Page 1

Application guidelines

Inverter scroll compressors

VZH028-035-044

single

R410A

http://cc.danfoss.com

Page 2

Page 3

Application Guidelines

VZH028-035-044 - single compressors

VZH scroll specificities .........................................................................................................5

Inverter compressors ...........................................................................................................6

Compressor size ........................................................................................................................................................................................... 6

Frequency converter variants ................................................................................................................................................................. 6

Compressor and frequency converter combinations .................................................................................................................... 6

VLT Compressor Drives literatures .........................................................................................................................................................6

Nomenclature and specifications ........................................................................................ 7

Compressor nomenclature ...................................................................................................................................................................... 7

Frequency converter nomenclature .....................................................................................................................................................8

Label ................................................................................................................................................................................................................. 8

Serial number................................................................................................................................................................................................ 8

Technical specifications .......................................................................................................9

Compressor specifications ....................................................................................................................................................................... 9

Frequency converter specifications ...................................................................................................................................................... 9

Oil return management ............................................................................................................................................................................ 9

Bearings lubrication ................................................................................................................................................................................... 9

Capacity tables ...........................................................................................................................................................................................10

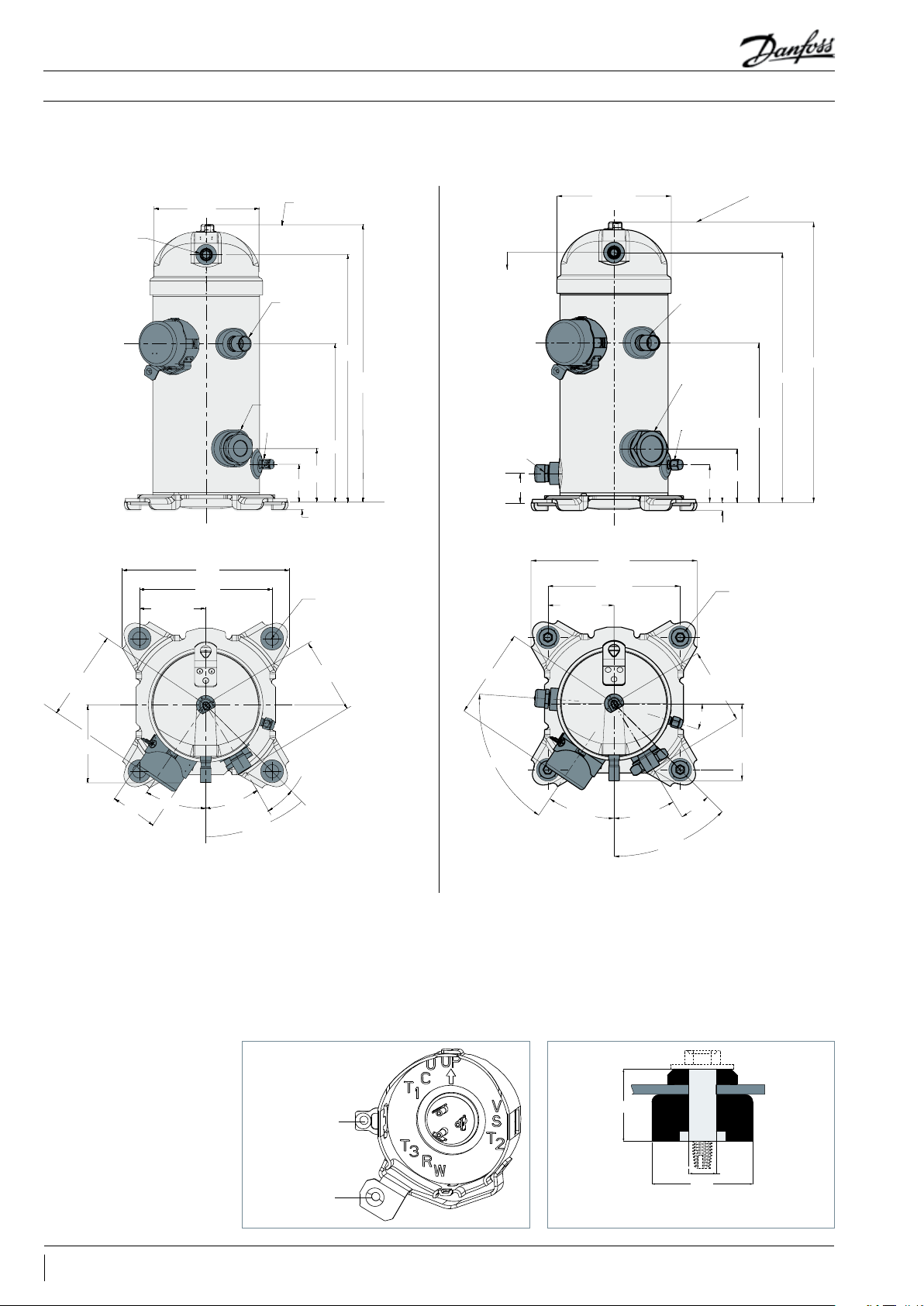

Dimensions .........................................................................................................................16

VZH028-035-044G/J/H OSG version ...................................................................................................................................................16

VZH028-035-044G/J .................................................................................................................................................................................16

OLS version ..................................................................................................................................................................................................16

Sight glass / Oil level sensor ..................................................................................................................................................................17

Schrader ........................................................................................................................................................................................................17

Suction & discharge connections ........................................................................................................................................................17

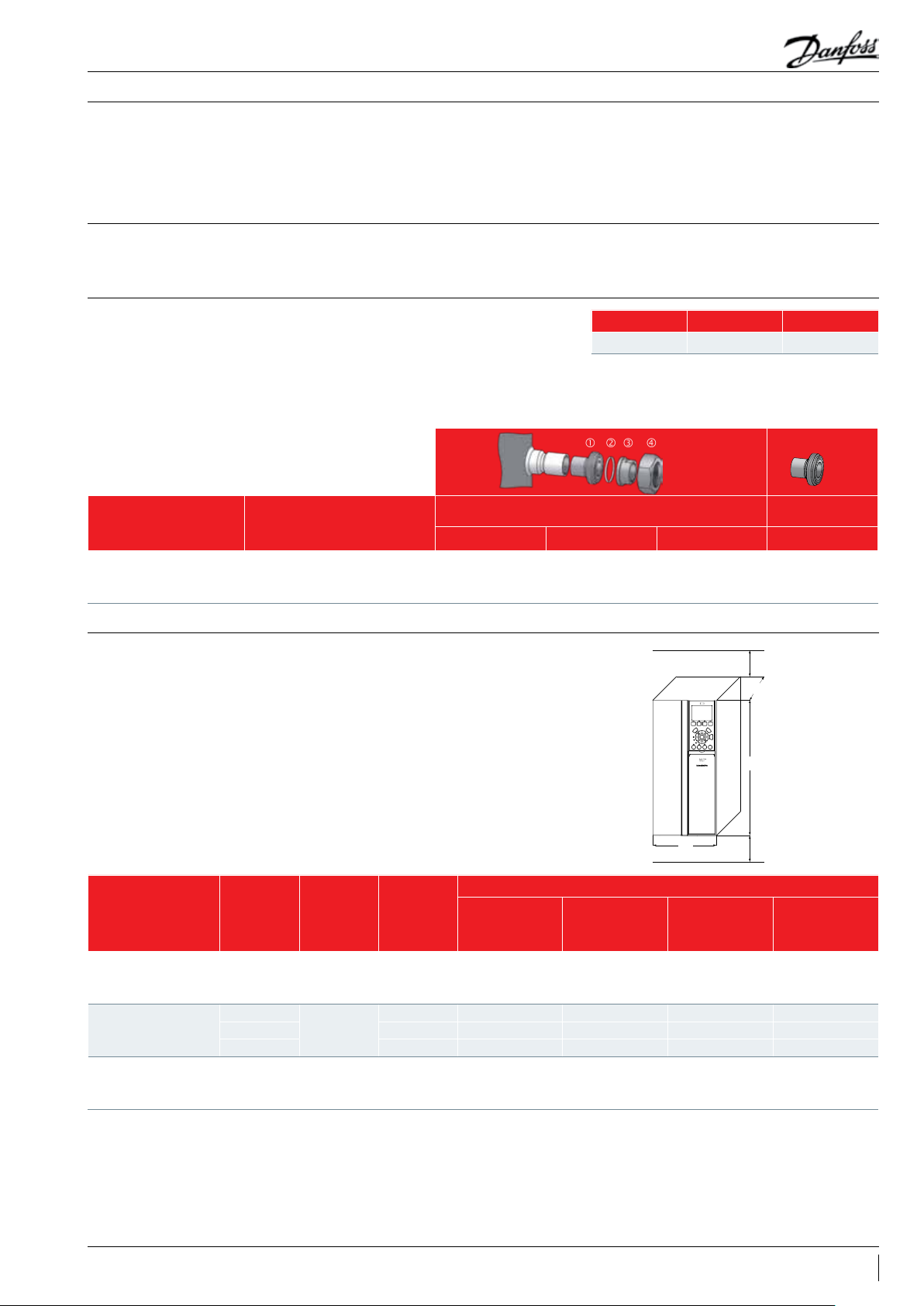

Frequency converter dimensions ........................................................................................................................................................17

CDS803 frequency converter ................................................................................................................................................................18

CDS303 frequency converter ................................................................................................................................................................18

Electrical data, connections and wiring ............................................................................19

Supply voltage ............................................................................................................................................................................................19

Compressor electrical specifications ..................................................................................................................................................19

Terminal cover mounting .......................................................................................................................................................................19

Terminal cover removal ...........................................................................................................................................................................19

Fuses ...............................................................................................................................................................................................................20

Wire sizes ......................................................................................................................................................................................................21

Wiring & EMC protection ........................................................................................................................................................................21

EMC correct installation of an IP20 frequency drive CDS803 ....................................................................................................22

Wiring diagram of CDS803 .....................................................................................................................................................................22

Wiring connections of CDS803 .............................................................................................................................................................23

EMC correct installation of an IP20 frequency drive CDS303 ....................................................................................................24

Wiring diagram of CDS303 .....................................................................................................................................................................24

Wiring connections of CDS303 .............................................................................................................................................................25

Electrical connections ..............................................................................................................................................................................25

Soft-start control ........................................................................................................................................................................................26

Phase sequency and reverse rotation protection ..........................................................................................................................26

IP rating .........................................................................................................................................................................................................26

Motor protection .......................................................................................................................................................................................26

Anti-reverse protection ...........................................................................................................................................................................26

Temperature protection ..........................................................................................................................................................................27

Voltage imbalance ....................................................................................................................................................................................27

Approvals and certificates .................................................................................................28

Low voltage directive 2014/35/EU ......................................................................................................................................................28

Internal free volume .................................................................................................................................................................................28

Approvals and certificates ......................................................................................................................................................................28

3AB225886435375en-001201

Page 4

Application Guidelines

VZH028-035-044 - single compressors

Operating conditions .........................................................................................................29

Application envelopes .............................................................................................................................................................................29

Short cycle timer function ......................................................................................................................................................................30

Discharge gas thermostat ......................................................................................................................................................................31

Oil return management function (single compressor) ................................................................................................................32

High and low pressure protection.......................................................................................................................................................32

Essential piping design considerations .............................................................................................................................................34

System design recommendations .....................................................................................34

Oil management ........................................................................................................................................................................................35

Heat exchangers ........................................................................................................................................................................................36

Refrigerant charge limits ........................................................................................................................................................................36

Off-cycle migration ...................................................................................................................................................................................36

Liquid floodback during operation .....................................................................................................................................................37

Manage superheat ....................................................................................................................................................................................38

Specific application recommendations ............................................................................40

Low ambient compressor operations ................................................................................................................................................40

Brazed plate heat exchangers ...............................................................................................................................................................41

Reversible heat pump systems .............................................................................................................................................................41

Sound generation in a refrigeration or air conditioning system .................................... 43

Running sound level ................................................................................................................................................................................43

Sound and vibration management ....................................................................................................................................................43

Compressor sound radiation .................................................................................................................................................................43

Mechanical vibrations ..............................................................................................................................................................................43

Speed by-pass .............................................................................................................................................................................................43

Gas pulsation ..............................................................................................................................................................................................43

Installation ..........................................................................................................................44

Compressor handling ..............................................................................................................................................................................44

Mounting ......................................................................................................................................................................................................44

Removing connections shipping plugs ............................................................................................................................................44

System cleanliness ....................................................................................................................................................................................45

Tubing ............................................................................................................................................................................................................45

Filter driers ...................................................................................................................................................................................................45

Brazing and soldering ..............................................................................................................................................................................45

Compressor connection ..........................................................................................................................................................................45

High voltage test .......................................................................................................................................................................................46

System pressure test ................................................................................................................................................................................46

Leak detection ............................................................................................................................................................................................47

Vacuum pump down and moisture removal ..................................................................................................................................47

Refrigerant charging ................................................................................................................................................................................47

Commissioning ..........................................................................................................................................................................................47

Oil level checking and top-up ...............................................................................................................................................................48

Trouble shooting ................................................................................................................49

Ordering information .........................................................................................................52

Kit ordering and shipping ......................................................................................................................................................................52

Packaging .....................................................................................................................................................................................................52

Ordering information and packaging ................................................................................................................................................52

VZH converter order information ........................................................................................................................................................53

Accessories ..........................................................................................................................54

Valves, adapters, connectors & gaskets for use on suction and discharge connections .................................................54

Crankcase heaters & thermostats ........................................................................................................................................................54

Lubricant, acoustic hoods and spare parts ......................................................................................................................................54

Spare parts frequency converter .........................................................................................................................................................55

