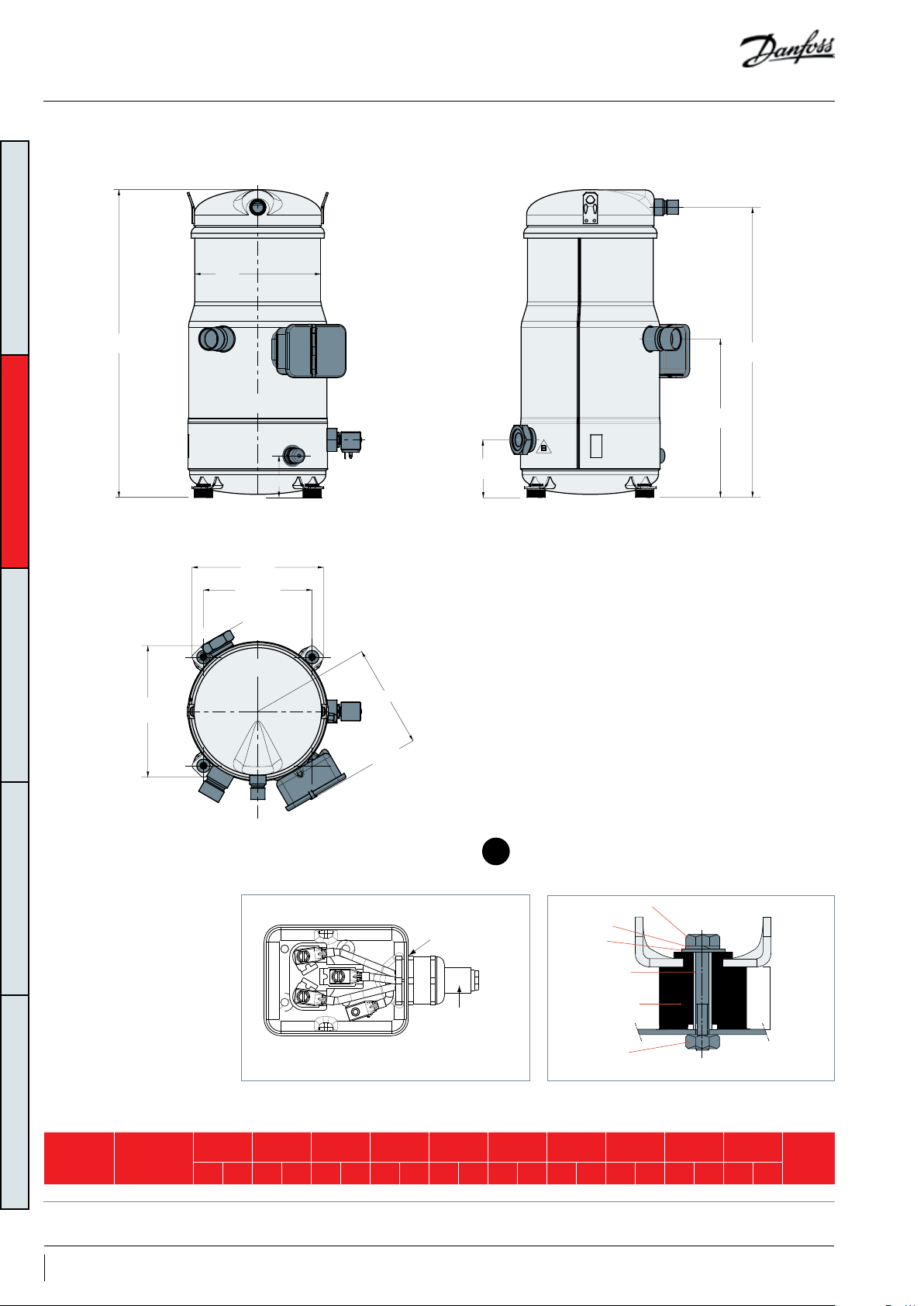

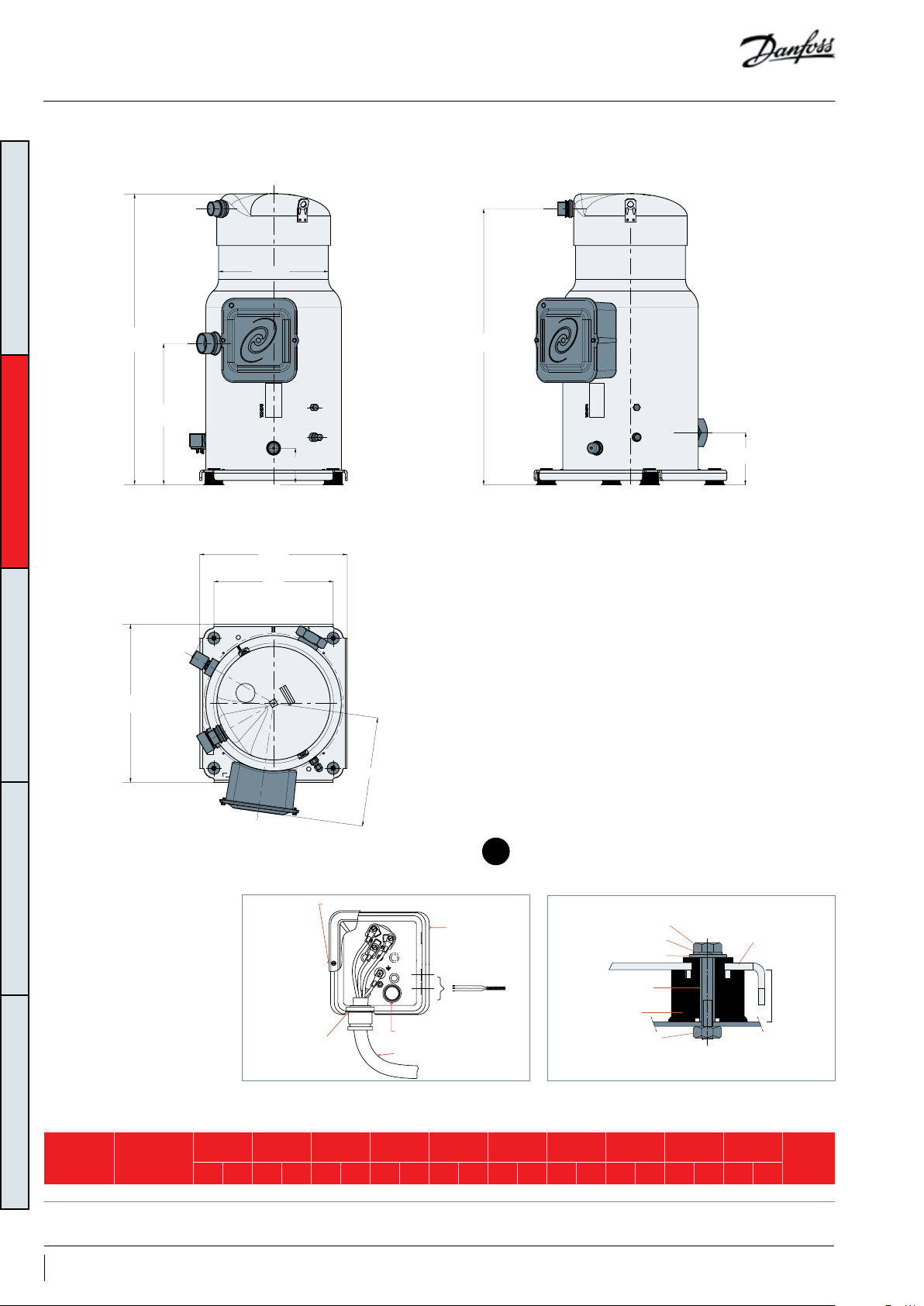

Page 14

Dimensions

VZH117-G/H unified version

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

ØD

H3

H2

H1

H4

H5

L1

L3

L4

L2

9

GrommetElectrical box

HM 8 bolt

Ø 33 mm

(1.30 inch) hole

Power supply

Version

Unified V ZH117-G/ H 220.8 8.69 276.9 10.92 507. 9 20.02 5 41.6 21.3 4 72 2.86 10 0 3.96 230 9.05 230 9.05 190 .5 7. 5 18 0.7 7.13 8560099

Compressor

model

D H1 H2 H3 H4 H5 L1 L2 L3 L4

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

Lock washer

Flat washer

Steel mounting

sleeve

Rubber grommet

Nut

14 AB221086441234en-001101

15 mm

(0.59 inch)

Outline

drawing

number

Page 15

Dimensions

VZH117-J single version VZH117-J manifolded version

H3

H2

ØD

ØD

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

H3

H2

Ø243

H1

H1

H4

L1

L3

L2

H5

L1

L3

L4

L2

H4

H5

L4

1110

GrommetElectrical box

HM 8 bolt

Lock washer

Flat washer

Steel mounting

Ø 40.5 mm

(1.59 inch) hole

Ø 16.5 mm

(0.65 inch)

knockout

Version

Single VZH117-J 220.8 8.69 276.9 10.92 507.9 20.02 541. 6 21.34 100 3.96 100 3.96 230 9.05 230 9.05 19 0.5 7. 5 200.4 7. 87 856 0031

Manifolding VZ H117-J 220.8 8.69 276.9 10.92 5 07.9 20.02 541.6 21.34 72 2.86 100 3.96 230 9.05 230 9.05 190 .5 7. 5 200.4 7. 87 8560058

Compressor

model

D H1 H2 H3 H4 H5 L1 L2 L3 L4

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

Power supply

sleeve

Rubber grommet

Nut

15 mm

(0.59 inch)

Outline

drawing

number

15AB221086441234en-001101

Page 16

Dimensions

VZH117-J unified version

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

H3

ØD

H2

H1

H4

H5

L1

L3

L4

L2

12

GrommetElectrical box

HM 8 bolt

Lock washer

Flat washer

Steel mounting

Ø 40.5 mm

(1.59 inch) hole

Ø 16.5 mm

(0.65 inch)

knockout

Version

Unified V ZH 117-J 220.8 8.69 276.9 10 .92 507.9 20.02 541. 6 21.34 72 2.86 10 0 3.96 230 9.05 230 9.05 190 .5 7. 5 200.4 7.8 7 856 0100

Compressor

model

D H1 H2 H3 H4 H5 L1 L2 L3 L4

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

Power supply

sleeve

Rubber grommet

Nut

16 AB221086441234en-001101

15 mm

(0.59 inch)

Outline

drawing

number

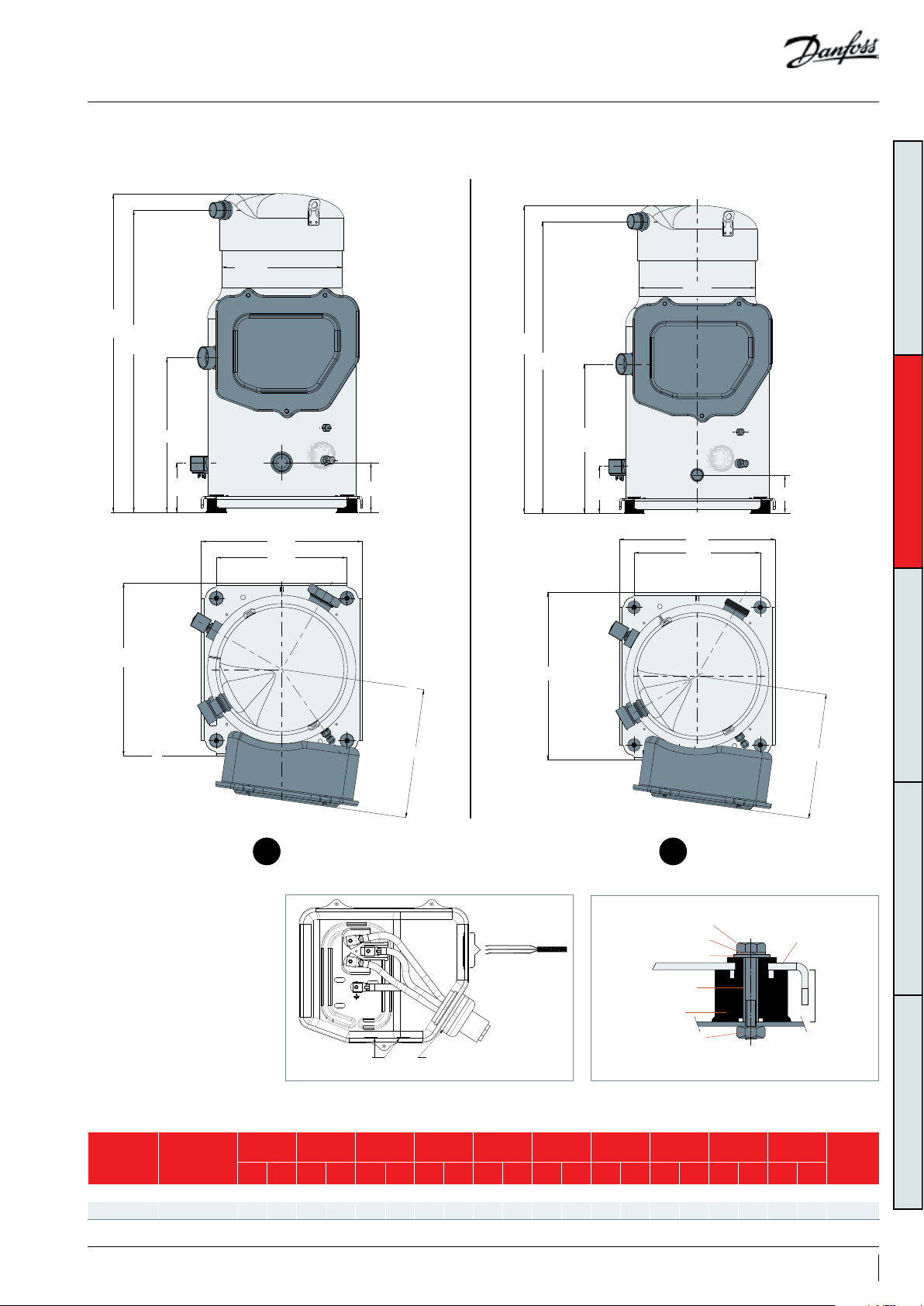

Page 17

Dimensions

Cover holding screw (x2) - Torque: 2.2 Nm

VZH170-G/H single version VZH170-G/H manifolded version

ØD

ØD

H3

H2

H3

H2

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

H1

H5

L1

L3

L2

H4

L2

L4

H1

H5

L1

L3

H4

L4

1413

GrommetElectrical box

Terminal box

Sump heater

Steel mounting sleeve

Rubber grommet

Ø 40.5 mm

(1.59 inch) hole

Ø 50.5 mm

Faston 1/4" tabs

Power supply

(1.99 inch) knockout

Version

Compressor

model

D H1 H2 H3 H4 H5 L1 L2 L3 L4

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

Single VZ H170 -G/H 257 10.12 329 12.97 644.5 25.39 686.5 2 7.04 104.1 4.10 10 4.1 4.10 345 13.58 371 14.61 279.4 11 257 10 .12 8 5511 86

Manifolding VZH170- G/ H 257 10.12 329 12 .97 644.5 25.39 686.5 2 7.0 4 83.6 3. 3 10 4.1 4.10 345 13.58 371 14.61 279.4 11 257 10 .12 8 5511 87

HM 8 bolt

Lock washer

Flat washer

Nut

Compressor

base plate

28 mm

(1.10 inch)

drawing

Outline

number

17AB221086441234en-001101

Page 18

Dimensions

Cover holding screw (x2) - Torque: 2.2 Nm

VZH170-G/H unified version

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

H3

H1

ØD

H2

H4

H5

L1

L3

L2

L4

15

GrommetElectrical box

Ø 40.5 mm

(1.59 inch) hole

Ø 50.5 mm

(1.99 inch) knockout

Version

Unified VZH170 -G/H 257 10.12 329 12.97 644.5 25. 39 686.5 2 7.0 4 83.6 3.3 120.5 4. 74 345 13. 58 371 14.61 279.4 11 257 10 .12 8560095

