Data sheet

VZ valve - 2/3/4-way

Description

VZ 2 VZ 3 VZ 4

VZ valves provide a high quality, cost effective

solution for the control of hot and/or chilled

water for fan coil units, small reheaters, and

recoolers in temperature control systems.

The valves are used in combination with

AMV(E) 130/140, AMV(E) 130H/140H and

AMV(E) 13 SU actuators.

Ordering VZ 2 Valve

Picture

()* recommended ∆p

Main data:

• DN 15, 20

• kVS 0.25 - 4.0 m3/h

• PN 16

• Logarithmic flow characteristic

• Temperature:

- Circ. water / glycolic water up to 50%:

2 … 120 °C

• Reduced kVS on B port (VZ3 & VZ4 only)

• Linear bypass on 3 and 4 port valves

• Valves are supplied with screwed plastic

cover for manual operation

• Connections: flat end or conex

DN k

(mm) (m3/h) (bar) Flat End

15

20

VS

0.25

0.4 06 5Z 5311

0.63 06 5Z5312

1.0 0 65Z5 313

1.6 0 65Z5 314

2.5 065Z5315

2.5

4.0 065Z5321

Max. ∆p

3.5 (1)*

2.5 (1)*

Code No.

065 Z5310

065Z5320

VZ 3 Valve

Picture

()* recommended ∆p

DN

(mm)

15

20

kVS (A-AB) kVS (B-AB)

m3/h

0.25 0.25

0.4 0.25 06 5Z 5411

0.63 0.4 06 5Z5412

1.0 0.63 06 5Z5413

1.6 1.0 0 65Z5 414

2.5 1.6 0 65Z5415

2.5 1.6

4.0 2.5 065Z5421

Max. ∆p

(bar)

3.5 (1)*

2.5 (1)*

Code No.

Flat End

065Z5410

065Z5420

© Danfoss | 2018.08 VD.HB.I7.02 | 1

Data sheet VZ valve - 2/3/4-way

2

vs

valve

k

Q

S∆p

=

Ordering (continuous)

VZ 4 Valve

kVS (A-AB) k

Picture

()* recommended ∆p

DN

(mm)

15

20

0.25 0.25

0.4 0.25 065Z5511

0.63 0.4 065Z5512

1.0 0.63 065Z5513

1.6 1.0 065Z 5514

2.5 1.6 065Z 5515

2.5 1.6

4.0 2.5 065Z5521

NOTE:

kVS - is the flow in m3/h of water at a temp erature between 5 °C

and 40 °C whic h passes through a valve open at th e nominal

stroke with 100 kPa (1 bar) pressure d rop.

Max. Δp is the p hysical limit of differe ntial pressure the valve will

close against . The recommended Δp - values i n parentheses ()

is based on the ge neration of noise, plug ero sion etc. It should

be checked ag ainst the Δp figure calcul ated from the chart on

page 4 or the eq uation below, with the valve full y opened at the

designed f low rate.

m3/h

(B - AB)

VS

Max. ∆p

(bar)

3.5 (1)*

2.5 (1)*

S = specific g ravity

Q = flow rate in m3/h

Δp

valve

(fully open).

Conversion factors

1 bar = 100 kPa = 14.5 psi

1 l/s = 1 kg/s = 3.6 m3/h

Code No.

Flat End

065Z5510

065Z5520

= pressure drop across val ve in bar

Accessories

Connection Pipe size DN Description Code No.

Tailpieces with

external thread

R /” 15

R ½” 20 003H6902

Consist of 2 union nuts,

2 tailpieces and 2 gaskets (Ms 58)

065Z7015

Technical data

Connection Pipe size DN Description Code No.

Tailpieces for

soldering

Control characteristic Logarithmic

Control range min. 50:1

Leakage loss, closed valve

Medium Circulation water / Glycolic water up to 50 %

Medium temperature °C 2 … 120

Max. operating pressure bar 1

Stroke mm 5.5

Connection External thread (flat connection (MS 58) or conex))

Materials

Body, seat and cone Dezincing free brass CuZn36Pb2As

Stem Stainless steel

Stuffing box EPDM

12 m m 15

15 mm 20 06 5Z7017

Consist of 2 union nuts, 2 solder bushes

and 2 gaskets (Ms 58)

