Page 1

Fact Sheet

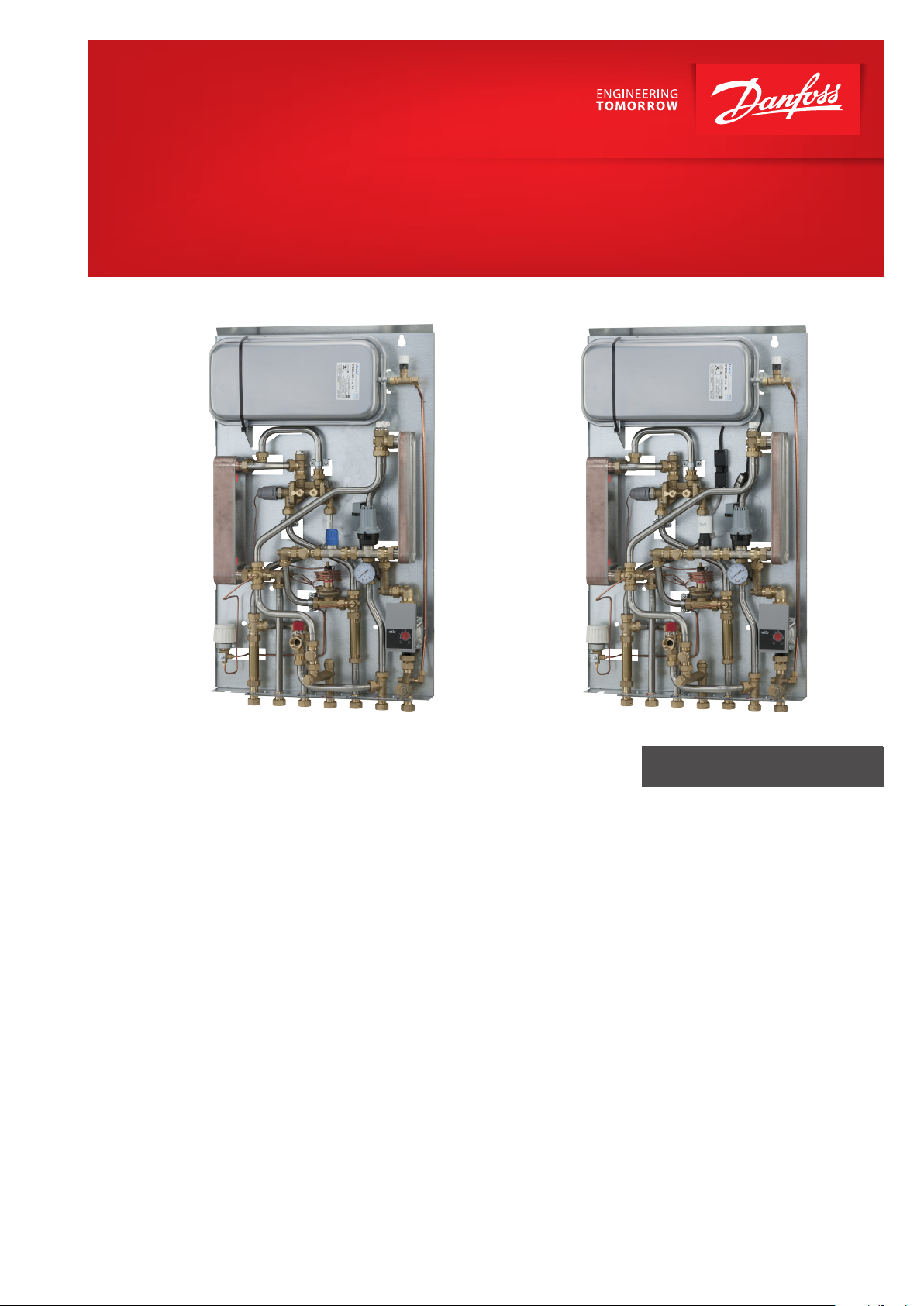

VX-F flat station for indirect heating and DHW

District heating substation for indirect heating and instantaneous domestic hot water. For apartments, single- and multi-family houses

Application

Die VX-F is a compact substation featuring high

performance and simple operation. The VX-F is

especially suitable for two-pipe systems and systems

with radiator or floor heating, supplied from a

secondary connected district heating system, a block

heating system or a centrally located boiler system in a

block of flats.

The VX-F range is available as built-in variant with a

recess box in sizes W 690 x H 1350 x D 150 and W 850 x

H 1350 x D 150 or as wall-mounted variant.

The VX-F stations are prepared for mounting separately

or for implemetation with with a VX-F distribution unit

with 3 to 12 heating circuits.

District heating (DH)

The flat station is prefabricated with interconnecting

components such as differential pressure controller,

strainer, thermal bypass and fitting piece and sensor

pockets for insertion of a heat meter.

Heating (HE)

The heating side consists of plate heat exchanger, safety valve, manometer, expansion vessel and A-labelled

low-energy circulation pump. A flow temperature controller, type FTC is used for flow temperature control

of the heating system. The VX-F stations are equipped

differently depending on the application, - floor heating

or radiator heating. VX-F stations for floor heating are

equipped with a safety thermostat and a zone valve

RA-C / thermal actuator TWA to prevent overheating.

