Fact sheet

VX Solo 22

District heating substation for small properties and apartment houses

FEATURES AND BENEFITS

• Indirect heating

• Connection pipes for DHW cylinder

• Supplied with Danfoss ECL 310, prepared

for WebAccess

• Equipped with A-labelled low-energy

pump

• Pipes and heat exchanger in stainless steel

• Minimized risk of lime scale and bacteria

formation

• The substation is very service-friendly due

to practical piping and assembly with nuts

and gaskets

Application

The VX Solo 22 is made in a compact design

and is especially suitable for supply of heating for small properties and apartment houses. The substation is suitable for two pipe

systems.

The substation features a plate heat exchanger for the heating circuit and it is prepared

for connection to a domestic hot water cylinder.

The VX Solo 22 is available in two basic variants, - one variant with Danfoss ECL 310 for

control of the heating circuit, and another

variant with Danfoss ECL 310 for control of

both the heating as well as the DHW cylinder

circuits.

The VX Solo 22 variants offer capacities ranging from 44 to 110 kW heating and 13 to 75

kW domestic hot water. Please contact our

sales department and together we shall find

the optimum solution for your exact requirements.

Construction

The VX Solo 22 is supplied with a brazed

plate heat exchanger for heating, electronic

actuator(s) and valve(s), safety valves, pump,

shut-off valves, mano- and thermometers,

strainers, sensor pockets, differential pressure controller as well as connections pipes

for DHW cylinder.

Actuators and pumps are electrically wired from factory and supplied

with CEE plug for connection to 220 V.

The electronic control is prepared for WebAccess, which enables remote control and

remote monitoring via the internet/intranet.

The substations are delivered preassembled,

electrically wired internally and the electronic control is tested for function and preset

from factory. The substation is supplied

without fitting piece for heat meter. Fitting

piece for heat meter is available as an option.

Design

The VX Solo 22 is designed for wall-mounting and during the construction much importance has been attached to a clear and

user-friendly placement of all components.

The VX Solo 22 can be supplied with a white-lacquered steel cover with door, which

enables easy access for meter reading and

service purposes.

Connection pipes for domestic hot water

cylinder (DHW)

As standard the VX Solo 22 is supplied with

primary connection pipes for DHW cylinder,

with or without actuator and electronic control of the cylinder circuit.

• Excellent operating economy

Heat exchanger for DHW heating

The heat exchanger used in the VX Solo

22 is a brazed, highly efficient Danfoss plate heat

exchanger, which has been tested and approved according to the PED-directive.

Reading and setting

All thermometers are placed so they are easy to

read. Components, which can be adjusted, are

easily accessible.

Service og maintenance

The substation is very service-friendly due to

practical piping and assembly with nuts and

gaskets. It is mounted on the wall and as all

pipes are placed in pipe bracket distance, it is

possible to establish a nice piping.

