MAKING MODERN LIVING POSSIBLE

VXi Solo H

Fully insulated district heating substation for single-family, semidetached and terraced houses as well as flats.

Substation for indirect heating with one heating circut. Designed for

wall-mounting with pipes connection in top or bottom. Electronic

temperature controller ECL 310/A230

Application

The VXi Solo H (ECL 310/A230) is a

fully insulated substation featuring

high performance and simple operation. VXi Solo H is especially suitable

for two-pipe systems and systems

with floor heating. The heating circuit

is controlled by electronic temperature controller Danfoss ECL 310/A230.

District heating (DH)

The substation is prefabricated with

interconnecting components such as

fitting piece and sensor pockets for

insertion of a heat meter mounted in

the DH return pipe, as well as strainer,

thermometer and ball valves.

Heating (HE)

The heating side consists of a stainless steel plate heat exchanger, safety valve, expansion vessel, strainer,

thermometers, manometer, circulatiopump and ball valves.

The radiator circuit is controlled by the

primary side flow controller with integrated control valve AHQM together

with the actuator AMV 150, the temperature by means of an electronic

temperature controller (ECL 310/

A230) .

Depending on substation’s application,

different heat exchangers dimensioned for central or floor heating can be

used.

Construction

All pipes are made of stainless steel.

The connections are made by nuts and

gaskets. The substation offers variable

connection possibilities, as connection of pipes can be established both

in the top or in the bottom of the substation.

The white removable center part in

the front insulation allows easy access to components for regulation and

maintenance purposes.

FEATURES AND BENEFITS

• District heating substation for singlefamily houses

• Indirect heating

• Fully insulated for very low heat losses

• Electronic temperature controller ECL

310/A230

• Capacity: 20-30 kW HE, 15 kW FH

• Low-energy circulation pump

• Minimum space required for

installation

• Pipes and plate heat exchanger

made of stainless steel

• Pipes connection in top or bottom of

substation

districtenergy.danfoss.com

VXi Solo H (ECL 310/A230)

550

POS.

Qty.

PART NUMBER

Description

11

003H6735

AVQM DN20 kvs=1.6

21

004B1852

XB06H-1, 26 pl

32

004B6040

Ball valve DN20 N/N

42

004B6093

Ball valve DN20 N/M

51

004B6100

Snavssamler Redan

62

004B6102

Filter f. TEE 3/4"

71

082G3090

AMV 150 230V

81

087H3040

ECL 310

91

087H3230

Sokkel ECL 210/310

10 2

087N0015

ESMC

11 1

144B2149

Tee DN20 3/4"x3/4"x1/2"

12 3

144B2151

Tee DN20 Omlx3/4"x1/2"

13 1

144B2152

Vinkel boret 1/8"

14 4

144B2160

Tee DN20 3x3/4"

15 1

144B2162

Tee DN20 3/4"x Oml. x 1/2"

16 3

144B2172

Prop 3/4" m. O-ring

17 1

144B2192

Passtk. 3/4" x 110

18 2

144B2379

Flatseal Ø24/17x2,75

19 1

144B2384

Sikkerhedsventil Syr 3 bar 1/2" x 3/4"

20 6

144B2408

Prop 3/4" m. insv. 6-kt

21 2

144B2476

Vinkel DN20 3/4" x Oml.

22 1

144B2516

Slutmuffe 3/4" Redan

23 1

145H3037

Vinkelnippel 69F 6x1/8"

24 47

145H3120

Pakning 3/4" m EPDM 282

25 2

145H3121

Pakning 1" 30x21,5x3

26 4

145H3133

Termometer (0 - 120)

27 1

145H3137

Pakning Ø11/5 x 1

28 1

145H3432 Brystnippel 3/4" x 1/2"

29 4

145H3443

Fjederbølge Ø15x9 f. termometer

30 1

145H3693

Beslag f. VX-Isol. Instrumentpanel

31 1

145H3695

Beslag VX-Isol. FJV-R

32 1

145H3696

Beslag VX-Isol. FJV-R

33 1

145H3697

Beslag f. VX-Isol Fjv-R

34 1

145H3699

Bagplade VX-Isoleret

35 1

145H3711

Grundfos UPM3 Auto L 15-70 130 EUX9

36 1

145H3739

Vinkel 3/8" M mess.