Domestic hot water (DHW

The domestic hot water is prepared in the heat exchanger based on the flow principle and the temperature is regulated by the self-acting controller with in-

tegrated differential pressure controller - the PTC2+P

with energy-saving function. Supreme ease of operation is obtained via the combined hydraulic and

thermostatic regulation of the PTC2+P controller. The

pressure-controlled part allows primary and secondary side flow through the heat exchanger, only when

hot water is tapped and blocks the flow immediately

after completion of the tapping process.

The thermostatic part controls the domestic hot water temperature. Thanks to the quick-acting hydraulic

control of the heat exchanger, it is largely protected

from the formation of lime scale and growth of bacteria.

The PTC2+P controller with integrated differential

pressure controller compensates for variations in supply temperature and varying differential pressure and

thereby ensures a constant domestic hot water temperature at all times. A thermostatic bypass enables

tapping of hot water without any delay, – ensuring the

best possible efficiency and economy. For registration

of the cold water consumption the VX-F is equipped

with a fitting piece for mounting of a cold water meter

in the DCW inlet.

Options

The VX-F is equipped with bypass function as a standard, but it is prepared for DHW circulation. Equipment for DHW circulation is optional and must be

ordered separately.

Design

All pipes are made of stainless steel. The connections

are made by nuts and gaskets. The Akva Lux II can be

delivered with white-lacquered steel cover for recess

mounting or for wall mounting. The VX-F is supplied

without recess box and door as standard. - This is

optional must be ordered separately

.

FEATURES AND BENEFITS

FEATURES AND BENEFITS

• Indirect heating, DHW heating based on

flow principle

• Innovative, energy-saving controller

PTC2 + P in combination with high

performance heat exchanger for ondemand water heating without no-load

losses function

• Thermostatic control of heating (HE)