Compressor

model

D H1 H2 H3 H4 H5 L1 L2 L3 L4

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

Faston 1/4" tabs

Power supply

Terminal box

Sump heater

Steel mounting sleeve

Rubber grommet

HM 8 bolt

Lock washer

Flat washer

Nut

18 AB221086441234en-001101

Compressor

base plate

28 mm

(1.10 inch)

Outline

drawing

number

Page 19

Dimensions

VZH170-J single version VZH170-J manifolded version

ØD

ØD

H3

H2

H1

H5

L1

L3

L2

H4

L4

H3

H2

H1

H5

L1

L3

L2

H4

L4

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

1716

GrommetElectrical box

HM 8 bolt

Lock washer

Sump heater

Flat washer

Steel mounting sleeve

Rubber grommet

Nut

Ø 50.5 mm (1.99 inch) hole

Ø 63.5 mm (2.50 inch) knockout

Version

Compressor

model

Ø 22.5 mm

(0.89 inch) knockout

D H1 H2 H3 H4 H5 L1 L2 L3 L4

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

Single V ZH170 -J 257 10 .12 329 12 .97 644.5 25.39 686.5 2 7.0 4 104.1 4.10 10 4.1 4.10 345 13.58 371 14.61 279.4 11 277 10 .90 85 51174

Manifolding VZH170 -J 257 10.12 329 12. 97 644.5 25. 39 686.5 2 7.0 4 83.6 3. 3 104.1 4 .10 345 13.58 371 14.61 279.4 11 277 10.9 0 8 5511 88

Compressor

base plate

28 mm

(1.10 inch)

Outline

drawing

number

19AB221086441234en-001101

Page 20

Dimensions

VZH170-J unified version

ØD

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

H3

H1

H4

L1

L3

L2

L4

H2

H5

18

GrommetElectrical box

HM 8 bolt

Lock washer

Sump heater

Steel mounting sleeve

Rubber grommet

Ø 22.5 mm

(0.89 inch) knockout

Version

Compressor

model

D H1 H2 H3 H4 H5 L1 L2 L3 L4

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

Unified VZH170 -J 257 10 .12 329 12 .97 644.5 25. 39 686.5 2 7.0 4 83.6 3. 3 12 0.5 4 .74 345 13 .58 371 14. 61 279.4 11 277 10 .90 8560096

Ø 50.5 mm (1.99 inch) hole

Ø 63.5 mm (2.50 inch) knockout

Flat washer

Nut

20 AB221086441234en-001101

Compressor

base plate

28 mm

(1.10 inch)

Outline

drawing

number

Page 21

Dimensions

Connection Details

VZH088

Single

Suction connection 1"1/8 1"1/8 1"1/8 1"3/8 1"3/8 1"3/8 1"5/8 1"5/8 1"5/8

Discharge connection 7/8 " 7/8" 7/8 " 7/8" 7/8 " 7/8" 1"1/8 1"1/8 1"1/8

Oil sight glass

Oil level sensor None Threaded M20x1.5 None Threaded M20x1.5 None Threaded M20x1.5

Oil equalization connection Rotolock 1"3/4 Rotolock 1"3/4 Rotolock 2"1/4

Oil drain connection Female 1/4" Flare incorporating a Schrader valve

Low pressure gauge port

(Schrader)

Outline

Compressor models Brazed connection size

VZH088

VZH117

VZH170

Threaded

(1"1/8 – 18

UNF)

1 2 3 7 8 9 13 14 154 5 6 10 11 12 16 17 18

Suction 1"1/8 1"3/4 1"1/8

Discharge 7/8" 1"1/4 7/8" 120Z03 67

Suction 1"3/8 1"3/4 1"3/8

Discharge 7/8" 1"1/4 7/8" 120Z03 67

Suction 1"5/8 2 "1/4 1"5/8

Discharge 1"1/8 1"3/4 1"1/8 120Z03 64

VZH088

Manifolding

None

VZH088

Unified

on oil

equalization

port

Male 1/4" Flare incorporating a Schrader valve

VZH117

Single

Threaded

(1"1/8 – 18

UNF)

Rotolock Solder sleeve ODF Code Number Code Number

VZH117

Manifolding

None

Rotolock adaptor set

(adaptor, gasket, sleeve, nut)

VZH117

Unified

on oil

equalization

port

VZH170

Single

Threaded

(1"1/8 – 18

UNF)

120Z0125

120Z0405

7765028

VZH170

Manifolding

None

Rotolock adaptor

( adaptor only)

VZH170

Unified

on oil

equalization

port

120Z03 64

120Z0431

120Z0432

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

VZH compressors are all delivered with suction

and discharge brazed connections only. They are

copper-plated steel connections.

Rotolock adaptors are available, refer to the

information above.

21AB221086441234en-001101

Page 22

Dimensions

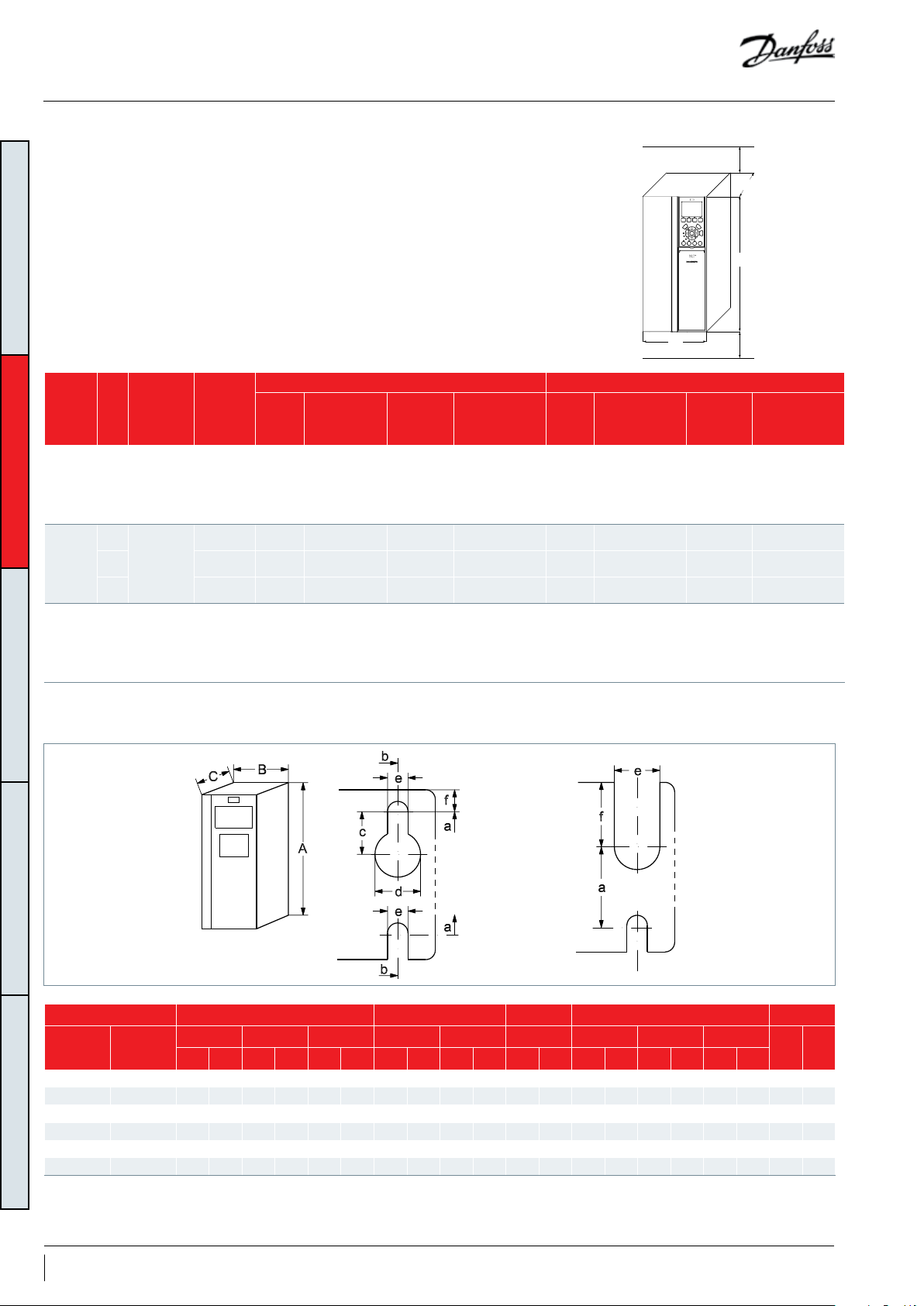

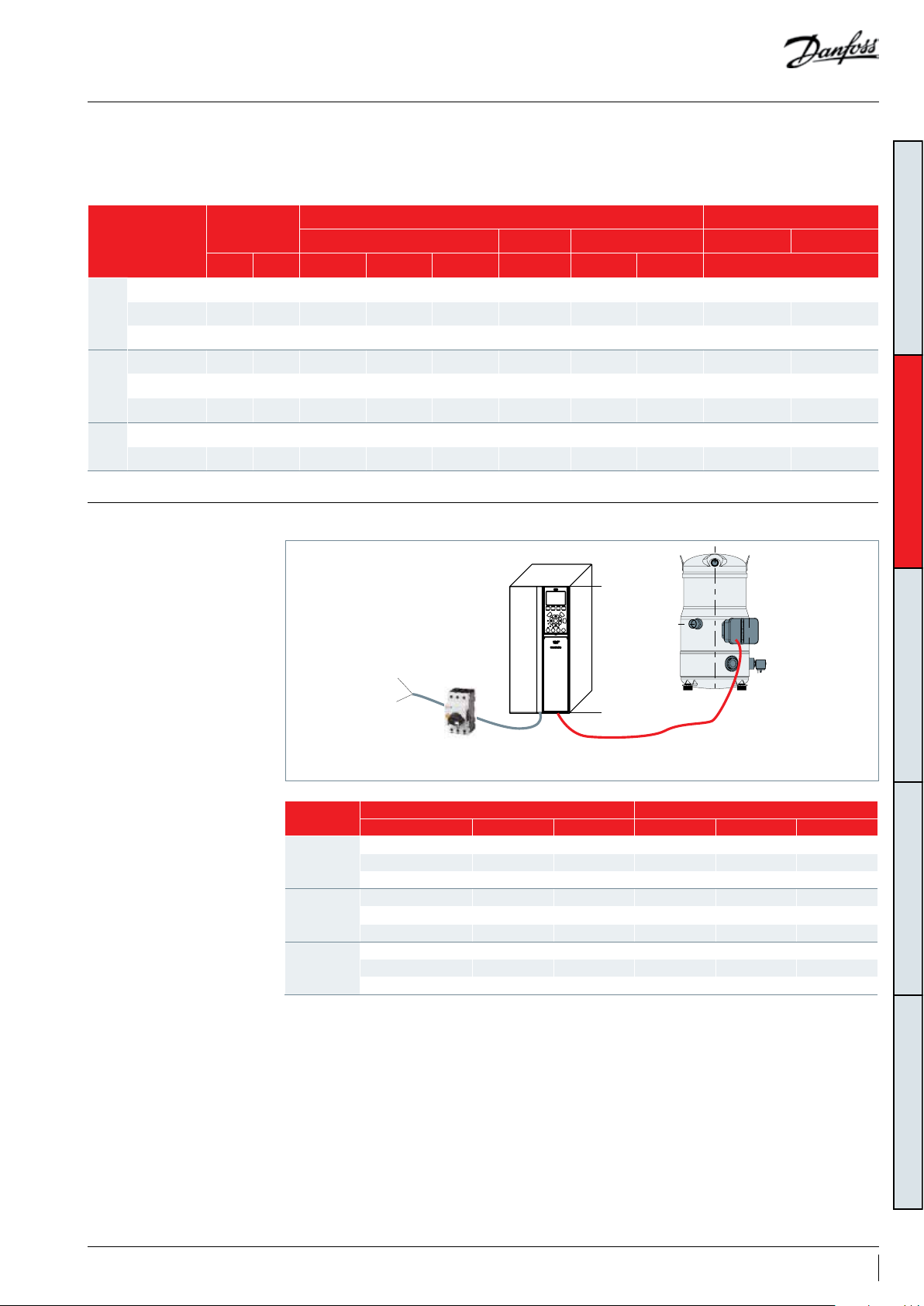

CDS303 Frequency

converter

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Drive

Drive

supply

power

voltage

200-240/3/

50-60

380-480/3/

50-60

525- 600/3/

50-60

kW

15

T2:

18. 5 V ZH117 C3

22 VZ H170 C3

15

T4:

18. 5 V ZH117 B4

22 VZ H170 B4

18

T6:

30 V ZH117 B4

30 VZ H170 B4

Compressor

voltage code

J

G

H

Frequency converter dimensions depend

on supply voltage, IP rating and power. The

table below gives an overview of the overall

dimensions and different drive enclosures (B1 B4). Details for each drive enclosure are on the

following pages.

IP20 IP55

Compressor

model

VZH088 B4

VZH088 B3

VZH088 B4

Drive

enclosure

Overall drive size

[H x W x L]

mm

(inch)

595x230x242

(23.43x 9.09x9. 53)

630x308x333

(24 .8x 12.13 x13.15)

630x308x333

(24 .8x 12.13 x13.15)

420x165x 249

(16.5x6. 5x9.76)

595x230x242

(23.42x9.09x 9.53)

595x230x242

(23.42x9.09x 9.53)

595x230x242

(23.42x9.09x 9.53)

595x230x242

(23.42x9.09x 9.53)

595x230x242

(23.42x9.09x 9.53)

Clearance

above/below

mm

(inch)

200

200

200

200

200

200

200

200

200

W

bracket supplied

2

(mm

)

enclosure

2pcs, ø24-28k28b

(8)

1pcs, ø32-36 k36b

1pcs, ø32-36 k36b

(8)

1pcs, ø36-40 k40b

1pcs, ø32-36 k36b

(8)

1pcs, ø36-40 k40b

(8)

(8)

(8)

(8)

(8)

(8)

3pcs, Ø13-22 B1

2pcs, ø24-28 k28b B2

2pcs, ø24-28 k28b B2

2pcs, ø24-28 k28b - - - -

2pcs, ø24-28 k28b - - - -

2pcs, ø24-28 k28b - - - -

Drive

C1

C1

C1

Overall drive size

[H x W x L]

mm

(inch)

680x308x310

(26.78x12 .13x12.20 )

680x308x310

(26.78x12 .13x12.20 )

680x308x310

(26.78x12 .13x12.20 )

480x242x260

(18.9x9. 45x10.24)

650x242x260

(25.6x 9.53x10.24)

650x242x260

(25.6x 9.53x10.24)

Clearance

above/below

mm

(inch)

200

(8)

200

(8)

200

(8)

100

(4)

200

(8)

200

(8)

Min 100/200

Clearance above for cooling

L

H

Min 100/200

Clearance above for cooling

bracket supplied

(mm2)

1pcs, ø32-36 k36b

1pcs, ø36-40 k40b

1pcs, ø32-36 k36b

1pcs, ø36-40 k40b

1pcs, ø32-36 k36b

1pcs, ø36-40 k40b

3pcs, ø3-32

3pcs, ø3-32

3pcs, ø14-40

For customers who needs other size brackets, please refer to accessories for ordering.

