Page 1

Fact sheet

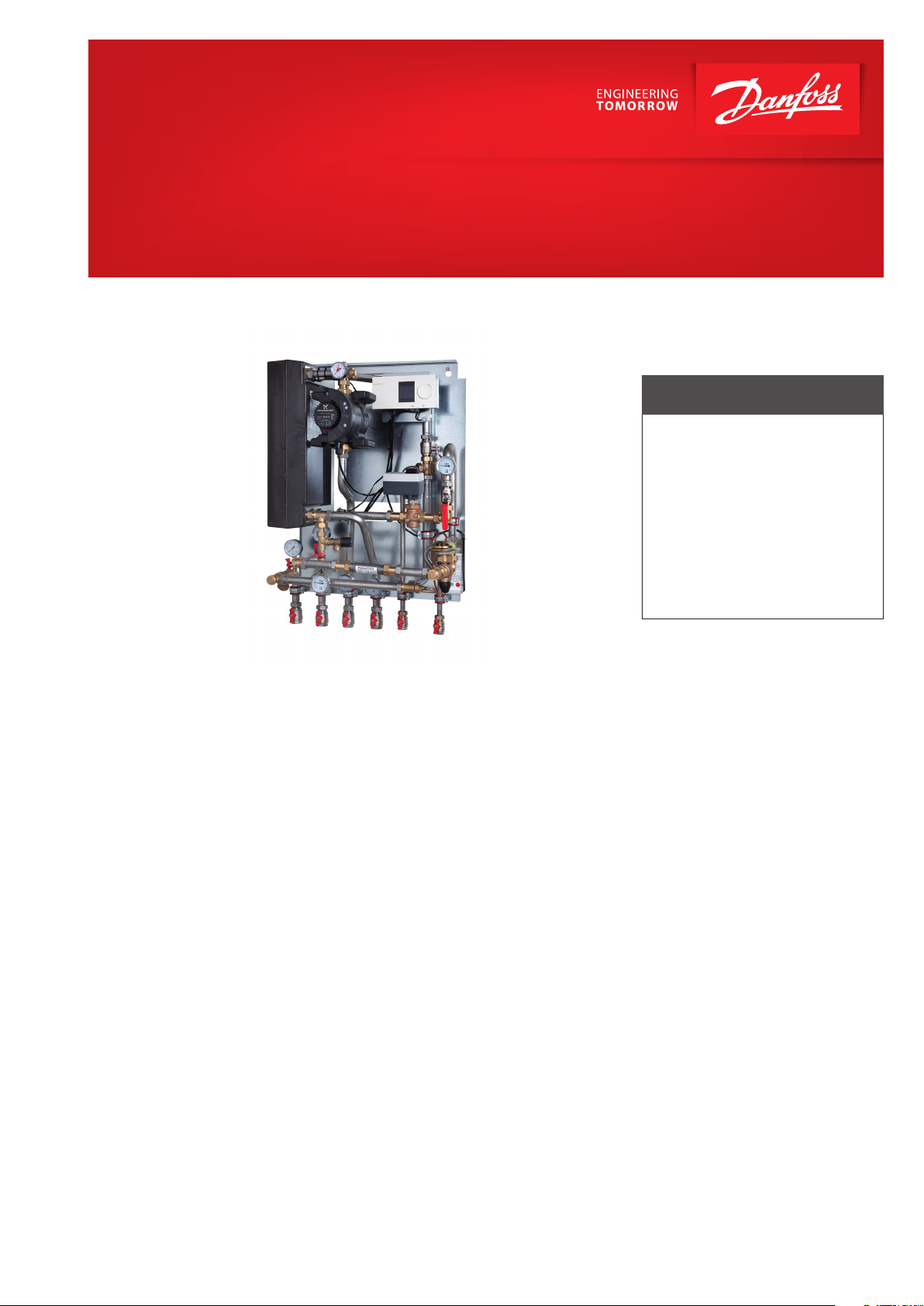

Termix VX-Compact-28-HWP

Indirect substation for apartment buildings with up to 25 apartments

FEATURES AND BENEFITS

• Substation for apartment buildings

• Indirect heating, connections

for domestic hot water tank

• Thermostatic or electronic regulation

of heating (HE) temperature

• Capacity: 35-75 kW heating

• Minimum space required for installation

• Pipes and plate heat exchanger

made of stainless steel

Application

The Termix VX Compact 28 is a complete solution for space heating with

optimal safety, ecient energy transfer, service-friendly construction and

a compact design. The substation is

applicable, if a heat exchanger is required or on a conversion to district

heating, where the existing equipment

is unsuitable for direct connection.