37 1

145H3740

Brystnippel F68 6x3/8" klemring

38 1

145H3749

Isolering VXi komplet

39 1

145H3753

Cimm 12L

40 1

145H3803

Manometer 0-4 bar m. slæbeviser

41 1 145H3803_1

42 1 145H3803_2

43 1

145H3811

Beslag f. veksler

44 2

145H3812

Beslag f. bundplade isolering

45 1

145H3814

Frontplade nederste

46 1

145H3815

Frontplade Danfoss

47 6

145H3817

Skrue M5x80 Cyl. hoved indv. 6 kt. DIN

912

Danfoss Standard

A3

1:7.5

Material

SizeScale

Projection

E

D

C

B

A

87

6

5

4

3

2

1

kg

Weight

General tolerance accuracy

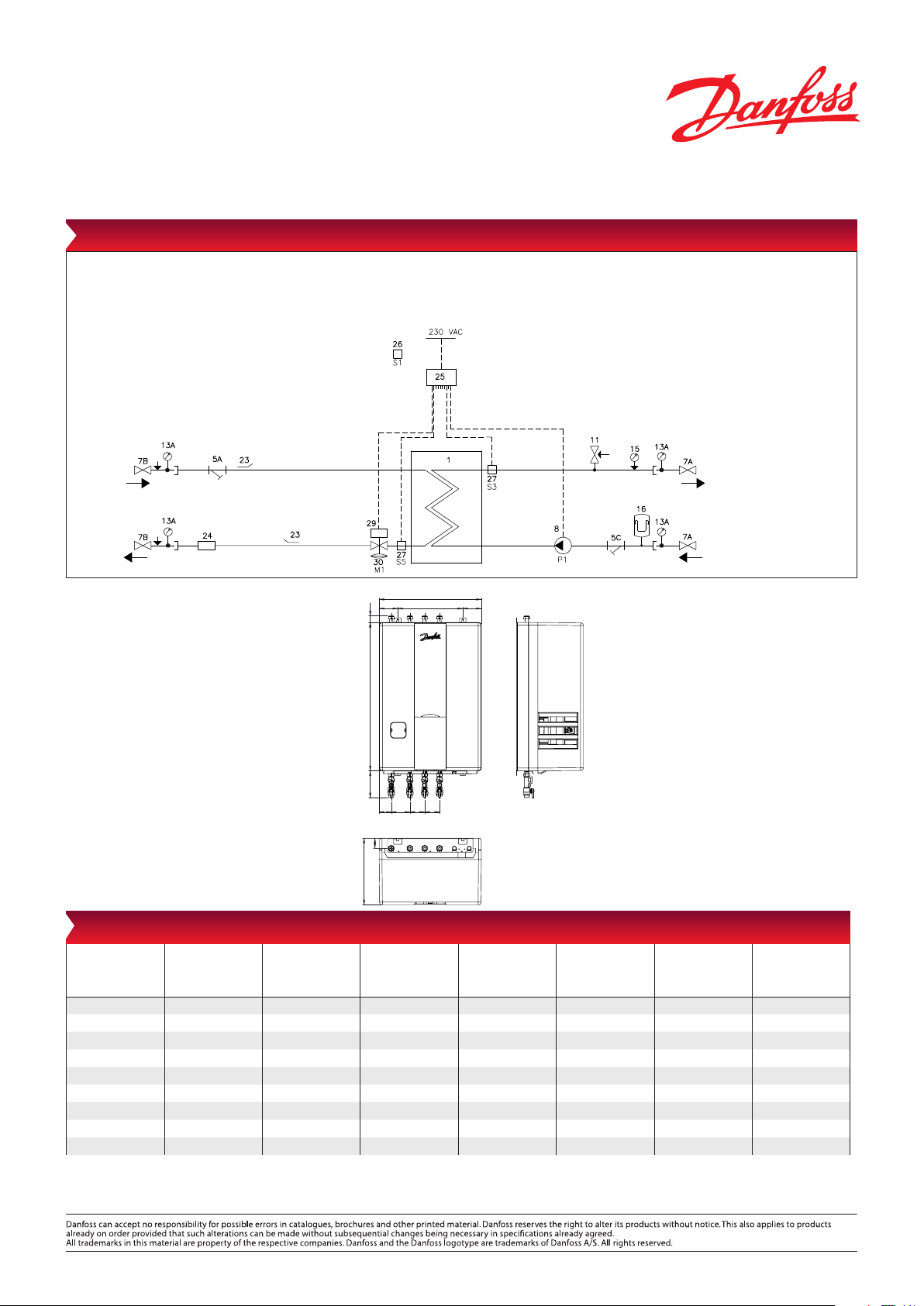

Circuit diagram - example

1 Plate heat exchanger HE, with insulation

5 Strainer

7 Ball valve

8 Circulation pump, HE

11 Safety valve HE, 3 bar ½”

13 Thermometer

15 Manometer

16 Expansion vessel 12 l

23 Sensor pocket for heat meter ½”

DH

Supply

DH

Return

Design specifications:

Nominal pressure (prim/sec.): PN 16 / PN 3

Max. supply temperature: 120 °C (design temp.)

Min. ΔP: See capacity examples

Brazing material (HEX): Copper

Weight incl. cover: 49 kg

(incl. packing)

Dimensions (mm):

With insulation: H 980 × W 550 × D 360

Electrical supply: 230 V AC

Connections sizes:

DH: G ¾“ ET (ext. thread)

HE, DHW cylinder: G ¾“ ET (int. thread)

100 350 100

35 800

145

65 100 80 80

1 234

55

1 2 3 4

360

top view

24 Fitting piece for heat meter 3/4” x 110 mm

25 Controller Danfoss ECL210/A230

26 Outdoor sensor, ESMT