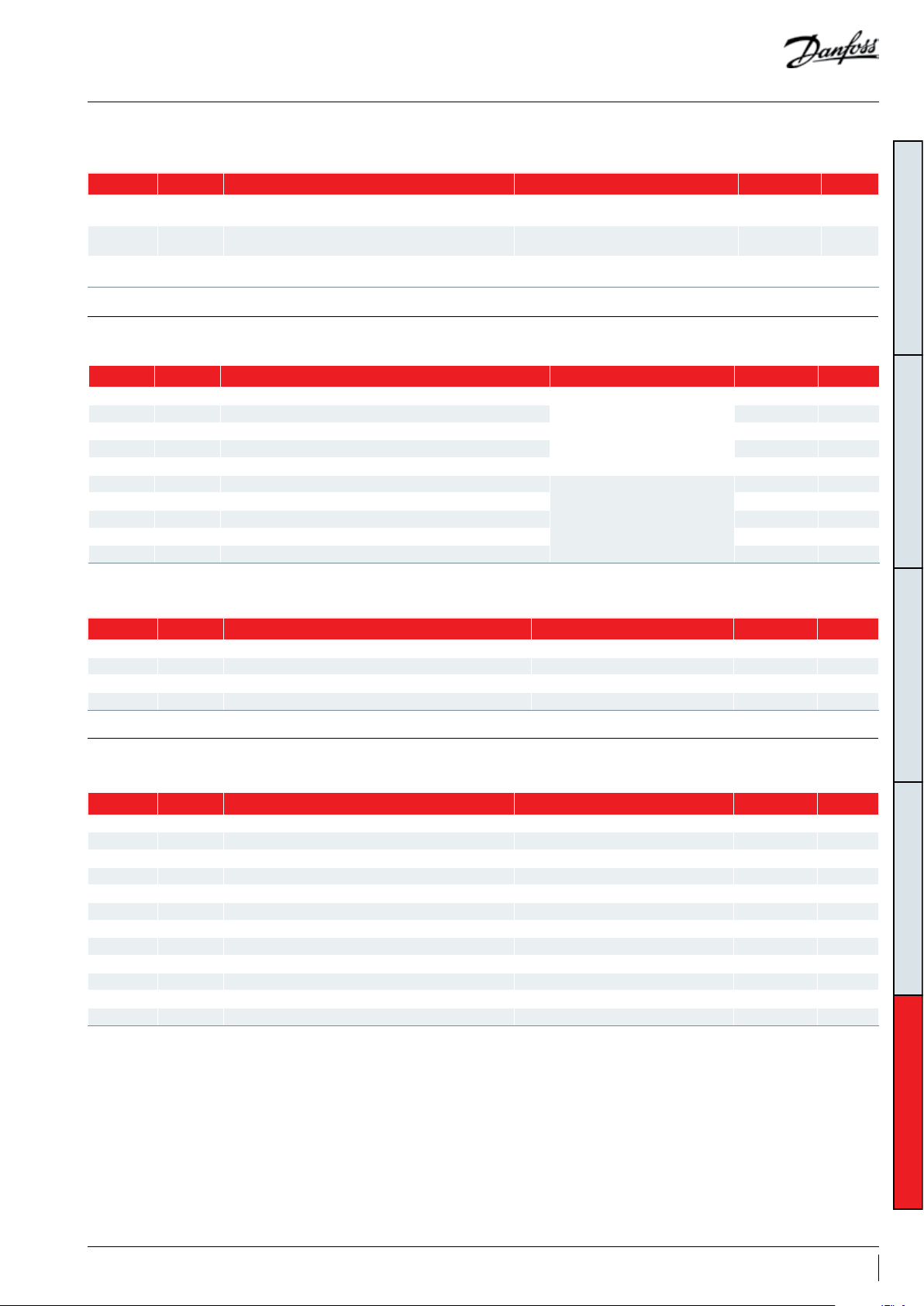

Enclosure Height Width Depth Mounting hole Max. Weight

Frame IP Class

B1 IP55 480 18.90 - - 454 17. 87 242 9. 53 210 8. 27 260 10. 24 19 0.75 9 0.35 9 0.35 23 51

B2 IP55 650 25. 59 - - 624 24.57 242 9.53 210 8.27 260 10.24 19 0.75 9 0. 35 9 0. 35 27 60

B3 IP20 399 15.71 420 16. 54 380 14.96 165 6.5 140 5 .51 249 9.8 12 0.47 6.8 0.27 7.9 0.31 12 26

B4 IP20 520 20.47 595 23.43 495 19 .49 230 9.06 200 7. 87 242 9. 53 - - 8.5 0. 33 15 0.59 23 51

C1 IP55 680 26.77 - - 648 2 5.51 308 12 .13 272 10.71 310 12. 20 19 0.75 9 0.35 9.8 0.39 45 99

C3 IP20 550 21.6 5 630 24.80 521 20.51 308 12 .13 270 10.63 333 13.11 - - 8.5 0.33 17 0.67 50 110

1)

A

Including decoupling plate.

The dimensions are only for the physical units, but when installing in an application it is necessary to add space for free air passage both above and below the units. The amount

of space for free air passage is listed in “frequency converter dimensions - Clearance above/below (mm/inch)”.

A A

mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch

1)

a B b C d e f

kg lb

22 AB221086441234en-001101

Page 23

Electrical data, connections and wiring

Supply voltage

Compressor electrical

specifications

Because VZH compressors are powered by a

frequency converter, the mains frequency, 50 or

60 Hz, is no longer an issue. Only the mains

voltage is to be taken into account. With 3 motor

voltage codes, the most common mains voltages

There is no modification for cooling capacity and

power input.

Since data published for code H is based on 575V

frequency converter supply, thus there will be no

coefficients modification applied for H code.

and frequencies are covered. Never connect the

VZH compressor directly to the mains power

supply in case of motor burnt.

VZH all published data and polynomials are

Voltage code Mains voltage range of drive

J 200-240V / 3ph / 50Hz & 60Hz (±10%)

G 380-480V / 3ph / 50Hz & 60Hz (±10%)

based on 208V frequency converter power supply

for code J and 400V for code G. When having

H 525-600V /3ph / 50Hz & 60Hz (±10%)

a supply of 230V, 380V or 460V the following

coefficients must be applied:

I

= 0.87* I

460

I

= 1.05* I

380

I

= 0.90* I

230

RW: Winding resistance per winding (in CDS303 parameter list)

RLA: Rated load current

MMT: Maximum must trip current

Note that parameter 1-30 in the frequency converter settings reflects the winding resistance per winding. This is not the same value

as measured at the motor terminals.

400

400

208

200 - 240 Volt

380 - 480 Volt

525 - 600 Volt

Compressor

VZH088-J 0.03 74. 8 93.5

VZH117-J 0.02 88.0 110 .0

VZH170-J 0.01 115.0 143.8

VZH088-G 0.10 37. 5 46.9

VZH117- G 0.08 44.0 55.0

VZH170- G 0.05 61.0 76.3

VZH088-H 0.10 37. 5 46.9

VZH117- H 0.08 44.0 55.0

VZH170- H 0.05 61.0 76.3

RW RLA MMT

(Ohm) (A) (A)

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

RLA (Rated Load Amp)

MMT (Maximum Must

Trip current)

Wiring connections

Rated Load Amp value is the current value at

maximum load, in the operating envelope, and at

maximum speed and rated drive input voltage.

The Maximum Must Trip current is defined

for compressors not equipped with their

own motor protection. This MMT value is the

maximum at which the compressor can be

operated in transient conditions and out of

the operating envelope. The tripping current

of external overcurrent protection, in this case

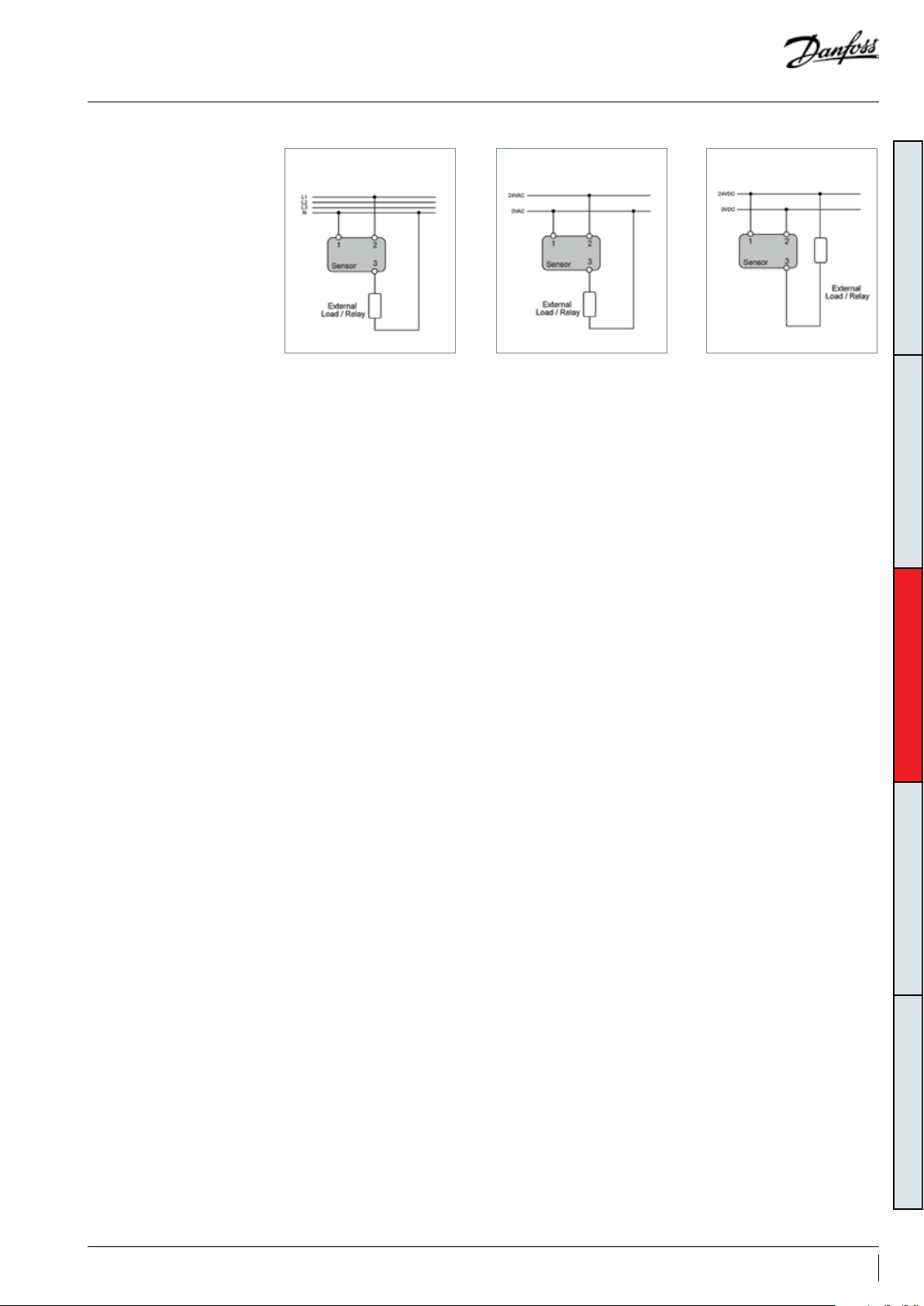

Electrical power is connected to the compressor

terminals by Ø 4.8 mm (3/16") screws. The

maximum thightening torque is 3 Nm. Use a 1/4"

ring terminal on the power leads.

RLA is the measured value at the compressor

terminals (after the drive).

preprogrammed in the drive, never exceeds the

MMT value.

For VZH compressors, according to

ULrequirements, MMT value is 125% of RLA. This

value is printed on the compressor nameplate.

Cable gland or similar protection

component must be used on electrical box’s

knockouts to against accidental contact with

electrical parts inside.

23AB221086441234en-001101

Page 24

Electrical data, connections and wiring

Cover holding screw (x2) - Torque: 2.2 Nm

VZH0 88/117- G/H The terminal box is provided with a φ 33mm

(φ1.3 inch) hole (ISO32) for power supply.

VZH0 88/117-J

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

VZH170-G/H

The terminal box is provided with a φ 40.5mm

(φ1.59 inch) hole (ISO40) for power supply and a

φ 16.5mm (φ0.65 inch) knockout (ISO16) .

φ 40.5mm (φ 1.59inch) (ISO 40) hole with possible

φ 50.5mm (φ 1.98inch)(ISO50) knockout for

power supply

Ø 16.5 mm

(0.65 inch)

knockout

Ø 33 mm

(1.30 inch) hole

Power supply

Ø 40.5 mm

(1.59 inch) hole

Power supply

Terminal box

VZH170-J

φ 50.5mm (φ 1.98inch) (ISO 50 & UL1”1/2

conduit) hole with possible φ 63.5mm (φ 2.5inch)

(ISO63 and UL 2”conduit) knockout for power

supply.

• 2 x φ 22.5mm (φ 0.89inch) (PG16 and UL .”

conduit) knockouts.

Ø 40.5 mm

(1.59 inch) hole

Ø 50.5 mm

(1.99 inch) knockout

Ø 22.5 mm

(0.89 inch) knockout

Sump heater

Faston 1/4" tabs

Power supply

Sump heater

Ø 50.5 mm (1.99 inch) hole

Ø 63.5 mm (2.50 inch) knockout

24 AB221086441234en-001101

Page 25

Electrical data, connections and wiring

Fuses / circuit breakers

Danfoss recommends using the fuses/circuit

breakers listed below to protect service

personnel and property in case of component

EN 50178

Frequency converter

CDS-15kW 125 A gG KTN -R125 JKS-150 JJN-125 2028220-125 K LN- R125 A2K-125R NZMB1-A100 NZMB2-A200

CDS-18.5 kW 125 A gG K TN-R12 5 JKS -150 JJN -125 2028220-125 KLN -R125 A 2K-125R NZMB2-A200 NZMB2-A200

200-240 V

CDS -22 kW 16 0 A gG F WX-150 - - 2028220-150 L25S-15 0 A25X-150 NZMB2-A200 NZMB2-A200

CDS-15 kW 63 A gG KTS-R50 JKS-50 JJS-50 5014006-050 KLS-R50 A6K-50R PKZM4-50 PKZM4-63

CDS-18.5 Kw 63 A gG KTS-R60 JKS-60 JJS-60 5014006 -063 KLS-R60 A6K-60R N ZMB1-A100 N ZMB1-A100

380-480 V

CDS -22 kW 80 A gG KTS-R80 JKS-80 JJS-80 2028220-100 KLS-R80 A6K-80R NZMB1-A100 NZM B1-A100

CDS-18.5 kW 40A gG KTS-R50 JKS-50 JJS-50 5014006-050 KLS-R50 A6K-50R NZMB1-A100 -

CDS-30 kW 63A gG KTS-R80 JKS-80 IJS-80 5014006- 080 KLS-R80 A6K-80R NZMB1-A100 -

525-600V

compliant fuses

Size Type Type RK1 Type J Type T Type RK1 Type RK1 Type RK1 Moeller type

Bussmann SIBA Little fuse IP20 IP55

UL Compliant fuses Recommended circuit breaker

break-down in the frequency converter. For

circuit breakers, Moeller types have been tested

and are recommended.

Wire sizes Below table lists maximum wiring sizes for the motor compressor power supply cables.

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

from network

to drive

I

Power input

Circuit breaker

From network to frequency converter From frequency converter to compressor

Typ e mm² AWG Type mm² AWG

CDS-15kW 25 4 VZH088-J 25 4

200 - 240 V

380 - 400 V

525 - 600 V

Note: The wire size here is the guidelines is the maximum wire size connectors can accept but not the actual needed cable. The needed cable size should be specified by the OEM depending on the unit design, ambient temperature, the wire material, current, etc...