4 AB225886435375en-001201

Page 5

Application Guidelines

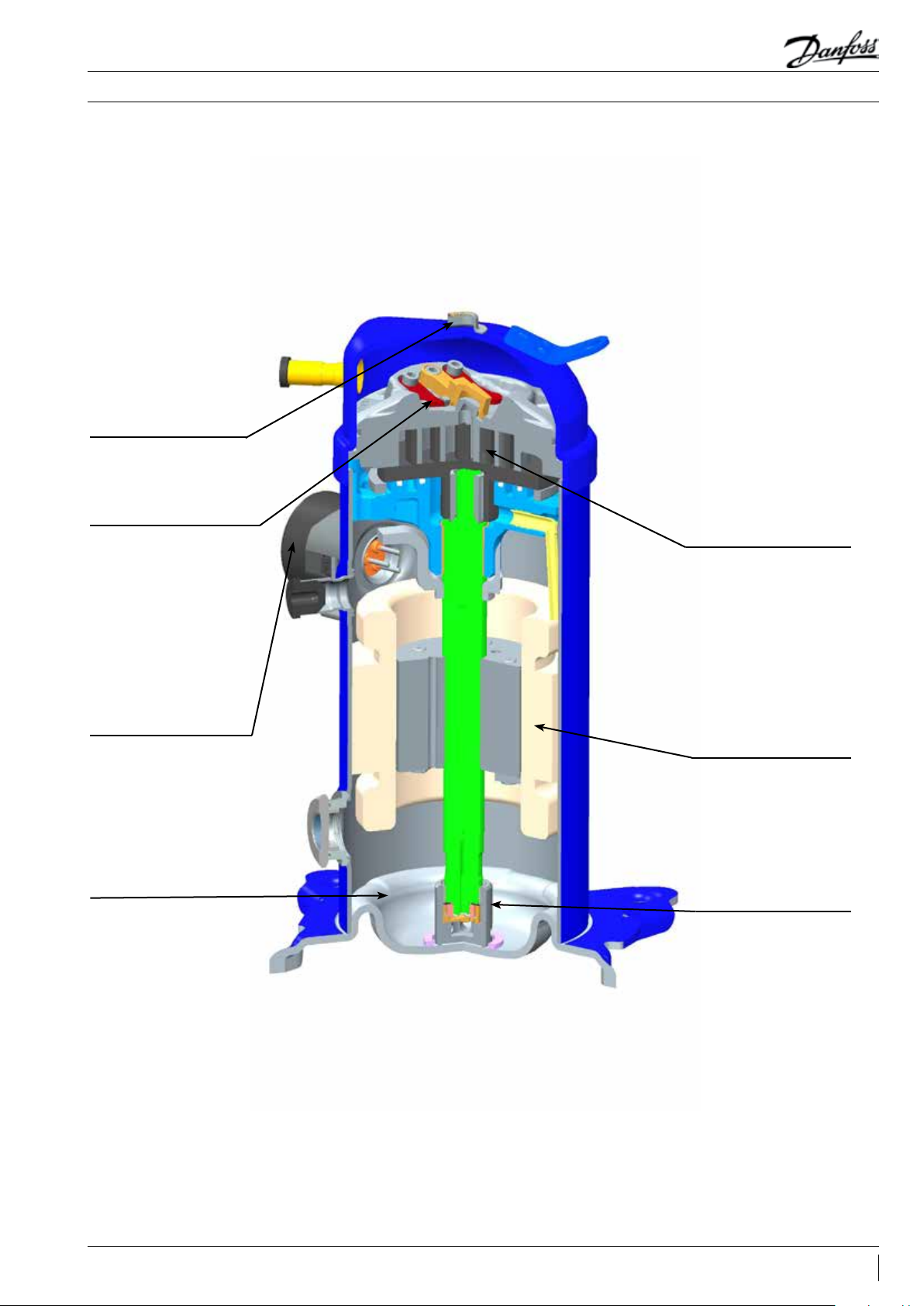

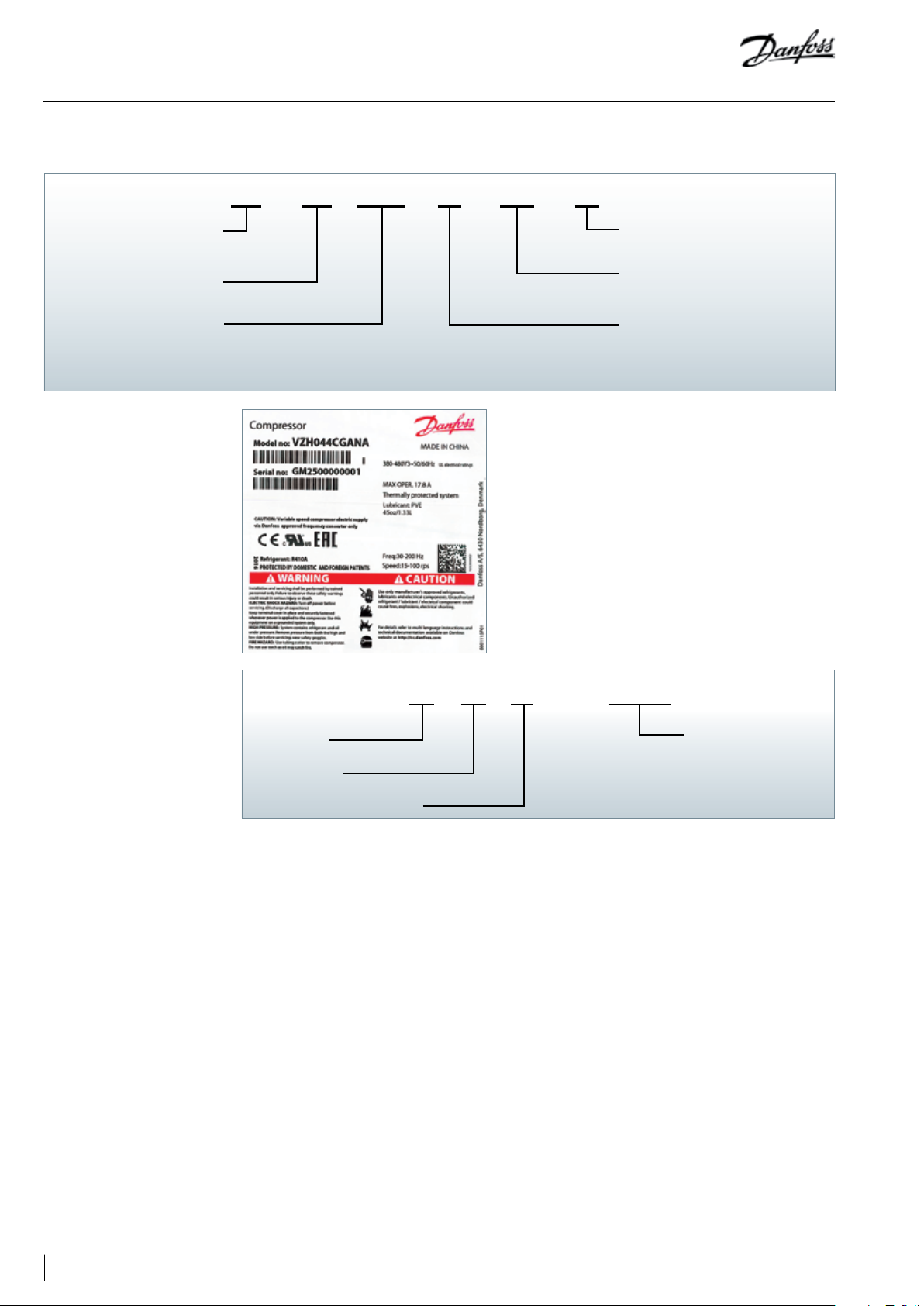

Discharge sensor (dome

sensor) for high discharge

temperature monitoring,

sensor is fitted into top

bracket. Discharge sensor

is optional.

Intermediate discharge

valves for better efficiency

at low pressure-ratio

VZH scroll specificities

Single compressors

Scrolls with optimized

volume ratio lead to better

heat pump application

EMC (Electro-Magnetic

Compatibility) bracket

provided allows for

grounding termination

of shielded wire-harness,

which reduces EMC

emissions between drive

and compressor

PVE 32 lubricant

New distributed IPM

motor lead to higher

power factor

Linear control oil pump

5AB225886435375en-001201

Page 6

Application Guidelines

Inverter compressors

Single compressors

Compressor size

Frequency converter variants

Inverter technology offers more flexibility

in compressor selection than fixed-speed

compressors. Selection of the right inverter

compressor size can be made by different

methods:

1. Maximum cooling capacity: Select a

compressor size which achieves the peak load

system cooling capacity demand at its maximum

speed.

2. Nominal cooling capacity: Select a compressor

size which achieves the nominal system cooling

capacity at a rotational speed of 3600 - 4500 rpm

(60-75 rps).

Different frequency converter variants are

available according to:

Frequency converter for VZH028-035-044

200V&400V: CDS803

1. Mains supply voltage:

- 200-240V/3ph/50-60Hz

- 380-480V/3ph/50-60Hz

2. IP class (CDS803 drives are available in IP20 or

IP21 (requiring additional kit) housings)

3. Best Seasonal Efficiency Ratio: Select a

compressor size which achieves the minimum

system cooling demand at its minimum speed.

Ensure that the compressor is able to cover the

peak load system cooling capacity. This selection

makes the compressor run for a maximum time at

part load where the system efficiency is highest.

Performance tables at three speeds can be found

in the following pages. Detailed performances

can be found in datasheets and in selection

programs.

3. RFI (Radio Frequency Interference) class H4

4. Printed Circuit Board (PCB) coated

Frequency converter for VZH028-035-044 575V:

CDS303

1. Mains supply voltage: 525-600V/3ph/50-60Hz

2. IP class: IP20

3. RFI class HX: No filter

4. PCB not coated

Compressor and frequency converter combinations

VLT Compressor Drives literatures

When the compressor size and mains voltage

have been defined in the above selection criteria,

the code number tables from the “Ordering

information and packaging” section provides the

appropriate frequency converter sizes and up

to eight corresponding code numbers for each

compressor model.

VLT Compressor Drives User’s Manual

(FRCC.ES.017.A1.02) introduces different VLT

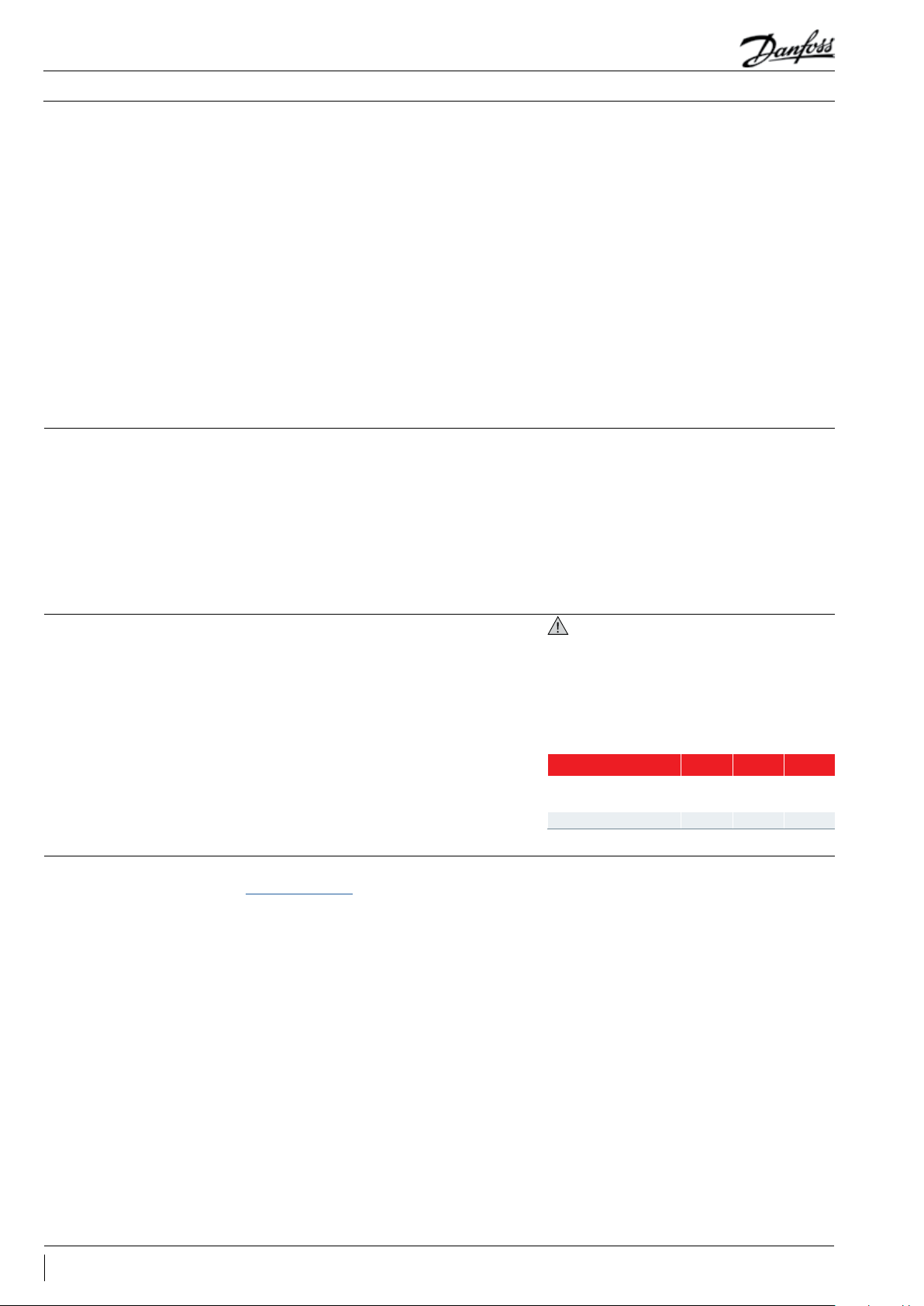

Note this compressor is equipped with

a four-pole electrical motor so the applied

frequency from the inverter will be 30 Hz

for 15 rps (900 rpm) up to 200 Hz for 100 rps

(6000 rpm).

Please refer to the table below

min max

Compressor speed

Drive output frequency Hz 30 200

Compressor Drives literatures: Operating

instructions, MCT 10 set-up, Modbus RTU

instructions, VLT drawings, etc..

rps 15 100

rpm 900 6000

6 AB225886435375en-001201

Page 7

Application Guidelines

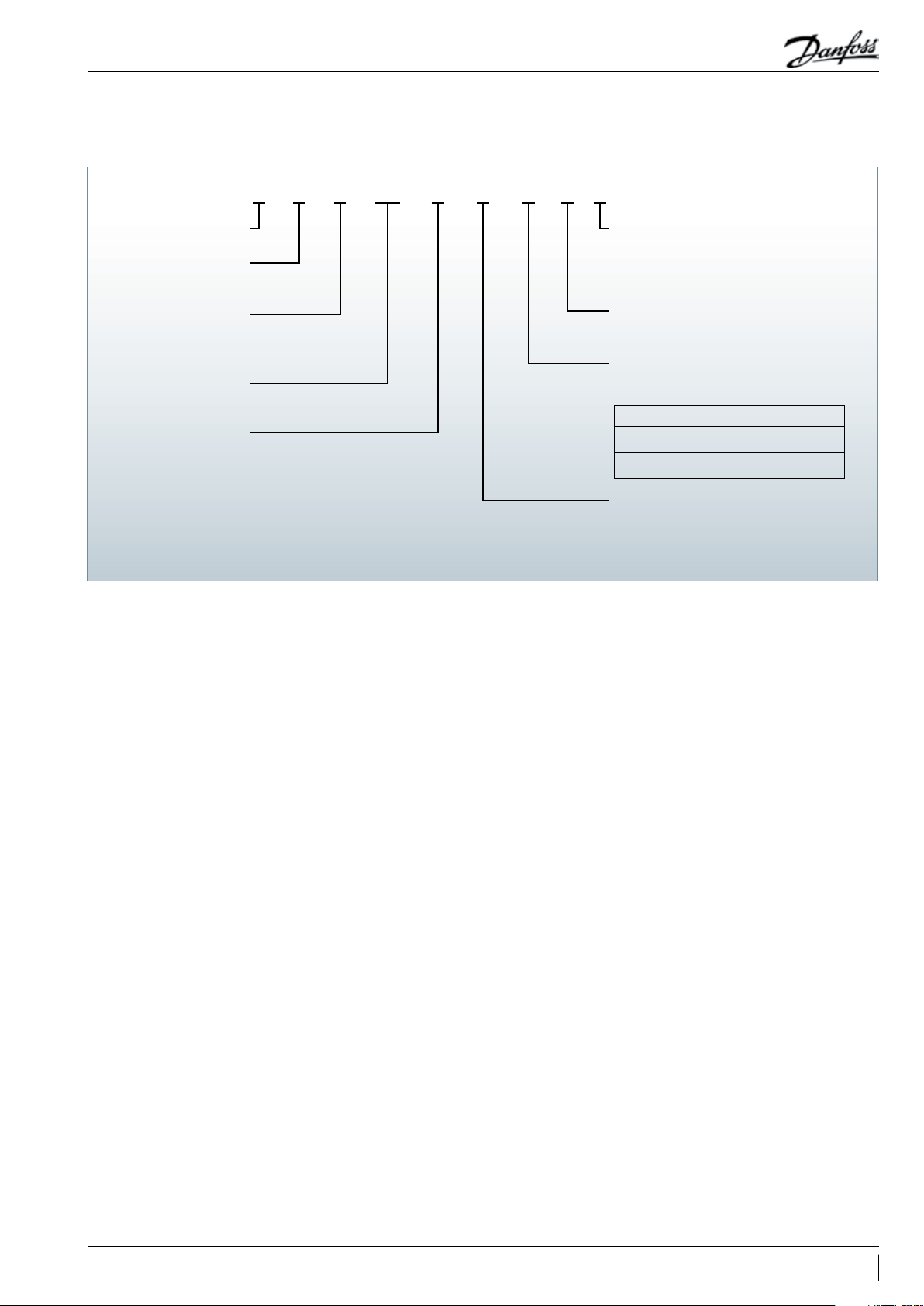

Compressor

nomenclature

Nomenclature and specifications

Single compressors

BNAGC044ZHV

Variable speed

Family

VZH scroll

Lubricant

PVE 32 (160 HV) lubricant,

R410A refrigerant

Swept volume

in cm³/rev

Design pressure ratio

C: IDV and IEER

optimized

Evolution index:

B : Max. evaporating temperature 27(°C)

on operation map

Motor protection type

N: no internal motor protection

(protection by drive)

Equipement version

A: brazed connections, OSG version

B: brazed connections, OLS version

Oil level switch

None

Threaded

OSG (oil sight glass)

version

OLS (oil level sensor)

version

Oil sight glass

Threaded

None

Motor voltage code to CDS803/CDS303 *

G: 380-480V/3~/50 & 60 Hz

H: 525-600V/3~/50&60Hz

J: 200-240V/3~/50 & 60 Hz

* main supply voltage to frequency converter

7AB225886435375en-001201

Page 8

A 1234567825

B

Application Guidelines

Frequency converter nomenclature

Nomenclature and specifications

Single compressors

H4E20T4P7K5803CDS

Dedicated compressor

drive for VZH scroll

Serie 803/303

output power

P6K0/P7K5/P10K/P11K

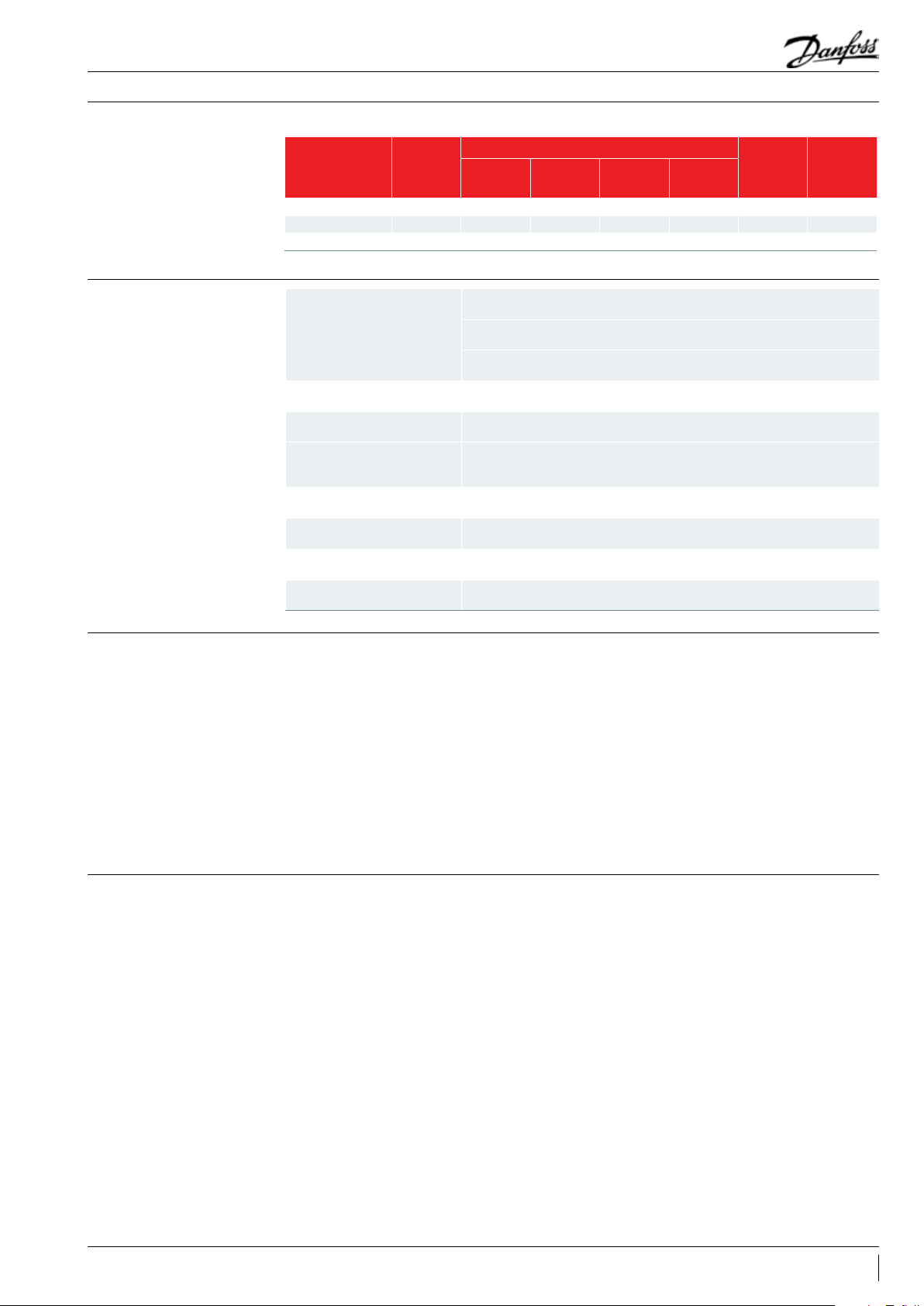

Label

in kW

RFI clas

H4/HX

Enclosure protection

IP rating

Main supply voltage

T2: 200-240V/3 ph/50-60 Hz

T4: 380-480V/3 ph/50-60 Hz

T6: 525-600V/3ph/50-60 Hz

Serial number

Year code

Month code

Plant assembly line code

8 Digit serial number

8 AB225886435375en-001201

Page 9

Application Guidelines

Technical specifications

Single compressors

Compressor

specifications

Frequency converter

specifications

Compressor model

VZH028 27. 8 1.5 5.0 6.0 10.0 1.3 26

VZH035 34.9 1.9 6.3 7.5 12.6 1.3 27

VZH044 44.5 2.4 8.0 9.6 16. 0 1.3 27

Mains supply voltage

Supply frequency 50 / 60 Hz

Output voltage 0 - 100 % of supply voltage

Standby power

Inputs

Programmable outputs

Protection functions Over-current protection, low / high current handling

Compressor functions

Swept

volume

(cm³/r ev)

15 rps

(m³/h)

CDS803-T2: 200 - 240 V +/-10% (3-phase)

CDS803-T4: 380 - 480 V +/-10% (3-phase)

CDS303-T6: 525 - 600V +/-10% (3-phase)

T2: P6K0/P7K5: 23.17W P10K: 26.23W

T4: P6K0/P7K5: 11.3W P10K: 25.5W

T6: P7K5: 17W P11K: 29kW

CDS803: 4 digital (0 - 24 V), 2 analog (0 /±10 V or 4 - 20 mA, scalable)

CDS303: 6 digital (0-24V), 2 analog (0/+-10V or 4-20mA, scalable)

CDS803: 2 digital (0- 24 V), 2 analog (0-24 V), 2 relay

CDS303: 2 digital(0-24V), 1 analogue(0-24V), 2 relay

Pressostat / thermostat function (CDS303 only), short cycle protection, oil

return management

Displacement

50 rps

(m³/h)

60 rps

(m³/h)

100 rps

(m³/h)

Oil charge

(Liters)

Net weight

(kg)

Oil return management

Bearings lubrication

Oil return management function only works

under auto mode: After running at low rpm

(less than 40 rps) for 120 minutes, the internal

lubrication algorithm in the drive will accelerate

the compressor speed to 60 rps or above for

60 seconds to ensure sufficient lubrication of

compressor moving parts.

Warning:

This function is enabled by parameter 28-10 as

default setting. Please notice when hands on

mode is selected, oil return management will

A specific oil pump ensures optimal bearing

lubrication at all compressor speeds. The specific

oil pump provides sufficient bearing lubrication

not work even if parameter 28-10 (oil return

management) is set to on. If compressors run

below 40 rps for more than 120 minutes, oil

return fault alarm (A208) will report on LCP

and stop the compressor. Please select hands

on mode carefully and only select hands

on mode if the OEM has implemented oil

return management in the system controller

and qualified oil management. Under such

conditions, the compressor could run below 40

rps continually and meanwhile disable drive oil

return management 28-10.

at low speeds as well as to avoid excessive Oil

Circulation Ratio (OCR) at high speeds.

9AB225886435375en-001201

Page 10

Application Guidelines

Technical specifications

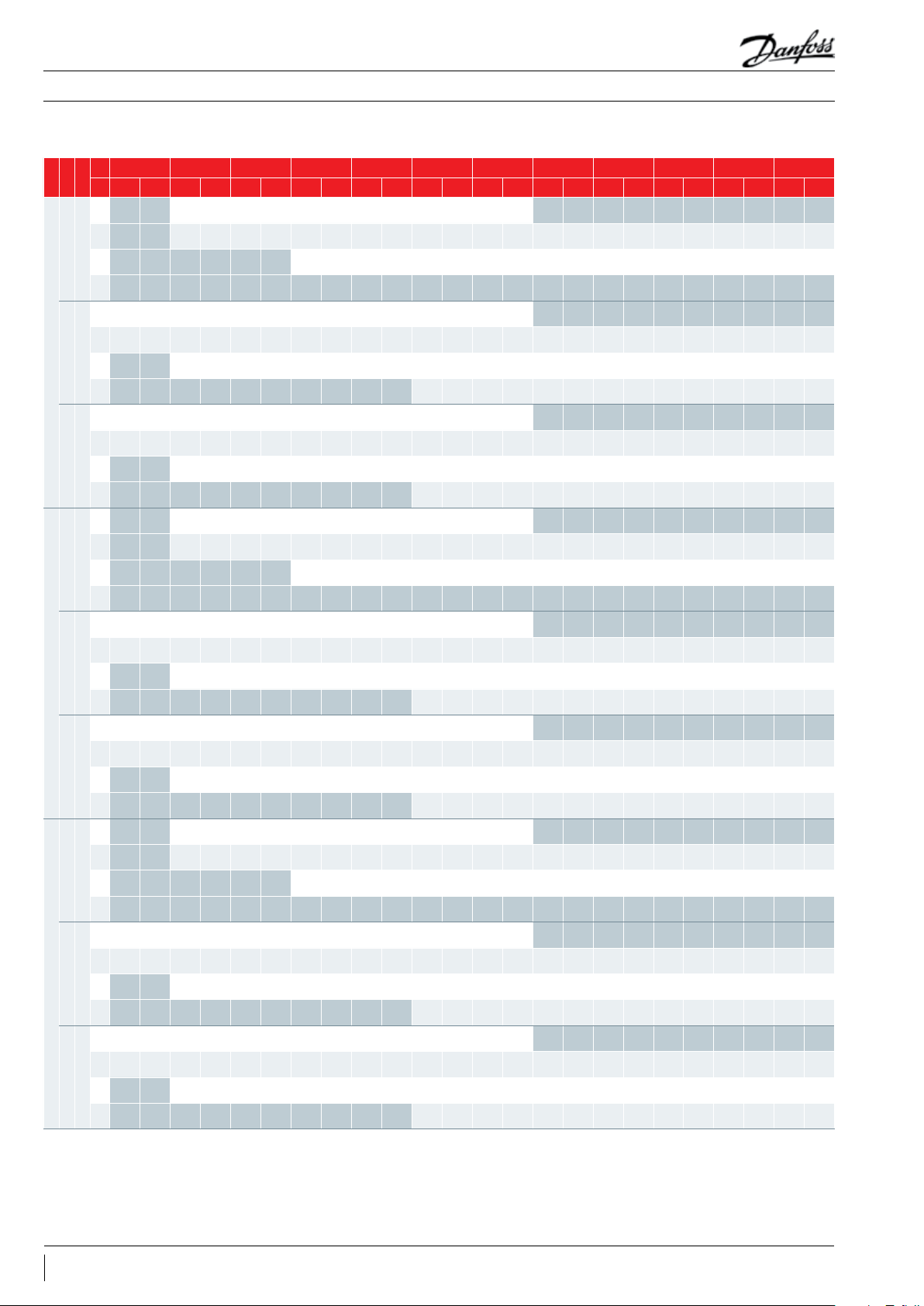

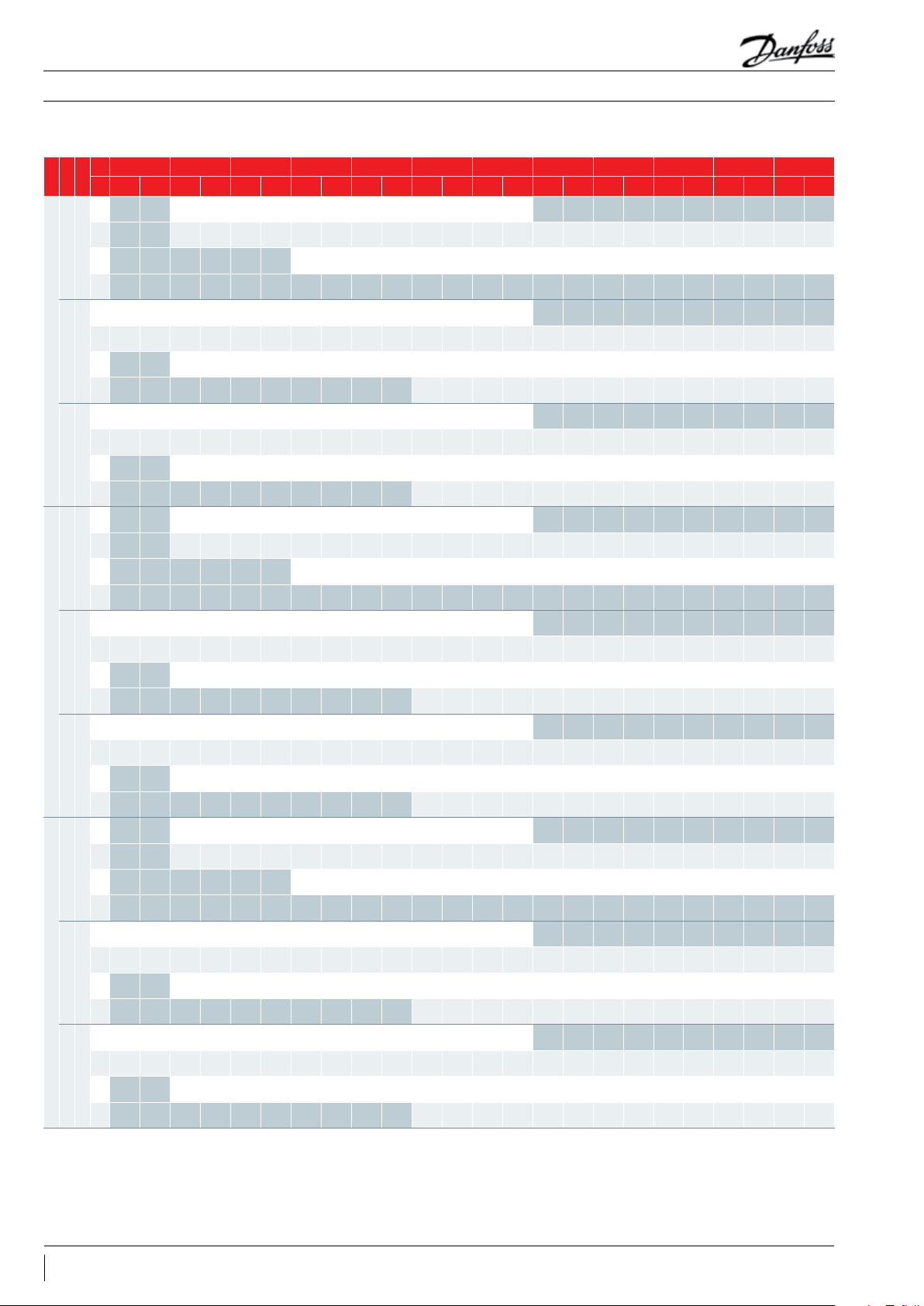

Capacity at EN12900 conditions - VZH028CJ-VZH035CJ-VZH044CJ

Te -30 -25 -20 -15 -10 -5 0 5 10 15 20 25

rps

rpm

Tc Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe

Models

5 - - 185 0 0.538 2310 0.525 2860 0.491 3500 0.431 4240 0.340 5100 0. 213 - - - - - - - - - -