A - AB ≤ 0.05 % of kVS

B - AB ≤ 1 % of kVS

065 Z7016

2 | VD.HB.I7.02 © Danfoss | 2018.08

Data sheet VZ valve - 2/3/4-way

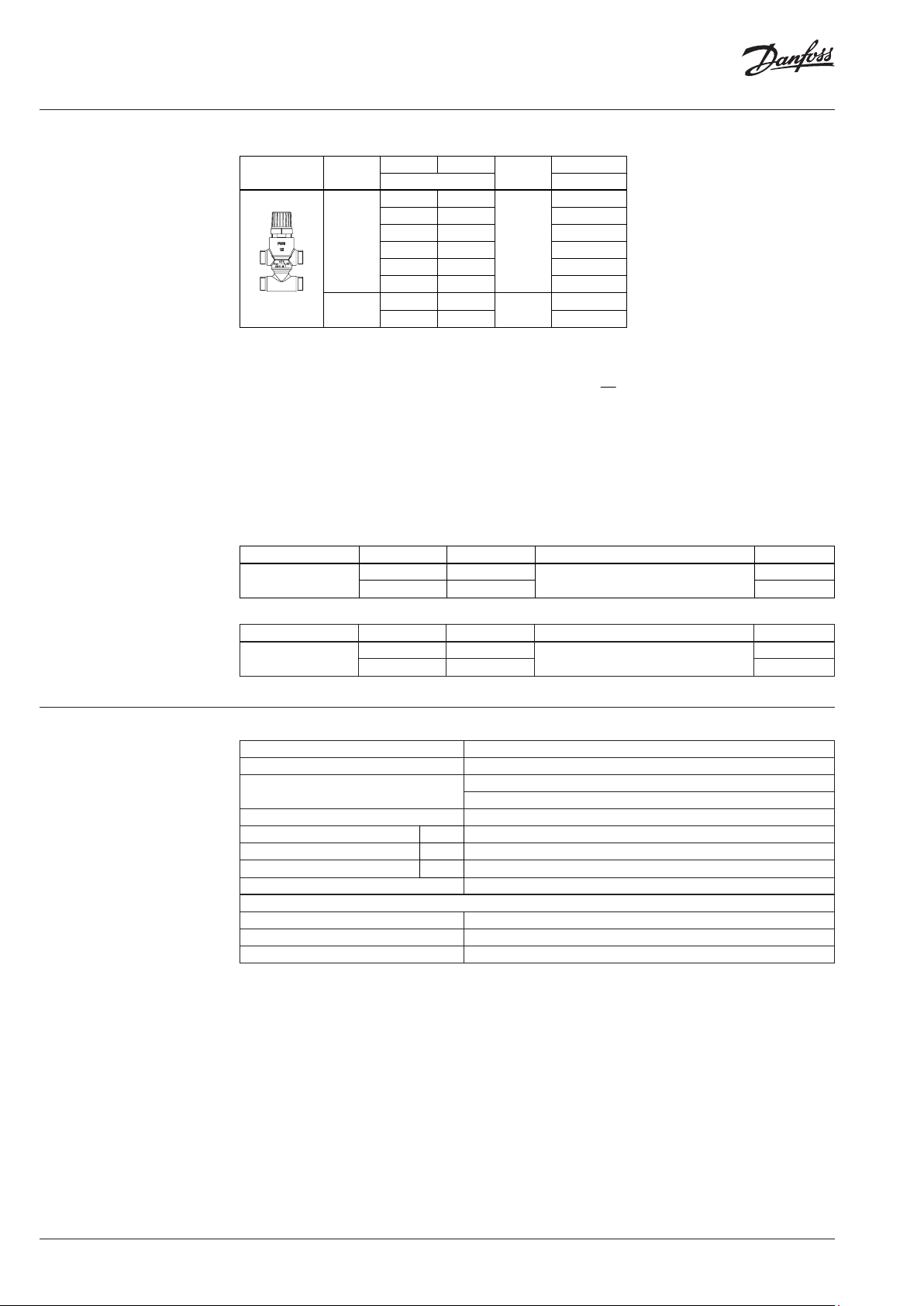

Pressure temperature

diagram

PN 16

Disposal

The valve must be dismantled and the elements

sorted into various material groups before

disposal.