CDS-18.5 kW 35 2 V ZH117-J 35 2

CDS -22 kW 50 1 V ZH170-J 50 1

CDS-15 kW 6 10 VZH088-G 6 10

CDS-18.5 Kw 10 8 V ZH117- G 10 8

CDS -22 kW 16 6 VZH17 0- G 16 6

CDS-18.5 kW (IP20) 10 8 VZH088-H 6 10

CDS-30kW (IP20) 25 4 VZH117- H 10 8

CDS-30kW (IP20) 25 4 VZH170H 16 6

from drive to

to compressor

25AB221086441234en-001101

Page 26

Electrical data, connections and wiring

Soft-start control

Phase sequence and reverse rotation protection

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

The CDS303 frequency converter generates by

design a compressor soft start with an default

initial ramp up of 2700rpm/s.

Current inrush will not exceed the frequency

converter maximum current.

The compressor will only operate properly

in a single direction. If electrical connections

are done correctly between the drive and the

compressor terminals (compressor T1/T2/T3 and

drive terminals U, V & W matching), the drive will

provide correct phase supply to the compressor,

and reverse rotation will be not possible:

• CDS terminal U (96) to VZH terminal T1

• CDS terminal V (97) to VZH terminal T2

• CDS terminal W (98) to VZH terminal T3

If compressor T1/T2/T3 and drive U, V & W

terminals are not matching, the compressor

can operate in a reverse rotation. This results in

excessive noise, no pressure differential between

Basically seen from the mains, the inrush peak

reach a level which is only a few percent more

than the rated nominal current.

suction and discharge, and suction line warming

rather than immediate cooling. The compressor

can be rapidly damaged in these conditions.

If reverse rotation symptoms occur, shut the

compressor down and connect the phases to

their proper terminals.

Mains connection to the CDS frequency

converter order has no influence on the output

phase sequence which is managed by the

frequency converter.

26 AB221086441234en-001101

Page 27

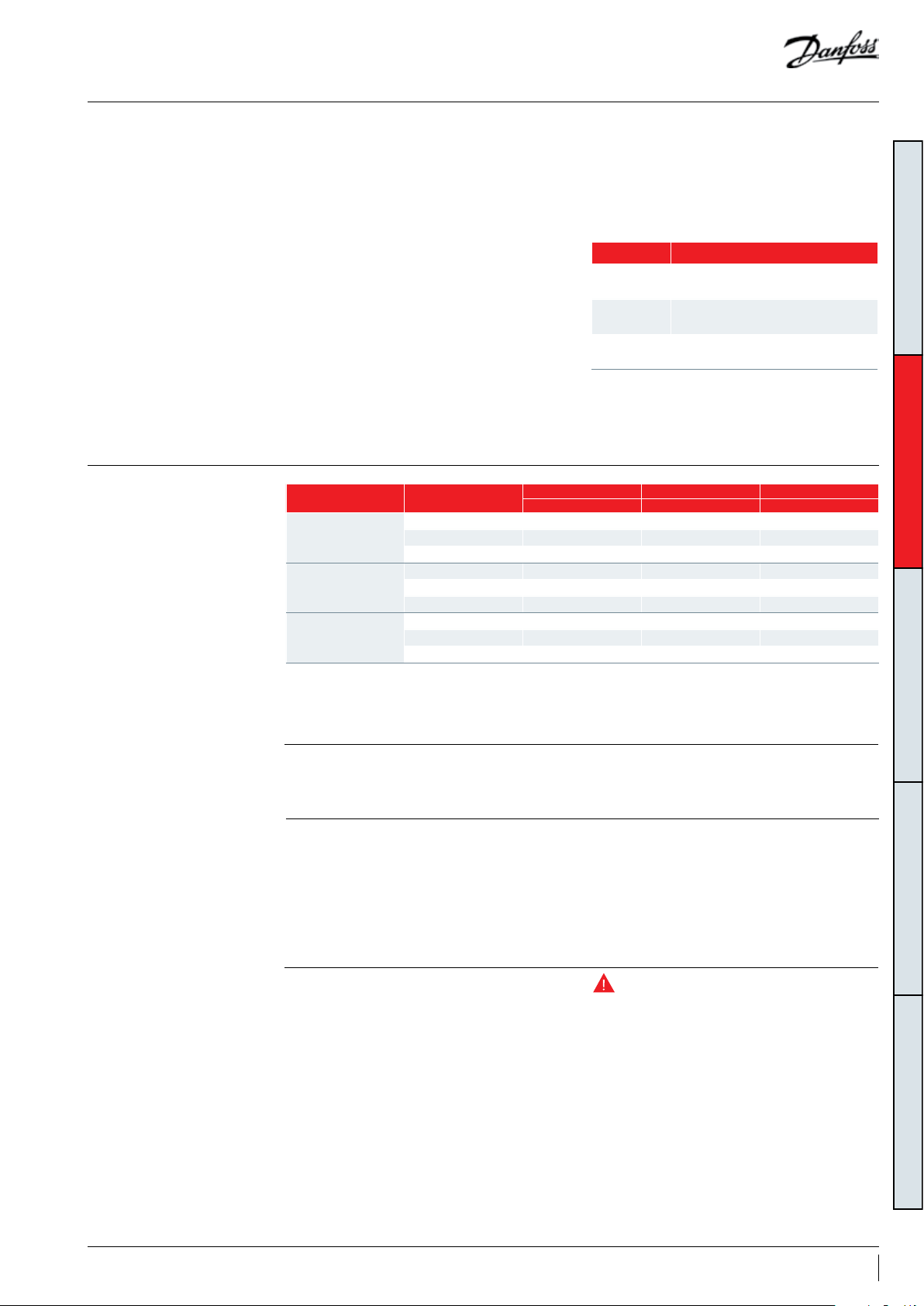

Electrical data, connections and wiring

IP rating

Motor protection

The compressor terminal box IP rating according

to CEI529 is IP54 when correctly sized IP54 rated

cable glands are used.

Element Numerals or letters Meaning for the protection of equipment

Against ingress of solid foreign objects

0

First characteristic

numeral

Second

characteristic

numeral

1

2

3

4

5

6

0

1

2

3

4

5

6

7

8

VZH scroll compressors are not equipped with

an internal motor protector. Motor protection

is provided by the variable speed drive. All

parameters are factory preset in order to

guaranty locked rotor or overload current

(non protected)

≥ 50 mm diameter

≥ 12.6 mm diameter

≥ 2.5 mm diameter

≥ 1.0 mm diameter

dust protected

dust tight

Agains ingress of water with harmful effects

(non protected

vertically dripping

dripping (15° tilted)

spaying

splashing

jetting

powerful jetting

temporary immersion

continuous immersion

When a warning situation is reached in the

current control, the CDS frequency converter

will automatically reduce the compressor

speed in order to keep the motor current of the

compressor below the maximum allowed.

protection.

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Voltage imbalance

The maximum allowable voltage imbalance

between each phase is 3%. Voltage imbalance

causes high amperage over one or several

phases, which in turn leads to overheating and

possible drive damage.

27AB221086441234en-001101

Page 28

Approval and certificates

certificates

Pressure equipment

directive 2014/68/EU

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

VZH compressors comply with the following approvals and certificates.Approvals and

CE

(European Directive)

UL

(Underwriters Laboratories)

EMC

2014/30/EU

Products VZH088 V ZH117 V ZH170

Fluids Group 2

Category PED II

Evaluation module D1

TS - service temperature LP

PS - service pressure LP

33.3 bar(g)

483 psi(g)

VZH code G & code J

All VZH models

All VZH models

-35°C < TS < +55°C

-31°F < TS < 131°F

33.3 bar(g)

483 psi(g)

-35°C < TS < +51°C

-31°F < TS < 123.8°F

30.2 bar(g)

438 psi(g)

Low voltage directive

2014/35/EU

Internal free volume

Products VZH088-117-170

Declaration of conformity

ref. Low voltage Directive 2014/35/EU

Internal free volume at LP side without oil

Products

VZH088 12. 7 775

VZH117 15.1 921

VZH170 29.9 1825

Contact Danfoss

litre cu.inch

28 AB221086441234en-001101

Page 29

Drive installation

Direct and indirect exposure of drive to water

Condensation

IP20 drives are intended for indoor or cabinet

mounting. Application example: drive fitted in

a machine room, basement or in an electrical

cabinet together with other electric / electronic

components such as the unit controller or

contactors.

For outdoor use the electrical cabinet must

be IP54 or the drive itself must be IP54 at

Condensation must always be avoided. There is a

specific risk of condensation when the frequency

converter or some of its components are

colder than moist ambient air. In this situation,

the moisture in the air can condense on the

electronic components.

• Operating with the frequency converter

constantly connected to the mains can help

to reduce the risk of condensation. Install a

cabinet heater in situations where there is a

real possibility of condensation due to ambient

conditions.

• If the drive is IP 20, then evaluate and prevent

possibility of condensation above drive.

Example: condensation on metallic frame above

drive, piping…

least. Application example: rooftop units or

condensing units.

If IP54 with LCP make sure that the gasket is

applied to ensure tightness.

It is recommended to place drive at least 30cm

(11.81 inches) from ground to protect against

floods.

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

If unavoidable, solutions like cabinet heater, a

pace heater, top hat on the drive, insulation in

the electric panel can be a solution.

PCB temp

dew

point

• Water resulting of condensation must not

accumulate on the bottom of electric panel.

Provide a drain for condensed water to run out

if necessary.

• No other forced cooling then internal drive fan.

Dust Exposure

Mechanical Mounting

Clearance

Avoid Dust forms and deposits on the surface

of the drive and inside on circuit boards and the

electronic components. These deposits act as

insulation layers and hamper heat transfer to

the ambient air, reducing the cooling capacity.

The components become warmer. This causes

accelerated aging of the electronic components,

and the service life of the unit decreases. Dust

deposits on the heat sink in the back of the unit

also decrease the service life of the unit.

For optimal cooling conditions, mount the drive

on vertical position. Allow a free air passage

Enclosure type* B1 B2/B3/B4/C1/C3 C2/C4

a (mm/inch) 100/3.94 200/7.87 225/8.86

b (mm/inch) 100/3.94 200/7.87 225/8.86

*: Enclosure please refer to drive enclosure table

in section “CDS303 Frequency converter”.

The drive cooling fans have small bearings into

which dust can penetrate and act as an abrasive.

This leads to bearing damage and fan failure.

Under the conditions described above, it is

advisable to clean the frequency converter

during periodic maintenance. Remove dust off

the heat sink and fans and clean the filter mats.

above and below the frequency converter.

See Table below:

Horizontal mounting is NOT the preferred

position, however if unavoidable, lay PCB

on the left side (270°) to avoid condensation

accumulation on the electronics.

29AB221086441234en-001101

Page 30

Drive installation

Ambient temperature The maximum ambient temperature for the drive

is 50°C (122°F).

Make sure that the clearance limits described

above are respected.

The drive must be installed on a wall or on a back

plate to ensure proper cooling

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Do not place the drive under direct sunlight.

Insulation inside the electrical panel can reduce

impact of sun radiation.

Test at the unit at highest ambient maximum

load is recommended. Look for over temperature

drive alarm

The drive could operate lower to -10C (14F)with

proper operation, such as inside the cabinet,

install the space heater. However, LCP may not

function well under such low temperature.

30 AB221086441234en-001101

Page 31

EMC installation

EMC Frequency converter (and other electrical

devices) generate electronic or magnetic fields

that may interfere with their environment. The

electromagnetic compatibility (EMC) of these

effects depends on the power and the harmonic

characteristics of the devices.

Category Definition

C1

Frequency converters installed in the first environment (home and

office) with a supply voltage less than 1000 V.

Frequency converters installed in the first environment (home and

C2

office) with a supply voltage less than 1000 V, which are not plugin and not movable, and must be installed and commissioned by a

professional.

C3

Frequency converters installed in the second environment (industrial)

with a supply voltage lower than 1000 V.

Frequency converters installed in the second environment with a

C4

supply voltage equal to or above 1000 V or rated current equal to or

above 400 A or intended for use in complex systems.

VZH compressor with drive package achieve EMC Class A Group 1 emission and immunity requirements.

EMC best practices • Use screened (shielded) cables for motor,

control wiring and communication.

• Separate cables for input power, motor wiring

and control wiring. Failure to isolate power,

motor, control and communication cables

can result in unintended behavior or reduced

performance. Minimum 200 mm (7.9 in)

The EMC product standard for frequency

converters defines 4 categories (C1, C2, C3, and

C4) with specified requirements for emission and

immunity. Table below states the definition of

the 4 categories and the equivalent classification

from EN 55011.

Equivalent emission

class in EN 55011

Class B

Class A Group 1

Class A Group 2

No limit line.

Make an EMC plan

clearance between power, motor and control

cables is required.

• Ensure VFD proper grounding

• Motor cables should be as short as possible to

reduce noise level and leakage currents.

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

EMC correct installation

of an frequency drive

CDS303

EMC qualification reports are available upon request to Danfoss technical support.

PLC etc. Panel

PLC

Min. 0.025 in ²

(16 mm²)

Equalizing cable

Control cables

Mains supply

L1

L2

L3

PE

Reinforced protective ground

Min. 7.9 in

(200 mm)