25 - - 14 60 0.773 1870 0.797 2350 0 .812 2910 0. 815 3550 0.799 4300 0.76 0 5140 0. 692 6100 0.591 718 0 0.452 8400 0.268 - -

30

180 0

45 - - - - - - 173 0 1.189 2180 1. 221 2710 1. 247 3310 1.262 4000 1.262 4790 1.241 5690 1.19 4 670 0 1.115 - -

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 3010 1.038 3790 1.053 4730 1.039 5840 0.982 7150 0.867 8680 0.678 104 40 0.402 - - - - - - - - - -

25 2370 1.489 3050 1. 524 3860 1. 569 4820 1.60 9 5930 1.630 7230 1. 618 8730 1.557 10 450 1.433 12400 1.2 32 14600 0.938 1708 0 0.537 - -

60

3600

45 - - 2280 2.290 2940 2.287 3700 2.318 4600 2.369 5640 2 .426 6850 2.473 8240 2.496 9830 2.482 116 40 2. 414 1368 0 2.278 1598 0 2.060

VZH028CJ

65 - - - - - - - - - - 3760 3.558 4 620 3. 607 5630 3.671 6790 3.736 8130 3.786 9660 3.809 - -

5 5030 1.941 6300 1.9 86 7830 1.976 9650 1.898 117 80 1.739 142 60 1.484 17120 1.12 0 - - - - - - - - - -

25 4000 2.614 515 0 2.744 6500 2.858 8080 2 .942 9920 2.982 120 60 2.964 145 20 2. 876 173 40 2.702 20540 2.4 31 2415 0 2.048 28210 1. 539 - -

100

6000

45 - - 3860 3.806 4980 3.929 6280 4.059 7790 4.183 9540 4.288 11560 4.359 138 80 4.384 16530 4.349 1953 0 4.240 22930 4.043 26730 3.74 6

65 - - - - - - - - - - 6 430 6.008 7910 6.125 9640 6. 233 116 20 6 .319 13890 6.369 16480 6. 370 - -

5 - - 2340 0.655 2930 0.638 3620 0.597 4430 0.524 5370 0.414 6460 0. 261 - - - - - - - - - -

25 - - 1850 0.940 2370 0.969 2970 0.988 3680 0.990 4500 0.971 5440 0.924 6 510 0.8 42 7720 0.719 9090 0.550 10630 0. 329 -

30

180 0

45 - - - - - - 2190 1.4 46 2770 1.48 4 3430 1. 516 419 0 1. 534 5070 1.534 6070 1.508 7200 1.450 8480 1. 355

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 3810 1.238 479 0 1.25 6 5980 1.240 7390 1.172 9050 1.034 10980 0.809 13210 0.480 - - - - - - - - - -

25 3000 1.776 3870 1. 818 4890 1.872 6100 1.92 0 7510 1.945 9160 1.930 11 050 1.858 13 220 1.710 15 690 1.4 69 1849 0 1.119 21620 0. 641 - -

60

3600

45 - - 2890 2.733 3720 2.728 4690 2.76 6 5820 2.827 714 0 2.894 8670 2.951 10 430 2.979 124 40 2 .961 1473 0 2.880 17320 2.718 20230 2.458

VZH035CJ

65 - - - - - - - - - - 4760 4.246 5850 4.304 712 0 4.380 8600 4.457 10290 4.518 122 30 4.544 - -

5 6360 2.320 7980 2 .374 9920 2. 363 12220 2.270 14920 2 .079 18060 1. 774 21670 1. 339 - - - - - - - - - -

25 5070 3.125 6520 3. 281 8220 3.417 10220 3 .517 12 560 3.565 152 60 3.54 4 18380 3.438 21950 3 .231 26000 2.907 30570 2.448 35710 1.8 40 - -

100

6000

45 - - 4890 4.551 6300 4.697 7950 4.853 9860 5. 001 120 80 5.127 14 630 5. 212 1757 0 5. 242 20920 5.200 24730 5.070 29020 4.835 3384 0 4. 479

65 - - - - - - - - - - 8140 7.18 4 10020 7.323 122 00 7.453 14710 7. 556 17580 7.615 20860 7. 616 - -

5 - - 3010 0.822 3760 0 .801 4650 0. 749 570 0 0.658 6910 0.520 8300 0.327 - - - - - - - - - -

25 - - 2380 1.180 3040 1.216 3820 1.24 0 4730 1.243 5780 1.219 6990 1.159 8370 1.057 9930 0.903 11 690 0.691 13670 0 .412 - -

30

180 0

45 - - - - - - 2820 1. 815 3560 1.863 4410 1.903 5390 1.926 6520 1.925 7810 1.893 9260 1. 820 10910 1.701

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 4900 1.555 617 0 1. 578 7690 1.558 9510 1.472 11 64 0 1. 299 14120 1.016 16990 0.602 - - - - - - - - - -

25 3860 2. 231 4970 2.283 6290 2 .351 7840 2 .411 9660 2.4 43 11770 2.424 14210 2.333 17000 2.147 20180 1.845

60

3600

45 - - 3720 3.432 4780 3 .427 6030 3.473 7480 3.550 9180 3.635 1114 0 3.706 13410 3.741 16000 3 .719 18 940 3. 617 22270 3.414 26 020 3.087

VZH044CJ

65 - - - - - - - - - - 6120 5.332 753 0 5.405 9160 5. 501 11 050 5.598 13240 5. 674 15730 5.707 - -

5 8180 2.903 10260 2.970 1275 0 2.956 15710 2.839 19180 2.601 23220 2. 219 27870 1.675 - - - - - - - - - -

25 6520 3.910 8380 4.105 10570 4. 275 13150 4.400 16150 4.460 19 630 4.434 23640 4. 301 28220 4.0 42 33430 3.636 39320 3.063 45920 2.302 - -

100

6000

45 - - 6280 5.693 8100 5.876 10220 6.071 126 80 6.257 1553 0 6 .413 1882 0 6.520 2260 0 6.558 26910 6.505 31800 6.342 37320 6.048 43520 5.603

65 - - - - - - - - - - 10460 8.987 128 80 9.16 2 15680 9.323 18910 9.452 2 2610 9. 527 26830 9.527 - -

Single compressors

-

23770 1.405 27810 0.805 - -

To: Evaporating temperature in °C Superheat = 10 K

Tc: Condensing temperature in °C Subcooling = 0 K

Qo: Cooling capacity in W Pe: Power input in kW (with drive loss)

Note: All performance test data after run-in 72hr

10 AB225886435375en-001201

Page 11

Application Guidelines

Technical specifications

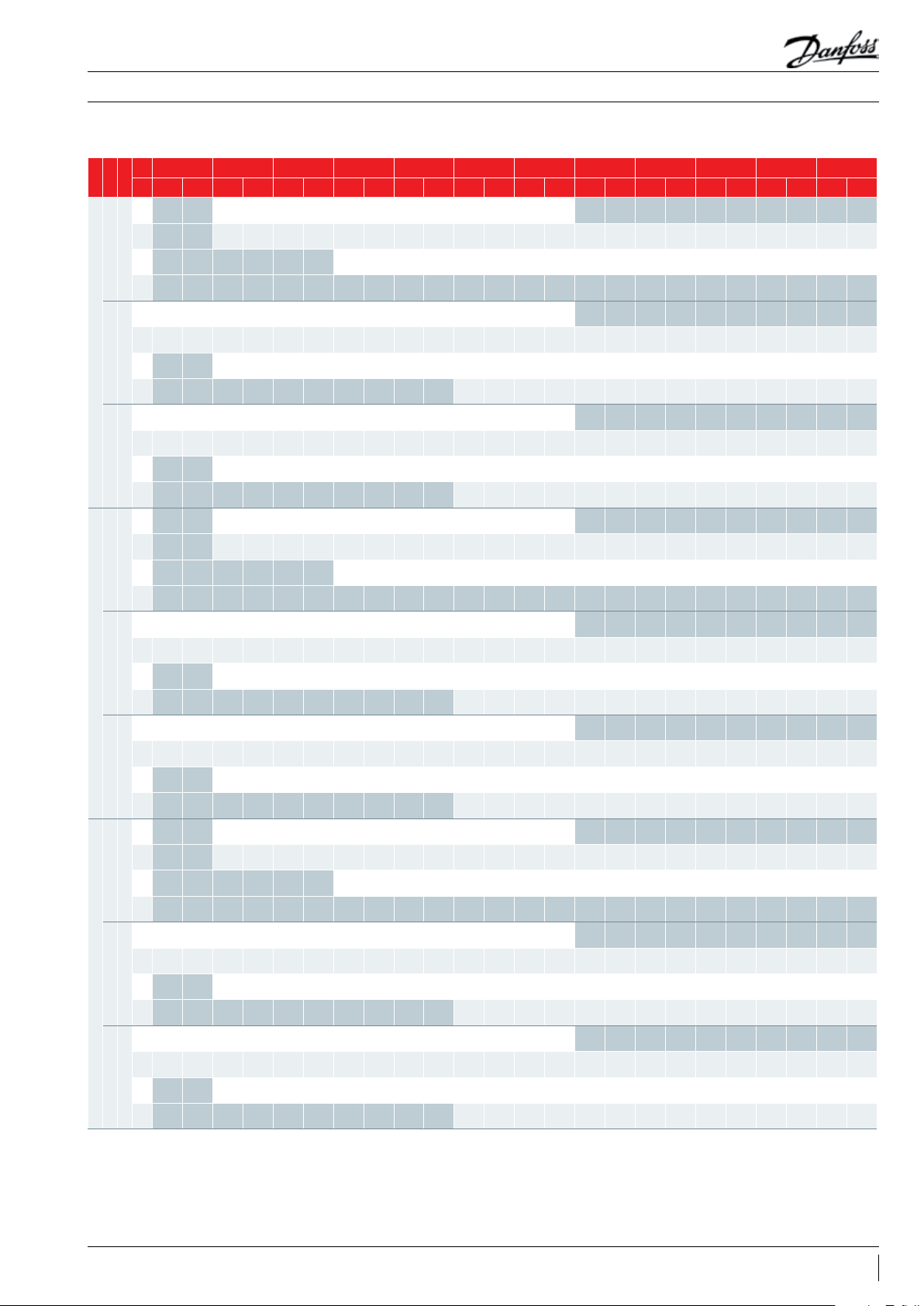

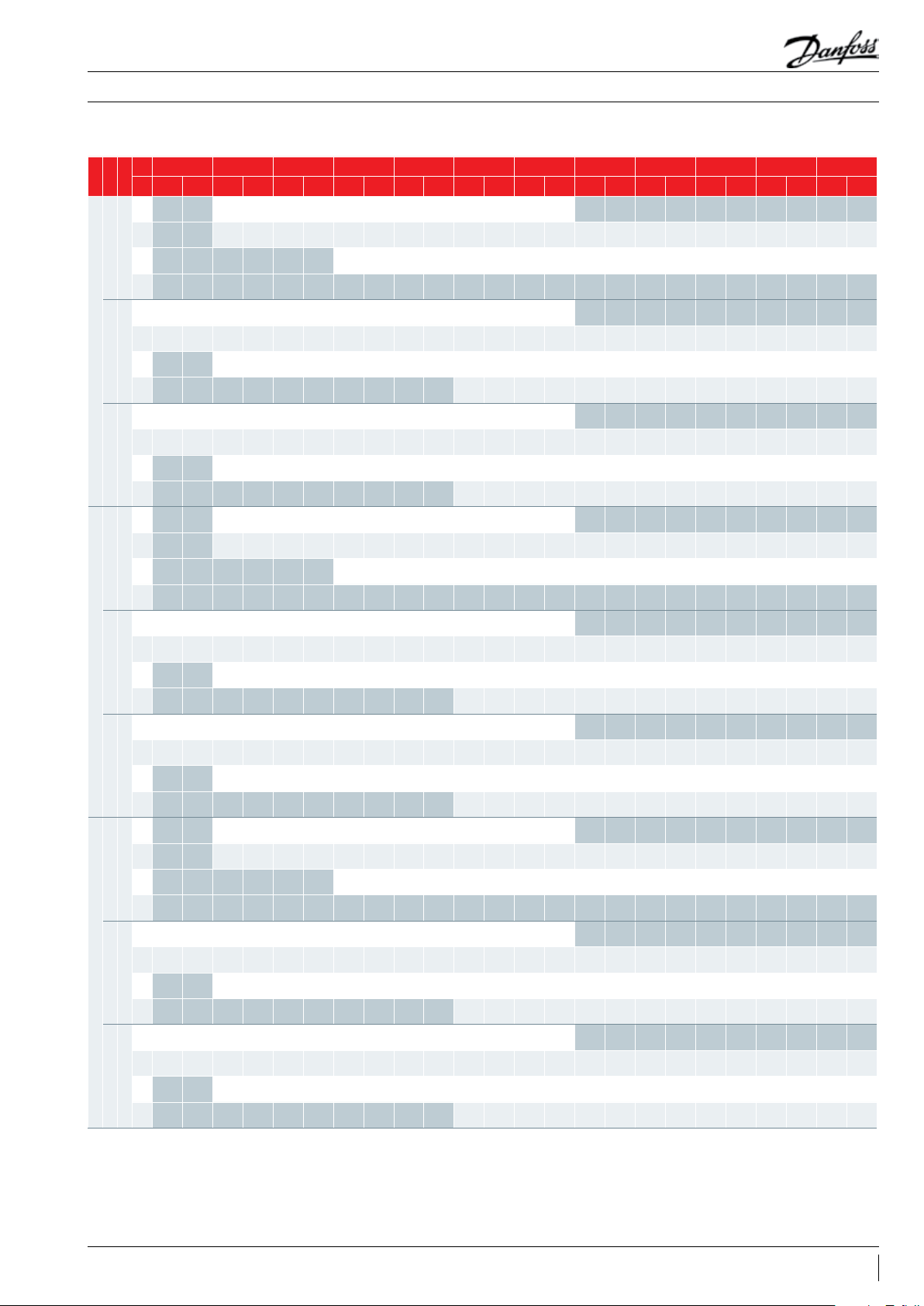

Capacity at ARI conditions - VZH028CJ-VZH035CJ-VZH044CJ

Te -30 -25 -20 -15 -10 -5 0 5 10 15 20 25

rps

rpm

Tc Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe

Models

5 - - 1960 0.538 2440 0.525 3020 0.491 3690 0. 431 4480 0. 340 5380 0.213 - - - - - - - - - -