www.danfoss.com

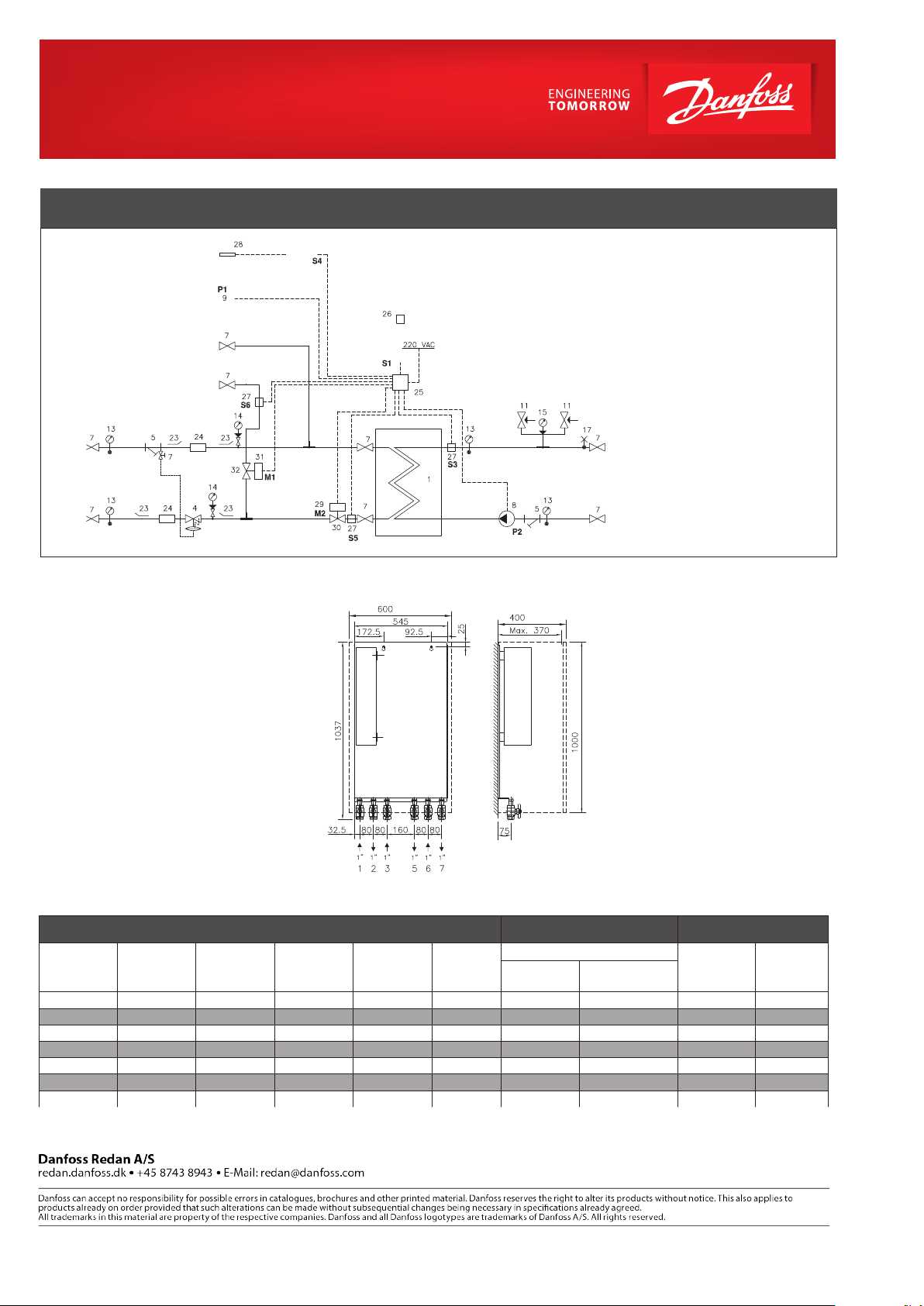

CIRCUIT DIAGRAM EXAMPLE

P, M and S

refer to the

Danfoss ECL

instruction

manual

Cylinder

Supply

Cylinder

Return

DH

Supply

DH

Return

Design specifications:

Nominal pressure (prim/sec): PN 10 / PN 10

Max. supply temperature.: 120 °C

Min. ΔP: 0,75 bar incl. differential

pressure controller

(alternatively 0,5 bar)

Weight: Max. 65 kg

Colour (cover): White RAL 9010

Electrical supply: 220 V AC

Dimensions (mm):

Without cover: H 1037 x W 545 x D 370

With cover: H 1037 x W 600 x D 400

1 Plate heat exchanger HE

4 Differential pressure controller

5 Strainer

6 Non-return valve

7 Ball valve

8 Pump HE

9 Connection for pump (circ.)

11 Safety valve, HE

13 Thermometer

14 Manometer w/shut-off valve

HE

Supply

HE

Return

Connections:

1. DCW inlet 5. DH return

2. DHW 6. HE supply

3. DCW outlet 7. HE return

4. DH supply

Options:

• White cover

• Ball valves

• Mounting of heat meter

• Pipe set with 7 pipes

• Pipe set with 4 pipes

• Circulation set

• Electrical control box

• Room thermostat TP 7000

• Insulation of pipes

• W/o cold water pipe

15 Manometer

17 Air valve

19 Drain valve/connection for

expansion vessel

23 Sensor pocket for heat meter

(optional)

24 Fitting piece for heat meter

(optional)

25 Controller Danfoss ECL310/A266

26 Outdoor sensor

27 Sensor forward/return

28 Sensor, DHW

29 Actuator 2

30 Valve 2

31 Actuator 1

32 Valve 1

DHW: Capacity examples with electronic control, ECL 310, A230 Connection for cylinder Tot al (winter)

Plate heat

exchanger

XB 37M-1 3 0 44 70/40 35/60 0.45 1257 20 - 0.75 1450

XB 37M-1 4 0 60 70/40 35/60 0.65 17 09 50 - 0.72 2630

XB 37M-1 5 0 75 70/40 35/60 0.40 2129 30 - 0.76 2350

XB 37L-1 40 37 70/46 45/57

XB 37L-1 20 15 70/31 30/35

XB 37M-1 4 0 75 90/45 40/ 74 0.54 14 63 - 30 0.68 1540

XB 37M-1 50 110 90/45 4 0/74 0. 57 2107 - 45 0.73 2250

1) Incl. differential pressure controller, (excl. heat meter), 2) Total flow calculated at 70% of the heating capacity + 100% DHW at 60/40°C and 65/40°C.

3) Example of substation for one-pipe system, 4) Floor heating.

Capacity

kW

HE circuit

Primary

°C

HE circuit

Secondary

°C

3

4

Pressure loss

Primary

1

bar

0.29 1348 30 - 0.67 1800

0.82 324 50 - 0.44 1660

Flow

Primary

l/h

DH supply 60° C

© Danfoss | DHS-SRMT/ PL | 2017 . 12

Yde lse, k W

DH supply

65° C

Pressure loss

Primary

2)

total

bar

Primary

total

VL.HE.L2.02

Flow

2)

l/h

Loading...

Loading...