between control

cables, motor cable

and mains cable

Decoupling plate

Grounding rail

Cable insulation

stripped

All cable entries in

one side of panel

Motor cable

Motor, 3 phases and

protective ground

31AB221086441234en-001101

Page 32

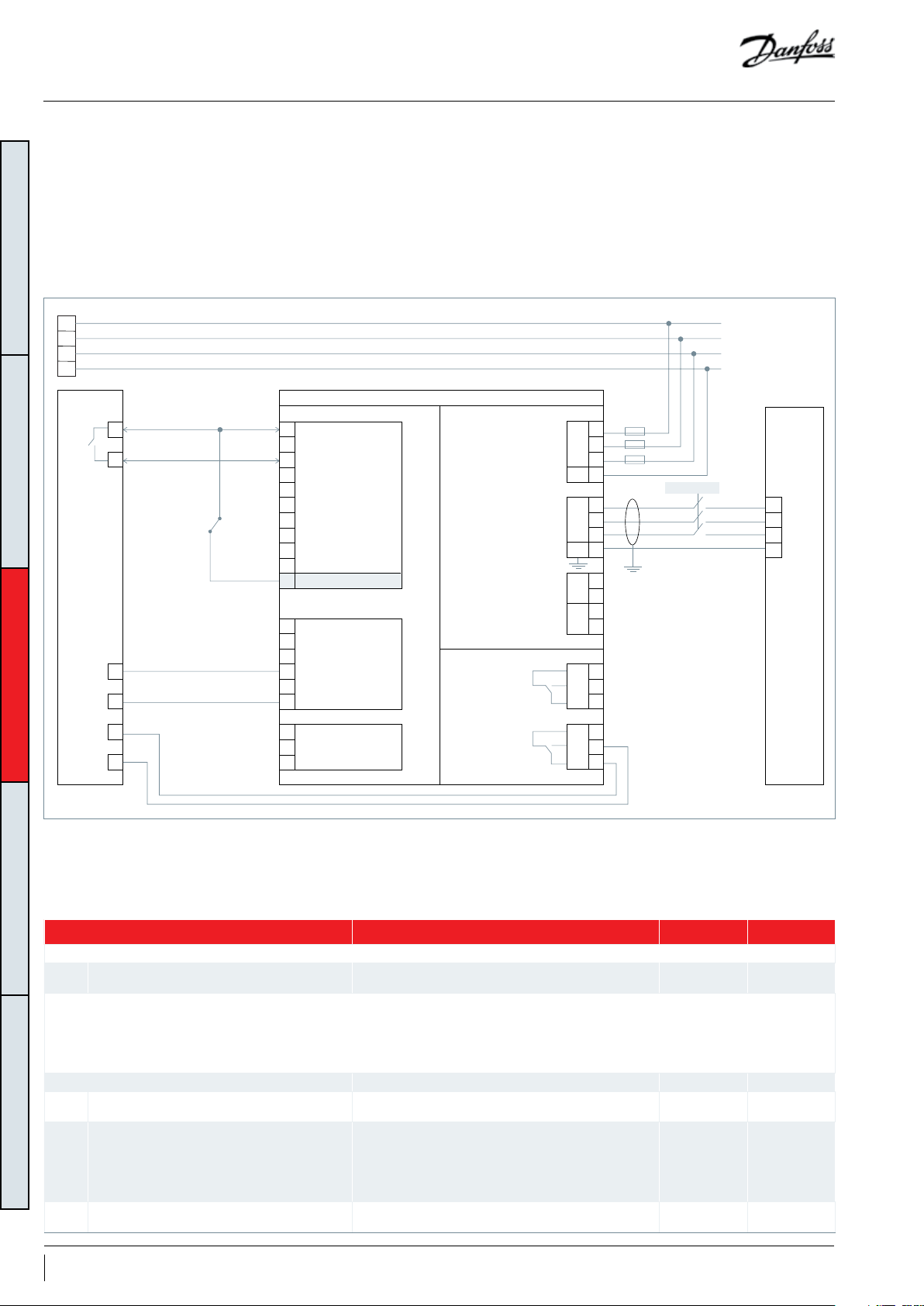

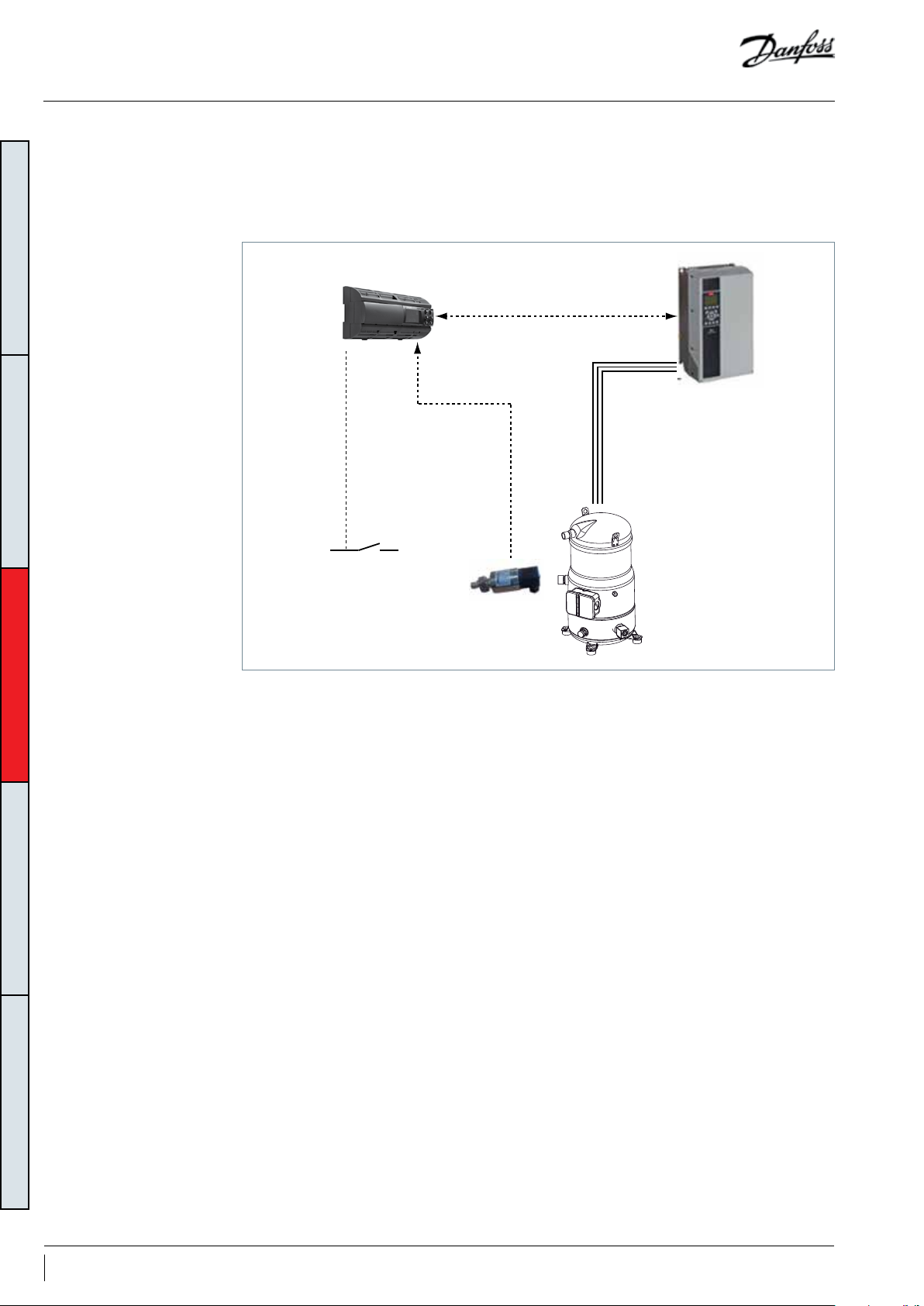

Unit Architecture

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

L1

L2

L3

PE

Comp. ON /OFF

Relay

Unit Controller

Analogue out

a

b

W

X

Start / Stop

HP switch

0-10V DC speed signal

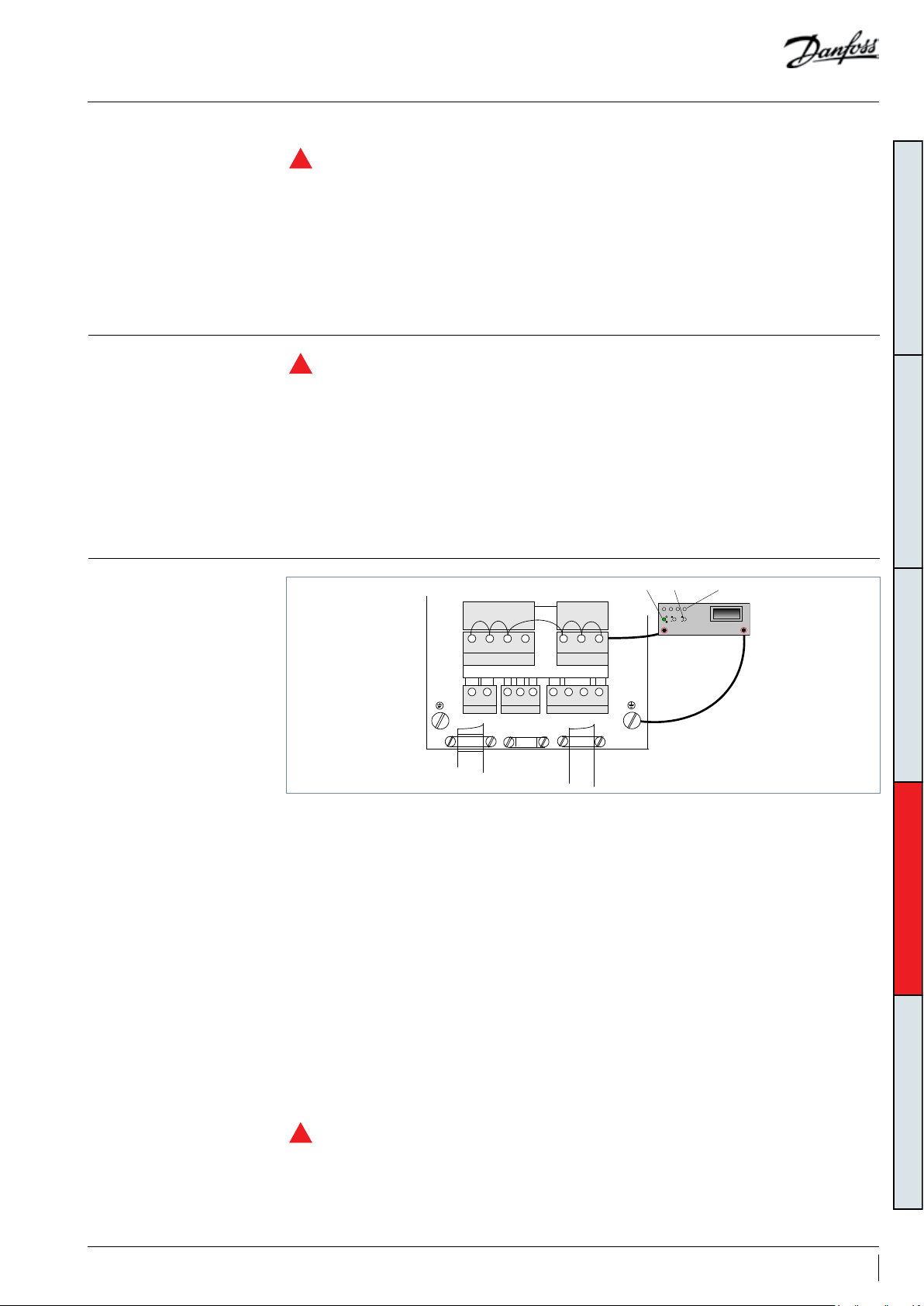

The frequency converter is pre-set for speed

open loop control. This means that the speed setpoint is given by a 0-10V, where 0V corresponds

to the minimum compressor speed and 10V is

maximum compressor speed.

SCHEMATIC DIAGRAM

CDS 303

+24V CC (150mA max.)

12

+24V CC

13

Digital Input

18

Digital Input

19

Digital Input

27

29

Digital Output

Digital Input

32

Digital Input

33

Digital Input Common

20

37

Safe Stop Input

Analog Output Common

39

42

Analog Output 1 0/4-20mA

+10V CC (15mA max.)

50

53

Analog Input 1

Analog Input 2

54

55

Analog Inputs Common

Relays

3 phase

power input

50/60Hz

Motor output

Load sharing

Brake resistor

Relay 1

The unit controller must have full control of

the compressor operation and application

protections such as compressor envelope

control, oil return management and short cycling

protection.

Below is the Danfoss proposed system

configuration and wiring.

L1 91

L2

L3

PE

U

V

W

PE

+DC

RR+

CM 01

NO

NC

Fuses

92

93

95

96

97

98

99

88-DC

89

81

82

02

03

Contactor

T1

T2

T3

PE

VZH

04

CM

NO

NC

05

06

Alarm

Digital input

61

Y

Z

COM Serial

68

P Communication

69

N RS-485

Relay 2

NOTE 1: Only relevant parameters or the ones different from factory defaults are shown.

NOTE 2: Oil boost, short cycle protection to be programmed in the unit controller

NOTE 3: Use Safe Stop for HP switch in CDS303 or use an output contactor (CDS803)

Drive parameters to adjust (See Note 1)

Drive parameters Description Value Default

Short cycle protection is done by unit controller

28.00 Short cycle protection

Short cycle protection is done in drive; If short cycle protection enabled in drive, the Terminal 18 start/stop will be ignored during minimum run

time. To be able to stop compressor during this minimum run time (Low pressure trip..), it is necessary to use Terminal 27 (Par 5.12) and set it to “Coast

inverse”

If Modbus is used it is not necessary to connect terminal 27, but a “Coasting” command must be sent to be able to stop compressor in case of an alarm

during minimum run time.

28.00 Short cycle protection Short cycle protection done by the drive. Enable Enable

28.01 Interval between starts

28.02 Minimum Run time

5.12 Terminal 27 Digital input Designated for the LP switch.

Short cycle protection done in unit controller: (preferred

option)

Start command is ignored until the timer (300s) has

elapsed. Only then, can the compressor start.

The compressor cannot stop until the set time (180s) has

elapsed.

The timer starts counting following a compressor start.

Stop command is ignored.

Only a coast (inverse) command can override the time

and stop the compressor.

Disable Enable

300 sec 300sec

180 sec 180sec

[2]* Coast

inverse

coast inverse

32 AB221086441234en-001101

Page 33

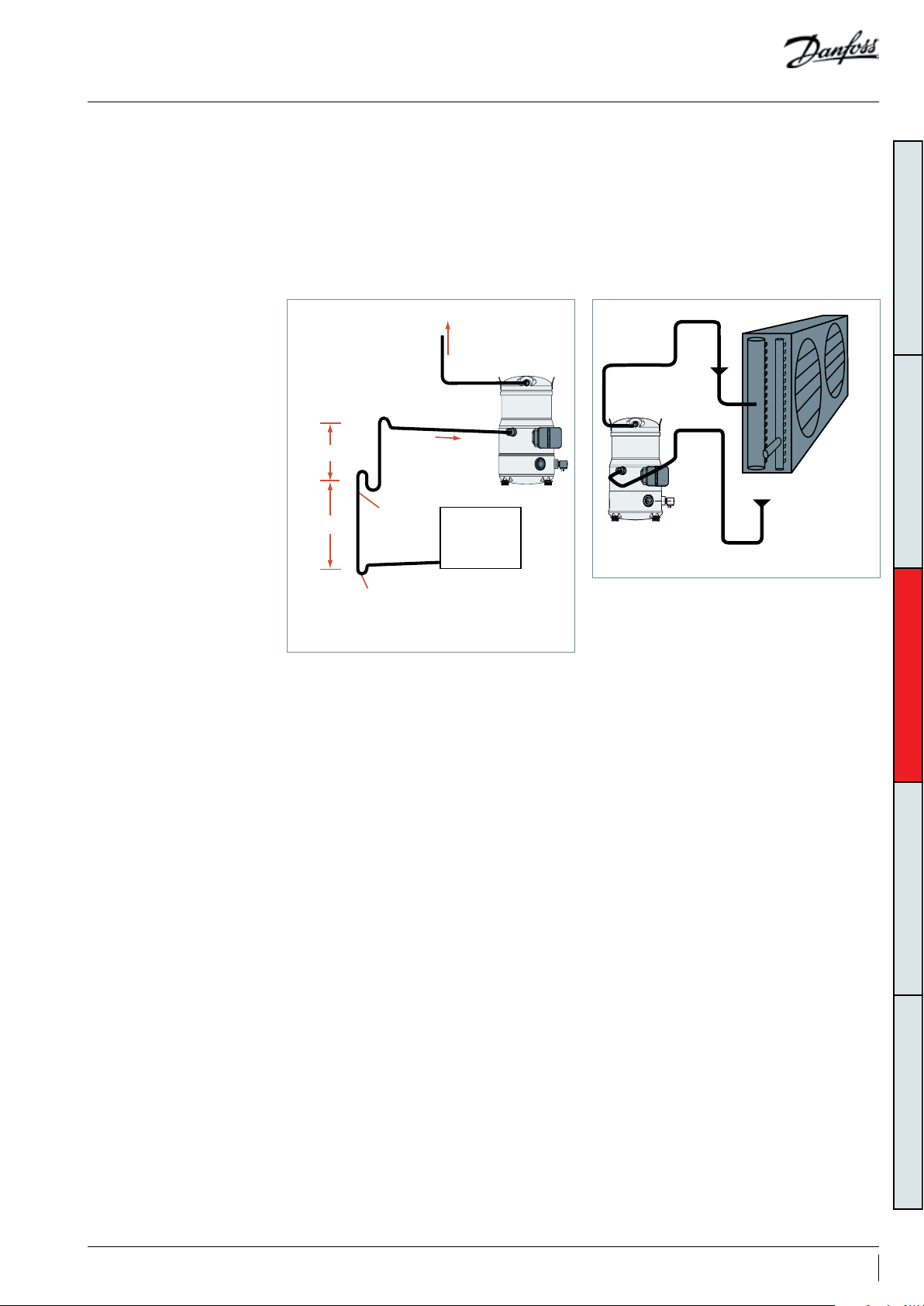

Design piping

General requirements Proper piping practices should be employed to:

1. Ensure adequate oil return, even under

minimum load conditions (refrigerant speed,

piping slopes…). For validation tests see section

“Manage oil in the circuit”.