25 - - 1570 0.773 2010 0.797 2520 0. 812 3110 0. 815 3800 0.799 4590 0.760 5490 0.692 6520 0. 591 7670 0.452 8950 0.268 - -

30

180 0

45 - - - - - - 1910 1.189 2410 1.221 2980 1.247 3640 1.262 4390 1.262 5250 1. 241 6230 1.19 4 7330 1.115 - -

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 3180 1.03 8 4000 1. 053 4990 1.039 617 0 0.982 7550 0.867 9150 0.678 11000 0.402 - - - - - - - - - -

25 2550 1.489 3280 1.524 4150 1. 569 516 0 1.6 09 6360 1. 630 7740 1.618 93 40 1.557 1116 0 1.433 13240 1. 232 15580 0.938 18220 0.537 - -

60

3600

45 - - 2530 2.290 3240 2.287 4080 2. 318 5060 2.369 6200 2.426 7520 2.473 9030 2.496 10770 2.482 1274 0 2 .414 14960 2. 278 1746 0 2.060

VZH028CJ

65 - - - - - - - - - - 4510 3.558 5520 3.607 6700 3.671 8070 3.736 9640 3.786 1143 0 3.809 - -

5 5320 1.941 6660 1.98 6 8280 1.976 10190 1. 898 1244 0 1.739 15 040 1.484 18040 1.120 - - - - - - - - - -

25 4300 2.614 5530 2 .744 6970 2. 858 8660 2.942 10620 2.982 12900 2.964 1553 0 2. 876 18520 2.702 21930 2.4 31 25770 2.048 30080 1.539 - -

100

6000

45 - - 4270 3.806 5500 3.929 6920 4.059 8580 4.183 1049 0 4.288 1270 0 4.359 15 230 4. 384 18110 4. 349 21380 4. 240 25070 4.0 43 2 9210 3. 746

65 - - - - - - - - - - 7700 6.008 9450 6.12 5 11470 6.233 13 800 6.319 16470 6.369 1950 0 6.370 - -

5 - - 2480 0.655 3090 0.638 3820 0 .597 4680 0.524 5670 0.414 6800 0. 261 - - - - - - - - - -

25 - - 19 90 0.9 40 2540 0.969 319 0 0.988 3940 0.990 4810 0.971 5810 0.924 6950 0.842 8250 0. 719 9700 0.550 113 30 0.329 -

30

180 0

45 - - - - - - 2420 1. 446 3040 1.48 4 3770 1.516 4600 1.534 5560 1.534 6650 1.50 8 7880 1. 450 9270 1.355

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 4030 1.2 38 5070 1.256 6320 1.240 7810 1.172 9550 1.034 1158 0 0.809 1392 0 0.480 - - - - - - - - - -

25 3230 1.776 4150 1.818 5250 1.872 6540 1.920 8050 1.945 9800 1.930 1182 0 1. 858 14130 1.710 16760 1.4 69 197 20 1. 119 23060 0.641 - -

60

3600

45 - - 3200 2 .733 4110 2.728 5170 2. 766 6 410 2.827 7850 2.894 9520 2.951 114 40 2.979 13 630 2.961 1612 0 2.880 18940 2.718 22110 2.458

VZH035CJ

65 - - - - - - - - - - 5700 4. 246 6990 4. 304 8480 4.380 10210 4.457 12200 4 .518 14 470 4.544 - -

5 6730 2.320 8430 2.374 104 80 2.363 1290 0 2.270 1574 0 2.079 190 40 1.774 22840 1. 339 - - - - - - - - - -

25 5450 3.125 7000 3.281 8820 3.417 10960 3 .517 13 450 3.565 16330 3.544 19 650 3.438 23450 3. 231 27 760 2.907 32620 2.448 38080 1.840 - -

100

6000

45 - - 5400 4 .551 6960 4.697 8760 4.853 108 60 5.0 01 13280 5 .127 16070 5 .212 19270 5.242 22930 5.20 0 27070 5.070 3174 0 4.835 36980 4.479

65 - - - - - - - - - - 9740 7.18 4 11960 7. 32 3 14 520 7.453 174 70 7. 556 20840 7. 615 246 80 7. 616 - -

5 - - 318 0 0.822 3980 0.801 4910 0.749 6010 0.658 7290 0. 520 8750 0.327 - - - - - - - - - -

25 - - 2550 1.180 3270 1.216 4100 1. 240 5070 1.243 6190 1.219 74 80 1.159 8940 1.057 10610 0.903 124 80 0 .691 145 80 0.412 - -

30

180 0

45 - - - - - - 3110 1.815 3920 1.863 4850 1.90 3 5920 1.926 715 0 1.925 8550 1. 893 10140 1. 820 11930 1.701

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 5180 1.555 6520 1. 578 8130 1.558 100 40 1.472 12 280 1.2 99 14900 1.016 17 900 0.602 - - - - - - - - - -

25 4150 2.231 5340 2.283 6750 2. 351 8 410 2. 411 1035 0 2.443 1260 0 2.424 152 00 2.333 18170 2 .147 21550 1. 845

60

3600

45 - - 4110 3.432 5280 3.427 6650 3.473 8240 3.550 1009 0 3.635 12 240 3.706 14710 3. 741 17 530 3.719 20730 3 .617 2436 0 3.414 28430 3.087

VZH044CJ

65 - - - - - - - - - - 7330 5. 332 8990 5.405 10910 5. 501 13130 5.598 15690 5 .674 18610 5.707 - -

5 8650 2.903 10 850 2.970 13470 2.956 16590 2.839 20240 2.601 24490 2. 219 29370 1.675 - - - - - - - - - -

25 7010 3.910 9000 4.105 113 40 4.275 140 90 4.400 173 00 4.460 21010 4.434 25280 4.301 30160 4.042 35700 3.636 41950 3.063 48970 2.302 - -

100

6000

45 - - 6950 5.693 8950 5.876 11 270 6.071 13960 6.257 170 80 6.413 20670 6.520 24790 6.558 29480 6.505 34 810 6.342 40820 6.048 4756 0 5.603

65 - - - - - - - - - - 12530 8.987 1538 0 9.162 186 80 9.323 22470 9.452 26800 9. 527 3174 0 9. 527 - -

To: Evaporating temperature in °C Superheat = 11.1 K

Tc: Condensing temperature in °C Subcooling = 8.3 K

Qo: Cooling capacity in W Pe: Power input in kW (with drive loss)

Rating point: ARI@60 rps

To/Tc/SH/SC: 7.2°C/54.4°C/11.1K/8.3K@60rps

Single compressors

-

25370 1.40 5 29650 0.805 - -

Note: All performance test data after run-in 72hr

11AB225886435375en-001201

Page 12

Application Guidelines

Technical specifications

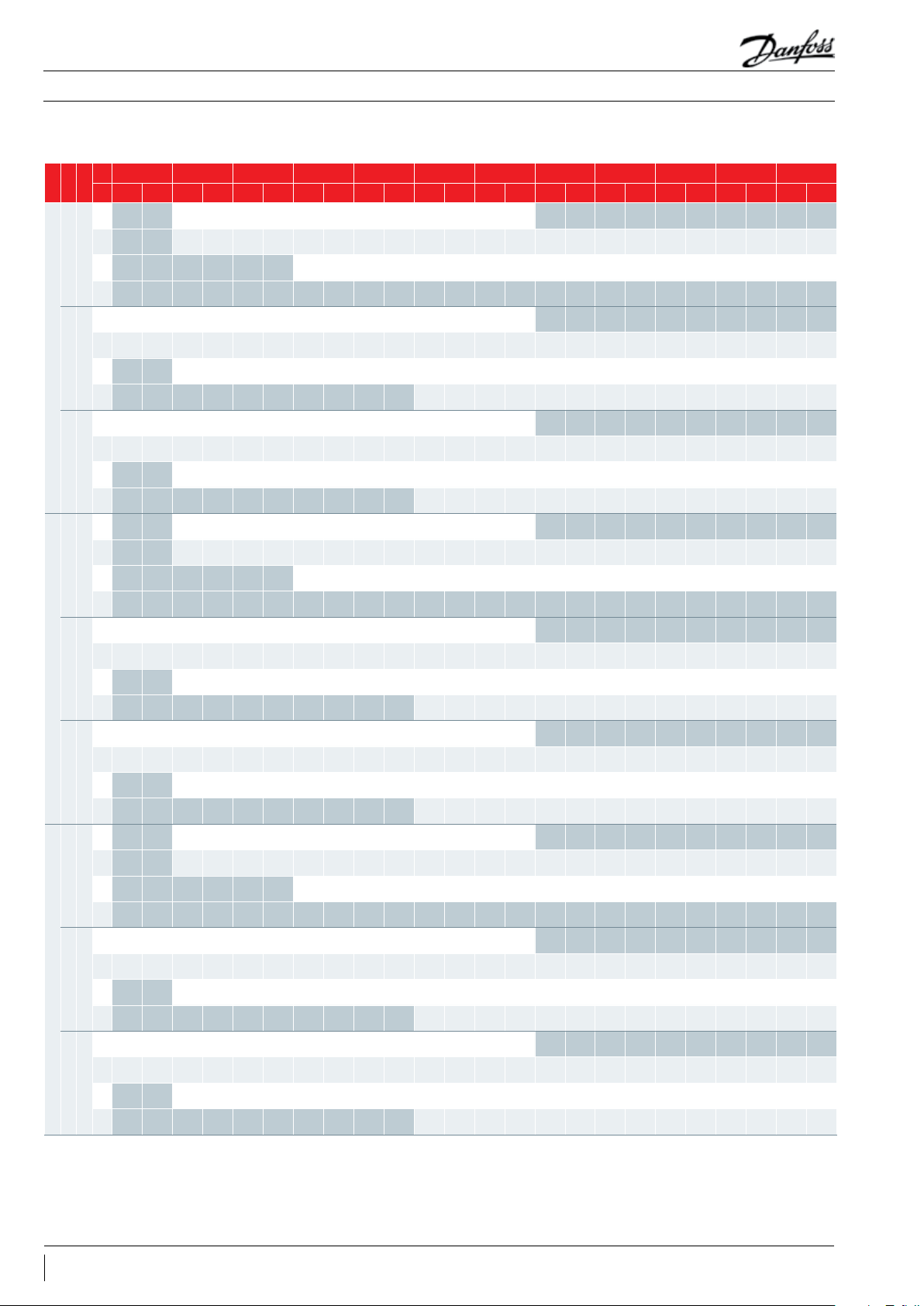

Capacity at EN12900 conditions - VZH028CH-VZH035CH-VZH044CH

Te -30 -25 -20 -15 -10 -5 0 5 10 15 20 25

rps

rpm

Tc Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe

Models

5 - - 185 0 0.557 2310 0.543 2860 0. 508 3500 0.446 4240 0.353 5100 0.223 - - - - - - - - - -

25 - - 14 60 0.799 1870 0.823 2350 0.839 2910 0. 842 3550 0.825 4300 0.785 5140 0.716 6100 0 .612 7180 0.469 8400 0 .281 - -

30

180 0

45 - - - - - - 173 0 1. 228 218 0 1. 261 2710 1. 288 3310 1.303 4000 1. 303 4790 1. 280 5690 1.232 670 0 1.151 - -

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 3010 1.037 3790 1.053 473 0 1.039 5840 0.982 715 0 0.866 8680 0.678 104 40 0.402 - - - - - - - - - -

25 2370 1.488 3050 1. 523 3860 1. 568 4820 1.60 8 5930 1.630 7230 1 .617 8730 1. 556 10 450 1.432 12 400 1. 231 14 600 0.938 1708 0 0.537 - -

60

3600

45 - - 2280 2.289 2940 2.286 370 0 2.317 4600 2.368 5640 2. 425 6850 2. 472 8240 2.496 9830 2. 481 116 40 2. 413 13 680 2.277 15980 2.059

VZH028CH

65 - - - - - - - - - - 3760 3.557 4 620 3.606 5630 3.670 6790 3.734 8130 3.785 9660 3. 807 - -

5 5030 1.894 630 0 1.938 7830 1.928 9650 1.852 1178 0 1.697 1426 0 1.44 8 1712 0 1.093 - - - - - - - - - -

25 4000 2.551 5150 2.678 6500 2.789 8080 2. 871 9 920 2.910 1206 0 2.893 14 520 2.806 1734 0 2.637 20540 2.372 24150 1.998 28210 1. 502 - -

100

6000

45 - - 3860 3.714 4980 3.834 6280 3.961 7790 4.082 9540 4.184 115 60 4.254 13880 4.279 1653 0 4.244 1953 0 4 .138 22930 3.946 26730 3.656

65 - - - - - - - - - - 6 430 5.863 7910 5.977 9640 6.083 116 20 6.167 13890 6 .216 16 480 6 .216 - -

5 - - 2340 0. 651 2930 0.634 3620 0. 593 4430 0. 520 5370 0. 411 6460 0. 258 - - - - - - - - - -

25 - - 1850 0.935 2370 0.963 2970 0.982 3680 0.984 4500 0.965 5440 0.918 6510 0. 836 7720 0.714 9090 0.546 10 630 0.325 -

30

180 0

45 - - - - - - 2190 1.438 2770 1. 476 3430 1.507 419 0 1.526 5070 1.525 6070 1.4 99 7200 1. 442 8480 1. 347

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 3810 1.242 4790 1.26 0 5980 1.244 7390 1.175 9050 1.037 109 80 0 .811 13210 0.4 81 - - - - - - - - - -

25 3000 1. 781 3870 1.823 4890 1. 877 6100 1.925 7510 1.951 916 0 1.93 6 1105 0 1. 863 1322 0 1. 715 1569 0 1.474 18 490 1.122 21620 0.6 43 - -

60

3600

45 - - 2890 2. 740 3720 2.736 4690 2.773 5820 2.835 7140 2.902 8 670 2.959 10430 2.987 124 40 2.969 1473 0 2.888 17320 2.726 20230 2.465

VZH035CH

65 - - - - - - - - - - 4760 4.258 5850 4.316 7120 4.392 8600 4.470 10290 4.531 12 230 4.557 - -

5 6360 2.378 7980 2.433 9920 2.421 12220 2.326 1492 0 2 .130 18060 1. 818 21670 1. 372 - - - - - - - - - -