27 Sensor Danfoss, ESMC

29 Danfoss actuator AMV 150

30 Danfoss flow controller with integrated

control valve AHQM

HE

Supply

HE

Return

Connections:

1. District heating (DH) supply

2. District heating (DH) return

3. Heating (HE) return

4. Heating (HE) supply

Options:

• KFE filling and drain valve ¼” (for mounting in ball

valve)

• Safety function - safety thermostat + actuator

• Connection of pipes can be established in the top

or in the bottom of the substation

• Prepared for insertion of heat meter

Wall

Heating: Capacity examples

Heating

capacity

Plate heat

exchanger

HE circuit

primary

[° C]

sedondary

HE circuit

[° C]

Pressure loss

primary*

[kPa]

20 XB06H-1 26 75/44 40/65 35 6.0 555 688

20 XB06H-1 26 80/49 45/70 35 6.0 555 688

20 XB06H-1 26 90/51 50/70 29 8.5 441 860

30 XB06H-1 40 75/44 40/65 55 6.0 842 1032

30 XB06H-1 40 80/49 45/75 55 6.0 832 1032

30 XB06H-1 40 90/51 50/70 40 9.0 662 1290

15 XB06L-1 24 75/32 30/40 22 9.4 300 1290

15 XB06L-1 24 80/32 30/40 21 9.4 269 1290

15 XB06L-1 24 90/32 30/40 20 9.4 222 1290

* Heat meter not incl.

Danfoss Redan A/S · District Heating · Omega 7, Søften · DK-8382 Hinnerup · Denmark

Tel.: +45 87 43 89 43 · Fax: +45 87 43 89 44 · redan@danfoss.com · www.redan.danfoss.dk

VL.JV.U1.02 © Danfoss 01/2017 DKDHR

Pressure loss

(only sec . side of

heat exchanger)

[kPa]

Flow rate

primary

([l/h]

Flow rate

secondary

[l/h]

Loading...

Loading...