To condenser

HP

max. 4m (13ft)

max. 4m (13ft)

0.5% slope

4m/s or more

(13ft/s or more)

U-trap,

as short as possible

8 to 12m/s

(26 to 40ft/s)

0.5% slope

4m/s or more

(13ft/s or more)

U trap, as short as possible

LP

Evaporator

2. Avoid condensed liquid refrigerant from

draining back to the compressor when stopped

(discharge piping upper loop). For validation

tests see section “Manage off cycle migration”.

General recommendations are described in the

figures below:

Upper loop

HP

LP

Condenser

3D flexibility

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

3. Piping should be designed with adequate

three-dimensional flexibility to avoid excess

vibration. It should not be in contact with the

surrounding structure, unless a proper tubing

mount has been installed. For more information

on noise and vibration, see section on: “Sound

and vibration management”.

4. The design in this guideline is for short circuit

application. However, for long circuit and split

system application, an oil separator and an

external non-return valve are mandatory to use.

33AB221086441234en-001101

Page 34

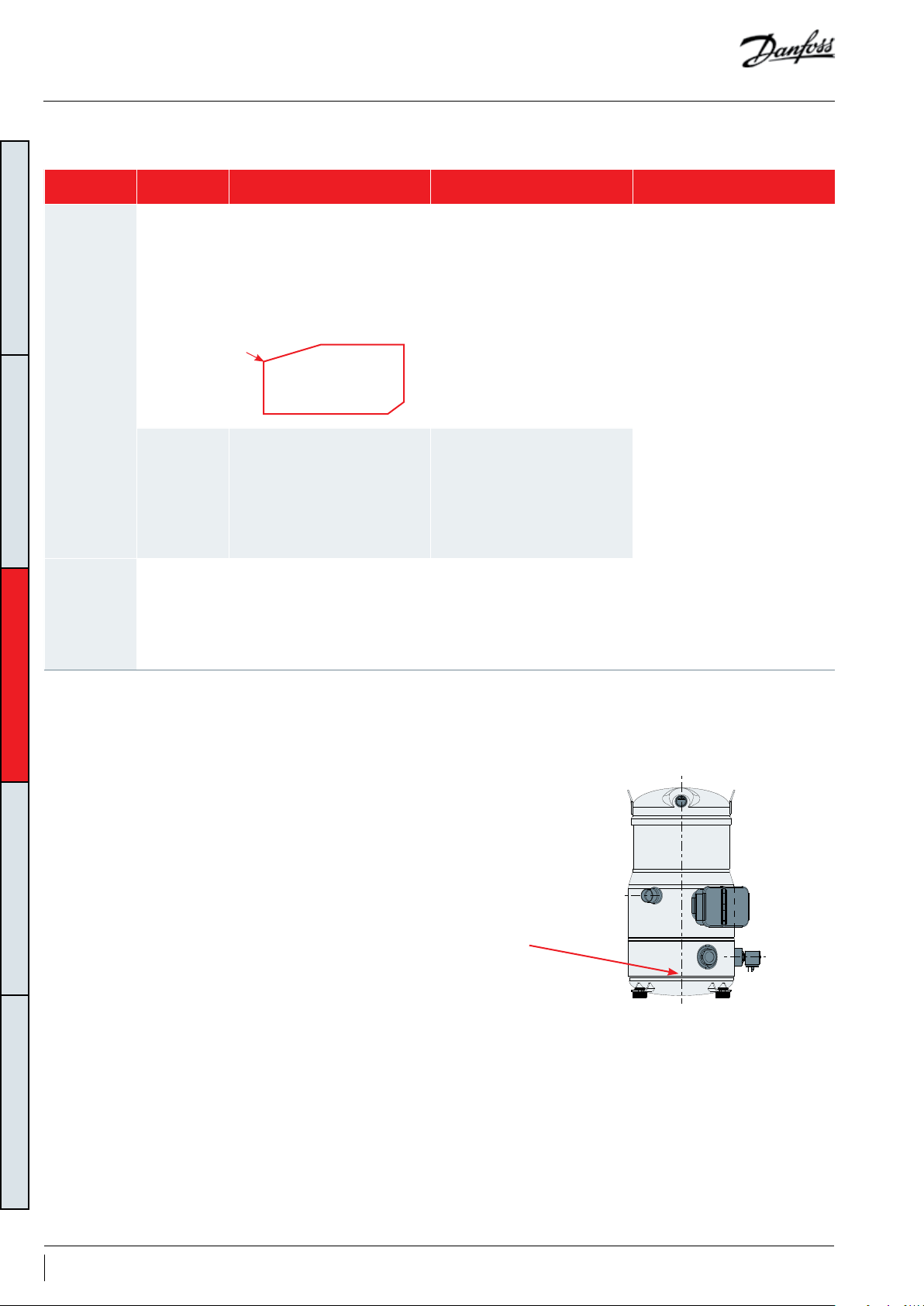

Design compressor mounting

General requirements

Single requirements

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Compressors used in single applications must be

mounted with flexible grommets.

Maximum inclination from the vertical plane

while operating must not exceed 3 degrees.

VZH compressors come delivered with four

rubber mounting grommets and metal sleeve

liners that serve to isolate the compressor from

the base frame. These grommets must always

The required bolt size for the VZH088 & 117

compressors is HM8-40. This bolt must be

tightened to a torque of 15 Nm (11 ft/lbs.).

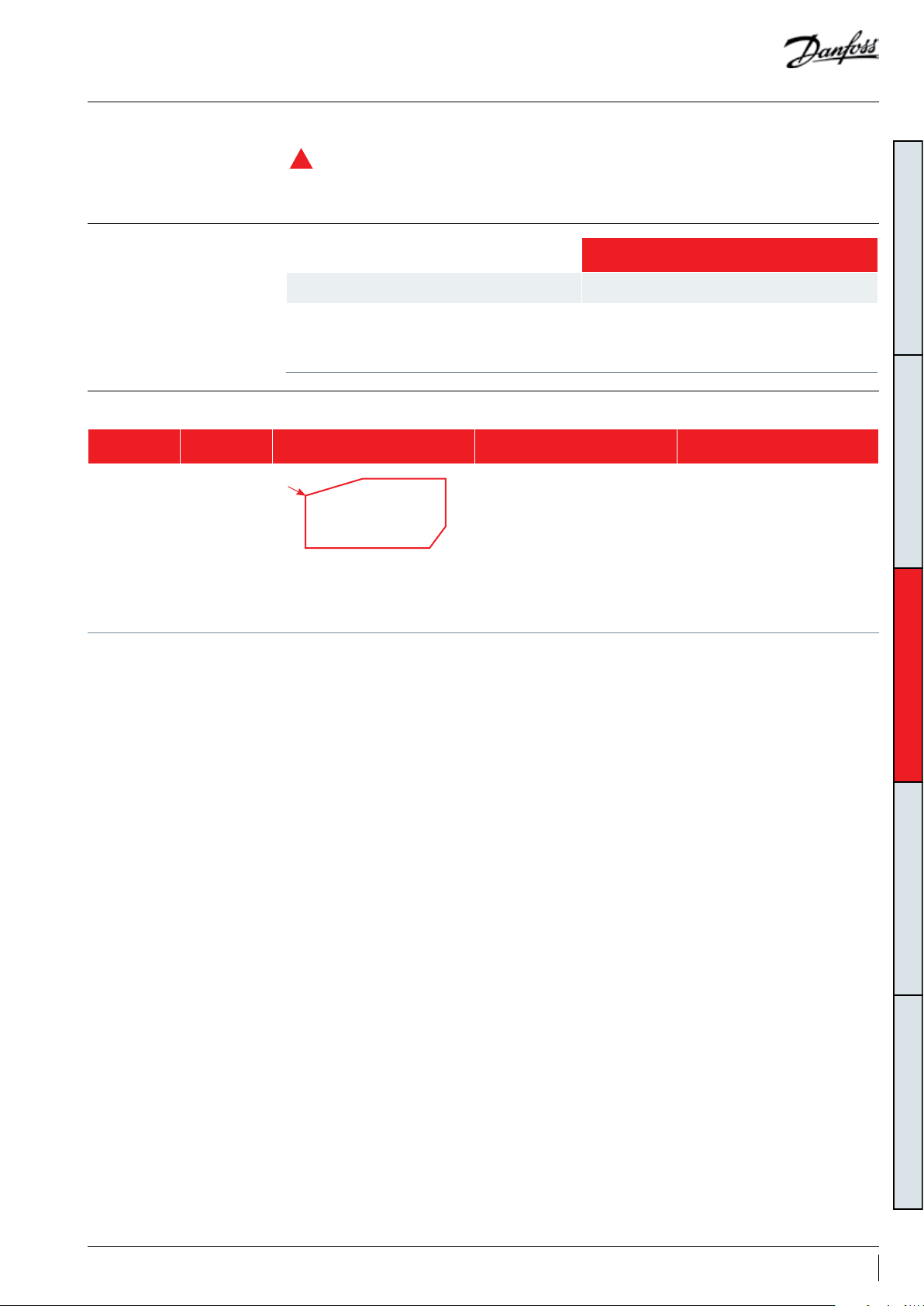

HM 8 bolt

Lock washer

Flat washer

Steel mounting

sleeve

Rubber grommet

Nut

15 mm

(0.59 inch)

During operation, the maximum inclination from

the vertical plane must not exceed 3 degrees.

be used to mount the compressor in a single

application. The grommets must be compressed

until contact between the flat washer and

the steel mounting sleeve is established. The

grommets attenuate to a great extent the

transmission of compressor vibrations to the base

frame.

The required bolt size for VZH170 compressors

is HM8-55 and must be tightened to a torque of

21Nm (15 ft/lbs).

HM 8 bolt

Lock washer

Flat washer

Steel mounting sleeve

Rubber grommet

Nut

Compressor

base plate

28 mm

(1.10 inch)

34 AB221086441234en-001101

Page 35

Manage oil in the circuit

Requirement

R

Oil level must be visible or full in the sight

glass when the compressor is running and when

all compressors of the circuit are stopped.

System evaluation

Single compressor

Non split Test N°1

1. Since each installation is unique, test can not validate

Split

the oil return, Oil separator is mandatory

2. Pay special attention to “Piping design” on field

3. Oil level must be checked and adjusted at

commissioning.

Test, criteria and solutions

Test N° Purpose Test condition Pass criteria Solutions

A

1. Top-up with oil, generally 3% of

the total system refrigerant charge

1

Check proper

oil return

Lowest foreseeable evaporation,

and highest foreseeable

condensation.

Minimum speed running 6 hours.

For reversible system, perform test

in both heating and cooling mode.

Oil level must be visible or full in the

sight glass when the compressor is

running.

(in weight). Above 3% look for

potential oil trap in the system.

2. Adjust oil boost function, for more

details see section”Oil management

logic”.

3. Oil separator can be added

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

35AB221086441234en-001101

Page 36

Manage sound and vibration

Typical sounds and vibrations in systems can be

broken down into the following three categories:

• Sound radiation (through air)

• Mechanical vibrations (through parts and

structure)

Compressor sound radiation

For sound radiating from the compressors,

the emission path is air and the sound waves

are travelling directly from the machine in all

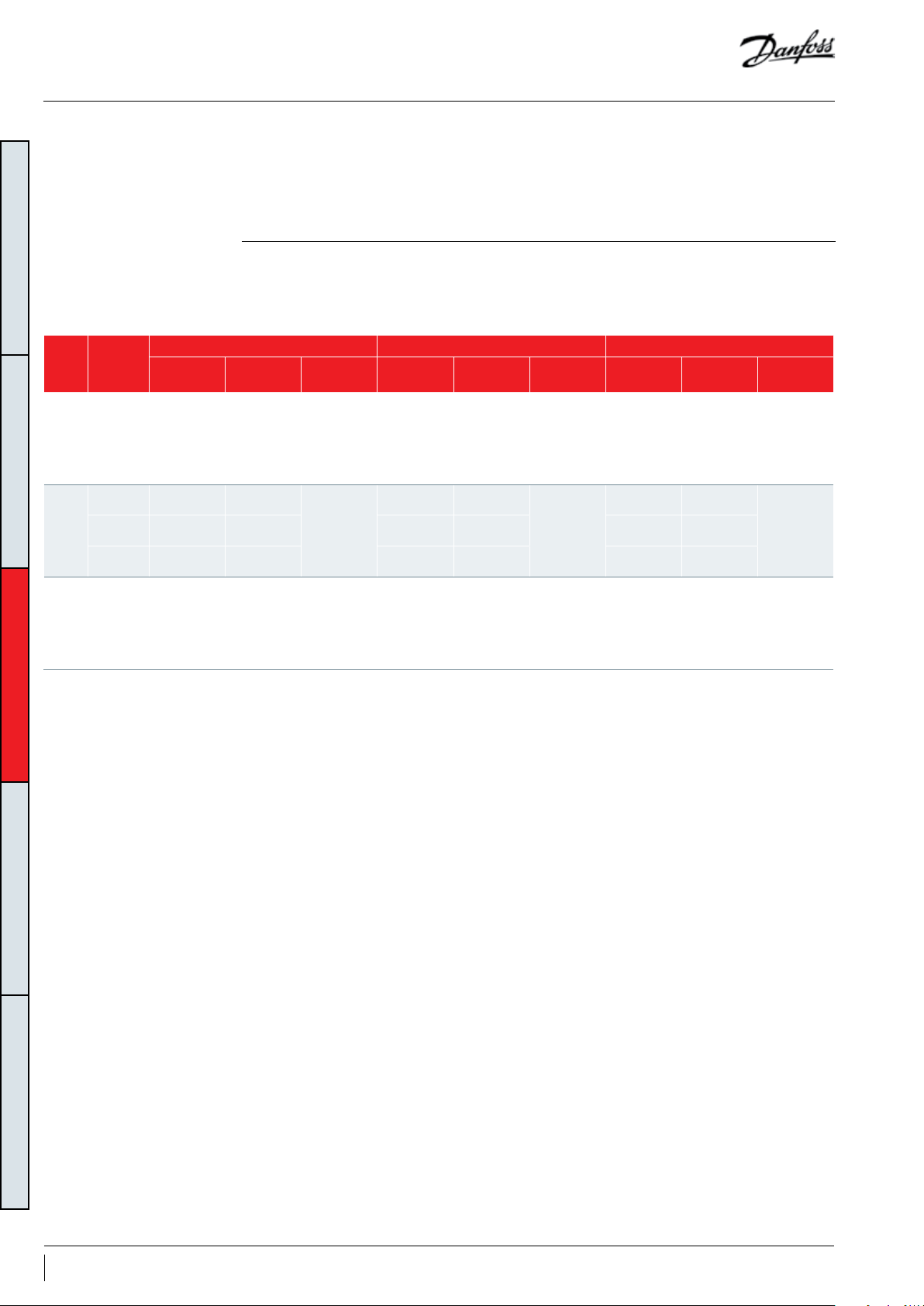

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Frequency

Model

VZH088

VZH117

VZH170

Average sound power for reference at ARI A/C conditions measured in free space.

Note: running sound level for 575V VZH is preliminary data

RPS

30 70 64

60 78 73 77 72 79 73

90 86 80 85 79 88 82

30 73 67

60 82 77 80 75 82 76

90 88 83 87 81 91 85

30 72 66

60 84 78 85 78 85 79

90 95 90 94 89 95 89

Without

accoustic

hood (dBA)

directions.