25 5070 3. 203 6520 3.363 8220 3.502 102 20 3.605 12560 3.653 152 60 3.632 183 80 3.523 2195 0 3 .3 11 26000 2.979 30570 2.509 35710 1.886 - -

100

6000

45 - - 4890 4.664 6300 4. 814 7950 4.973 9860 5 .125 120 80 5.254 14630 5 .341 17 570 5.372 20920 5.329 24730 5 .195 29020 4.954 33840 4.590

65 - - - - - - - - - - 8140 7. 36 2 10020 7.50 5 1220 0 7. 638 14710 7. 743 17580 7. 80 4 20860 7. 80 5 - -

5 - - 3010 0. 855 3760 0.833 4650 0.779 570 0 0.685 6910 0.542 8300 0.344 - - - - - - - - - -

25 - - 2380 1.226 3040 1.26 4 3820 1.288 4730 1.292 5780 1. 266 6990 1.204 8370 1.098 9930 0.939 1169 0 0.720 13670 0.433 - -

30

180 0

45 - - - - - - 2820 1.8 85 3560 1.935 4410 1.976 5390 2.000 6520 1.999 7810 1.964 9260 1. 889 10 910 1.765

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 4900 1.573 6170 1. 596 7690 1.576 9510 1.489 116 40 1. 314 14120 1. 028 169 90 0.609 - - - - - - - - - -

25 3860 2.257 4970 2 .310 6290 2.378 7840 2.439 9660 2.471 11770 2.452 14210 2.360 17000 2.172 20180 1.867

60

3600

45 - - 3720 3.472 4780 3.467 6030 3. 514 74 80 3.592 9180 3.677 1114 0 3 .749 13410 3.785 16000 3.762 18940 3.659 22270 3.453 26020 3.123

VZH044CH

65 - - - - - - - - - - 6120 5.395 7530 5.468 916 0 5.565 110 50 5.663 13240 5 .740 157 30 5.7 74 - -

5 8180 2.896 10260 2.963 12750 2.949 15710 2 .832 1918 0 2.594 23220 2. 214 27870 1.671 - - - - - - - - - -

25 6520 3.900 8380 4.095 10570 4.265 13150 4.390 16150 4.449 196 30 4.423 23640 4. 291 28220 4.032 33430 3.627 39320 3.056 45920 2.297 - -

100

6000

45 - - 6280 5.679 810 0 5.862 10220 6.056 126 80 6. 241 15530 6.398 1882 0 6.505 22600 6.542 26910 6.489 318 00 6.327 37320 6.033 43520 5.589

65 - - - - - - - - - - 10460 8.965 128 80 9.13 9 15680 9. 301 18910 9.429 22610 9.504 26830 9.504 - -

Single compressors

-

23770 1.422 27810 0. 815 - -

To: Evaporating temperature in °C Superheat = 10 K

Tc: Condensing temperature in °C Subcooling = 0 K

Qo: Cooling capacity in W Pe: Power input in kW (with drive loss)

Note: All performance test data after run-in 72hr

12 AB225886435375en-001201

Page 13

Application Guidelines

Technical specifications

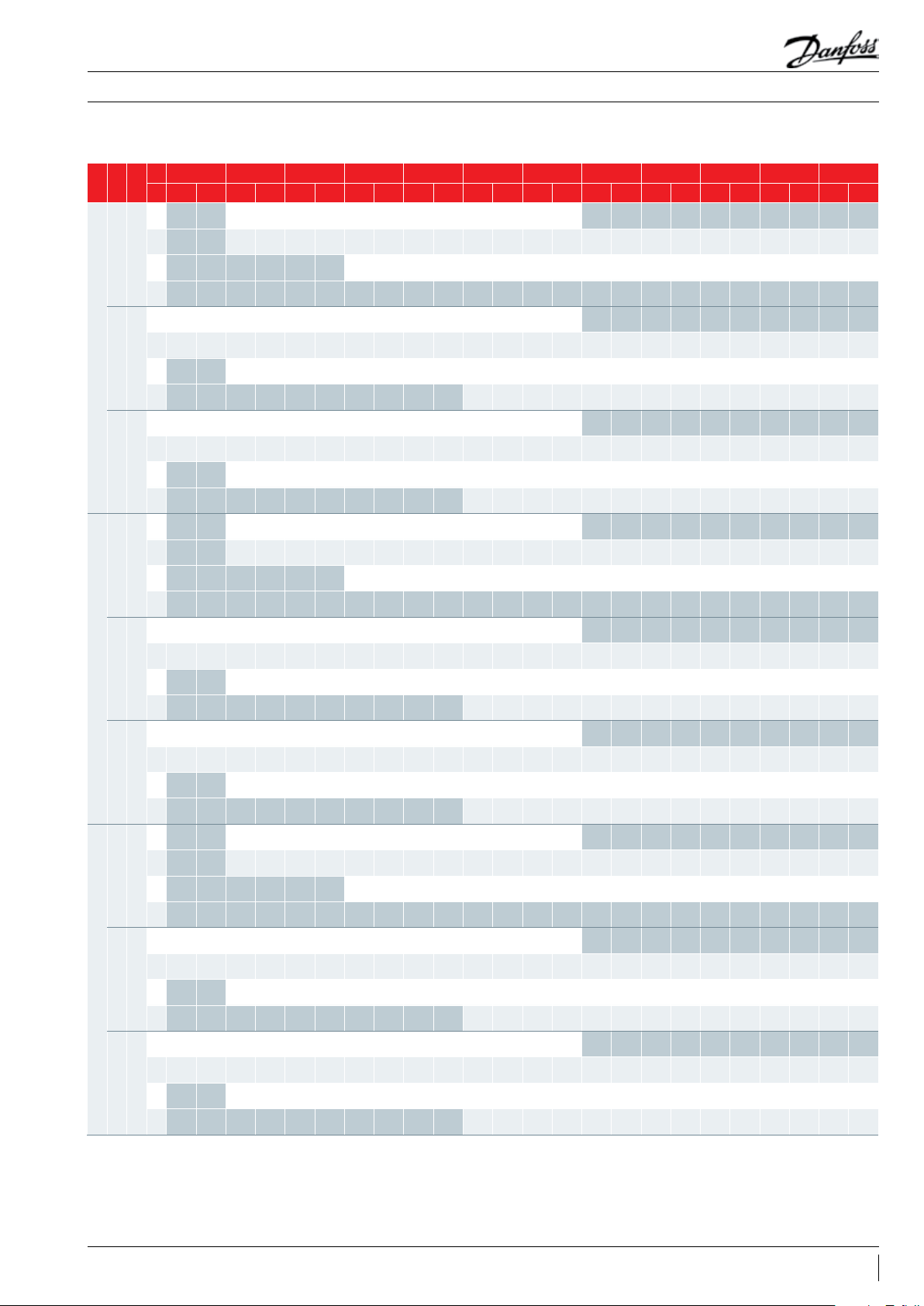

Capacity at ARI conditions - VZH028CH-VZH035CH-VZH044CH

Te -30 -25 -20 -15 -10 -5 0 5 10 15 20 25

rps

rpm

Tc Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe

Models

5 - - 1960 0.557 2440 0.543 3020 0.508 3690 0.446 4480 0. 353 5380 0.223 - - - - - - - - - -

25 - - 1570 0.799 2010 0.823 2520 0.839 3110 0.842 3800 0.825 4590 0.785 5490 0.716 6520 0. 612 7670 0.469 8950 0. 281 - -

30

180 0

45 - - - - - - 1910 1.228 2410 1. 261 2980 1. 288 3640 1.30 3 4390 1. 303 5250 1.280 6230 1.232 7330 1.151 - -

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 3180 1.037 4000 1.053 499 0 1. 039 6170 0.982 7550 0.866 9 150 0 .678 11000 0.402 - - - - - - - - - -

25 2550 1.488 3280 1.523 4150 1.568 5160 1.60 8 6360 1.630 7 740 1.617 9340 1. 556 1116 0 1.432 13240 1.231 15580 0.938 1822 0 0.537 - -

60

3600

45 - - 2530 2.289 3240 2.286 4080 2.317 5060 2.368 6200 2.42 5 7520 2 .472 9030 2.496 10770 2.481 1274 0 2. 413 14960 2.277 174 60 2.059

VZH028CH

65 - - - - - - - - - - 4510 3.557 5520 3.606 6700 3.670 8070 3.734 9640 3.785 1143 0 3. 807 - -

5 5320 1. 894 6660 1.938 8280 1.928 10190 1.852 12440 1.6 97 150 40 1.448 18040 1. 093 - - - - - - - - - -

25 4300 2 .551 553 0 2.678 6970 2.789 8660 2.871 10620 2 .910 1290 0 2.893 15530 2.806 18520 2.637 2193 0 2.372 25770 1.998 30080 1.5 02 - -

100

6000

45 - - 4270 3.714 5500 3.834 6920 3.9 61 8580 4.082 10 490 4 .184 12700 4.254 152 30 4.279 18 110 4.24 4 2138 0 4 .138 25070 3.94 6 2 9210 3.656

65 - - - - - - - - - - 7700 5.863 9450 5.977 11470 6.083 13 800 6 .167 16470 6.216 1950 0 6. 216 - -

5 - - 2480 0.651 3090 0.634 3820 0.593 4680 0.520 5670 0 .411 6800 0.258 - - - - - - - - - -

25 - - 19 90 0.935 2540 0.963 3190 0.982 3940 0.984 4810 0.965 5810 0.918 6950 0.836 8250 0.714 9700 0.546 113 30 0. 325 -

30

180 0

45 - - - - - - 2420 1.438 3040 1.476 3770 1.507 4600 1. 526 5560 1. 525 6650 1.499 7880 1.442 9270 1. 347

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 4030 1.242 5070 1.2 60 6320 1.244 7810 1.175 9550 1.037 1158 0 0 .811 13920 0.4 81 - - - - - - - - - -

25 3230 1.781 4150 1. 823 5250 1.877 654 0 1.925 8050 1.951 9800 1.936 118 20 1. 863 14130 1.715 1676 0 1. 474 19 720 1.12 2 23060 0.6 43 - -

60

3600

45 - - 3200 2.74 0 4 110 2.736 5170 2.773 6 410 2. 835 7850 2.902 9520 2.959 11 44 0 2.987 136 30 2.969 1612 0 2.888 18940 2.726 2 2110 2.465

VZH035CH

65 - - - - - - - - - - 5700 4.258 6990 4. 316 8480 4.392 10210 4. 470 122 00 4 .531 14470 4.557 - -

5 6730 2 .378 8430 2.433 104 80 2.421 12 900 2.326 1574 0 2.13 0 190 40 1.818 22840 1. 372 - - - - - - - - - -

25 5450 3.203 7000 3.363 8820 3.502 10960 3.605 13450 3.653 16330 3.632 19650 3.523 23450 3 .311 27760 2.979 32620 2.509 38080 1.886 - -

100

6000

45 - - 5400 4.664 6960 4.814 8760 4.973 108 60 5 .125 13280 5.254 16 070 5.341 19270 5.372 22930 5. 329 27070 5.195 3174 0 4.954 36980 4.590

65 - - - - - - - - - - 9740 7.3 62 11960 7. 50 5 14 520 7.6 38 17470 7. 743 20840 7.80 4 24680 7. 80 5 - -

5 - - 318 0 0.855 3980 0.833 4910 0.779 6010 0.685 7290 0.542 8750 0.344 - - - - - - - - - -

25 - - 2550 1. 226 3270 1.26 4 410 0 1.2 88 5070 1.292 6190 1. 266 7480 1.20 4 8940 1.098 10610 0.939 12 480 0.720 14 580 0.433 - -

30

180 0

45 - - - - - - 3110 1.885 3920 1. 935 4850 1.976 5920 2.000 715 0 1.999 8550 1.964 1014 0 1.8 89 11 930 1.76 5

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 5180 1.57 3 6520 1. 596 8130 1.576 10040 1.48 9 12280 1. 314 149 00 1. 028 17 900 0.609 - -

25 4150 2 .257 5340 2.310 6750 2.378 8410 2.439 10350 2. 471 12600 2.452 15200 2.360 1 8170 2 .172 21550 1. 867 25370 1.422 29650 0. 815 - -

60

3600

45 -

VZH044CH

65 - - - - - - - - - - 7330 5. 395 8990 5.468 10910 5.565 13130 5.663 15690 5 .740 18610 5.774 - -

5 8650 2.896 108 50 2.963 13470 2.949 1659 0 2.832 20240 2.594 24490 2.214 29370 1.671 - - - - - - - - - -

25 7010 3.900 9000 4.095 11 34 0 4.265 14090 4. 390 17 300 4.4 49 21010 4 .423 25280 4 .291 30160 4.032 35700 3.627 419 50 3.056 48970 2.297 - -

100

6000

45 - - 6950 5.679 8950 5.862 11270 6.056 13960 6. 241 1708 0 6.398 20670 6.505 24790 6.542 29480 6.489 34810 6.327 40820 6.033 47560 5.589

65 - - - - - - - - - - 12530 8.965 15 380 9.139 186 80 9. 301 22470 9.429 26800 9.504 31740 9.504 - -

To: Evaporating temperature in °C Superheat = 11.1 K

Tc: Condensing temperature in °C Subcooling = 8.3 K

Qo: Cooling capacity in W Pe: Power input in kW (with drive loss)

Rating point: ARI@60 rps

To/Tc/SH/SC: 7.2°C/54.4°C/11.1K/8.3K@60rps

- 4110 3.472 5280 3.467 6650 3.514 8240 3.592 10090 3.677 12240 3 .749 14710 3.785 175 30 3.762 20730 3. 659 24360 3.453 28430 3.12 3

Single compressors

-

Note: All performance test data after run-in 72hr

13AB225886435375en-001201

Page 14

Application Guidelines

Technical specifications

Capacity at EN12900 conditions - VZH028CG-VZH035CG-VZH044CG

Te -30 -25 -20 -15 -10 -5 0 5 10 15 20 25

rps

rpm

Tc Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe

Models

5 - - 185 0 0.533 2310 0. 519 2860 0.486 3500 0.426 424 0 0.336 510 0 0 .211 - - - - - - - - - -

25 - - 14 60 0 .766 18 70 0.789 2350 0.804 2 910 0.807 3550 0.791 4300 0.752 514 0 0.686 6100 0.586 7180 0.4 47 8400 0.265 - -

30

180 0

45 - - - - - - 173 0 1.177 2180 1.208 2710 1. 234 3310 1.249 4000 1. 249 479 0 1.22 8 5690 1.18 2 670 0 1.10 4 - -

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 3010 1.027 3790 1.043 473 0 1.029 5840 0.972 7150 0.858 8680 0.671 10440 0.398 - - - - - - - - - -

25 2370 1.474 3050 1. 509 3860 1.553 4820 1.593 5930 1.614 7230 1.602 8730 1. 541 10450 1.419 124 00 1.219 14600 0.929 170 80 0.532 - -

60

3600

45 - - 2280 2.268 2940 2. 264 370 0 2.295 4600 2.346 5640 2.402 6850 2.449 8240 2.472 9830 2 .457 116 40 2.390 136 80 2.255 15980 2.040

VZH028CG

65 - - - - - - - - - - 3760 3.523 4620 3.571 5630 3.635 6790 3.699 813 0 3 .749 9660 3.771 - -