The Termix VX Compact 28 substation

is ideal, where a high level of security

against burst pipes and water damage

in the heating system is required.

District heating (DH)

The district heating circuit is prefabricated with motorized control valve,

dierential pressure controller, thermometers, ball valves, tting piece

and sensor pockets for insertion of

aheat meter.

Heating (HE)

The heating circuit consists of a plate

heat exchanger, safety valve, manometer, thermometers, ball valves, drain

valve, air valve and circulation pump.

The heating temperature can be controlled by the electronic controller

with an outdoor temperature sensor.

Domestic hot water (DHW)

Termix VX Compact 28 is supplied

with connection pipes for a DHW

tank on the supply line.

Options

As an option the substation can be

equipped with a thermostat with

safety monitor. This is possible only

for substations with electronic controller.

Construction

All pipes are made of stainless steel.

The connections are made by nuts

and gaskets. The Termix VX Compact

28 is delivered with a white-lacquered steel cover.

www.danfoss.com

Page 2

Danfoss GmbH Fernwärme- und Regelungstechnik · Carl-Legien-Str. 8 · 63073 Oenbach

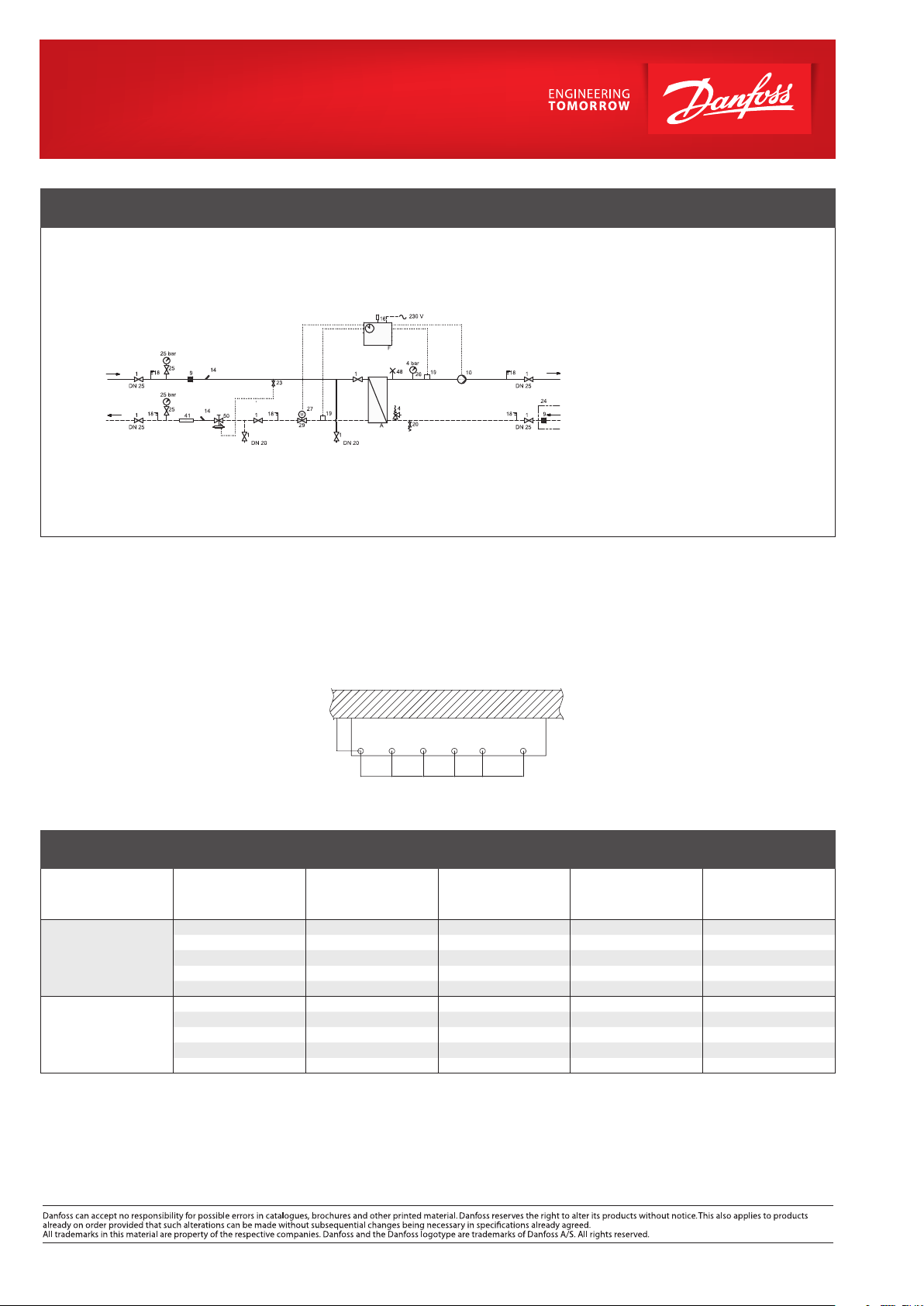

CIRCUIT DIAGRAM – EXAMPLE

DH

supply

DH

return

HE

supply

HE

return

A Plate heat exchanger HE

F Electronic controller

1 Ball valve

4 Safety valve

9 Strainer

10 Circulation pump

14 Sensor pocket, energy meter

16 Outdoor sensor

18 Thermometer

19 Surface sensor

20 Filling/drain valve