200V 400V 575V

With accoustic

hood (dBA)

Acoustic hood

code

120Z0510

(single

version)

120Z0512

(manifolding

/unified

version)

120Z0514

(single

version)

120Z0516

(manifolding

/unified

version)

120Z0519

(single

version)

120Z0520

(manifolding

/unified

version)

Without

accoustic

hood (dBA)

69 62

71 64

72 65

With accoustic

hood (dBA)

• Gas pulsation (through refrigerant)

The following sections focus on the causes and

methods of mitigation for each of the above

sources.

Sound levels are as follows:

• For compressors running alone:

Acoustic hood

code

120Z05 09

(single

version)

120Z0511

((manifolding

/unified

version)

120Z0513

(single

version)

120Z0515

(manifolding

/unified

version)

120Z0517

(single

version)

120Z0518

(manifolding

/unified

version)

Without

accoustic

hood (dBA)

72 66

72 66

77 71

With accoustic

hood (dBA)

Acoustic hood

120Z05 09

version)

120Z0511

(manifolding

version)

120Z0513

120Z0515

(manifolding

120Z0517

version)

120Z0518

(manifolding

version)

code

(single

/unified

(single

version)

/unified

version)

(single

/unified

Mitigations methods:

We can consider two means to reduce

compressors sound radiations:

1. Acoustic hoods are quick and easy to install

and do not increase the overall size of the

compressors. Acoustic hoods are available from

Danfoss as accessories.

Refer to the table above for sound levels,

attenuation and code numbers.

2. Use of sound-insulation materials on the inside

of unit panels is also an effective means to reduce

radiation.

36 AB221086441234en-001101

Page 37

Manage sound and vibration

Mechanical vibrations

A compressor generates some vibrations that

propagate into the surrounding parts and

structure. The vibration level of a VZH compressor

alone does not exceed 127 µm peak to peak.

However, when system structure natural

frequencies are close to running frequency,

vibrations are amplified due to resonance

phenomenon.

A high vibration level is damageable for piping

reliability and generates high sound levels.

Mitigations methods:

1. Danfoss VZH scroll compressors are designed

to produce minimal vibration during operations.

To ensure minimum vibrations transmission

to the structure, strictly follow mounting

requirements (mounting feet, rails etc..). For

further information on mounting requirements,

please refer to “Design compressor mounting”.

2. Ensure that there is no direct contact (without

insulation) between vibrating components and

structure.

This could be challenging on a variable system as

all resonant frequencies between min speed to

maximum speed will be exited.

It is mandatory to check that piping vibrations

are acceptable across speed range. This test

can be done by increasing slowly speed and

monitoring piping behavior through, strain gage,

acceleration, or displacement measurement.

As alternative visual check with strobe light can

also emphasis high piping displacement.

If some resonant frequencies generate high

piping vibration, problem can be solved by

increasing piping stiffness with brackets or

changing layout. Dampers can also be installed

to mitigate vibration.

If some frequencies continue to produce

unacceptable vibration levels, speed by-pass is

adjustable in the frequency converter, in order

to avoid some frequency ranges. Four by-pass

ranges are adjustable, and settings can be made

in parameter group 4.6x

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Gas pulsation

3. Resonance phenomenon

To avoid resonance phenomenon, pipings and

frame must have natural frequencies as far as

possible from running frequencies.

The Danfoss VZH scroll compressor has been

designed and tested to ensure that gas pulsation

is optimized for the most commonly encountered

air conditioning pressure ratio. Manifolded

compressors are equivalents to lagged sources

of gas pulsation. Therefore, pulse level can vary

during time.

Mitigations methods:

If an unacceptable level is identified, a discharge

muffler with the appropriate resonant volume

and mass can be installed.

37AB221086441234en-001101

Page 38

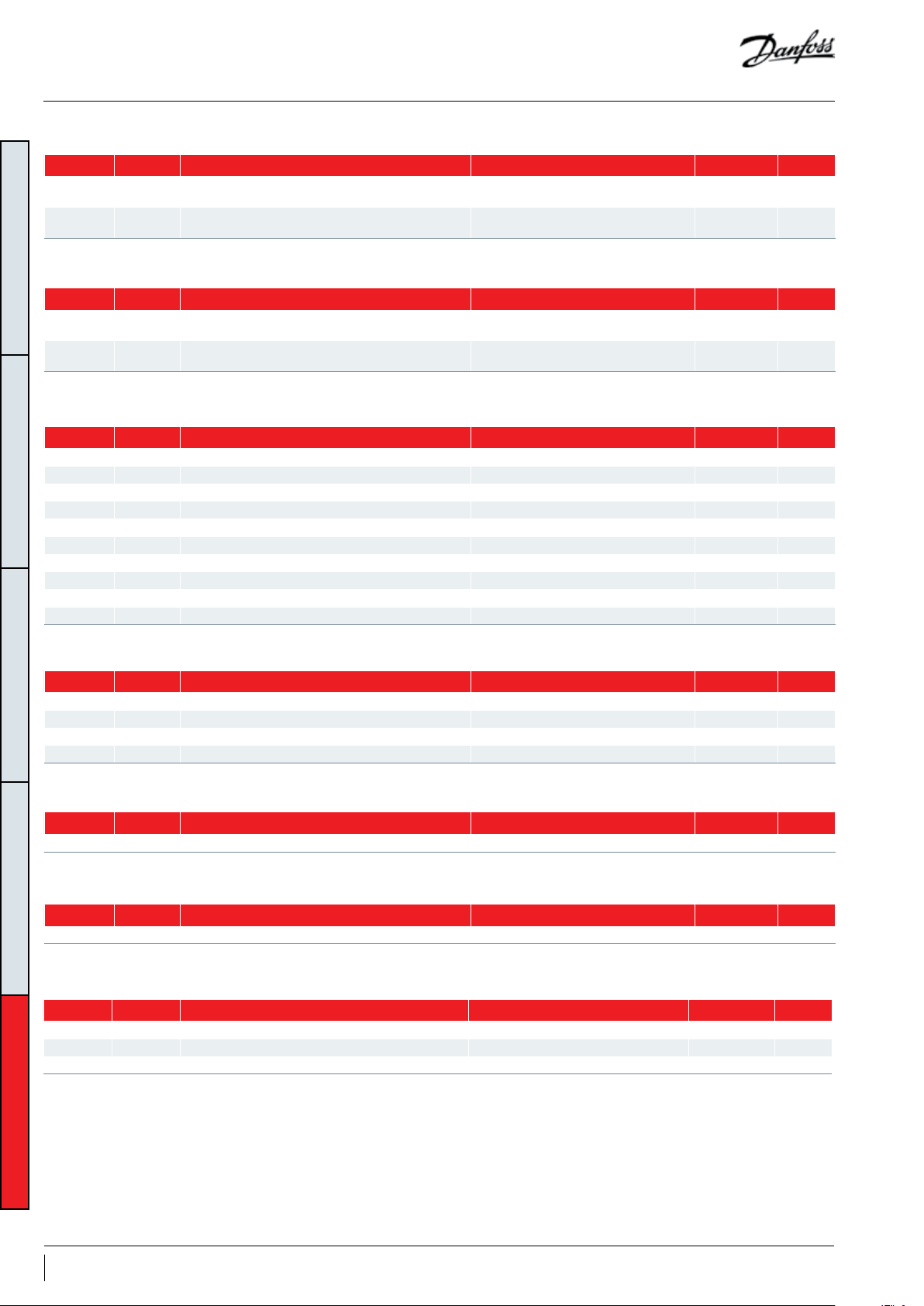

Manage speed limit

Speed limit requirement

Speed limit guerantees compressor

R

reliability and must be respect. In drive control

logic, default setting values have been qualified

by Danfoss. Customer could change the default

values in the acceptable range if the changes

have been qualified by OEM.

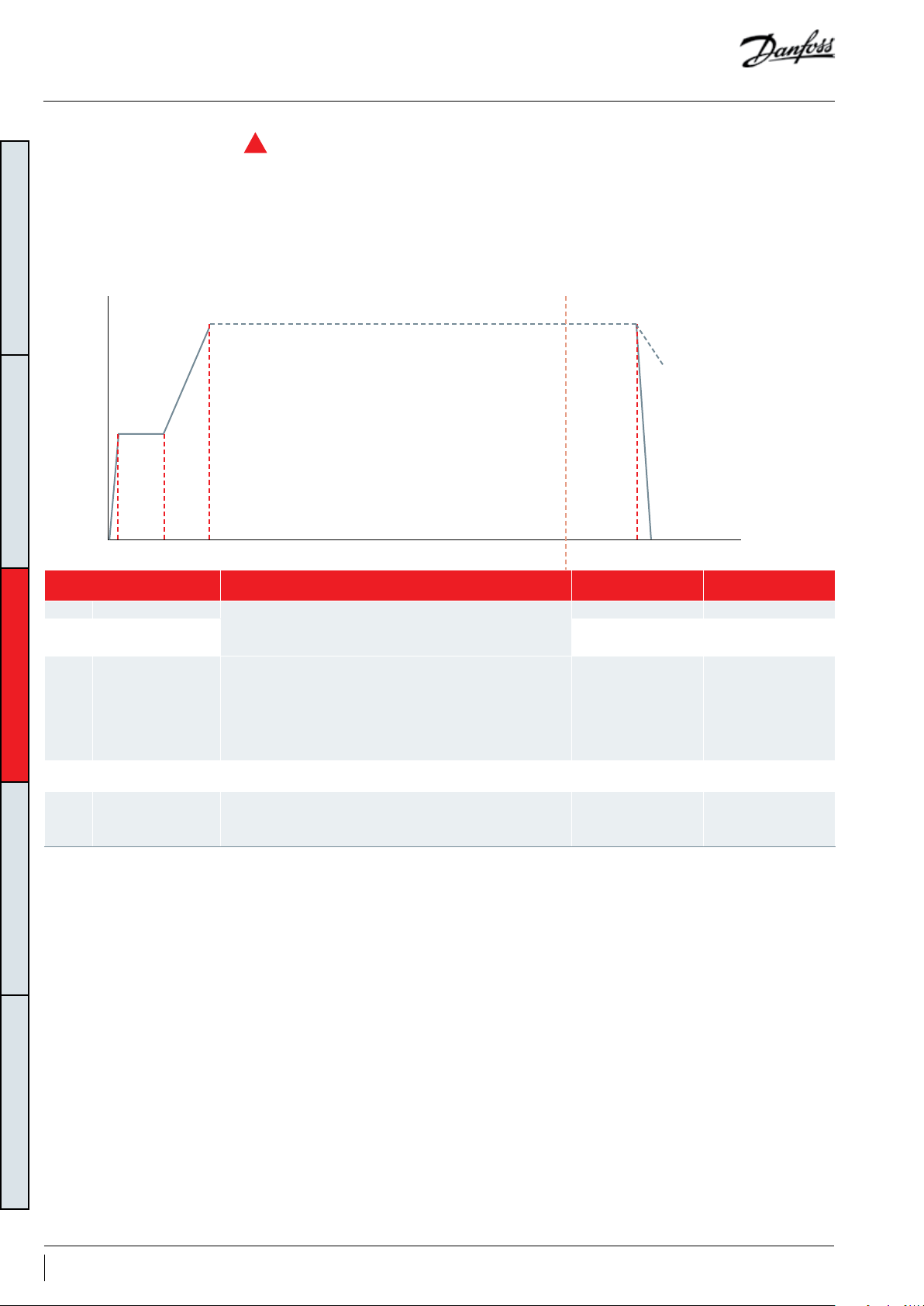

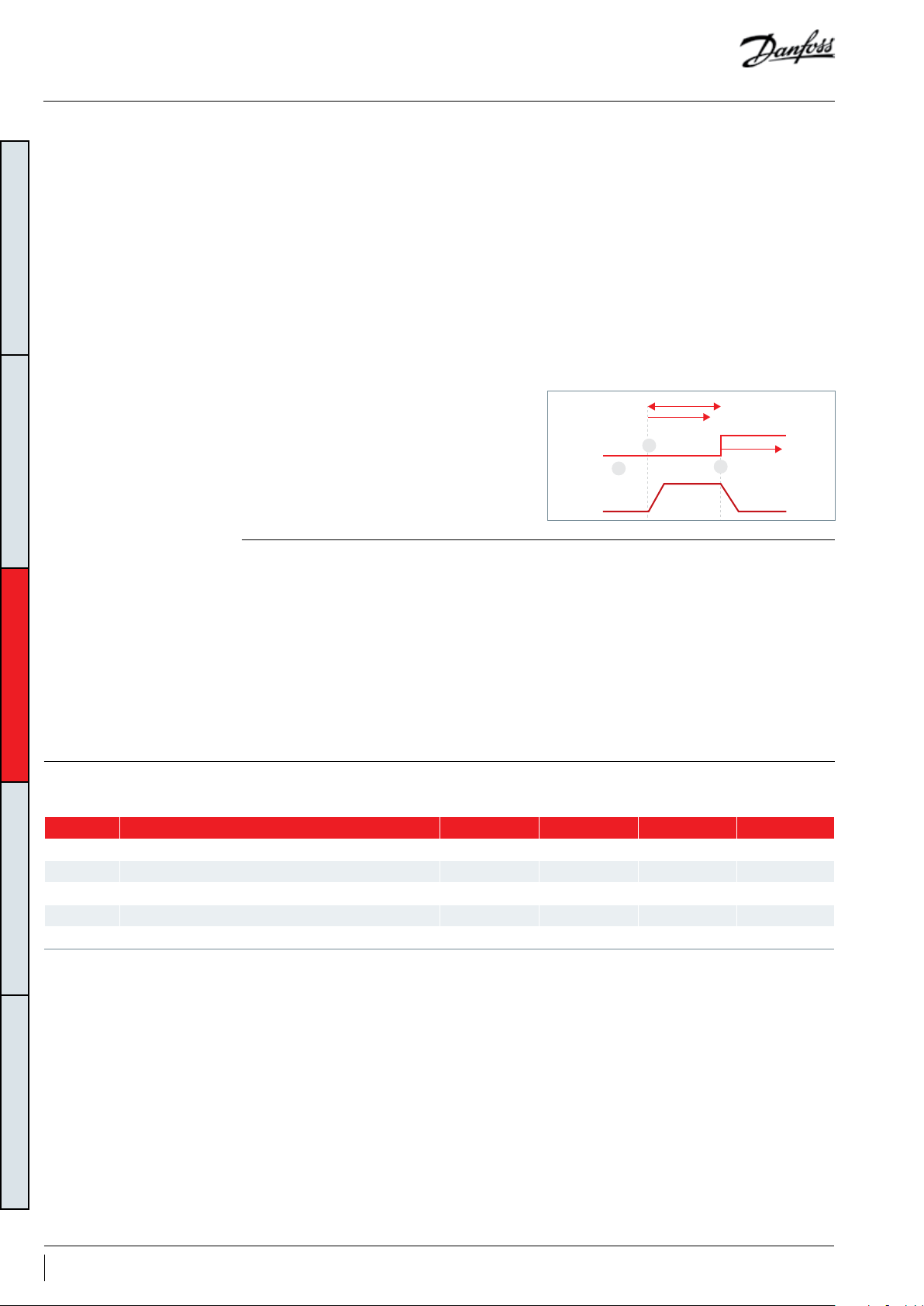

Start/Stop/Ramp setting

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

6000

P3-41

Ramp 1 ramp up time

Speed (RPM)

Start delay

Start

P1-71

speed 1-74

P3-82

Start ramp

up time

0

Drive parameters Description

1.71 Start delay (s) Start-up sequence: at start, compressor runs at start speed (1.74)

1.74 Start speed (RPS) 30rps 1800rpm

3.41

3.42

3.82

Ramp 1 ramp up

time (s)

Ramp 1 ramp down

time (s)

Starting/stopping

ramp Time (s)

during the Start delay (1.71)

During this time the speed set-point is ignored

Defines speed ramp up slope.