5 5030 1.92 2 6300 1.966 7830 1.956 9650 1.879 11780 1.722 14260 1.4 69 17120 1.10 9 - - - - - - - - - -

25 4000 2.588 5150 2.717 6500 2.830 8080 2.913 9920 2.952 120 60 2 .935 14520 2. 847 173 40 2.676 20540 2.407 24150 2.028 28210 1.524 - -

100

6000

45 - - 3860 3.768 4980 3.890 6280 4 .018 7790 4 .141 9540 4.245 115 60 4. 316 138 80 4 .341 1653 0 4. 306 19530 4 .198 22930 4.003 26730 3.709

65 - - - - - - - - - - 6 430 5.9 49 7910 6.064 9640 6.172 1162 0 6. 257 13890 6.306 16 480 6. 307 - -

5 - - 2340 0.648 2930 0.632 3620 0.591 4430 0.519 5370 0 .410 6460 0.258 - - - - - - - - - -

25 - - 1850 0.9 31 2370 0.959 2970 0.978 3680 0.981 4500 0.962 5440 0. 914 6 510 0.833 7720 0.712 9090 0. 545 10 630 0.325 -

30

180 0

45 - - - - - - 2190 1.432 2770 1. 470 3430 1.501 419 0 1. 519 5070 1. 519 6070 1.4 93 7200 1. 436 8480 1.342

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 3810 1.226 479 0 1. 244 5980 1.228 7390 1.160 9050 1. 024 109 80 0.8 01 13210 0.475 - - - - - - - - - -

25 3000 1. 759 3870 1.80 0 4890 1.853 610 0 1.901 7510 1.926 916 0 1 .911 11 050 1.839 13 220 1.693 15 690 1.455 18 490 1.108 21620 0.635 - -

60

3600

45 - - 2890 2.706 3720 2 .701 4690 2.738 5820 2.799 7140 2.865 8670 2.921 10430 2.949 12 440 2.932 14730 2.851 17320 2.691 20230 2.434

VZH035CG

65 - - - - - - - - - - 4760 4.204 5850 4.261 712 0 4. 337 8600 4. 413 1029 0 4.473 12230 4.499 - -

5 6360 2.297 7980 2. 351 9920 2.339 12220 2. 247 14920 2.058 18060 1.757 21670 1.326 - - - - - - - - - -

25 5070 3.094 6520 3. 249 8220 3.384 102 20 3.483 12560 3. 530 1526 0 3.509 183 80 3.404 219 50 3.199 26000 2.878 30570 2.424 35710 1. 822 - -

100

6000

45 - - 4890 4.506 6300 4.651 7950 4.805 9860 4.952 120 80 5.076 14630 5 .161 17570 5.190 20920 5 .148 24730 5.019 29020 4.787 3384 0 4.434

65 - - - - - - - - - - 8140 7.112 1002 0 7. 251 12 200 7. 37 9 14710 7. 48 1 17 580 7. 54 0 20860 7. 54 0 - -

5 - - 3010 0 .812 3760 0.791 4650 0.74 0 5700 0.650 6910 0 .513 8300 0.32 3 - - - - - - - - - -

25 - - 2380 1.166 3040 1. 201 3820 1.224 4730 1.22 8 5780 1. 204 6990 1.145 8370 1.043 9930 0. 891 116 90 0.682 13670 0.407 - -

30

180 0

45 - - - - - - 2820 1.792 3560 1.8 40 4 410 1. 879 5390 1.9 02 6520 1.901 7810 1.869 9260 1.798 10910 1.6 80

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 4900 1.5 40 6170 1.5 62 7690 1.542 9510 1.457 1164 0 1.28 6 1412 0 1.006 1699 0 0.596 - - - - - - - - - -

25 3860 2.209 4970 2. 261 6290 2.327 7840 2.387 9660 2 .419 117 70 2.400 14210 2.310 17000 2 .126 20180 1. 827

60

3600

45 - - 3720 3.398 478 0 3.393 6030 3.439 7480 3. 515 9180 3.599 1114 0 3.669 13410 3.704 16000 3.682 1894 0 3.581 22270 3.380 26020 3.056

VZH044CG

65 - - - - - - - - - - 6120 5. 280 7530 5.352 9160 5. 447 11 050 5.543 13240 5.618 1573 0 5.651 - -

5 8180 2.897 10260 2.964 12 750 2.950 15710 2.834 19180 2.596 23220 2.215 27870 1.672 - - - - - - - - - -

25 6520 3.902 8380 4.097 10570 4. 267 13150 4.392 16150 4.4 51 1963 0 4.425 23640 4.293 28220 4.034 33430 3.629 39320 3.057 45920 2.298 - -

100

6000

45 - - 6280 5.682 8100 5. 865 10220 6.059 126 80 6. 244 1553 0 6. 401 18820 6.508 2260 0 6.545 26910 6.492 3180 0 6.329 37320 6.036 43520 5.592

65 - - - - - - - - - - 10460 8.969 128 80 9.143 15680 9.305 18910 9. 433 22610 9.508 26830 9. 509 - -

Single compressors

-

23770 1.391 27810 0.797 - -

To: Evaporating temperature in °C Superheat = 10 K

Tc: Condensing temperature in °C Subcooling = 0 K

Qo: Cooling capacity in W Pe: Power input in kW (with drive loss)

Note: All performance test data after run-in 72hr

14 AB225886435375en-001201

Page 15

Application Guidelines

Technical specifications

Capacity at ARI conditions - VZH028CG-VZH035CG-VZH044CG

Te -30 -25 -20 -15 -10 -5 0 5 10 15 20 25

rps

rpm

Models

VZH028CG

VZH035CG

VZH044CG

To: Evaporating temperature in °C Superheat = 11.1 K

Tc: Condensing temperature in °C Subcooling = 8.3 K

Qo: Cooling capacity in W Pe: Power input in kW (with drive loss)

Rating point: ARI@60 rps

To/Tc/SH/SC: 7.2°C/54.4°C/11.1K/8.3K@60rps

Tc Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe

5 - - 1960 0.533 2440 0 .519 3020 0.486 3690 0. 426 4480 0.336 5380 0. 211 - - - - - - - - - -

25 - - 1570 0.766 2010 0.789 2520 0.804 3110 0.807 3800 0.791 4590 0.752 5490 0.686 6520 0.586 7670 0.447 8950 0.265 - -

30

180 0

45 - - - - - - 1910 1.17 7 2410 1. 208 2980 1.234 3640 1.249 4390 1. 249 5250 1. 228 6230 1.182 7330 1.10 4 - -

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 3180 1.027 4000 1.043 4990 1.029 6170 0.972 7550 0.858 9150 0.671 11000 0. 398 - - - - - - - - - -

25 2550 1.474 3280 1.509 415 0 1.553 516 0 1.593 6360 1. 614 774 0 1.602 9340 1. 541 1116 0 1. 419 13240 1.219 1558 0 0.929 182 20 0.532 - -

60

3600

45 - - 2530 2.268 3240 2.264 4080 2.295 5060 2.346 6200 2.4 02 7520 2.449 9030 2 .472 10770 2.457 12 740 2.390 14960 2.255 174 60 2.040

65 - - - - - - - - - 4510 3.523 5520 3.571 670 0 3.635 8 070 3.699 9640 3.749 11430 3.771 - -

5 5320 1.92 2 6660 1.96 6 8280 1.956 10190 1.879 124 40 1. 722 150 40 1.4 69 18 040 1.109 - - - - - - - - - -

25 4300 2.588 5530 2 .717 6970 2.830 8660 2 .913 10 620 2.952 129 00 2 .935 15530 2.8 47 18520 2.676 219 30 2.407 25770 2.028 30080 1. 524 - -

100

6000

45 - - 4270 3.768 550 0 3.890 6920 4 .018 8580 4 .141 10490 4.245 1270 0 4. 316 1523 0 4.341 18 110 4.306 21380 4.198 25070 4.003 29210 3.709

65 - - - - - - - - - - 7700 5.949 9450 6.064 11 470 6.17 2 138 00 6.257 16470 6.306 195 00 6.307 - -

5 - - 248 0 0.648 3090 0.632 3820 0.591 4680 0. 519 5670 0.410 6800 0.258 - - - - - - - - - -

25 - - 19 90 0 .931 2540 0.959 3190 0.978 3940 0.981 4810 0.962 5810 0.914 6950 0. 833 8250 0 .712 9700 0.545 113 30 0.325 - -

30

180 0

45 - - - - - - 2420 1.432 3040 1.470 3770 1.501 4600 1. 519 5560 1.519 6650 1.493 7880 1.436 9270 1.342

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 4030 1. 226 5070 1. 244 6320 1. 228 7810 1.160 9550 1.024 1158 0 0. 801 13920 0 .475 - - - - - - - - - -

25 3230 1.759 4150 1. 800 5250 1.853 6540 1.901 8050 1.926 9800 1.911 1182 0 1.839 14130 1.693 16760 1. 455 19720 1.108 23060 0.635 - -

60

3600

45 - - 3200 2.706 4110 2 .701 517 0 2.738 6 410 2.799 7850 2.865 9520 2.921 114 40 2.949 13630 2.932 16120 2.851 18940 2.691 2 2110 2.434

65 - - - - - - - - - - 5700 4.20 4 6990 4 .261 8480 4.337 10210 4. 413 122 00 4. 473 14470 4.499 - -

5 6730 2.297 8430 2 .351 10480 2.339 1290 0 2 .247 1574 0 2.058 19 040 1.757 22840 1. 326 - - - - - - - - - -

25 5450 3.094 7000 3. 249 8820 3.384 10960 3.483 13450 3. 530 16330 3.509 19650 3.404 23450 3 .199 27760 2.878 32620 2. 424 38080 1.822 - -

100

6000

45 - - 5400 4.506 6960 4.651 8760 4.805 1086 0 4.952 1328 0 5.076 16070 5.161 19270 5.190 22930 5.14 8 27070 5 .019 31740 4.787 36980 4.434

65 - - - - - - - - - - 9740 7.112 11960 7.2 51 1452 0 7.379 1747 0 7. 481 20840 7. 54 0 24 680 7. 54 0 - -

5 - - 318 0 0.812 3980 0.791 4910 0.74 0 6010 0.650 7290 0 .513 8750 0.323 - - - - - - - - - -

25 - - 2550 1.16 6 3270 1.201 4100 1.224 5070 1.22 8 619 0 1.204 74 80 1.145 8940 1.043 10610 0.891 124 80 0.682 14580 0.407 - -

30

180 0

45 - - - - - - 3110 1.792 3920 1.840 4850 1.879 5920 1.902 7150 1.901 8550 1.869 10140 1.798 119 30 1.6 80

65 - - - - - - - - - - - - - - - - - - - - - - - -

5 5180 1. 540 6520 1. 562 8130 1.542 10 040 1.457 122 80 1. 286 1490 0 1. 006 179 00 0.596 - - - - - - - - - -

25 4150 2.209 5340 2 .261 6750 2.327 8410 2. 387 1035 0 2.419 126 00 2.400 15200 2 .310 18170 2.12 6 21550 1.827 25370

60

3600

45 - - 4110 3.398 5280 3. 393 6650 3.439 824 0 3 .515 10090 3. 599 12 240 3.669 14710 3.704 17 530 3.682 20730 3.581 24360 3.380 28430 3.056

65 - - - - - - - - - - 7330 5.280 8990 5.352 10910 5.447 13130 5.543 15 690 5.618 18 610 5.651 - -

5 8650 2. 897 10850 2.964 13 470 2.950 16590 2.834 20240 2. 596 24490 2. 215 29370 1.672 - - - - - - - - - -

25 7010 3.902 9000 4.097 1134 0 4. 267 14090 4.392 173 00 4 .451 21010 4.425 25280 4.293 3016 0 4.034 35700 3.629 41950 3.057 48970 2.298 - -

100

6000

45 - - 6950 5.682 8950 5.865 112 70 6.059 13960 6. 244 17 080 6.4 01 20670 6. 508 24790 6. 545 29480 6.492 34 810 6. 329 40820 6.036 47560 5.592

65 - - - - - - - - - - 12530 8.969 153 80 9.143 186 80 9. 305 22470 9.433 26800 9. 508 3174 0 9.509 - -

Single compressors

1.391 29650 0.797 - -

Note: All performance test data after run-in 72hr

15AB225886435375en-001201

Page 16

Overall height:

op of sensor bracket

Application Guidelines

Dimensions

Single compressors

VZH028-035-044G/J/H

OSG version

Ø164.5

Discharge line

1/2"

(95.25)

239

190.5

Top of sensor bracket

Suction

3/4"

Oil Sight Glass

1 1/8"

Schrader valve

and cover

55.0

78.0

11

230.5

Ø19.5

4X

360.4

404.4

VZH028-035-044G/J

OLS version

Discharge line

1/2"

Oil level sensor

prism

42.5

(95.25)

Ø164.5

239

190.5

Suction line

3/4"

Organ pipe

tting

Schrader valve

and cover

55.0

11

78.0

Ø19.5

4X

T

404.4

360.4

230.5

129.5

111.3

70.6

(34°) (31°)

109.7

14°±2°

45°±2°

129.5

(60°)

Terminal box (quick connect spade terminals)

109.7

Suction line

(17°)

discharge line

(34°)

(31°)

14°±2°

45°±2°

Note: Manifolding drawing is preliminary version

Mounting Grommet

111.3

All dimensions in mm

16 AB225886435375en-001201

Earth grounding

EMC bracket to

terminations of

shielded wire

29.5

Ø11

Ø 41

Recommended torque for

mounting bolts: 11 Nm (±1 Nm)

Page 17

Application Guidelines

Dimensions

Single compressors

Sight glass / Oil level sensor

VZH compressors OSG versions come equipped

with a threaded oil sight glass with 1"1/8 – 18

UNEF connection. It can be used for a visual

check of oil amount and condition.

Schrader

The oil fill connection and gauge port is a 1/4"

male flare connector incorporating a schrader

valve.

Suction & discharge connections

VZH compressors are all delivered with suction

and discharge brazed connections only. They are

copper-plated steel connections.

Rotolock adaptors are available, refer to the

“Accessories” section.

Compressor models Brazed connection size

VZH028-044

Suction 3/4" 1-1/4" 3/4"

Discharge 1/2" 1" 1/2" 120Z0365

VZH oil level sensor version compressors come

equipped with a screw-in optical part on oil level

switch port located below the electrical box.

Suction Discharge

VZH028-035-044 3/4" 1/2"

Rotolock adaptor set

(adaptor, gasket, sleeve, nut)

Rotolock Solder sleeve ODF Code Number Code Number

120Z0126

Rotolock adaptor

( adaptor only)

120Z0366

Frequency converter dimensions

Drive supply voltage

T2: 200-240/3/50-60

T4: 380-480/3/50-60

T6: 525-600/3/50 -60

Frequency converter dimensions depend

on supply voltage, IP rating and power. The

table below gives an overview of the overall

Min 100

Clearance above for cooling

L

dimensions and different drive enclosures

(H3, H4, H5, A3 and B3). Details for each drive

enclosure are on the following pages.