temperature

• Capacity: 15 kW HE / 37-55 kW DHW

• Minimum space required for installation

• For mounting in recess box or on the wall

• Pipes and heat exchanger made of

stainless steel

• Minimized risk of lime scale and bacteria

formation

www.danfoss.com

Page 2

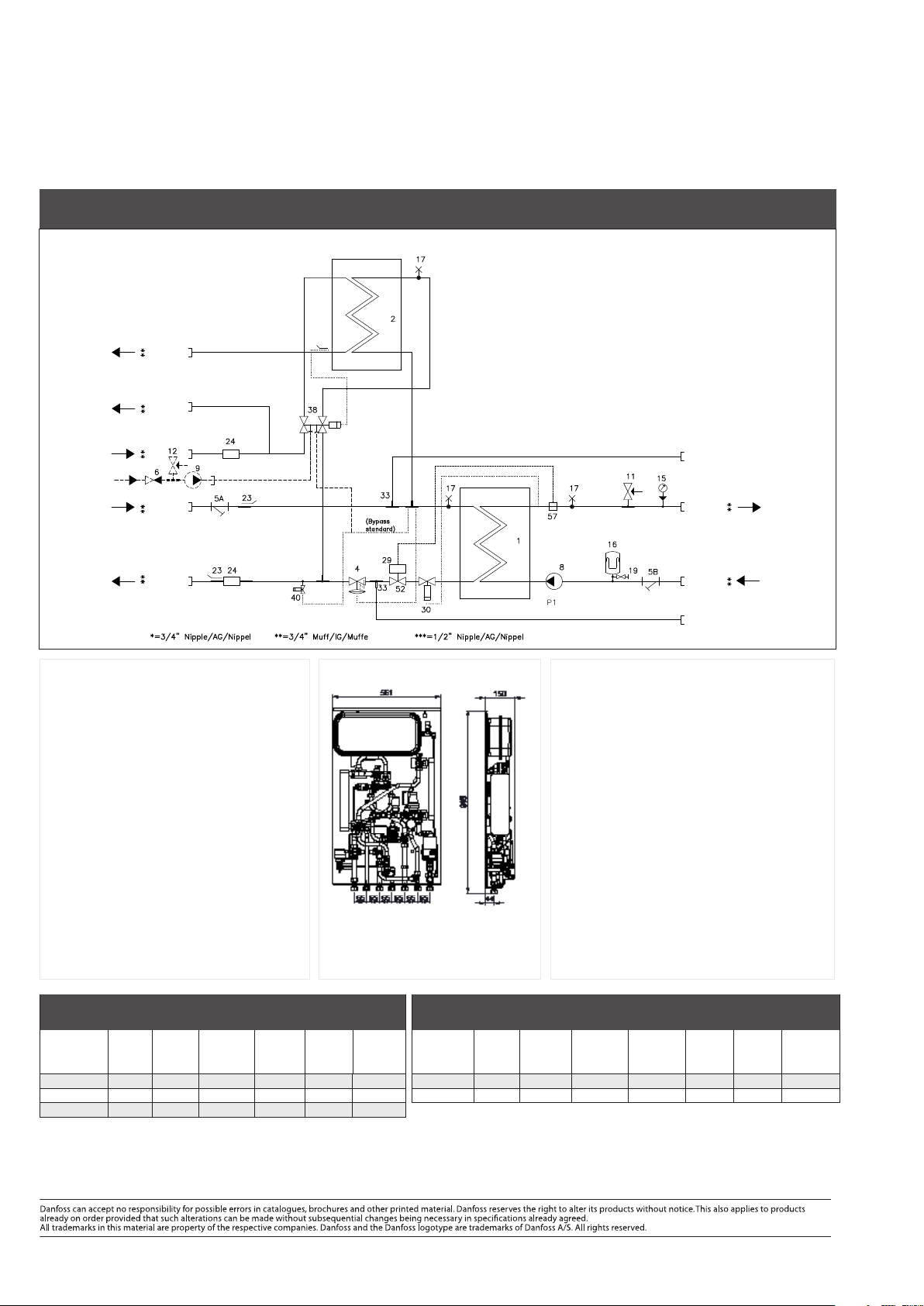

SHALTPLAN - BEISPIEL

CIRCUIT DIAGRAM - EXAMPLE - Variant with floor heating and circulation

DHW

DCW

DCW

DHW circ.

Circulation set 145H3985

DH

Supply

DH

Return

Design specifications:

Nominal pressure (prim/sec.): PN 16

Max. suppy temperature: 100 °C (design temp.)

Min. ΔP: See capacity examples

DCW static pressure: p

Brazing material (HEX): Copper

min

= 2 bar

Weight w/o cover.: Max. 30 kg

(incl. packing)

Dimensions (mm): H 945 × W 561 × D 150

Electrical supply: 230 V AC

Recirculation:

Remember to order circulation set for systems that

feature DHW recirculation.

1 Plate heat ex changer HE

2 Plate heat ex changer DHW

4 Differential pressure controller

5 Strainer

6 Non-ret ur valve

7 Ball valve

8 Circulatio n pump HE 230 V

9 Circulatio n pump DHW

11 Safety va le HE 3 bar ½”

12 Safe ty valve DHW 10 bar ½”

15 Manometer

16 Exp ansion vessel 10 L

17 Air vent

19 Fill / Drain val ve

23 Sensor poc ket for heat meter ½”

24 Fitting pi ece for heat meter 3/4” x 110 mm

Circ.

Dimensional sketch:

Connection sizes:

DH: G ¾“ (ET)

DCW, DHW, HE: G ¾“ (ET)

Circulation: R ½“ (IT)

29 Actu ator TWA

30 Ther mostat FTC/RAC

33 Blin d plate

38 PTC2 con troller

40 Danf oss FJVR for bypass/circulati on

52 Zone val ve RA-C

57 Safe ty thermostat ST55

HE

Supply

Floor heating

Supply

Floor heating

Return

HE

Return

Connections:

1. Domestic cold water (DCW)

2. Domestic hot water (DCW)

3. Domestic hot water (DCW)

4. District heating (DH) Supply

5. District heating (DH) Return

6. Heating (HE) Supply

7. Heating (HE) Return

Accessories and options:

Recess box B690 x H1350 x D150 mm: 145H4044

Door for 145H4044 incl. of mounting rail: 145H4104

Recess box B850 x H1350 x D150 mm: 145H4105

Door for 145H4105 incl. of mounting rail: 145H4106

Circulation set: 145H3985

Mounting feet for recess box (2 pcs.) 145H4232

Mounting rail incl. of ball valves 145H4195

Variants:

145F3900: VX-F Floor heating w/zone valve, ST55

145F3901: VX-F Floor heating w/zone valve, ST55, circ.

145F3902: VX-F radiator heating w/RA-C/FTC

145F3903: VX-F radiator heating w/RA-C/FTC, circ.

DHW: Capacity examples, 10 °C/50 °C

DHW

Typ e

XB 06H+-1 40

XB 06H+-1 40

XB 06H+-1 40

* heat meter not incl.

Capacity

kW

37

45

55

Tem p.

primary

60/18. 22 10/50

60/18.91 10/50

60/19.77 10/50

[°C]

Tem p.

sekundary

[°C]

Pressure

*primary

Flow rate

loss

primary

27 762,5 13,2 6

40 942,9 16,13

59 117 7,1 19.70

[l/h]

Flow rate

secundary

[l/min]

Heating: Capacity examples

Heating

Typ e

Capacity

XB 06H-1 16 10 70/40,35 35/60 38 28 7,4 346,8 5

XB 06H-1 16 10 60/30,75 30/40 62 294,4 865,2 27

* heat meter not incl.

kW

Tem p.

primary

[° C]

Tem p.

sekundary

° C]

Danfoss Redan A/S · District Heating · Omega 7, Søften · DK-8382 Hinnerup · Denmark

Tel.: +45 87 43 89 43 · Fax: +45 87 43 89 44 · redan@danfoss.com · www.redan.danfoss.dk

© Danfoss | Produced by Danfoss Redan | 2016.12

Pressure

loss *prim.

[kPa]

Flow rate

primary

[l/h]

Flow rate

primary

[l/h]

Pressure

loss *sec.

[kPa]

VL.LZ.F1.02

Loading...

Loading...