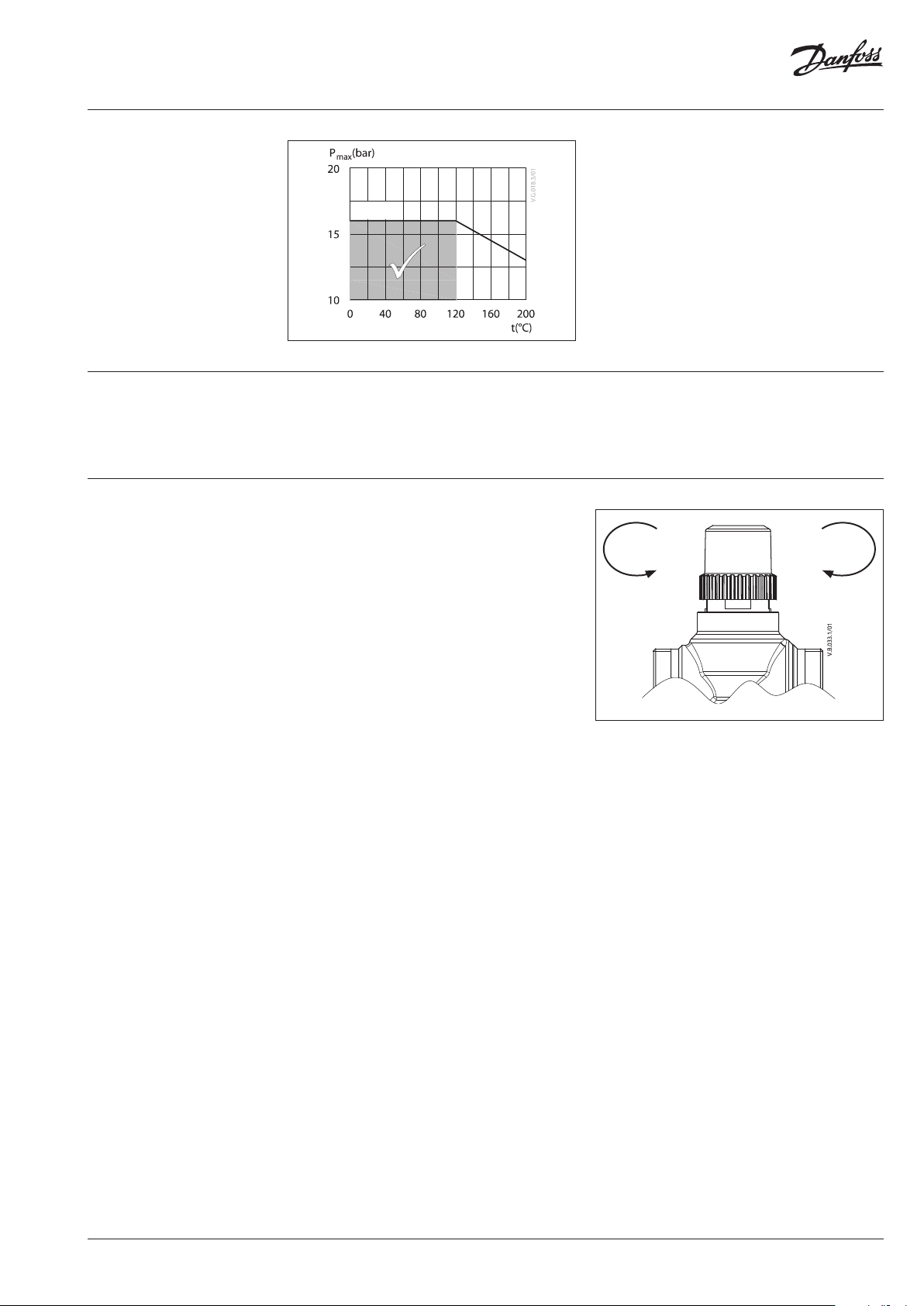

Manual operation Valves are supplied with screwed plastic cover

for manual operation.

Note: The flow is reduced on 75 % in case of

using plastic cover.

Closing

A-AB

Opening

A-AB

VD.HB.I7.02 | 3© Danfoss | 2018.08

Data sheet VZ valve - 2/3/4-way

Installation Hydraulic connections

Mount according to flow direction as indicated

on the valve body. AB is always the outlet port;

inlets are A (two port) or A and B (three or four

port).

Valve mounting

Before mounting the valve be sure that the pipes

are clean and free from swarf. It is essential that

the pipes are lined up squarely with the valve at

each connection and are free from vibrations.

The valve should be adequately supported to

prevent stress being applied to the connections

during operation. A maximum tightening

torque of 25 to 30 Nm should be applied to the

connections.

Install the valve so that the actuator will be

mounted in a vertical or horizontal position but

not upside down.