Ramp 1 ramp up time (s) is the time it takes to increase

compressor speed from 0rps to 90rps. It is a linear ramp thus

gives constant acceleration during ramping.

Eg: if current speed is 55rps and desired speed is 100rps, then

compressor will take 90sec (180sec/90rps)*(100-55)rps=90sec

Defines speed ramp down slope. in similar way that ramp-up. 180sec 15-360 0s

Fast acceleration from standstill to minimum speed with a quick

ramp.

The start / stop command bypasses the normal ramp time and

the frequency converter ramps the compressor fast.

Ramp 1 ramp down time

P3-42

Stop

P3-82

Ramp 1 ramp down time

Time (s)

Default value

(recommended)

60sec 10-300s

1800-3600rpm

180sec 15-3600s

2sec 0-5s

Range

30-60rps

38 AB221086441234en-001101

Page 39

Manage superheat

Requirement

System evaluation

During normal operation, refrigerant enters

the compressor as a superheated vapor. Liquid

flood back occurs when a part of the refrigerant

entering the compressor is still in liquid state.

In steady state conditions,

• the expansion device must ensure a suction

superheat within 5K to 30K (9 to 54°F).

• Oil superheat must be higher than 10K (18°F).

Use the table in relation with the application to

quickly evaluate the potential tests to perform.

Application Tests to perform

Non reversible Liquid flood back test

Reversible

Liquid flood back test

Defrost test

Liquid flood back can cause oil dilution and, in

extreme situations lead to liquid slugging that

can damage compression parts.

In transient conditions,

• cumulative time with oil SH below 10K should

not exceed 1700h during lifetime and not last

more than 60s per event.

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

39AB221086441234en-001101

Page 40

Manage superheat

Test, criteria and solutions

Test N° Purpose Test condition Pass criteria Solutions

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Liquid flood

back test

Steady-state

Transi ent

Liquid flood back testing must be

carried out under expansion valve

threshold operating conditions:

•Lowest foreseeable evaporation,

and highest foreseeable

condensation.

•Minimum speed running.

For reversible system, perform test

in both heating and cooling mode

A

Tests must be carried out with most

unfavorable conditions :

• fan staging,

• compressor staging

• …

Suction superheat >5K(9°F)

1. Check expansion valve selection

and setting.

-For Thermostatic expansion valve

(TXV) check bulb position...

-For Electronic expansion valve

(EXV) check measurement chain and

PID....

2. Add a suction accumulator*.

Oil superheat shall not be more than

30 sec below the safe limit (10K/18°F)

Check liquid

Defrost test

*Suction accumulator offers protection by trapping the liquid refrigerant upstream from the compressor. The accumulator should be sized at least 50 % of the total system

charge. Suction accumulator dimensions can impact oil return (gas velocity, oil return hole size…), therefore oil return has to be checked according to section “Manage oil in the

circuit”.

floodback

during defrost

cycle

Defrost test must be carried out

in the most unfavorable condition

(at 0°C (32°F) evaporating

temperature).

Oil superheat shall not be more than

30 sec below the safe limit (10K/18°F)

1. Check defrost logic.

In reversible systems, the defrost

logic can be worked out to limit

liquid floodback effect. (for more

details see “Control Logic”).

2. Add a suction accumulator*.

Oil temperature sensor must be placed between

oil sight glass and compressor baseplate. Some

thermal paste shall be used to improve the

conductivity. The sensor must also be correctly

thermally insulated from the ambiance.

The Oil superheat is defined as:

(Oil temperature - Evaporating temperature)

40 AB221086441234en-001101

Page 41

Manage off cycle migration

Requirement

System evaluation

R

Off -cycle refrigerant migration happens:

• when the compressor is located at the coldest

part of the installation, refrigerant vapor

condenses in the compressor.

• or directly in liquid-phase by gravity or pressure

difference.

• Compressor can tolerate occasional flooded

start, but it should remain exceptional situation

and unit design must prevent that this situation

happen at each start

When the compressor restarts, the refrigerant

diluted in the oil, or stored in evaporator,

generates poor lubrication conditions, and may

reduce bearings life time. In extreme situations,

this leads to liquid slugging that can damage the

compressor scroll set.

• Right after start, liquid refrigerant must not flow

massively to compressor

• The charge limit is a threshold beyond some

protective measures must be taken to limit risk

of liquid slugging and extreme dilution at start.

Use the table below in relation with the system

charge and the application to quickly define

necessary safeties to implement.

Application BELOW charge limit ABOVE charge limit

Ensure tightness between condenser & evaporator when system is OFF

• Thermostatic expansion Valve (TXV) , Liquid Line Solenoid Valve LLSV** strongly

All

Non split No test or additional safeties required

recommended

• Electronic expansion valve (EXV) must close when system stop including in power shut

down situation

• Surface Sump Heater *

• External Non-Return Valve

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Since each installation is unique, refrigerant charge may vary

Split

• Surface Sump Heater *

• Liquid Line Solenoid Valve**+ pump-down cycle***

• External Non-Return Valve

Charge limit is defined in table below:

Single

Models Refrigerant charge limit

(kg) (lb)

VZH088 6.0 13

VZH117 8.0 18

VZH170 13. 0 29

41AB221086441234en-001101

Page 42

Manage off cycle migration

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

*Surface Sump heater

The surface sump heater are designed to protect

the compressor against off-cycle migration of

refrigerant.

For VZH088-117 the surface sump heater is

Compressor Surrounding

Ambient

Unit has enclosure, no wind 48W SSH

Unit has no enclosure, with

wind

Unit has no enclosure,

wind >5m/s (ft/s)& ambient

temperature <-5°C

Surface Sump Heater

80W SSH

80W SSH + additional

SSH/thermal insulation

For VZH170, the 56W surface sump seater is

located below the sump, associated with a

thermal insulation.

The heater must be turned on whenever all the

compressors are off.

Surface sump heater accessories are available

from Danfoss (see section “Accessories”).

located on the compressor shell.

For better standby energy consumption, Danfoss

provides 48W and 80W two optional surface

sump heater. The selection of surface sump

heater could refer to below principle:

VZH088-117

VZ H170

**Liquid line solenoid valve (LLSV)

A LLSV is used to isolate the liquid charge

on the condenser side, thereby preventing

against charge transfer to the compressor

during off -cycles. The quantity of refrigerant

on the low-pressure side of the system can be

further reduced by using a pump-down cycle in

association with the LLSV.

***Pump-down cycle

By decreasing pressure in the sump, pump down:

• Evacuates refrigerant from oil

• Set the sump saturating pressure much

lower than ambiance temperature and due

to that, avoid refrigerant condensation in the

compressor.

• Pump-down must be set higher than

2.3 bar(g) / 33(psig).

For more details on pump-down cycle see

section “Control Logic”.

42 AB221086441234en-001101

Page 43

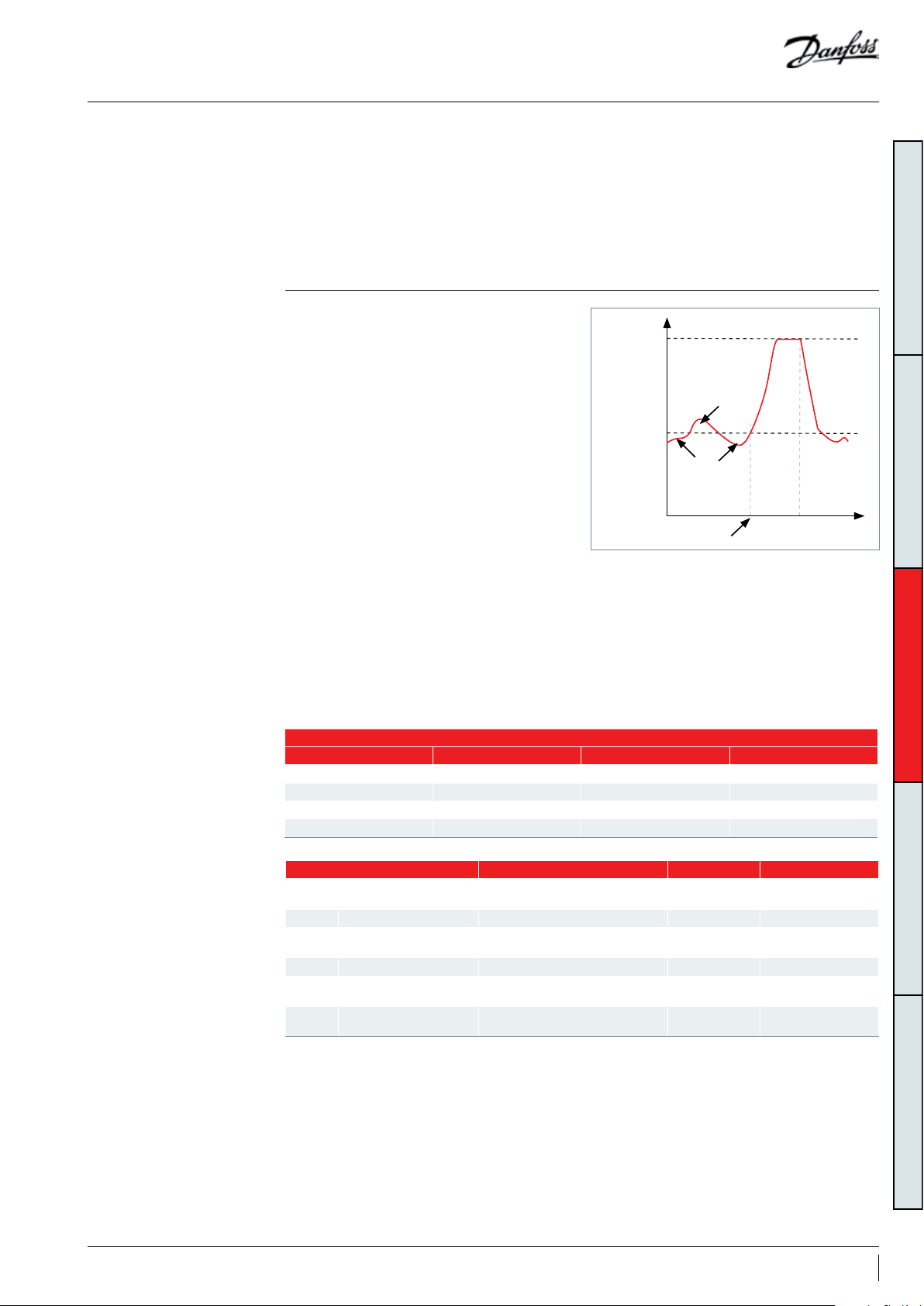

Manage operating envelope

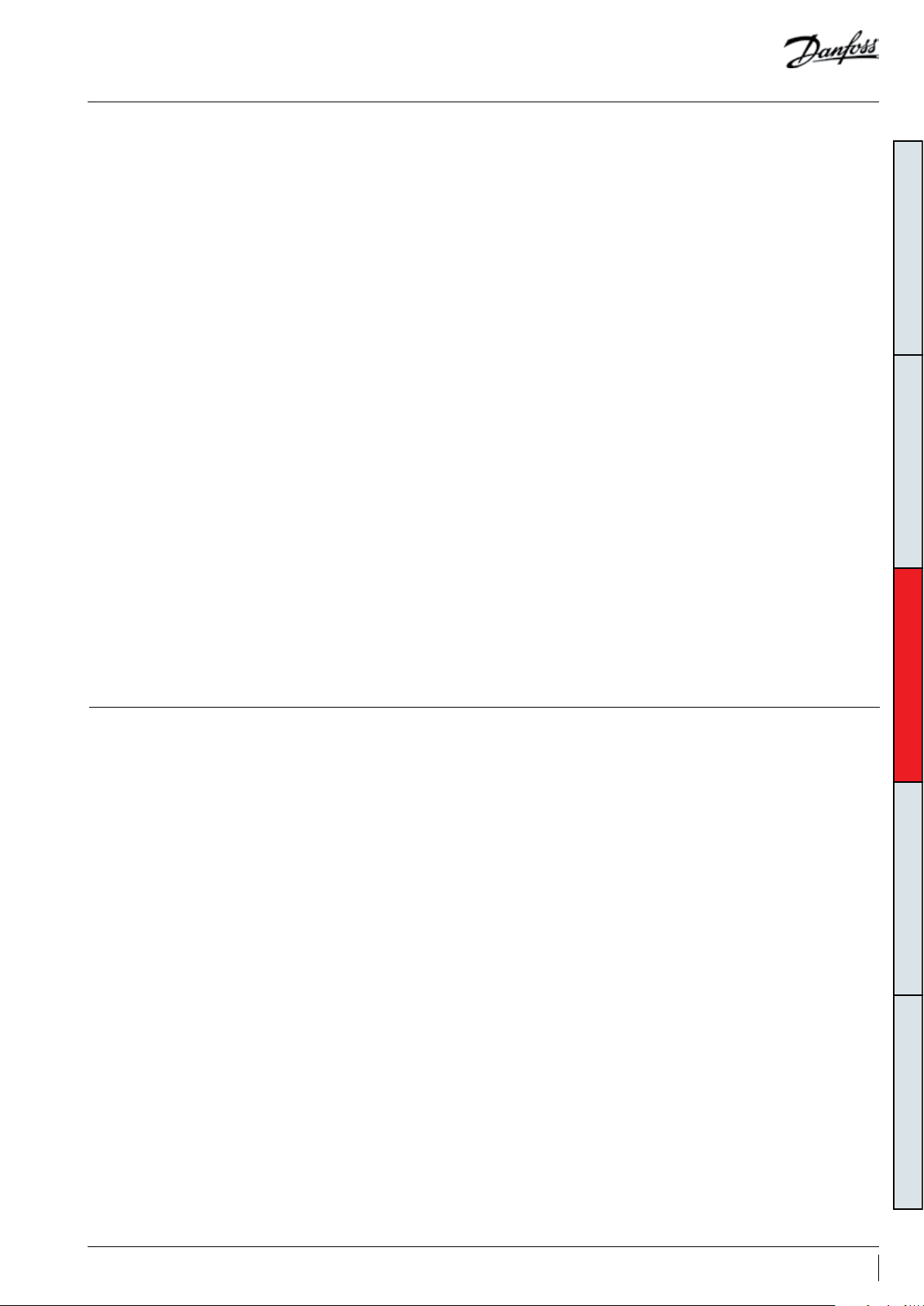

Requirement

Single envelope control

R

The operating envelope for VZH scroll

compressors is given in the figures below and

guarantees reliable operations of the compressor

for steady-state operation.

Moreover, the discharge gas temperature must

not exceed 135°C (275°F). Steady-state operation

envelope is valid for a suction superheat within

5K to 30K (9°F to 54°F) range.

VZH operating map - 575V/400V/208V

-22 -4 5-13 14 23 32 41 50 59 68

75

70

65

60

55

50

45

40

35

30

25

Condensing temperature (°C)

20

15

-30 -20 -15-25 -10 -5 0 5 10 15 20

30-90rps

High PR (5-10K)

(9°F-18°F)

Evaporating temperature (°C)

25-100rps

30-90rps

Low PR (5-10K)

(9°F-18°F)

(°F)

167

158

149

140

131

122

113

104

95

86

77

68

59

GENERAL INFORMATIONPRODUCT INFORMATIONSYSTEM DESIGNINTEGRATION INTO SYSTEMORDERING INFORMATION

Note: for superheat above 10K, the envelop will narrow down based on 135°C discharge temperature restriction.

Note: Red and Gray filled area are limited to 30-90rps.

for 380V power input, permitted highest condensing temperature will decrease accordingly:

-High PR: 25-100rps, condensing temperature from 60°C to 56°C (140°F to 133°F); 30-90rps, condensing temperature from 68°C to 65°C (154°F to 149°F).