23 Ball valve

24 Delivered loose with unit

25 Manometer with ball valve

26 Manometer

27 Actuator

29 2-way motorized valve

41 Fitting piece, energy meter

48 Air escape, manual

50 Di. pressure cont. ow limiter

Technical parameters:

Nominal pressure: PN 16

DH supply temperature: T

Brazing material (HEX): Copper

Weight: approx. 50 kg

Dimensions (mm):

H 940 × W 620 × D 420

Electrical supply: 230 V AC

max

= 120 °C

HEATING: CAPACITY EXAMPLES

Substation

type

Type 1

Type 2

Heating

capacity

[kW]

50 90 / 55 50 / 70

50

35

50

35 80 / 60 55 / 75

75 90 / 55 50 / 70

75 80 / 55 50 / 70

55 75 / 55 50 / 70

75 90 / 60 55 / 75

55 80 / 60 55 / 75

Connections:

1 District heating supply (DH)

2 District heating return (DH)

3 Heating supply (HE)

4 Heating return (HE)

5 Tank supply (DHW)

6 Tank return (DCW)

seen from above

Heating circuit

primary

[°C]

80 / 55 50 / 70

75 / 55 50 / 70

90 / 60 55 / 75

Heating circuit

secondary

[°C]

wall

Connections sizes:

DH: 1” (ext. thread)

HE: 1” (int. thread)

DCW + DHW: ¾” (int. thread)

Options:

• Thermostat with safety monitor

Flow rate

primary

[l / h]

1200 2238

1830 2238

1823 1623

1426 2238

1797 1623

1801 3378

2735 3378

2723 2460

2140 3378

2687 2460

Flow rate

secondary

[l / h]

Technische Beratung/Angebote: Tel.: 069 / 8902 - 960 · Fax: 069 / 8902 466 - 948 · anfrage-fw@danfoss.com

Auftragsabwicklung: Tel.: 069 / 8902 - 970 · Fax: 069 / 8902 466 - 949 · verkauf-fw@danfoss.com

© Danfoss | DHS-SRMT/ PL | 2016 . 04

VL.IE.I2.02

Loading...

Loading...