H

plate

Min 100

Clearance above for cooling

W

IP20

Drive power

kW

6

7.5 VZH035 H4 29 6x135x241 359x135x241 100/4

10 VZH044 H5 334x150x255 402 x150x255 100/4

6

7.5 VZH035 H3 255x100x206 329x100x206 100/4

10 VZH044 H4 296x135x241 359x135x241 100/4

7.5 VZH028 A3 268x13 0x2 05 374x130x205 100/4

11 H VZH035 B3 399x165x249 420x165x249 100/4

11 VZH044 B3 399x165x249 420x165x249 100/4

Compressor

voltage code

J

G

Compressor

model

VZH028 H4 29 6x135x241 359x135x241 100/4

VZH028 H3 255x100x206 329x100x206 100/4

Drive enclosure

Overall drive size

(H x W x L) mm

Overall drive size

(H x W x L) mm

incl. decoupling

Clearance above/

below

(mm/inch)

17AB225886435375en-001201

Page 18

Application Guidelines

CDS803 frequency converter

Dimensions

Single compressors

B

b

D

C

a

A

a

e

f

99 99

Decoupling Plate

e

Decoupling Plate Illustration

Enclosure Height (mm) Width (mm) Depth (mm) Mounting hole (mm) Max. Weight

Frame IP Class A A

1)

a B b C d e f kg

H3 IP20 255 329 240 10 0 74 206 11 5.5 8.1 4.5

H4 IP20 296 359 275 135 105 241 12.6 7 8.4 7.9

H5 IP20 334 402 314 150 12 0 255 12.6 7 8.5 9.5

1)

A

Including decoupling plate.

The dimensions are only for the physical units, but when installing in an application it is necessary to add space for free air passage both above and below the units. The amount

of space for free air passage is listed in “frequency converter dimensions - Clearance above/below (mm/inch)”.

CDS303 frequency converter

Enclosure Height (mm) Width (mm) Depth (mm) Mounting hole (mm) Max. Weight

Frame IP Class A A

1)

a B b C d e f kg

A3 IP20 268 374 257 130 110 205 11 5.5 9 6.6

B3 IP20 399 420 380 165 140 249 12 6.8 7.9 12

1)

A

Including decoupling plate.

The dimensions are only for the physical units, but when installing in an application it is necessary to add space for free air passage both above and below the units. The amount

of space for free air passage is listed in “frequency converter dimensions - Clearance above/below (mm/inch)”.

18 AB225886435375en-001201

Page 19

Application Guidelines

Electrical data, connections and wiring

Single compressors

Supply voltage

Compressor electrical

specifications

RLA (Rated Load Amp)

MOC (Max Operating

Current)

Because VZH compressors are powered by a

frequency converter, the mains frequency, 50 or

60 Hz, is no longer an issue. Only the mains

voltage is to be taken into account. With 3 motor

voltage codes, the most common mains voltages

and frequencies are covered. Never connect the

VZH compressor directly to the mains power

supply in the case motor burns out.

Compressor rated

voltage (V)

414 V max.

210 V max.

RW: Winding resistance per winding, measured at motor terminals

RLA: Rated load Amp

Model

VZH044CG /VZH044CH

VZH035CG /VZH035CH 12. 4 14.3

VZH028CG /VZH028CH 10.3 11. 8

VZH044CJ

VZH035CJ 26.6 30.6

VZH028CJ 22.0 25.3

RW(Ω) at 20°C line

Rated Load Amp value is the current value at

maximum load, in the operating envelope, and

Max operating current is the maximum

continuous current which is 115% (VZH044-J is

Voltage code Mains voltage range of drive

J

G

H

to line

0.708±7%

0.185±7 %

200-240 V / 3 ph / 50 Hz &

200-240 V / 3 ph / 60 Hz (±10%)

380-480 V / 3 ph / 50 Hz &

380-480 V / 3 ph / 60 Hz (±10%)

525-600 V / 3ph / 50Hz &

525-600 V /3ph / 60Hz (±10%)

RLA (A)

15. 5 17.8

33.3 36

Max Operating

Current (A)

at maximum speed and maximum drive input

voltage.

108%) of RLA. This value is printed on compressor

nameplate.

Wiring connections

VZH scroll compressors will only compress gas

while rotating counter-clockwise (when viewed

from the top of the compressor).

The drawing shows electrical terminal labeling

and should be used as a reference when wiring

the compressor.

U, V & W of the drive and the compressor must be

connected accordingly.

For use of EMC bracket with shielded cable, it is

recommended to have a thread cutting screw

(#10-32) having a torque of 3NM.

Terminal cover mounting The terminal cover and gasket should be installed

prior to operation of the compressor. The terminal

cover has two outside tabs, 180 degrees apart,

Terminal cover removal

push

Earth grounding

EMC bracket to

terminations of

shielded wire

that engage the terminal fence. When installing

the cover, check that it is not pinching the lead

wires.

push

push

19AB225886435375en-001201

Page 20

Application Guidelines

Electrical data, connections and wiring

Single compressors

Fuses

Danfoss recommends using the fuses listed

below to protect service personnel and property

in case of component break-down in the

frequency converter.

For circuit breakers, Moeller types have been

tested and are recommended. Other types of

circuit breakers may be used provided they limit

the energy to a level equal to or lower than the

Moeller types.

UL Compliant fuses Recommended circuit breaker

CDS 803

3x200-240 V IP20

4 TR/VZH028 FRS-R-50 KTN-R50 JKS-50 JJN-50 50 PKZM4-50

5 TR/VZH035 FRS-R-50 KTN-R50 JKS-50 JJN-50 50 PKZM4-50

6.5 TR/VZH044 FRS-R-60 KTN-R60 JKS-60 JJN-60 60 PKZM4-63

3x380-480 V IP20

4 TR/VZH028 FRS-R-25 KTS-R25 JKS-25 JJS -25 25 PK ZM4-25

5 TR/VZH035 FRS-R-25 KTS-R25 JKS-25 JJS -25 25 PK ZM4-25

6.5 TR/VZH044 FRS-R-30 KTS-R30 JKS-30 JJS-30 30 PKZM4-36

CDS 303

525-600V

CDS 303-7.5k W 20A gG KTS-R20 JKS-20 JJS-20 5017906 -020 KLSR020 A6K-20R PKZM4-50

CDS 303-11k W 30A gG KTS-R30 JKS-30 JJS-30 50179 06 -030 KLSR030 A6K-30R PKZM4-50

Bussmann Bussmann Bussmann Bussmann Max fuse

Type RK5 Type RK1 Type J Type T Typ e G Moeller type

EN 50178

Compliant fuses

Size Ty pe Type RK1 Type J Typ e T Type RK1 Type RK1 Type RK1 Moeller type

UL Non UL IP20

UL Compliant fuses

Bussmann SIBA Little fuse

Recommended

circuit breaker

20 AB225886435375en-001201

Page 21

Application Guidelines

Electrical data, connections and wiring

Single compressors

Wire sizes Below table lists recommended wiring sizes for the motor compressor power supply cables. These

wiring sizes are valid for a cable length up to 20m.

From network to frequency converter From frequency converter to compressor

Typ e mm² AWG Typ e mm² AWG

CDS803-6kW(IP20) 6 10 V ZH028 -J 6 10

200 - 240 V

380 - 400 V

525 - 600 V

Note: 1.The wire size here is the guideline but not the actual cable required. The required cable size should be specified by the OEM

depending on the unit design, ambient temperature, the wire material, current, etc.

CDS803-7.5kW(IP20) 6 10 VZH035-J 6 10

CDS803-10kW(IP20) 6 10 V ZH04 4-J 6 10

CDS803-6kW(IP20) 4 10 VZH028-G 4 10

CDS803-7.5kW(IP20) 4 10 VZH035-G 4 10

CDS803-10kW(IP20) 4 10 VZH044-G 4 10

CDS303-7.5kW(IP20) 4 10 VZH028-H 6 10

CDS303-11kW(IP20) 4 10 VZH035-H 6 10

CDS303-11kW(IP20) 4 10 VZH044-H 6 10

Wiring & EMC protection The motor compressor power supply from

the CDS803/303 frequency converter to the

VZH compressor must be done with a braided

screened/shielded cable. This cable needs to

have its screen/shielding conduit connected to

earth on both ends. Avoid terminating this cable

connection with twisting ends (pigtails) because

that would result in an antenna phenomenon

and decrease the effectiveness of the cable.

Control cables to the CDS803/303 frequency

converter must use the same installation

principles as the motor power supply cable.

The motor compressor cable must be installed in

a conduit separated from the control and mains

cables.

Physical installation of the frequency converter

on the mounting plate must ensure good

electrical contact between the mounting plate

and the metal chassis of the converter. Use starwashers and galvanically conductive installation

plates to secure good electrical connections.

Refer to instructions MG18N202/MG34M402 for

tightening torques and screw sizes.

Note that the CDS803/303 must be mounted on

a plain wall to ensure a good air flow through its

heat exchanger.

21AB225886435375en-001201

Page 22

Application Guidelines

Electrical data, connections and wiring

EMC correct installation of an IP20 frequency drive CDS803

EMC qualification reports are available upon request to Danfoss technical support.

Single compressors

Wiring diagram of CDS803

3 Phase

power

input

PLC etc.

PLC

Mains-supply

L1

L2

L3

PE

Reinforced protective earth

L1

L2

L3

PE

Min. 16 mm

Equalizing cable

Control cables

2

Min. 200 mm

between control

cable, mains cable

and between mains

motor cable

Panel

Com.

On

Warn.

Alarm

StatusQuick

Main

Menu

Menu

Menu

k

c

a

B

OK

Auto

Hand

Reset

On

On

Output

contactor etc.

Earthing rail

Cable insulation stripped

All cable entries in

one side of panel

Motor cable

Motor, 3 phases and

Protective earth

U

V

W

PE

Motor

22 AB225886435375en-001201

+10 V DC

0-10 V DC0/4-20 mA

0-10 V DC0/4-20 mA

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN/OUT)

42 0/4-20 mA A OUT / DIG OUT

45 0/4-20 mA A OUT / DIG OUT

12 (+24 V OUT)

18 (DIGI IN)

19 (DIGI IN)

20 (COM D IN)

27 (DIGI IN)

29 (DIGI IN)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

Bus ter.

1 2

Bus ter.

RS-485

Interface

ON

ON=Terminated

OFF=Unterminated

(Com RS-485 ) 61

UDC-

UDC+

relay2

relay1

(N RS-485) 69

(P RS-485) 68

Not present on all power sizes

06

240 V AC 3 A

05

04

03

240 V AC 3 A

02

01

RS-485

Do not connect shield to 61

(PNP)-Source

(NPN)-Sink

Page 23

RELAY

2

CDS803

Application Guidelines

Electrical data, connections and wiring

Wiring connections of CDS803

L1 91 L1 U 96 T1/U

L2 92 L2 V 97 T2/V

L3 93 L3 W 98 T3/W

95 PE PE 99

45 0/4-20 mA A OUT / DIG OUT

42 0/4-20 mA A OUT / DIG OUT

50 +10 V OUT NC

53 A IN NO 02

54 A IN COM 01

55 COM A IN/OUT

12 +24 V OUT CO M 04

18 DIGI IN

19 DIGI IN

27 DIGI IN

29 DIGI IN

20 COM D IN

N RS-485 69

P RS-485 68

Com RS-485 61

1

03

RELAY

NC 06

NO 05

Single compressors

Legends:

A: Analog

DIGI: Digital

IN: Input

OUT: Output

COM: Common

NC: Normally-closed

NO: Normally-open

Open loop Process loop

91,92,93 3 phases mains input x x

95 Earth x x

42,45

0/4-20 mA Analague Output or Digital

Output

- -

50 +10V DC Output - 53 0-10V or 4-20mA Analague Input x 54 0-10V or 4-20mA Analague Input - x

55 Com Analague In/Out x 12 +24V output - 18 External On/Off(NO) x x

19 Digital Input - 27 Safety Device e.g.: HP/LP switch x x

29 Digital Input - 20 Com Digital Input - 98 To Compressor T3 x x

97 To Compressor T2 x x

96 To Compressor T1 x x

99 Earth x x

03,02,01 Relay 1 - -

06,05,04 Relay 2 - -

69,68 RS485 Bus - -

61 RS485 Bus Com - -

-: Optional connection

X: Mandatory connection

The CDS803 frequency converter is factory

preset with parameters for the open loop control

principle. The process loop control principle can

be selected by changing parameters in the “Quick

menu.”

Open loop: preset on input 53

0 - 10 V control

Frequency converter in slave mode

Process loop: preset on input 54

4 - 20 mA control

Frequency converter under own PID controller

23AB225886435375en-001201

Page 24

Application Guidelines

Electrical data, connections and wiring

EMC correct installation of an IP20 frequency drive CDS303

EMC qualification reports are available upon request to Danfoss technical support.

PLC etc. Panel

PLC

Min. 0.025 in ²

(16 mm²)

Equalizing cable

Control cables

Single compressors

Grounding rail

Cable insulation

stripped

All cable entries in

one side of panel

Wiring diagram of CDS303

Mains supply

L1

L2

L3

PE

Reinforced protective ground

3 Phase

power

input

DC bus

+10Vdc

-10Vdc +10Vdc

0/4-20 mA

-10Vdc +10Vdc

0/4-20 mA

91 (L1)

92 (L2)

93 (L3)

95

PE

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

12 (+24V OUT)

13 (+24V OUT)

18 (D IN)

19 (D IN)

20

(COM D IN)

27

(D IN/OUT)

*

29

(D IN/OUT)

32 (D IN)

33 (D IN)

*

37 (D IN)

Min. 7.9 in

(200 mm)

between control

cables, motor cable

and mains cable

S201

1 2

ON

ON/I=0-20mA

S202

OFF/U=0-10V

ON

21

24V

0V

24V

0V

Switch Mode

Power Supply

10Vdc

15mA 130/200mA

+ - + -

P 5-00

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

24Vdc

S801

21

RS-485

Interface

ON

5V

Motor cable

Motor, 3 phases and

protective ground

(W) 98

(PE) 99

(R+) 82

(R-) 81

relay1

relay2

*

(COM A OUT) 39

(A OUT) 42

ON=Terminated

OFF=Open

S801

(P RS-485) 68

(N RS-485) 69

(COM RS-485) 61

(U) 96

(V) 97

03

02

01

06

05

04

0V

Brake

resistor

240Vac, 2A

240Vac, 2A

400Vac, 2A

Analog Output

0/4-20 mA

(PNP) = Source

(NPN) = Sink

130BA025.17

RS-485

24 AB225886435375en-001201

Page 25

RELAY

2

CDS303

Application Guidelines

Electrical data, connections and wiring

Wiring connections of CDS303

L1 91 L1 U 96 T1/U

L2 92 L2 V 97 T2/V

L3 93 L3 W 98 T3/W

95 PE PE 99

39 Ana out COM

42 Ana out +

50 Ana out +10 V NC

53 Ana in 0 ± 10 V NO 02

54 Ana in 0 ± 10 V COM 01

55 Ana in COM

12 +24V COM 04

13 +24V

18 Dig in

19 Dig in

27 Dig in/out

29 Dig in/out

32 Dig in N- RS485 69

33 Dig in P+ RS485 68

20 Dig in COM COM RS485 61

37 Dig in

1

RELAY

NC 06

NO 05

230V or 24V

~

2 A max

Single compressors

Legends:

Ana: Analogue

Dig: Digital

in: Input

out: Output

COM: Common

NC: Normally-closed

NO: Normally-open

Open loop Process loop