Leave sufficient clearance to allow the

dismantling of the actuator from the valve body

for maintenance purposes.

The valve must not be installed in an explosive

atmosphere or at an ambient temperature

higher than 50 °C or lower than 2 °C. It must not

be subjected to steam jets, water jets or dripping

liquid.

The valve is supplied complete with installation

instructions. The water quality should meet

VDI 2035 requirements.

AMV(E) 130/140, AMV(E) 130H/140H + VZ

AMV(E) 13 SU + VZ

Note that the actuator may be rotated up to

360° with respect to the valve body, by

loosening the retaining fixture. After this

operation retighten.

Ensure that the direction of flow is correct as

shown in typical application examples

(fig.1 and 2). The three way valve must be

installed as a mixing valve. If possible the valves

should be positioned in the return side.

Note:

Install a strainer upstream of the valve

(e.g. Danfoss FVR/FVF)

Fig. 1 Mixing valve used in mixing application

Fig. 2 Mixing valve used in diverting application

AMV(E)

FVR/FVF

4 | VD.HB.I7.02 © Danfoss | 2018.08

Data sheet VZ valve - 2/3/4-way

21

1

ΔPΔP

ΔP

N authority, Valve

56,0

0252

25

authority valve hence

31,0

029

9

authority valve hence

Sizing Example

Flow rate: 0.3 m3/h

System pressure drop: 20 kPa

Locate the horizontal line representing a flow

rate of 0.3 m3/h (line A). The valve authority is

given by the equation:

Where:

Δ P1 = pressure drop across the fully open valve,

Δ P2 = pressure drop across the rest of the circuit

with a fully open valve

The ideal valve would give a pressure drop equal

to the system pressure drop (i.e. an authority of

0.5):

If P1 = P

N = P1/2P1 = 0.5

In this example an authority of 0.5 would be

given by a valve having a pressure drop of 20 kPa

at that flow rate (point B).

The intersection of line A with a vertical line

drawn from B lies between two diagonal lines;

this means that no ideally-sized valve is available.

The intersection of line A with the diagonal lines

gives the pressure drops stated by real, rather

than ideal, valves. In this case, a valve with kVS 0.6

would give a pressure drop of 25 kPa (point C):

The second-largest valve, with kVS 1, would give a

pressure drop of 9 kPa (point D):

Generally, for a 3 port application, the smaller

valve would be selected (resulting in a valve

authority higher than 0.5, and therefore

improved controllability). However, this will

increase the total pressure and should be

2

checked by the system designer for compatibility

with available pump head, etc. The ideal

authority is 0.5 with a preferred range of

between 0.4 and 0.7.

Design

to close

A

2 Port

AB

to close A- AB

A AB

B

3 Port

to close A- AB

A AB

B B

4 Port

VD.HB.I7.02 | 5© Danfoss | 2018.08

Data sheet VZ valve - 2/3/4-way

Dimensions

92

92

92

H

h

L

d

H

d

h

L

H

d

h

L

AMV(E) 130/140 + VZ 4AMV(E) 130/140 + VZ 3AMV(E) 130/140 + VZ 2

92

1

H

1

h

d

c

L

AMV(E) 130H/140H + VZ .

2

H

AMV(E) 13 SU + VZ .

121

d

L

Valve t ype d

L H H

1

VZ 2 / DN 15 G ½” 65

VZ 2 / DN 20 G ¾” 77 0.49

VZ 3 / DN 15 G ½” 65

VZ 3 / DN 20 G ¾” 77 0.50

119 12 5 155

VZ 4 / DN 15 G ½” 65

VZ 4 / DN 20 G ¾” 77 50 0.62

Tailpieces for soldering

Ød L

G

½” 12 15 0.11

¾” 15 20 0.17

mm

Weight

(kg)

G

Ød

L

H

h h

2

1

mm

26.5

52.5

35

65

Tailpieces with external thread

R L Weig ht

G

(“) (mm) (kg)

½” ⁄ 23 0. 11

¾” ½ 26 0.17

c

Valve weight

-

40 0.51

G

(kg)

0.38

0.39

R

L

6 | VD.HB.I7.02 © Danfoss | 2018.08

Data sheet VZ valve - 2/3/4-way

VD.HB.I7.02 | 7© Danfoss | 2018.08

Data sheet VZ valve - 2/3/4-way

© Danfoss | DHS-SRMT/SI | 2018.088 | VD.HB.I7.02

Loading...

Loading...